Patents

Literature

75results about How to "Stable and mature process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Volume production method of pressureless sintering boron carbide ceramic bullet-proof sheets

InactiveCN104446483AImprove single furnace production capacityHigh degree of automationMicrometerAdhesive

The invention discloses a volume production method of pressureless sintering boron carbide ceramic bullet-proof sheets. The volume production method comprises the following steps: (1) putting various raw materials in material mixing and pulping equipment according to a formula proportion, wherein the raw materials are composed of a solid material A and a liquid material B, the material A comprises the following components in percentage by weight: 75-97wt% of boron carbide powder, 0-15.0wt% of sintering aids, 1.0-12.0wt% of carbon source, 0.5-6.0wt% of adhesive, and 0.5-6.0wt% of dispersant, and the sum of the percentages by weight of the components is 100%; the material B is deionized water; mixed ball milling or high speed stirring is performed on the material A and the material B to prepare a sizing agent, wherein the solid content of the sizing agent is 30-70 wt%; the sintering aids are one or more of nanometer level to micrometer level ZrC, TiC, SiC, AlN and TiB2. The method has the advantages of high yield of a single furnace, high degree of automation, non grinding processing of products, low cost and suitability for mass production, and low-cost and stable mass production is achieved.

Owner:NINGBO VULCAN TECH CO LTD

Aluminum cladding method for lithium ion positive electrode material

InactiveCN103872331ANo reduction in gram capacityImprove uniformityCell electrodesSecondary cellsSolventMuffle furnace

The invention discloses an aluminum cladding method for a lithium ion positive electrode material. The aluminum cladding method comprises the following steps: (1) preparing a cladding-free positive electrode material by a conventional method; (b) preparing an aluminum salt solution from an inorganic aluminum salt and a solvent, wherein the aluminum salt solution is taken as a cladding solution, the aluminum salt is selected from aluminum nitrate, aluminum chloride, aluminum sulfate and aluminum acetate and the solvent is selected from ethanol, methanol and isopropanol; (c) adding the cladding-free positive electrode material into the aluminum salt solution, agitating and heating till the solution reflows; (d) after the solution reflows for 30 minutes, filtering to remove the solvent and drying in vacuum at 70-100 DEG C to prepare a semi-finished product; and (e) putting the semi-finished product into a muffle furnace for roasting, and naturally cooling to room temperature to obtain the aluminum-cladded positive electrode material. Compared with the prior art, the aluminum cladding method for the lithium ion positive electrode material disclosed by the invention not only can prolong the cycle life and improve the heat stability of the positive electrode material under high-charging cut-off voltage, but also can reduce the cladding cost and improve the cladding consistency.

Owner:NINGDE AMPEREX TECH

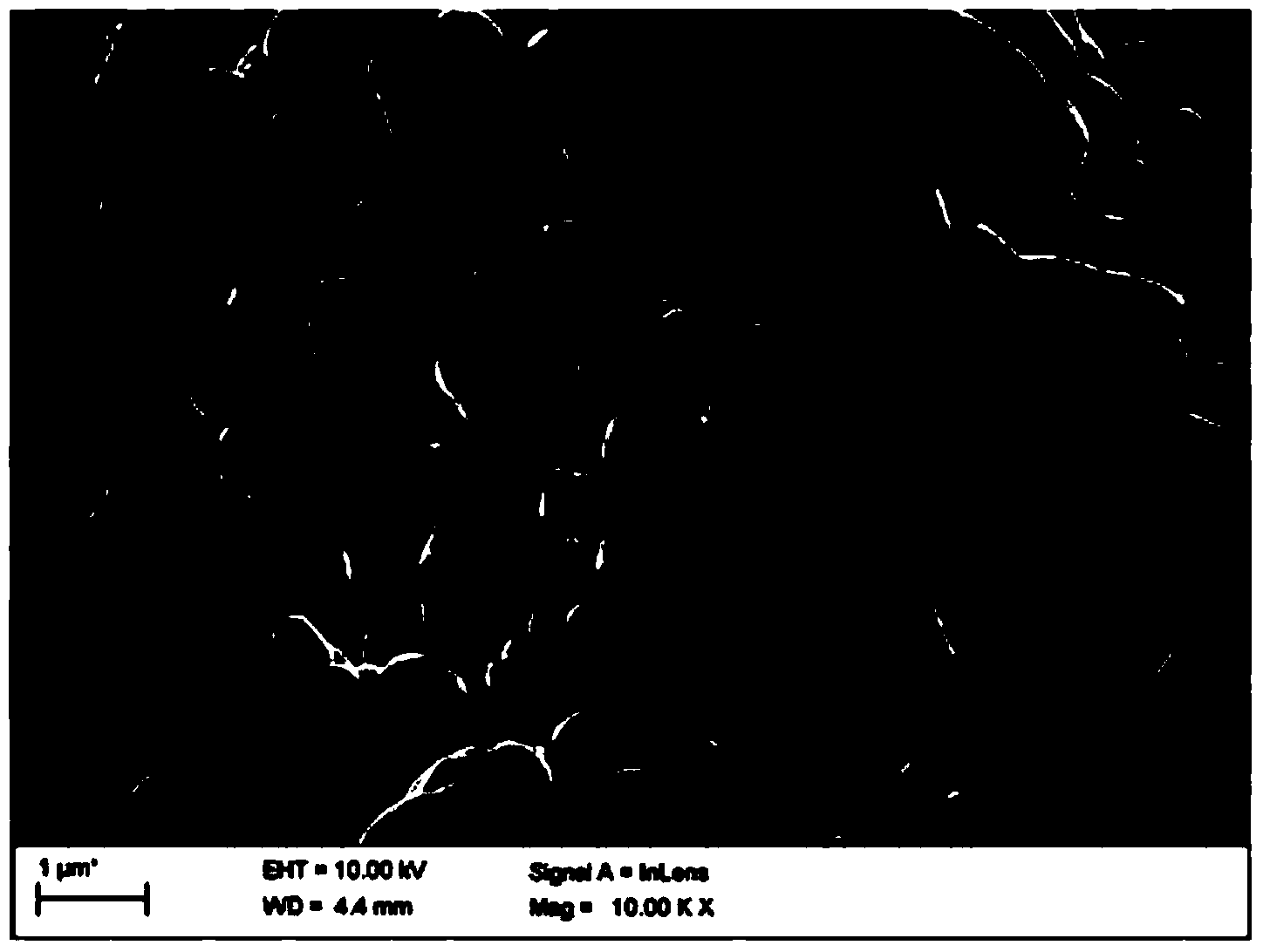

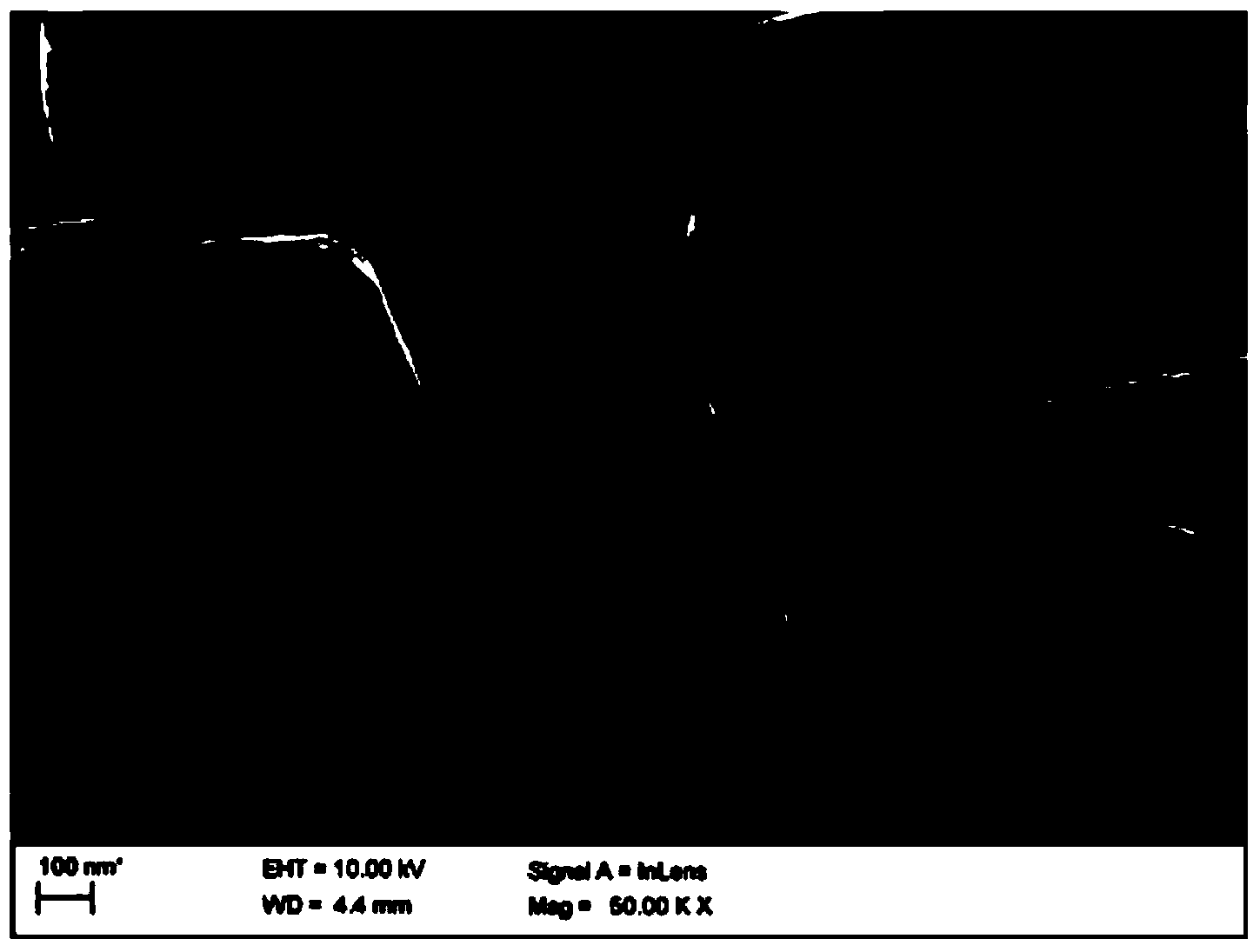

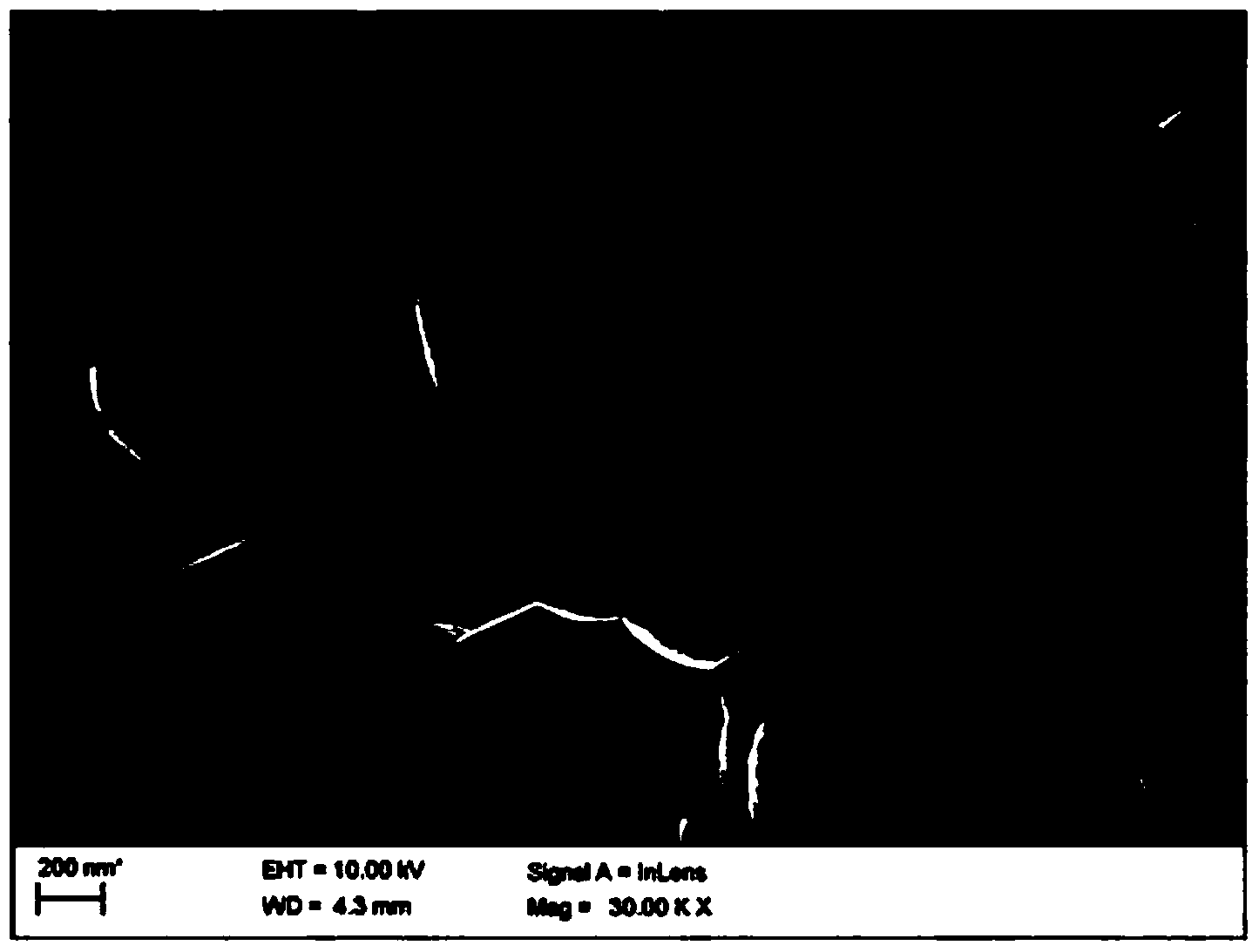

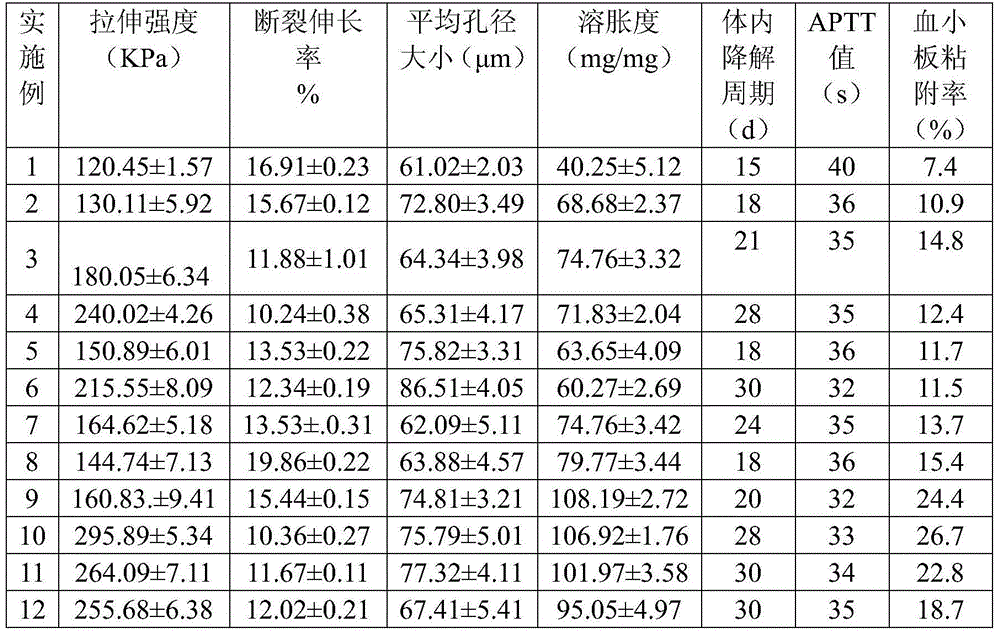

Method for preparing microfiber hemostatic collagen sponge

InactiveCN104558675AHas advantagesEfficient use ofAbsorbent padsBandagesSurgical operationProtein solution

The invention relates to a method for preparing microfiber hemostatic collagen sponge. The method comprises the following steps of: aggregating collagen molecules by the charge effect by adjusting pH, temperature and the salt concentration of collagen protein solution, freeze-drying the obtained and assembled collagen, then preparing into the collagen protein sponge, and then carrying out thermal crosslinking to obtain the microfiber hemostatic collagen sponge. The microfiber hemostatic collagen sponge prepared by adopting the method has uniform porous structure, good hydrophilic performance, high mechanical strength and degradation resistance and good hemostatic performance, and the defects that the traditional collagen sponge is easy in degradation, poor in mechanical property, easy in collapse in the application process and difficult in maintenance of the inherent form and the like are solved. The preparation method is simple and feasible, and is stable in process, and the prepared microfiber hemostatic collagen sponge can be widely applied in hemostasis and restoration of wounds of burns, traumas and surgical operation, and has good application prospect.

Owner:无锡贝迪生物工程股份有限公司

Diamond powder having surface-coated non-diamond phase carbon layer and production method thereof

InactiveCN101205422AImprove performanceLow priceInorganic pigment treatmentChemical treatmentCarbon layer

The invention discloses diamond powder coated with a non-diamond carbon layer and a production method thereof.The product has the non-diamond carbon layer coated on the surface of the diamond powder abrasives, and the mass of the non-diamond carbon layer is 0.05 to 10 percent of the total mass of the diamond powder. During the manufacture process, organic compounds are used for surface coating treatment to the diamond powder abrasives; the treated diamond powder abrasives are placed under non-oxidation atmosphere and heat treated at 400 to 1000 DEG C in a high temperature furnace for two to ten hours; the organic compounds are carbonized, and a coating film composed of the non-diamond carbon layer is formed on the surface of the diamond powder abrasives. The product has steady performance, low price, and good grinding force and processing surface planeness. The product adopts general chemical processing method and heat treatment method during manufacturing, which has mature and stable technique, little equipment input and low manufacture cost.

Owner:HENAN UNION ABRASIVES

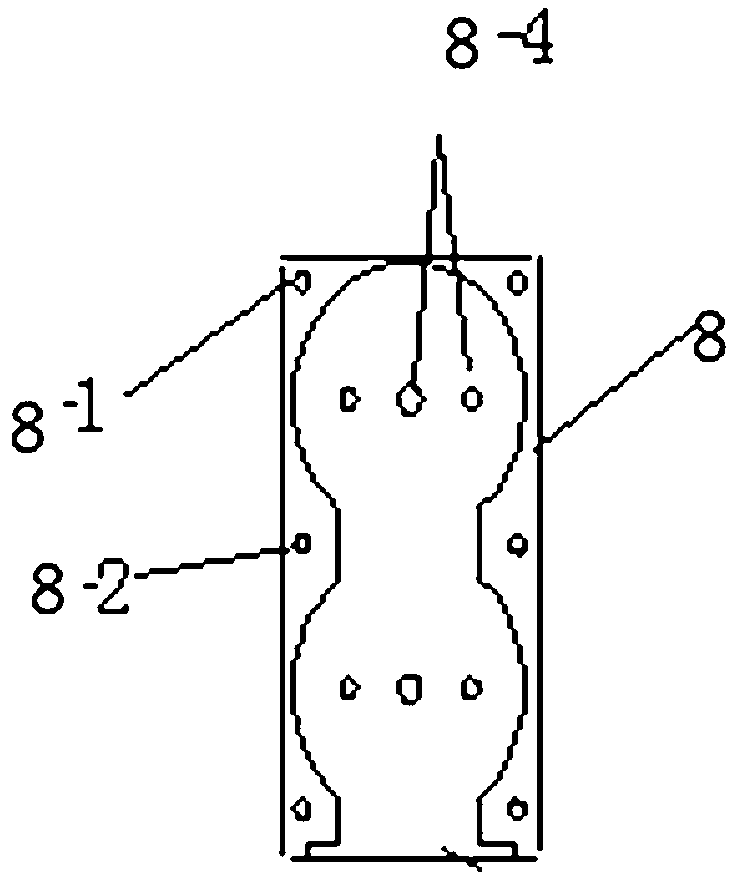

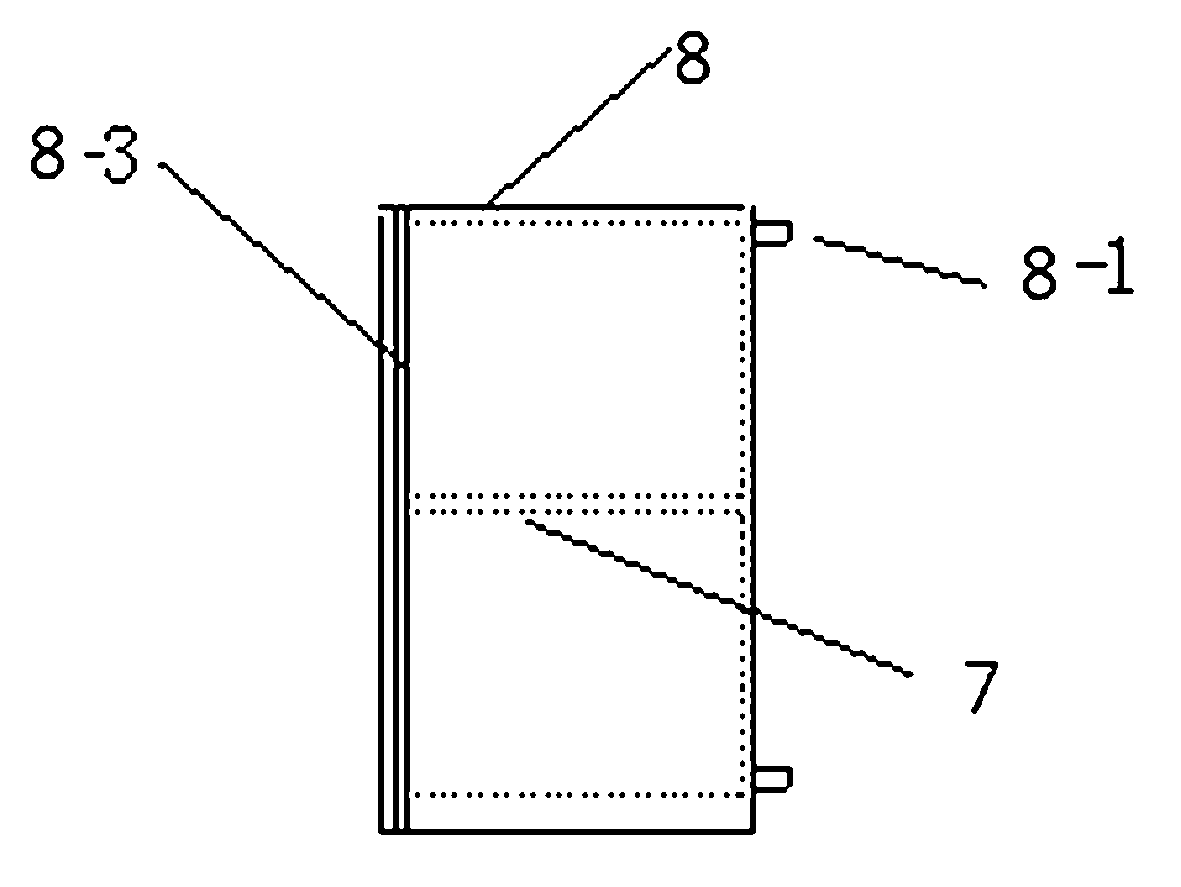

Metamaterial phased array antenna with wide-angle beam scanning

InactiveCN105356054AImproved radiation patternImprove radiation efficiencyWaveguide mouthsAntenna arraysAxial ratioImpedance matching

The present invention relates to a metamaterial phased array antenna with wide-angle beam scanning. The phased array antenna is a planar structure and is formed by periodically arranging a plurality of antenna units. A typical phased array antenna unit is formed by a metal waveguide, a loading media and a feeder port. The array plane of the phased array antenna is covered by a metamaterial to play the role of impedance matching in a wide-angle beam scanning range. According to the phased array antenna in the invention, the sending and receiving of an electromagnetic signal can be realized in the wide-angle range, the radiation efficiency of the antenna is improved, and the cross polarization characteristic or circular polarization axial ratio characteristic of radiation waves is improved.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Three-dimensional embossment process for all-polyester cony-hair-like napped surfaces

InactiveCN110219093AAchieve three-dimensional effectStable and mature processPattern makingWarp knittingPolyesterWork in process

The invention discloses a three-dimensional embossment process for all-polyester cony-hair-like napped surfaces. The three-dimensional embossment process includes the steps of 1) weaving, 2) presetting, 3) dyeing, 4) cloth washing and softening, 5) semi-finished product resetting, 6) decoration spraying, 7) shearing, 8) hot blowing, 9) combing, 10) luster finishing, and 11) finished product resetting. The process has the advantages that the process is mature, stable, and convenient to operate; the three-dimensional all-polyester cony-hair-like napped surfaces can be effectively obtained, and an embossment effect can be achieved.

Owner:常熟市易美纺织品有限公司

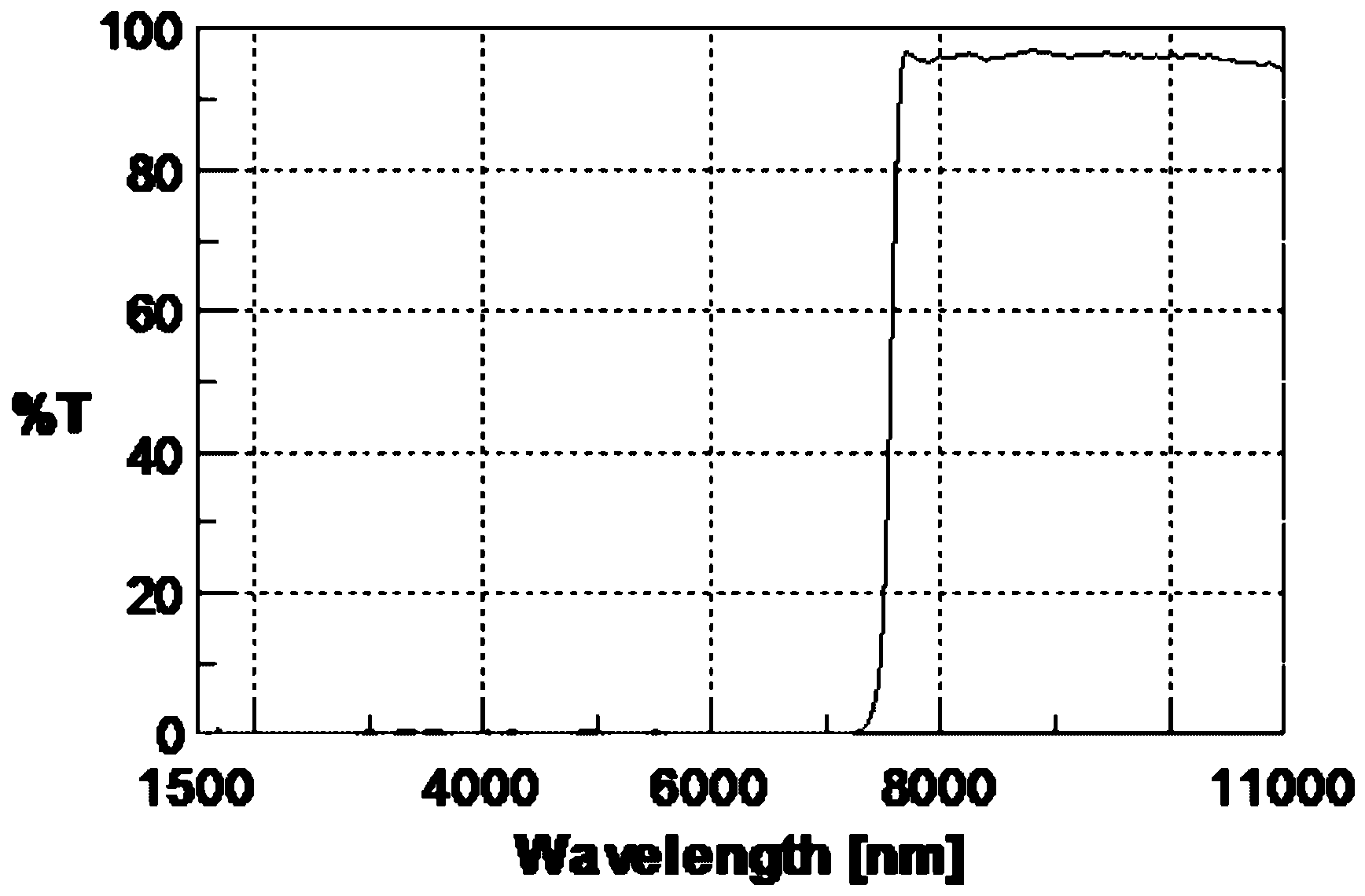

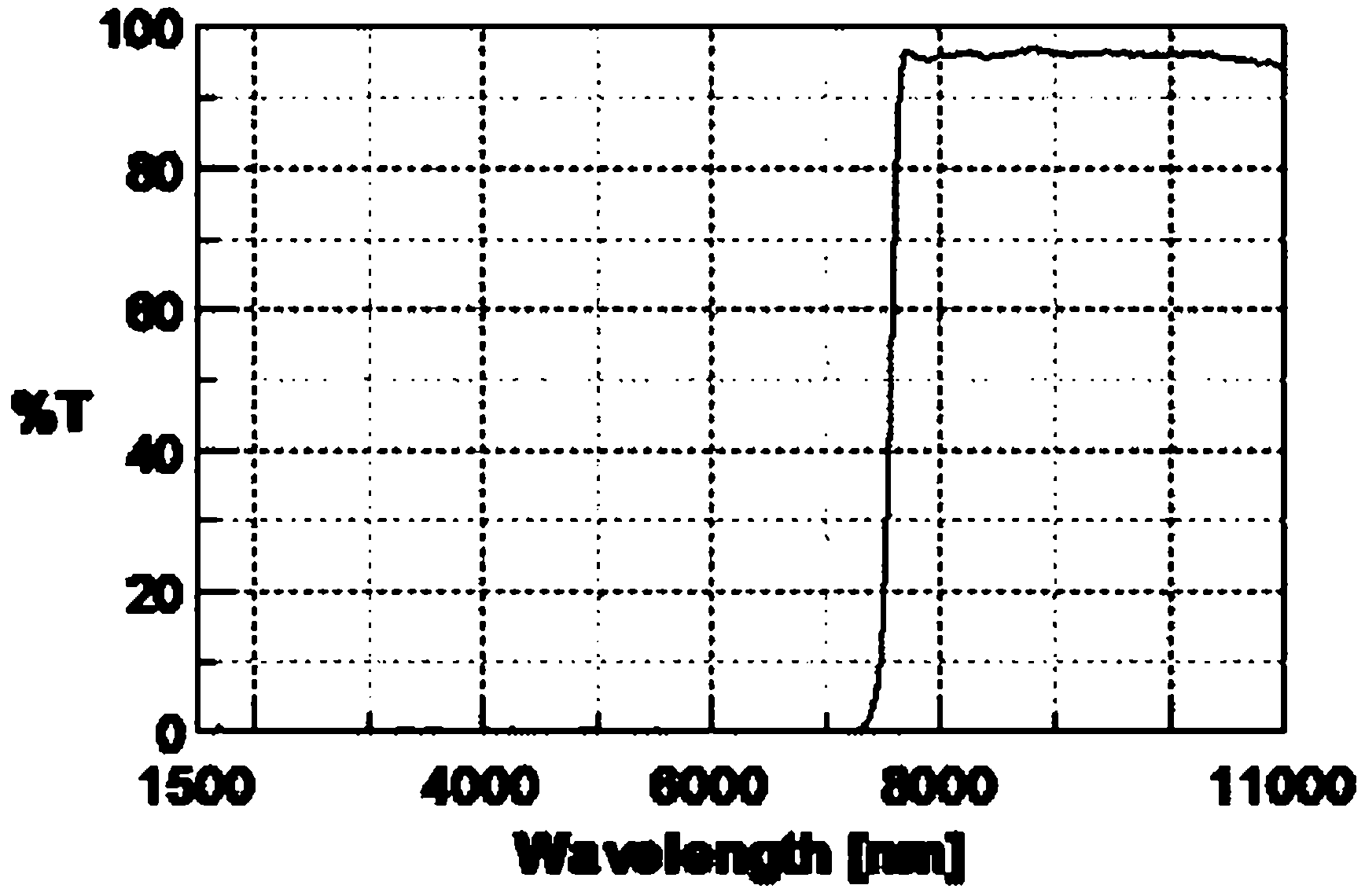

7.6-micron front cut-off infrared optical filter and making method thereof

InactiveCN102540313AGood signal to noise ratioSuppress background distractionsVacuum evaporation coatingSputtering coatingCooking & bakingGas phase

The invention discloses a 7.6-micron front cut-off infrared optical filter and a making method thereof. The optical filter is characterized in that: single crystal germanium (Ge) with the size of phi 25.4*1.0mm is used as a substrate, the surface aperture N of the substrate is less than or equal to 5, the local aperture delta N is less than or equal to 0.5, the parallelism theta is less than or equal to 1', and the surface finishment is superior to 60 / 40; zinc sulfide (ZnS) and single crystal germanium (Ge) are used as coating materials, and a plurality of layers of interference films are respectively deposited on two surfaces of the single crystal Ge substrate; Sub absolute value 2.42(0.5HL0.5H)<8>3.0(0.5HL0.5H)<7> Air is adopted in the design of a first side film system; Sub absolute value 1.2(0.5HL0.5H)<6>1.6(0.5HL0.5H)<7>2.32(0.5HL0.5H)<6> Air is adopted in the design of a second side film system; according to the adopted evaporation process conditions, heating and baking of below 300 DEG C are performed in a vacuum environment with the vacuum degree of less than or equal to 10<-3>Pa, and a physical vapor deposition mode and ion source aided coating are adopted; and the 7.6-micron front cut-off infrared optical filter has excellent signal-to-noise ratio and good background interference suppression. The optical filter can be widely used for detecting the temperature of a far infrared object.

Owner:MULTI IR OPTOELECTRONICS

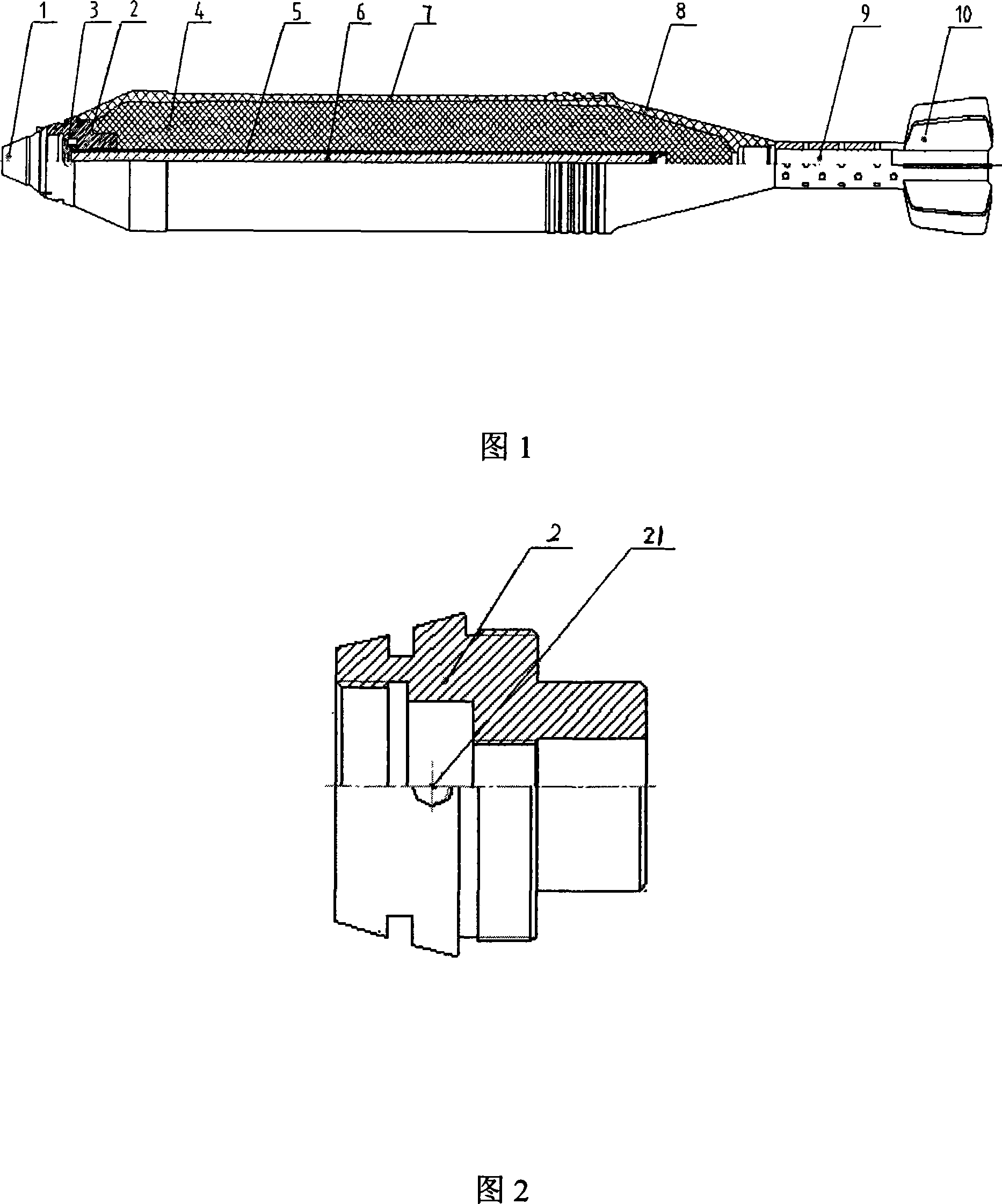

Forest firefighting mortar bomb

InactiveCN101229416AGuaranteed uniformityEffective throwingAmmunition projectilesFire rescueFirefightingEngineering

The invention relates to a mortar bomb used for fire extinguishing in forest, which is divided into a working part and a propelling part. The working part consists of a fuse, a connecting screw, a medicine package, fire fighting powder, a central slinging medicine pipe, slinging medicine, a shell and a fairing; the pushing part consists of a bomb tail and a basal medicine pipe. The connecting screw of the working part is fixed at the front end of the shell and the front end of the connecting screw fixes the fuse; the central slinging medicine pipe is an acerose metal thin-walled piece that passes through the shell at an axial direction, the front end of which is connected with the fuse through the medicine package and fixed by the connecting screw. The slinging medicine is packed in the central slinging medicine pipe and the fire fighting powder is filled between the central slinging medicine pipe and the shell. The bomb of the invention adopts a mortar that is equipped with a large quantity in saturday night soldier reserve components as a launching platform, thus having far slinging distance, high safety performance, high reliability, large medicine packing amount, high fire fighting efficiency and low production and use cost.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

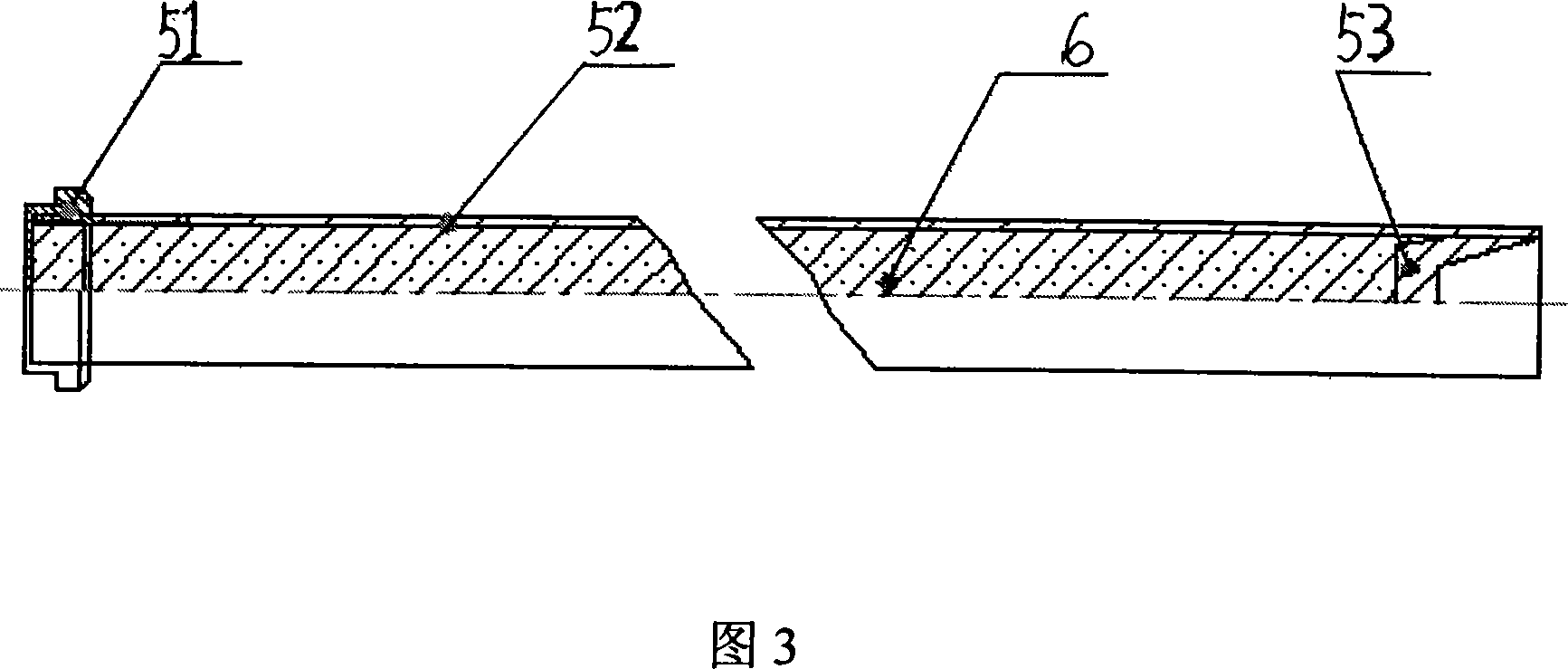

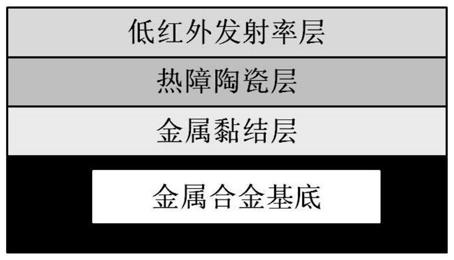

Thermal barrier/high-temperature low infrared emissivity integrated coating, metal composite material with coating and preparation method thereof

ActiveCN110117764AImprove temperature resistanceImprove thermal insulation performance and bond strengthMolten spray coatingBonding strengthMetal

The invention discloses a thermal barrier / high-temperature low infrared emissivity integrated coating. The coating is of a multilayer stacked structure. The multilayer stacked structure successively comprises a metal bonding layer, a thermal barrier ceramic layer and a low infrared emissivity layer from inside to outside. The thermal barrier ceramic layer is a rare earth hexaaluminate layer, and the low infrared emissivity layer is a Bi2O3-MgO-Al2O3-Li2O-SiO2 serial glass coating containing a conductive phase Pd powder. The integrated coating has the advantages of heat-insulating property, high-temperature low infrared emissivity, high bonding strength and the like. The metal composite material with the coating is simple and manure in process, relatively low in cost and easy for scaled production and application.

Owner:NAT UNIV OF DEFENSE TECH

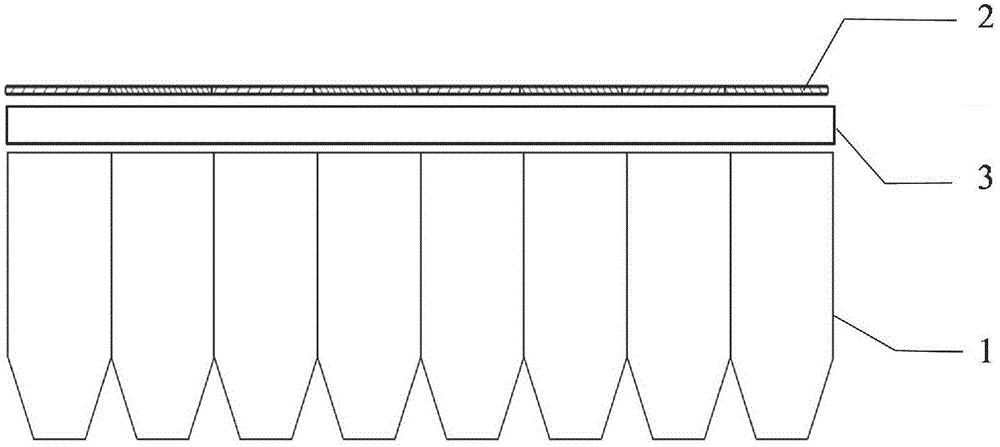

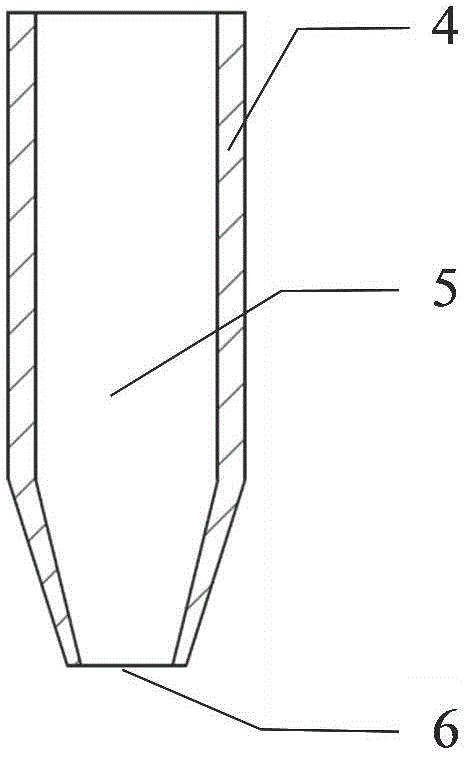

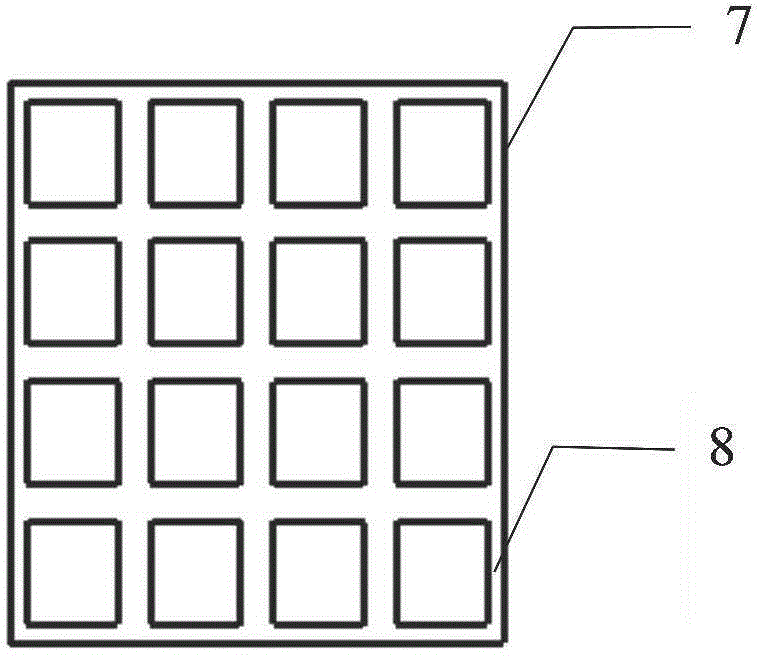

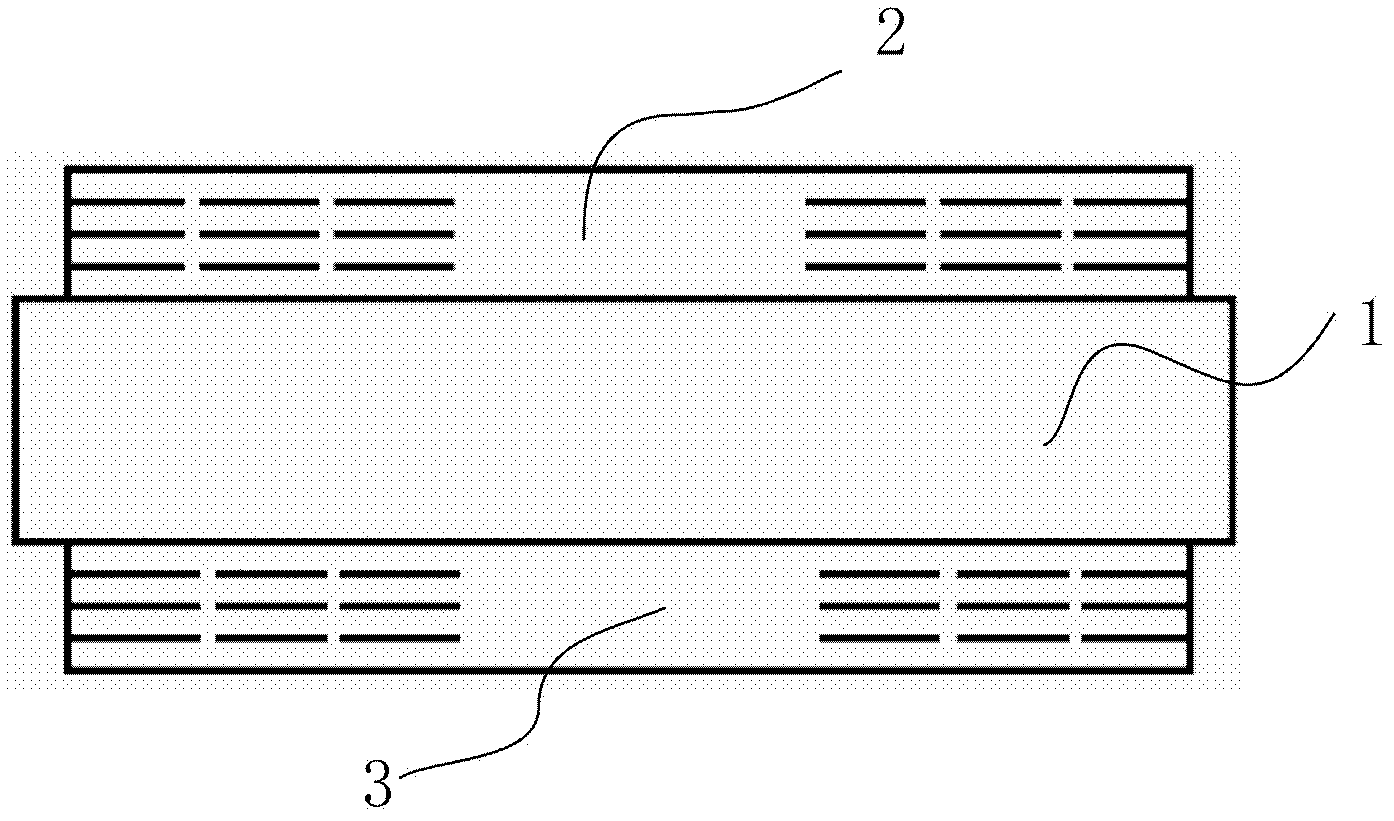

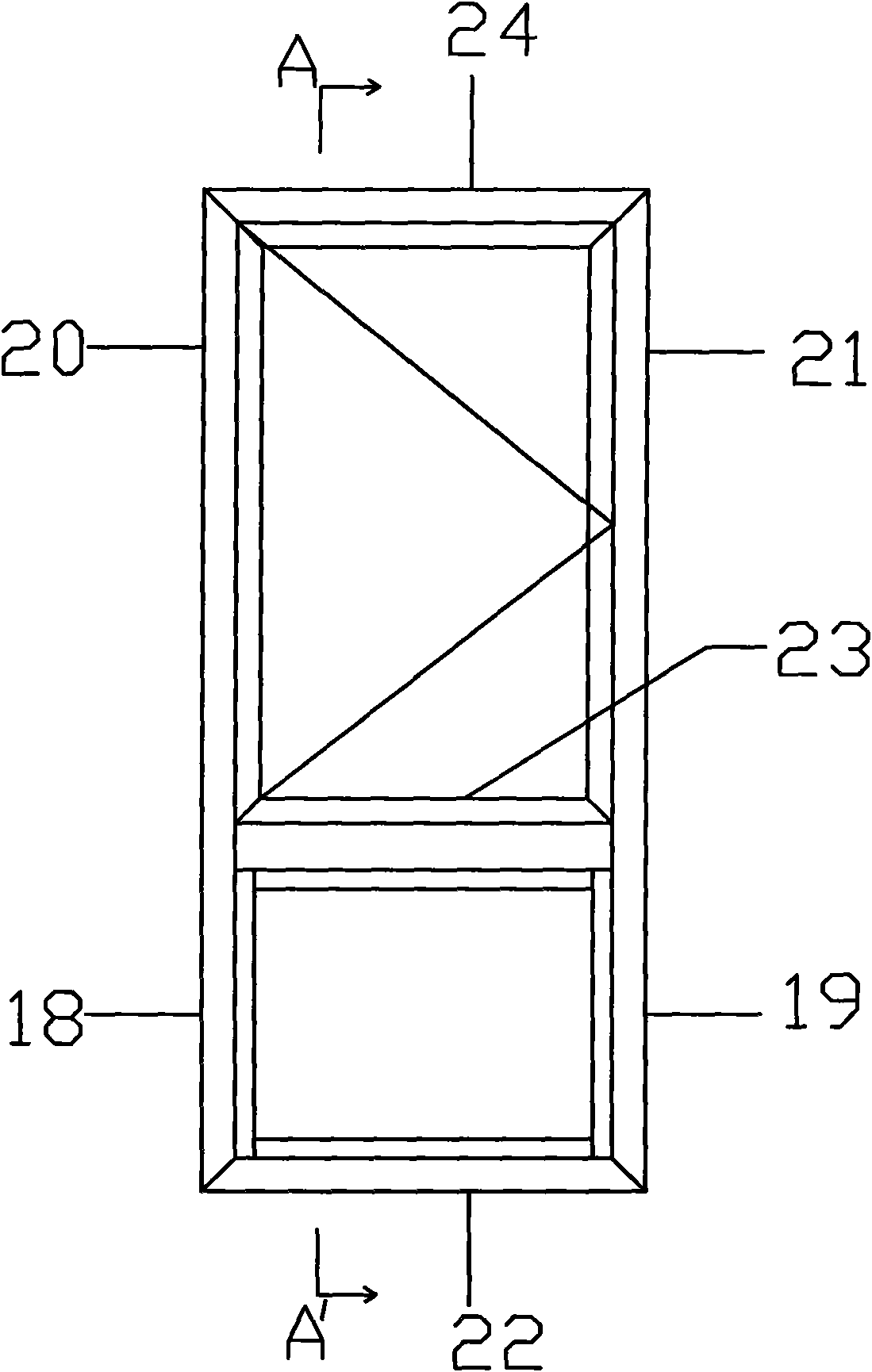

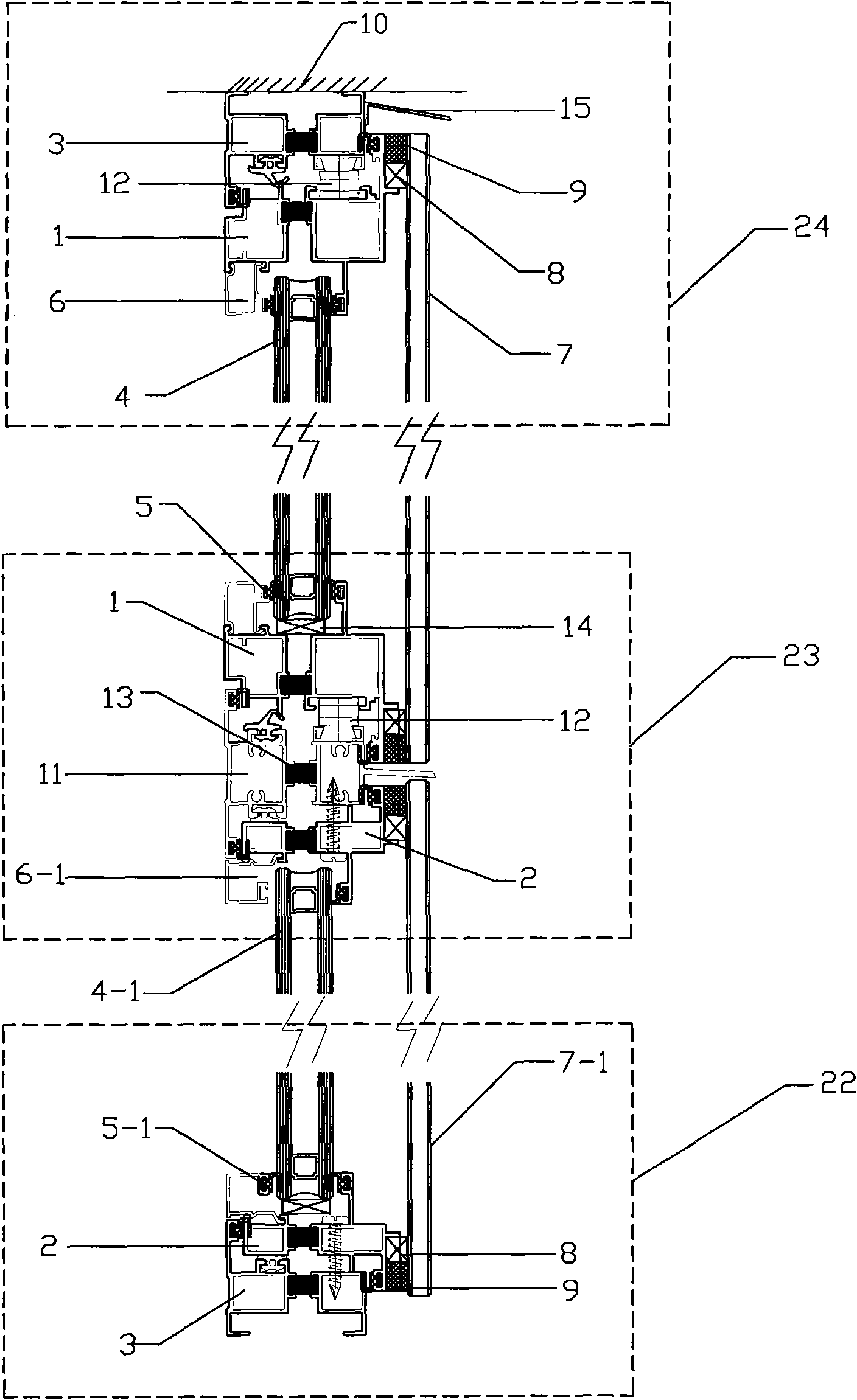

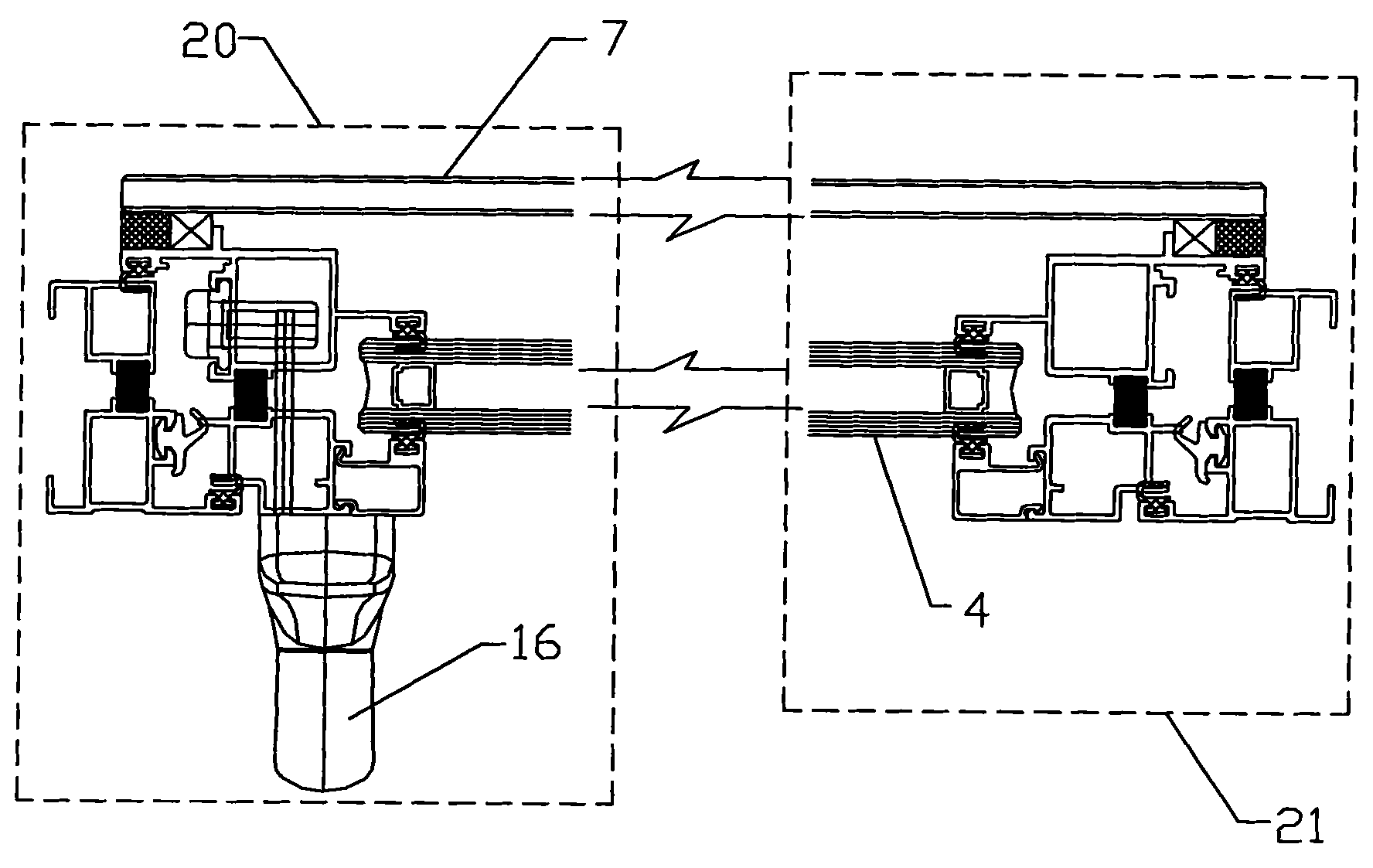

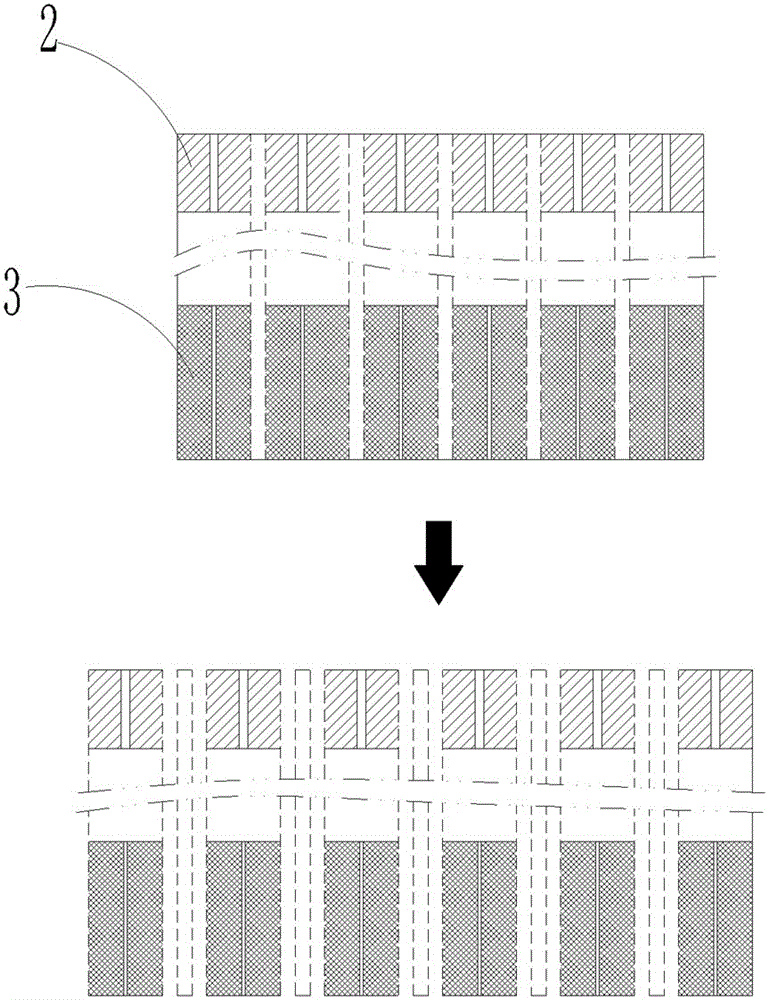

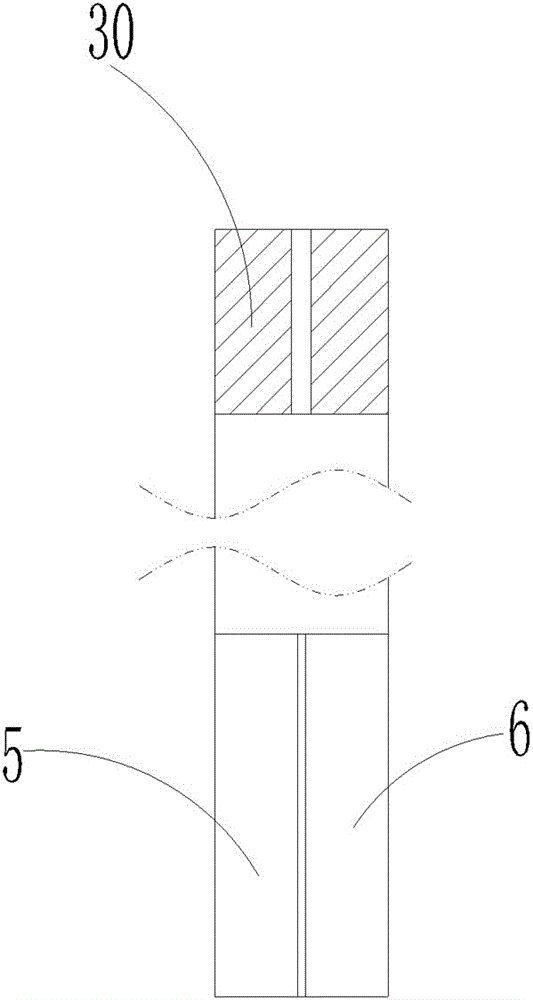

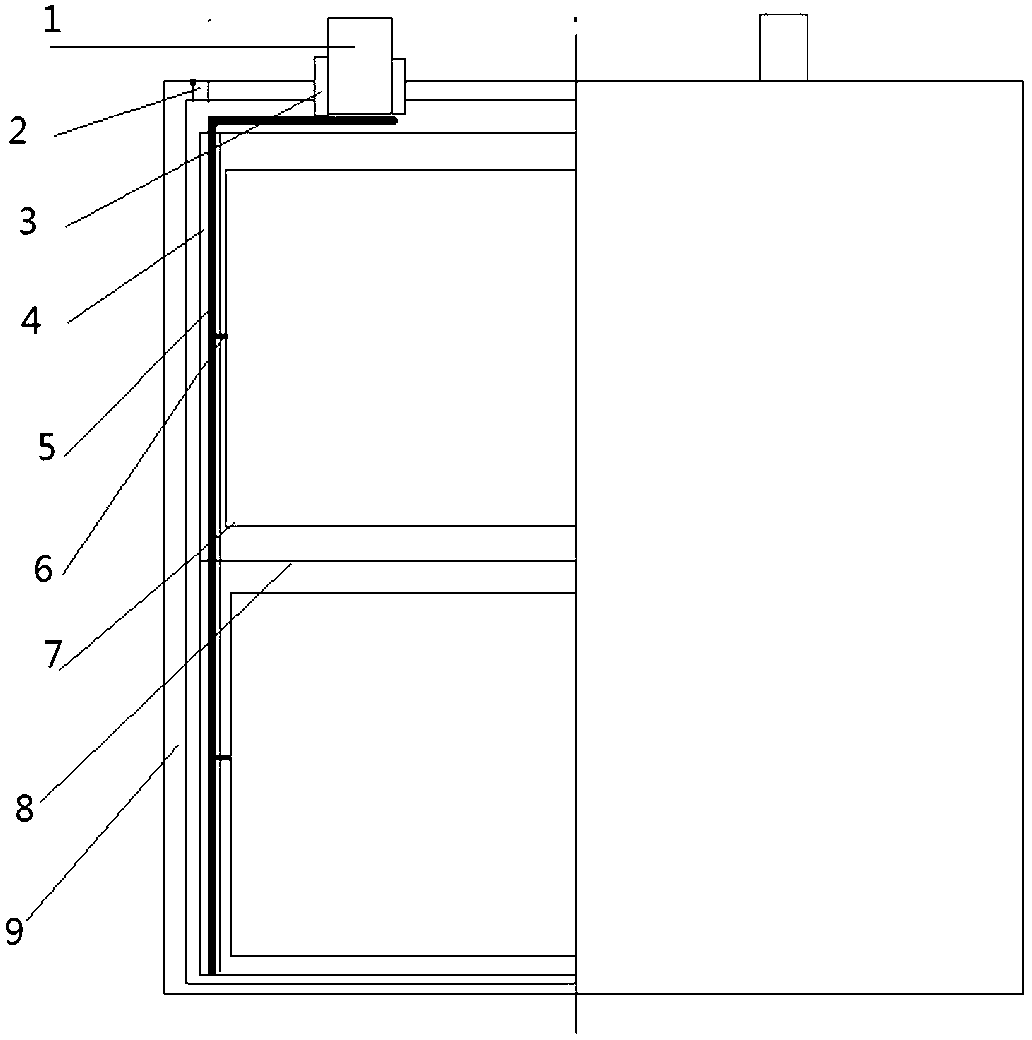

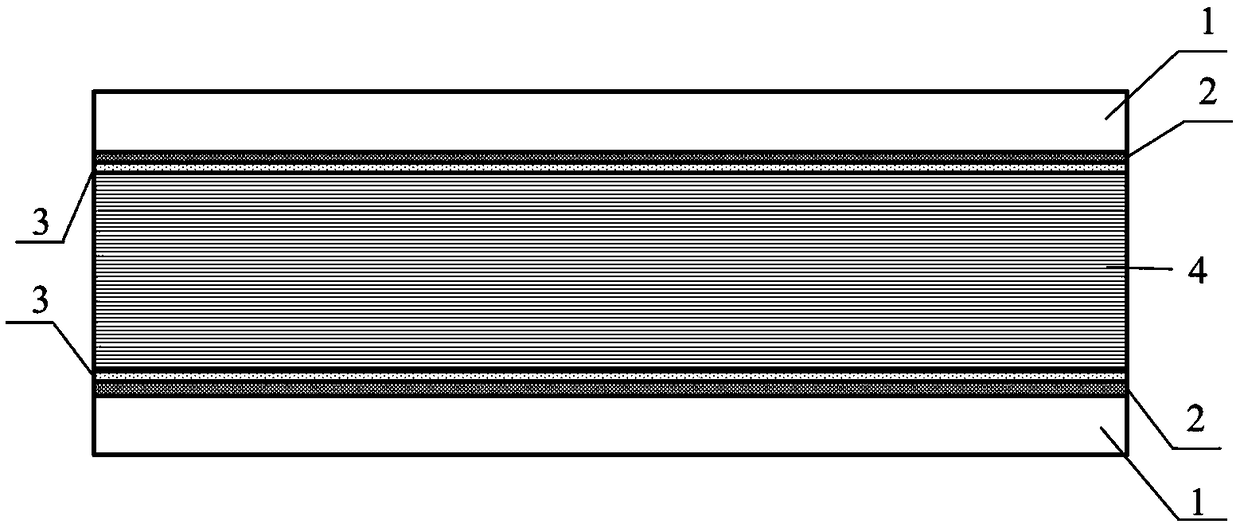

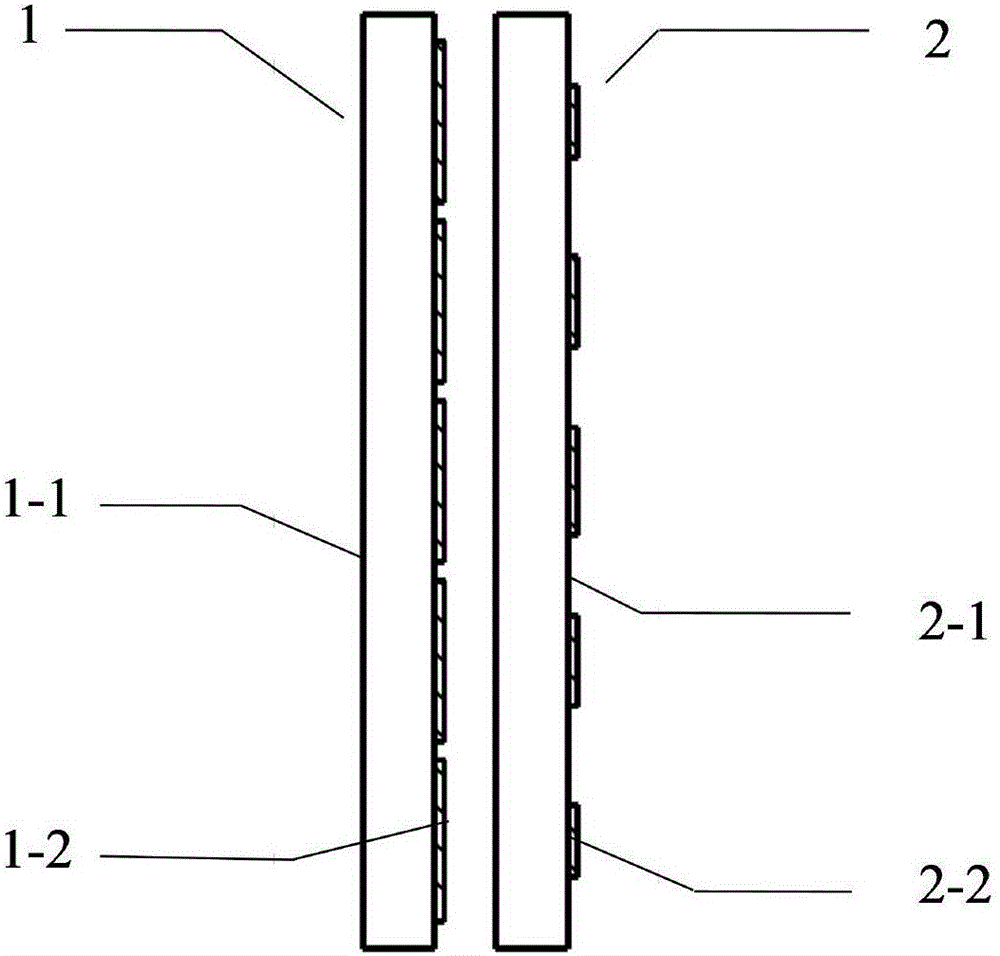

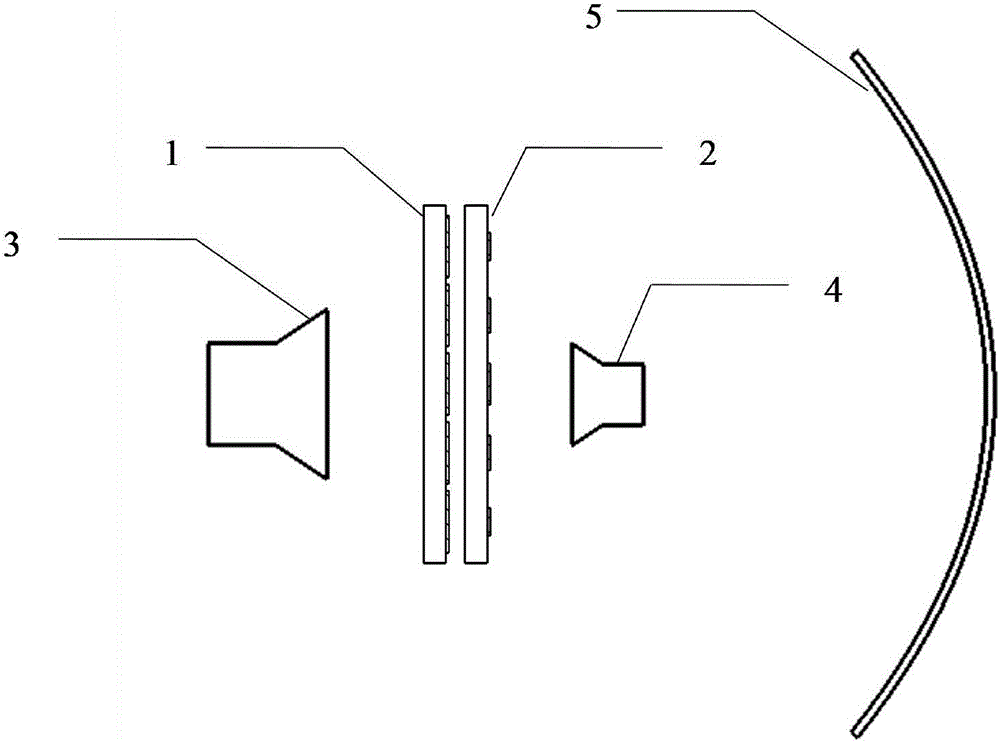

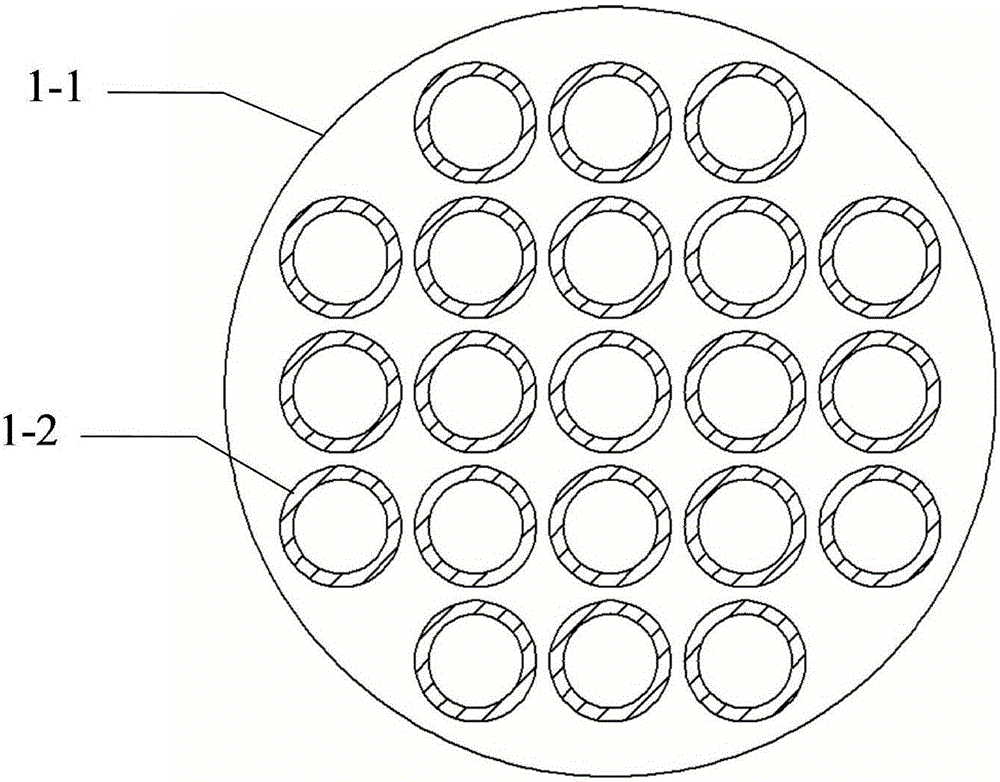

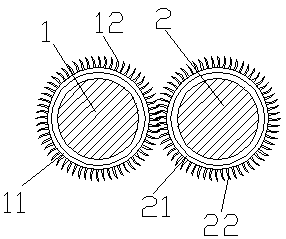

Frame-hiding three-glass energy-saving sound insulating window and manufacture method thereof

ActiveCN102052045AStable and mature processImprove tensile propertiesNoise insulation doors/windowsSealing arrangementsFoaming agentAdhesive

The invention relates to a frame-hiding three-glass energy-saving sound insulating window and a manufacture method thereof. The sound insulating window is characterized by comprising a flat opening window sash (1) consisting of a hollow glass inner layer and a single glass outer layer, a fixed window sash (2) and a window outer frame (3), wherein a muntin (11) needs to be arranged between the flat opening window sash (1) and the fixed window sash (2) according to design style; the hollow glass (4) is fixedly connected with the flat opening window sash (1) by a seal adhesive tape (5) and a flat opening window sash press strip (6); the single glass (7) is fixedly connected with the outer side of the flat opening window sash (1) by a double-side adhesive tape (8) and silicone structure adhesive (9); the top surface of the window outer frame (3) is in flexible embedded seal connection with a wall body (10) by a polyurethane foaming agent; and the top surface of the flat opening window sash (1) is connected with a window frame by a stainless steel sliding support (12). The invention has the advantages of firm and durable structure, tensile resistance, high shearing strength, stable quality, high noise reducing and sound insulating performance, air tightness, high watertight performance, high heat preserving performance and attractive appearance.

Owner:武汉鸿和岗科技有限公司

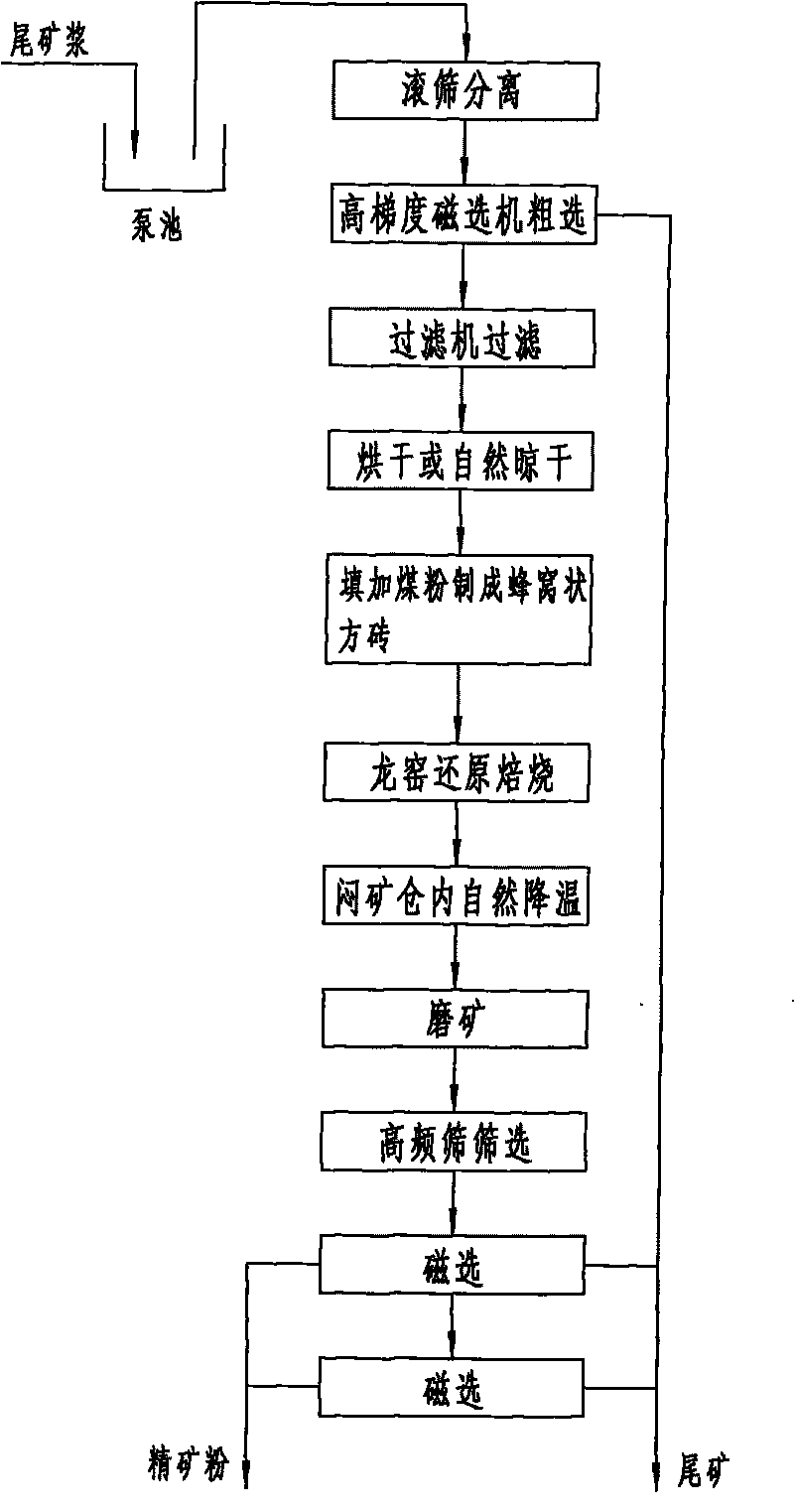

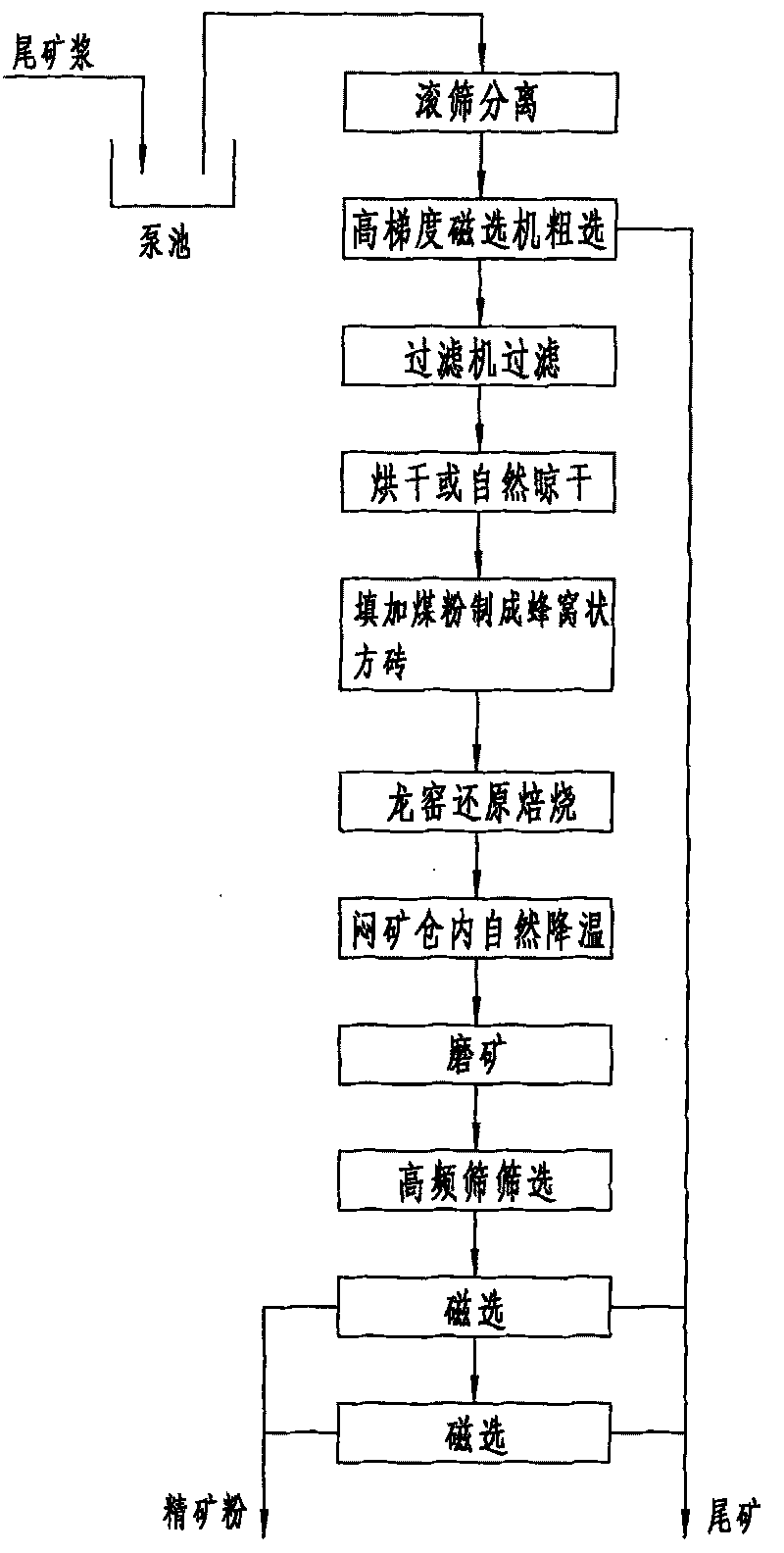

Process for roasting and restoring tailings with weak-intensity magnetism by dragon kiln

The invention relates to the field of tailings recovering, in particular to a process for roasting and restoring tailings with weak-intensity magnetism by using a dragon kiln, solving the problems of complicated process, great investment, high energy consumption, low tailing recovering ratio and the like existing in the traditional iron tailings recovering technology in China. The process comprises the following steps of: a, separating tailing pulp by a rolling sieve, roughing by a magnetic separator to obtain roughed tailings; b, filtrating and baking / naturally drying the roughed tailings; c, adding coal dust in the roughed tailings according to an appropriate proportion to prepare alveolate shaped quadrels; d, placing the alveolate shaped quadrels into a kiln chamber of the dragon kiln for restoring and roasting, dropping the reduced-restored alveolate shaped quadrels in the kiln chamber in a sealed ore storage bin below, and naturally cooling the alveolate shaped quadrels at an air isolated environment; and e, carting and grinding the cooled alveolate shaped quadrels, sieving by a high-frequency sieve and selecting fined ore powder by the magnetic separator. The process is mature and stable with easy operation and low cost, can increase the tailing recovering ratio by 6-15 percent, is suitable for recycling the tailings, and can be widely popularized with strong adaptability to the tailings.

Owner:马雨田

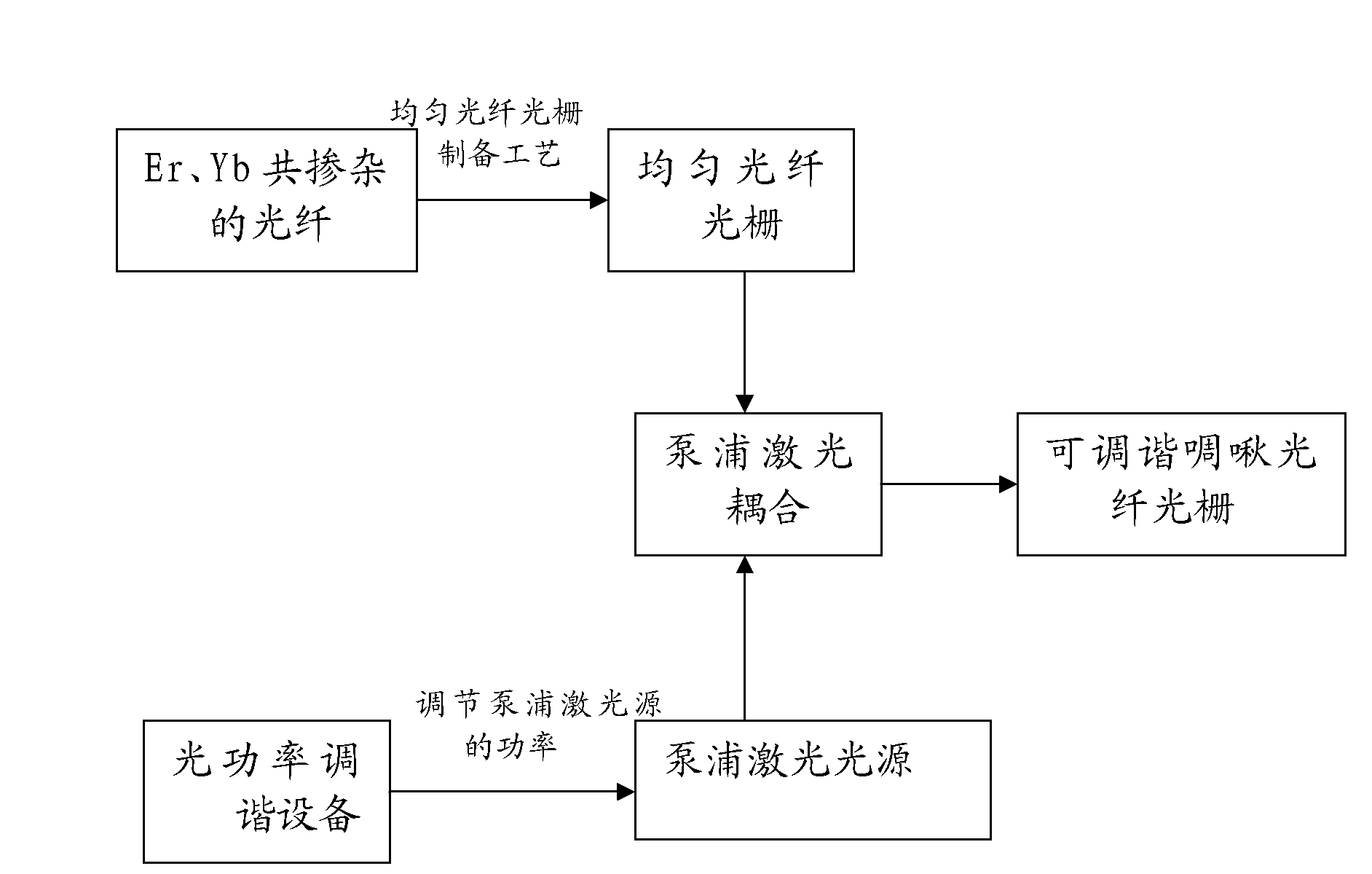

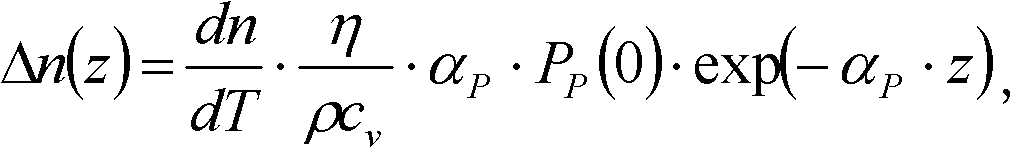

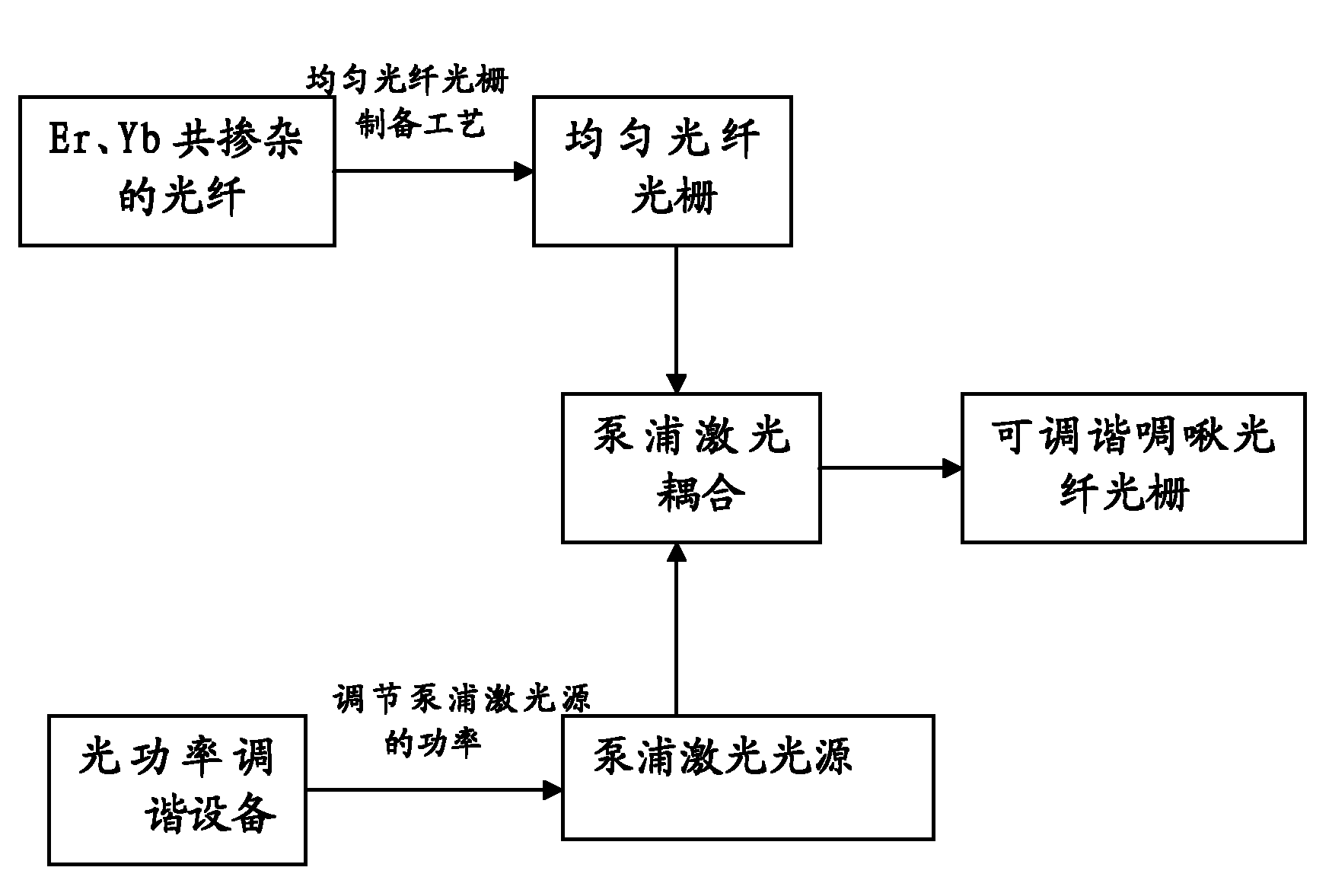

Method for manufacturing tunable chirped fiber grating

InactiveCN102122023ALow costReduce manufacturing costCladded optical fibreOptical waveguide light guideRare-earth elementFiber

The invention discloses a method for manufacturing a tunable chirped fiber grating. The method manufactures the fiber grating based on optical fiber doped in rare earth element, couples pump light into the manufactured fiber grating, and changes the refractive index of the fiber grating via a temperature gradient formed by the pump light in the fiber grating so as to convert the routine fiber grating into the chirped fiber grating. Furthermore, the method changes the refractive index of the temperature gradient field and the fiber grating by changing the power of the coupled pump light in order to implement the tunable characteristics of the chirped fiber grating and realize the tunable chirped fiber grating based on a light tuning mode. Compared with the prior art, the method in the invention is simple in process, stable in process, low in cost and quick in response speed.

Owner:JINAN UNIVERSITY

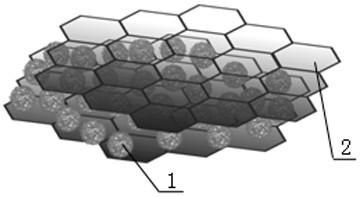

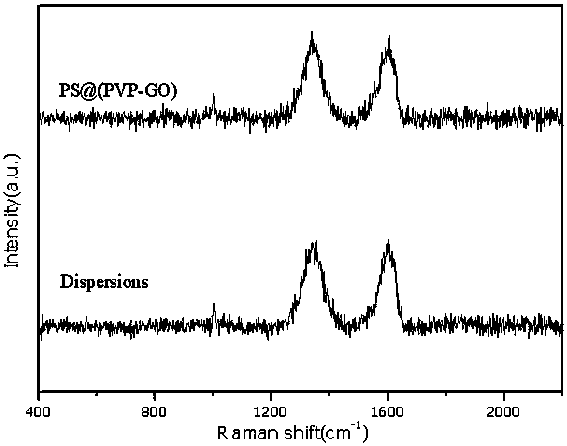

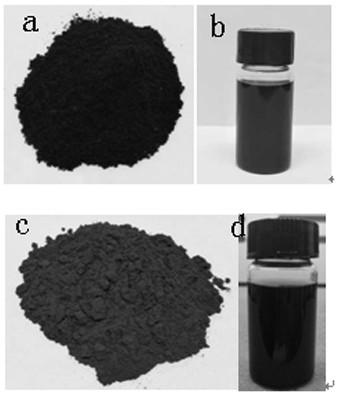

Preparation method of modified graphene powder capable of being redispersible in oil

ActiveCN109575642AOvercoming the disadvantages of secondary reunionDispersion stabilityCarbon compoundsPigment treatment with macromolecular organic compoundsHigh concentrationMicrosphere

The invention discloses a preparation method of modified graphene powder capable of being redispersible in oil, and belongs to the technical field of graphene. The method can solve the problems of poor dispersibility and stability, complex process, large energy consumption and high cost of the existing graphene in non-polar organic solvents. The method includes, firstly, taking a GO aqueous solution as a raw material, adjusting the GO aqueous solution to be alkaline, and adding PVP to prepare a GO aqueous stable dispersion; secondly, adding polymer monomers (such as styrene, methyl methacrylate and the like) and an initiator at a certain temperature, polymerizing loaded polymer microspheres in situ on the PVP-modified GO surface, and after further thermal reduction, removing water by a spraying (cold and hot drying) method to prepare the modified graphene powder. The modified graphene powder can be dispersed in the non-polar organic solvents under the action of ultrasound. The preparation process is simple, the prepared modified powder oily dispersion has high concentration, excellent dispersibility and stability, and accelerates the engineering application pace of graphene in thefields of corrosion prevention and the like.

Owner:ZHONGBEI UNIV

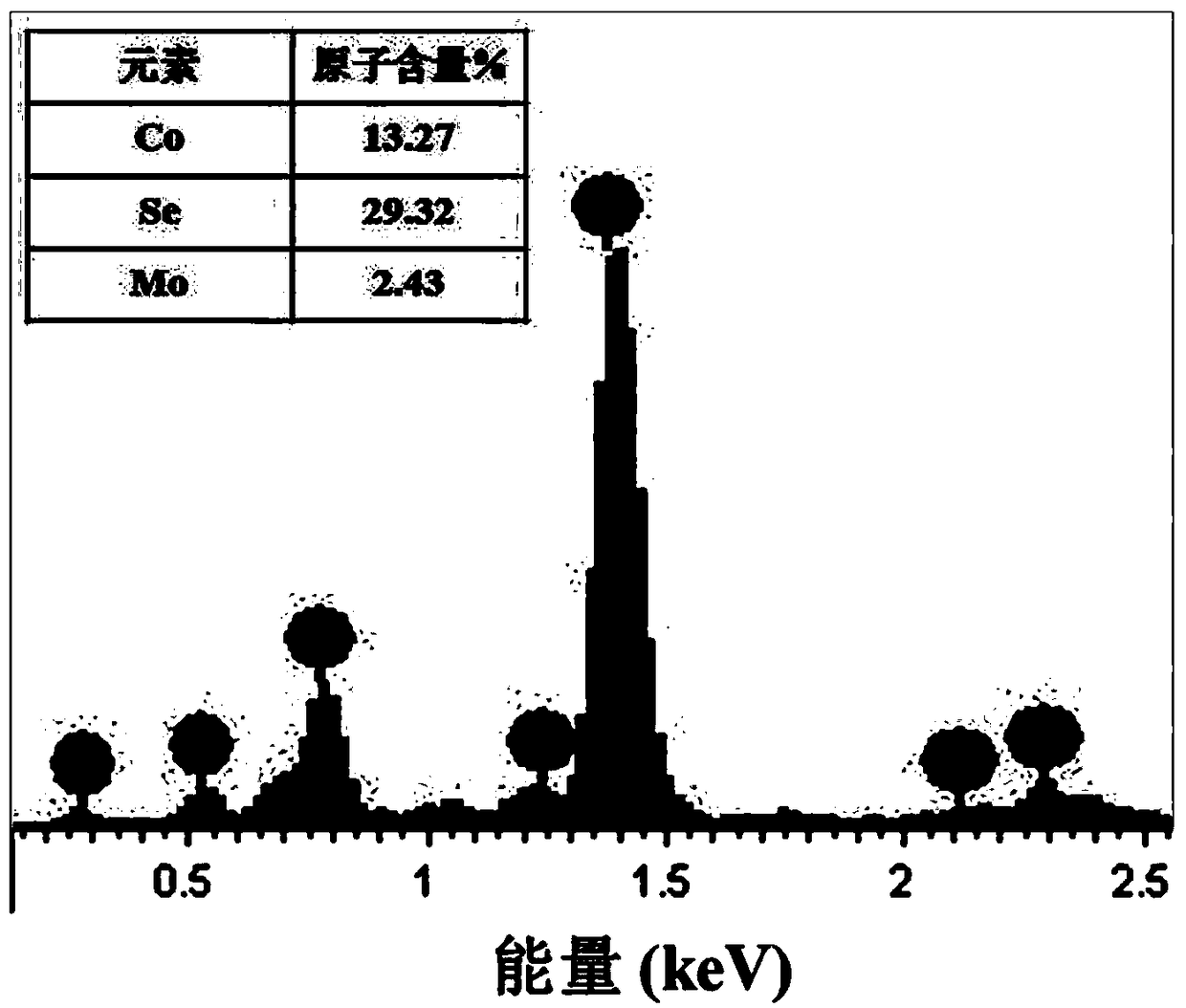

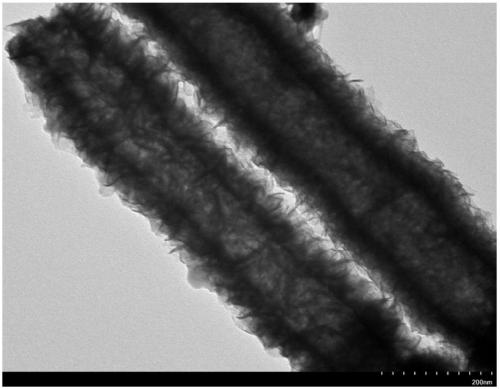

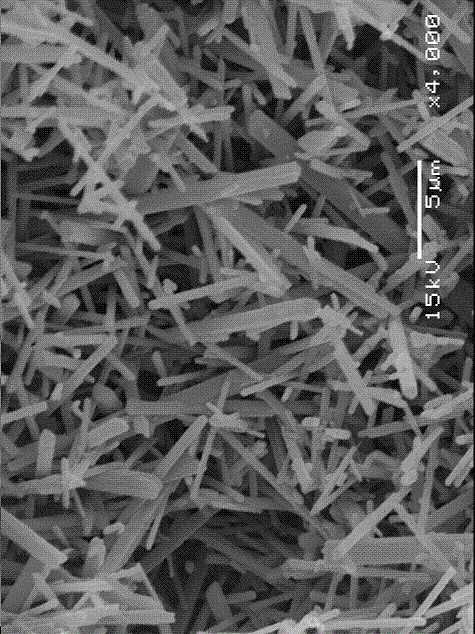

Hollow tubular cobalt-selenium compound/molybdenum-selenium compound composite nano-material and preparation method and application thereof

ActiveCN109092331AImprove electrochemical performanceStable and mature processPhysical/chemical process catalystsElectrodesDecompositionUrea

The invention discloses a hollow tubular cobalt-selenium compound / molybdenum-selenium compound composite nano-material, a preparation method and an application thereof. Firstly, a solid one-dimensional Co precursor nanomaterial is obtained through reaction of cobalt salt with urea in a liquid phase environment; then, the solid one-dimensional Co precursor nanomaterial is dispersed in a molybdate deionized water solution, and the hollow tubular CoSe2@MoSe2 composite nanomaterial is obtained by further liquid-phase selenization reaction. The adopted raw materials and process devices are simple,the preparation cost is low, the product yield is high, the prepared composite material can serve as a catalyst applied to catalytic hydrogen evolution of electrolysis water because of the advantagesof its composition and structure, shows the excellent performance of catalytic hydrogen evolution, and has the huge potential application value in the field of hydrogen production through electric water decomposition.

Owner:ANHUI NORMAL UNIV

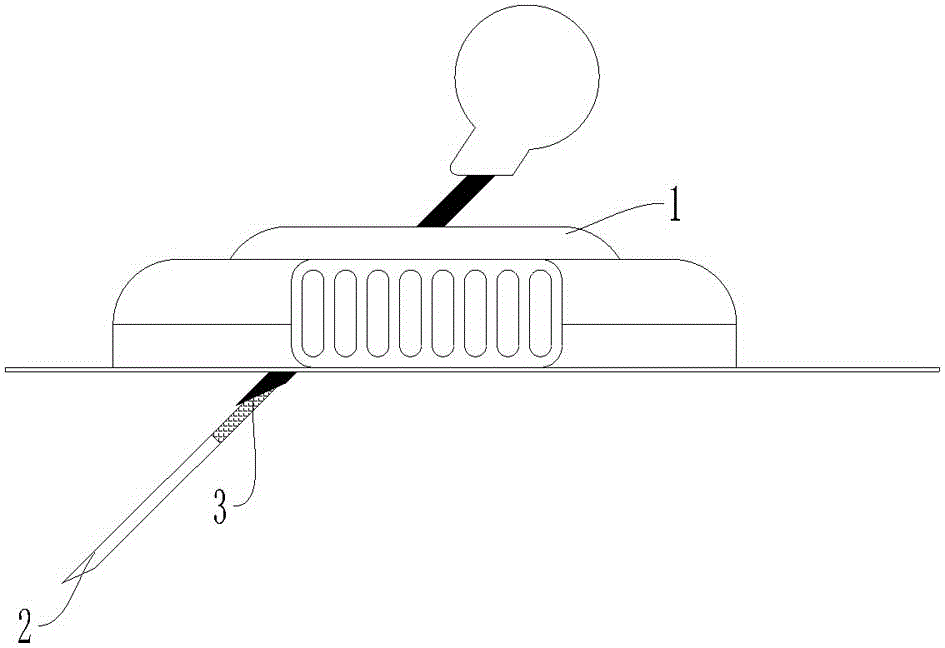

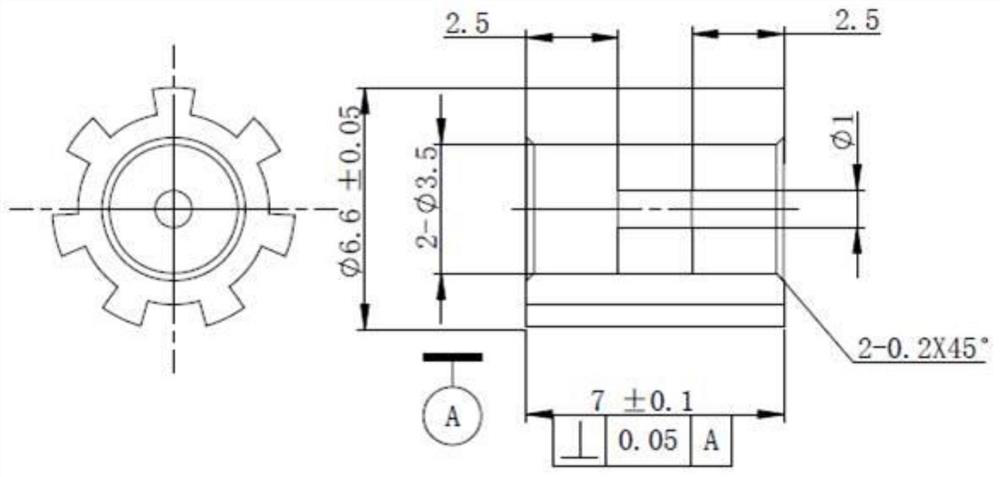

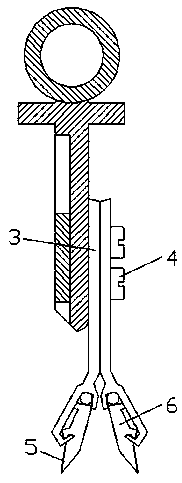

Subcutaneous tissue involvement type glucose microsensor and preparation method thereof

ActiveCN105411607ASolve the conduction problemSignal acquisition is stableDiagnostic recording/measuringSensorsGlucose polymersD-Glucose

The invention provides a microsensor, and in particular relates to a subcutaneous tissue involvement type glucose microsensor and a preparation method thereof. The subcutaneous tissue involvement type glucose microsensor comprises a base, wherein the base is internally provided with a lead part extending outwards, the tail end of the lead part is connected with a sensor part, and the sensor part and the lead part are arranged on an insulation substrate layer. The subcutaneous tissue involvement type glucose microsensor and the preparation method have the advantages that the structure is compact, the operation performance is improved, and the service life is prolonged.

Owner:杭州瀚科医疗科技有限公司

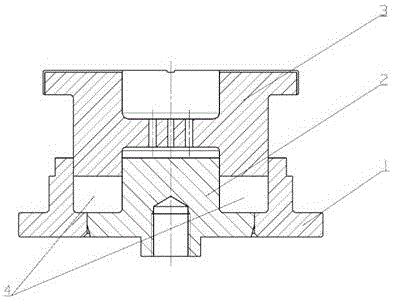

Ferro-phosphorus aluminum borate whisker preform manufacturing method

ActiveCN106702487AFully automatedAchieve mass productionPolycrystalline material growthFrom solid stateNumerical controlAluminium hydroxide

Ferro-phosphorus aluminum borate whisker preform manufacturing method of the invention comprises the following steps of 1, processing raw material: adopting, by weight, 69-90 parts of aluminium hydroxide, 7-28 parts of boric acid , 0.5-3 parts of ferro-phosphorus, grinding the three materials into fine powder, mixing evenly by using a blender mixer, putting the mixture into a crucible and removing water in the material; 2, pressing and molding a preform blank: according to size, shape and volume fraction of the required whisker preform, determining all press parameters including feed-weight and pressing pressure, putting the processed material into a mould, and pressing and molding the preform blank by using a press machine; 3, sintering at high temperature the preform blank; 4, processing and forming the preform: according to the shape and size of the required whisker preform, turning and processing the preform to a finished product by using a numerical control machine tool. The ferro-phosphorus aluminum borate whisker preform manufacturing method is capable of achieving automation of the aluminum borate whisker preform, and is low in cost, simple in operation, high in production efficiency, and can be applied to pistons, and therefore the cost is reduced.

Owner:BINZHOU BOHAI PISTON CO LTD

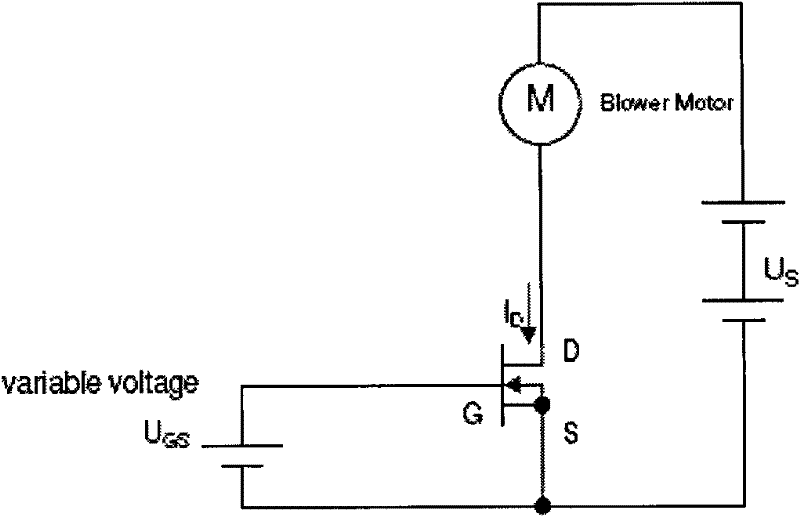

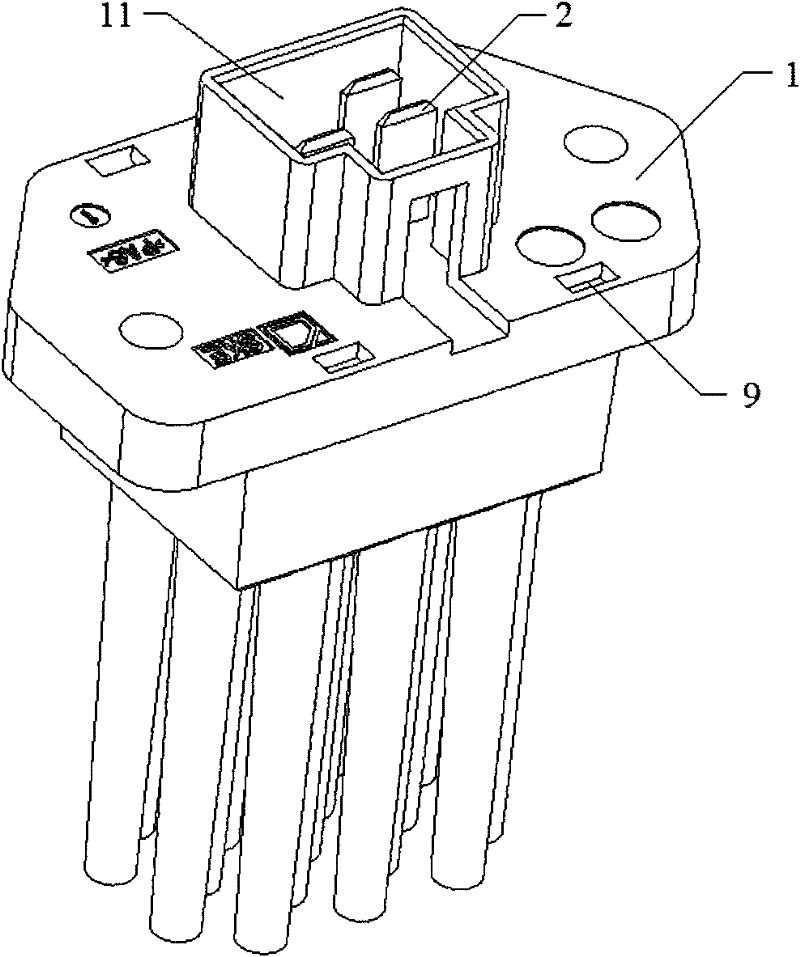

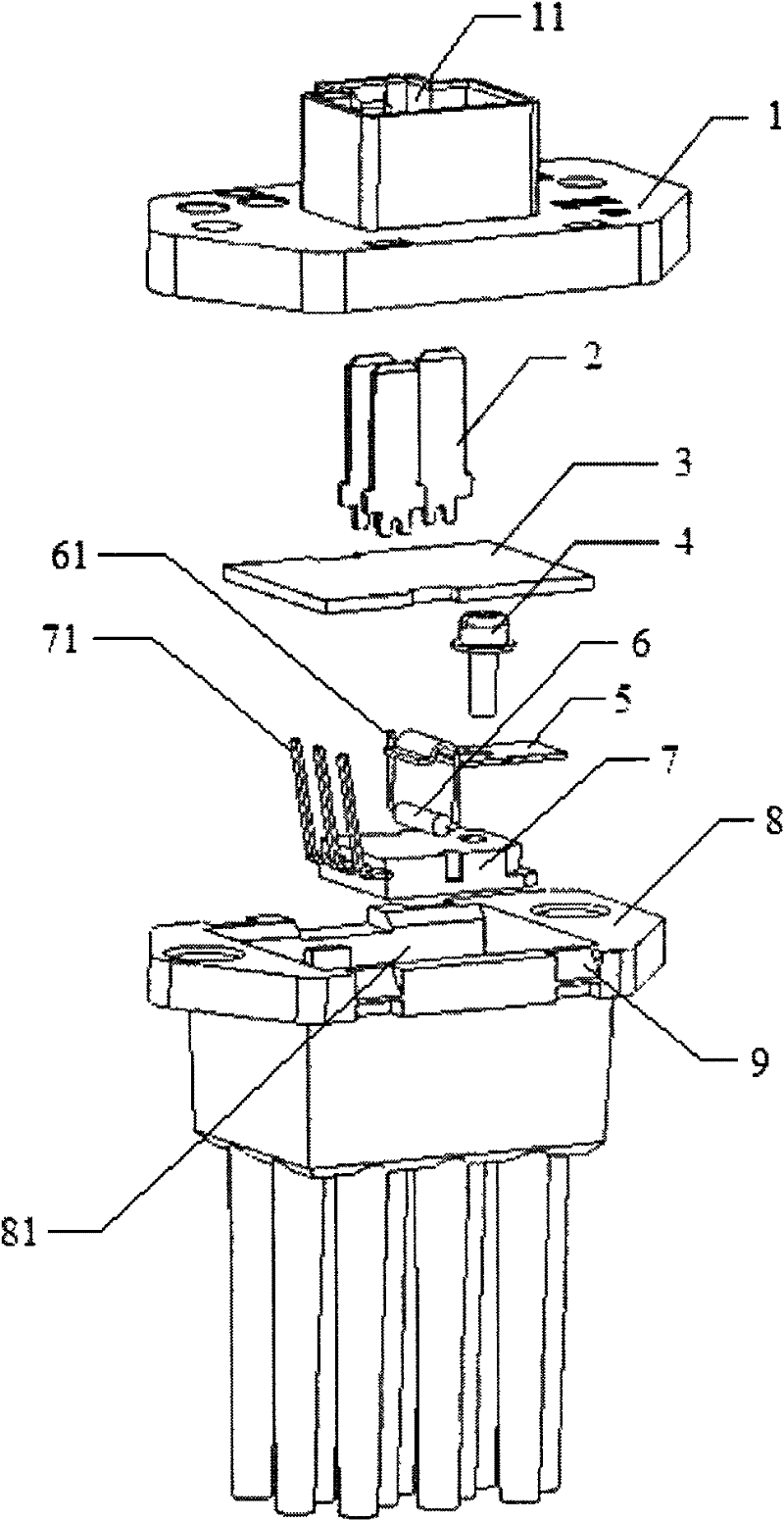

Speed regulation module of fan

InactiveCN102444600APrecise and continuous control of wind speedImprove reliabilityPump controlNon-positive displacement fluid enginesEngineeringPrinted circuit board

The invention relates to a speed regulation module of a fan, which comprises a plastic base (1), a pin (2), a printed circuit board (PCB) (3), screws (4), a metal pressing sheet (5), a temperature fuse (6), a metal oxide semiconductor (MOS) pipe (7), a radiator (8) and a fastener (9). The pin (2) is welded on the PCB (3), the temperature fuse (6) is arranged on the MOS pipe (7) through the metal pressing sheet (5), and the metal pressing sheet (5), the temperature fuse (6) and the MOS pipe (7) are fixed in the radiator (8) through the screws (4). The temperature fuse (6) and the MOS pipe (7) are welded on the PCB (3) covered on the radiator (8), and the plastic base (1) is fastened on the radiator (8) through the fastener (9). Compared with the prior art, the speed regulation module of the fan has the advantages of being stable in working, reliable in performance, easy to design and change, low in cost and the like.

Owner:上海克拉电子有限公司

Cylindrical coil core explosion-proof lithium ion battery and processing method

InactiveCN102856583ASolve the explosionExcellent barometric strengthFinal product manufactureSecondary cellsEngineeringPlastic film

The invention discloses a cylindrical coil core explosion-proof lithium ion battery comprising a shell, outer pole lugs, a cylindrical coil core and electrolyte, wherein the cylindrical coil core is composed of a plurality of coil core units, which are connected in parallel, the plurality of coil core units are clamped and fixed by two auxiliary modules of coil core, the shell is packaged by an aluminum-plastic film flexible package bag, two outer pole lugs are hermetically adhered at the bag opening of the aluminum-plastic film flexible package bag, and the pole lugs of all coil core units are connected with the outer pole lugs through corresponding anode and cathode current collectors. The invention further discloses a processing method of the battery. The lithium ion battery and the processing method disclosed by the invention are simple in production technique and low in cost; the safety performance is excellent, and the battery explosion problem is solved; and the advantages of simple technique and high production efficiency of cylindrical coil core batteries are combined, so that the technique is mature and stable, the production cost is low and the production efficiency is high.

Owner:SHANDONG TIANYANG NEW ENERGY

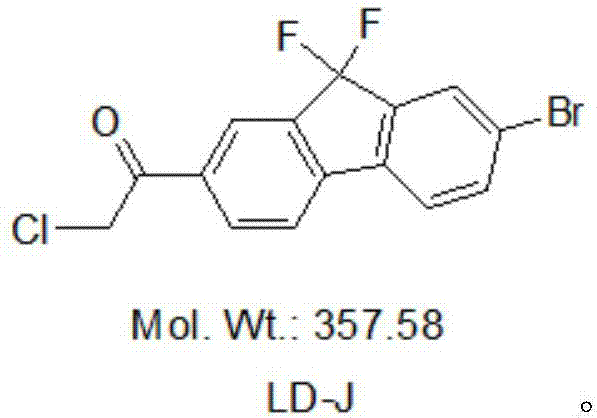

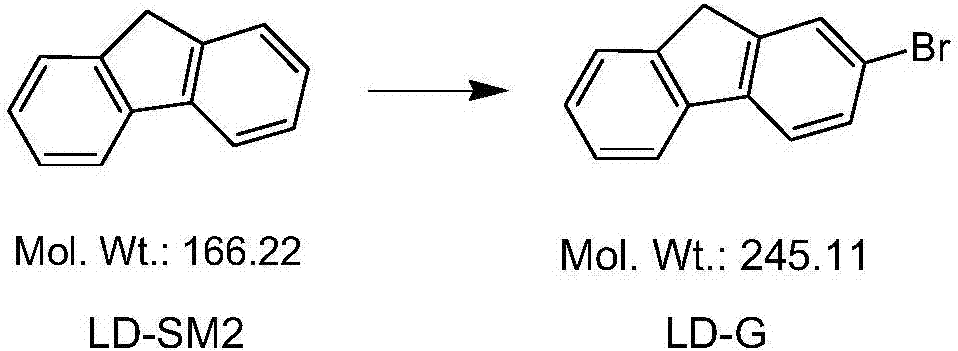

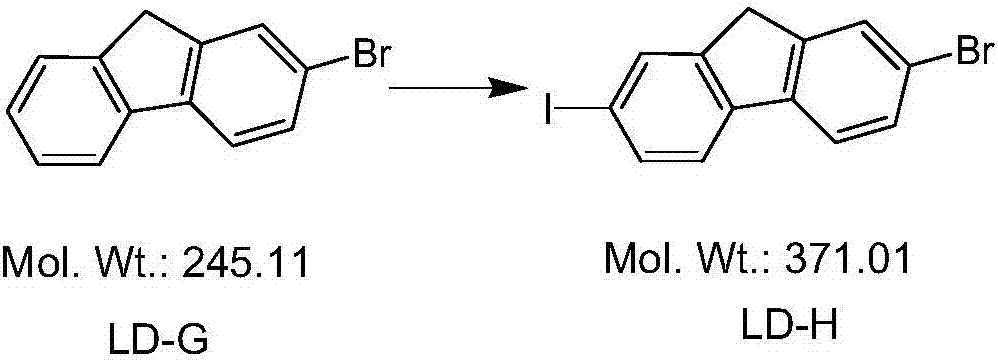

Ledipasvir key intermediate and preparation method thereof

InactiveCN107879908AStable and mature processImprove product qualityCarbonyl compound preparation by condensationHalogenated hydrocarbon preparationCombinatorial chemistryLedipasvir

The invention discloses a ledipasvir key intermediate LD-J, a structure of the ledipasvir key intermediate LD-J and a preparation method of the ledipasvir key intermediate LD-J. The preparation methodcomprises the following steps: (A1) preparing LD-G; (A2) preparing LD-H; (A3) preparing LD-I; (A4) preparing a Grignard reagent; and (A5) preparing LD-J. The ledipasvir key intermediate LD-J and thepreparation method thereof have the advantages that the process is mature and stable, the product is stable in quality, the production process is safe and reliable, and the preparation method is suitable for industrial production.

Owner:安徽诺全药业有限公司

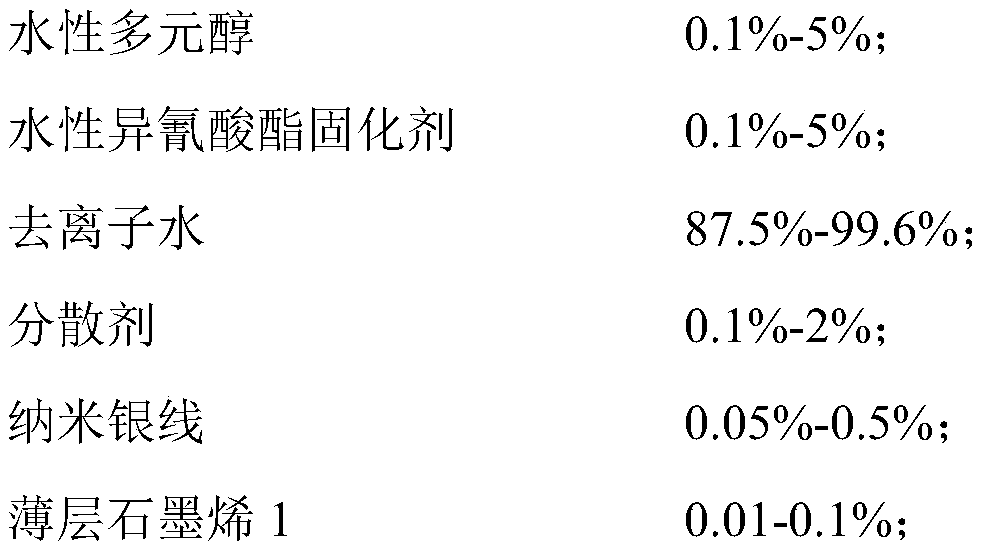

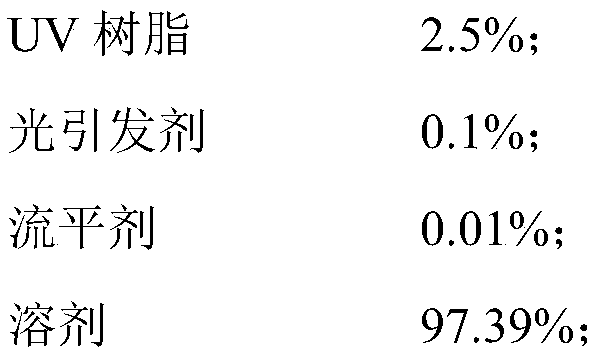

Special flexible transparent conducting film for handwriting board and flexible handwriting film based on such special flexible transparent conducting film

ActiveCN109031812AGood flexibilityImprove surface roughnessNon-linear opticsInput/output processes for data processingHandwritingFilm base

The invention discloses a special flexible transparent conducting film for a handwriting board and a flexible handwriting film based on such special flexible transparent conducting film. The flexibletransparent conducting film is formed by orderly setting a conducting layer and a protection layer on a non-hardened side of a PET film, the flexible handwriting film based on the flexible transparentconducting film is formed by taking the flexible transparent conducting film as a first electrode layer and a second electrode layer, wherein a conducting side of the first electrode layer is opposite to the conducting side of the second electrode layer and the conducting sides are adhered together through liquid crystal polymer. The flexible handwriting film provided by the invention has the characteristics of high flexibility, high contrast ratio, wide spectrum, wide view of angle, low threshold voltage, low cost, being easy to produce in a manner of large-size industrial production, and soon.

Owner:合肥微晶材料科技有限公司

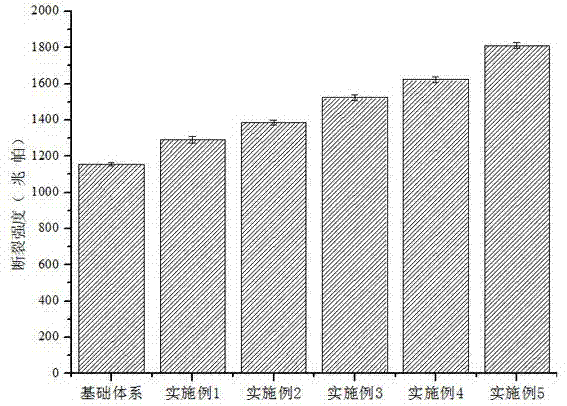

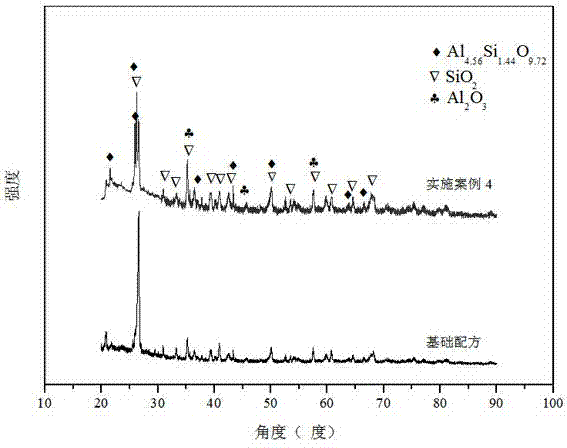

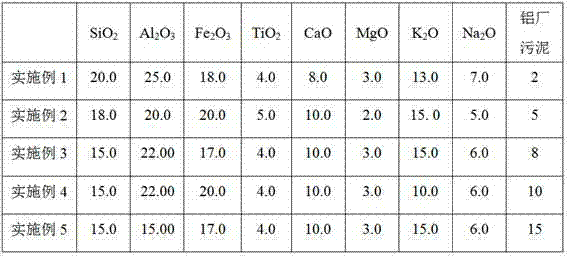

Electrical porcelain added with aluminum manufacturer sludge and preparation method thereof

The invention discloses an electrical porcelain added with aluminum manufacturer sludge and a preparation method thereof. Raw materials for the electrical porcelain added with the aluminum manufacturer sludge include, by weight, SiO2 10-20%, Al2O3 10-25%, Fe2O3 10-20%, TiO2 1-5%, CaO 2-10%, MgO 0-3%, K2O 5-15%, Na2O 3-8% and the aluminum manufacturer sludge 2-15%. The added aluminum manufacturer sludge can promote crystallization process of a mullite phase in the electrical porcelain, and the breakage strength of the electrical porcelain is remarkably improved; waste reutilization is achieved, and the electrical porcelain has important economic and social benefit. The electrical porcelain is simple in raw material preparation, easy to obtain and stable and mature in process and meets the practical and industrial conditions.

Owner:FUZHOU UNIV

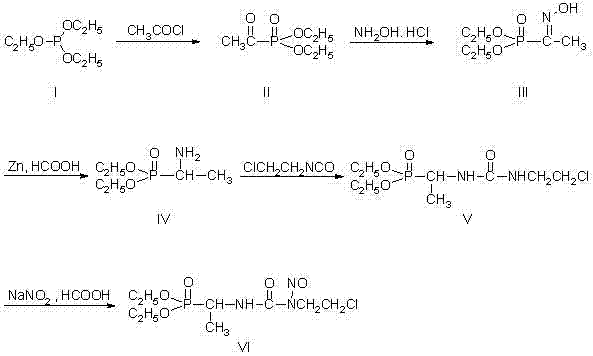

Synthetic method of fotemustine bulk drug

InactiveCN102311456AStable and mature processEasy to controlGroup 5/15 element organic compoundsHydroxylamineTriethylphosphite

The invention belongs to the field of medical chemistry, and especially discloses a synthetic method of a fotemustine bulk drug. The synthetic method uses triethyl phosphite (I) as an initial raw material to obtain a compound (II) through an acetylation reaction; an oximation reaction is carried on the compound (II) and hydrochloric acid hydroxylamine to obtain a compound (III), which is reduced to obtain a compound (IV); the compound (IV) reacts with 2-chloroethyl isocyanate to generate a compound (V), which is directly treated with nitrosation, without separation, to obtain an objective product (VI). The invention has advantages of a mature, stable and simply controlled technology, simple production steps, good product quality, high yield, cheap and easily available raw material and mild reaction conditions.

Owner:SHANDONG RUIYING PIONEER PHARMA

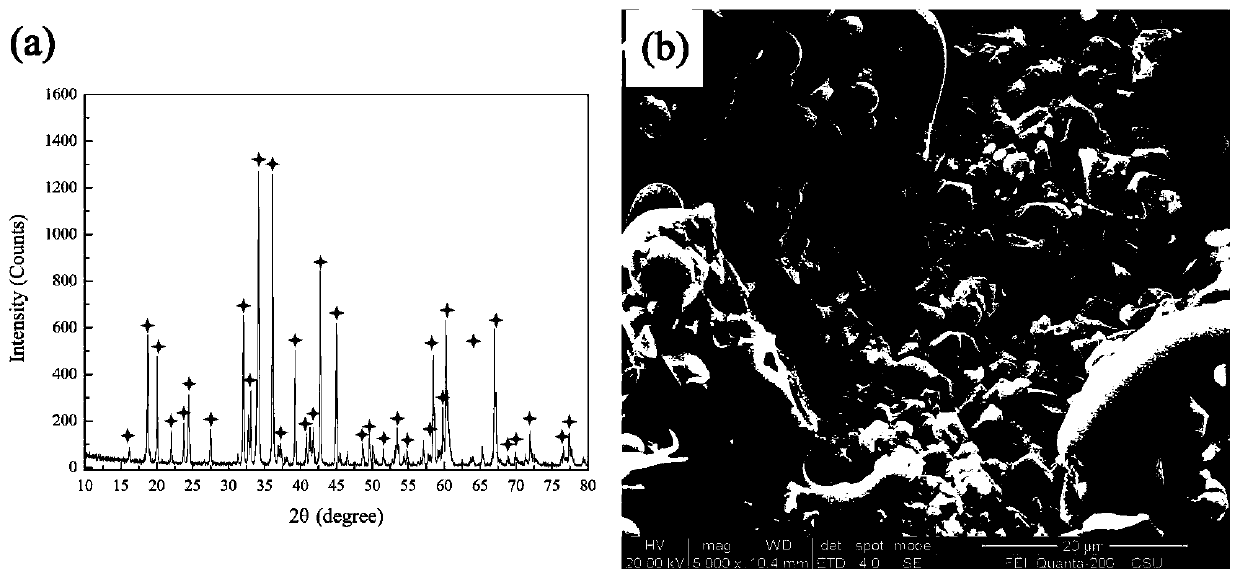

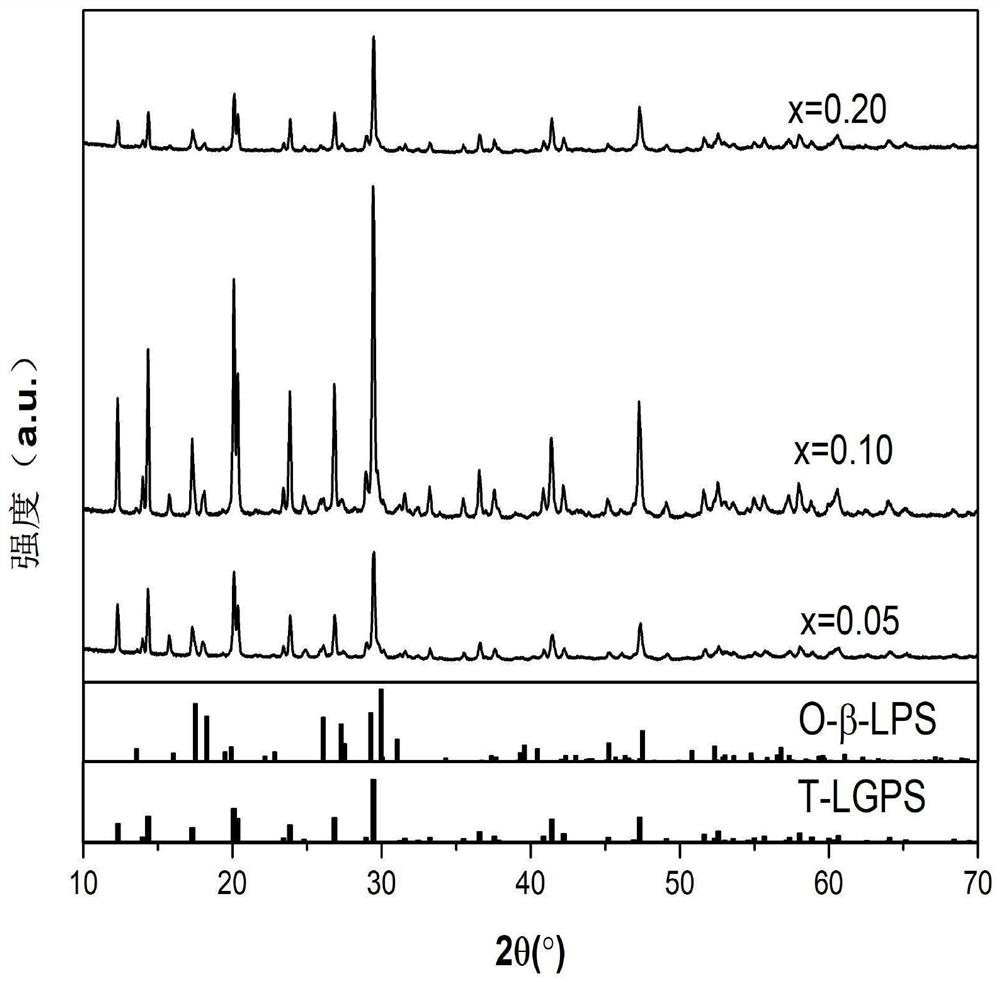

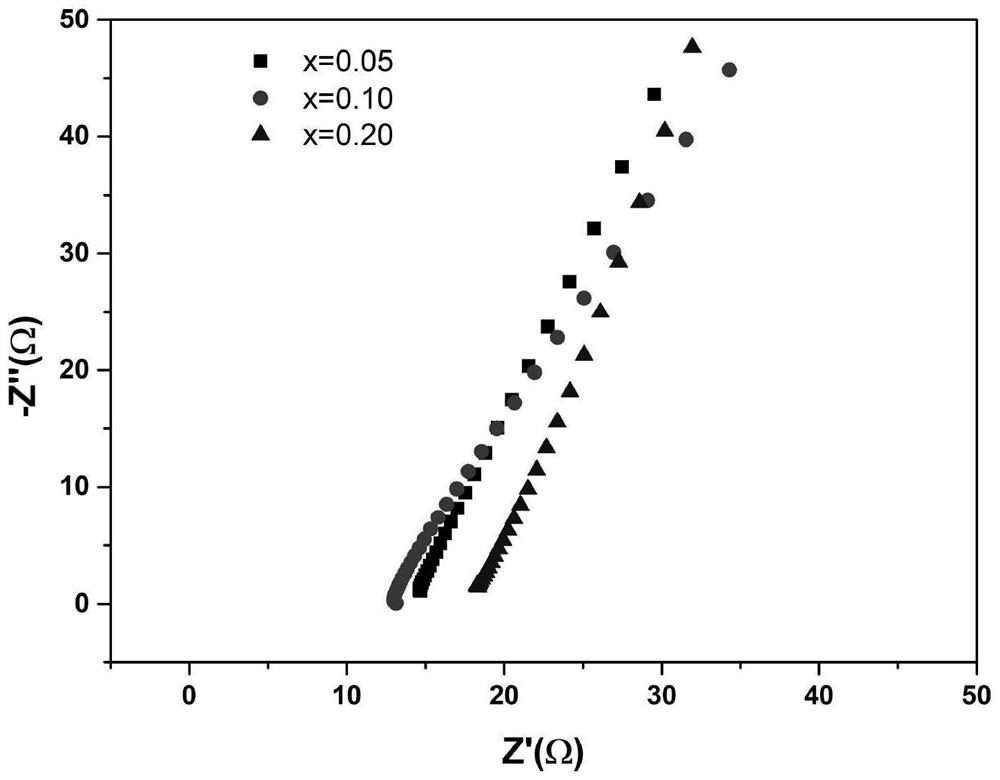

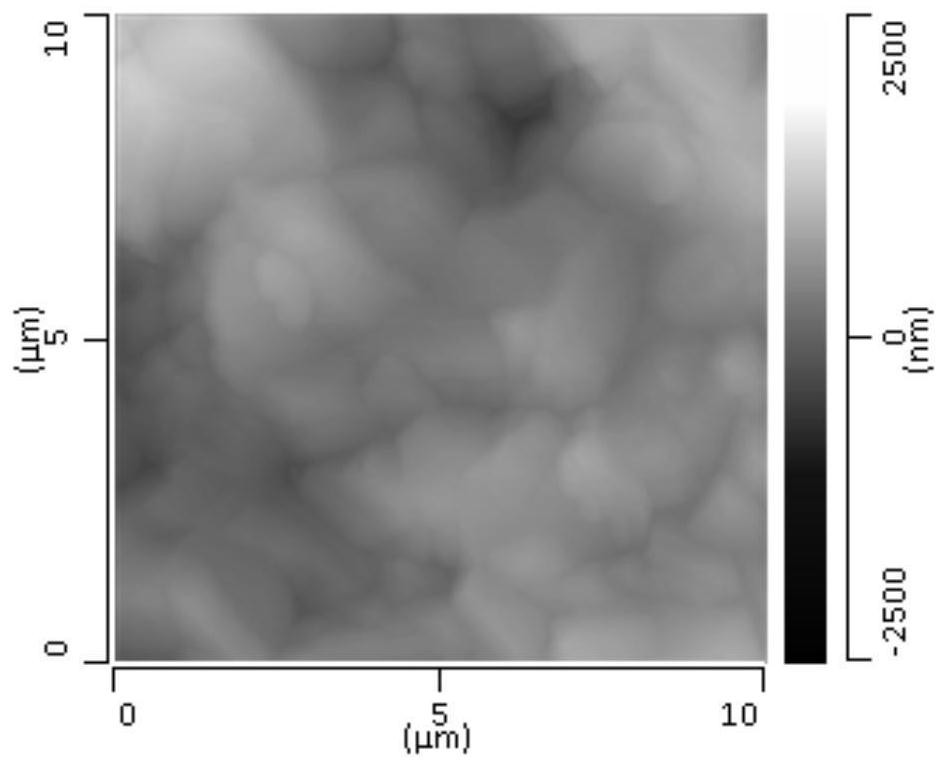

Al<3+> doped and modified LGPS type lithium ion solid electrolyte and preparation method thereof

ActiveCN113823830AExcellent conductivity performanceMeet application needsFinal product manufactureElectrolyte accumulators manufactureCompression moldingSolid state electrolyte

The invention discloses an Al<3+> doped and modified LGPS type lithium ion solid electrolyte and a preparation method thereof. The general formula of the solid electrolyte is Li10.35Ge1.35-0.75xAlxP1.65S12, wherein x is more than or equal to 0.05 and less than or equal to 0.20 in the general formula. The solid electrolyte is prepared by adopting a traditional solid phase process. The preparation method comprises the working procedures of batching, primary ball milling, compression molding, primary sintering, secondary ball milling, compression molding, secondary sintering, gold plating and the like. According to the Al<3+> doped and modified LGPS type lithium ion solid electrolyte provided by the invention, Al<3+> is doped in the Ge<4+> position in the LGPS structure, so that the LGPS type lithium ion solid electrolyte with excellent room-temperature lithium ion conductivity performance is obtained, and the room-temperature lithium ion conductivity can reach 22.1 mS / cm. The preparation method of the lithium ion solid electrolyte is stable and mature in process, the adopted raw materials are easy to obtain, and the lithium ion solid electrolyte has universality and industrial practicability and is easy to industrialize.

Owner:SICHUAN UNIV

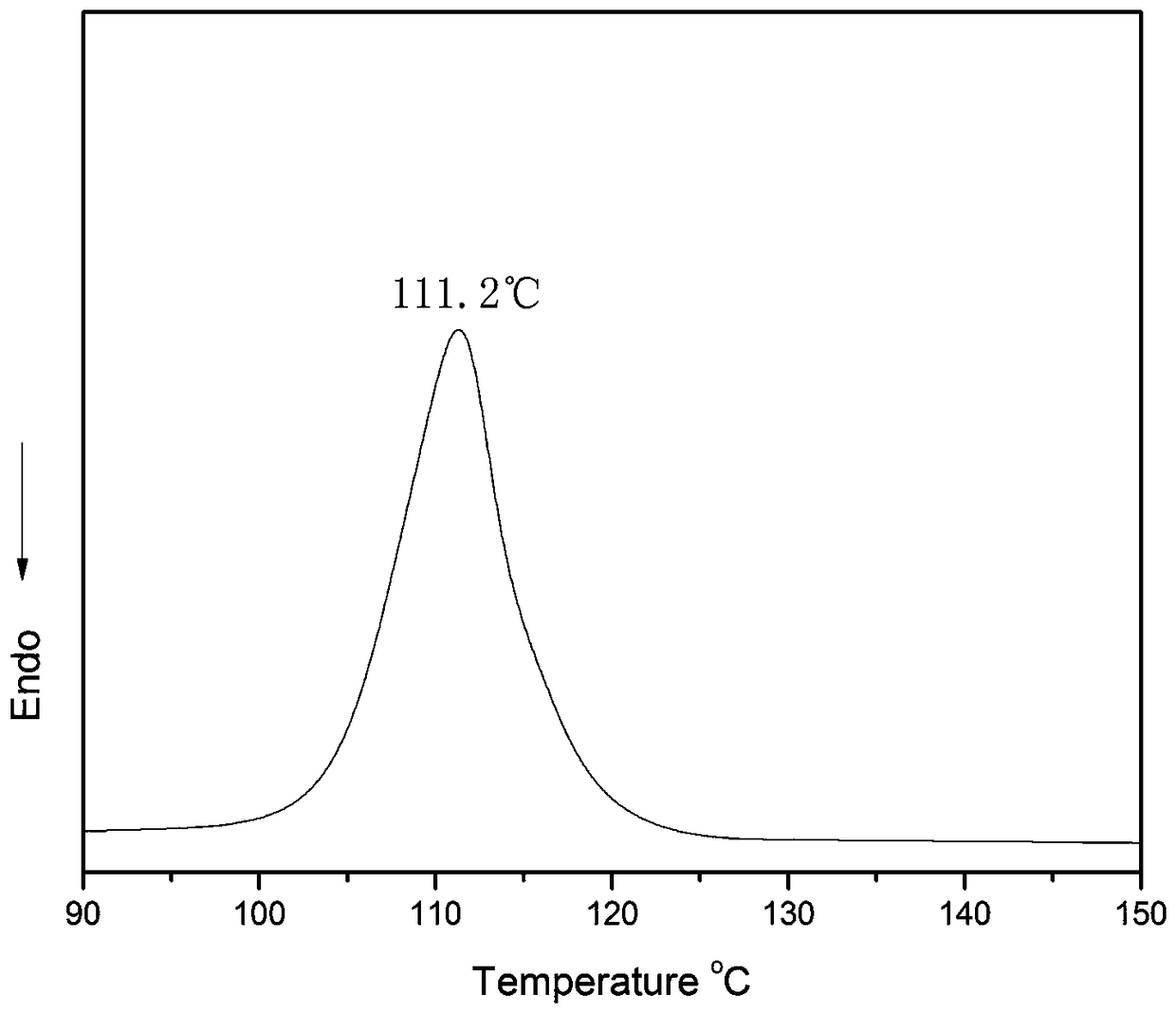

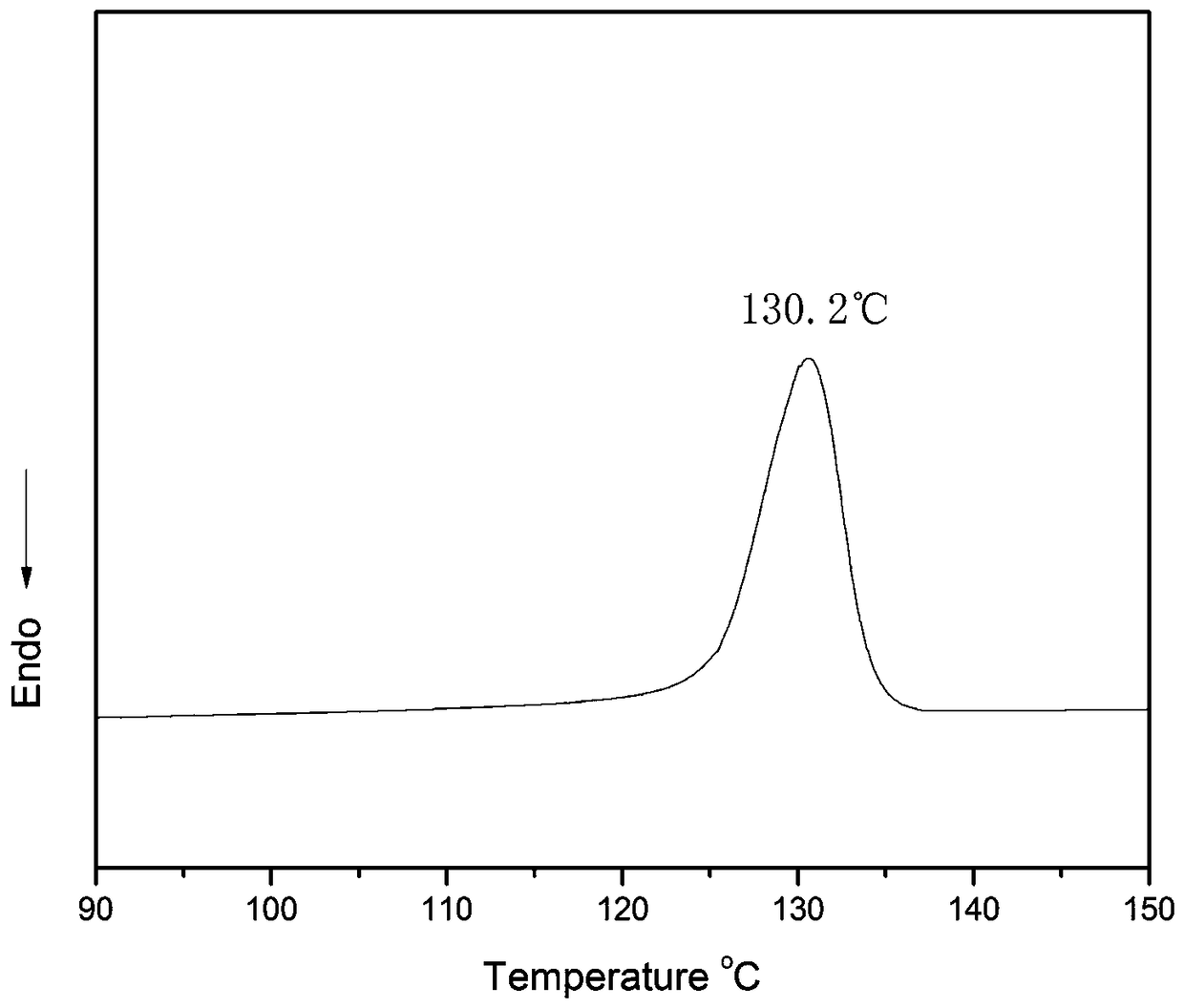

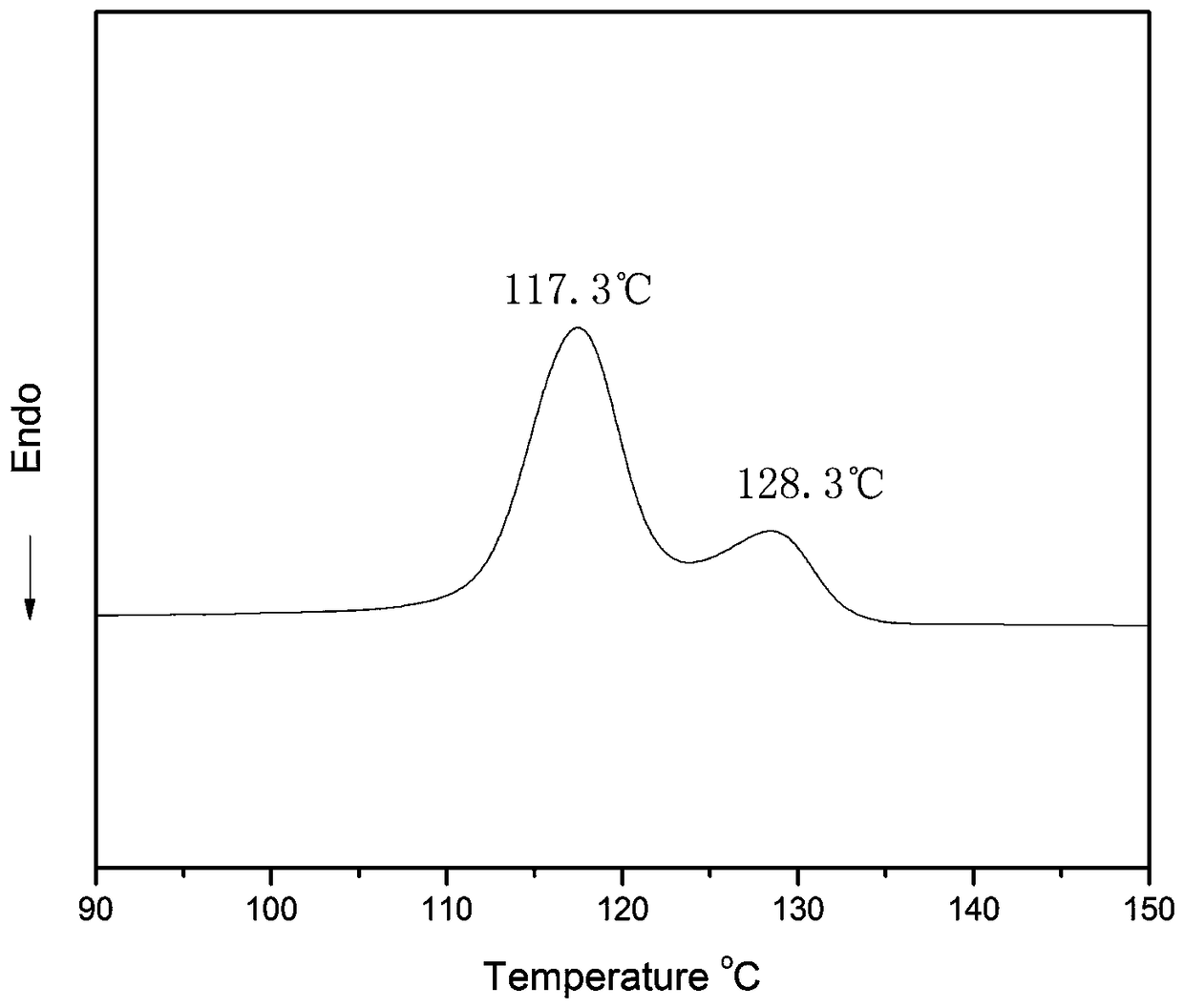

Doublet crystallization polypropylene composite material and preparation method thereof

The invention discloses a doublet crystallization polypropylene composite material and a preparation method thereof. The composite material comprises the following components by mass fraction ratio: 80-99.9% of an isotactic polypropylene content, 0.01-10% of an anti-oxidant content, 0.01-20% of an inertia filling material, and 0.01-5% of a crystallization control agent. The above components are subjected to high-speed mixing, a parallel double screw extruder is used for extruded pelletizing to prepare the composite material. The composite material has double crystallization peaks, a crystallization temperature scope is between 105 DEG C and 135 DEG C, the high-temperature crystallization peak is at 120 DEG C and 135 DEG C, and the low-temperature peak is 105 DEG C and 120 DEG C. The composite material has the advantages of high rigidity and high modulus, and has excellent impact toughness resistance and heat resistance.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

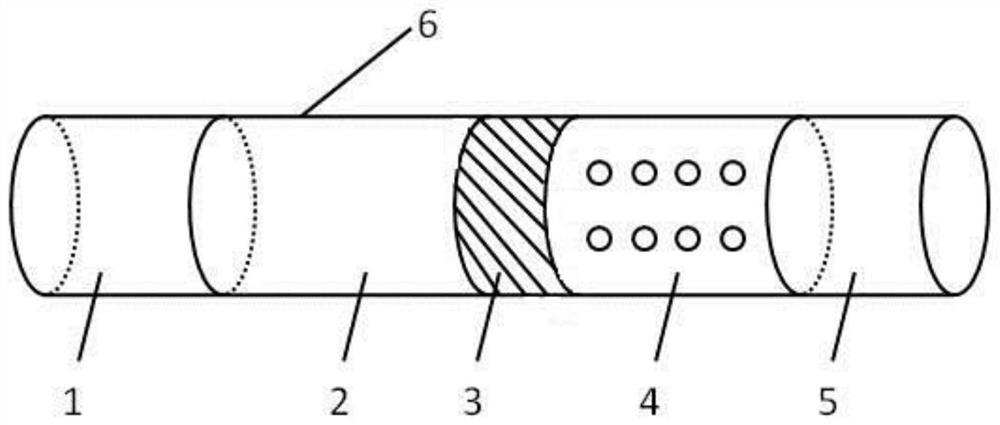

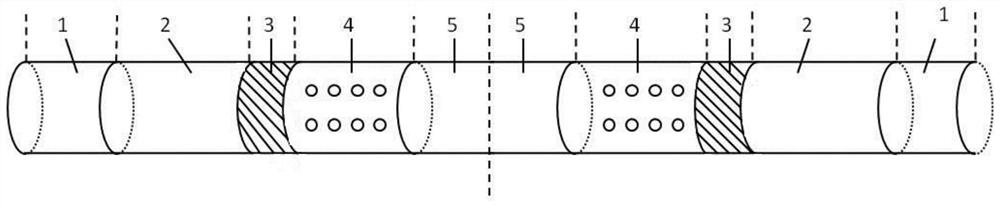

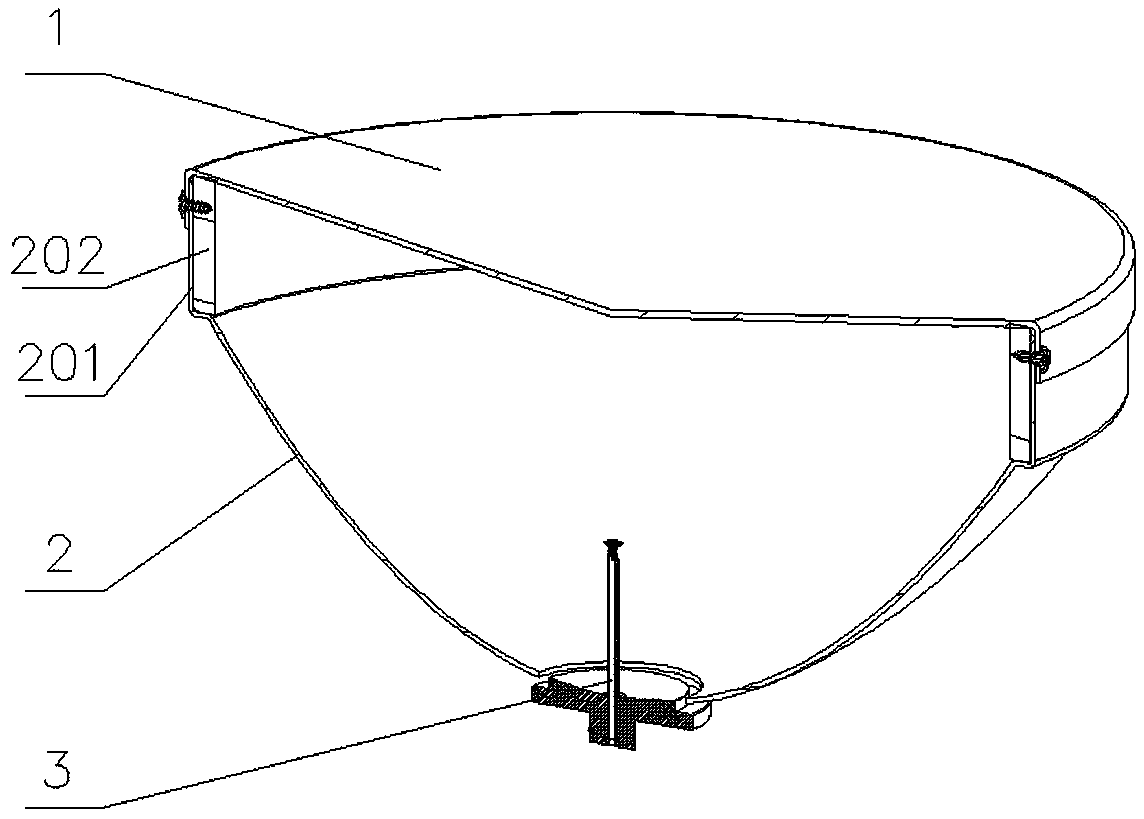

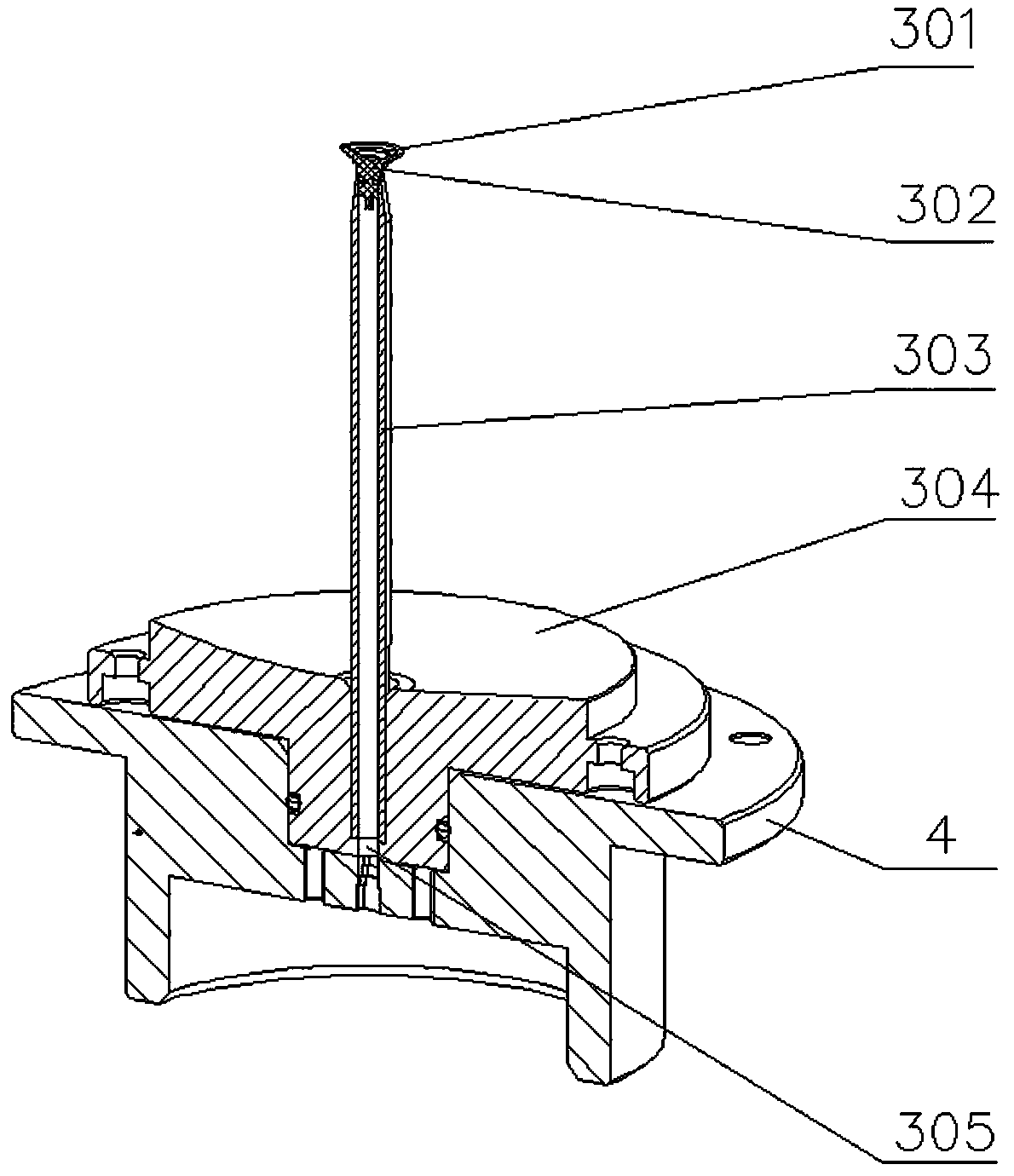

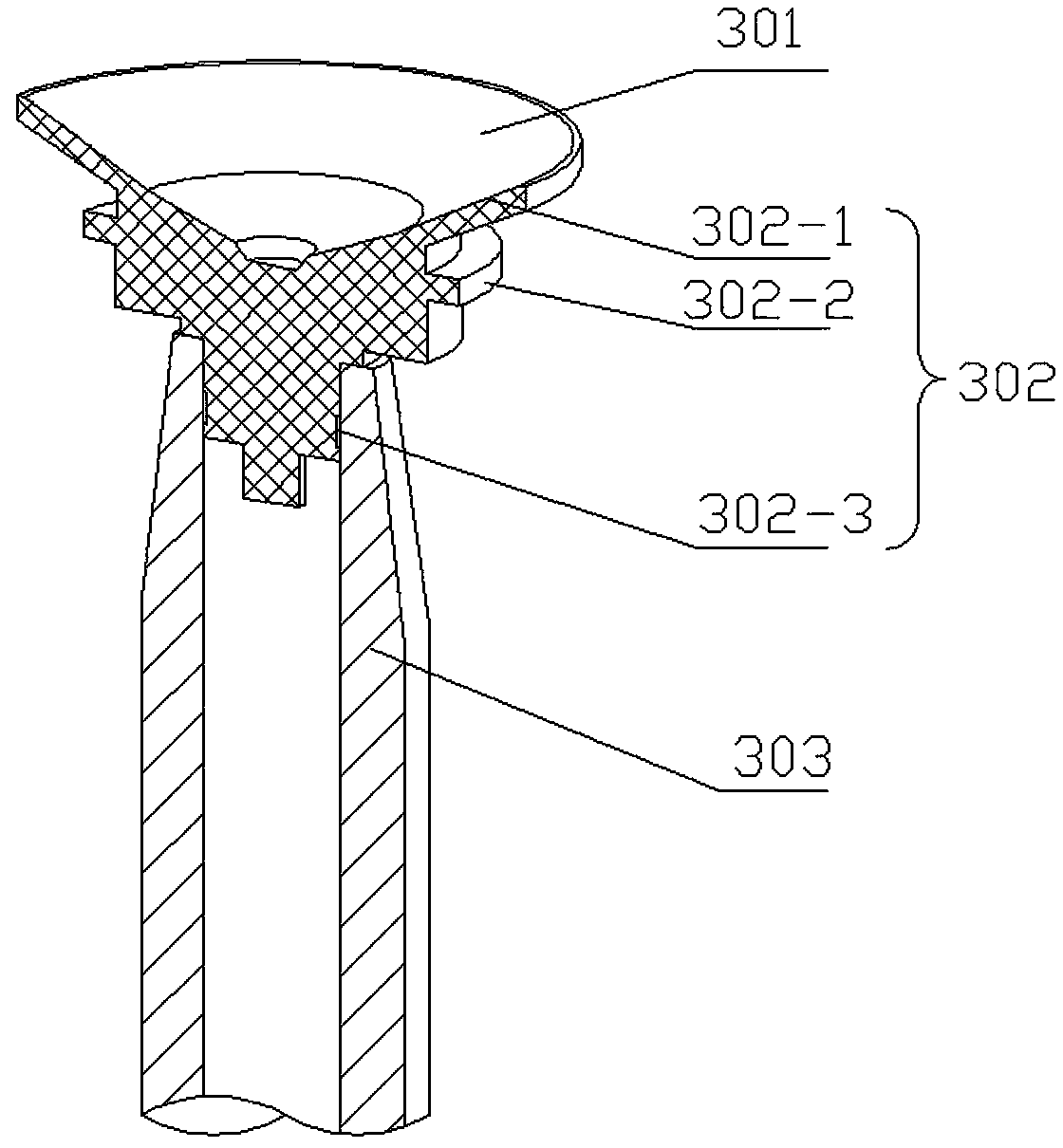

Granular aerosol generating product and rolling forming method thereof

The invention provides a granular aerosol generating product and a rolling forming method thereof. The aerosol generating product is formed by rolling a filter tip section (comprising an acetate fiber filter tip 1, a cavity 2 and a cooling material 3) wrapped by forming paper, a granular section (tobacco particles 4) and a sheet section (ordered sheet 5) wrapped by the forming paper through packaging paper 6 through a binary composite filter tip forming machine. The aerosol generating product has the advantages that the used tobacco particle plugging structure is an ordered sheet prepared from natural plants such as tobacco, tea and Chinese herbal medicines, and is firm in plugging and good in air permeability; and compared with a traditional filling process, the rolling forming method is high in efficiency, the process is more mature and stable, conversion of the preparation method of the granular aerosol generating product from the filling process to the rolling process can be achieved, and development of the granular aerosol generating product, especially the novel granular tobacco industry, is facilitated.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

E-band high-performance antenna

PendingCN108598680AOptimize the installation methodEasy to produceRadiating elements structural formsRadiating element housingsMicrowaveDielectric loss

The invention relates to the technical field of a microwave antenna, and specifically relates to an E-band high-performance antenna, comprising a reflective surface, an antenna cover and a feed source; the feed source comprises a feed source base, a waveguide tube, radiation dielectric and a secondary reflective surface; a through hole is formed in the central position of the feed source base; a waveguide port is formed in one, positioned on the exterior of the reflective surface, of the through hole, and the waveguide tube is inserted in one end positioned in the inner cavity of the reflective surface; the radiation dielectric adopts a T-shaped structure, and comprises lower part dielectric inserted in the waveguide tube and opposite to one end of the feed source base, and upper part dielectric arranged on the exterior of the waveguide tube; an annular groove is formed in the outer edge of the lower part dielectric; at least one layer of annular stage is arranged on the outer edge ofthe upper part dielectric; a conical groove is formed in the end plane, opposite to the lower part dielectric, of the upper part dielectric; and the secondary reflective surface is matched with the conical groove in shapes and attached in the conical groove. The E-band high-performance antenna is simple and convenient to mount, easy to produce, low in cost, low in dielectric loss and high in frequency band.

Owner:TONGYU COMM INC

Plane-form frequency reuse antenna sub-reflection surface

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Spinning production process of super-fine polyester blended yarn

ActiveCN108708010AIncrease production capacityImprove yarn qualityFibre mixingCombing machinesPolyesterFiber

The invention discloses a spinning production process of a super-fine polyester blended yarn. The spinning production process includes the steps: (1) mixed sliver carding: carding mixed slicers of super-fine polyester fibers by a drawing frame with two transformation needle loops after a sliver mixing machine; (2) recombing: performing transformation by a wool type combing machine, performing combing by a card wire and spiral method, and increasing the density of last three rows of a circular comb to 25 specifications by double top comb structures; (3) combination: mixing the fibers by a drawing frame with two transformation needle loops; (4) twistless roving: adopting a twistless wool type roving machine; (5) twisted roving; (6) spinning. By the mode, the spinning production process of the super-fine polyester blended yarn is particularly designed according to properties such as various characteristics and internal indicators of 0.8dtex super-fine polyester fibers, improved equipmentand parameters are adopted, production effects are good, the process tends to be mature and stable, generation of card neps and twitty yarns is decreased, and yarn quality is good.

Owner:JIANGSU LIANHONG TEXTILE

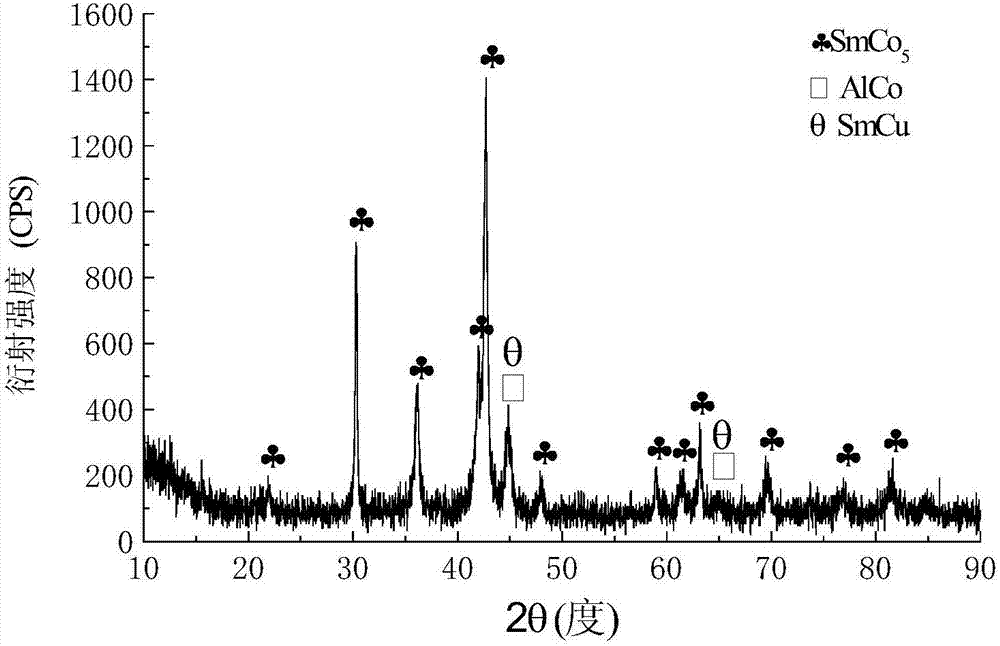

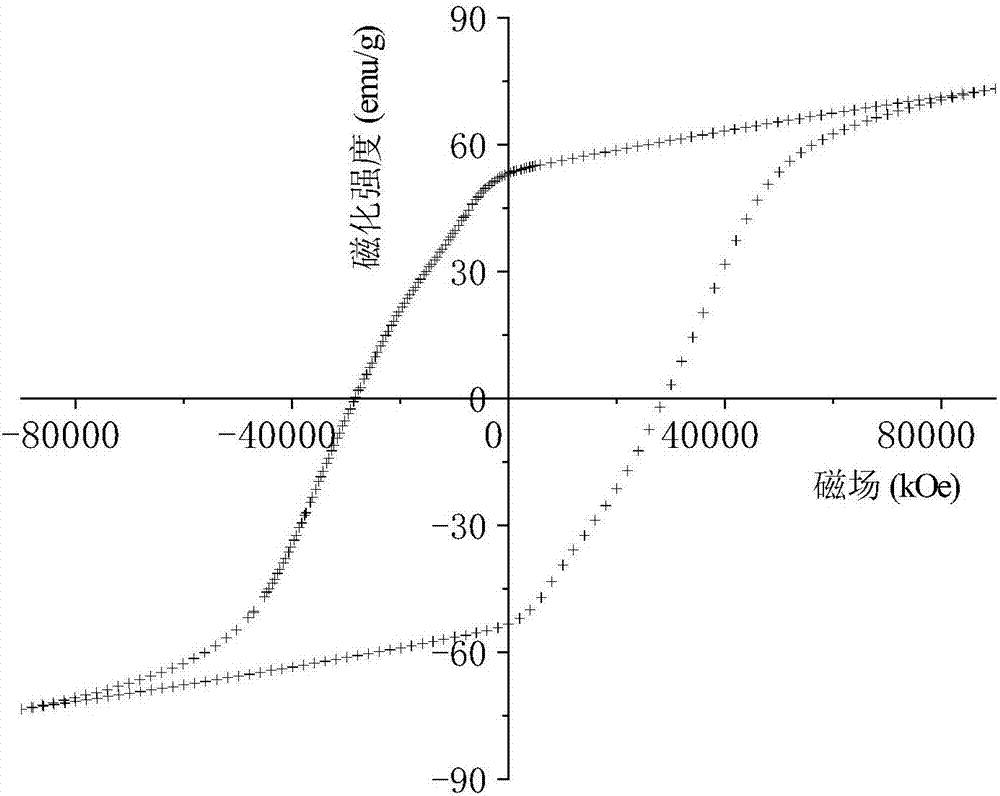

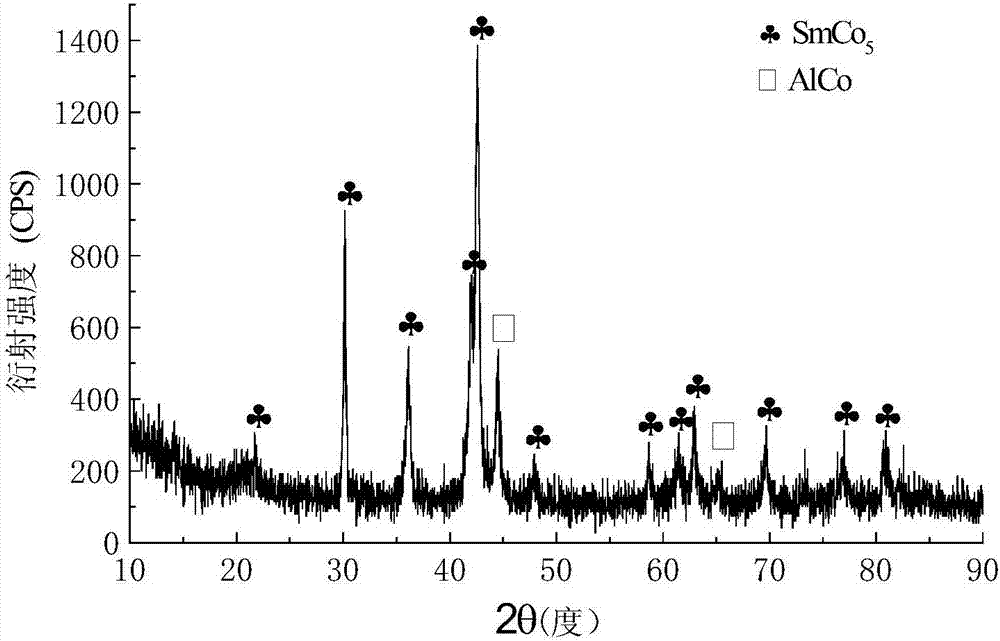

SmCo5 permanent magnet ribbon magnet and preparation method thereof

InactiveCN106887291AIncreased anisotropyHigh magnetizationInductances/transformers/magnets manufactureMagnetic materialsMagnetic transitionsSingle element

The invention provides a SmCo5 permanent magnet ribbon magnet and a preparation method thereof, and relates to magnets of hard magnetic material containing rare earth metals and magnetic transition metals, the composition general formula of the elements of the ribbon magnets is SmxCoyAlzCuuFev, through the addition of different amounts of Al-Cu-Fe alloy in SmCo5 alloy composition, which is equivalent to regularly adding Al-Cu-Fe alloy composition elements in a multi-component mode in the SmCo5 series alloy, to form a multi-element multi-phase strengthening mechanism, the SmCo5 permanent magnet ribbon magnet whose element composition general formula is SmxCoyAlzCuuFev is prepared. The shortcomings are overcome for such cases when in the existing technology after single elements are added, while improvements are made on one or limited several performances of the magnet material, often other performances result in reductions or changes, so that the performance has large differences from the theoretical value, and when a variety of elements are added, no rules can be followed, and inconveniences are brought to the subsequent research.

Owner:HEBEI UNIV OF TECH

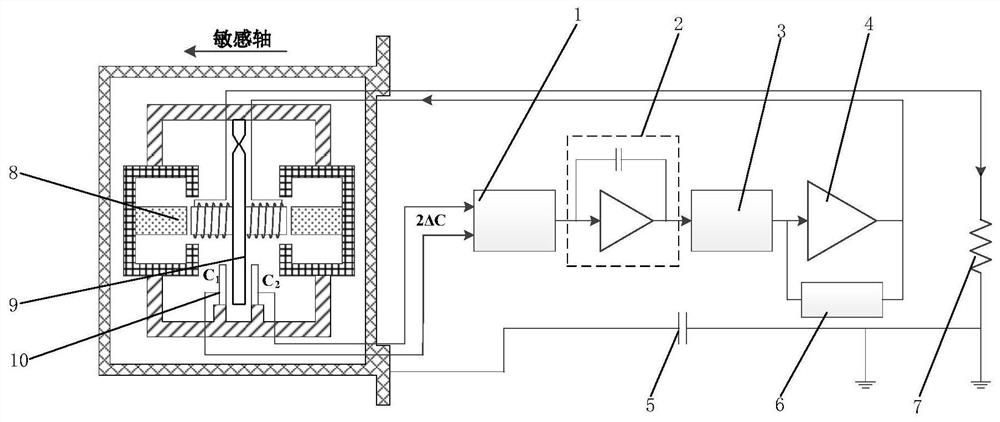

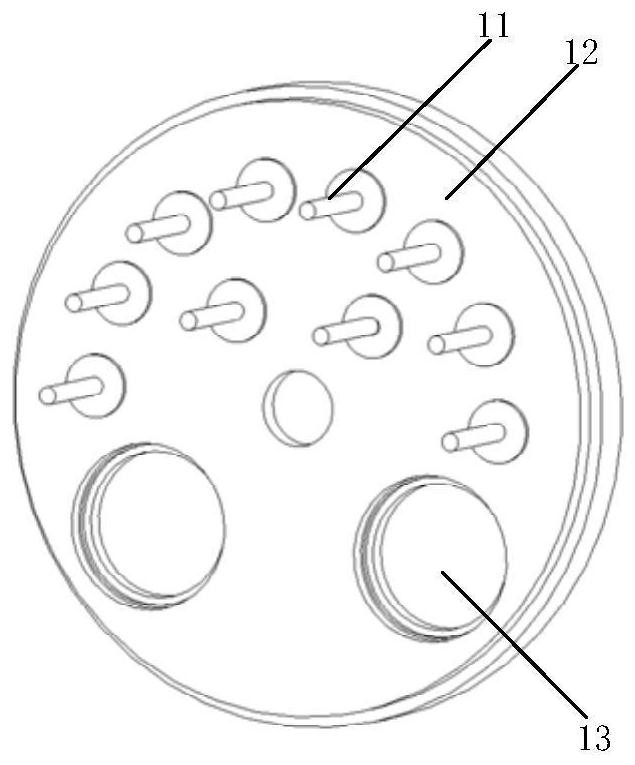

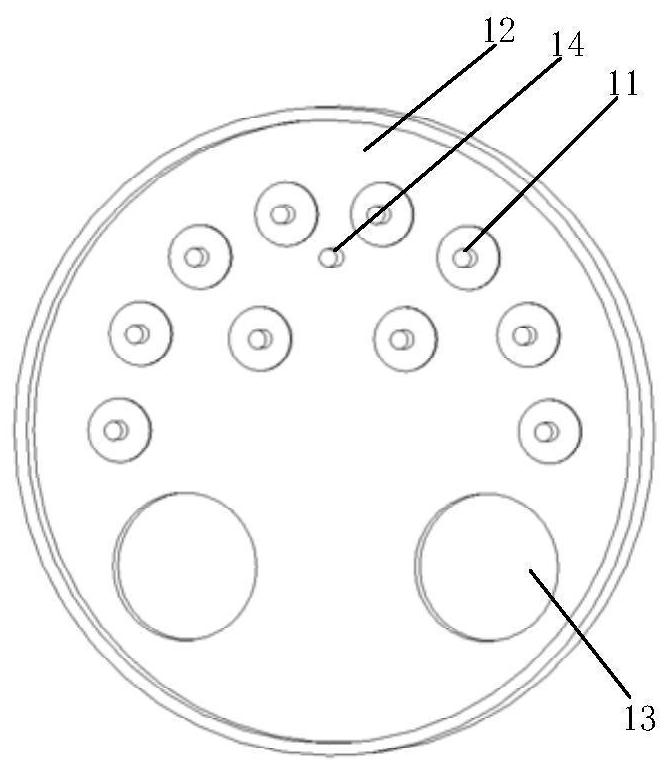

Servo control circuit, quartz flexible accelerometer based on servo control circuit and manufacturing method

ActiveCN111983259AImprove anti-electromagnetic interference performanceAvoid damageAcceleration measurementCapacitanceLow-pass filter

The invention belongs to the technical field of hybrid integrated circuits, and discloses a servo control circuit, a quartz flexible accelerometer based on the servo control circuit and a manufacturing method. The servo control circuit comprises a differential capacitance detector, a current integrator, an RC low-pass filter, a transconductance / compensation amplifier, a resistance-capacitance feedback network and a capacitor; the quartz flexible accelerometer comprises a connection quartz watch head and a servo assembly. The quartz watch head comprises a shell, a pendulous reed, a differentialcapacitance sensor and a torquer are arranged in the shell, the differential capacitance sensor and the torquer are coaxially arranged with the pendulous reed, the servo assembly comprises an outer shell, the outer shell is connected with the shell, a base plate is arranged between the outer shell and the shell, one side of the base plate is connected with the outer shell, and a servo control circuit and a cover plate covering the servo control circuit are arranged on the other side. The shell is provided with a first binding post and a plurality of second binding posts, the first binding post is electroplated with a gold layer, and the first binding post is in bonding connection with a thick film bonding pad connected with the capacitor through gold wires. The defect that an existing quartz flexible accelerometer is poor in anti-interference capacity is overcome, and the measurement precision of the quartz flexible accelerometer is improved.

Owner:XIAN MICROELECTRONICS TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com