Patents

Literature

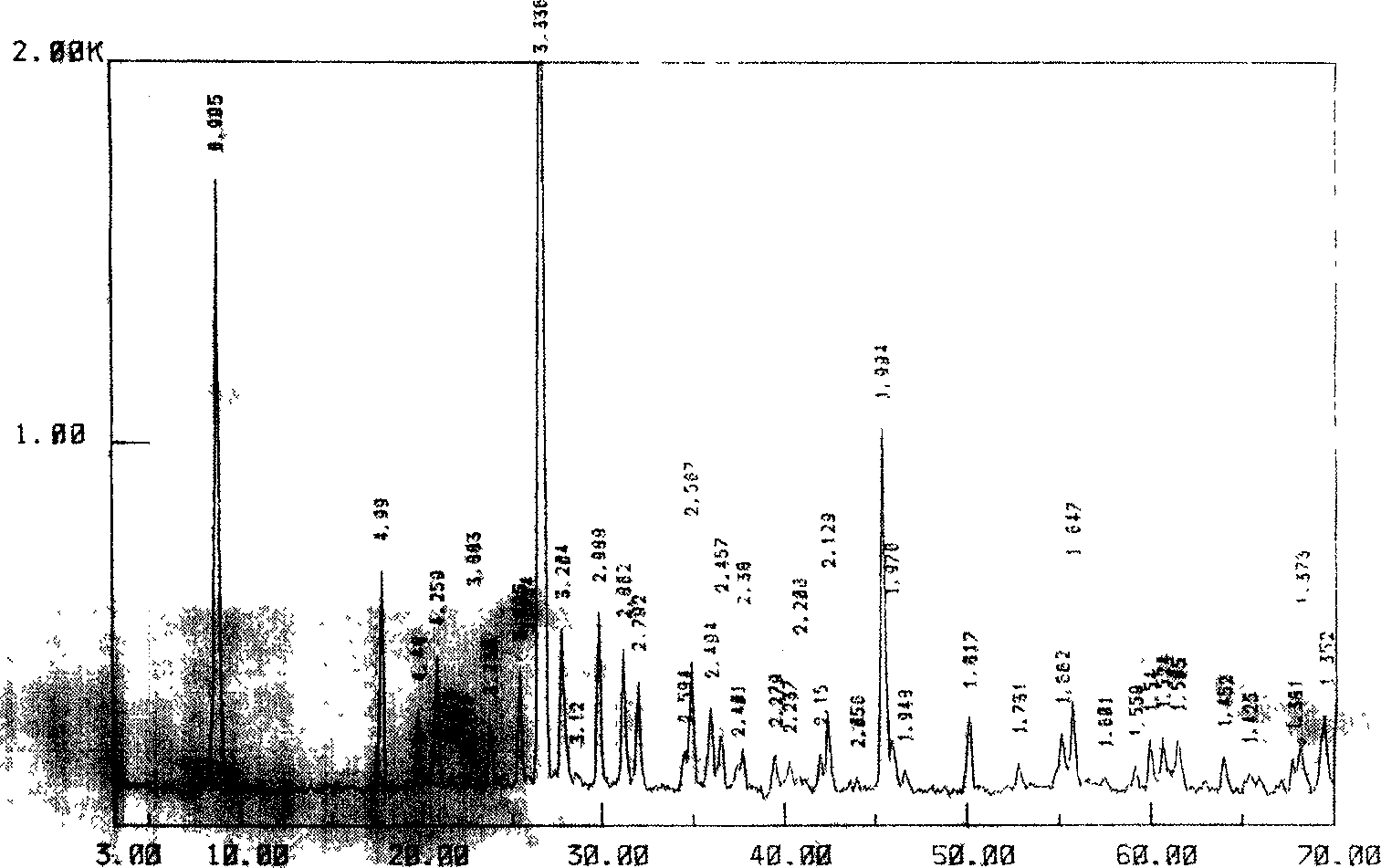

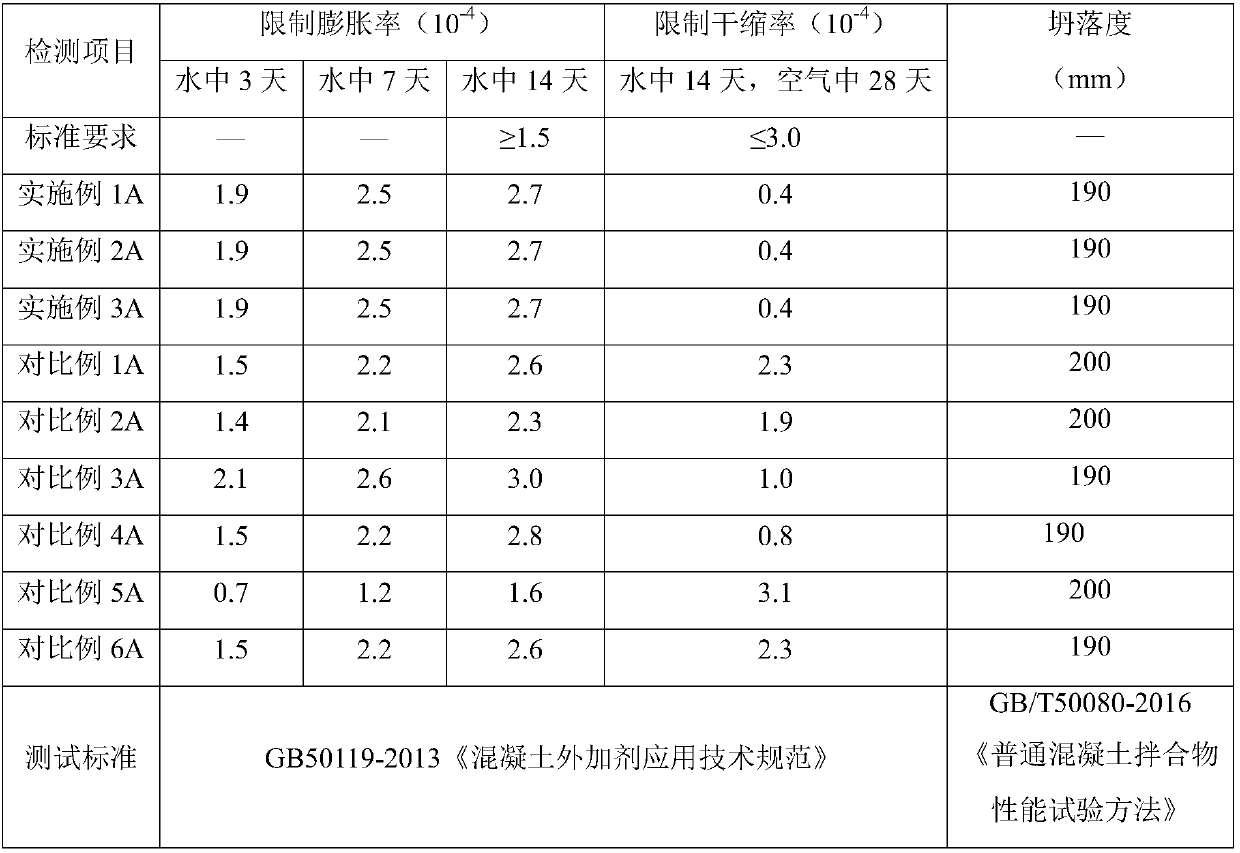

75 results about "Aluminum Acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A topical astringent that is used as an antiseptic agent. Aluminum acetate is used to treat inflammation, itching, and stinging of the infected skin and promotes healing.

Aluminum cladding method for lithium ion positive electrode material

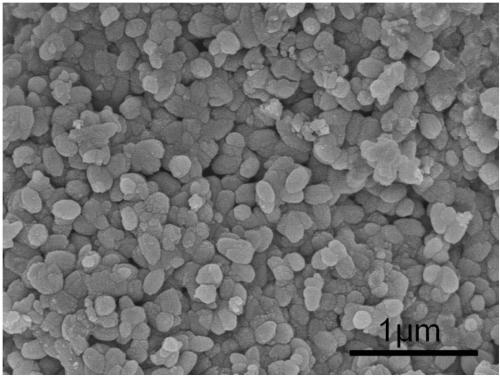

InactiveCN103872331ANo reduction in gram capacityImprove uniformityCell electrodesSecondary cellsSolventMuffle furnace

The invention discloses an aluminum cladding method for a lithium ion positive electrode material. The aluminum cladding method comprises the following steps: (1) preparing a cladding-free positive electrode material by a conventional method; (b) preparing an aluminum salt solution from an inorganic aluminum salt and a solvent, wherein the aluminum salt solution is taken as a cladding solution, the aluminum salt is selected from aluminum nitrate, aluminum chloride, aluminum sulfate and aluminum acetate and the solvent is selected from ethanol, methanol and isopropanol; (c) adding the cladding-free positive electrode material into the aluminum salt solution, agitating and heating till the solution reflows; (d) after the solution reflows for 30 minutes, filtering to remove the solvent and drying in vacuum at 70-100 DEG C to prepare a semi-finished product; and (e) putting the semi-finished product into a muffle furnace for roasting, and naturally cooling to room temperature to obtain the aluminum-cladded positive electrode material. Compared with the prior art, the aluminum cladding method for the lithium ion positive electrode material disclosed by the invention not only can prolong the cycle life and improve the heat stability of the positive electrode material under high-charging cut-off voltage, but also can reduce the cladding cost and improve the cladding consistency.

Owner:NINGDE AMPEREX TECH

Cataluminescence sensitive material for rapid determination of formaldehyde and sulfur dioxide

InactiveCN105527276ARapid determinationAccurate measurementChemiluminescene/bioluminescenceFiltrationAluminum Acetate

A cataluminescence sensitive material for rapid determination of formaldehyde and sulfur dioxide is a composite material comprising platinum-atom-doped Al2O3, CaO and In2O3. A preparation method is as follows: aluminum acetate, calcium chloride and indium nitrate solution are prepared into a solution, a small amount of agar is added to form a gel, the gel is dried and calcined to obtain composite powder comprising Al2O3, CaO and In2O3, the composite powder and chloroplatinic acid are added into an aqueous solution of glucose, and the composite material comprising Pt-atom-doped Al2O3, CaO and In2O3 can be obatiend by xenon lamp irradiation, filtration, water washing and drying. The sensitive material is used for making a gas sensor, and trace amounts of formaldehyde and sulfur dioxide in the air can be quickly and accurately determined in the field without common coexistent matter interference.

Owner:BEIJING UNION UNIVERSITY

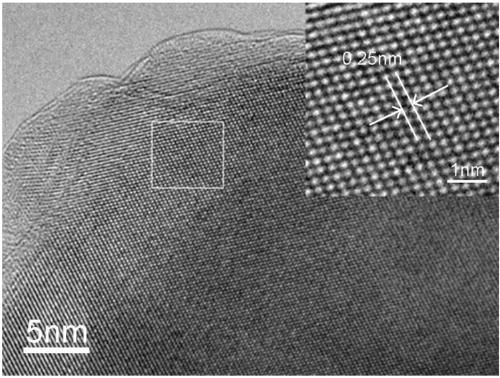

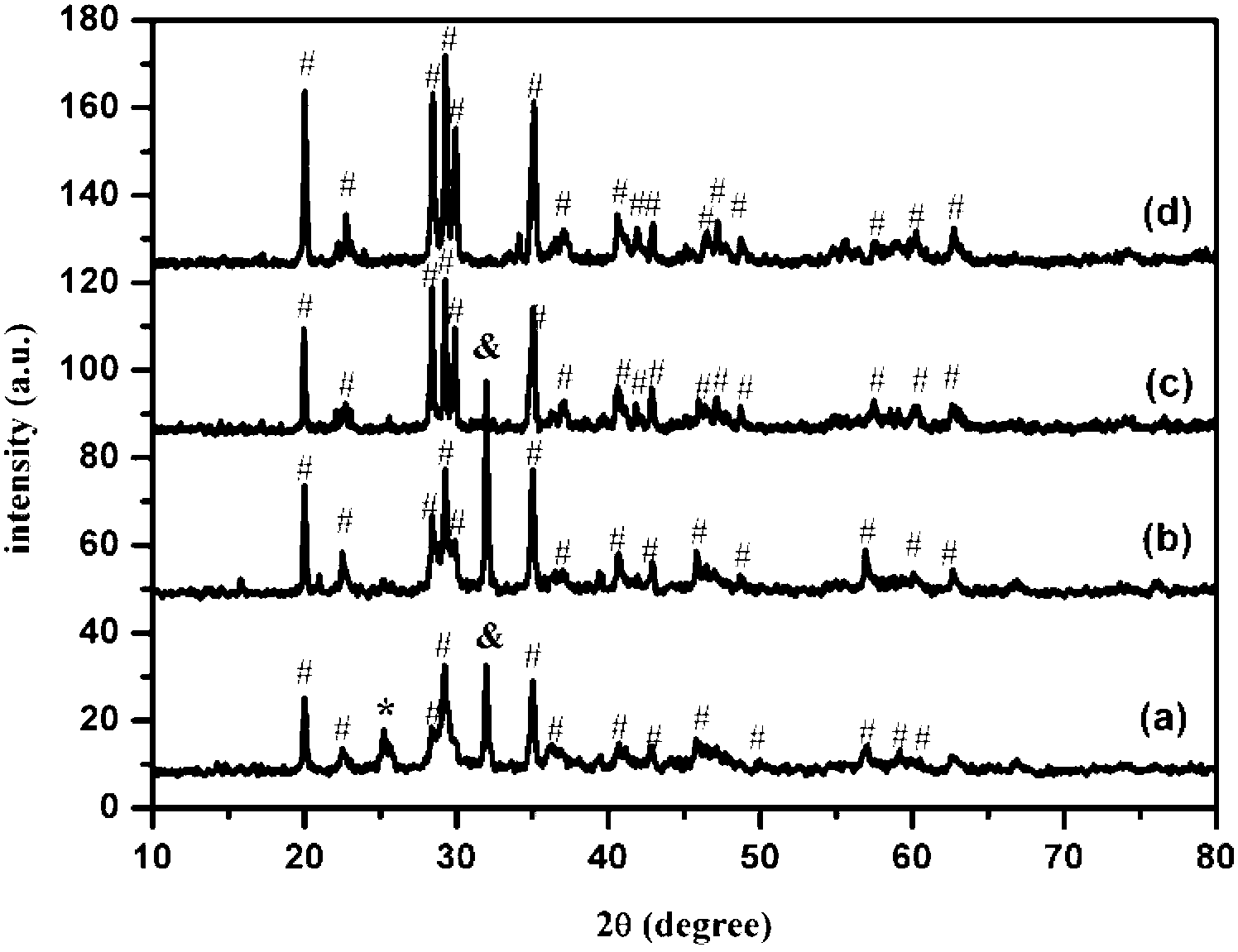

Preparation method for nanometer aluminum nitride powder

InactiveCN109019536AImprove stabilityHigh purityMaterial nanotechnologyNitrogen compoundsAir atmosphereAluminum Acetate

The invention discloses a preparation method for nanometer aluminum nitride powder. The preparation method comprises the following steps: uniformly mixing a solid aluminum sourcesuch as aluminum nitrate, aluminum carbonate, aluminum isopropoxide, aluminum sulfate, aluminum acetate, basic aluminum acetate and alkaline aluminum acetate with a solid nitrogen source such as urea and melamine accordingto a molar ratio of elemental aluminum to the solid nitrogen source of 1: 1 to 1: 6; and carrying out calcining at 600 to 1000 DEG C for 1 to 6 h in a baking atmosphere; and then performing decarburization treatment in an air atmosphere at 300 to 650 DEG C for 1 to 4 h to obtain the high-purity aluminum nitride powder. The aluminum nitride powder prepared by using the method of the invention hashigh purity and a particle size distribution range of 15 to 90 nm; the preparation method is simple in process and easy to operate; the raw materials are widely available; synthesis cost is low; and the method is environmental friendly, economic and practicable and is a green process capable of realizing large-scale industrial production.

Owner:SHAANXI NORMAL UNIV +1

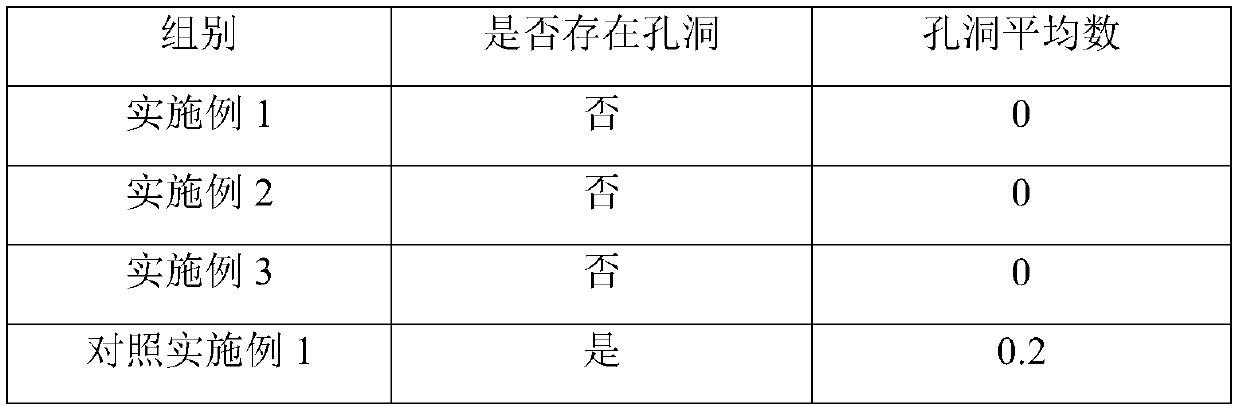

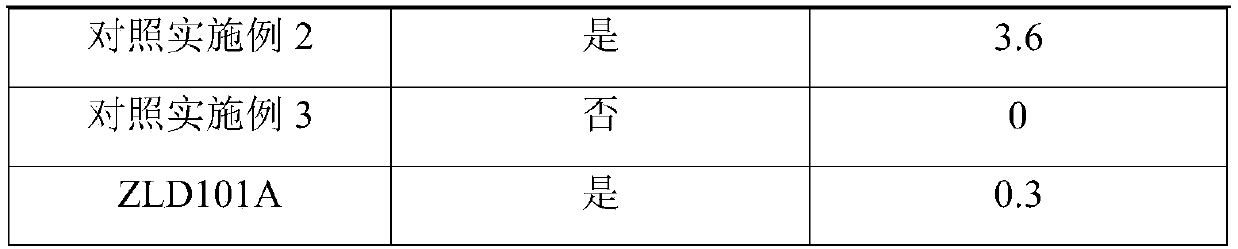

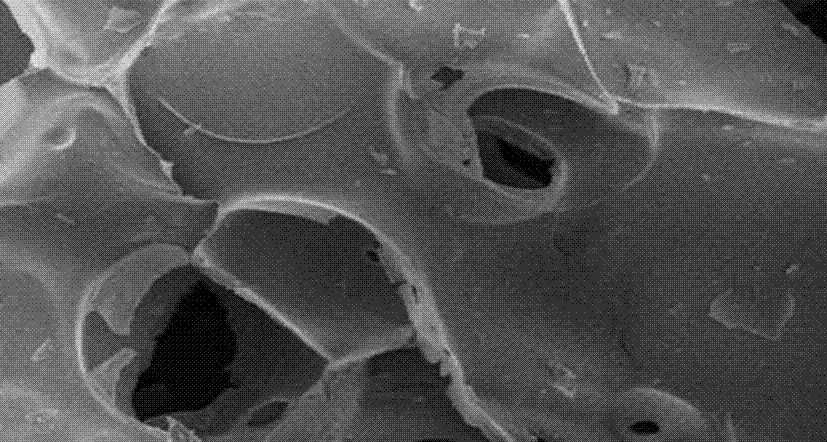

Magnesium and magnesium alloy chemical oxidation process

InactiveCN1673412AEasy to operateReduce porosityMetallic material coating processesSulfite saltDehydrogenation

The chemical magnesium and magnesium alloy oxidizing process includes the technological steps of dehydrogenation, chemically deoiling, washing with hot water, washing with cold water, polishing, washing with cold water and chemical oxidization. The chemical oxidizing solution consists of methyl tetrahydroxyl phthalic anhydride, potassium sulfate or aluminum acetate, boric acid, potassium dichromate or sodium dichromate or sodium tripolyhosphate or sodium sulfite, ammonium molybdate or diammonium biphophate, ammonium nickel sulfate, deionized water and optional dithio dipropyl sulfonate in certain proportion. The present invention can obtain chemical oxide film with corrosion rate not more than 3.739 mm / a. In different chemical oxidizing conditions, oxide films of different colors may be prepared. The present invention may be applied in aeronautics, astronautics, electronics, communication, building, automobile and other industry.

Owner:SHENYANG POLYTECHNIC UNIV

Method for preparing textured ZnO membrane with pyramid-like structure

InactiveCN101562216ANo pollutionFinal product manufactureLiquid/solution decomposition chemical coatingChemical productsSolvent

The invention relates to a method for preparing a textured ZnO membrane with a pyramid-like structure. The method comprises the following steps: taking zinc acetate as a Zn source, indium nitrate or indium acetate as a doped indium source, aluminum nitrate or aluminum acetate as a doped aluminum source, gallium nitrate or gallium acetate as a doped gallium source and anhydrous ethanol and / or water as a solvent; preparing a zinc source solution and a doped source solution with certain concentration respectively, and mixing the zinc source solution and the doped source solution; adding glacial acetic acid into the mixture; using high-purity N2 or air as carrier gas; and conveying the reaction liquid into a membrane precipitation chamber for growth, wherein a substrate can be glass or stainless steel and the like, and the growth temperature is between 300 and 550 DEG C. The method adopts cheap and nontoxic chemical products and utilizes a low-cost ultrasonic atomizer to directly obtain the ZnO membrane with a textured structure and light scattering characteristic under the condition of not requiring the doping of B2H6, so that the method cannot pollute the environment, belongs to 'environment-friendly' technology, and can be suitable for the preparation of the large-area (for example, S is equal to 1.2X0.6 meter) ZnO transparent conductive film.

Owner:NANKAI UNIV

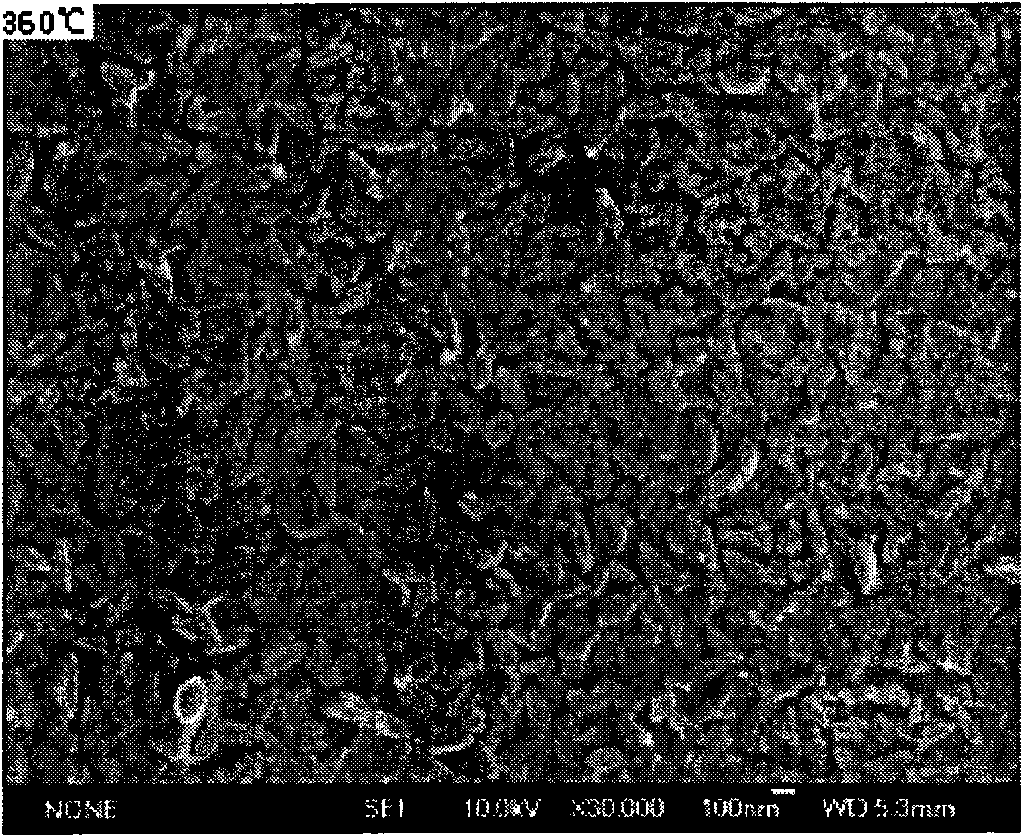

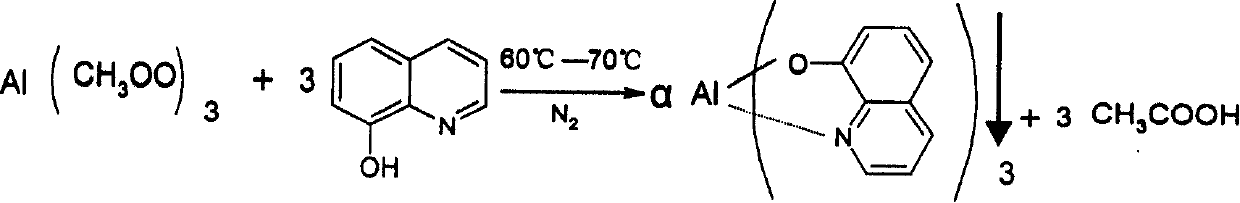

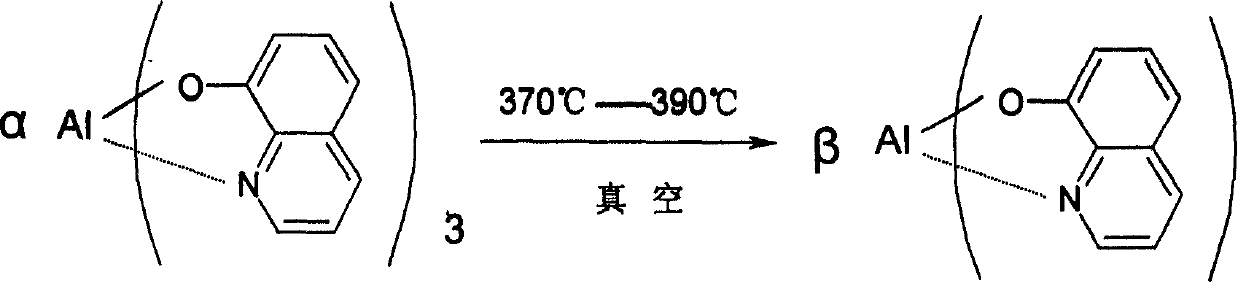

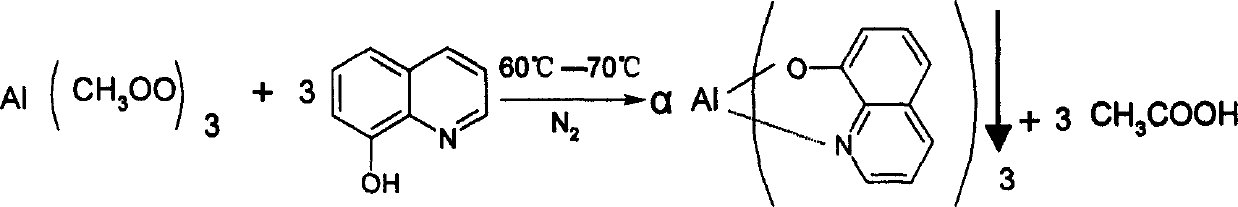

8- hydroxy quinoline bryhtening blue light and preparation method

InactiveCN1597669ARich materialSufficient sourceGroup 3/13 element organic compoundsQuinolineNitrogen gas

A 8-hydroxyquinolyl aluminium able to emit blue light is prepared from 8-hydroxyquinoline crystal, anhydrous aluminium acetate, absolute methanol, acetone, pyridine and NN-dimethylformamide through reaction, washing, filtering, baking, vacuum heating, constant temp, cooling, N2 protection recrystallizingand test analysing.

Owner:TAIYUAN UNIV OF TECH

Aluminate surface modified microcrystal white mica active filler and its preparation method

InactiveCN1255486CEasy to modifyLow costPigment treatment with non-polymer organic compoundsSocial benefitsViscosity

The invention discloses a microcrystalline muscovite active powder filler modified on the surface of an aluminate coupling agent and a preparation method thereof. The microcrystalline muscovite powder is used as a raw material. The muscovite powder material is dried at about 110 °C to remove all adsorbed moisture; melt the aluminate (for wax-like solids), and melt the aluminate at a temperature slightly higher than the melting point of 70 to 73 °C; Dry the material and put it into a high-speed mixer; preheat the material, make the material stir at a high speed in the high-speed mixer for about 30 minutes, and control the temperature to be ≤73°C; weigh the aluminate, and the weight is based on material: aluminate = 100:0.5 ~3.9; high-speed mixing of materials, slowly and evenly pour the aluminate into the high-speed mixer, high-speed mixing for about 20 minutes, and control the temperature to be ≤90 °C; modification effect testing, using viscosity testing and other methods to test and evaluate the modification effect. Evaluation. It has abundant resources, convenient modification process, low cost, good effect, wide application and obvious economic and social benefits.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Mesoporous molecular sieve supported composite metal oxide alcoholysis catalyst, and preparation method of alcoholysis catalyst

InactiveCN103285907AReduce generationIncrease the rate of the positive reactionMolecular sieve catalystsGroup 5/15 element organic compoundsPtru catalystPhosphoric acid

The invention discloses a mesoporous molecular sieve supported composite metal oxide alcoholysis catalyst, and a preparation method of the alcoholysis catalyst. A mixed solution of alkali metal acetates, aluminium acetate, magnesium acetate, titanium acetate and rare earth metal acetates is physically adsorbed on a mesoporous molecular sieve SBA-15, and composite metal oxides are supported on the mesoporous molecular sieve SBA-15 after a calcining process. By adding the catalyst, the synthetic yield and purity of triethyl phosphate are extremely raised, and the catalyst is easy to separate and repeatedly usable.

Owner:安徽生力农化有限公司

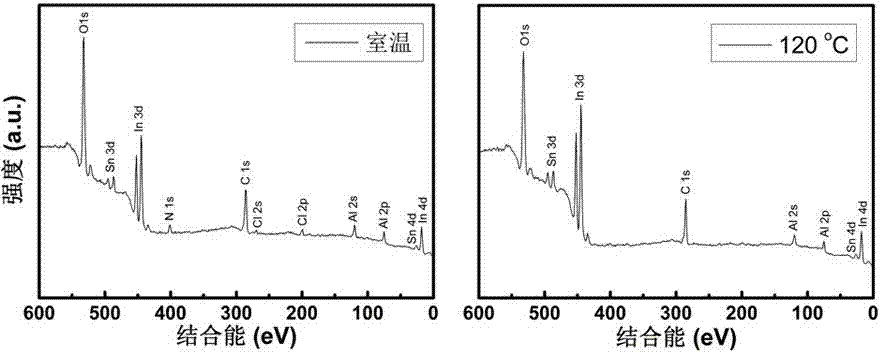

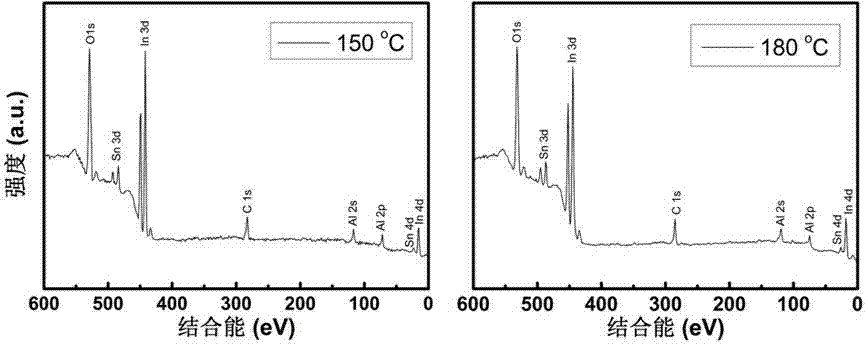

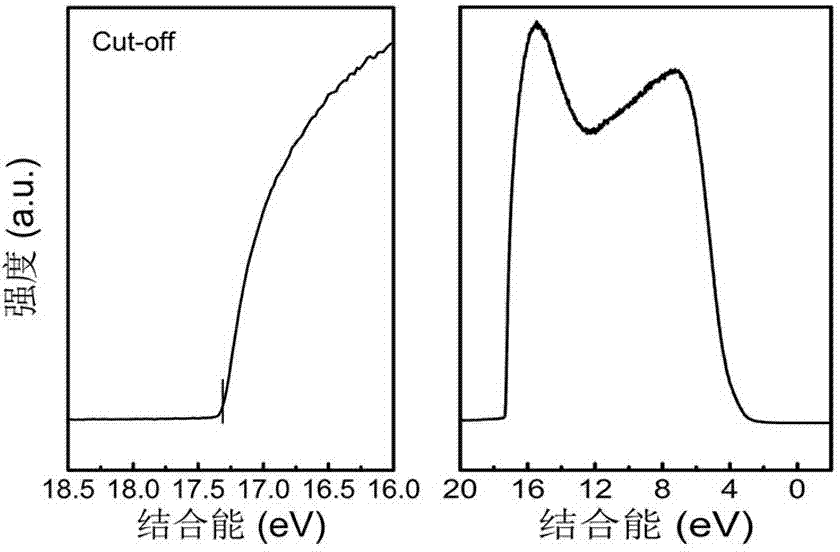

Alumina precursor solution, and preparation method and application thereof

InactiveCN103194741AWide variety of sourcesLow priceSolid/suspension decomposition chemical coatingChemistryAluminum chloride anhydrous

The invention discloses alumina precursor solution and a preparation method and application thereof. The preparation method comprises the following steps of: (a), adding anhydrous aluminium chloride in heated glacial acetic acid, and reacting at constant temperature for 8-10 min to obtain semi-transparent aluminium acetate colloid; (b), centrifuging the aluminium acetate colloid at a high speed for 10-15min in a high-speed centrifugal machine to obtain aluminium acetate particles; and (C), putting the aluminium acetate particles obtained in the step (b) into deionized water, acetone or alcohol solvent, so as to obtain a solution with the mass concentration of 20-40%, and oscillating or stirring to obtain the alumina precursor solution. The preparation method disclosed by the invention is simple and convenient to operate and low in cost; the prepared precursor solution can be stored for a long time, therefore, alumina and an alumina film prepared from the solution at a low temperature are excellent in performance; particularly, the film is uniform in thickness, continuous and dense and is applicable to the photoelectric and chemical fields.

Owner:SUZHOU UNIV

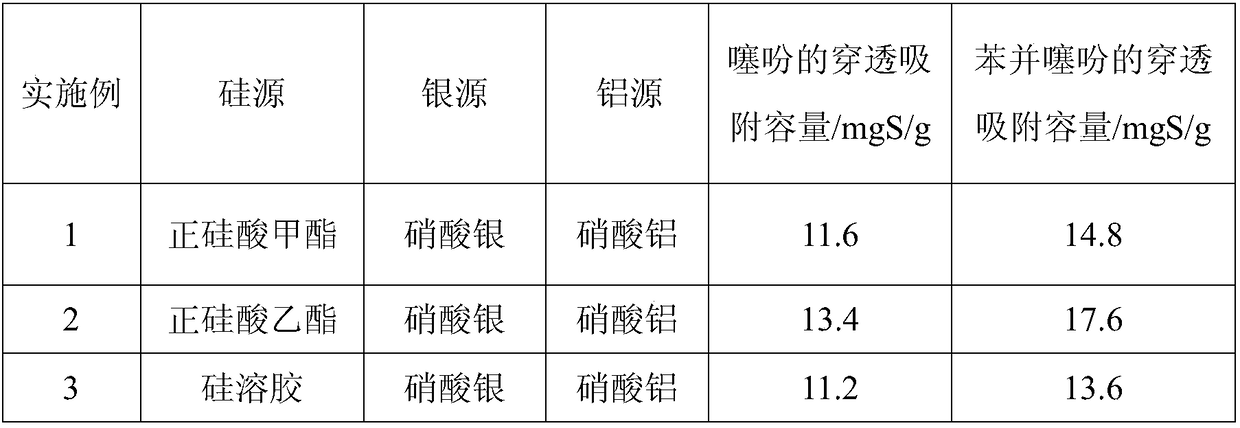

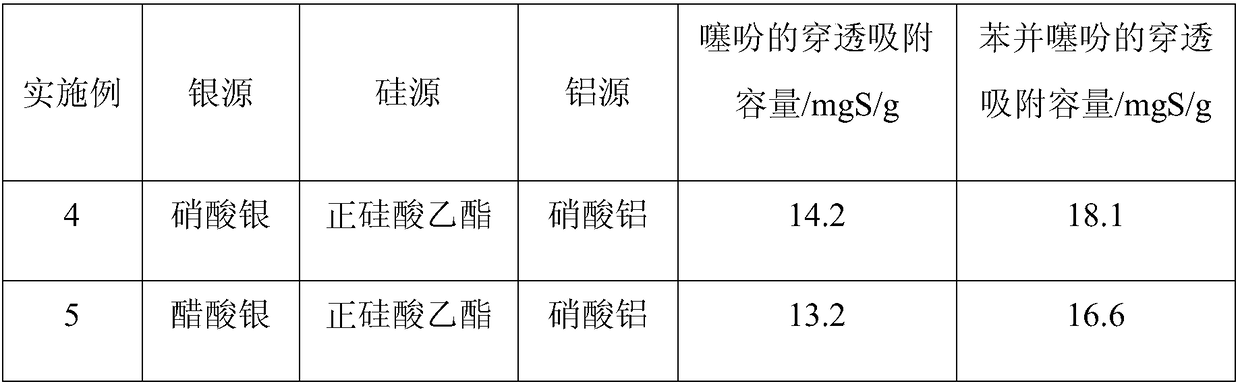

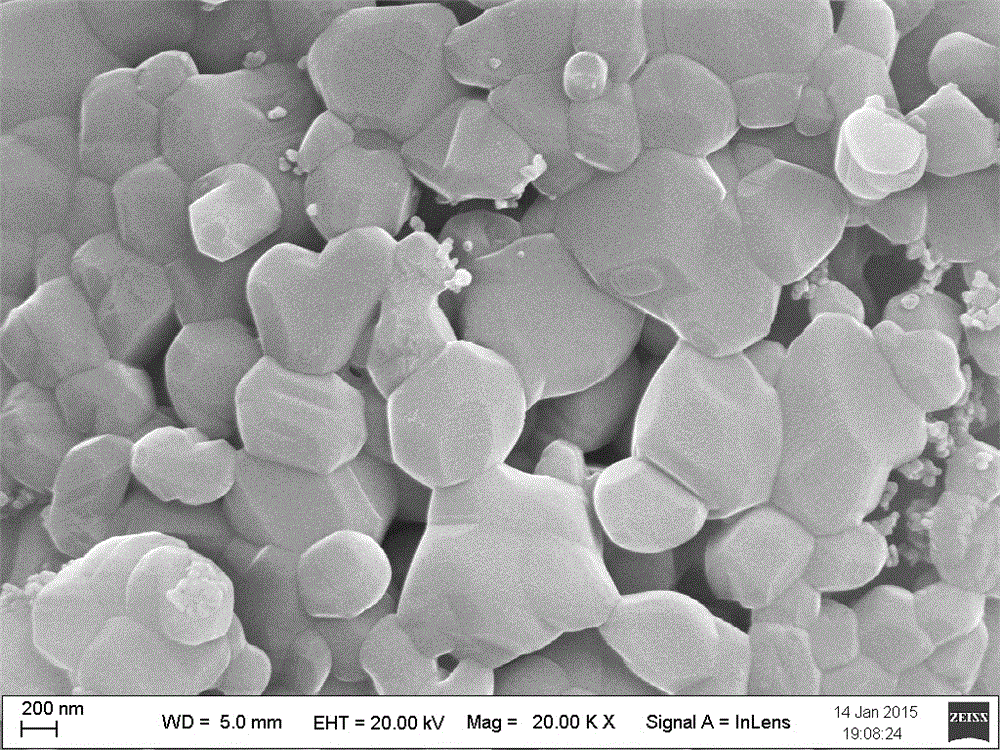

Method for removing thiophene sulfur in fuel oil

InactiveCN108192656AHigh porosityLarge specific surface areaHydrocarbon oils refiningHydrocarbon oils treatment productsSorbentFixed bed

The invention discloses a method for removing thiophene sulfur in fuel oil and belongs to the technical field of fuel oil processing. The method comprises the following steps: using tetramethyl orthosilicate, tetraethyl orthosilicate, silica sol, water glass or the like as a silicon source; using silver acetate, silver nitrate or the like as a silver source; using aluminum nitrate, aluminum acetate or aluminum oxalate as an aluminum source; preparing an Ag2O / SiO2-Al2O3 composite aerogel with a sol-gel-atmospheric pressure drying method; quantitatively filling in a fixed bed adsorption device;injecting a simulated gasoline containing thiophene sulfur at a certain temperature and space velocity; and collecting the adsorbed simulated gasoline at a lower outlet of a reaction device for chromatographic analysis. Results show that the Ag2O / SiO2-Al2O3 composite aerogel has good adsorption performance for thiophene sulfur; an Ag2O / SiO2-Al2O3 composite aerogel adsorbent in the invention is simple in preparation method, low in cost, capable of being repeatedly used, high in economic efficiency, environmentally friendly, mild in adsorption condition and low in requirement on adsorption equipment.

Owner:ZHEJIANG UNIV OF TECH

Coat fabric finishing process

InactiveCN104480709AImprove antibacterial propertiesGood antifoulingFibre treatmentAcrylic resinDimethylol urea

The invention discloses a coat fabric finishing process. The coat fabric finishing process comprises the following steps: (1) adding 2.3 parts by mass of dimethylol urea, 1.7 parts by mass of sodium alga acid and 3.4 parts by mass of aluminum acetate into 8.7 parts by mass of deionized water, mixing and uniformly stirring; (2) slowly adding 4.2 parts by mass of acrylic resin and 1.7 parts by mass of triethanolamine at the same time, and continuing stirring until the materials are fully and uniformly mixed to prepare a finishing agent; (3) padding the fabric in an impregnating solution containing the finishing agent, and drying the fabric at the constant temperature. The fabric finished by the coat finishing process is excellent in antimicrobial property, excellent in antifouling property and strong in washing fastness.

Owner:CHANGSHU ZHONGHONG KNITTING MILL

Method for preparing lithium magnalium co-doped synergic nitrogen-sulfur doped carbon-coated modified barium titanate lithium cathode material

ActiveCN106816597AImprove ionic conductivityUniform particle sizeCell electrodesSecondary cellsBarium titanateMuffle furnace

The invention relates to a method for preparing a lithium magnalium co-doped synergic nitrogen-sulfur doped carbon-coated modified barium titanate lithium cathode material. The method is characterized by comprising the following steps: mixing barium nitrate, lithium nitrate, magnesium acetate, aluminum acetate, nano titanium dioxide and acetylene black in a ball mill, sintering obtained powder in a muffle furnace, presintering for 4 hours at constant temperature of 650 DEG C to decompose salts, further sintering for 14 hours at 980 DEG C, and naturally cooling to the room temperature, so as to obtain lithium magnalium co-doped barium titanate lithium; putting the obtained lithium magnalium co-doped barium titanate lithium into a porcelain boat, putting into a tubular atmosphere furnace, putting another porcelain boat with cystine into the tubular atmosphere furnace, placing at upstream of air flow, treating for 2 hours at 680 DEG C in the presence of argon as a protection gas, naturally cooling to the room temperature, and grinding a product into powder, thereby obtaining a product, namely, the lithium magnalium co-doped synergic nitrogen-sulfur doped carbon-coated modified barium titanate lithium cathode material.

Owner:NINGBO UNIV

Method for preparing copper-lead complex salt

InactiveCN101711985ASimple reaction conditionsHigh reaction yieldMetal/metal-oxides/metal-hydroxide catalystsSalicylic acidDissolution

The invention relates to a method for preparing a copper-lead complex salt, which comprises the following steps of: (1) putting resorcinol acid, salicylic acid and water into a reaction kettle, mixing and stirring the mixture until complete dissolution, adding solid copper acetate and solid aluminum acetate into the mixed solution, and stirring the mixture to perform reaction for 0.5 to 1.5 hours so as to obtain the mixed solution; (2) dropping aqueous solution of sodium hydrate, and stirring the mixture to perform reaction for 3.5 to 4.5 hours after dropping to finish a complex reaction; and (3) filtering a reactant after the complex reaction, washing the reactant until the reactant is neutral, and drying the reactant to obtain a solid namely the finished product of the copper-lead complex salt. By determining the optimal reaction condition, the reaction yield is improved and the method is more suitable for requirements on industrial production so as to meet the market requirements and obtain successful exports. Besides, the method improves the market competitiveness of an enterprise and ensures that the product can be widely promoted and applied in the market.

Owner:TIANJIN CHEM REAGENT RES INST

Liquid hardening agent with high wear resistance and preparation method thereof

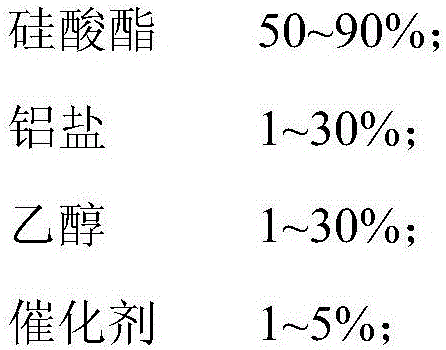

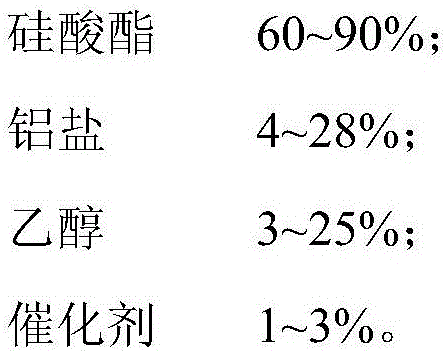

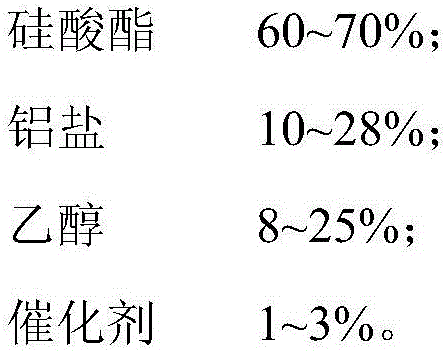

The invention relates to a liquid hardening agent with high wear resistance and a preparation method thereof. In terms of 100% of the mass of the hardening agent, the liquid hardening agent is prepared from the following raw materials: 50-90% of silicate ester, 1-30% of aluminum salts, 1-30% of alcohol and 1-5% of a catalyst, wherein the silicate ester is selected from one or a combination of more of methyl silicate, ethyl silicate, tri(methyl silicate), and preformed polymer of methyl silicate and ethyl silicate; the aluminum salt is selected from one or a combination of more of aluminum chloride, aluminum nitrate, aluminum chlorohydrate, polymer aluminum nitrate, aluminum formate, aluminum acetate, aluminum methoxide, aluminum ethylate and aluminum isopropoxide. According to the liquid hardening agent, silicate ester and the aluminum salt are adopted as the main ingredients, so that the content of the active ingredients is higher than that of a common water-based product, and the permeability is extremely high, and therefore, the hardness and wear resistance of cement can be remarkably improved. Meanwhile, the preparation method is simple and is beneficial to reduction in the industrial production cost.

Owner:HANGZHOU GELING NEW MATERIAL TECH

Method for preparing aluminum oxide coating on surface of silicon carbide fiber

ActiveCN105132897AImprove adhesionEvenly distributedSolid/suspension decomposition chemical coatingCarbide siliconEthylic acid

The invention discloses a method for preparing an aluminum oxide coating on the surface of silicon carbide fiber. The method mainly comprises the operating steps that aluminum acetate, glycerine and acetic acid are added into deionized water according to the proportion, after the aluminum acetate, the glycerine and the acetic acid are dissolved, ammonium hydroxide is added drop by drop for adjusting the pH value, and sediment is obtained; after the sediment is washed through the deionized water, suction filtration is conducted; the sediment is added into the deionized water again to be dispersed; a nitric acid solution is added into the solution, and aluminum oxide sol is prepared after reflux, heating and stirring are conducted; and the silicon carbide fiber is placed into an impregnation tank filled with the aluminum oxide sol for impregnation, and finally the silicon carbide fiber coated with the aluminum oxide coating is obtained after drying treatment and heat treatment are conducted. The aluminum oxide coating is excellent in oxidation resistance, and the high-temperature performance of the silicon carbide fiber can be improved greatly; in addition, the adhesion performance between the aluminum oxide coating and the silicon carbide fiber is good, and the coating is distributed uniformly on the surface of the fiber and is not prone to falling off.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

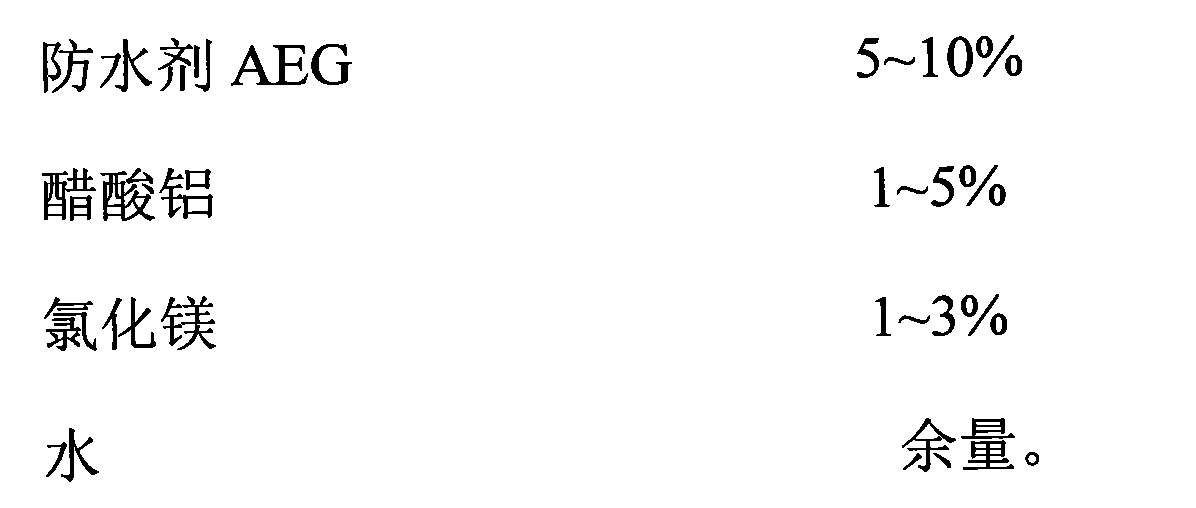

Cotton fabric durable water repellent finishing agent

InactiveCN102011314AReasonable formulaImprove work performanceVegetal fibresChlorideAluminum Acetate

The invention discloses a cotton fabric durable water repellent finishing agent which comprises a waterproofing agent AEG, aluminum acetate, magnesium chloride and water through mixing. The invention has the advantages of reasonable formula, good working effect and low production cost.

Owner:张启辉

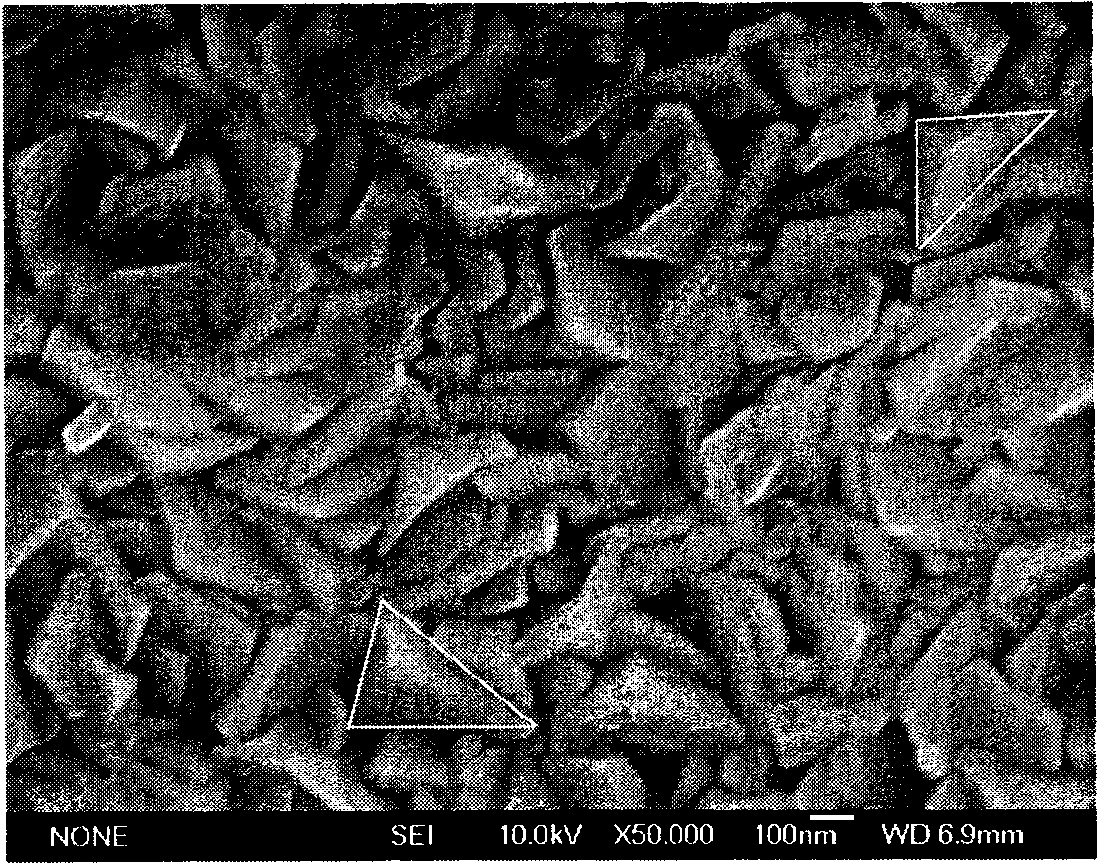

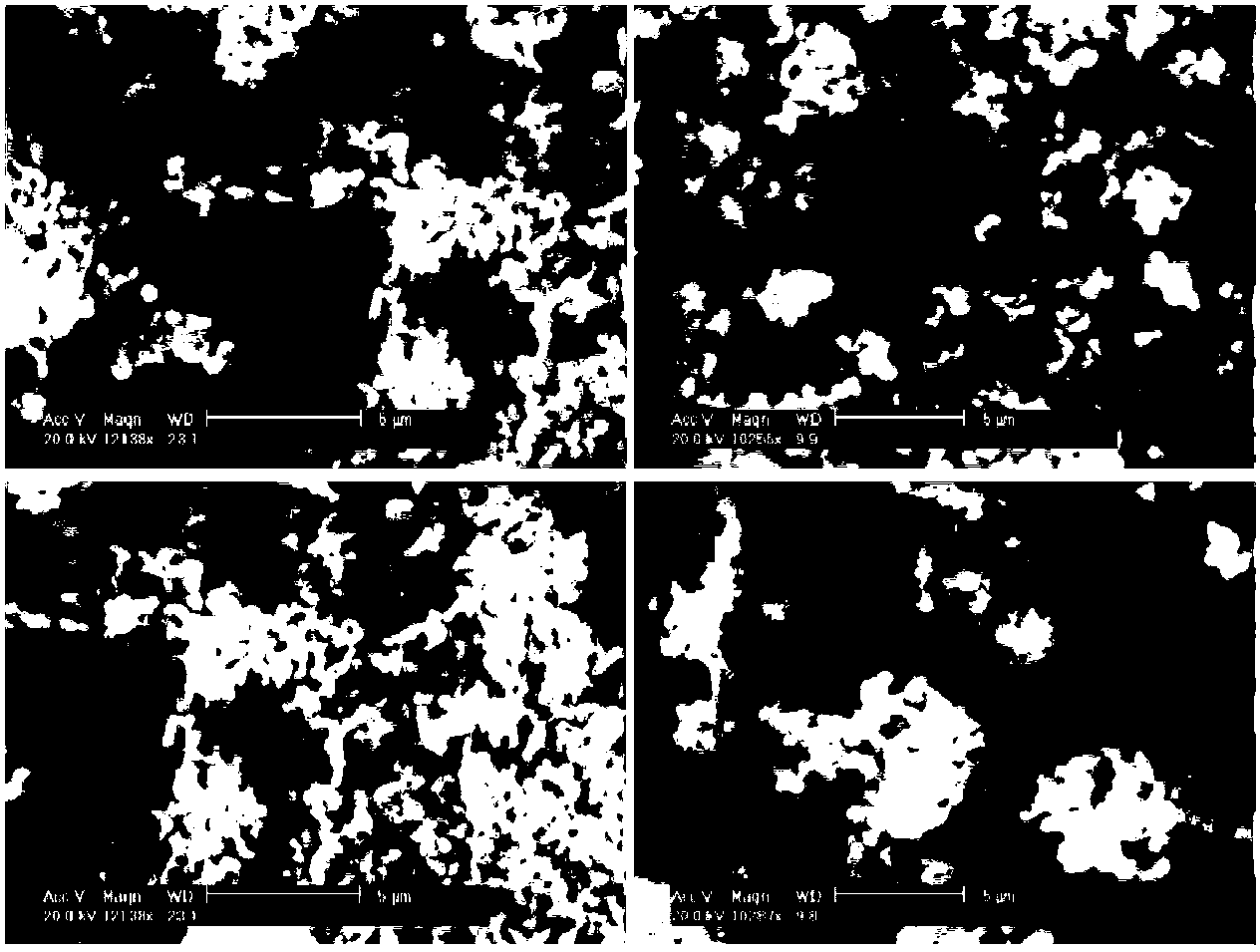

High-brightness nano strontium-aluminate long-afterglow luminous material and preparation method and application thereof

InactiveCN102703068ACalcination temperature is lowSave energyLuminescent compositionsEuropiumAluminum Acetate

The invention discloses high-brightness nano strontium-aluminate long-afterglow luminous material and a preparation method and application thereof; the preparation method comprises the following steps: mixing strontium acetate semihydrate, aluminum acetate basic, europium acetate, dysprosium acetate and urea according to a mol ratio (0.005-0.02): (0.01-0.04): (0.0004-0.0008): (0.0008-0.0012): (0.02-0.08) and preparing the high-brightness nano strontium-aluminate long-afterglow luminous material through an alcohol-heat synthesis-burning method. Compared with a traditional high-temperature solid-phase method, pure-phase SrA12O4:Eu<2+>,Dy<3+> can be obtained at 1150 degrees centigrade by the preparation method provided by the invention; a burning temperature is reduced greatly; energy source is saved; prepared strontium-aluminate long-afterglow luminous material has good luminous strength and relatively long afterglow time; the preparation method provided by the invention is characterized by safe and nontoxic use, simple and easy operation, low cost, high efficiency and easy industrial application.

Owner:JINAN UNIVERSITY

Mass concrete mixture and construction method of pouring wall body by mass concrete mixture

ActiveCN107673713AImprove stabilityGuaranteed waterproof qualityBuilding material handlingSlagSuperplasticizer

The invention relates to a mass concrete mixture and a construction method of pouring a wall body by the mass concrete mixture. The technical scheme adopted by the invention is that the mass concretemixture is prepared from the following raw materials in parts by weight: 165 parts of water, 214 parts of portland blast furnace slag cement, 743 parts of sand, 1070 parts of gravel, 103 parts of flyash, 95 parts of mineral powder, 4.94 parts of admixture and 0.9 part of polypropylene fibers, wherein the admixture is prepared from a JH-GHL polycarboxylate superplasticizer, an H-III type concrete mortar water-proofing agent, a UEA-H type concrete expanding agent, basic aluminum acetate and delta-aluminum oxide of which the weight ratio is 4 to 3 to 2 to 0.2 to 0.3. The construction method comprises the steps of pre-construction preparation, weighing of the raw materials, stirring of the raw materials, pouring, vibrating, primary leveling, maintenance, secondary leveling and measurement of the temperature. In the construction process of a mass concrete structure, indwelling of a post pouring belt can be avoided, the construction progress is speeded up and the construction period is shortened; in addition, without structural cracks, the overall stability of the structure is improved and the waterproof quality of a project can be ensured.

Owner:BCEG ROAD & BRIDGE CONSTR

Anti-creasing agent

InactiveCN102465455AAvoid wrinklesDoes not affect wearing comfortFibre treatmentEpoxyPolymer science

The invention relates to an anti-creasing agent, more specifically to an anti-creasing agent for clothes. The anti-creasing agent contains the following components of: by weight, 5-15 parts of aluminum acetate, 10-20 parts of an aminated epoxy resin, 5-8 parts of polyethylene glycol oleyl ether, 10-20 parts of a softening agent, 2-8 parts of lactic acid, 1-5 parts of potassium hydroxide, and 200-500 parts of water. The anti-creasing agent provided by the invention has advantages of full function, simple preparation technology and low cost, and is applicable to be widely used at home.

Owner:CHENGDU SHUNFA DISINFECTANT & WASHING TECH

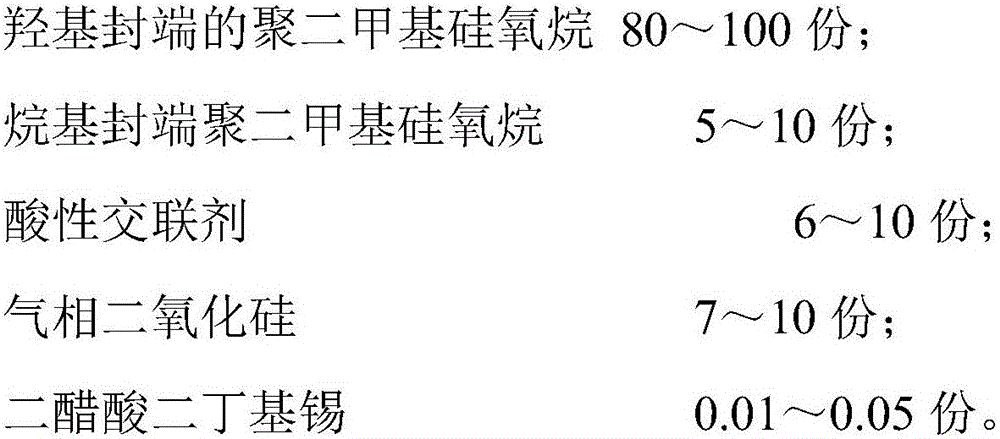

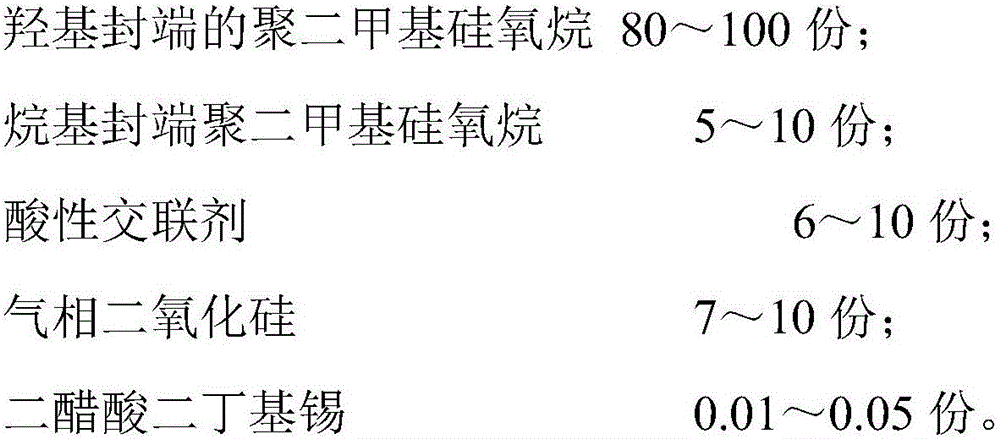

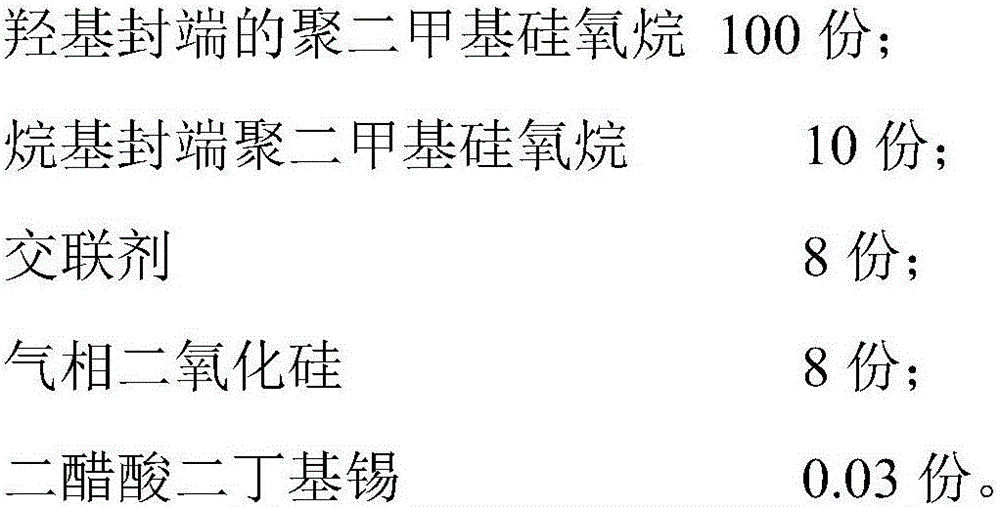

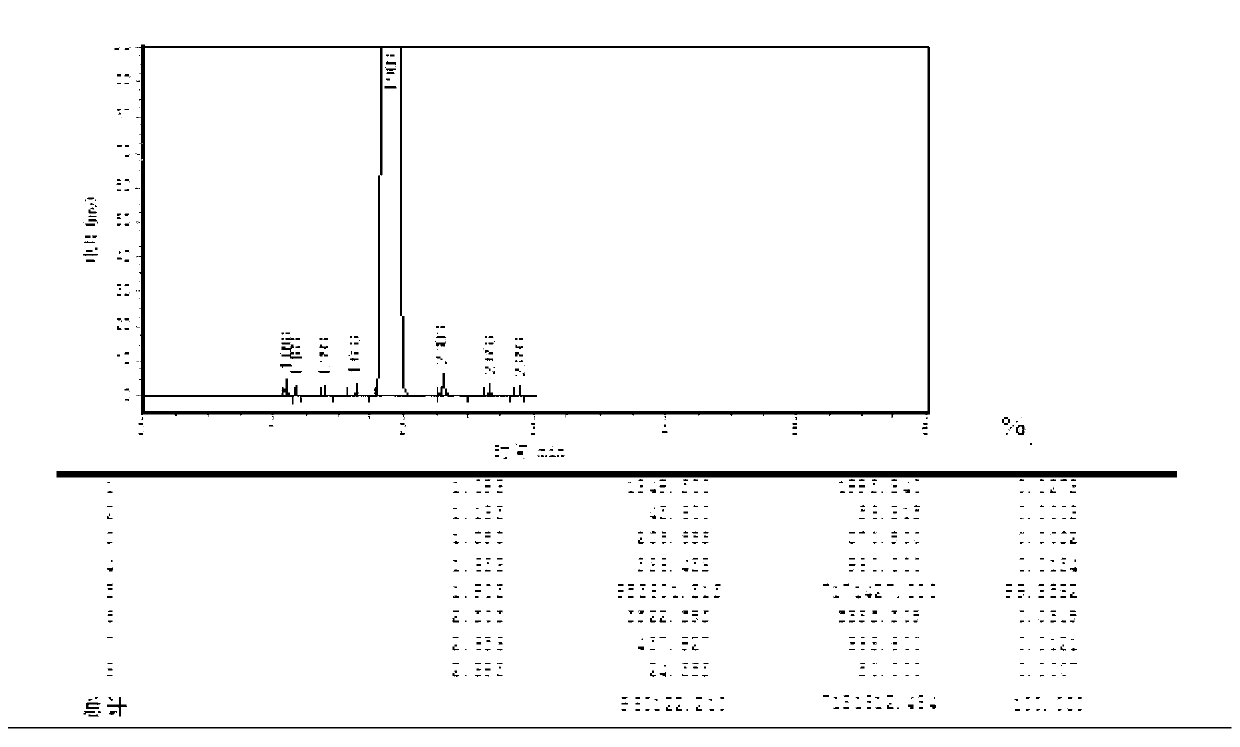

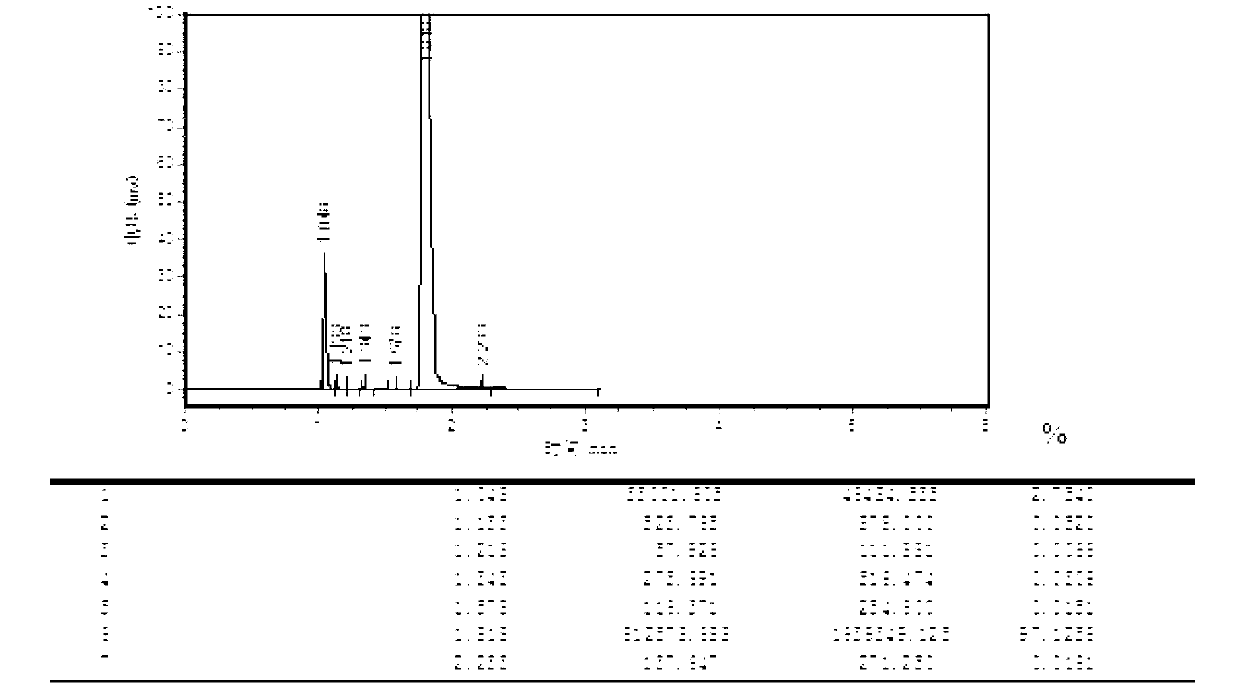

Polymeric acid cross-linking agent, preparation method and sealant with cross-linking agent

ActiveCN106832291AReduce the degree of polymerizationMild reaction conditionsNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkAcetic acid

The invention discloses a polymeric acid cross-linking agent, a preparation method and a sealant with the cross-linking agent, and relates to the field of cross-linking agents. The preparation method comprises the following steps: uniformly mixing 100 parts of an alkyl triacetyl oxo group and 1-5 parts of aluminum acetate in a reaction kettle, heating to 70-90 DEG C to react for 8-10 hours, filtering off the aluminum acetate, and removing acetic anhydride generated in the reaction from filtrate, thereby obtaining polymeric alkyl triorganoacetoxysilane, wherein the polymeric acid cross-linking agent comprises the following components in percentage by mass: 14-17.3% of an alkyl triorganoacetoxysilane monomer, 60-61.5% of alkyl triorganoacetoxysilane dimer, 16.3-19.3% of alkyl triorganoacetoxysilane trimer and the balance of impurities. A cross-linking agent of which the RTV (Room Temperature Vulcanized Silicone Rubber) crystallization point is remarkably reduced can be prepared, and in addition, the cross-linking agent is relatively gentle when being used and can form complete RTV.

Owner:湖北新蓝天新材料股份有限公司

Simulated birdshot for bird impact resistance tests for aircrafts

InactiveCN102519316ANo pollution in the processHealth effectsTraining ammunitionCeramic shaping apparatusAdditive ingredientDiameter ratio

The invention relates to a simulated birdshot for bird impact resistance tests for aircrafts. The simulated birdshot is a regular cylinder structure with the length-diameter ratio equal to 2. The simulated birdshot for bird impact resistance tests for aircrafts consists of ingredients including water, gelatine, sodium carboxymethylcellulose and aluminum acetate basic, and the mass proportion of the ingredients is 80+ / -2:8+ / -1:2:1. As the main ingredients of the simulated birdshot are the gelatine and the water, the gelatine and the water do not pollute environments, sites can be cleaned conveniently after the tests, the environments are not polluted, and adverse effects to health of test staffs are avoided. The appearance of the simulated birdshot is guaranteed by a special mold, the standard birdshot which meets requirements of test standards can be manufactured, a manufacturing process is simple, and cost is low.

Owner:CHINA AIRPLANT STRENGTH RES INST

Formula for anti-aging PE (polyethylene) thin films

The invention discloses a formula for anti-aging PE (polyethylene) thin films. The anti-aging PE thin films in the formula comprise, by weight, 80-90 parts of PE, 20-25 parts of PS (polystyrene), 5-8 parts of trimethylolpropane triacrylate, 3-7 parts of sorbitol, 6-11 parts of phenol, 2-5 parts of formaldehyde, 4-8 parts of caustic soda, 2-6 parts of plasticizer glycerin, 1-4 parts of thermoplastic polyurethane, 2-5 parts of zinc stearate, 2-6 parts of borax, 3-8 parts of kaolin, 1-4 parts of aluminum acetate coupling agents and 100-200 parts of water. The formula has the advantages that the anti-aging PE thin films are excellent in strength, toughness and anti-aging performance, processes for the anti-aging PE thin films are simple, are convenient to implement, low in raw material cost, high in production efficiency and easy to industrially implement and can be used for producing the anti-aging PE thin films by the aid of ordinary plastic film blowing machines.

Owner:王莹

Alcoholysis catalyst comprising metal oxides loaded by mesoporous molecular sieve and preparation method thereof

InactiveCN103272628AReduce generationIncrease the rate of the positive reactionMolecular sieve catalystsGroup 5/15 element organic compoundsMolecular sievePtru catalyst

The invention discloses an alcoholysis catalyst comprising metal oxides loaded by a mesoporous molecular sieve and a preparation method thereof. The preparation method comprises the step that an aluminum acetate-magnesium acetate-titanium acetate-rare earth metal acetate mixed solution is physically adsorbed on a SBA-15 mesoporous molecular sieve; and the SBA-15 mesoporous molecular sieve is calcined so that metal oxides are loaded on the SBA-15 mesoporous molecular sieve. Through utilization of the alcoholysis catalyst, a triethyl phosphate yield and triethyl phosphate purity are greatly improved. The alcoholysis catalyst can be separated easily and can be recycled.

Owner:安徽生力农化有限公司

Stainless steel wiredrawing liquid composition and preparation method thereof

InactiveCN103351928APlay a role in corrosion inhibitionGood dispersionLubricant compositionEpoxyWater based

The invention provides a stainless steel wiredrawing liquid composition and a preparation method thereof. The composition is characterized by comprising the following raw materials by weight parts: 0.3-0.5 parts of triisopropanolamine, 1-2 parts of oleic acid, 6-8 parts of polyvinyl alcohol, 1-2 parts of propylene glycol, 1-2 parts of fatty alcohol polyoxyethylene ether AEO-3, 1-2 parts of an aluminum acetate coupling agent DL-411, 1-2 parts of epoxy butyl oleate, 0.2-0.3 parts of azodiisobutyronitrile, 1-2 parts of a film forming auxiliary agent and 100-120 parts of water. According to the invention, a water base is used to achieve a relatively good heat dissipation effect, the triisopropanolamine plays a role of corrosion inhibition, and an initiation reaction is carried out through the azodiisobutyronitrile so that a protective film is formed among the oleic acid, the polyvinyl alcohol, the propylene glycol, etc., thereby increasing intermiscibility with the water and improving a protective effect of the wiredrawing composition. A silane coupling agent KH 550 is used to play a bridging role, thereby increasing dispersibility of each component and preventing depositing and layering phenomena after a long-term storage.

Owner:安徽富华电子集团有限公司

Thermal printing paper with good color rendering property and processing technology thereof

PendingCN111235948AImprove the display effectImprove resistance to damageNon-fibrous pulp additionPaper coatingTrifluoromethanesulfonic anhydrideBenzoic acid

The invention discloses a thermal printing paper with good color rendering property. The thermal printing paper comprises the following components: 45-55 parts of a degradable inorganic filler, 0.2-0.4 part of N-dimethylformamide, 0.8-1.2 parts of p-toluenesulfonic acid, 0.3-0.5 part of trifluoromethanesulfonic anhydride, 5-8 parts of aluminum acetate, 13-15 parts of p-hydroxybenzoic acid, 3-5 parts of beewax, 2-4 parts of a film forming agent, 2-3 parts of an antioxidant and 1-2 parts of an ultraviolet light absorber. The processing technique comprises the following steps: proportionally weighing a proper amount of N-dimethylformamide, p-toluenesulfonic acid and trifluoromethanesulfonic anhydride, mixing with an organic solvent to obtain a mixed solution, adding a degradable inorganic filler, continuing stirring and mixing to obtain a color developing layer coating, uniformly coating the base paper base layer with the color developing layer coating, spraying the color developing layerwith a mixed solution of aluminum acetate and p-hydroxybenzoic acid, weighing a proper amount of beeswax in proportion, adding an organic solvent mixed solution, heating the beeswax dissolved solution to 40-45 DEG C, adding the film forming agent, the antioxidant and the ultraviolet light absorber, carrying out stirring and mixing, and uniformly coating a display layer with a protective layer solution.

Owner:安徽军号信息科技有限公司

Preparation method of aluminum oxide coating adopting silicon carbide fibers as matrix

The present invention provides a preparation method of an aluminum oxide coating adopting silicon carbide fibers as matrix. The preparation method comprises: mixing an aluminum acetate solution and an ammonia water solution according to a certain ratio to obtain a milk white solution and produce white precipitate, filtering, washing the precipitate with deionized water, adding the precipitate to deionized water to uniformly disperse, adding an appropriate amount of an acetic acid solution, adding the mixed solution to a water bath pot, heating, maintaining the stirring until a clear transparent aluminum oxide sol is obtained, and immersing silicon carbide fibers into the prepared aluminum oxide sol to obtain the silicon carbide fibers having the aluminum oxide coating. According to the present invention, the used raw materials are aluminum acetate and ammonia water, such that the price is cheap, the cost is low, and the toxicity on human body is low; and the preparation method has characteristics of short time consumption, simple operation and no requirement of special equipment, and is suitable for mass production.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

Aluminum-zirconium co-doped silicon carbide/boron nitride fiber and preparation method thereof

ActiveCN109825901AMake up for shrinkage defectsImprove mechanical propertiesFibre chemical featuresBoron nitrideDimethylsilane

The invention discloses aluminum-zirconium co-doped silicon carbide / boron nitride fiber and a preparation method thereof. The method includes the following steps that aluminum acetate, zirconium acetoacetate and polyborosilicazane are mixed, polydimethylsilane is injected to uniformly cover the surface of a mixture, heat preservation is conducted after heating, and after dissolving with xylene, filtering, and vacuum distillation, fine materials are obtained; the fine materials are subjected to melt spinning, sintering is conducted, and the aluminum-zirconium co-doped silicon carbide / boron nitride fiber is obtained. Aluminum, zirconium, boron and nitrogen elements are introduced into a precursor, N elements are re-introduced in the sintering process, especially the interface of the siliconcarbide / boron nitride fiber contains nanon silicon carbide nitride, the strength of the prepared aluminum-zirconium co-doped silicon carbide / boron nitride fiber is 3.5+ / -0.3 GPa at room temperature, and the elastic modulus is 280+20 GPa. After treatment in an air environment of 1100 DEG C for 100 hours, the strength retention rate of the fiber still reaches 85% or above, and the fiber has practical value and a wide application prospect in the field of high-performance fiber.

Owner:JIANGXI JIAJIEXINDA NEW MATERIAL TECH CO LTD

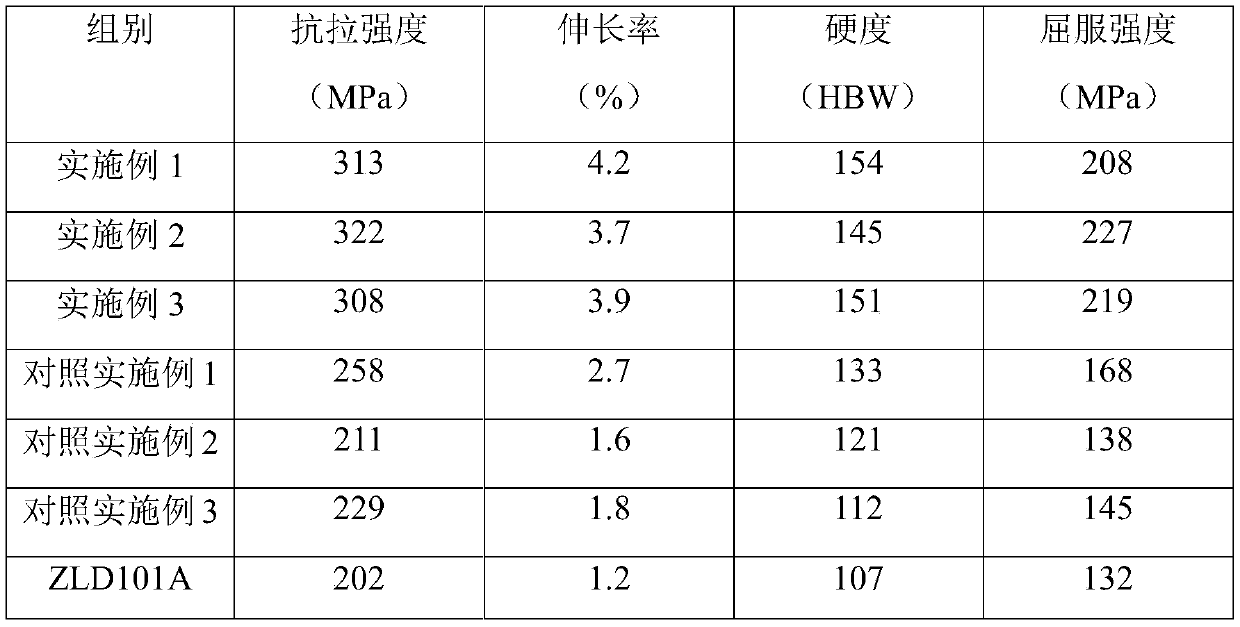

Aluminum alloy refining material and preparation method and application thereof

The invention discloses an aluminum alloy refining material and a preparation method and an application thereof and relates to the field of aluminum alloy modifiers. The aluminum alloy refining material comprises the following raw materials in percentage by weight: 5-8% of potassium fluoroaluminate, 7-11% of sodium fluoroaluminate, 3-5% of disodium hydrogen phosphate hydrate, 5-7% of potassium chloride, 4-8% of sodium chloride, 0.4-0.8% of barium acetate, 3-6% of barium nitrate, 0.2-0.9% of samarium fluoride, 0.2-0.9% of aluminum acetate, 6-8% of aluminum chloride, 15-20% of lepidolite compound powder and the balance of pure aluminum. The aluminum alloy refining material has the beneficial effects that the four modifiers of barium, sodium, lithium and samarium are combined according to thecharacteristics and a sintered body with a loose structure is prepared by adopting spray deposition and extrusion calcination in one step, so that the metamorphic activity is effectively retained andthe material has the characteristics of short metamorphic incubation period, long effective metamorphic time and stable metamorphic effect; and the lepidolite powder can serve as a modifier carrier for degassing and slag removal and the alloy hardness can be significantly increased by utilizing high hardness matters contained in the lepidolite powder.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

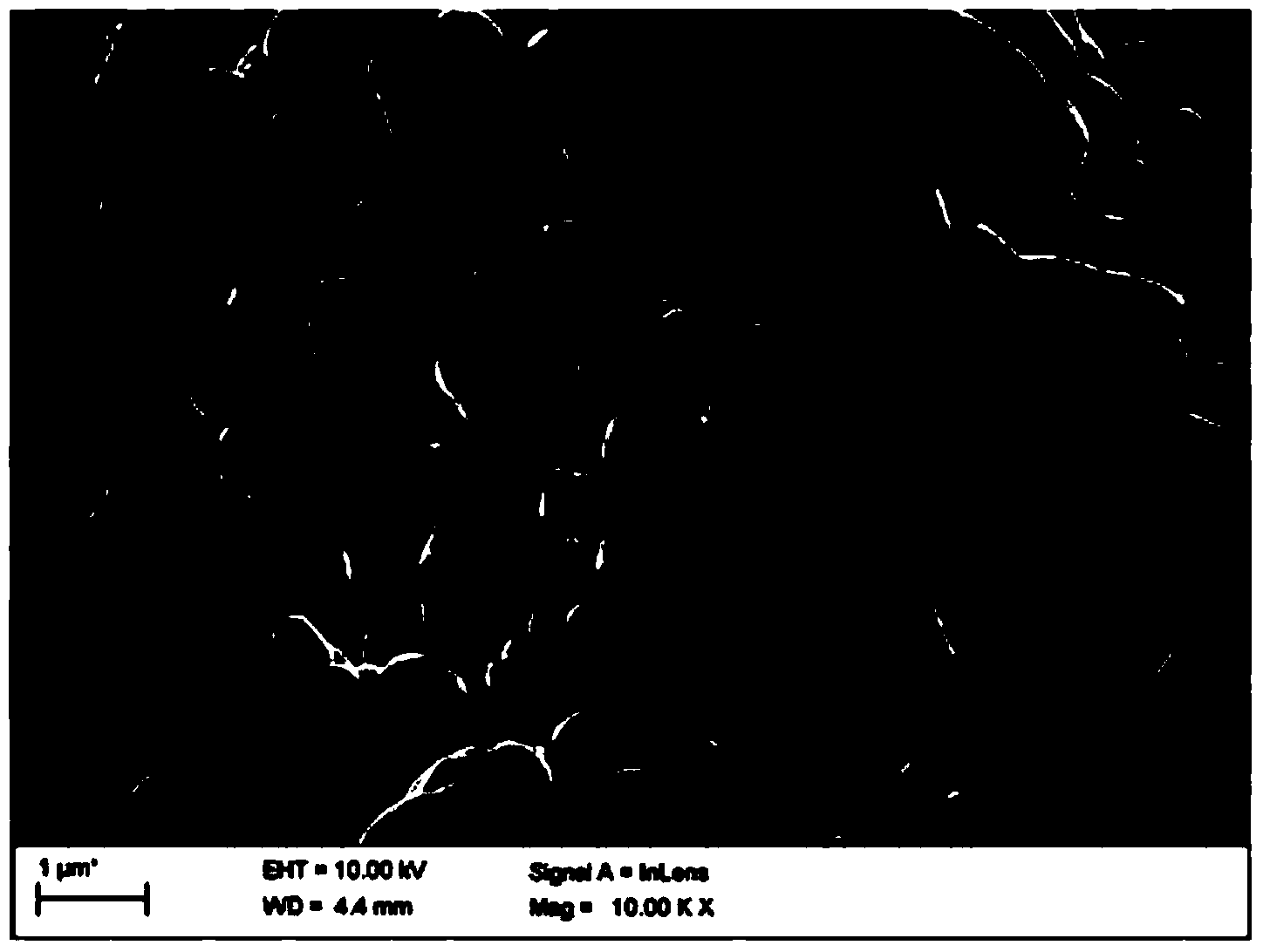

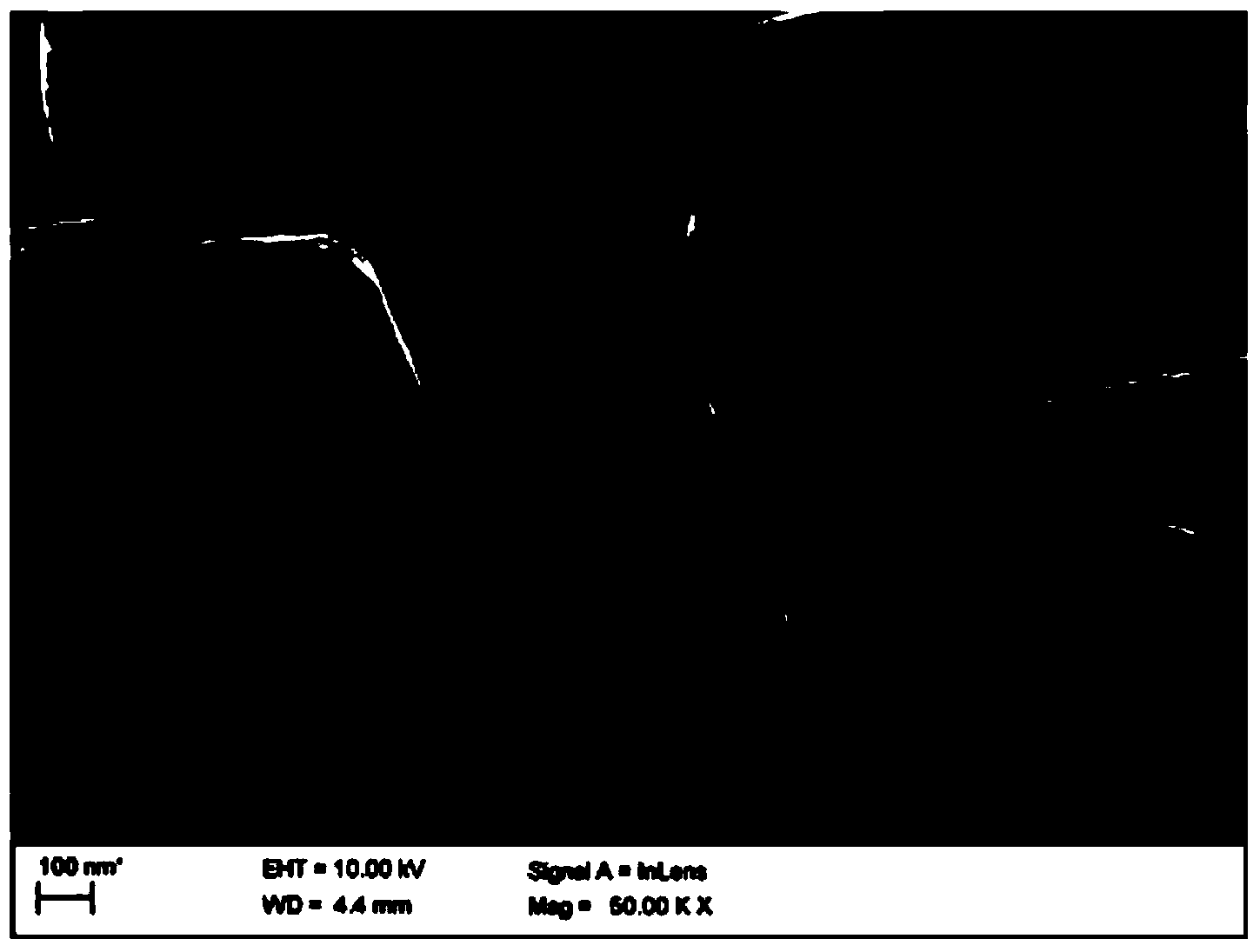

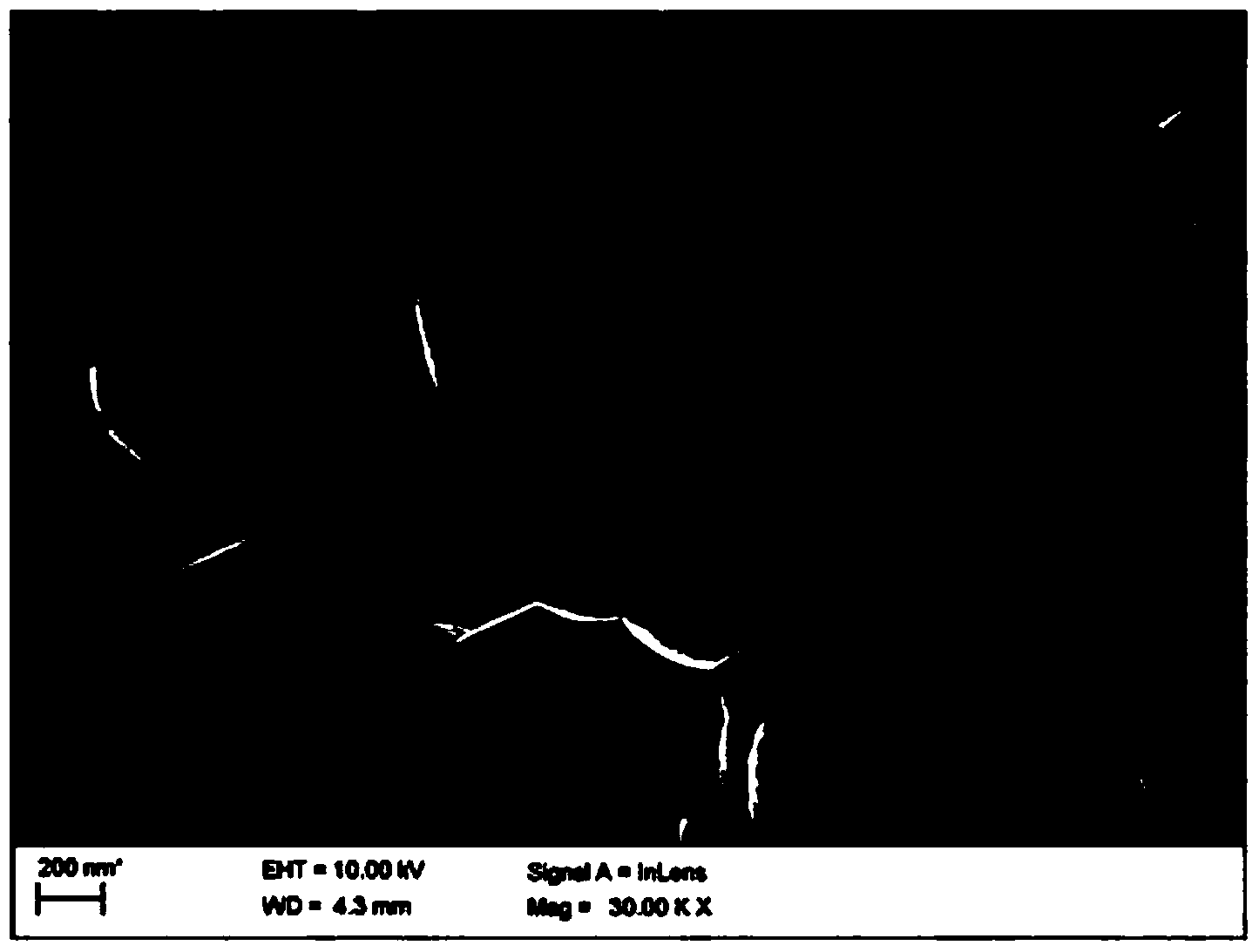

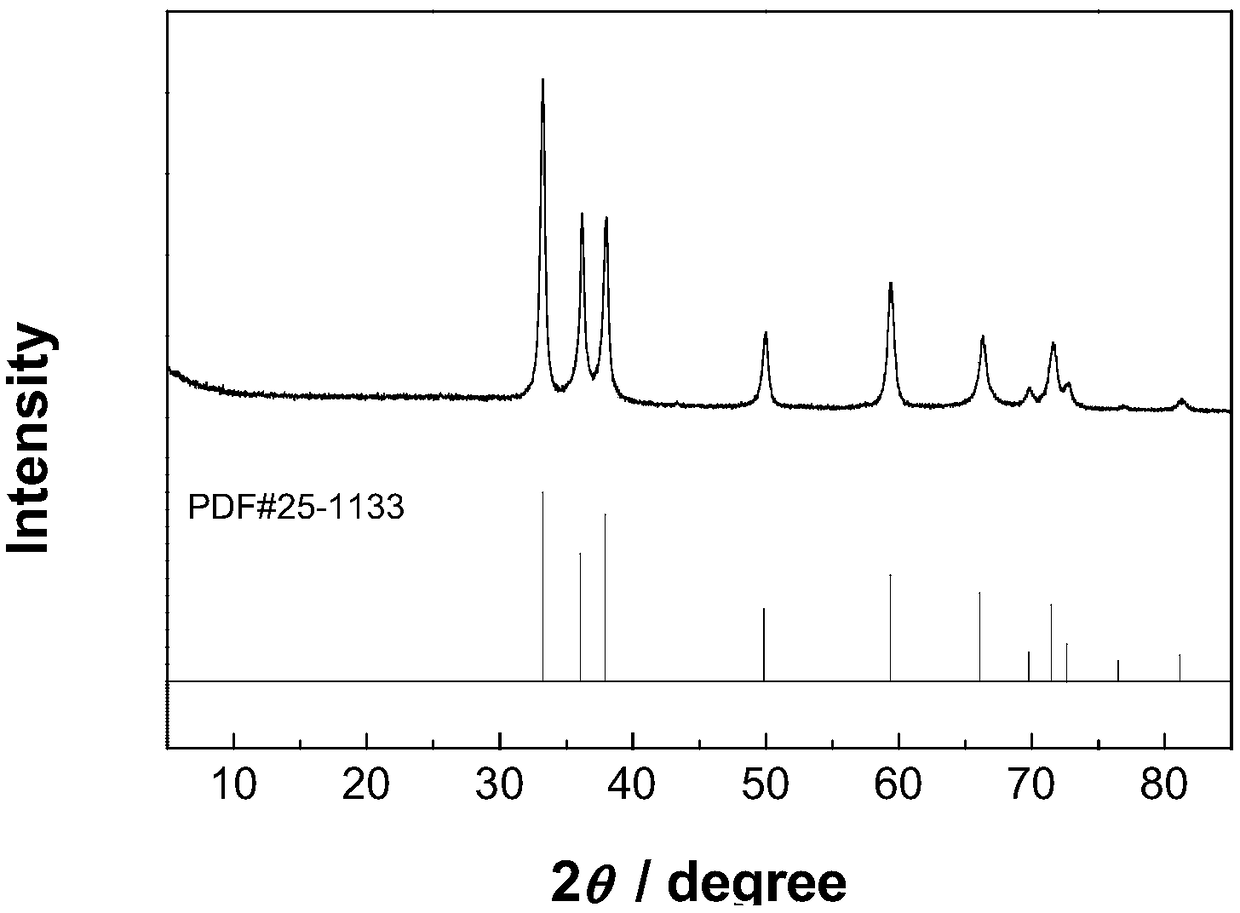

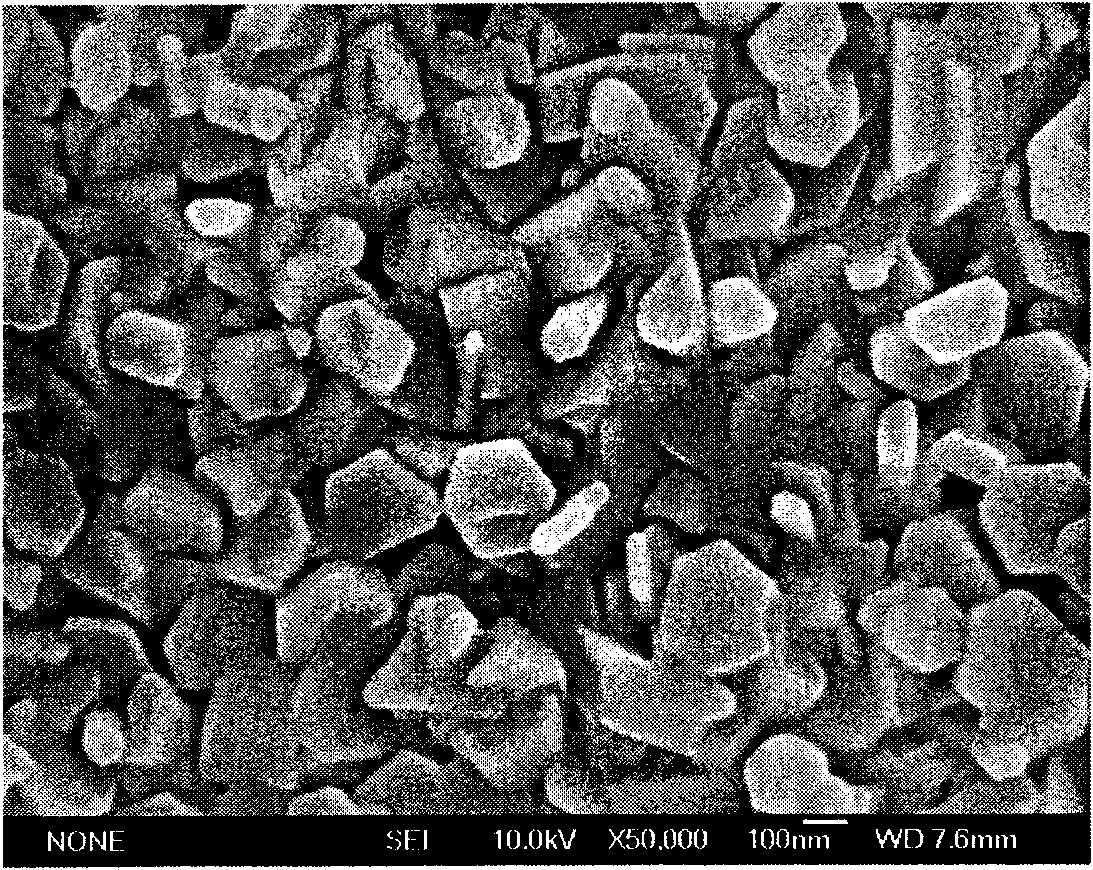

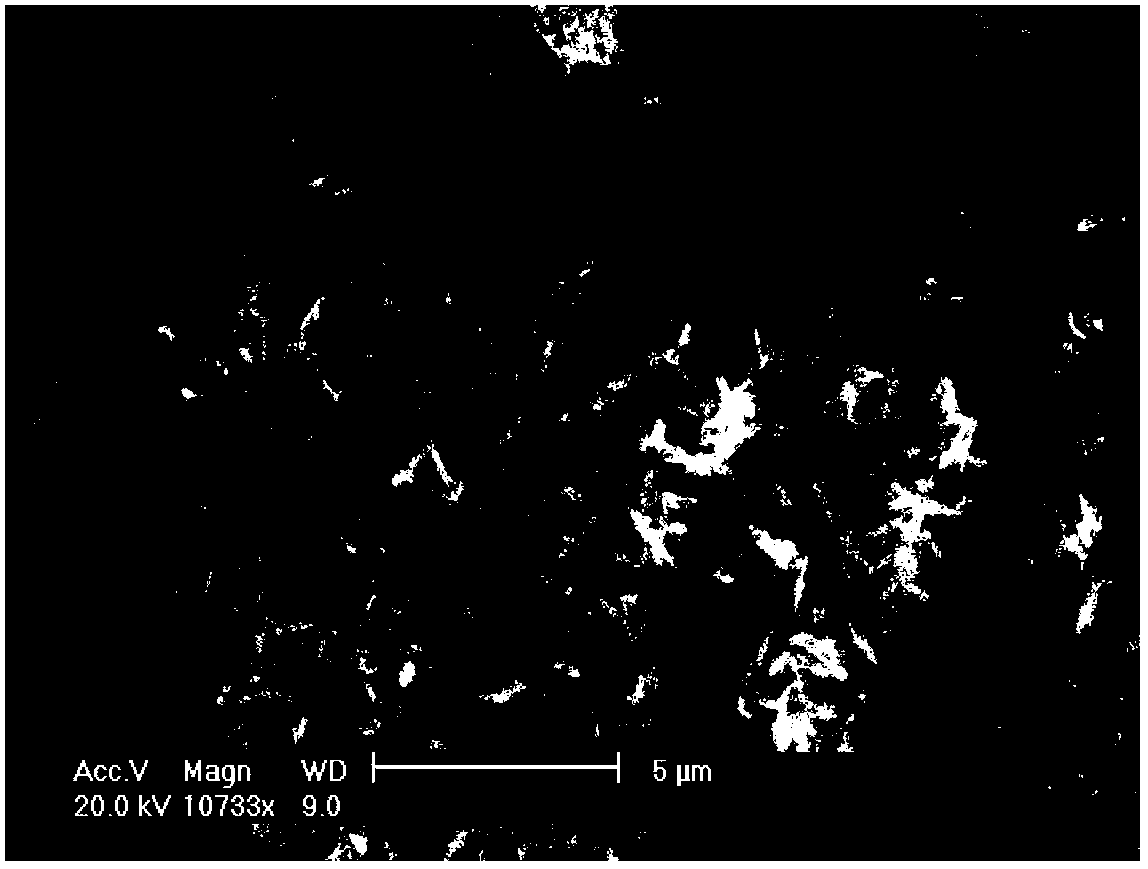

Ni-based catalyst prepared through solution combustion and method thereof

ActiveCN107999078AImprove conversion rateHigh selectivityOrganic compound preparationPreparation by hydrogenationMuffle furnaceAluminum Acetate

The invention relates to the technical field of a Ni-based catalyst, in particular to a Ni-based catalyst prepared through solution combustion and a preparation method thereof. The Ni-based catalyst is prepared from the following method including the steps of taking a certain amount of nickel nitrate hexahydrate or nickel acetate or nickel chloride and aluminum nitrate nonahydrate or aluminum acetate or aluminum chloride; using polypyrrolidone as a morphological regulating and controlling agent; adding a deionized water and ethylene glycol mixed solution; performing ultrasound processing to obtain a precursor test solution; raising the temperature through a muffle furnace program; burning the test solution in the muffle furnace; preparing a combustion body test specimen; then, performing cooing, grinding and sieving; performing high-temperature reduction by H2 to obtain the Ni-based catalyst prepared through solution combustion. The method belongs to a method for simply and fast preparing the Ni-based catalyst. The prepared catalyst test specimen is a flaky micro porous material; when the catalyst is used for synthesizing 1,4-butanediol through butynediol hydrogenation, the characteristics of high conversion rate and selectivity of the 1,4-butanediol, high stability and the like are realized. The industrialization is easy.

Owner:XINJIANG MARKORCHEM

Alcoholysis catalyst comprising palladium and metal oxides loaded by mesoporous molecular sieve and preparation method thereof

InactiveCN103272629AReduce generationIncrease the rate of the positive reactionMolecular sieve catalystsGroup 5/15 element organic compoundsPtru catalystPhysisorption

The invention discloses an alcoholysis catalyst comprising palladium and metal oxides loaded by a mesoporous molecular sieve and a preparation method thereof. The preparation method comprises the step that a palladium chloride solution is physically adsorbed on a SBA-15 mesoporous molecular sieve; carbon monoxide is fed into the SBA-15 mesoporous molecular sieve so that palladium chloride is reduced into metal palladium and the metal palladium is loaded on the SBA-15 mesoporous molecular sieve; an aluminum acetate-magnesium acetate-titanium acetate-rare earth metal acetate mixed solution is physically adsorbed on the SBA-15 mesoporous molecular sieve; and the SBA-15 mesoporous molecular sieve is calcined so that palladium and metal oxides are loaded on the SBA-15 mesoporous molecular sieve. Through utilization of the alcoholysis catalyst, a triethyl phosphate yield and triethyl phosphate purity are greatly improved. The alcoholysis catalyst can be separated easily and can be recycled.

Owner:安徽生力农化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com