Deep ultraviolet APD detection diode based on Ir2O3/Ga2O3 and manufacturing method thereof

A technology for detection diodes and manufacturing methods, which is applied in the field of deep ultraviolet APD detection diodes, can solve problems such as lack of withstand voltage and breakdown resistance, and achieve improved bulk avalanche breakdown voltage, high breakdown electric field, and high withstand voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Wide bandgap semiconductor material Ga 2 o 3 , because the light transmittance of the material in the solar blind area can reach 80% or even more than 90%, it is very suitable for the photoelectric detection of the deep ultraviolet light solar blind area. Its photoelectric sensitivity is high, and it has both the transparency of sapphire and the conductivity of SiC. It is an ideal semiconductor material for the study of devices, especially deep ultraviolet photodetectors.

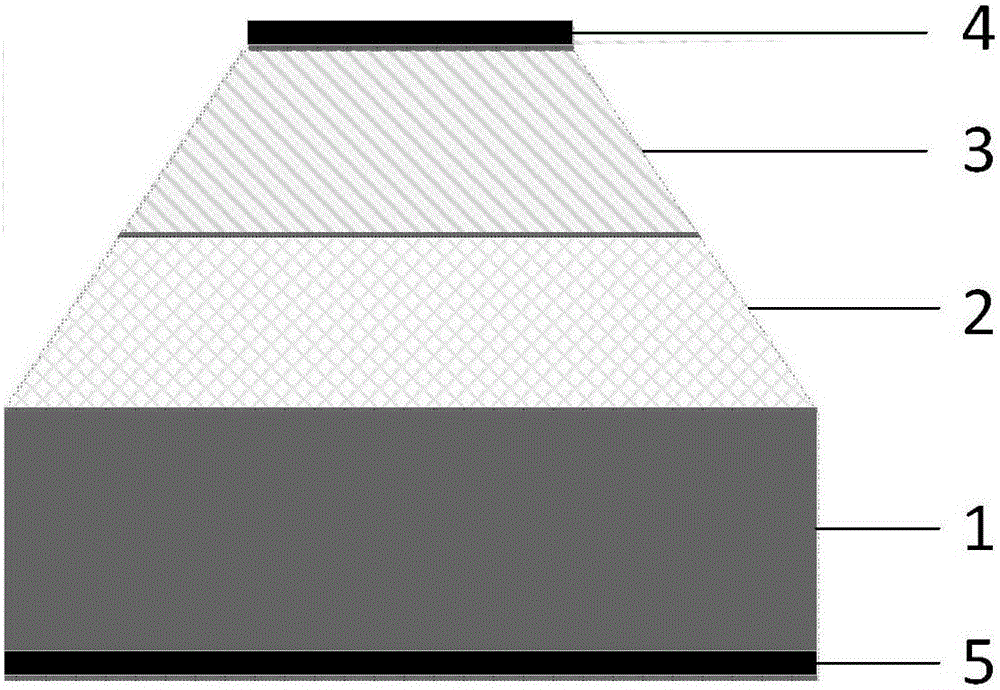

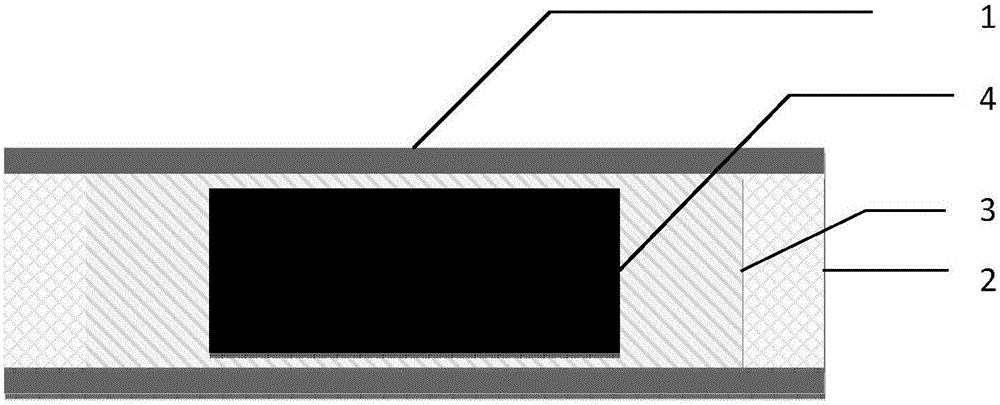

[0049] See figure 1 and figure 2 , figure 1 A kind of based on Ir provided for the embodiment of the present invention 2 o 3 / Ga 2 o 3 The cross-sectional schematic diagram of the deep ultraviolet APD detection diode; figure 2 A kind of based on Ir provided for the embodiment of the present invention 2 o 3 / Ga 2 o 3 The schematic top view of the deep ultraviolet APD detection diode. The APD detection diode consists of β-Ga 2 o 3 Composed of a substrate 1, an N-type homoepitaxial laye...

Embodiment 2

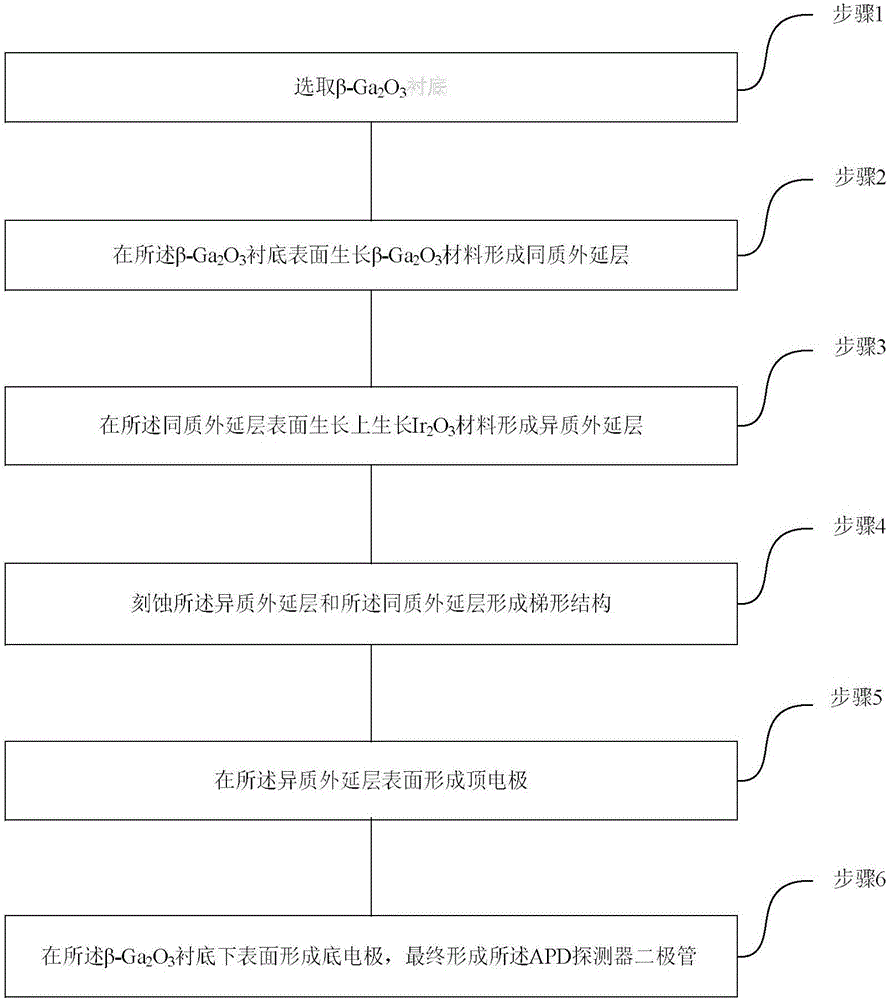

[0080] See Figure 4a-Figure 4g and Figure 5 , Image 6 with Figure 7 . Figure 4a-Figure 4g A kind of based on Ir provided for the embodiment of the present invention 2 o 3 / Ga 2 o 3 Schematic diagram of the fabrication method of the deep ultraviolet APD detection diode; Figure 5 A schematic diagram of a first photolithography mask provided by an embodiment of the present invention; Image 6 A schematic diagram of a second photolithography mask provided by an embodiment of the present invention; and Figure 7 A schematic diagram of a third photolithography mask provided by an embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment is based on the Ir 2 o 3 / Ga 2 o 3 The fabrication method of the deep ultraviolet APD detection diode is described in detail as follows:

[0081] Step 1: See Figure 4a , to prepare the substrate for β-Ga 2 o 3 , the thickness is 200 μm-600 μm, and the substrate is pretreated and clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com