Aluminum cladding method for lithium ion positive electrode material

A positive electrode material and aluminum coating technology, which is applied in the field of aluminum coating of lithium ion positive electrode materials, can solve the problems of solvents harmful to the human body and the environment, poor coating uniformity, and high energy consumption in production, so as to reduce hazards and improve uniformity , the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Prepare the coating solution: use aluminum nitrate nonahydrate and ethanol to prepare a 1mol / L aluminum salt solution as the coating solution;

[0039] 2) Coating: 100 g of uncoated ternary cathode material LiCo 1 / 3 Ni 1 / 3 mn 1 / 3 o 2 Add it into the aluminum salt solution, heat up to reflux at 2°C / min after stirring, and the molar ratio of the element Al in the solution to the transition metal element M of the positive electrode material is Al / M=0.005;

[0040] 3) Solvent removal: after refluxing for 30 minutes, filter with suction, and dry under vacuum at 100°C to obtain a semi-finished product;

[0041] 4) Roasting: Put the semi-finished product in a muffle furnace, bake it at 500°C for 5h, and cool it down to room temperature naturally to get aluminum-coated LiCo 1 / 3 Ni 1 / 3 mn 1 / 3 o 2 Cathode material.

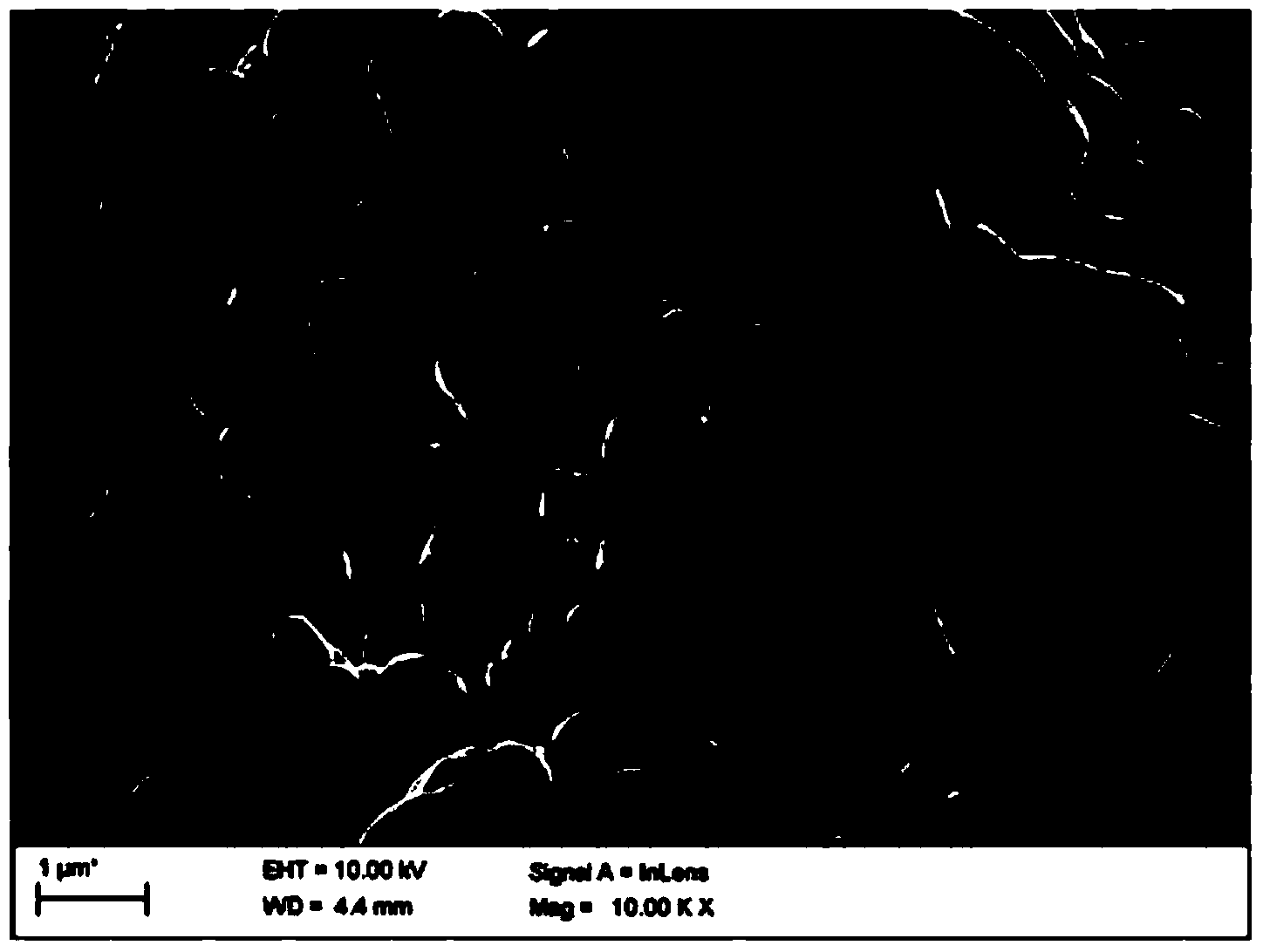

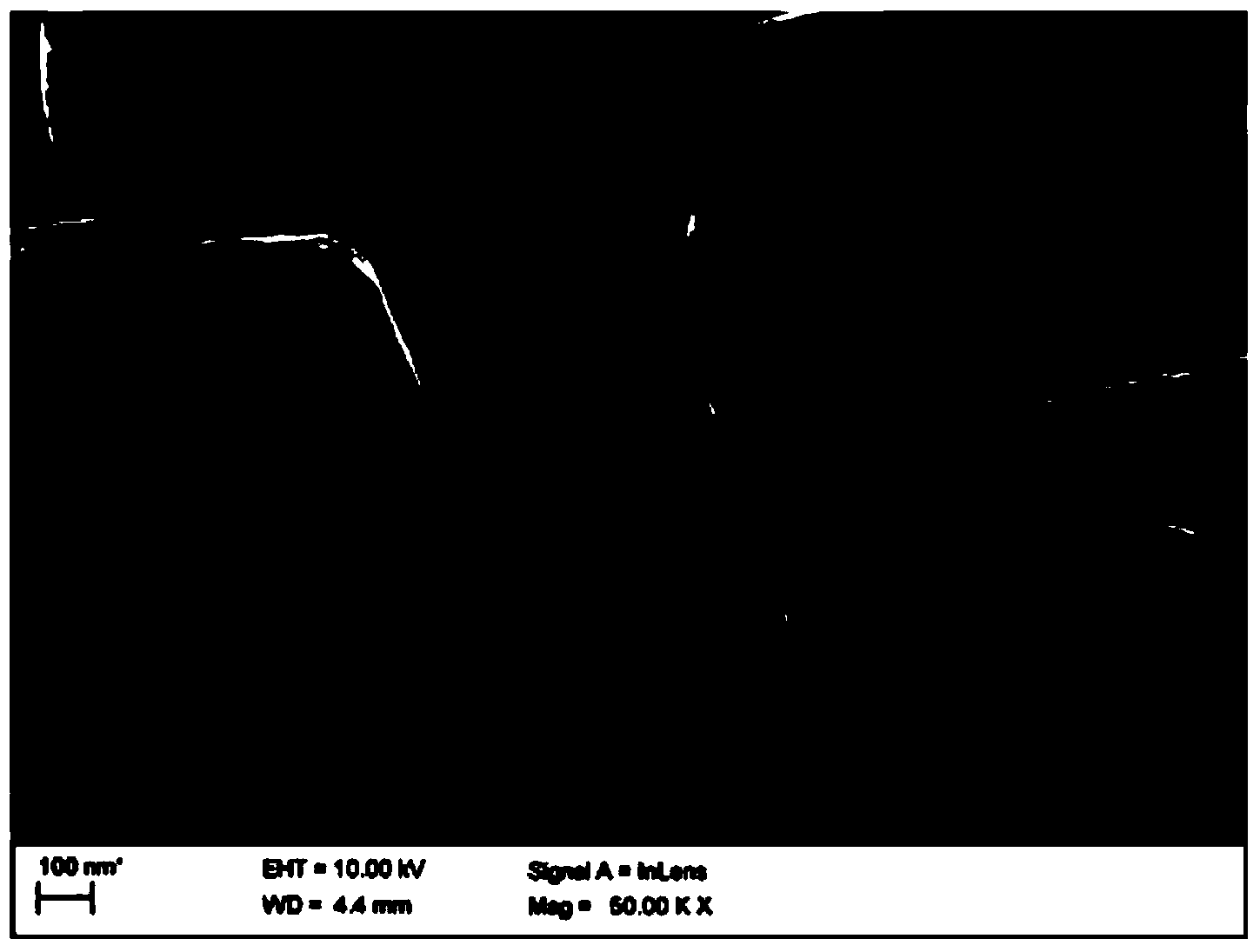

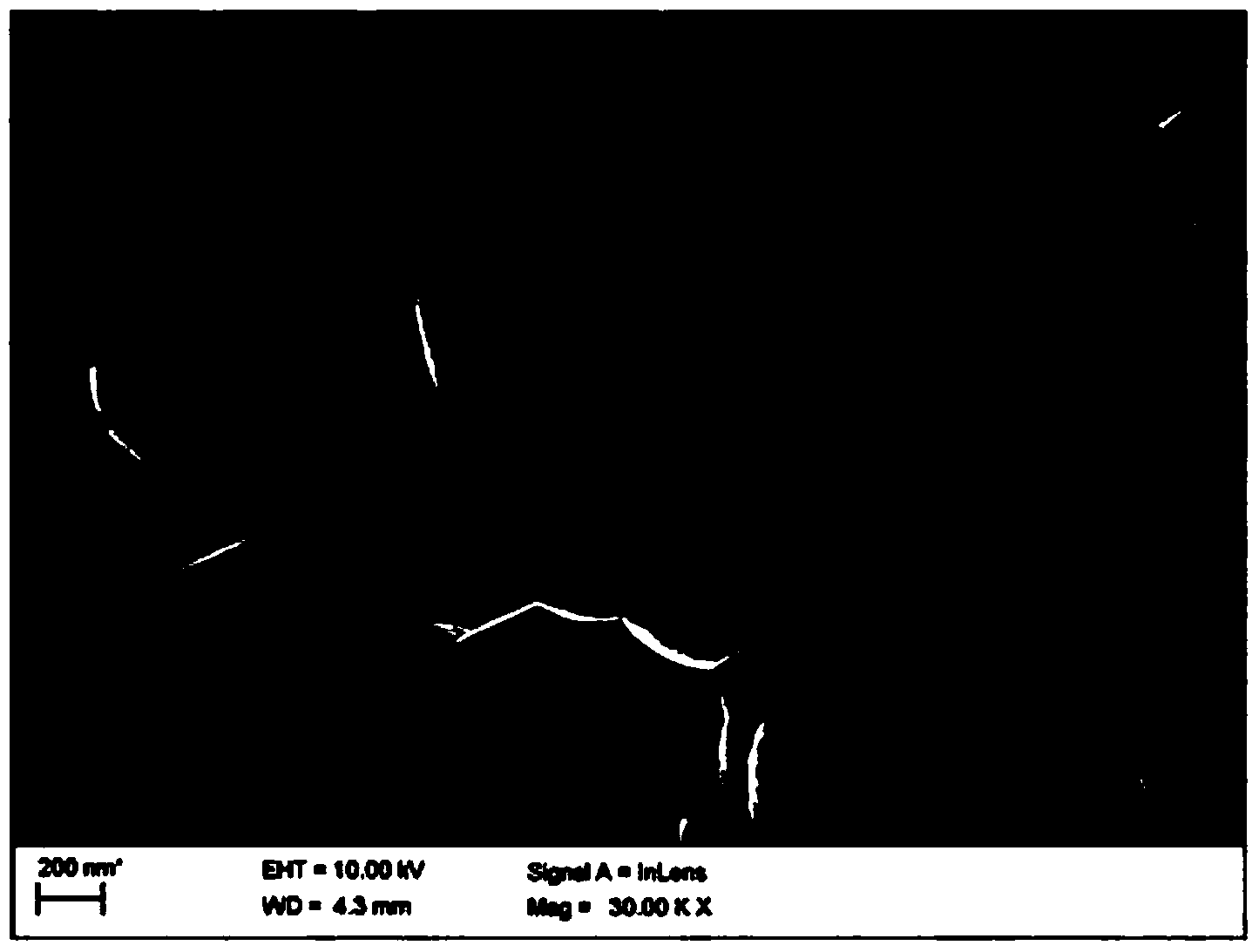

[0042] Scanning electron microscopy was used to observe the morphology of the precursor alumina coated, the results are as follows Figure 3-4 Shown; XRD...

Embodiment 2~5

[0045] Using the materials and dosages listed in Table 1, the aluminum-coated cathode material was prepared according to the method of Example 1.

[0046] Table 1, materials used in Examples 1 to 5 and consumption comparison table

[0047]

[0048] Electrochemical performance analysis:

[0049]The active material samples synthesized in Comparative Example 1 and Examples 1 to 5 were respectively mixed with conductive carbon and binder polyvinylidene fluoride (PVDF) in a mass ratio of 90:5:5 in N-methylpyrrolidone (NMP ) in a solvent, stirred at room temperature for 12 hours, and made into a positive electrode slurry; the positive electrode slurry was scraped onto an Al foil current collector with a thickness of 16 μm, vacuum-dried at 120°C for 12 hours, and punched into a 14.0 mm in diameter after cold pressing. Disc; the negative electrode uses a metal lithium sheet with a diameter of 15.0mm, the electrolyte uses a 1mol / L LiPF6 solution (the solvent is EC and EMC with a vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com