Thermal barrier/high-temperature low infrared emissivity integrated coating, metal composite material with coating and preparation method thereof

A metal composite material, low infrared emission technology, applied in coating, metal material coating process, melt spraying and other directions, can solve the problem of high thermal barrier coating emissivity, achieve high thermal expansion coefficient, improve temperature resistance and High temperature thermal shock performance, effect of delaying coating failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

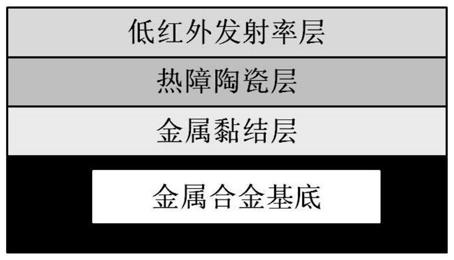

[0053] Such as figure 1 As shown, a thermal barrier / high temperature low infrared emissivity integrated coating, the coating is a multi-layer superimposed structure, including CoNiCrAlY metal bonding layer, SmMgAl 11 o 19 Thermal barrier ceramic layer and low infrared emissivity layer. Among them, the low infrared emissivity layer is made of Bi 2 o 3 -Sm 2 o 3 -MgO-Al 2 o 3 -Li 2 O-SiO 2 Glass is the binding phase, and Pd powder is used as the conductive phase, and the Pd powder accounts for 82% of the total mass of the low infrared emissivity layer.

[0054] The thickness of the above-mentioned CoNiCrAlY metal bonding layer is 0.08mm, SmMgAl 11 o 19 The thickness of the thermal barrier ceramic layer is 0.35mm, the thickness of the low infrared emissivity layer is 0.025mm, and the total thickness of the coating is 0.455mm.

[0055] The coated metal composite material in this embodiment includes a high-temperature nickel-based alloy substrate and the above-mentioned...

Embodiment 2

[0069] A thermal barrier / high temperature low infrared emissivity integrated coating, the thermal barrier / high temperature low infrared emissivity integrated coating is a multi-layer superimposed structure, including CoNiCrAlY metal bonding layer, SmMgAl 11 o 19 Thermal barrier ceramic layer and low infrared emissivity layer. Among them, the low infrared emissivity layer is made of Bi 2 o 3 -Sm 2 o 3 -MgO-Al 2 o 3 -Li 2 O-SiO 2 Glass is the binding phase, and Pd powder is used as the conductive phase, and the Pd powder accounts for 82% of the total mass of the low infrared emissivity layer.

[0070] The thickness of the above-mentioned CoNiCrAlY metal bonding layer is 0.05mm, SmMgAl 11 o 19 The thickness of the thermal barrier ceramic layer is 0.08mm, the thickness of the low infrared emissivity layer is 0.02mm, and the total thickness of the coating is 0.15mm.

[0071] The coated metal composite material in this embodiment includes a high-temperature nickel-based a...

Embodiment 3

[0085] A thermal barrier / high temperature and low infrared emissivity integrated coating, the thermal barrier / high temperature and low infrared emissivity integrated coating is a multi-layer superimposed structure, including CoNiCrAlY metal bonding layer, NdMgAl 11 o 19 Thermal barrier ceramic layer and low infrared emissivity layer. Among them, the low infrared emissivity layer is made of Bi 2 o 3 -Nd 2 o 3 -MgO-Al 2 o 3 -Li 2 O-SiO 2 Glass is the bonding phase, and Pd powder is used as the conductive phase, and the Pd powder accounts for 80% of the total mass of the low infrared emissivity layer.

[0086] The thickness of the above CoNiCrAlY metal bonding layer is 0.08mm, NdMgAl 11 o 19 The thickness of the thermal barrier ceramic layer is 0.25mm, the thickness of the low infrared emissivity layer is 0.02mm, and the total thickness of the coating is 0.35mm.

[0087] The coated metal composite material in this embodiment includes a high-temperature nickel-based all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com