7.6-micron front cut-off infrared optical filter and making method thereof

An infrared filter and the technology of its manufacturing method, which are applied in the field of 7.6 micron front-cut infrared filter and its manufacture, can solve the problems of poor precision and low signal-to-noise ratio, achieve high precision and sensitivity, excellent performance, and stable process mature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

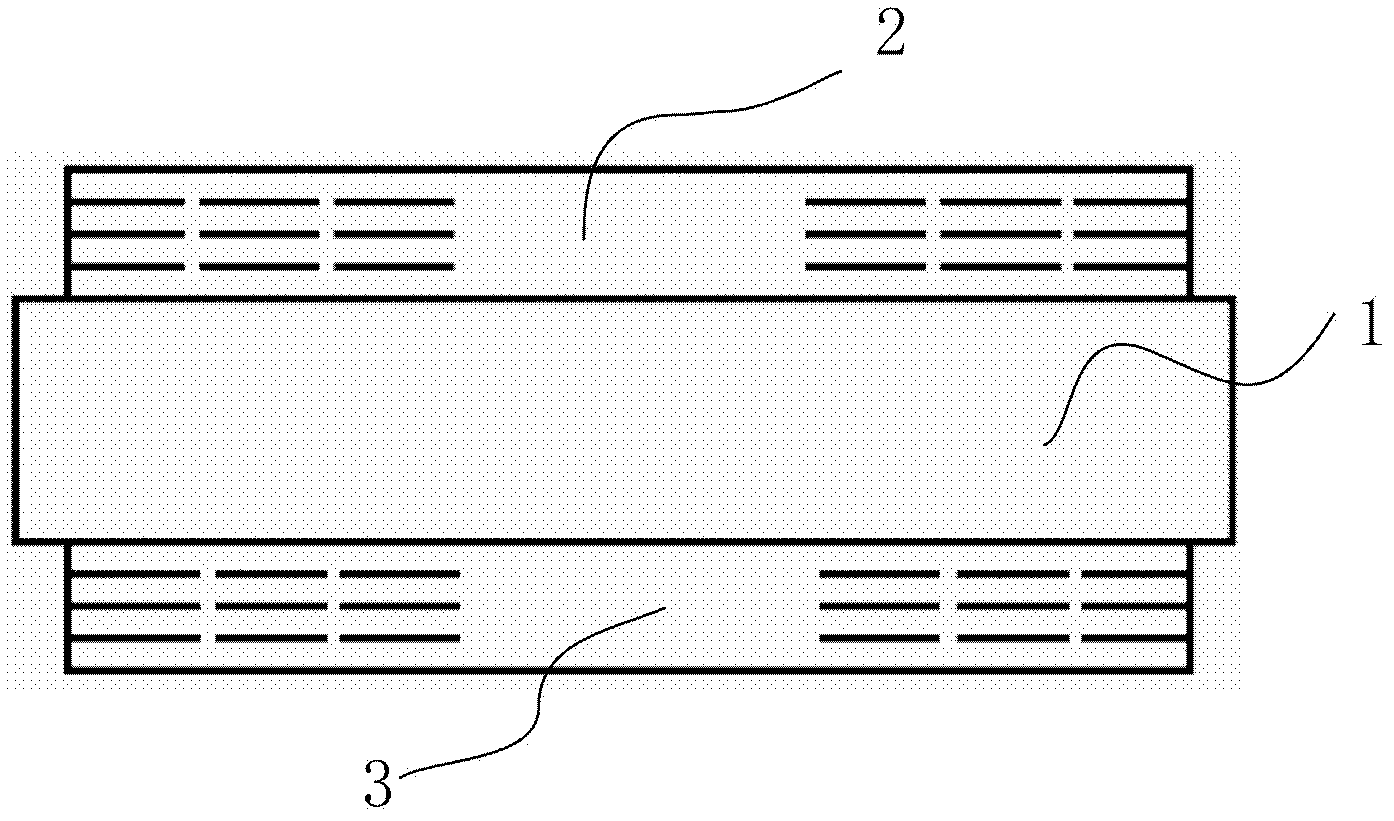

[0021] A kind of 7.6 micron front cut-off infrared filter that present embodiment provides, its structure is:

[0022] (1) Single-crystal germanium Ge with a size of Φ25.4×1.0mm is used as the substrate, the surface aperture N≤5, the local aperture ΔN≤0.5, the parallelism θ≤1’, and the surface finish is better than 60 / 40;

[0023] (2) Zinc sulfide ZnS and single crystal germanium Ge are selected as the coating material, and multi-layer interference films are deposited on the two surfaces of the single crystal germanium Ge substrate;

[0024] (3) Sub|2.42(.5HL.5H) is used for the design of the first film film system 8 3.0 (.5HL.5H) 7 |Air;

[0025] The film system design of the second surface adopts Sub|1.2(.5HL.5H) 6 1.6(.5HL.5H) 7 2.32(.5HL.5H) 6 |Air;

[0026] The corresponding meanings in the film system are: Sub is substrate, Air is air, H is λc / 4 single crystal germanium film layer, L is λc / 4 zinc sulfide film layer, λc=2μm, 2.42, 1.2 and other numbers in the struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com