Preparation method of ternary positive electrode material

A cathode material and mixing technology, which is applied in the field of preparation of ternary cathode materials, to achieve the effects of improved cycle performance, high ion conductivity, and low explosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of ternary cathode material of the present invention comprises the following steps:

[0039] 1. Weigh the precursor according to the material design ratio, where the precursor includes lithium source, nickel source, manganese source or cobalt source.

[0040] The lithium source includes lithium acetate, sulfate, nitrate, carbonate, and lithium chloride or lithium hydroxide.

[0041] Described nickel source, manganese source, cobalt source can be following one or more, the sulfate, nitrate, carbonate, acetate, hydroxide, chloride, oxide of nickel, manganese or cobalt element , and oxidized copolymers of two or three elements;

[0042] 2. Put the precursor into the high-speed mixer and start mixing. While mixing, use a spray diffuser to spray the grinding medium in the grinding medium tank into the high-speed mixer.

[0043] The grinding medium is one of n-nonane, isononane, and liquid paraffin solution, and the volume of the grinding medium is 0....

Embodiment 1

[0058] Take 10.5kg of lithium hydroxide and nickel-cobalt-manganese oxide with a ratio of 80:10:10 and put it into a high-speed mixer, and the molar ratio of lithium hydroxide to nickel-cobalt-manganese oxide is 1.05:1.

[0059] The grinding medium n-nonane is sprayed into the grinding medium tank in the form of spray infusion, and the spray speed is 1.8g / min. When the total amount of liquid injected reaches half of the total amount of solids, the spraying is stopped.

[0060] Continue to stir. After the total mixing time reaches 25 minutes, dry at 120°C. The evaporated solvent is condensed by the condenser and then flows back into the grinding medium tank for repeated spraying.

[0061] After the material is dried for 15 minutes, it is sintered at 750° C. under oxygen for 12 hours, and the sintered material is crushed to obtain the desired positive electrode material.

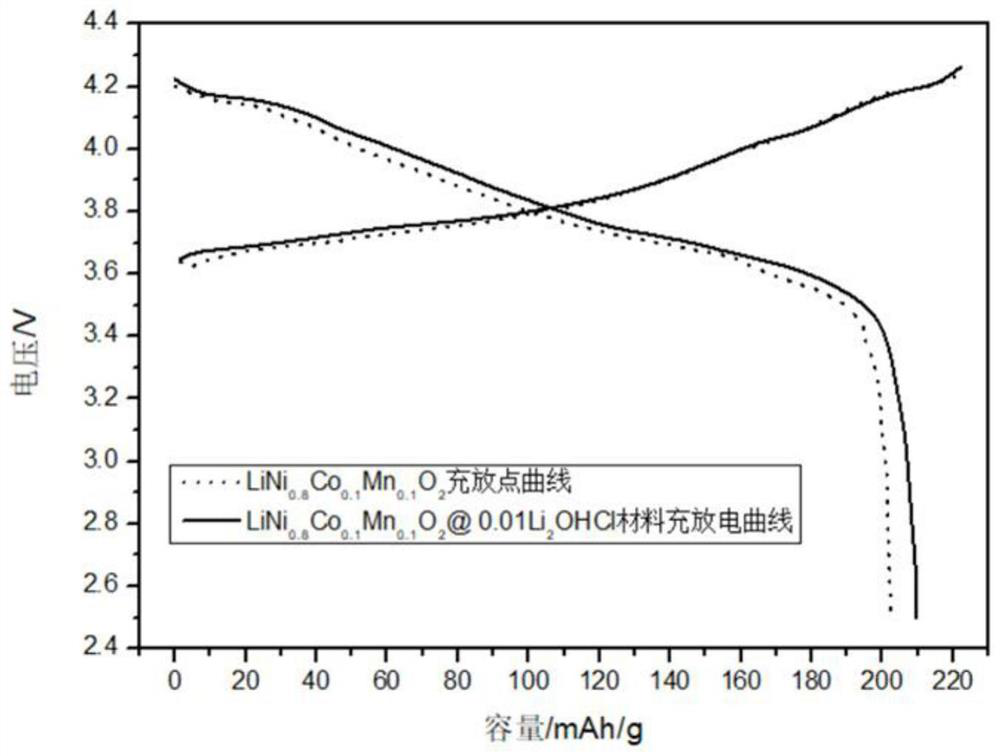

[0062] Afterwards, the material and 17.7g LiCl material were mixed evenly by the same wet method and then d...

Embodiment 2

[0066] Take 5.3 kg of lithium hydroxide and nickel-cobalt-manganese oxide with a ratio of 70:20:10 and put it into a high-speed mixer, and the molar ratio of lithium hydroxide to nickel-cobalt-manganese oxide is 1.2:1.

[0067] The liquid paraffin of the grinding medium is sprayed into the grinding medium tank in the form of spray infusion, and the spray speed is 0.9g / min. When the total amount of liquid injected reaches 0.3 times of the total amount of solids, the spraying is stopped.

[0068] Continue to stir. After the total mixing time reaches 30 minutes, dry at 130°C. The evaporated solvent is condensed by the condenser and then flows back into the grinding medium tank for repeated spraying.

[0069] After the material is dried for 15 minutes, it is sintered at 800° C. under oxygen for 12 hours. The sintered material is crushed to obtain the desired positive electrode material.

[0070] Afterwards, the material was mixed with 540.75 g of LiBr to Li at a molar ratio of 1:2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com