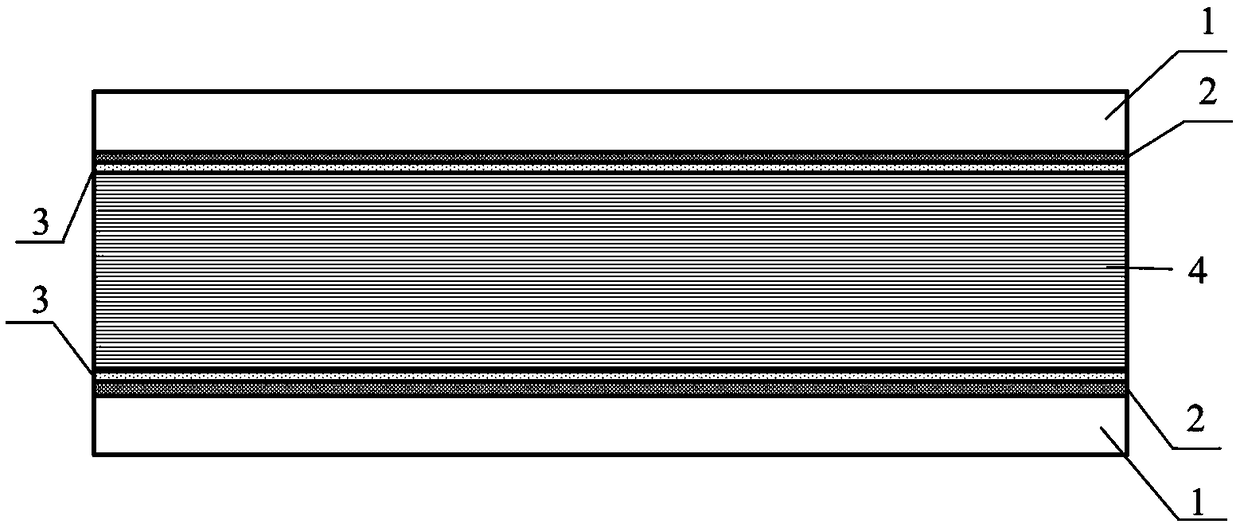

Special flexible transparent conducting film for handwriting board and flexible handwriting film based on such special flexible transparent conducting film

A technology of transparent conductive film and handwriting board, which is applied in nonlinear optics, electrical digital data processing, input/output process of data processing, etc. The effect of wide pitch distribution, simple industrial production and wide wavelength reflection spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

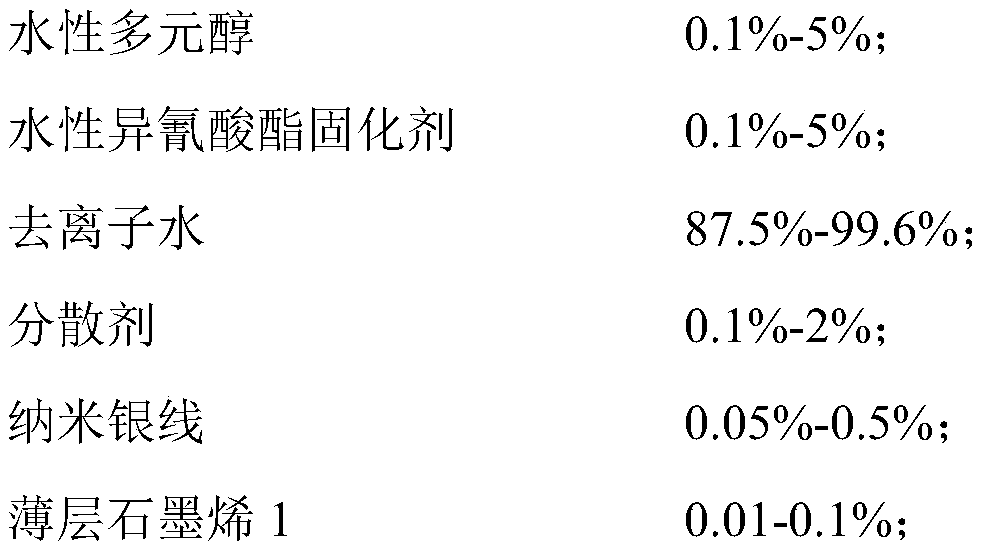

[0046] (1) Preparation of flexible transparent conductive film: In a clean room, add 3g of water-based polyether polyol VOANOL CP 450, 3g of water-based isocyanate curing agent Bayhydur 305, 92.75g of deionized water, and 1g of dispersant hydroxyethyl cellulose in sequence Dispersion cylinder, mechanically stir; then add 0.2g nano-silver wire WJAG1 and 0.05g thin-layer graphene WJSG1410 in turn, continue stirring until uniform, and then grind and disperse to obtain conductive ink; use dimple coating process to uniform the conductive ink coated on the non-hardened surface of PET, and dried in an IR oven (110°C, 20s) to obtain a conductive layer.

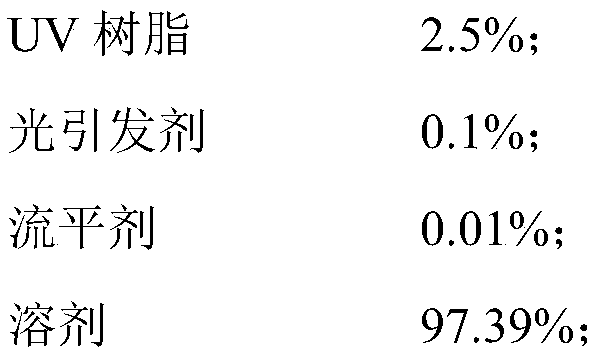

[0047] Mix 99.95g of UV protection solution and 0.05g of thin-layer graphene (thin-layer graphene used is 1-3 layers, particle size D50 is 4-7μm, KNG-G2-2 of Xiamen Kaina) and spread it on the above-mentioned Conductive layer surface, and then cured by UV (500mJ / cm 2 , 10s) to form a 100nm thick protective layer to prepare a flexible...

Embodiment 2

[0055] (1) Preparation of flexible transparent conductive film: In a clean room, add 3g of water-based polyether polyol VOANOL CP 450, 3g of water-based isocyanate curing agent Bayhydur 305, 92.75g of deionized water, and 1g of dispersant hydroxyethyl cellulose in sequence Dispersion cylinder, mechanical stirring; then add 0.2g nano-silver wire WJAG1, 0.05g thin-layer graphene (thin-layer graphene used is 1-3 layers, particle size D50 is 4-7μm, KNG- G2-3), continue to stir uniformly, and then grind and disperse to obtain conductive ink; use the dimple coating process to uniformly coat the conductive ink on the non-hardened surface of PET, and dry it in an IR oven (110°C, 20s) to obtain conductive layer;

[0056] Mix 99.95g of UV protection solution and 0.05g of thin-layer graphene KNG-G2-2 uniformly and apply on the surface of the above-mentioned conductive layer, UV curing (500mJ / cm 2 , 10s) to form a 100nm thick protective layer to prepare a flexible transparent conductive ...

Embodiment 3

[0060] (1) Preparation of flexible transparent conductive film: In a clean room, add 3g of water-based polyether polyol VOANOL CP 450, 3g of water-based isocyanate curing agent Bayhydur 305, 92.75g of deionized water, and 1g of dispersant hydroxyethyl cellulose in sequence Dispersion cylinder, mechanically stir; Then add 0.2g nano-silver wire successively (the used nano-silver wire diameter is 40nm, aspect ratio 600-900, is the WJAG3 of Hefei Microcrystalline Material Technology Co., Ltd., available in the market), 0.05g Thin-layer graphene WJSG1410, continue to stir until uniform, and then grind and disperse to prepare conductive ink; use the micro-recessed coating process to uniformly coat the conductive ink on the non-hardened PET surface, and dry it in an IR oven (110°C, 20s) A conductive layer is produced.

[0061] Mix 99.95g of UV protection solution and 0.05g of thin-layer graphene (the average thickness of the thin-layer graphene used is 5nm, the particle size D50 is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com