Preparation method for nanometer aluminum nitride powder

A nano-aluminum nitride and powder technology, which is applied in chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve the problems of harsh reaction conditions, low product purity, and high raw material cost, and achieve good stability, high purity, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Grind and mix 2.1962g basic aluminum acetate and 6.1488g melamine evenly. The molar ratio of aluminum to melamine is 1:4. 2 It is calcined at 900°C for 3 hours. After cooling, it is decarburized at 600°C for 1 hour in an air atmosphere, and then cooled to obtain nano aluminum nitride powder.

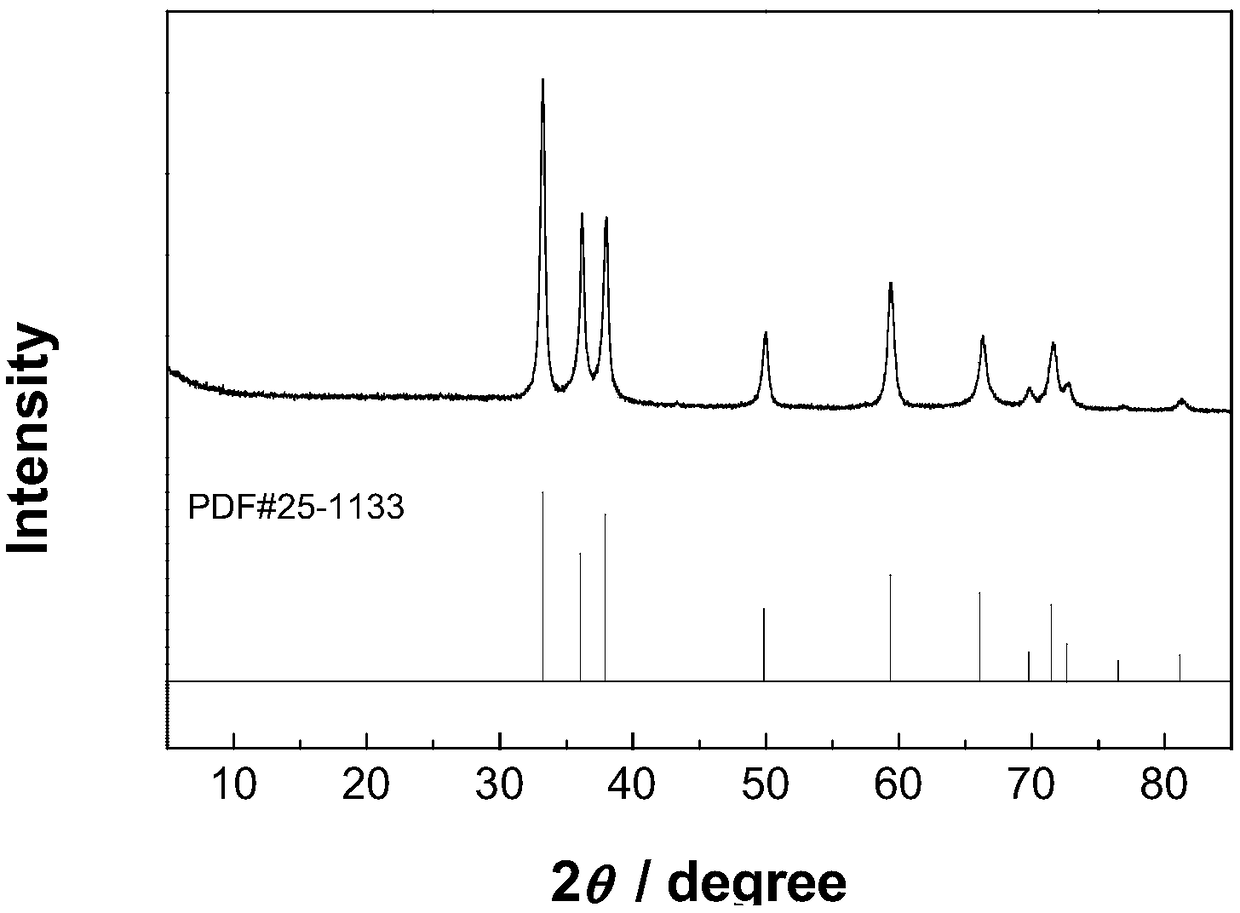

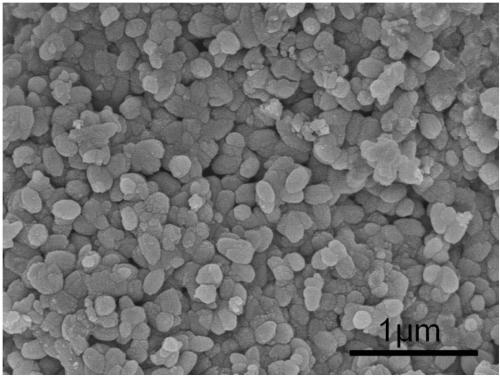

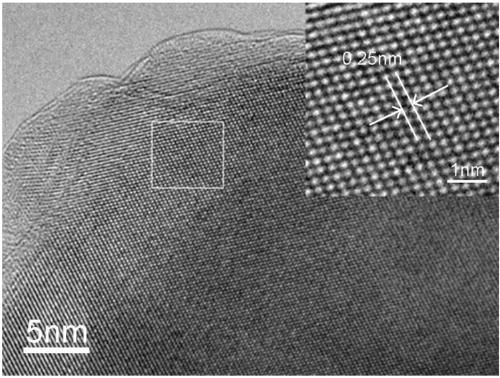

[0042] by figure 1 It can be seen that the XRD diffraction peak of the synthesized aluminum nitride is completely consistent with the standard diffraction peak, without any other peaks, and the purity of the synthesized aluminum nitride on the surface is very high. The aluminum nitride crystal size calculated by the Scherrer formula at the diffraction peak position with a 2θ value of 50° is 17.54 nm, which is the average value of the crystal grain size in the vertical direction of 50° (102 crystal plane). From the electron microscope image, the average particle size of aluminum nitride particles can be obtained as 90nm (see Figure 2~4 ).

Embodiment 2

[0044] Grind and mix 2.1962g basic aluminum acetate and 6.1488g melamine evenly. The molar ratio of aluminum to melamine is 1:4. 2 Calcined at 800℃ for 4 hours, after cooling, perform decarburization treatment at 600℃ in air atmosphere for 1 hour, and cool to obtain nano aluminum nitride powder (see Figure 5 ).

Embodiment 3

[0046] Grind and mix 2.1962g basic aluminum acetate and 6.1488g melamine evenly. The molar ratio of aluminum to melamine is 1:4. 2 Calcined at 900℃ for 3 hours. After cooling, perform decarburization treatment at 700℃ in air atmosphere for 1 hour. Cool to obtain nano aluminum nitride powder (see Image 6 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com