Lithium ion battery with high energy density

A lithium-ion battery, high energy density technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reducing the proportion of active materials, increasing the energy density of electrodes and energy storage devices, etc., to improve energy density, The effect of reducing the proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

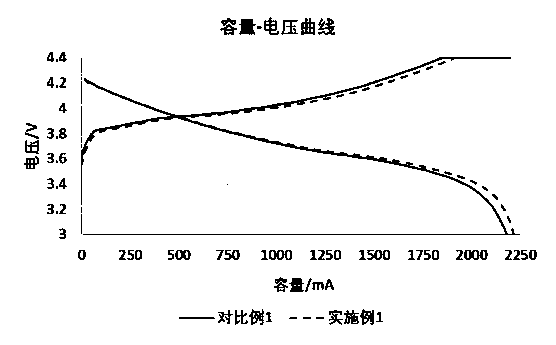

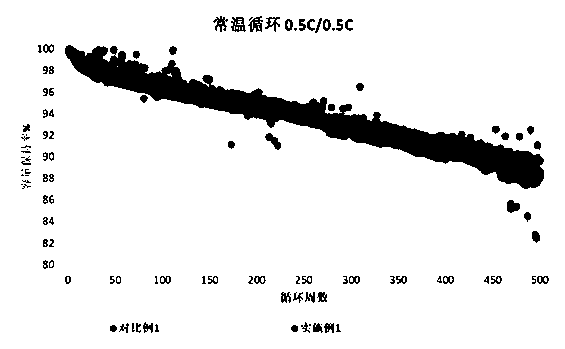

Embodiment 1

[0033] The model of the lithium-ion battery in this embodiment: 385763P;

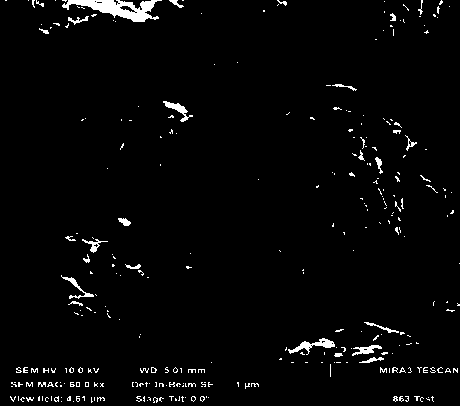

[0034] (1) Positive electrode: active material of positive electrode system, lithium cobaltate, physical and chemical properties of lithium cobaltate: D50: 19.5um, specific surface area: 0.12m 2 / g, the conductive agent used in the positive electrode system is single-walled carbon nanotubes, the diameter d of single-walled carbon nanotubes: 1.6nm, and the specific surface area: 98m 2 / g, length: 8um, the addition amount is 0.06%, the compacted density of the positive pole piece is: 3.84-3.88 g / cm 3 .

[0035] (2) Negative electrode: Negative electrode is artificial graphite, the physical and chemical properties of artificial graphite: D50: 19.2um, specific surface area: 1.32m 2 / g, tap density: ≥1.0g / cm 3 , the compacted density of the negative pole piece is: 1.65-1.67 g / cm 3 .

[0036] (3) Electrolyte system: The volume ratio of EC / DEC / EMC in the solvent of the electrolyte system is 1:1:1, and the ...

Embodiment 2

[0067] The model of the lithium-ion battery in this embodiment: 355272P;

[0068] (1) Positive electrode: positive electrode system active material lithium cobalt oxide, physical and chemical properties of lithium cobalt oxide: D50: 17.15um, specific surface area: 0.15m 2 / g, the conductive agent used in the positive electrode system is single-walled carbon nanotubes, the diameter d of single-walled carbon nanotubes: 1.6nm, and the specific surface area: 98m 2 / g, length: 8um, the addition amount is 0.04%, the compacted density of the positive electrode sheet is: 3.90-3.94 g / cm 3 .

[0069] (2) Negative electrode: the negative electrode is artificial graphite and modified natural graphite, the ratio of artificial graphite and modified natural graphite is 1:1, the physical and chemical properties of artificial graphite and modified natural graphite: D50: 14.2um, specific surface area: 1.35m 2 / g, tap density: ≥1.0g / cm 3 , the compacted density of the negative pole piece is: ...

Embodiment 3

[0101] The model of the lithium-ion battery in this embodiment: 385763P;

[0102] (1) Positive electrode: The active materials of the positive electrode system are lithium cobalt oxide and lithium nickel cobalt manganese oxide. The amount of lithium nickel cobalt manganese oxide added is 25% of the total amount of lithium cobalt oxide and lithium nickel cobalt manganese oxide. Physical and chemical properties of lithium cobalt oxide: D50 :13um, specific surface area: 0.25m 2 / g, the conductive agent used in the positive electrode system is single-walled carbon nanotubes and multi-walled carbon nanotubes, the diameter d of single-walled carbon nanotubes: 1.2nm, and the specific surface area: 85m 2 / g, length: 5um, diameter d of multi-walled carbon nanotubes: 30nm; specific surface area: 85m 2 / g length: 5um; the total amount of conductive agent added is 0.06%, the amount of single-walled carbon nanotubes added is 9% of the total amount of single-walled carbon nanotubes and mul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com