Patents

Literature

97 results about "Equipment Recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

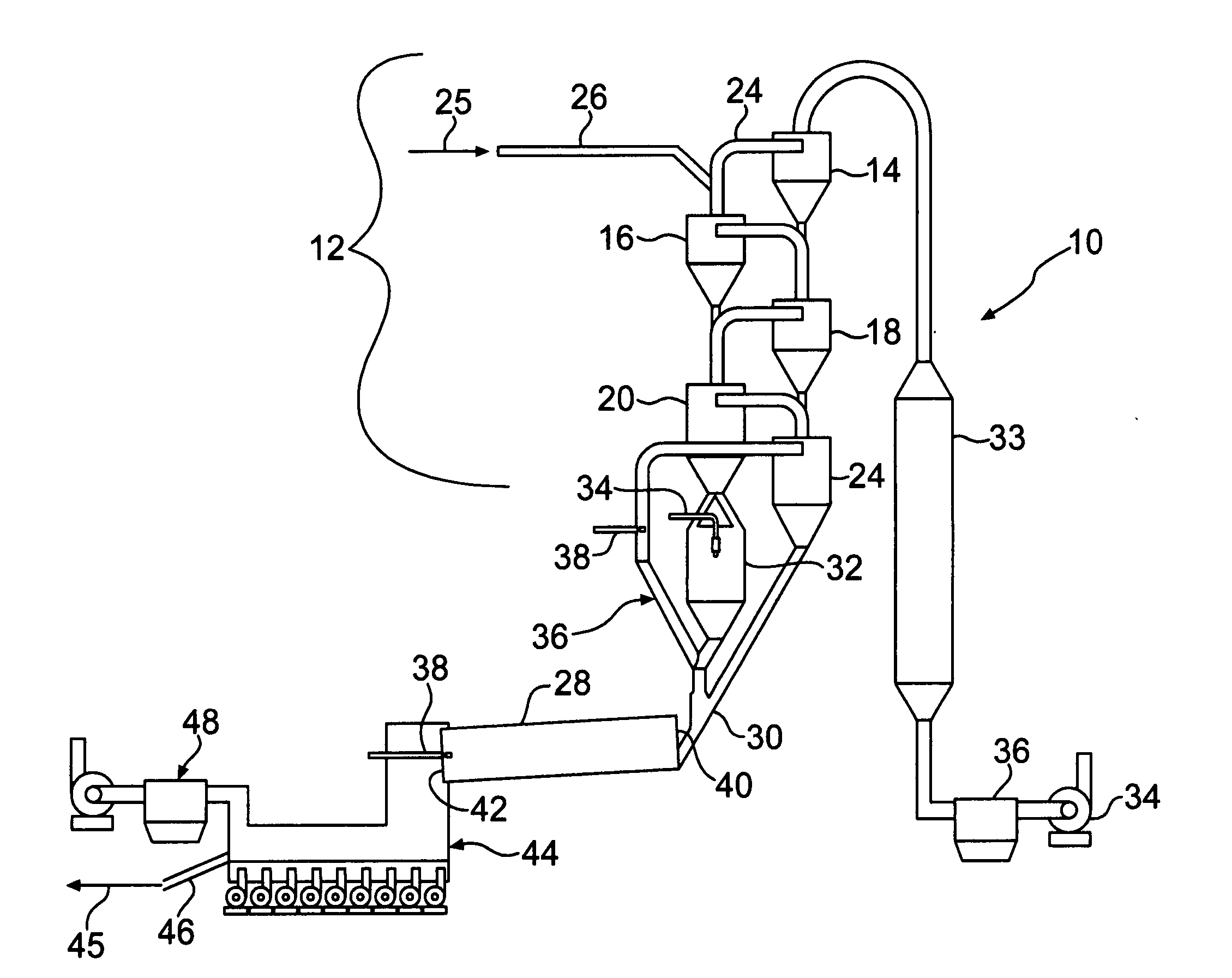

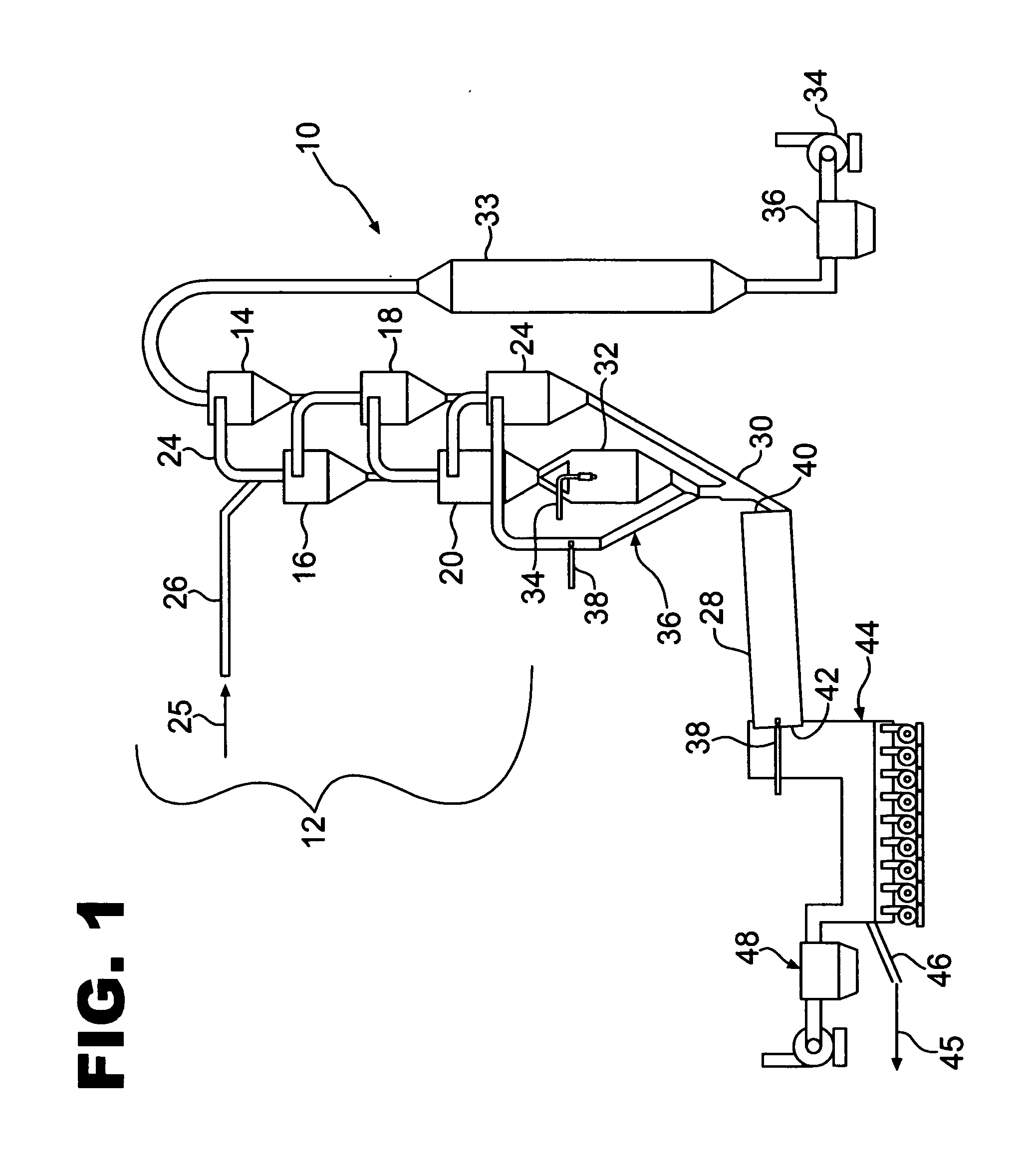

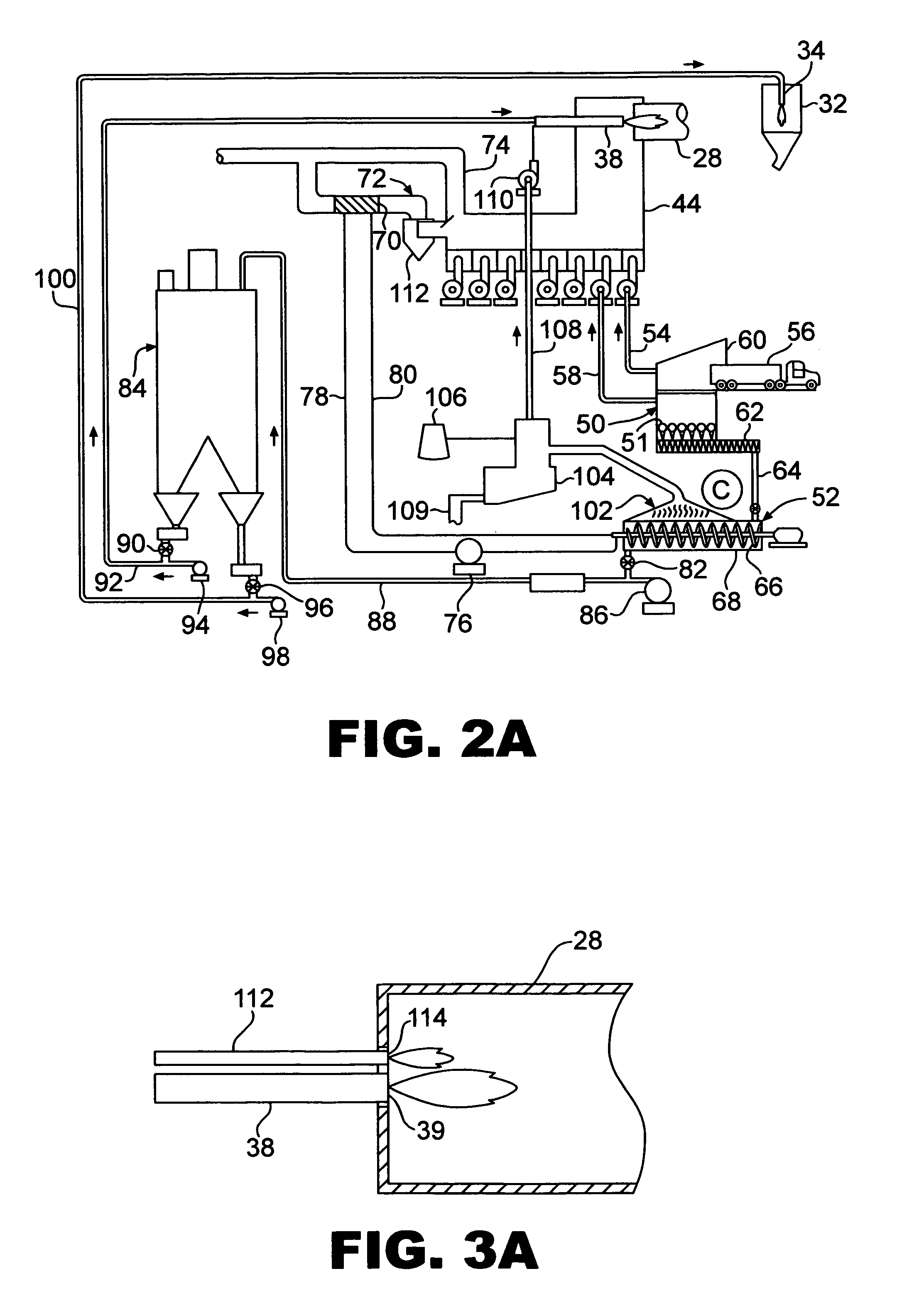

Method and apparatus for drying wet bio-solids using excess heat recovered from cement manufacturing process equipment

InactiveUS20050274293A1Avoid landfill disposalRotary drum furnacesBiofuelsProcess equipmentProcess engineering

Method and apparatus for drying wet bio-solids by utilizing waste heat from one of a clinker cooler or kiln exhaust gases in a cement making process.

Owner:LEHIGH CEMENT

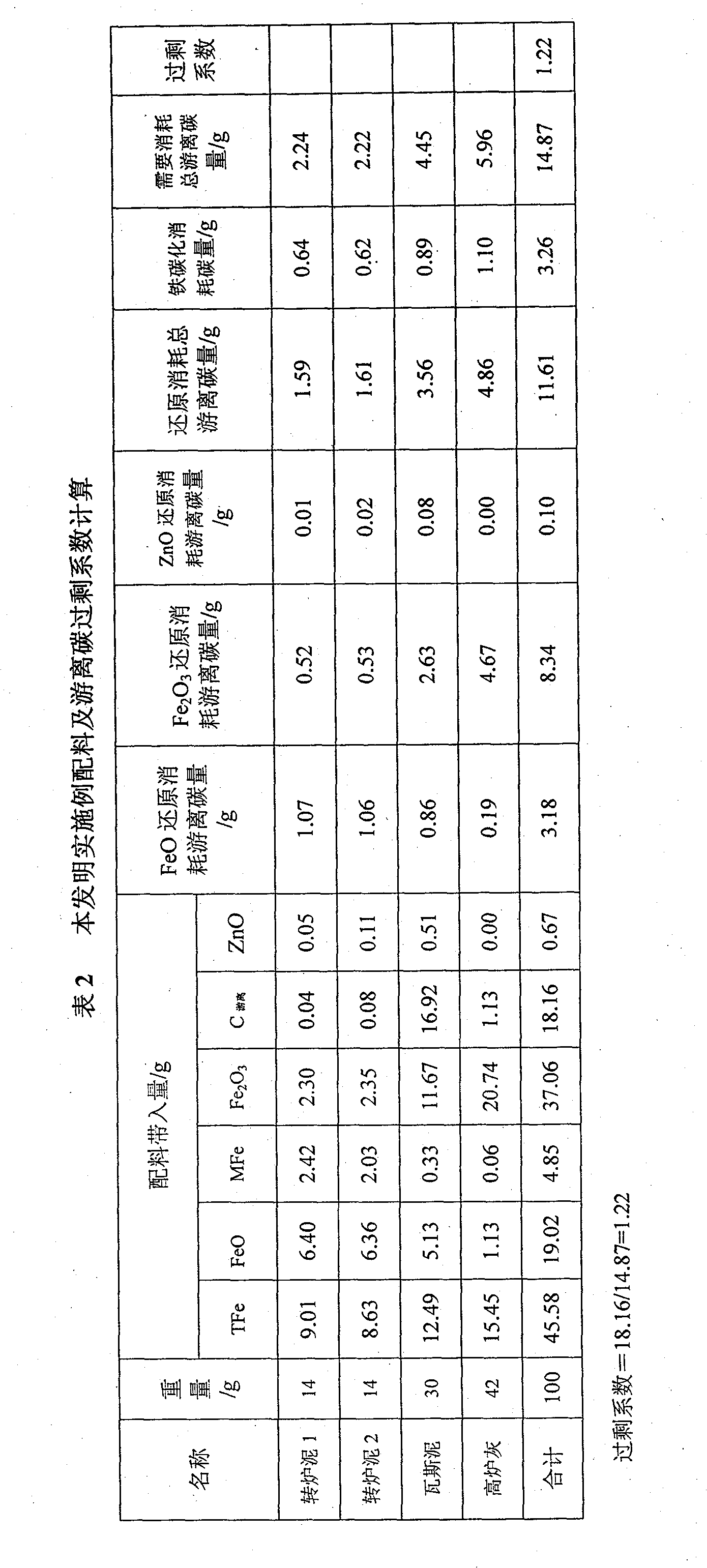

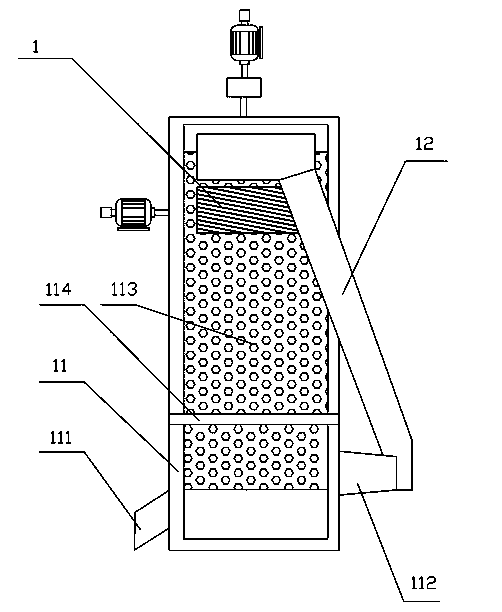

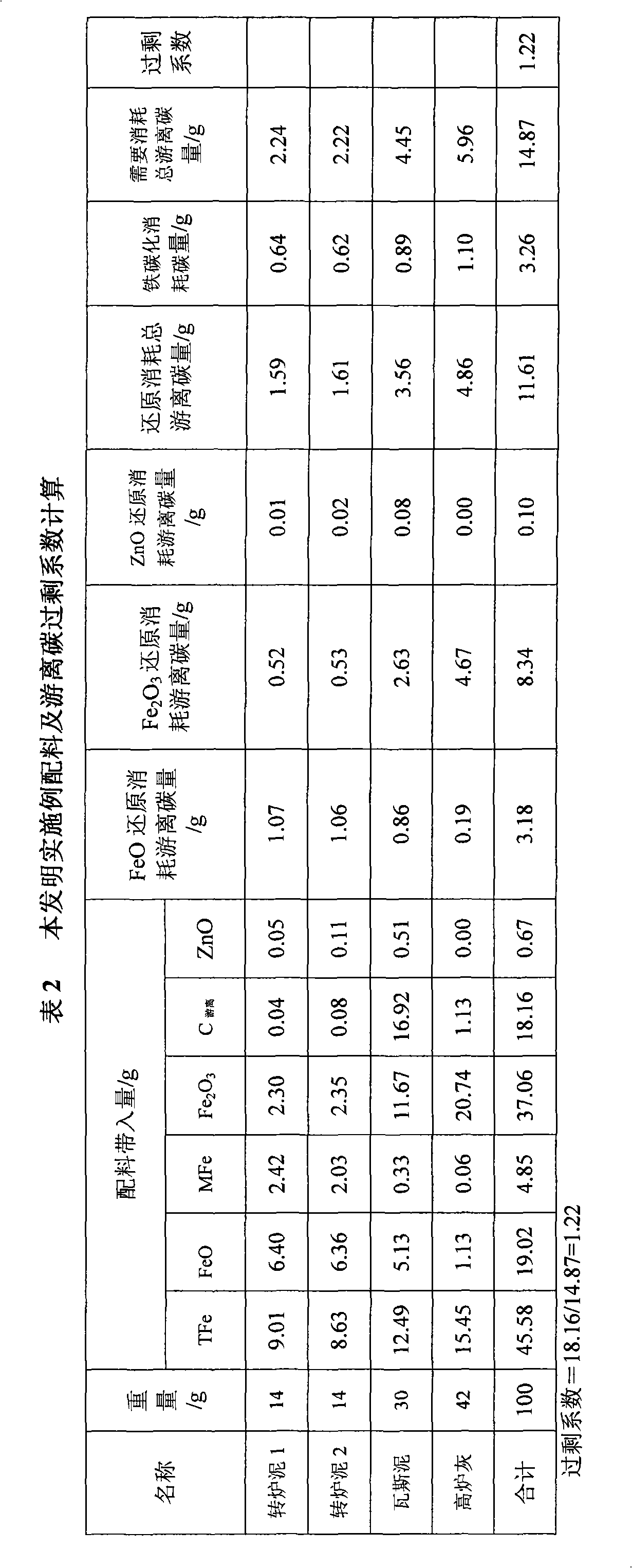

Method for reclaiming zinc-iron-containing dust and sludge

ActiveCN101818263AGood contact reaction conditionsLow costBlast furnace detailsProcess efficiency improvementMaterials preparationSludge

The invention provides a method for reclaiming zinc-iron-containing dust and sludge. The method comprises the following steps of: (1) material preparation, namely performing calculation according to components of different dusts and sludge to ensure that the excess coefficient of free carbon in the materials reaches 1.0 to 1.4; (2) material mixing, namely uniformly mixing and drying the materials to be sent to a storage bin for later use; (3) material feeding, namely continuously and uniformly adding dust and sludge from the storage bin into molten iron flow from a main molten iron trough and other positions through feed equipment according to determined weight by calculation, and reducing ferric oxide and zinc oxide in the dust and sludge by using heat of high-temperature molten iron; and (4) zinc and iron separation, namely recovering zinc-containing smoke by using dust-collection equipment of a casting house to obtain a zinc oxide product or zinc oxide enriched dust so as to realize zinc and iron separation. The zinc-iron-containing dust and sludge can be recovered by using conventional equipment without adding a reducing agent or a catalyst, or needing any special equipment, and has the advantages of convenience and operability, short process, low cost and good effect; and the recovery rate of iron reaches over 90 percent, and the recovery rate of zinc is more than 95 percent.

Owner:ANGANG STEEL CO LTD

Method and device for recycling rubber from waste radial tire

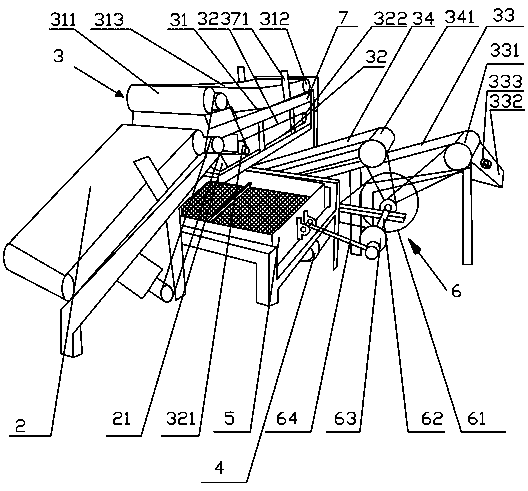

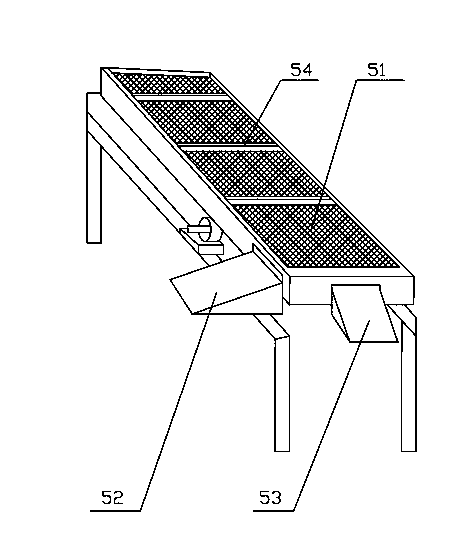

InactiveCN103770245AAutomatic separationReduce labor intensityPlastic recyclingMechanical material recoveryMechanical engineeringEquipment Recycling

The invention discloses a method and a device for recycling rubber from waste radial tire. The problems that by using the existing equipment for recycling rubber product, the steel wire cannot be completely removed and the efficiency is low are solved. The device comprises a rubber grinder, a feeding device, a multi-stage separating device and a driving device, wherein one end of the feeding device is used for feeding, and the other end corresponds to a magnetic wheel on the separating device, a filter device is arranged below the separating device, the filter device comprises a filter net, a filter discharge port and a processing port communicated with a rubber grinder conveyor; the feeding device, the separating device and the filter device are in transmission connection with the driving device. The processing method comprises the steps of slicing the rubber, grinding the rubber, feeding, separating and filtering. The separating device is capable of fast and automatically separating the steel wire from the rubber powder, the risk existed in manually removing the steel wire by an operator is avoided, the labor intensity of the worker is greatly reduced, and the personal safety of the operator is guaranteed.

Owner:WENZHOU HUABANG RUBBER

Method for treating zinc-iron-containing dust and sludge

ActiveCN101818264ARealize separation and recoveryLow costBlast furnace detailsManufacturing convertersZincSmoke

The invention provides a method for treating zinc-iron-containing dust and sludge. The method comprises the following steps of: (1) material preparation, namely performing calculation according to components of different dusts and sludge to ensure that the excess coefficient of free carbon in the materials reaches 1.0 to 1.4; (2) material mixing, namely uniformly mixing the materials and drying natural particle materials or cold bound pellets to be sent to a storage bin for later use; (3) material feeding, namely adding dust and sludge into an empty molten iron tank after molten iron is just poured from the molten iron tank and preheating the dust and sludge materials by using waste heat of the empty molten iron tank; (4) zinc and iron separation, namely recovering zinc-containing smoke by using dust-collection equipment; and (5) material melting, namely further reducing the dust and sludge materials by using high-temperature molten iron in a blast furnace casting process and melting the reduced materials, and mixing the melted materials and blast furnace molten iron to form molten iron for a converter. The zinc-iron-containing dust and sludge can be recovered by using conventional equipment without adding a reducing agent or a catalyst, or needing any special equipment, and has the advantages of convenience and operability, short process, low cost and good effect; and the recovery rate of iron reaches over 90 percent, and the recovery rate of zinc is more than 95 percent.

Owner:ANGANG STEEL CO LTD

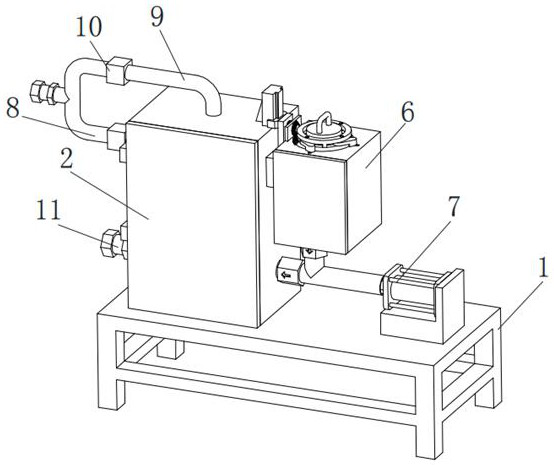

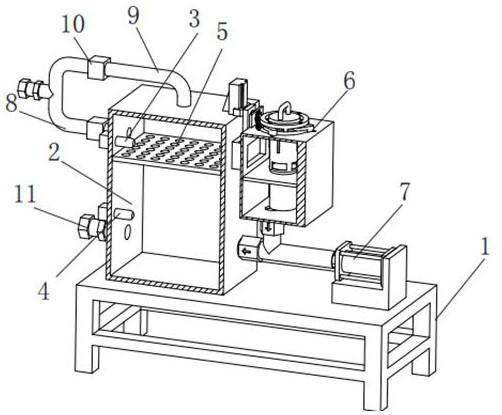

Fine sand recovery device

InactiveCN102000628AReduce churnSolve the coarseness of the fineness modulusWet separationEngineeringSlurry

The invention discloses a fine sand recovery device comprising a support frame, a material storage box and a material returning box, wherein the material storage box storing sewage and the material returning box storing mortar subjected to centrifugal classification are respectively arranged on the support frame; a sand-water separating device is arranged above the material storage box; the material returning box is provided with a swirler; a front-end outlet of the swirler is arranged above the sand-water separating device, and a rear-end outlet of the swirler is communicated with the material returning box; a slurry delivering machine is arranged below the swirler and is driven by a motor; and a delivery pipeline communicated to the upper end of the swirler is arranged on the slurry delivering machine. The fine sand recovery device has novel and unique structure, is stable in operation, not only enhances the fine sand recovery capacity of equipment, effectively reduces the loss quantity of fine sands and enables the loss quantity to be controlled within 5-10 percent, but also well solves the problems of excessively coarse fineness moldulus and excessively low stone powder content of finished sands, which are generated in an artificial aggregate processing system.

Owner:ZHEJIANG ZHEKUANG HEAVY IND CO LTD

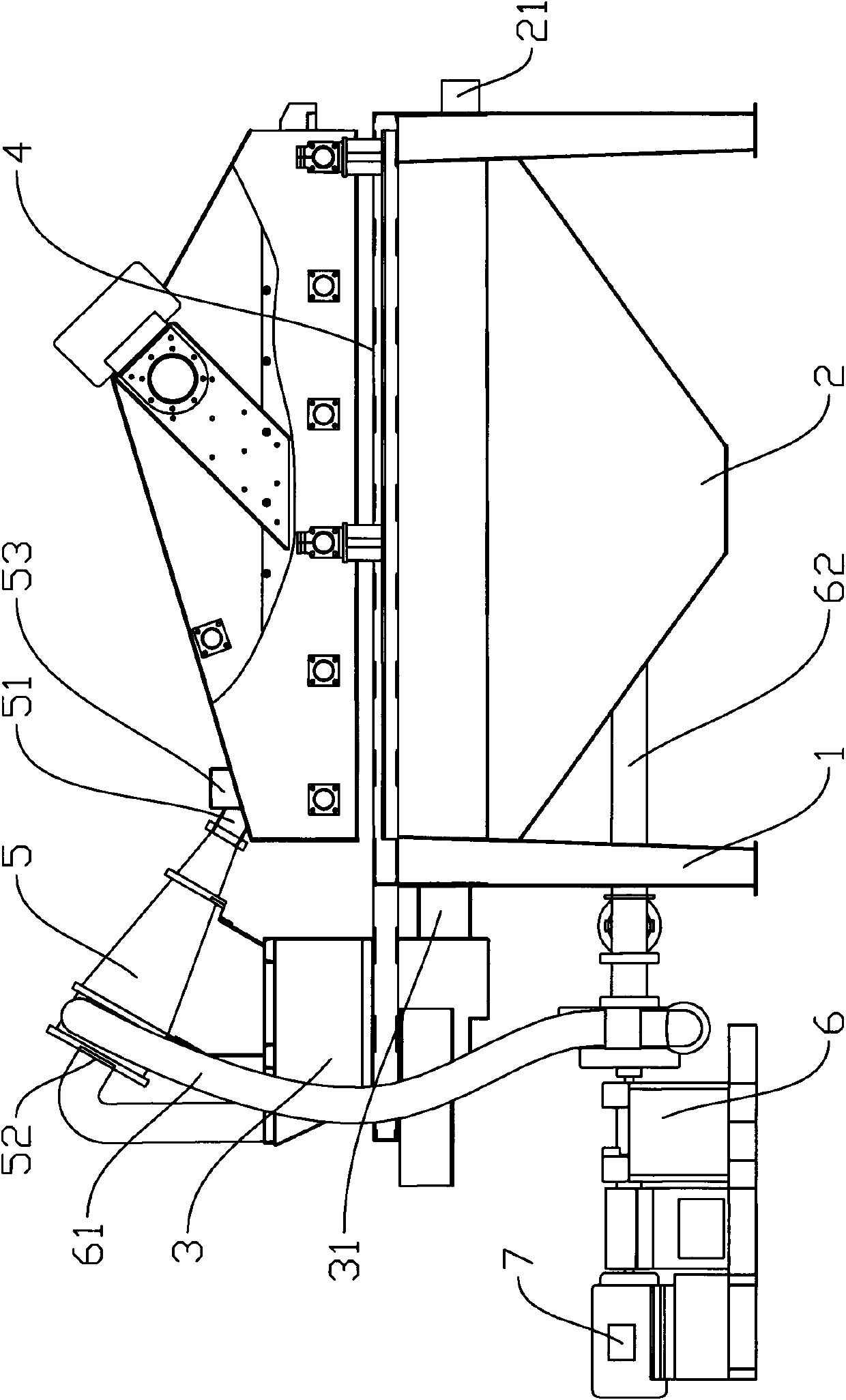

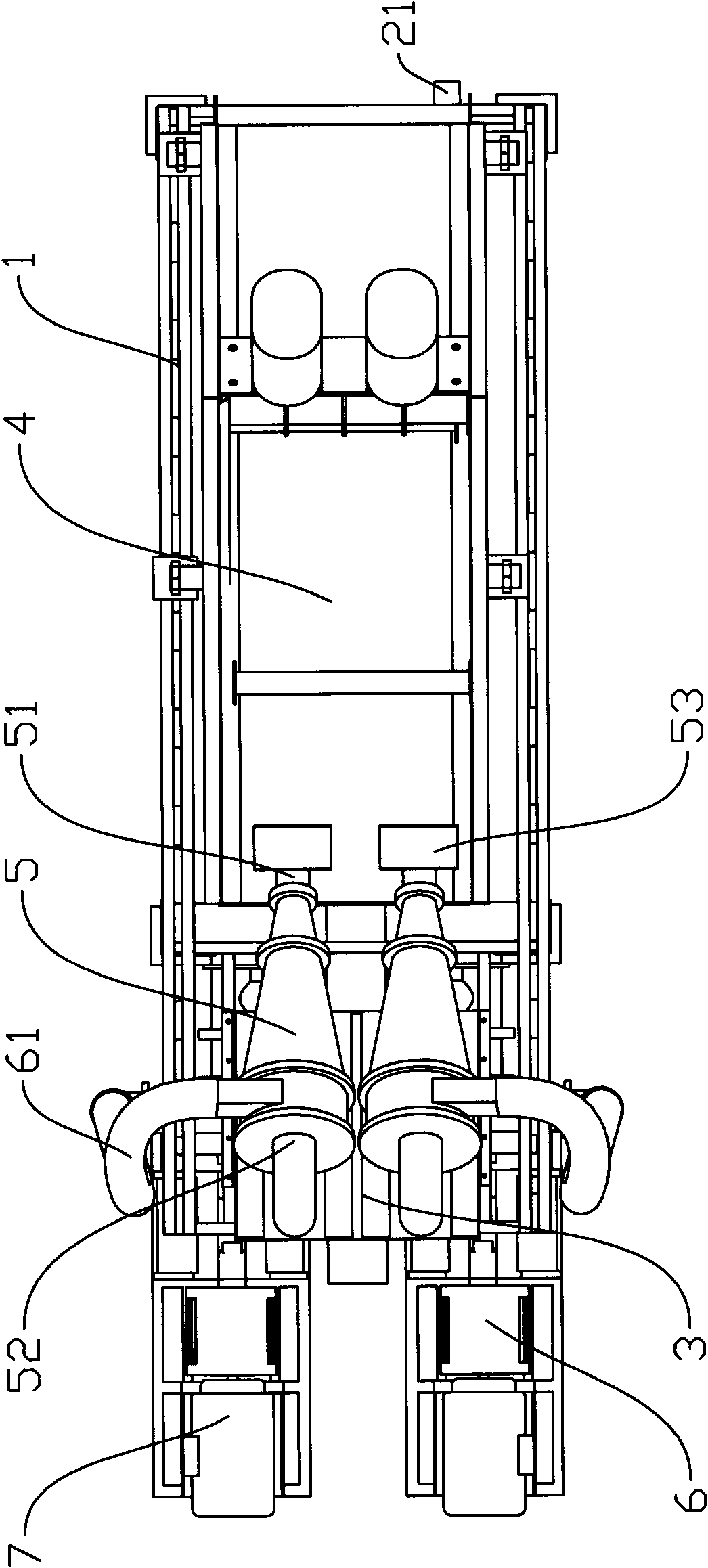

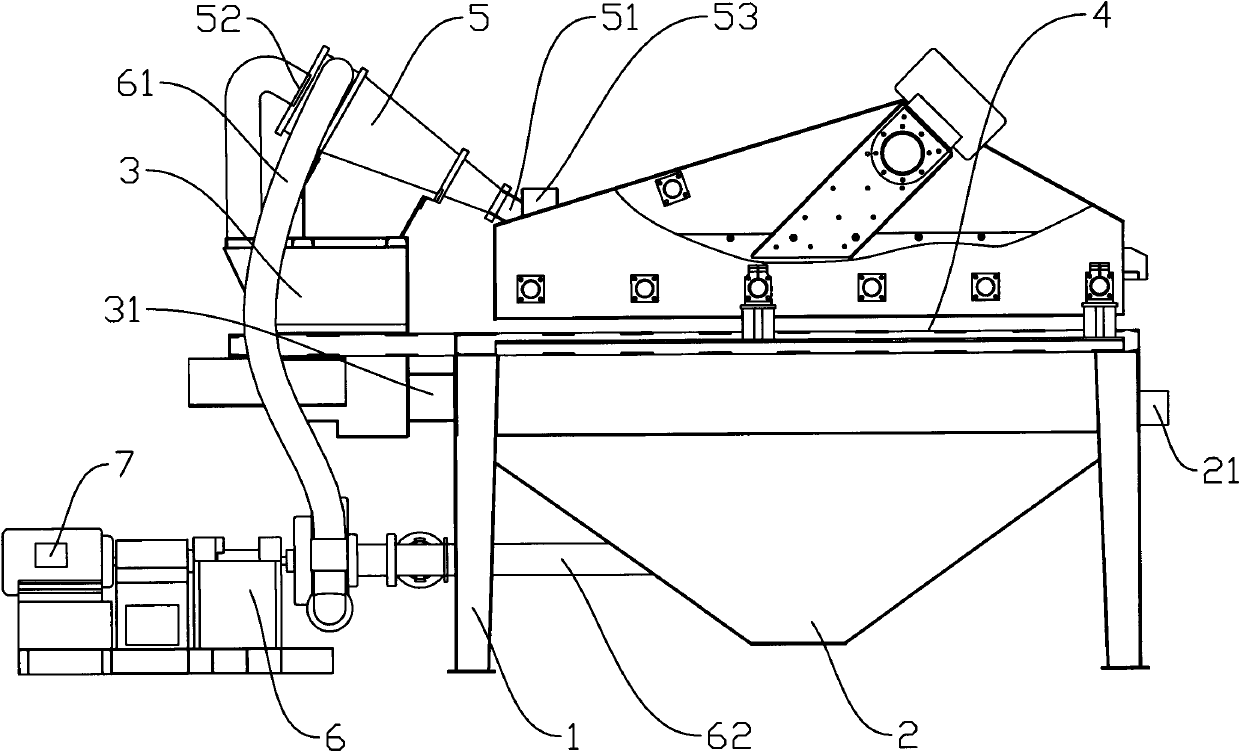

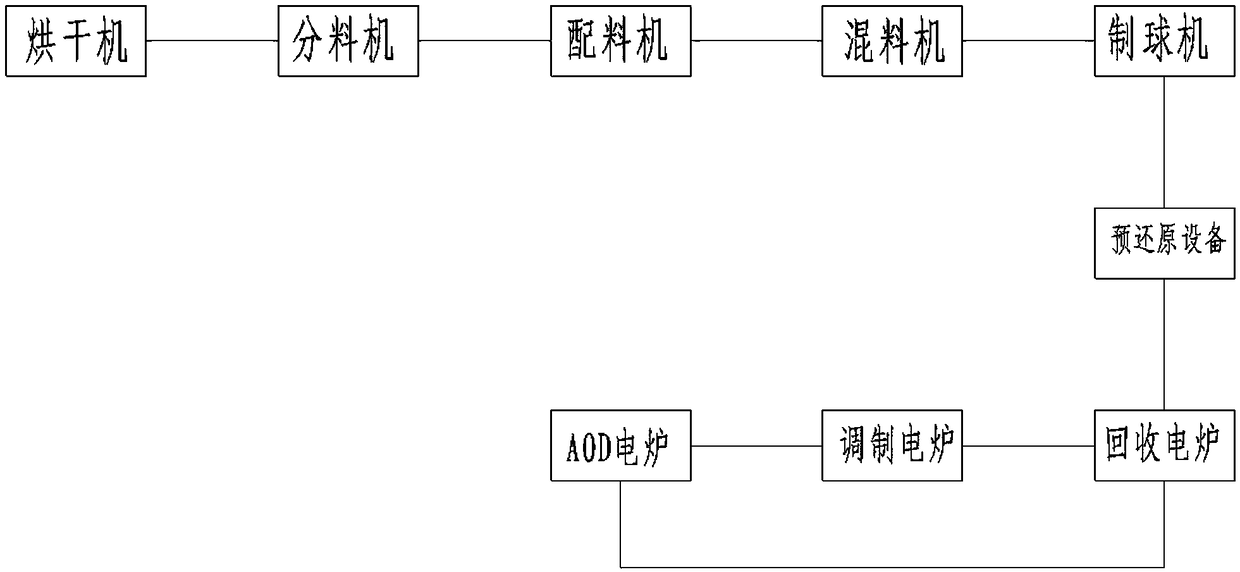

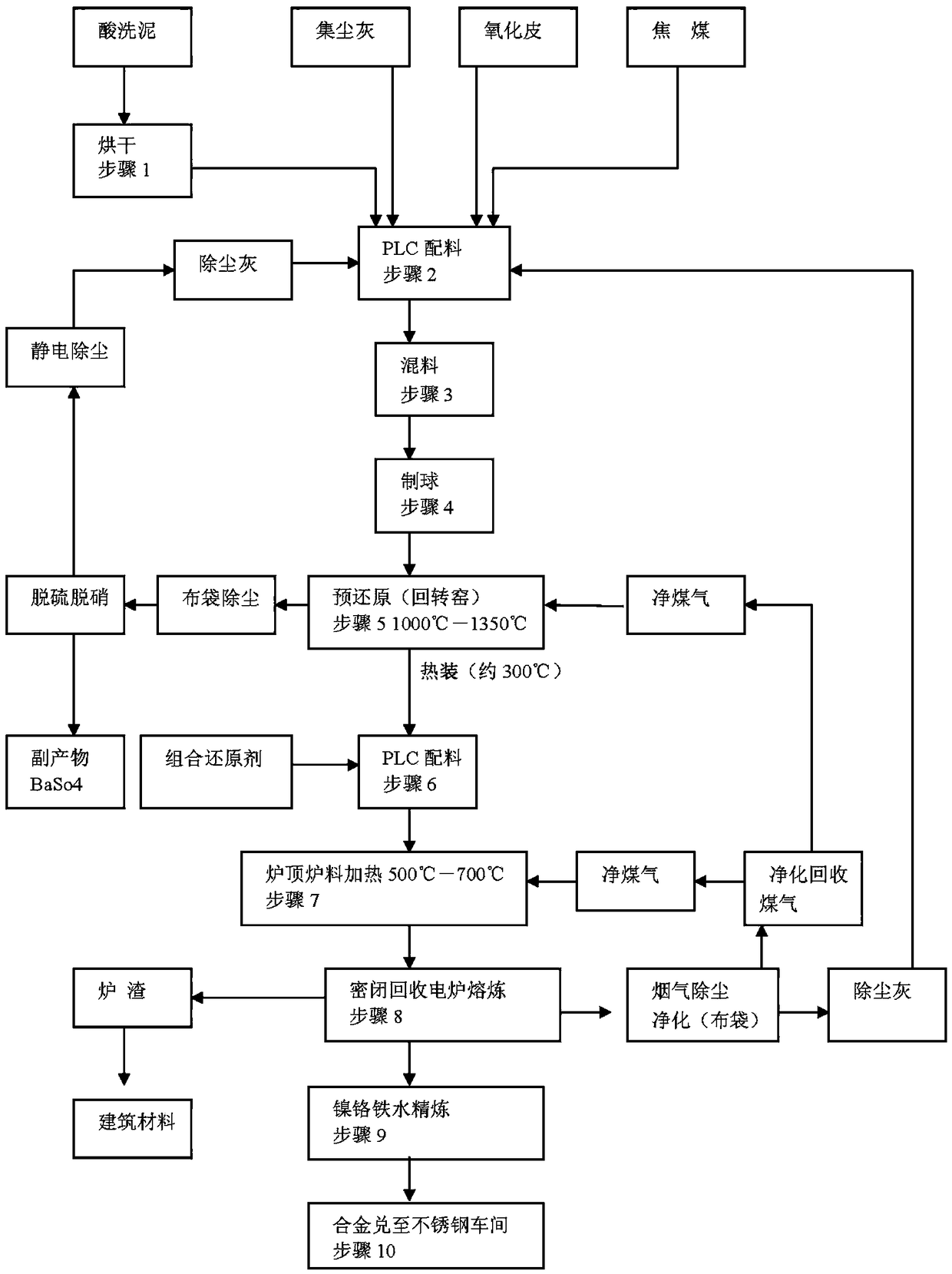

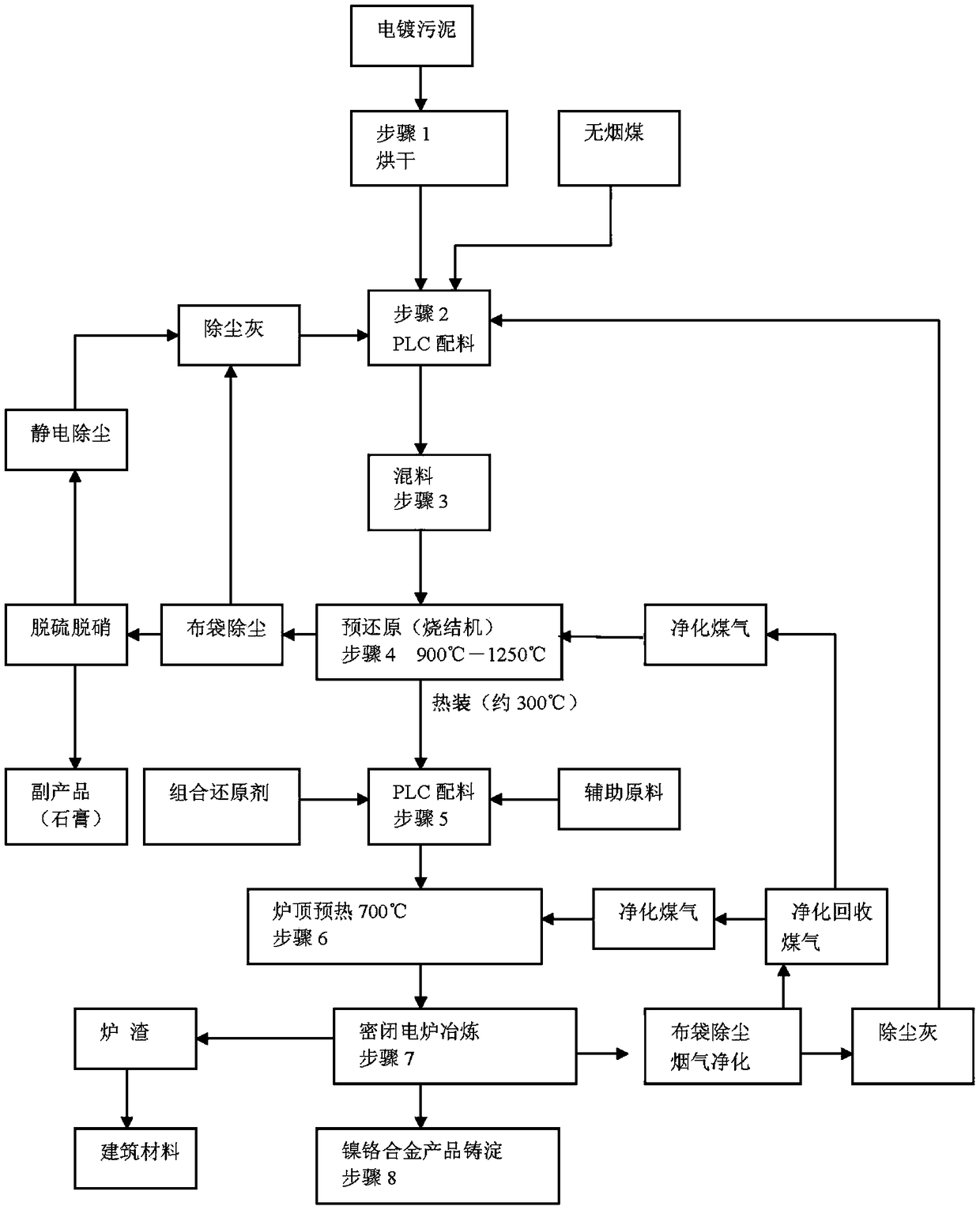

Metallurgical chemical solid waste recycling system and method thereof

ActiveCN109468466AAchieve mechanical propertiesRealize automatic controlProcess efficiency improvementSocial benefitsNichrome

The invention discloses a metallurgical chemical solid waste recycling system and a method thereof. The metallurgical chemical solid waste recycling system comprises a drier, a separator, a proportioning machine, a mixer, a ball forming machine, pre-reduction equipment, a recycling electric furnace, a modulating electric furnace and an AOD refining furnace. The metallurgical chemical solid waste recycling system disclosed by the invention has the main beneficial effects that (1) the recycling electric furnace can recycle gas; materials are thermally charged into the furnace; molten iron is thermally mixed and refined; the equipment is high in mechanization degree and automation degree; the wastes are subjected to complete harmless treatment; the yield of each machine is high; the comprehensive energy consumption of production is low; and the metallurgical chemical solid waste recycling system is suitable for industrial production; (2) the produced products are alloy materials containing metal elements such as nickel, chromium and copper; the product quality can be regulated and controlled according to relevant standards and the customer requirements; high-quality products with different specifications can be produced; the products are widely applied; and the additional value is high; and (3) the recycle rate of the valuable metal elements in the wastes is high; resources are fully utilized; and good economical benefits and social benefits are achieved.

Owner:龙岩山青冶金科技有限公司

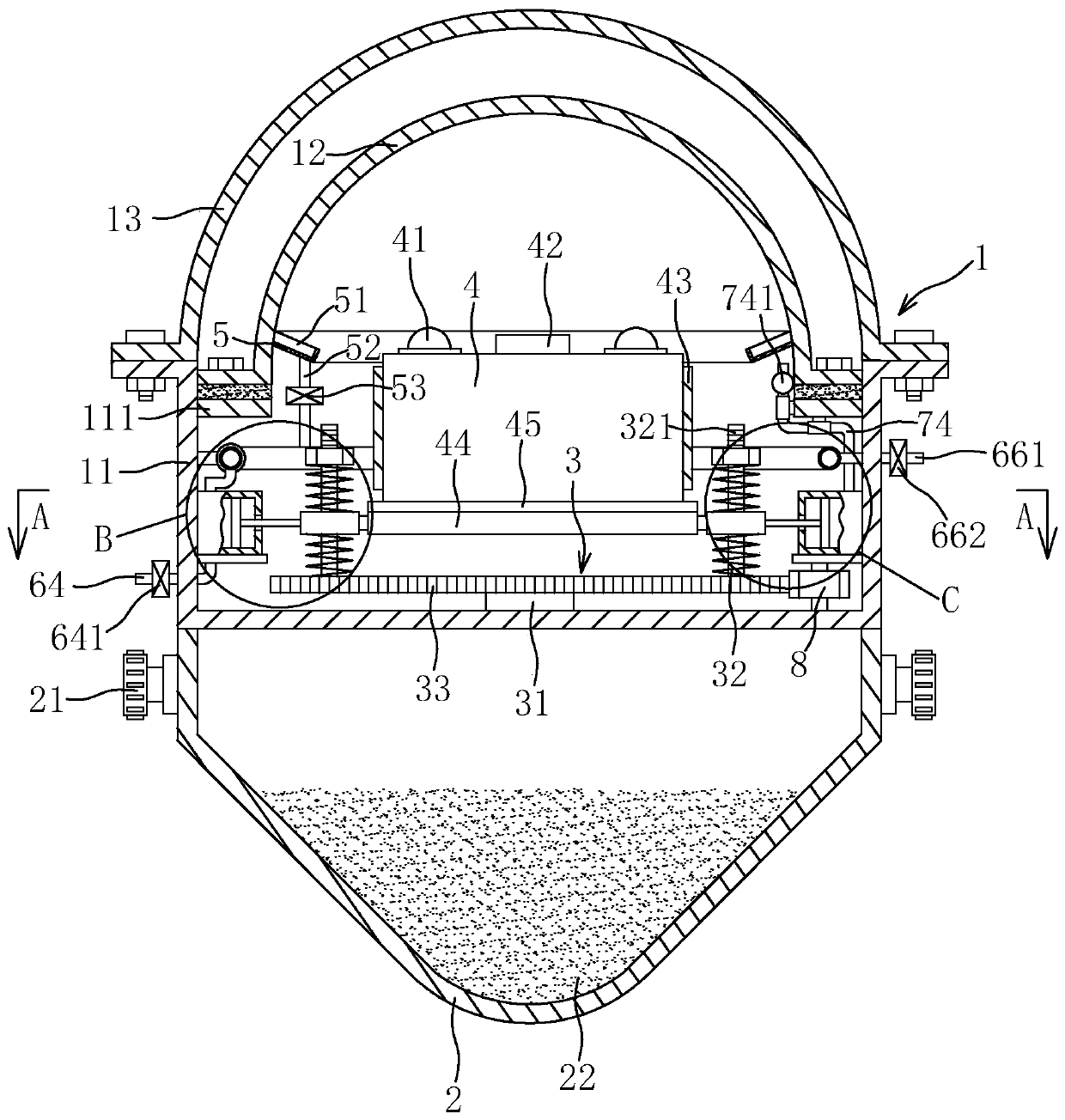

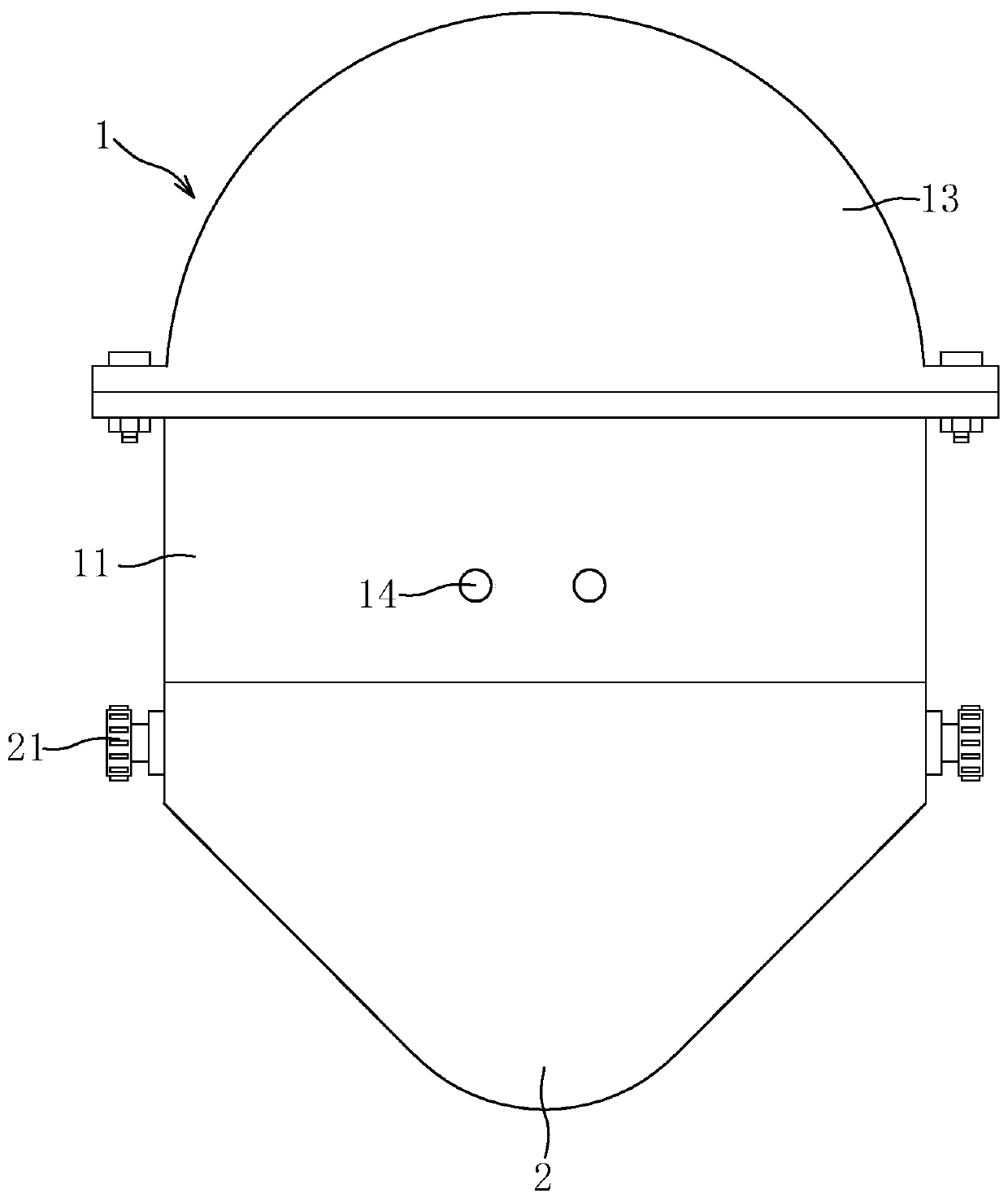

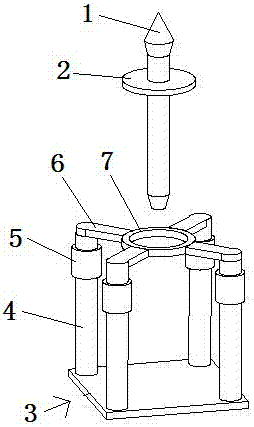

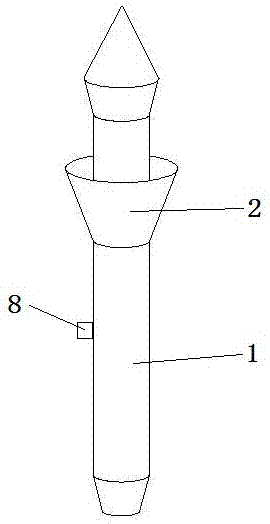

Beacon device for recycling ocean detection equipment

ActiveCN110641620AAvoid vibrationAvoid causing damage to the detection deviceBatteries circuit arrangementsWaterborne vesselsEnvironmental engineeringMechanical engineering

The invention belongs to the technical field of ocean detection, and relates to a beacon device for recycling ocean detection equipment. The beacon device comprises a shell, the shell comprises a body, the bottom of the body is provided with a rotary table, and a plurality of guide rods are arranged on the rotary table; each guide rod is provided with a sleeve in a sleeved manner; each guide rod is provided with a shock absorption mechanism which can reduce the up and down vibration of the sleeve; a detection device is fixedly connected with each sleeve; the body is provided with a first barrel, the first barrel is internally provided with a first piston, the first piston is provided with a first piston rod, one end of the first piston rod is connected with a first connecting rod, the first barrel is connected with a water inlet pipe and a water drain pipe, the water inlet pipe is provided with a water inlet one-way valve, and one end of the water drain pipe is connected with an annular water pipe which is fixed in the body; and the annular water pipe is provided with a water outlet pipe, one end of the water outlet pipe extends out of the body, and the water outlet pipe is provided with a drainage one-way valve. The beacon device for recycling the ocean detection equipment has the advantages of effectively reducing the vibration of the device and improving the heat dissipationperformance of the device at the same time.

Owner:ZHEJIANG OCEAN UNIV

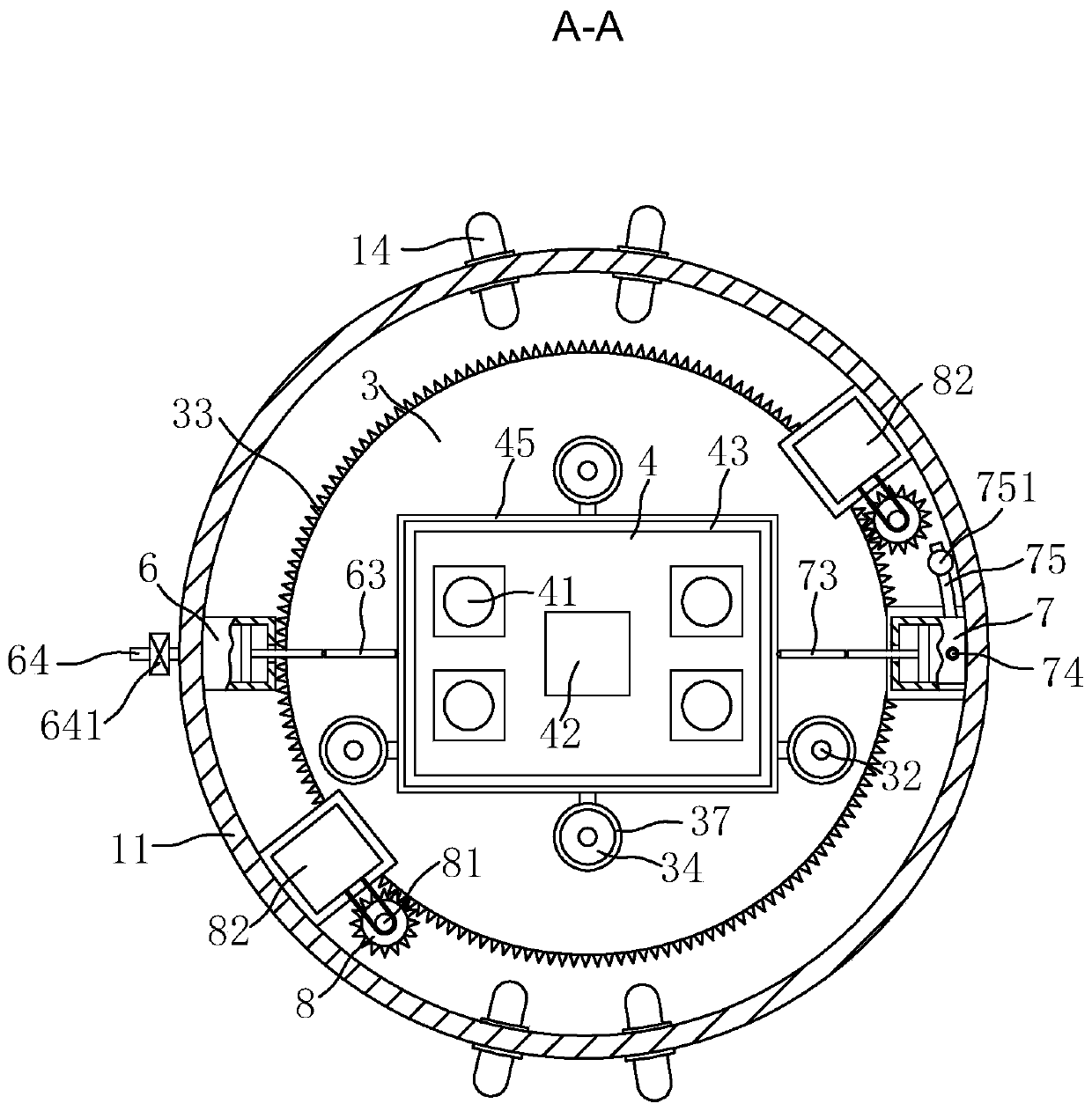

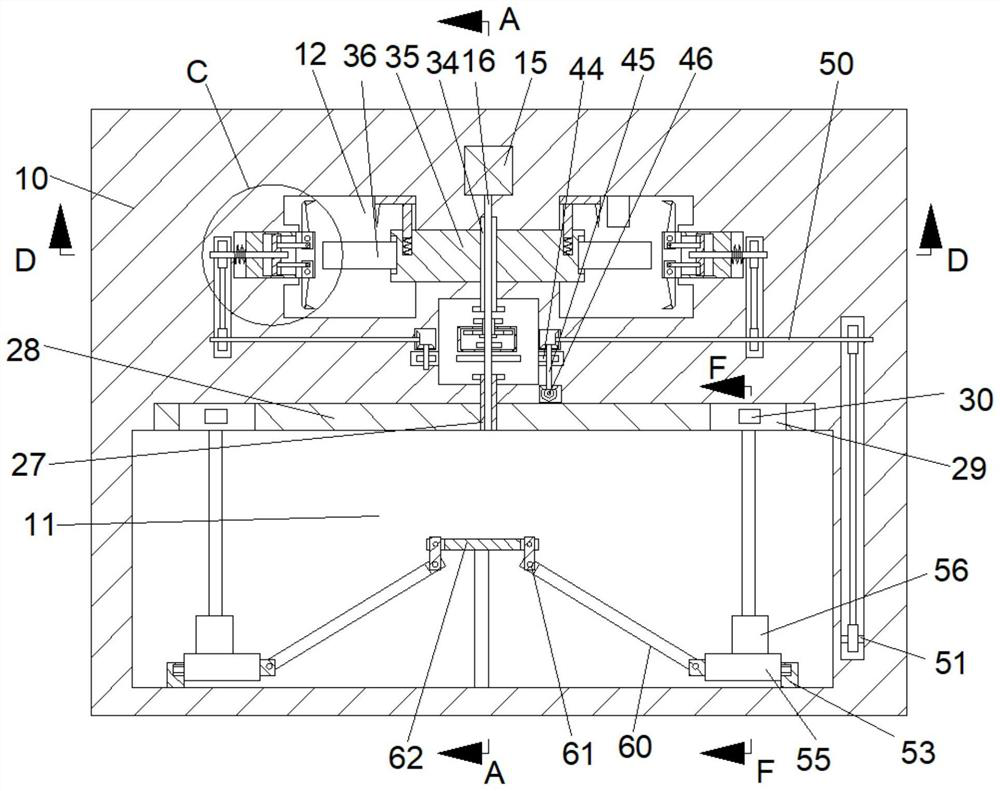

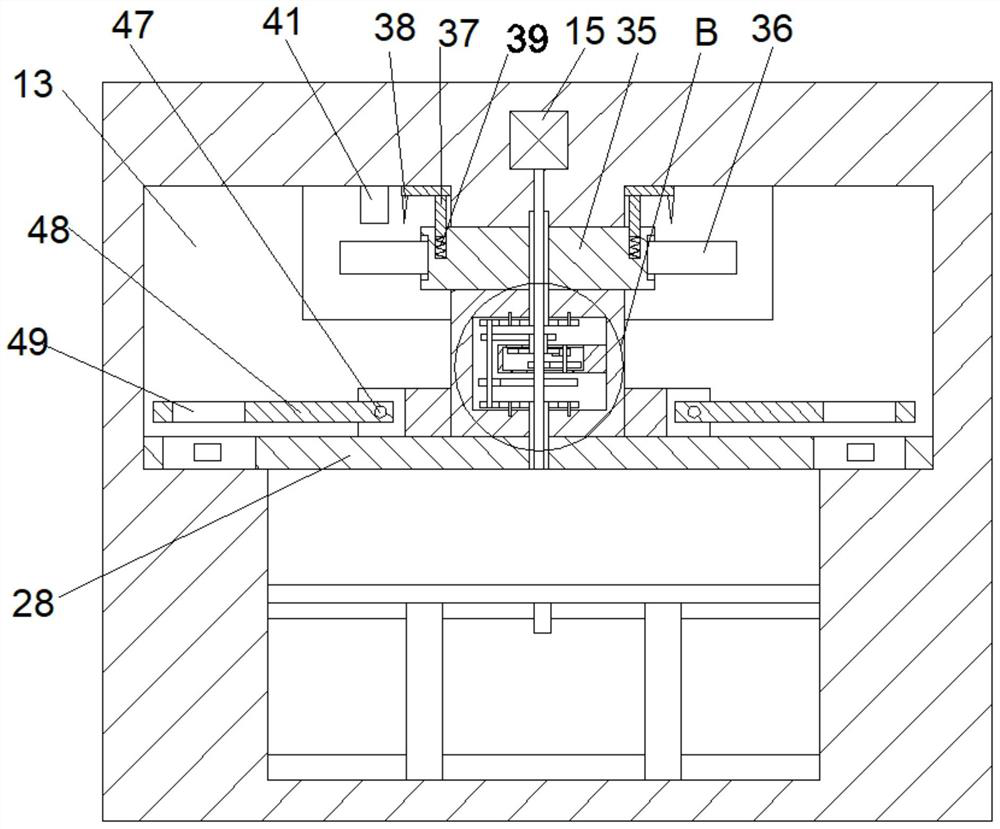

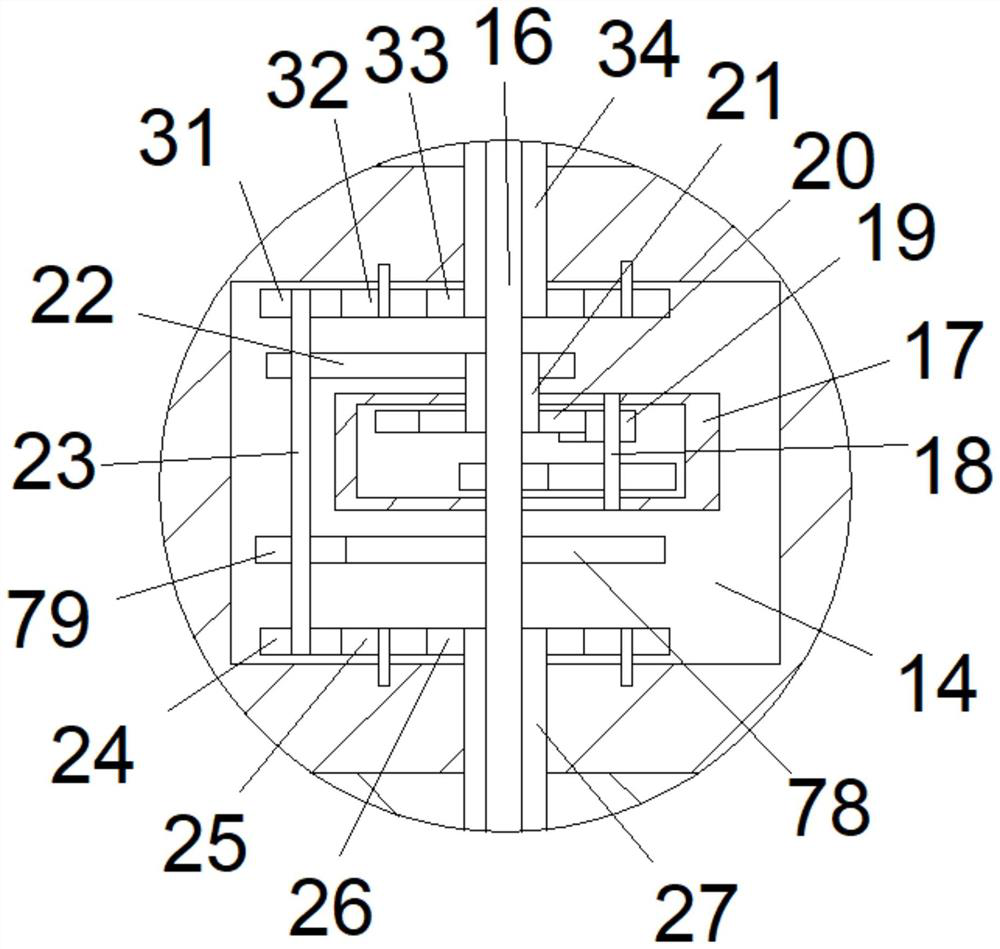

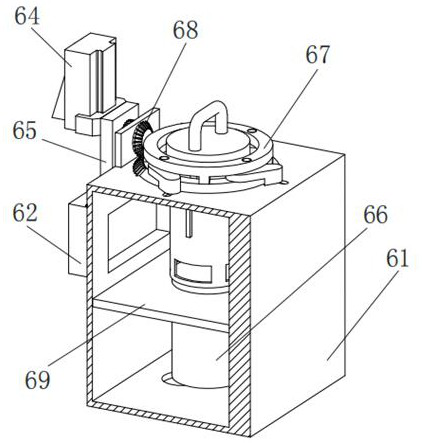

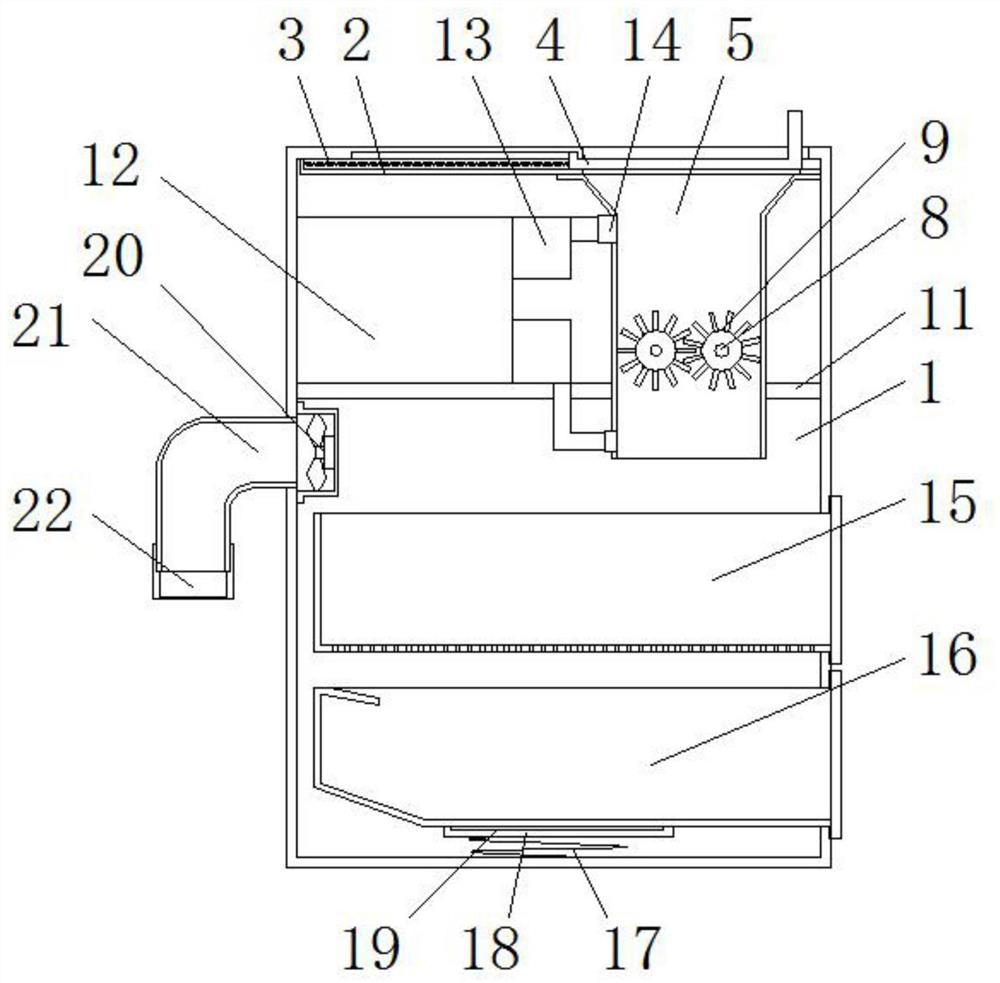

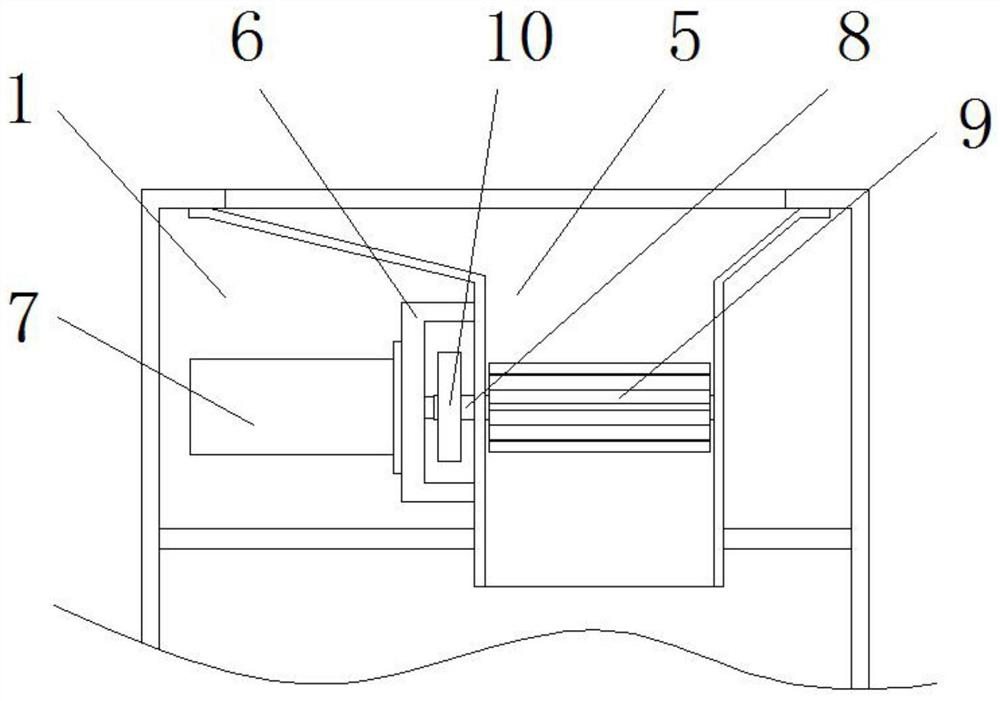

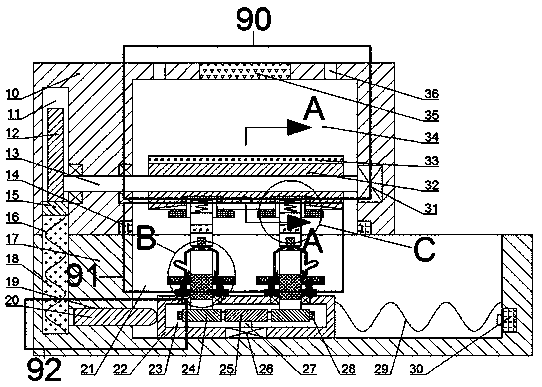

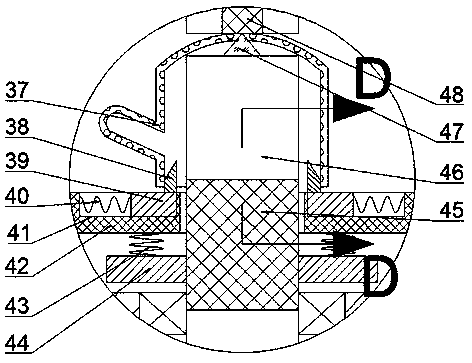

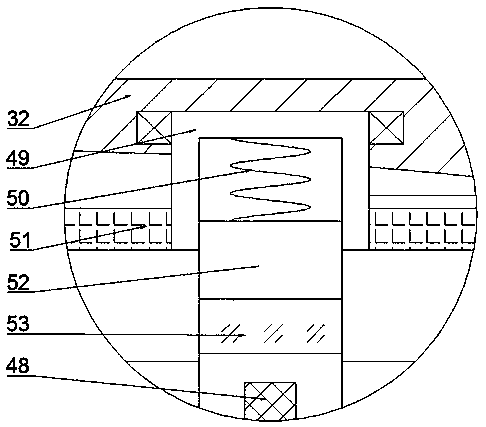

Recovery equipment for motor stator copper wires

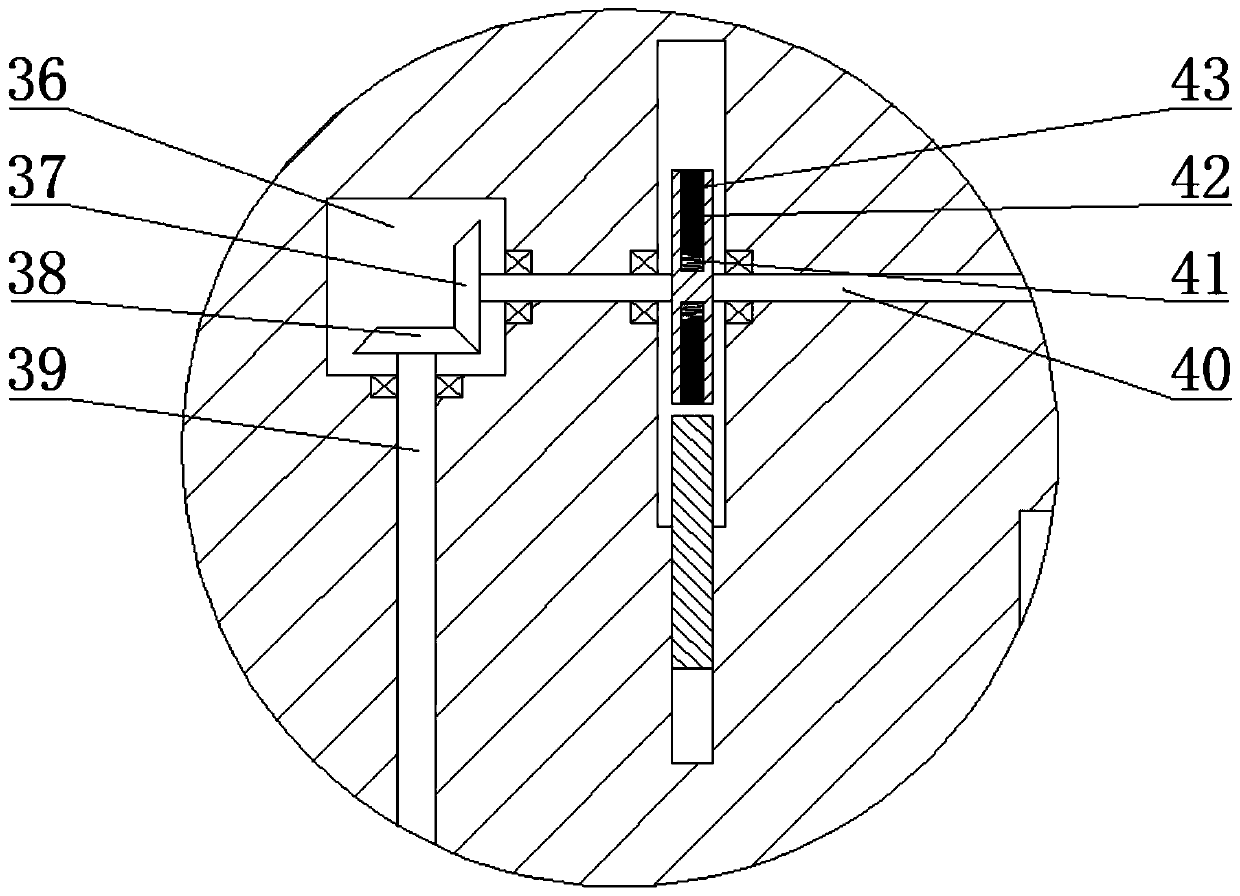

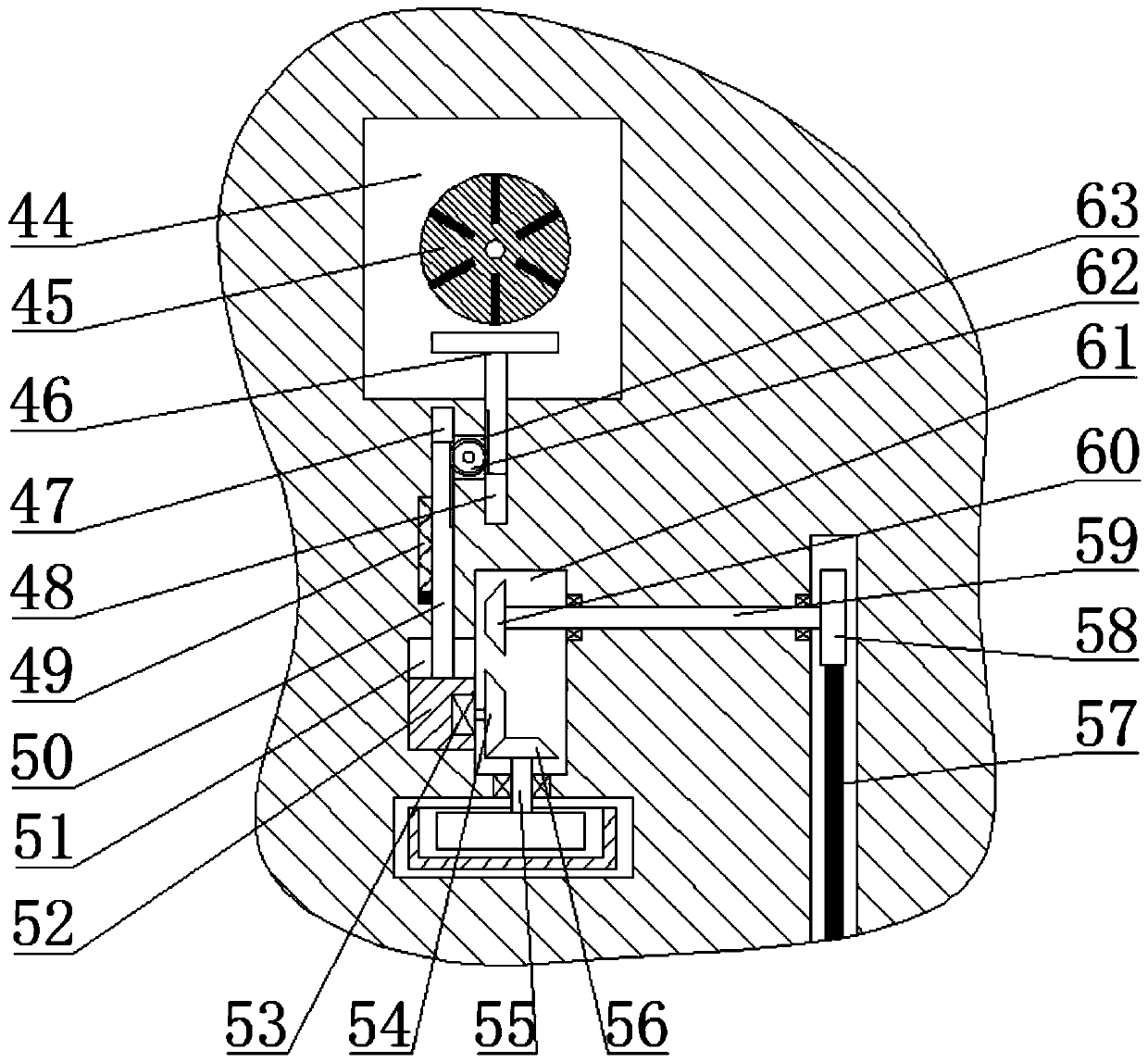

InactiveCN113441512AImprove efficiencySolid waste disposalElectronic waste recyclingElectric machineCopper wire

The invention discloses recovery equipment for motor stator copper wires. The recovery equipment comprises a machine body, a storage cavity is formed in the lower portion of the machine body, an annular stripping cavity is formed in the upper portion of the storage cavity, lifting cavities are formed in the front side and the rear side of the stripping cavity, a power cavity is formed in the middle of the machine body, a feeding mechanism is arranged in the storage cavity, decomposition mechanisms are arranged at the left portion and the right portion of the stripping cavity, and a power mechanism is arranged in the power cavity. When the equipment is used for recovering stators, a batch of stators are directly loaded into the equipment, the feeding mechanism can pick up a plurality of stators at a time in a sleeve ring mode, the stators are lifted upwards and conveyed to a rotating disc, then the stators are lifted by an overturning rod to be arranged on a sleeve rod in a sleeving mode, and then a rotating block drives the sleeve rod to rotate, so that cutters can cut off copper wire at one ends of the stators, then the copper wires are grabbed and drawn out from the other ends through clamping claws, the copper wires are separated from metal pieces, the process is continuously circulated in the equipment and can be carried out at the same time, and the efficiency can be greatly improved.

Owner:惠州市信虹达智能科技有限公司

Silicon carbide ceramic membrane filtering device

ActiveCN113368698AImprove filtering effectImprove filtration efficiencySemi-permeable membranesCarbide siliconCeramic membrane

The invention discloses a silicon carbide ceramic membrane filtering device, and belongs to the technical field of filtering equipment, wherein the silicon carbide ceramic membrane filtering device comprises a workbench, a filtering box, a first water pressure sensor, a second water pressure sensor, a silicon carbide ceramic membrane, impurity removal equipment and backflow equipment. When the device works, dead-end filtering is firstly carried out, if the pressure borne by the first water pressure sensor is far larger than that borne by the second water pressure sensor, it is indicated that impurities block the silicon carbide ceramic membrane after long-time filtering, and at the moment, the first water pressure sensor and the second water pressure sensor transmit signals to carry out cross-flow filtering; impurities in the silicon carbide ceramic membrane can be taken out through cross-flow filtration, then waste water carries the impurities to enter the impurity removal equipment, then the impurities are recycled by the impurity removal equipment, the remaining liquid returns to the filtering box again through the backflow equipment, and cleaning of the silicon carbide ceramic membrane is completed; and after cleaning of the silicon carbide ceramic membrane is completed, the whole device can continue to return to a dead-end filtering state, so that the filtering efficiency is improved.

Owner:山东浦创流体技术有限公司

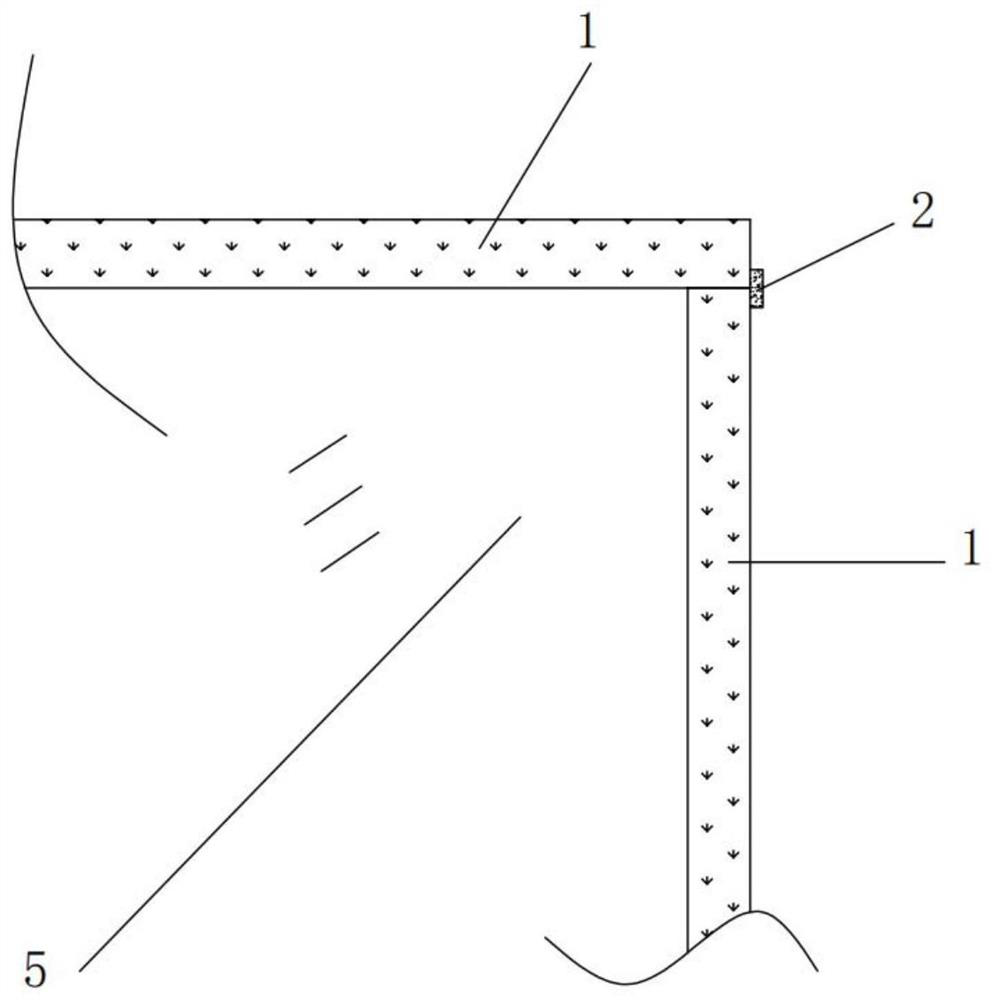

Wood product surface waterborne opening white paint coating processing process

InactiveCN107442371AEnsure performance requirementsEnsure process requirementsPretreated surfacesCoatingsStainingPulp and paper industry

The invention provides a wood product surface waterborne opening white paint coating processing process. The processing process comprises the first step of white blank sanding, the second step of spraying of waterborne clear primer, the third step of drying, the fourth step of sanding, the fifth step of spraying of waterborne opening white primer, the sixth step of drying, the seventh step of sanding, the eighth step of spraying of waterborne opening white finish, the ninth step of drying, the tenth step of staining and the eleventh step of drying. The single-component waterborne primer, waterborne opening white primer and waterborne opening white finish are adopted, the physical performance and technological requirements of a paint film are ensured, an equipment recycling system can be better utilized for recycling, the coating using effective rate is greatly improved, the effective rate reaches 79.5% or above, the coating cost is reduced, and the surface of a wood product is smooth, flat, uniform and free of oil accumulation.

Owner:MENGTIAN HOUSEHOLD GRP CO LTD

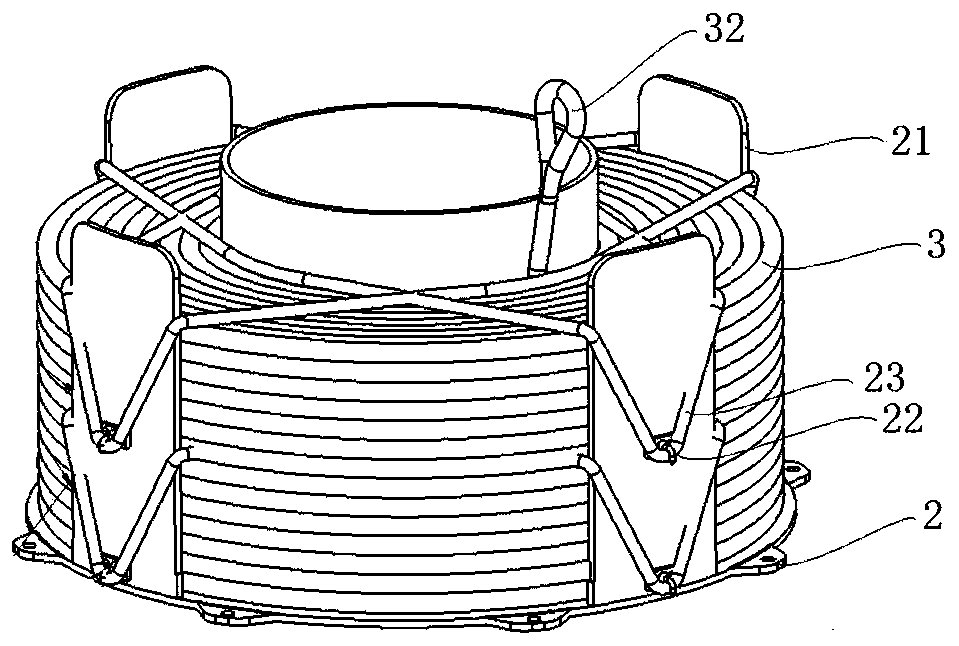

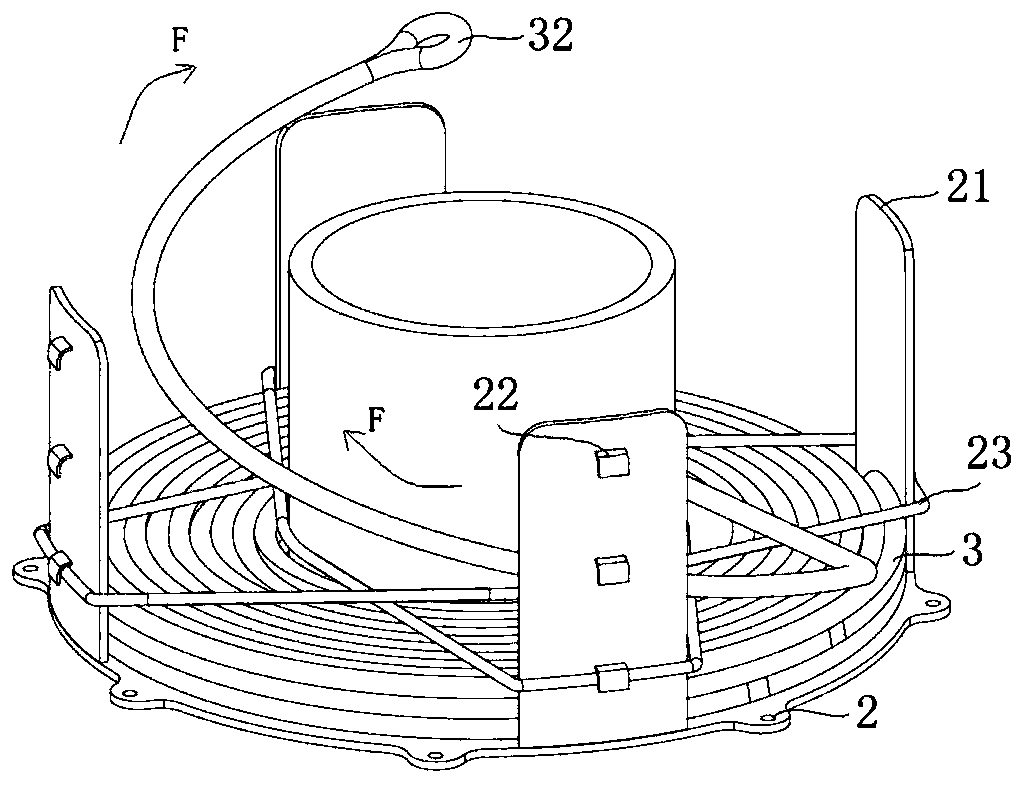

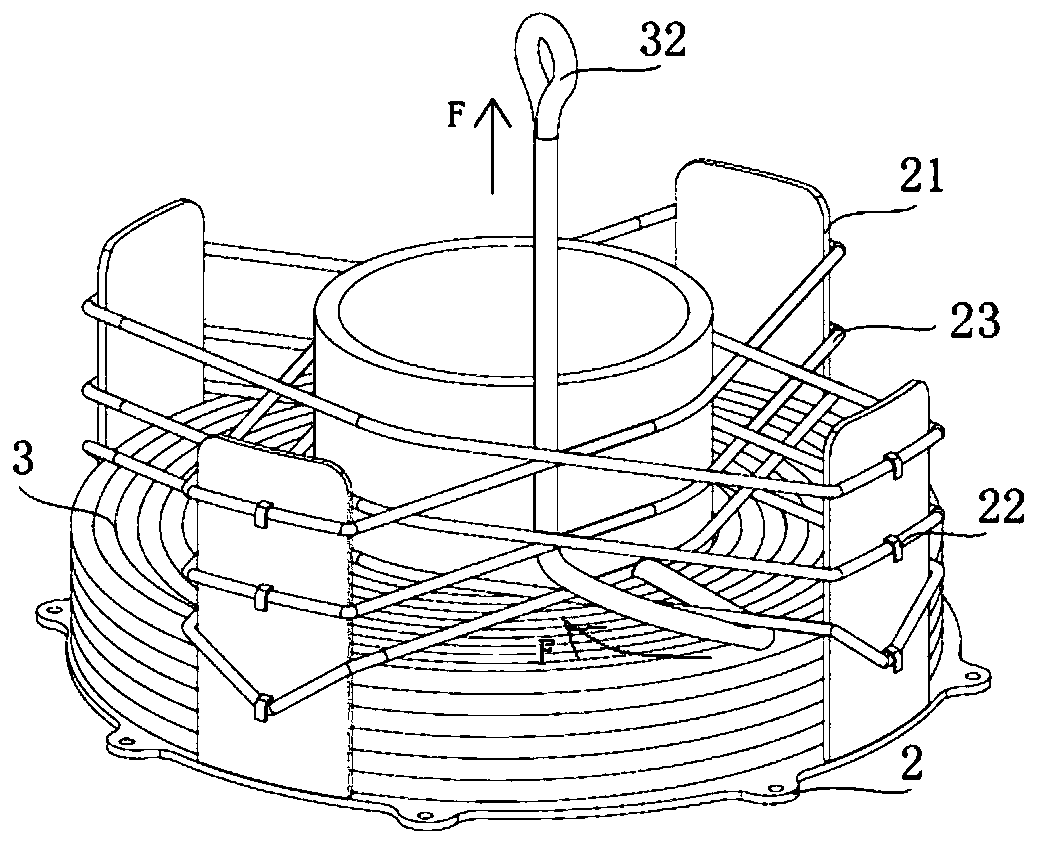

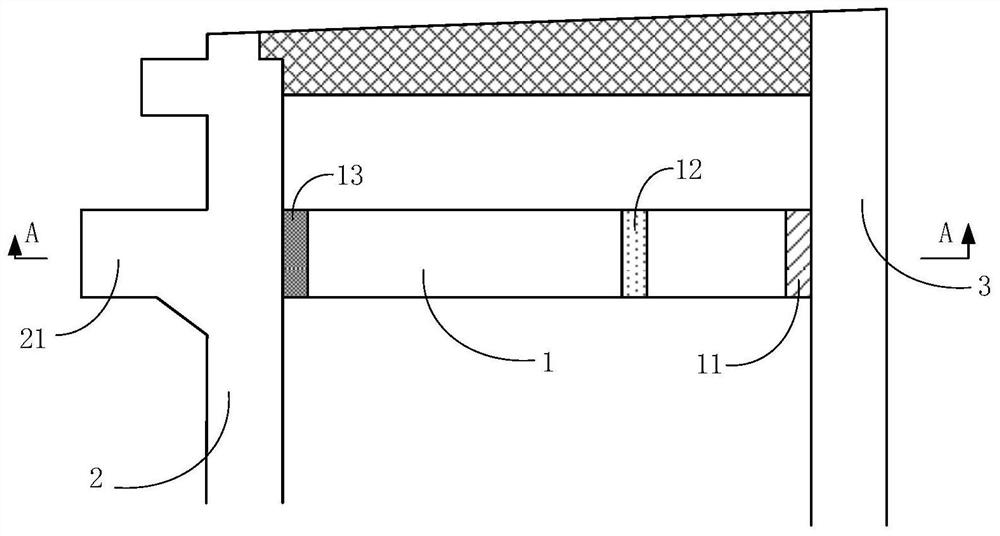

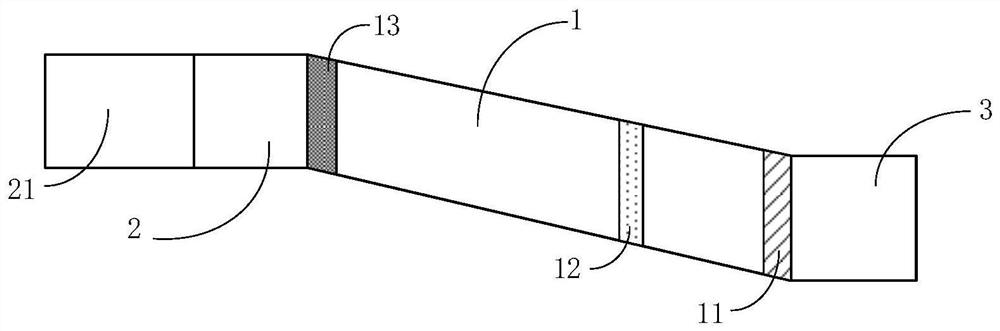

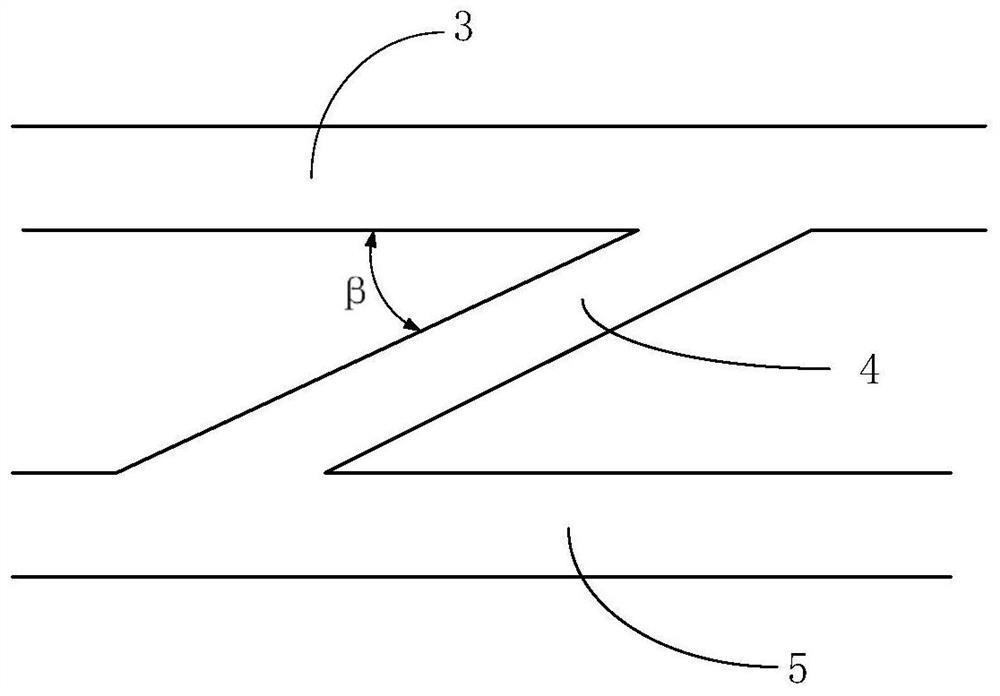

Mooring rope releasing device and underwater equipment recycling and fishing device

PendingCN109808858ALoose collapse noDistortion and discountVessel salvagingUnderwater equipmentMarine engineeringFishing

The invention discloses a mooring rope releasing device and an underwater equipment recycling and fishing device. The mooring rope releasing device comprises a mooring rope storage container and a mooring rope, wherein the mooring rope storage container is of a cavity structure defined by an internal cylinder, an external cylinder and a bottom plate, multiple symmetric through grooves are uniformly formed in the outer wall of the external cylinder, and multiple hooks are longitudinally arranged in the area defined by the through grooves; the mooring rope is tightly coiled in the mooring rope storage container from bottom to top and from the inner wall of the external cylinder to the outer wall of the internal cylinder, and is tightened by one group of elastic tightening rings when the mooring rope is coiled for every multiple layers, one end of the mooring rope penetrates out of a through hole preformed in the bottom plate of the mooring rope storage container and is taken as a mooringrope fixed end, and the other end of the mooring rope penetrates out of the center of a cross ring of one group of tightening rings and is taken as a mooring rope release end. The mooring rope is tightened by multiple groups of elastic tightening rings, so that the mooring rope is orderly and tightly stored in the mooring rope storage container, and is prevented from loosening, collapse and twisting in a releasing process, and smooth recycling and fishing work of underwater equipment is guaranteed.

Owner:750 TEST SITE OF CHINA SHIPBUILDING IND CORP

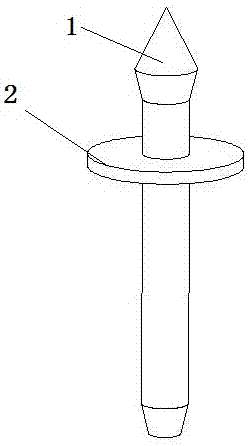

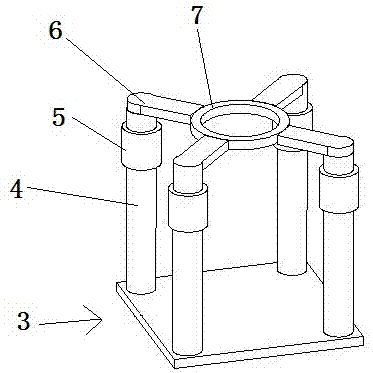

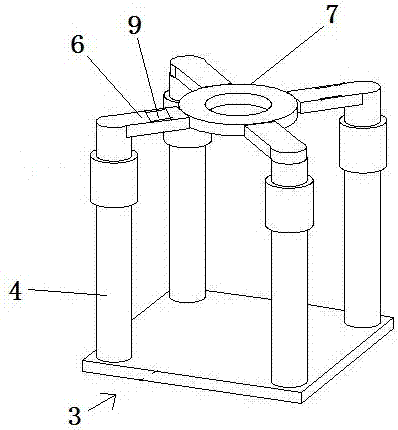

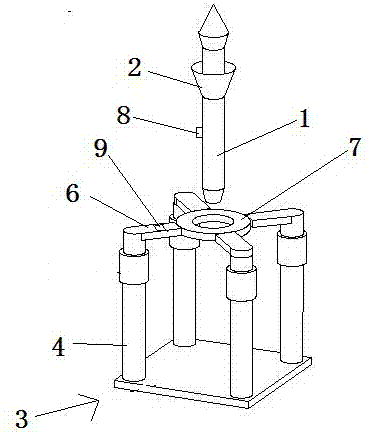

Rocket recycling device with stress ring

InactiveCN107499540ASolve the problem of easy to fall and cause explosionSimple structureSystems for re-entry to earthCosmonautic landing devicesRocketGravitation

Owner:FOSHAN SHENHANG SCI & TECH CO LTD

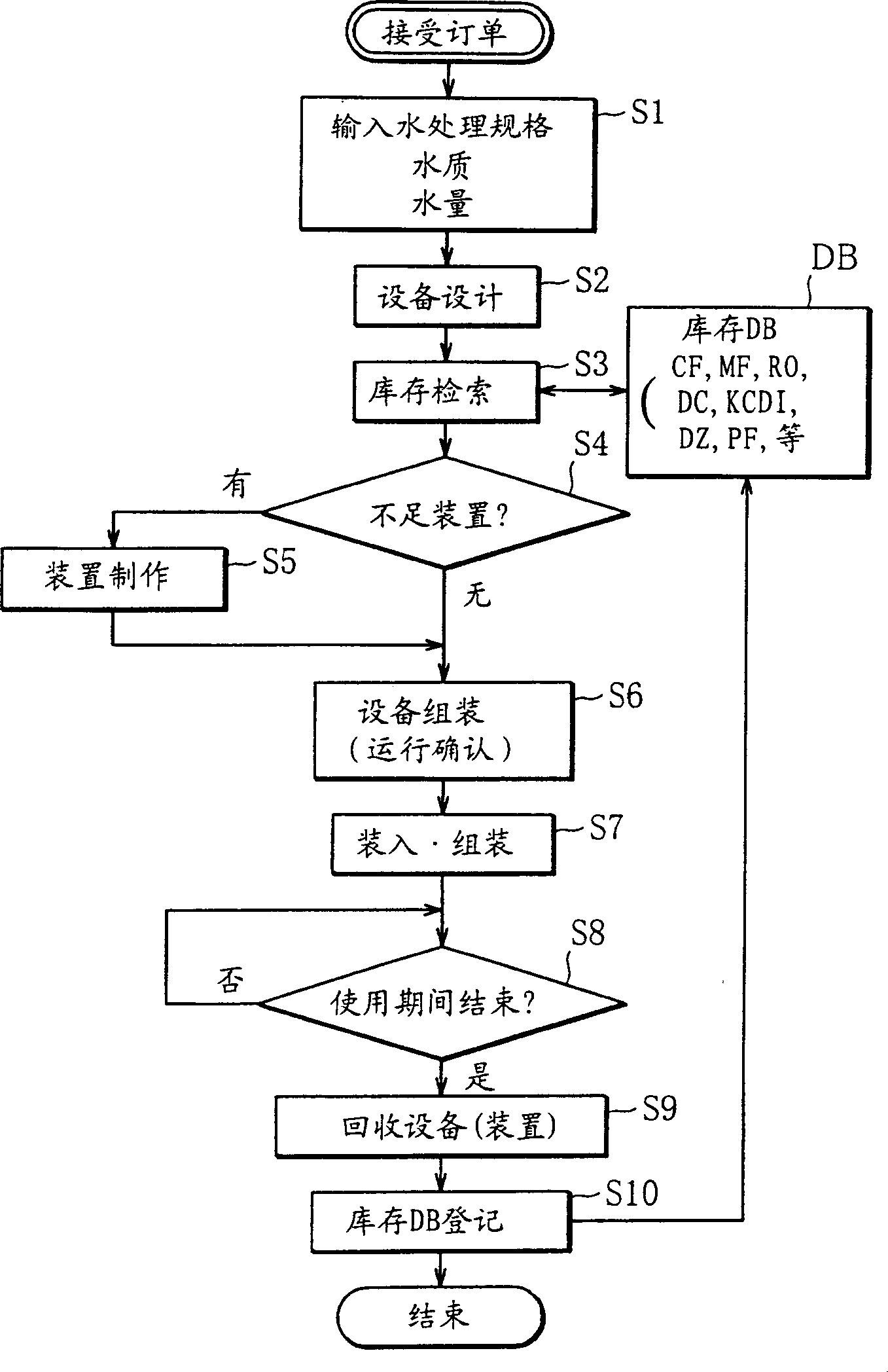

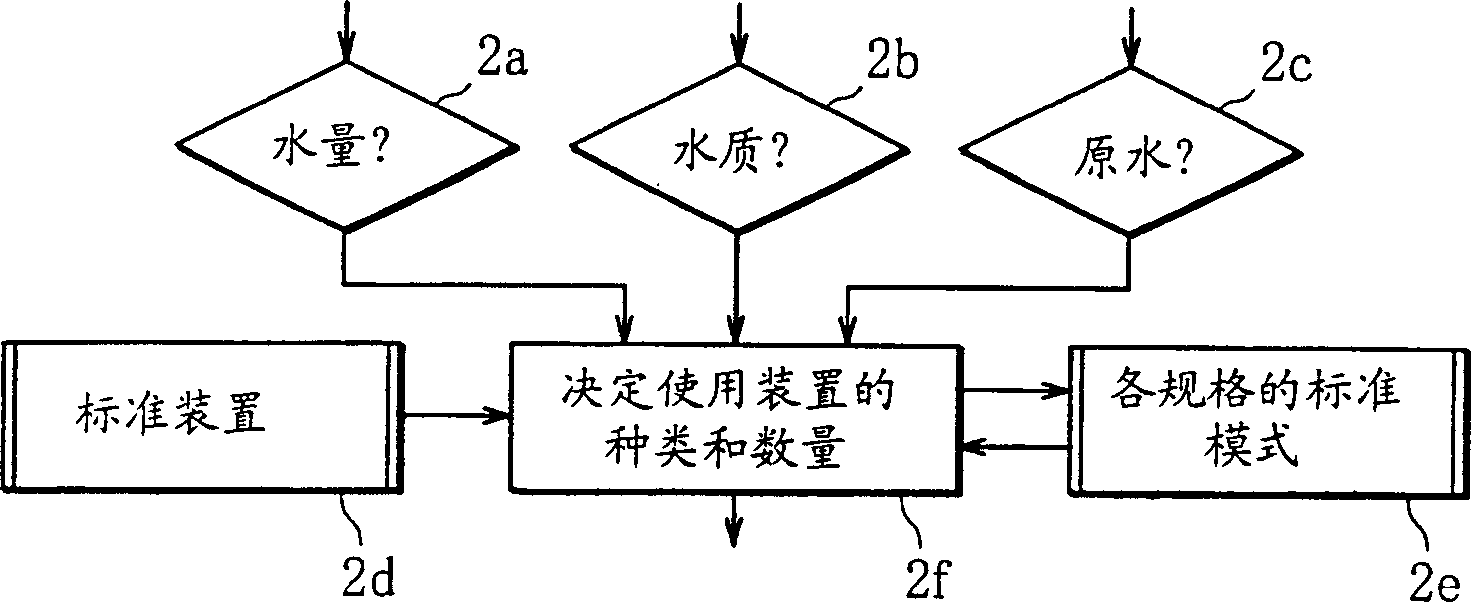

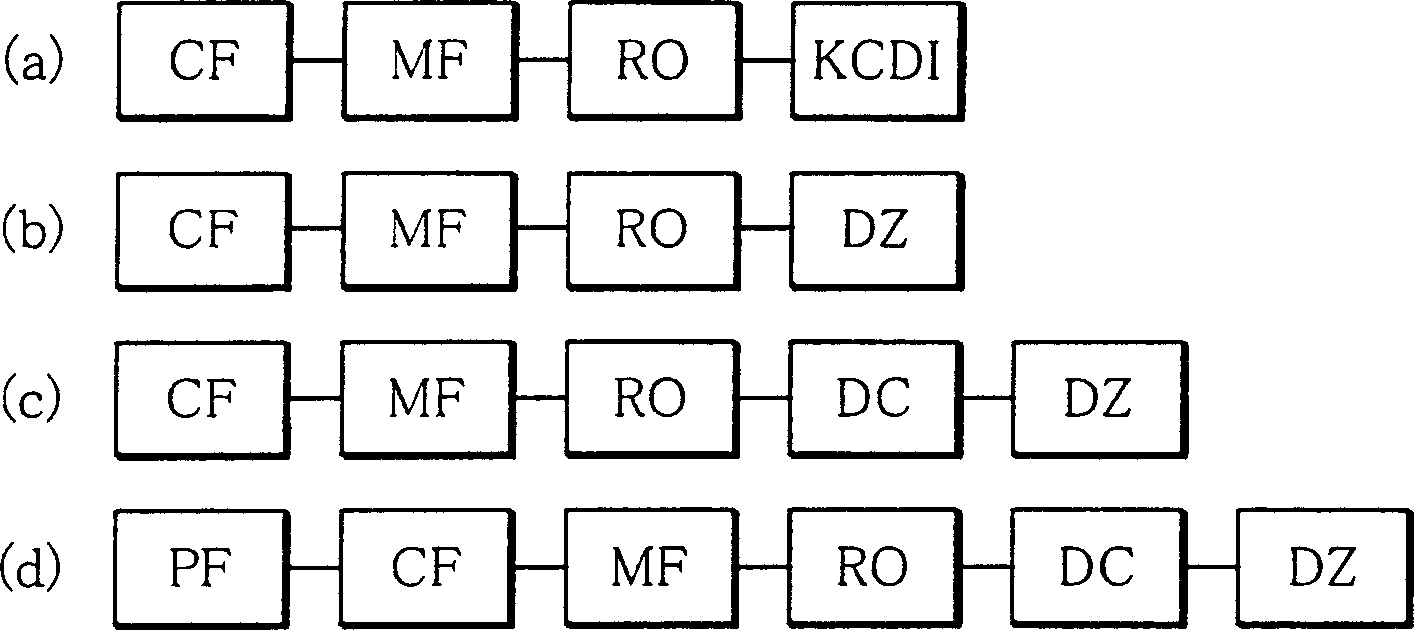

Supply system of water treatment apparatus

InactiveCN1377834AData processing applicationsDispersed particle separationInventory managementTreated water

PROBLEM TO BE SOLVED: To provide a system for leasing water treatment equipment suitable for managing temporary demand of treated water (purified water) in a factory or the like by temporarily leasing the water treatment equipment. SOLUTION: This system, provided with an inventory control database to control the inventories of a plurality of types of units, comprises equipment design means to design the equipment specification which meets the water treatment specification, inventory judgment means to judge if the unit is in stock which is necessary to compose the equipment specification referring to the inventory control database according to the designed equipment specification, equipment composing means to compose the water treatment equipment of the equipment specification using the units in stock, meanwhile to make the units out of stock according to the judgment, and equipment withdrawal means to put the plurality of the units composing the water treatment equipment back in the inventory when the water treatment equipment is withdrawn and to register the information about the units put back into the inventory in the inventory control database for reuse.

Owner:KURITA WATER INDUSTRIES LTD

Goaf collapse alarm device

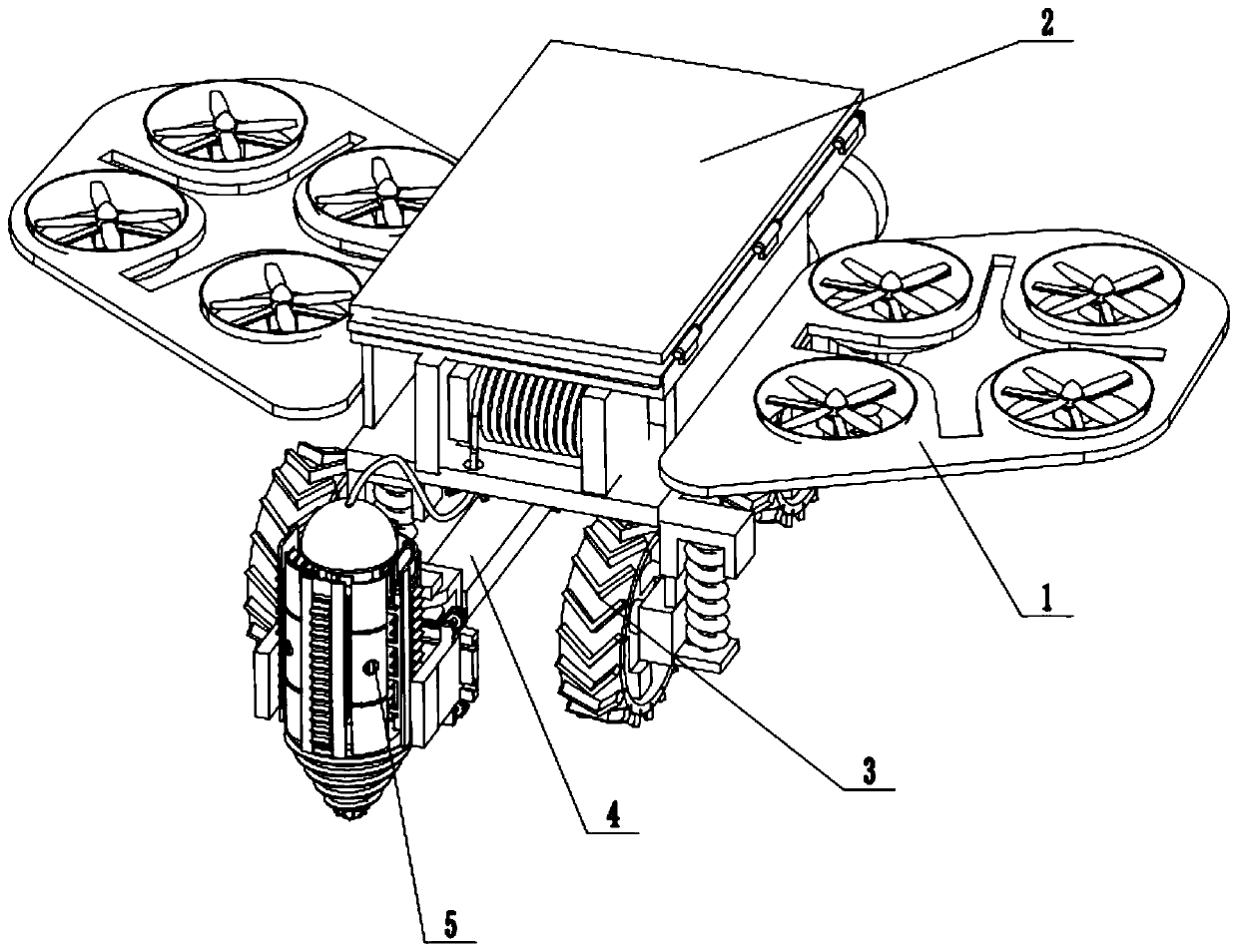

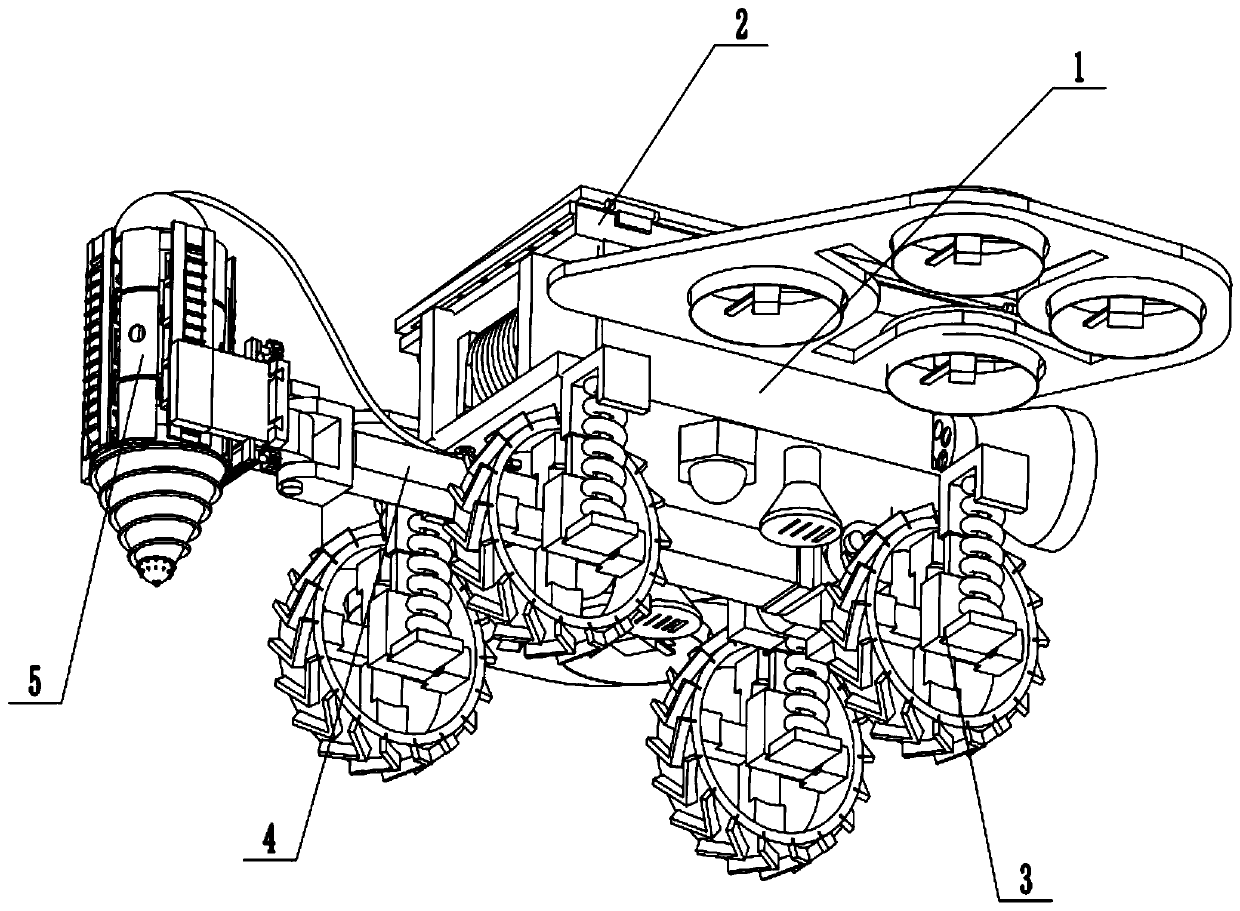

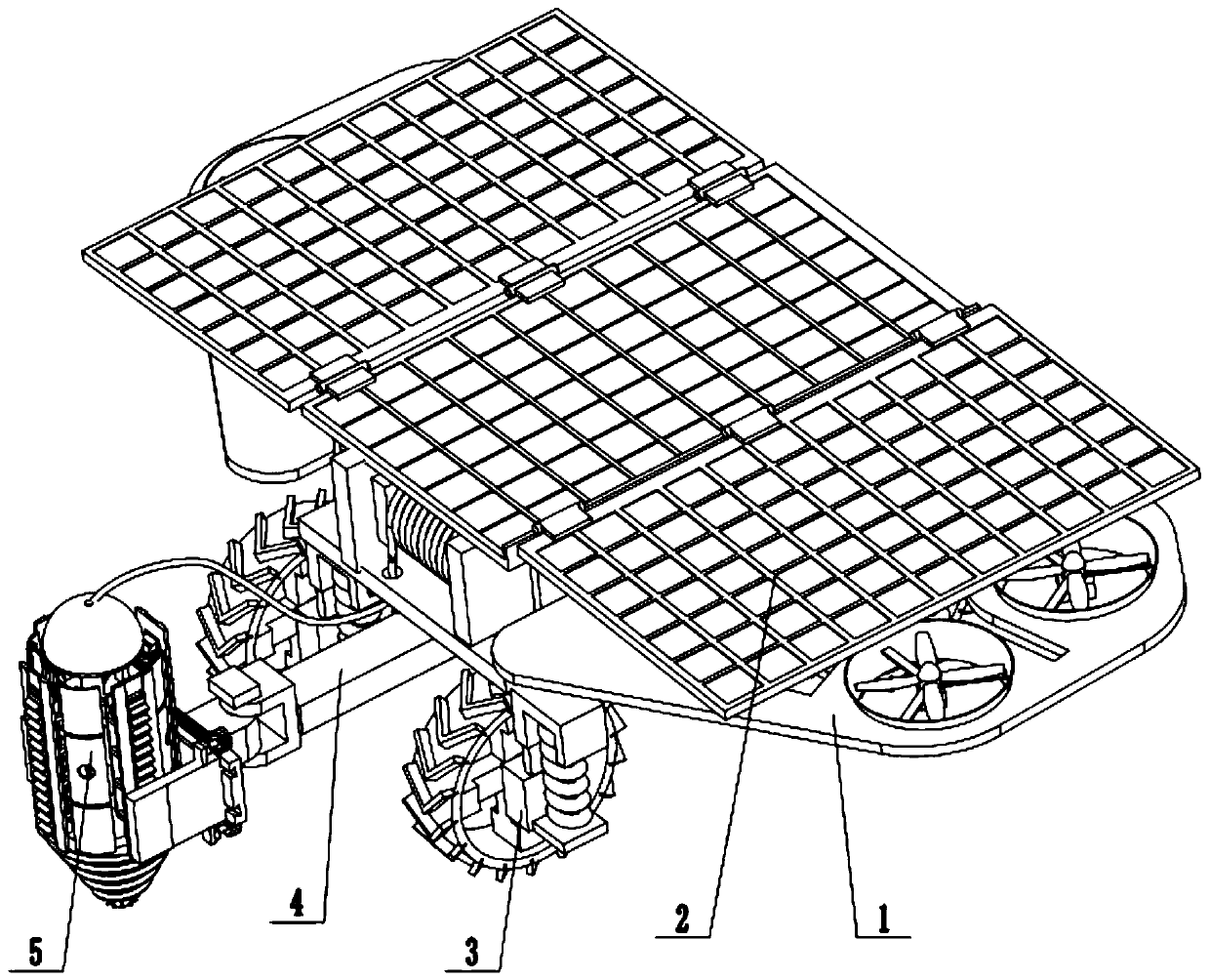

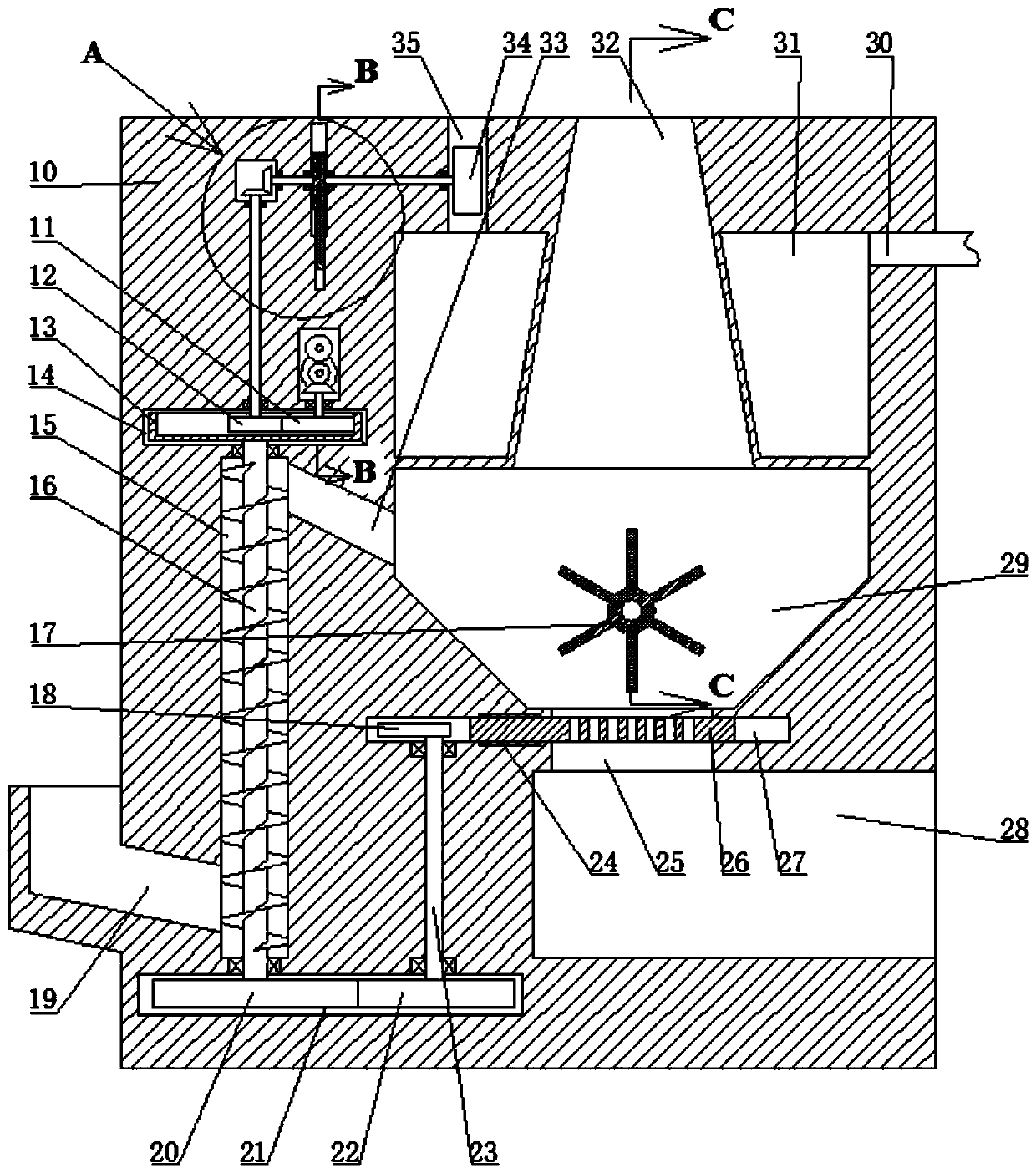

ActiveCN111354166AAchieve self-sufficiencySave energySolar panel attachmentsAlarmsLoudspeakerAlarm device

The invention discloses a goaf collapse warning device which comprises a ground warning flight part, a solar energy part, a walking part, a mechanical arm part and an underground detection part, the ground warning flight part is provided with a controller, and the walking part is controlled by the controller to drive equipment to move to a designated position for drilling detection; solar energy is converted into electric energy through the solar energy part to supply power to equipment. The underground detection part is clamped by the mechanical arm part to be drilled into the ground; variousunderground data of the goaf are detected in real time through the underground detection part; when collapse is about to happen, the ground warning flight part rapidly flies to flicker the alarm lampand gives out alarm sound through the alarm loudspeaker, and casualties and economic losses of personnel are reduced. After collapse is finished, the underground detection part automatically returnsto the ground to complete equipment recycling, the detection cost is reduced, the danger of manual operation is avoided, and the equipment completes integration of goaf detection, collapse warning andequipment recycling.

Owner:山东省地矿工程集团有限公司

Waste incineration system

ActiveCN110186049ASimple structureSave resourcesIncinerator apparatusCombined combustion mitigationSystem structureTurbofan

The invention provides a waste incineration system. The waste incineration system comprises an airframe, an incineration chamber and a feeding chamber arranged in the airframe, wherein a flue passageis arranged in the top wall of the incineration chamber; the circumferential wall of the flue passage is surrounded by steam chambers; water inlet holes are formed in the right side walls of the steamchambers; air outlets are formed in the top walls of the steam chambers; centrifugal chambers are arranged in the left walls of the air outlets; drive chambers are arranged in the left side walls ofthe centrifugal chambers; first rotating shafts penetrating through the centrifugal chambers are rotationally arranged between the drive chambers and the air outlets; the outer surfaces of the first rotating shafts in the drive chambers are fixedly provided with first bevel gears; and turbofans are fixedly arranged on the outer surfaces of the first rotating shafts in the air outlets. By means ofthe waste incineration system, the feeding and ash screening of the system can be achieved by using the same power source, so that the system structure is simplified; and meanwhile, the system recycles waste heat from waste incineration to provide power for the system, so that resources are saved.

Owner:温州转宇纺织有限公司

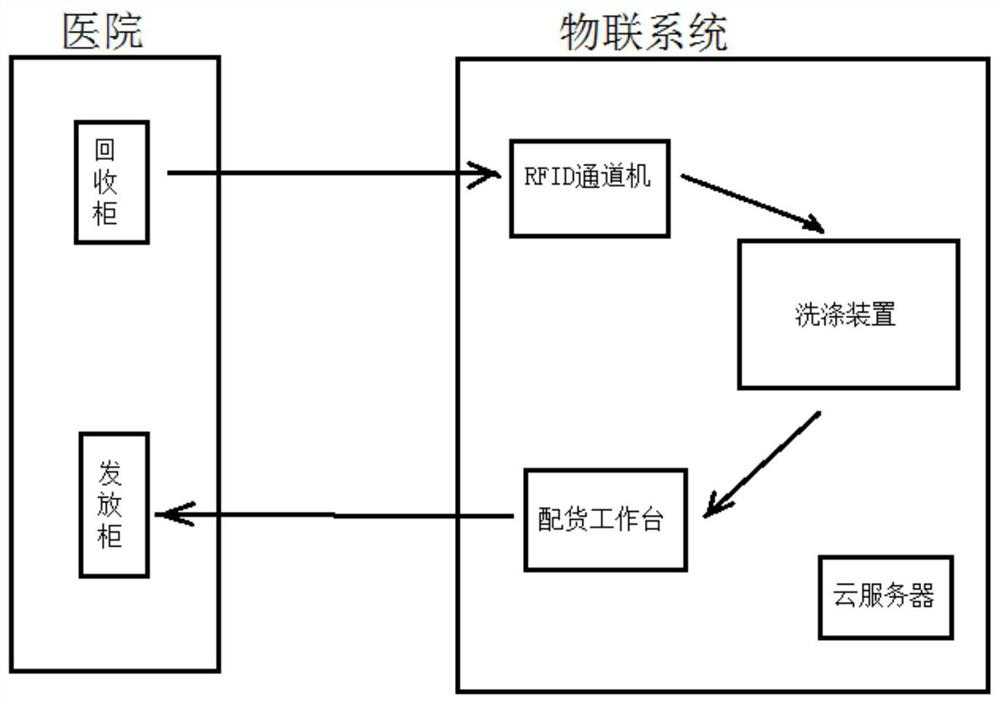

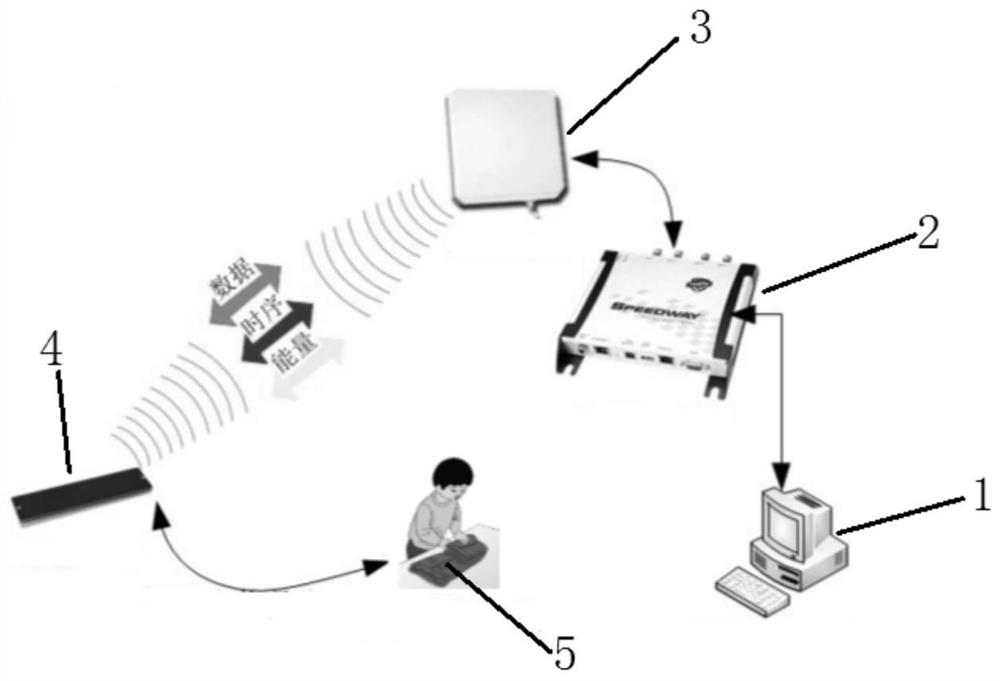

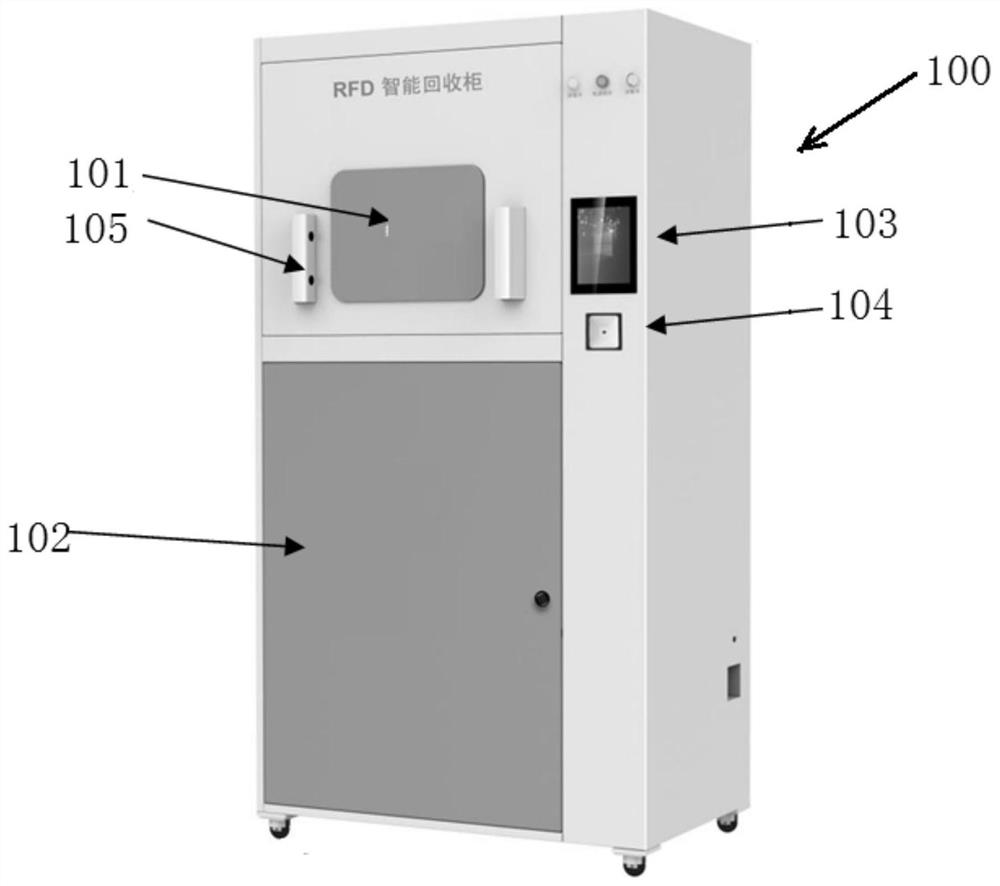

Internet-of-things system and method for medical textiles

PendingCN113436714ARealize out-of-stock operationRealize safe operation of occupational protectionCo-operative working arrangementsHealthcare resources and facilitiesOperating systemEquipment Recycling

The invention discloses an internet-of-things system and method for medical textiles, a washing label is arranged on each medical textile by using an RFID technology, and the system further comprises the following equipment: a recovery cabinet for recovering dirty medical textiles; the recovery cabinet is provided with a first RFID reader-writer, and the first RFID reader-writer is used for identifying the RFID tags of the recovered medical textiles; the distribution cabinet comprises a work clothes cabinet and a bedding and clothing cabinet; the work clothes cabinet is used for distributing clean work clothes of doctors and nurses, and the bedding and clothing cabinet is used for distributing clean hospital clothes, bedding articles and operating kits; wherein second RFID reader-writers are arranged in the work clothes cabinet and the bedding and clothing cabinet, and the second RFID reader-writers are used for identifying the RFID tags in the work clothes cabinet and the bedding and clothing cabinet. According to the internet-of-things system and method for the medical textiles, the medical textiles can be recycled and distributed in a self-service mode, personnel contact and checking and confirming processes in the handover process are reduced, and management and distribution of the medical textiles are completed more safely and with high quality.

Owner:海恩康(天津)医疗科技有限公司

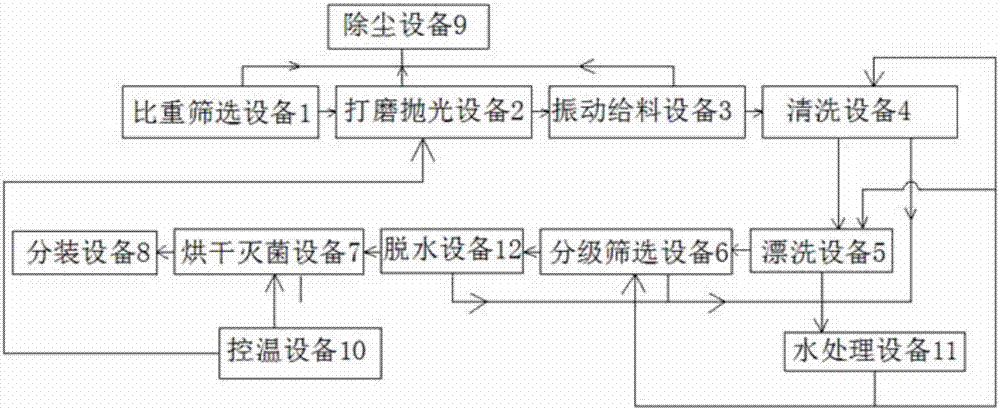

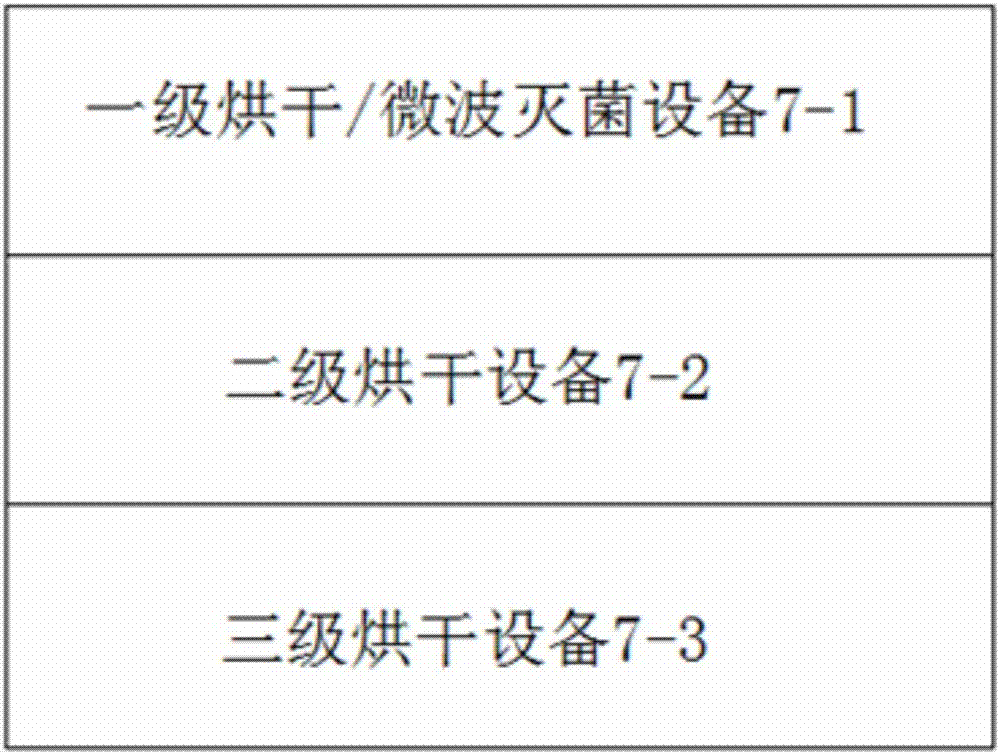

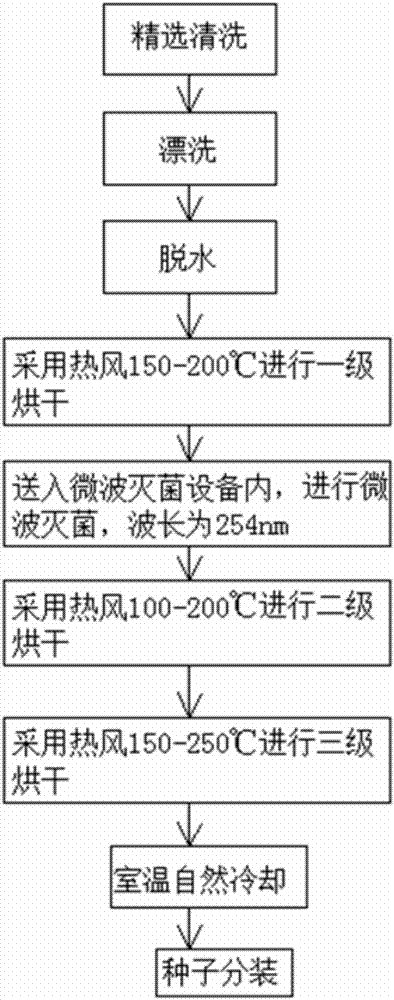

Full-automatic elaborate selecting, grinding, polishing, cleaning, drying and sterilizing production system

InactiveCN106914300AAchieve reuseSmall footprintSeed preservation by irradiation/electric treatmentSeed preservation by dryingEngineeringDehydration

The invention discloses a full-automatic elaborate selecting, grinding, polishing, cleaning, drying and sterilizing production system, and relates to the technical field of seed processing equipment. Specific gravity screening equipment is connected with grinding and polishing equipment. The grinding and polishing equipment is connected with vibration feeding equipment. The vibration feeding equipment is connected with cleaning equipment. The cleaning equipment is connected with rinsing equipment. The rinsing equipment is connected with classified screening equipment. The classified screening equipment is connected with dehydration equipment. The dehydration equipment is connected with drying and sterilizing equipment. The drying and sterilizing equipment is connected with split charging equipment. Equipment recycling is achieved; and meanwhile, the occupied area of the equipment can be effectively decreased, investment cost is reduced, cost is greatly lowered, and practicability is made higher.

Owner:甘肃御宝泽农垦御米生物开发有限公司

Batch recovery process and equipment for preparing membrane electrode catalyst by spraying method

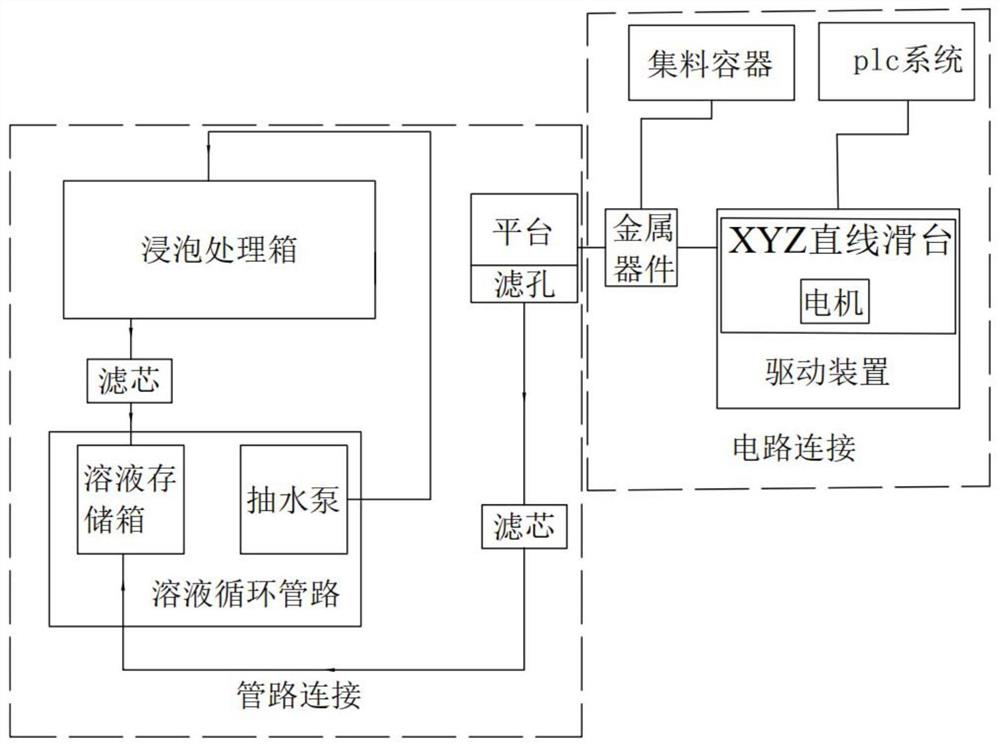

ActiveCN112542594AAvoid damageAvoid accumulationFuel cells disposal/recyclingFinal product manufacturePtru catalystFuel cells

The invention discloses a batch recovery process and equipment for preparing a membrane electrode catalyst by a spraying method. According to the invention, a catalyst exceeding a spraying area in a spraying process is recovered; before the catalyst layer is prepared, the auxiliary equipment is completely coated with a carrier sheet, it is guaranteed that catalyst slurry completely falls on the carrier sheet outside an effective area, and then efficient recovery of the catalyst adhering to hardware auxiliary equipment such as a clamp is achieved through the procedures of soaking, scraping, collecting, washing and vacuum drying. The cost is reduced, and meanwhile, the air environment pollution is reduced. Meanwhile, the invention further discloses batch recovery equipment for the fuel cellcatalyst, which can achieve batch work of the catalyst recovery method, improve the working efficiency, increase the utilization rate of raw materials in production, and reduce the manufacturing cost.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

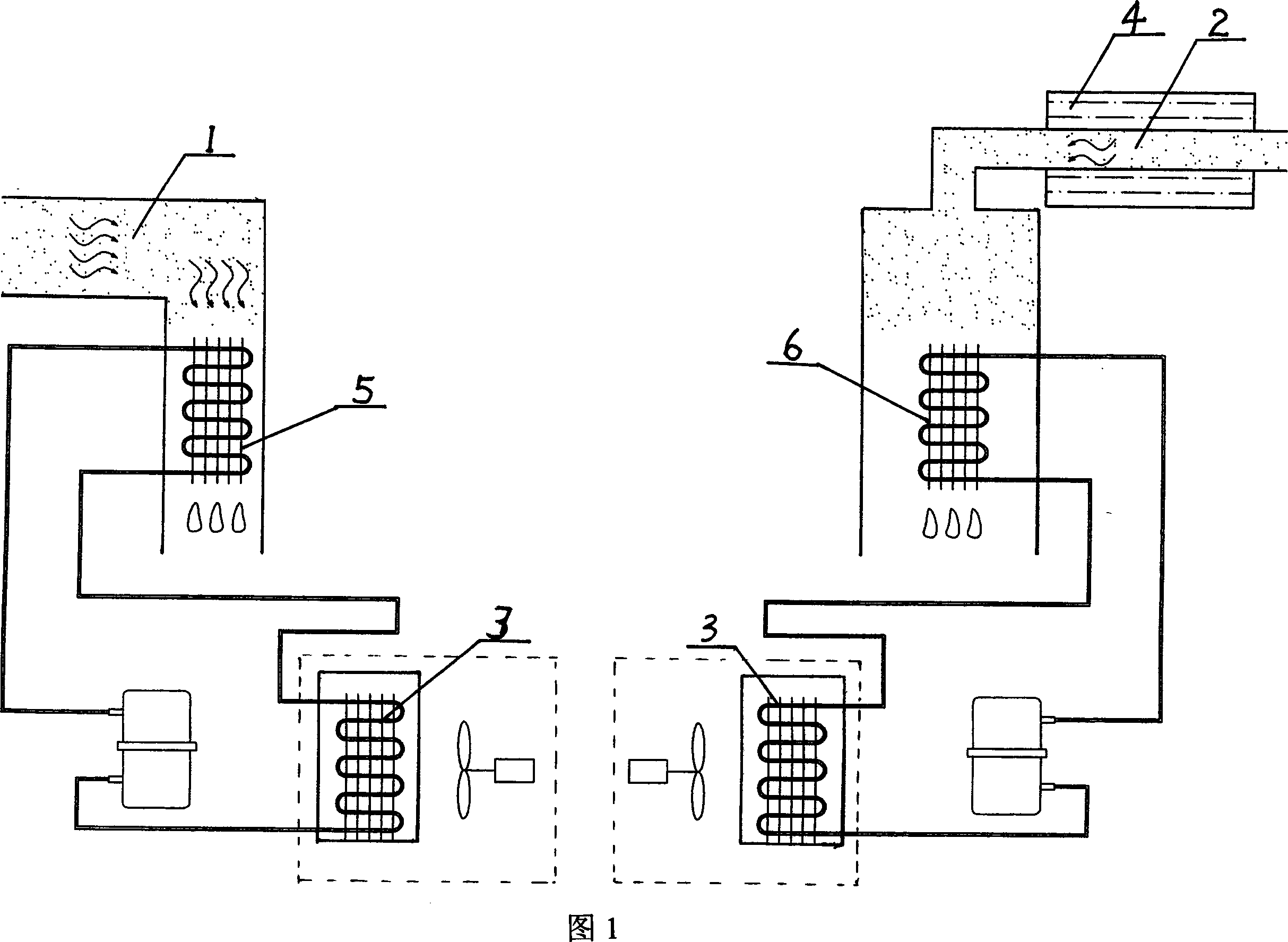

Device for recovering solvent in wind cooling type dry washing machine

InactiveCN1944778AImprove work efficiencyLow running costDry-cleaning apparatusDistillation separationEngineeringSolvent

The wind cooled solvent recovering device for dry washing machine includes a stoving channel, a distilling channel and a cooling recovery unit connected together. The cooling recovery unit has wind cooled heat exchanger in the cooling recovery loop; and the distilling channel is provided with one medium type or one wind cooled heat exchanger. The present invention has high solvent recovering efficiency, low running cost, simple recovering device structure and other advantages.

Owner:张家港市成事机械有限公司

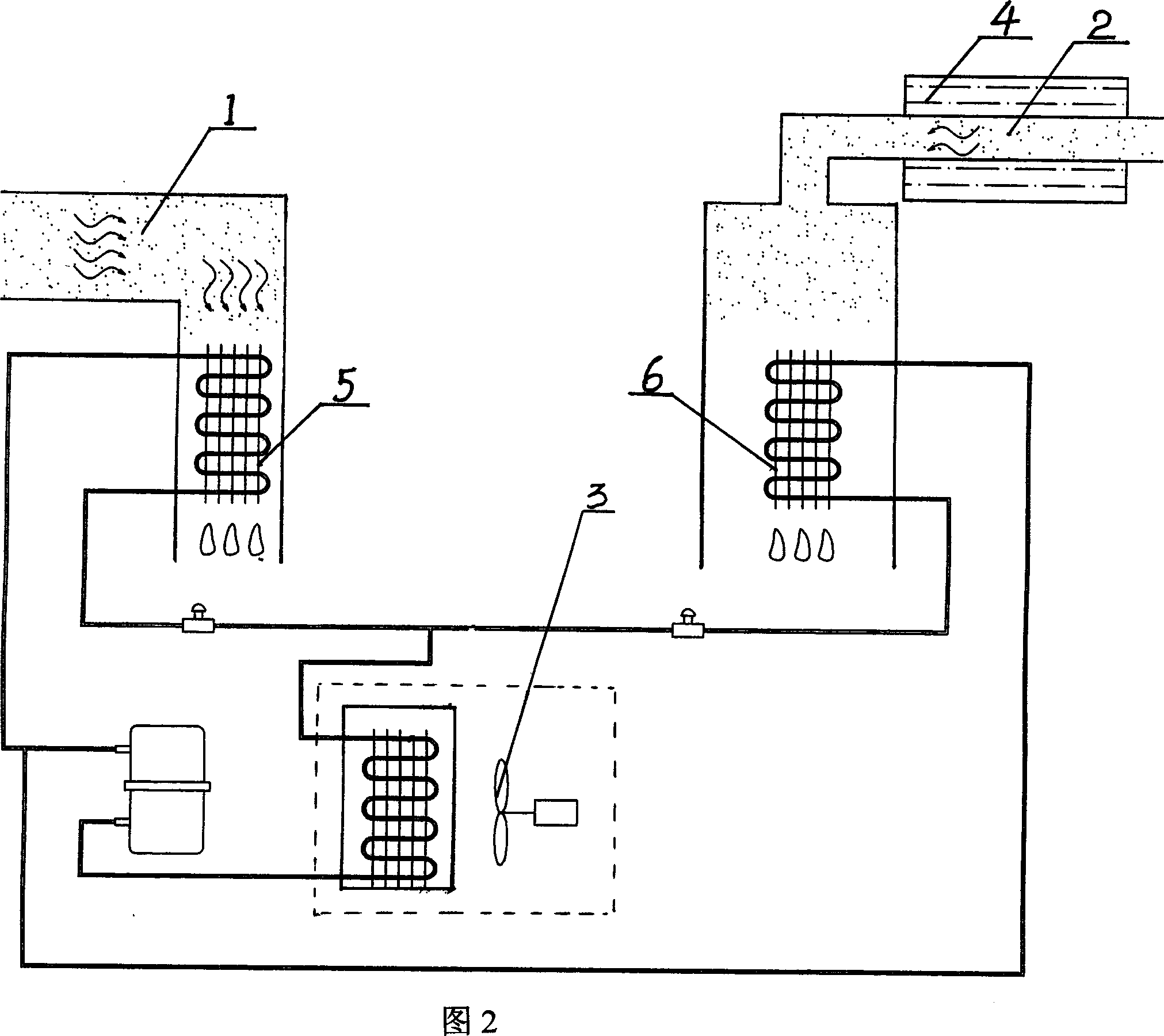

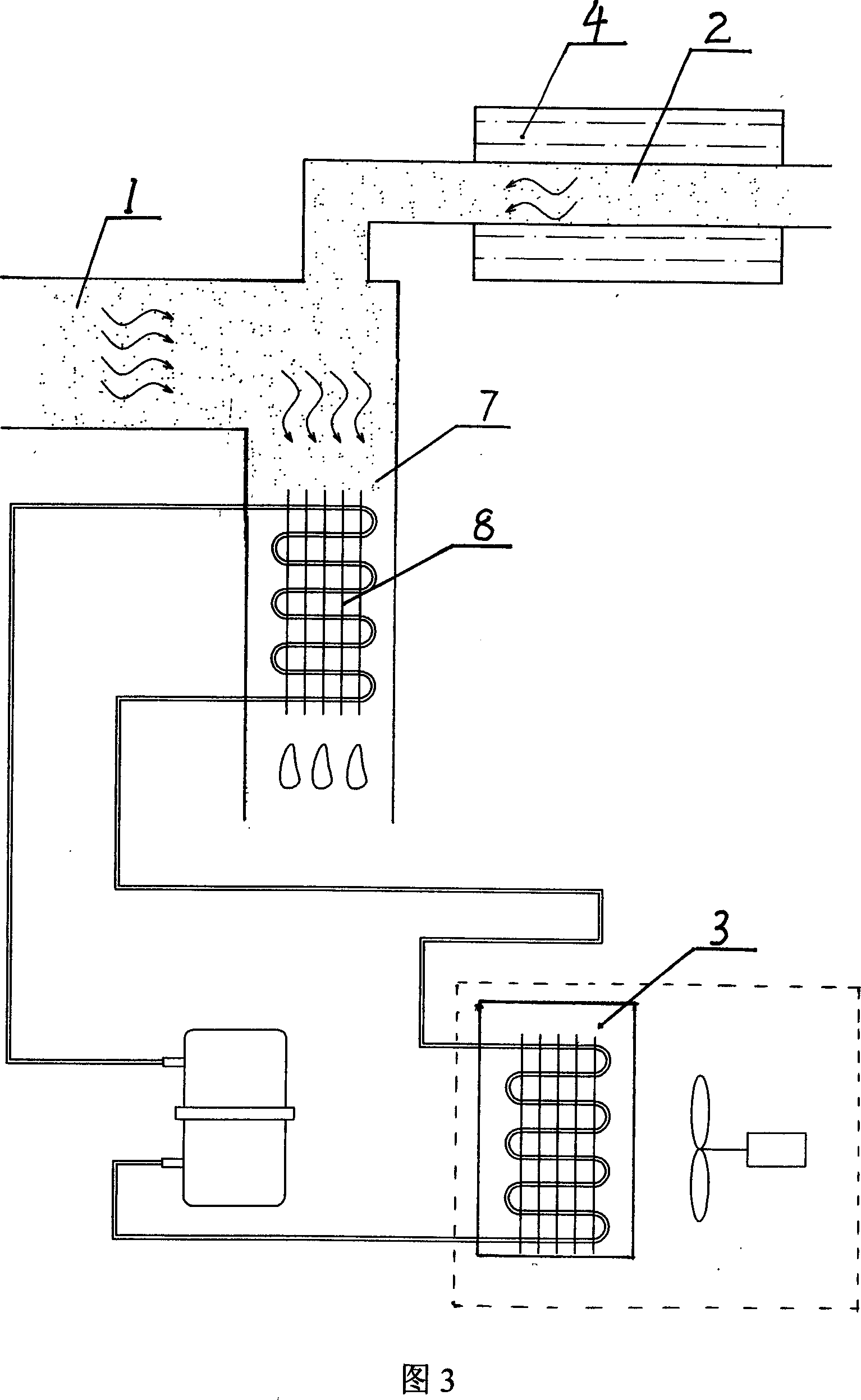

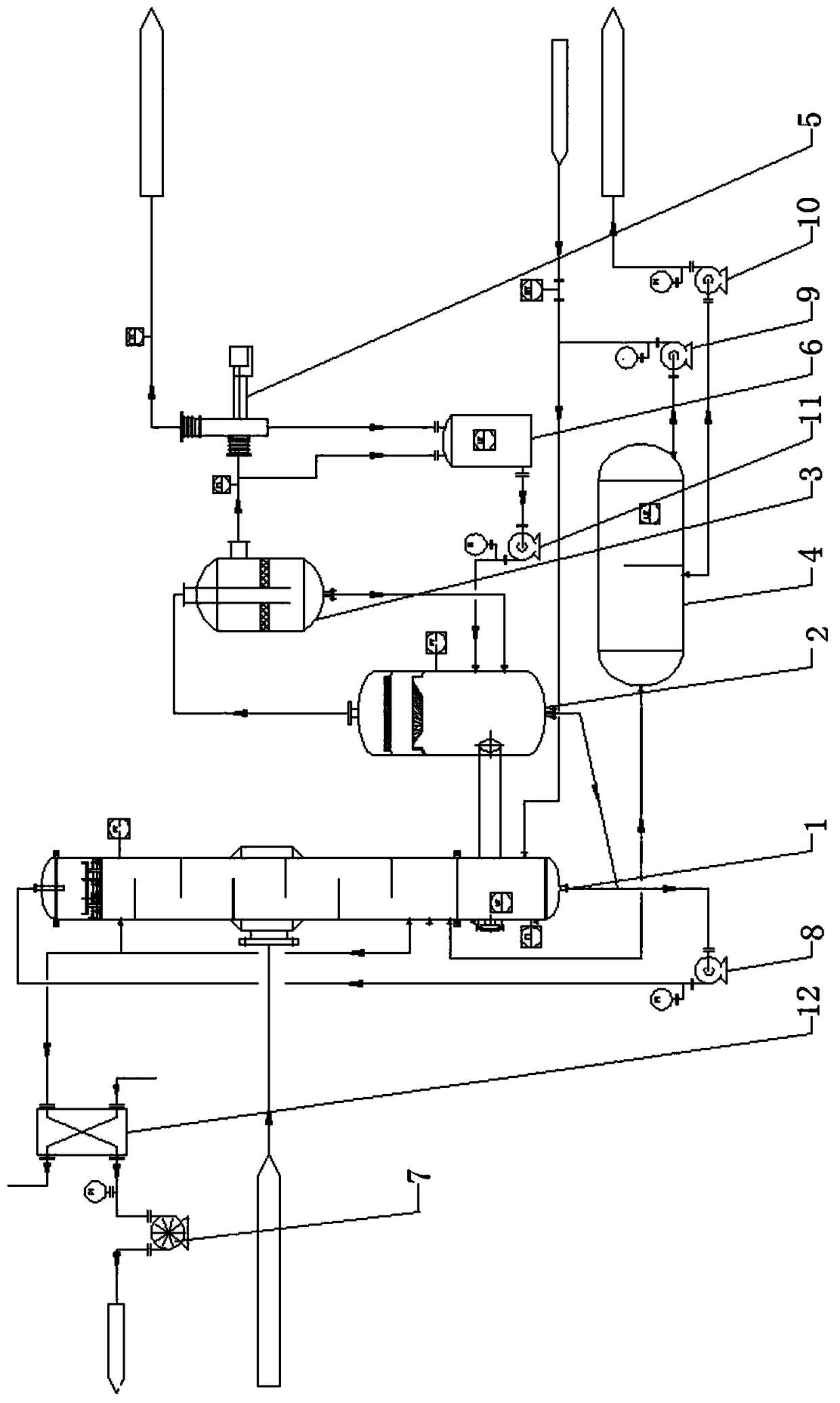

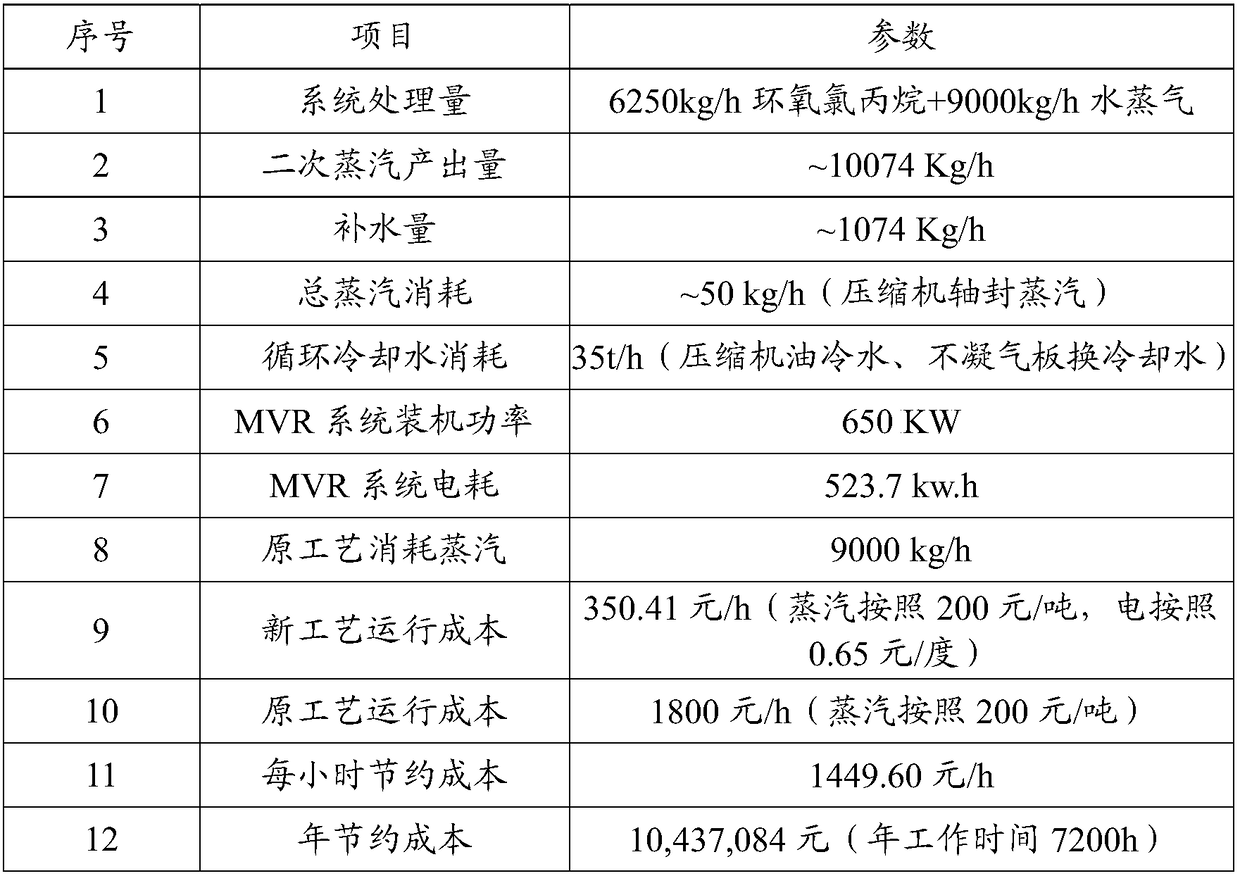

Equipment and process of utilizing MVR technology to recover waste heat

ActiveCN109134405AReduce energy consumptionHigh degree of processing automationOrganic chemistryChemical industryEngineeringPollution

The invention discloses equipment of utilizing an MVR technology to recover waste heat. The equipment comprises a falling film heat exchanger, a falling film separator and a secondary separator whichare connected in sequence, the falling film heat exchanger is connected with a phase separation device, and the secondary separator is connected with a compressor and a liquid collection device. The equipment utilizes the mechanical vapor recompression technology to recover the waste heat, the energy consumption is greatly reduced and is only 1 / 6 to 1 / 5 of that of a traditional rectification process, the thermal efficiency is high, dependence on traditional boiler equipment is reduced, pollutants are also reduced, no pollution is caused to the environment, energy is saved, and the environmentis protected. The invention also discloses a process adopting the equipment for recovering the waste heat, the process greatly reduces the energy consumption of a traditional rectification system by recovering the waste heat of waste steam on the top of a tower, the operation is simple, the process is controllable, the quality of products is stable and excellent, and remarkable economic benefits are obtained; meanwhile, the process has high automation degree, continuous operation can be conducted, the production efficiency is high, requirements for sustainable development are met, and the process can be widely used in actual industrial production processes.

Owner:SHENZHEN SUNEVAP TECH

Quick recovery method for inclined thick coal seam working face

InactiveCN111734413AImprove security management and control capabilitiesQuick clean upUnderground miningSurface miningSludgeArchitectural engineering

The embodiment of the invention provides a quick recovery method for an inclined thick coal seam working face. The method comprises the steps of building a withdrawing channel, the withdrawing channelis connected with a rubber belt transportation roadway and an air return roadway, and subsection and stepped blasting digging is adopted during building of the withdrawing channel; recovering tail large frames, tail transmission parts and scraper chains of a front scraper conveyor and a rear scraper conveyor through the air return roadway; and lifting and recovering a bracket on a terrace throughthe withdrawing channel. The recovery speed of machine lane equipment is increased by building a recovery connection lane and the withdrawal channel, and meanwhile, quick drainage and sludge cleaningwork of a lower opening of the withdrawal channel are facilitated; the construction period of the gently inclined thick coal seam working face withdrawing channel is shortened through the construction mode of combining subsection and stepped blasting digging with coal mining machine bottom sweeping, and the safety management and control capacity in the withdrawing channel supporting process is further improved; when the inclination angle of the working face is large, a terrace direct-dragging mode is adopted, the safety control capacity in the recovery period is improved, and the recovery speed of the working face is increased; an equipment recovery transfer station is arranged, and the utilization rate of special vehicles is increased.

Owner:陈芳

Network equipment recovery device

InactiveCN111842424AAvoid easy separationEasy to disassembleSolid waste disposalElectronic waste recyclingEmbedded systemReliability engineering

The invention relates to the field of recovery of hardware equipment, in particular to a network equipment recovery device. The technical problem to be solved by the invention is to provide a networkequipment recovery device. The network equipment recovery device comprises a workbench, a positioning-loose antenna removal mechanism, a loop antenna separation mechanism, a positioning and housing circuit board separation mechanism, a router, a control panel, a lower housing recovery box and a second transportation mechanism, wherein the workbench is provided with the positioning-loose antenna removal mechanism, the loop antenna separation mechanism, the positioning and housing circuit board separation mechanism, the lower housing recovery box and the second transportation mechanism. By adopting the network equipment recovery device provided by the invention, the removal of router antennae, the separation of the router antennae, and the separation of the upper part and the lower part of arouter housing can be realized, the router can be separated in batches, and the incomplete separation of the router and the ignorance of the circuit board at the antenna position of the router can beeliminated, thereby effectively improving the recovery value.

Owner:冯志爽

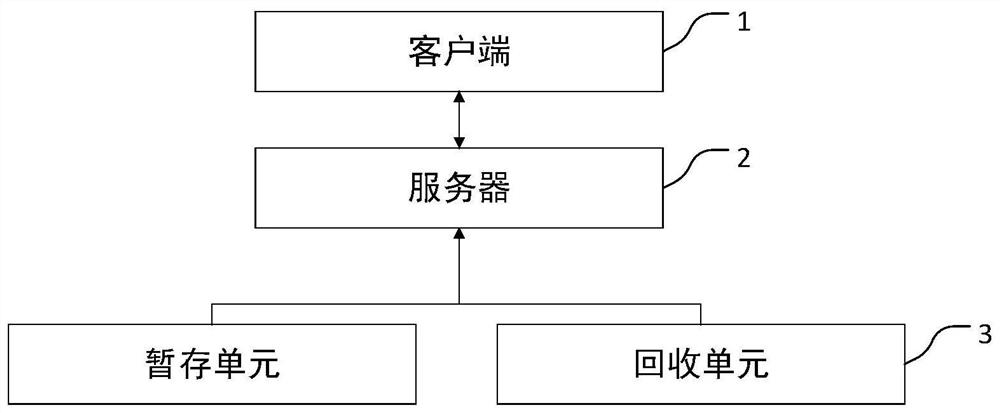

Waste mineral oil management and control system and method

PendingCN112329957ARealize automatic management and controlImprove management and control efficiencySustainable waste treatmentCo-operative working arrangementsControl systemMineral oil

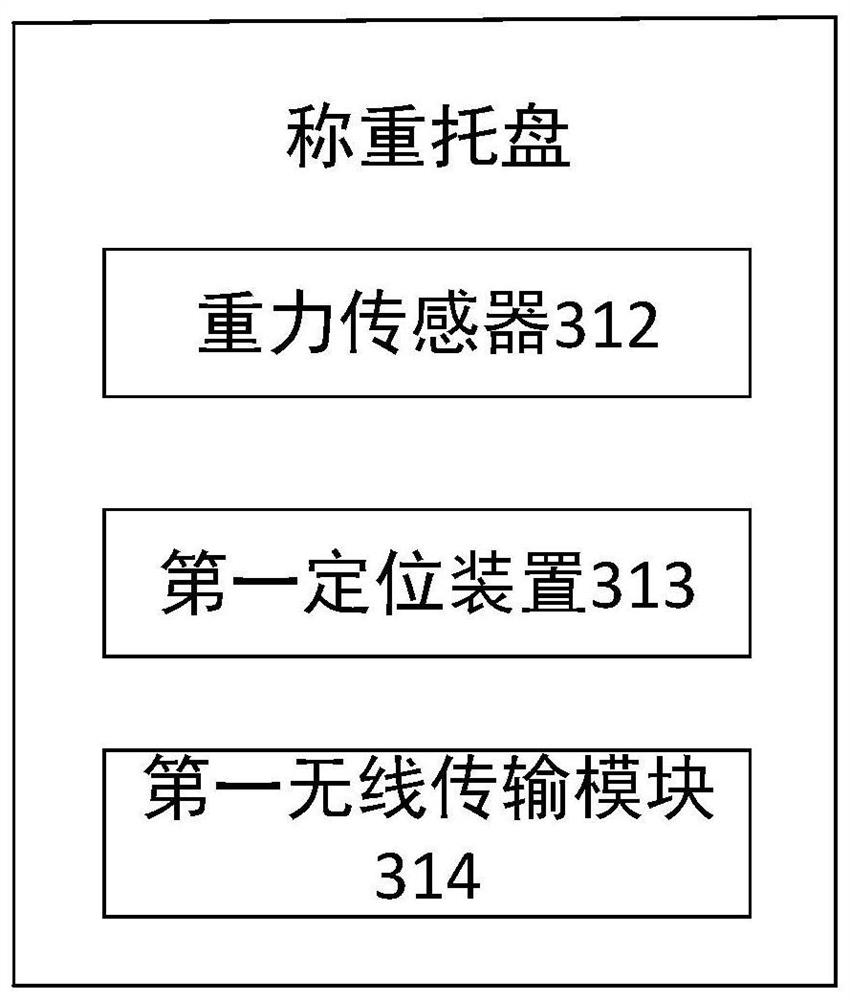

The invention relates to a waste mineral oil management and control system, which comprises a client, a server, a recovery unit and a temporary storage unit, the recycling unit comprises a plurality of recycling stations and transfer equipment, each recycling station comprises an oil collecting barrel and a weighing tray, the oil collecting barrels are used for collecting waste mineral oil, and the weighing trays are used for sending positioning data of the recycling stations and gravity data of the oil collecting barrels to the server; the transfer equipment comprises a transport vehicle, andpositioning data of the transport vehicle is uploaded to the server; the temporary storage unit comprises a plurality of temporary storage cabins, and the temporary storage cabins upload positioningdata to the server in real time; the client is in communication connection with the server, obtains data uploaded by the recycling unit and the temporary storage unit from the server, and judges whether the oil collecting barrel of the recycling station needs to be recycled or not according to the gravity data of the oil collecting barrel, and calculates the transport vehicle and the temporary storage cabin which are closest to the corresponding recycle bin point at present according to the positioning data of each recycle bin point, the positioning data of each transport vehicle and the positioning data of each temporary storage cabin, .

Owner:NINGDE POWER SUPPLY COMPANY STATE GRID FUJIAN ELECTRIC POWER +2

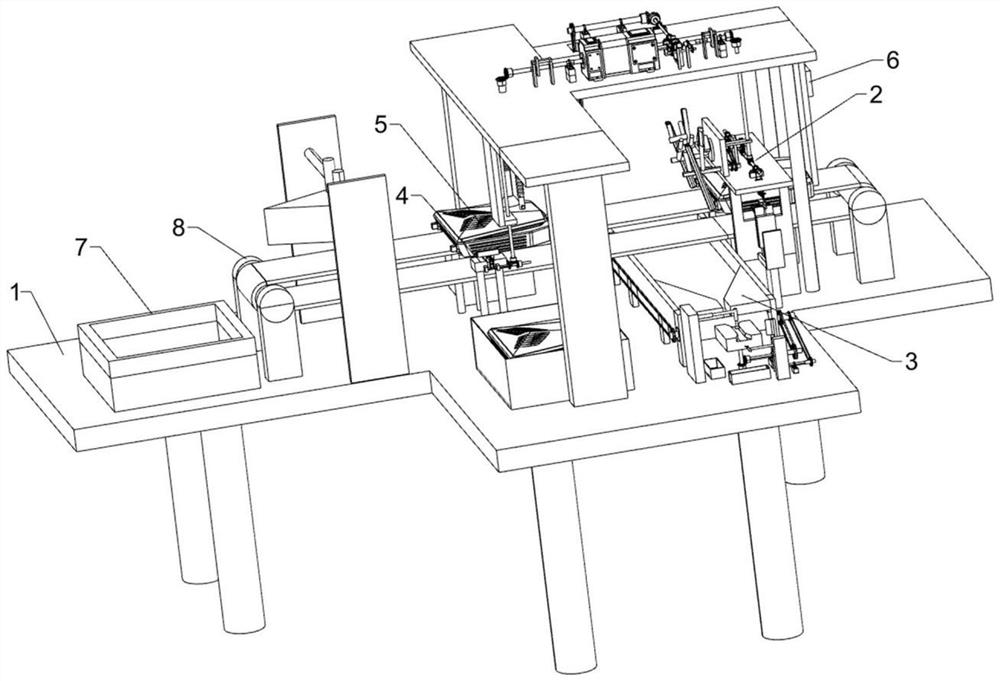

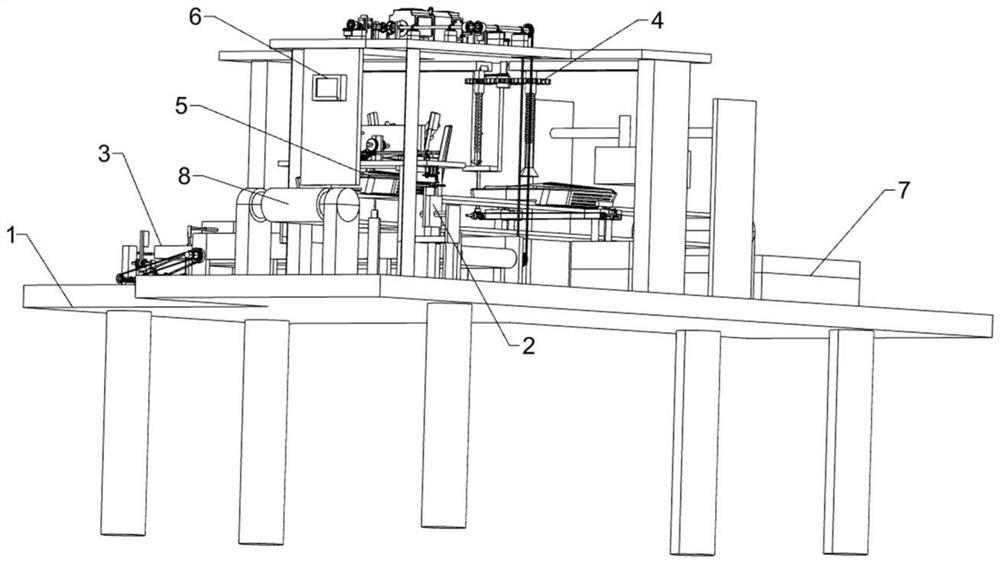

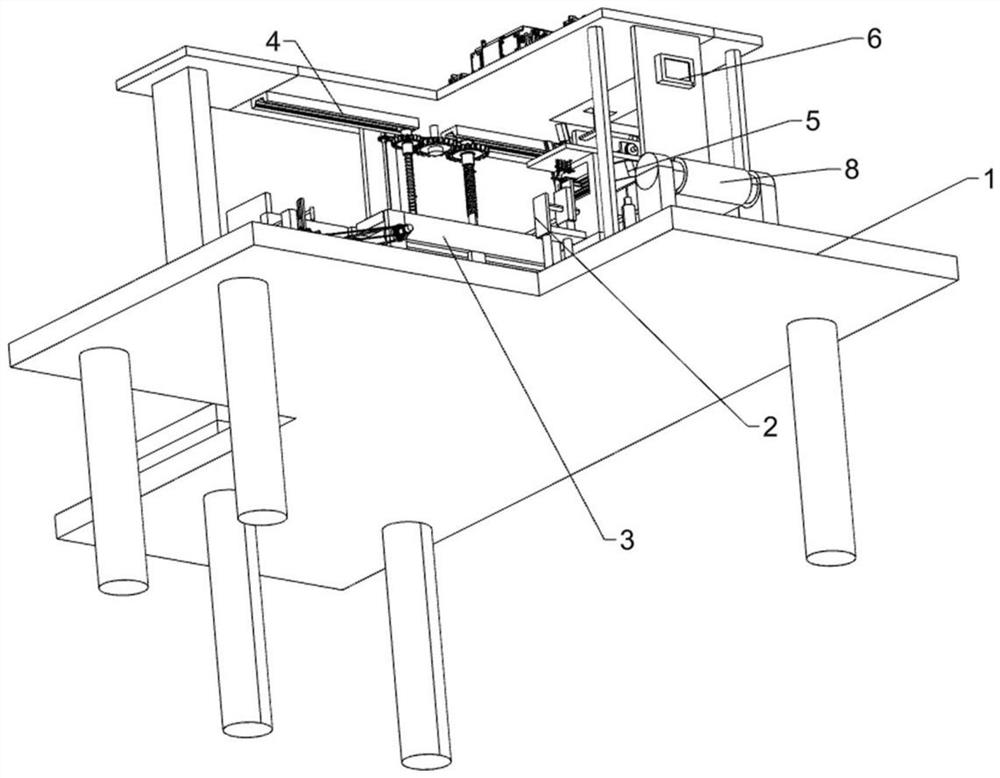

Equipment recycling and warehousing method and equipment recycling and warehousing system based on 3D vision

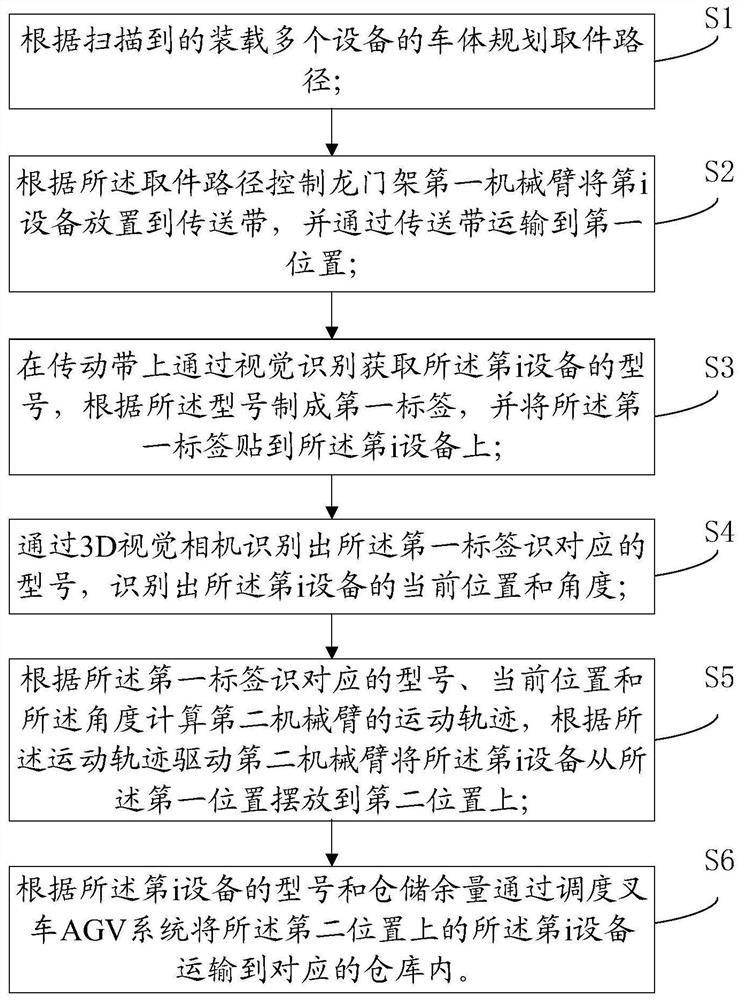

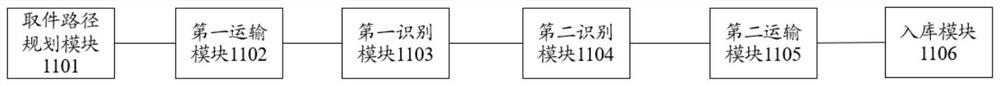

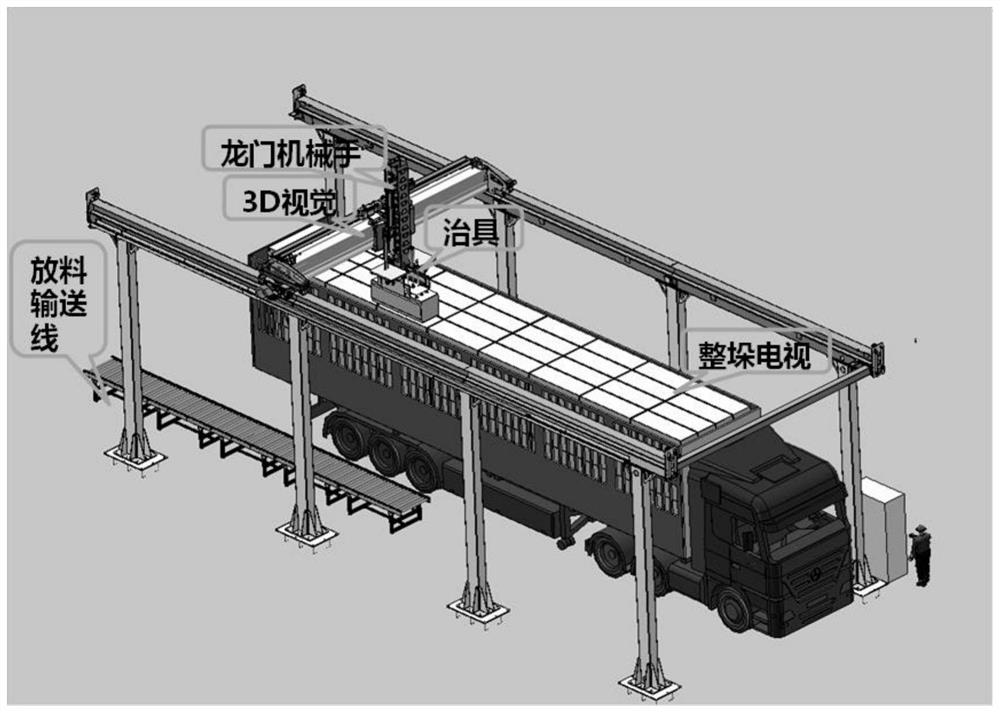

InactiveCN113800167ARealize automatic cage loadingRealize automatic storageConveyorsCo-operative working arrangementsPortal frameIndustrial engineering

The invention discloses an equipment recycling and warehousing method and equipment recycling and warehousing system based on 3D vision, and relates to the field of warehousing systems. The method comprises the steps that a piece taking path is planned according to a scanned vehicle body loaded with multiple pieces of equipment, a first mechanical arm of a portal frame is controlled to place the ith equipment on a conveying belt according to the piece taking path, the ith equipment is conveyed to a first position through the conveying belt, and automatic equipment unloading is completed; the model corresponding to a first label is recognized through a 3D vision camera, the current position and angle of the ith equipment are recognized, the movement track of a second mechanical arm is calculated according to the information, the second mechanical arm is driven to place the ith equipment from the first position to a second position according to the movement track, automatic caging of the equipment of realized, according to the type of the ith equipment and the storage allowance, the ith equipment at the second position is transported into the corresponding warehouse through a dispatching forklift AGV system, and automatic warehousing of the equipment is achieved. According to the scheme, on the basis of 3D vision, the warehousing processes such as unloading, caging and warehousing are unmanned.

Owner:湖北浩蓝智造科技有限公司

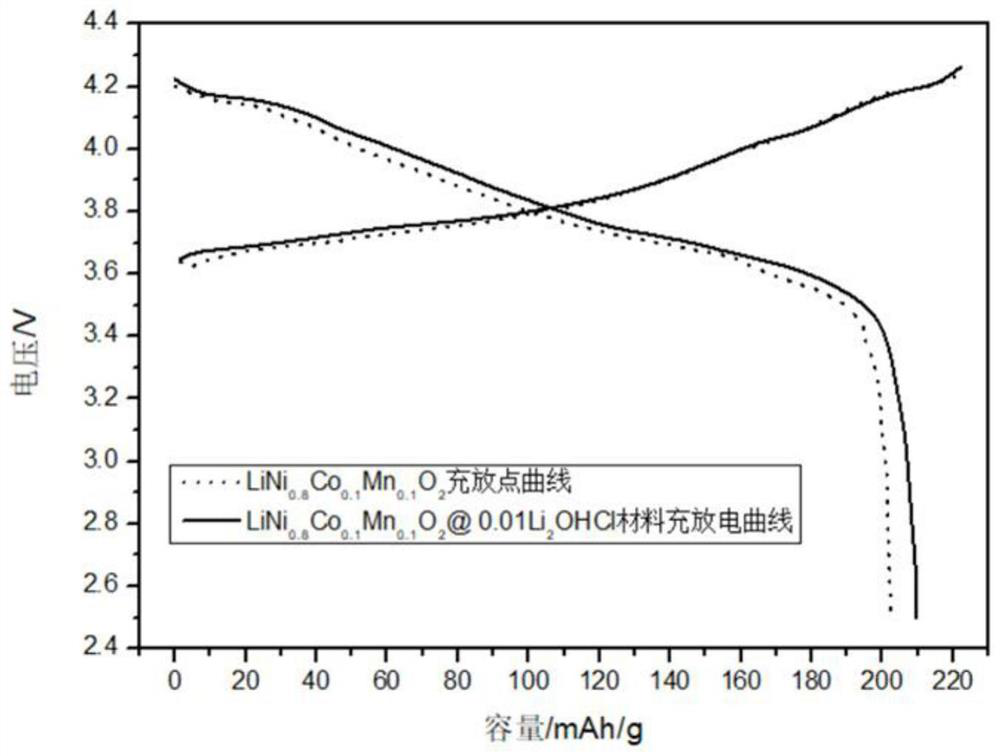

Preparation method of ternary positive electrode material

PendingCN114380342ANo reduction in gram capacityImprove the first effectCell electrodesLithium compoundsMetallurgyElectrical battery

The invention relates to a preparation method of a ternary positive electrode material. The preparation method comprises the following steps: mixing a precursor, spraying a grinding medium into a high-speed mixer, mixing and drying; the dried and recycled gas is recycled into the grinding medium tank through condensing and filtering equipment; and sintering the dried precursor at high temperature to obtain the ternary positive electrode material. Mixing the ternary positive electrode material with at least one coating raw material of LiX, a mixture of Li2O and LiX and a mixture of LiX and LiOH, and drying to obtain a coating raw material; and calcining the coated raw material to obtain the Li2OH < X > coated high-nickel ternary material. According to the invention, a ternary positive electrode material raw material is prepared by taking a high-boiling-point organic system solution as a medium through mixing, a grinding medium is added in an atomizing manner, a mixed material and an organic system recycling system are added, and the high-nickel ternary material is coated with Li2OH, so that the first effect and the cycle performance of the battery are improved from the perspective of lithium source supplementation; and the gram volume of the material is not reduced.

Owner:CHINA FIRST AUTOMOBILE

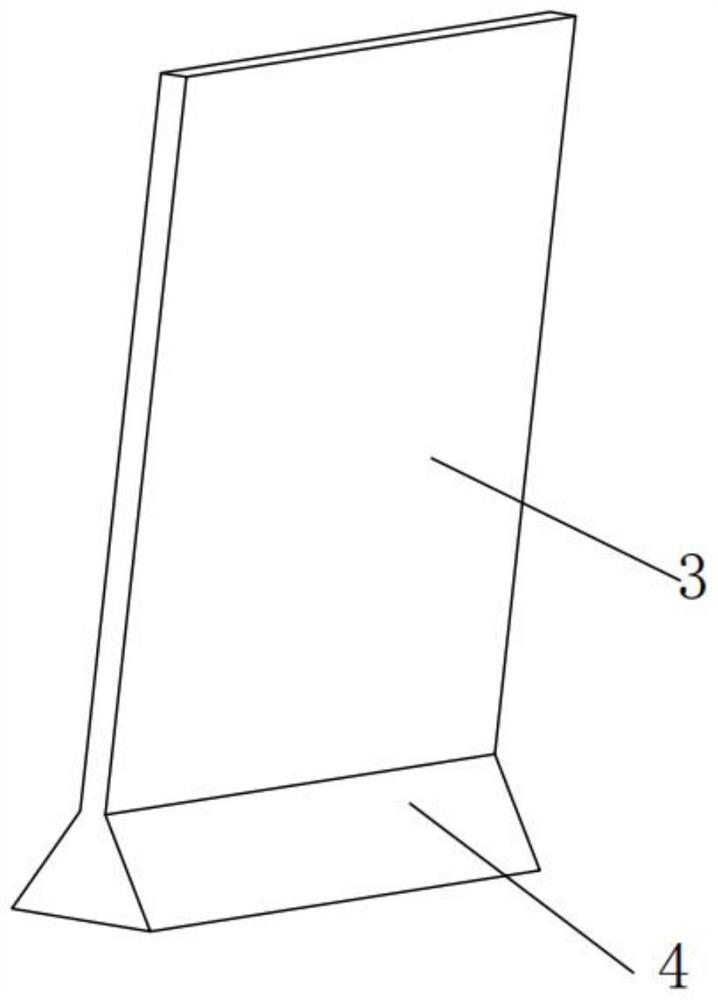

Rocket recycling device with thermal infrared imager

InactiveCN107514940ASolve the problem of easy to fall and cause explosionSimple structureRadiation pyrometrySystems for re-entry to earthRocketSpaceflight

A rocket recovery device with an infrared thermal imager, relating to the field of aerospace equipment recovery, including a rocket recovery platform and a rocket; the rocket recovery platform includes a support platform, an infrared light emitter, three or more support frames and multiple Connecting rod; the connecting rod is installed on the upper end of the supporting frame, and the other end of the connecting rod is connected to the supporting platform, and the connecting rod is designed to surround the supporting platform; a round hole is arranged in the middle of the supporting platform; a funnel device is installed in the upper part of the main body of the rocket; An infrared camera is also installed. The rocket flies back to the sky above the rocket recovery platform through high-precision GPS and other devices, opens the funnel device, and then lands at the middle of the support platform until the funnel device touches the support platform, and the gravity of the rocket fully acts on the support platform through the funnel device On, the rocket completes its landing. The structure and principle of the present invention are very simple, and can be applied to sea and land, and the present invention also well solves the problem that the rocket is easy to fall and cause explosion during the early recovery process.

Owner:FOSHAN SHENHANG SCI & TECH CO LTD

Waste treatment equipment for biotechnological preventive medicine

InactiveCN113426802ASolving Recycling ProblemsEffective initial disinfectSolid waste disposalDispersed particle separationDisinfectantMedical waste

The invention relates to the technical field of medical waste treatment, in particular to waste treatment equipment for biotechnological preventive medicine, and solves the defects that a waste treatment device for preventive medicine cannot perform equipment crushing and disinfection and has risks of virus transmission and equipment recycling. The waste treatment equipment comprises a treatment box, a lining plate is welded to the inner side of the top of the treatment box, a first spring is welded in one side of the lining plate, a cover plate is clamped on the inner side of the top of the treatment box, a material guiding pipe is welded to the bottom of the lining plate, a motor base is welded to one side of the material guiding pipe, a motor is fixed to the outer side of the motor base through screws, two connecting shafts are connected to the inner side of the material guiding pipe through bearings, the surfaces of the two connecting shafts are sleeved with pressing rollers, gears are connected to the ends of the connecting shafts in a sleeving mode, and a mounting plate is welded to the inner side of the treatment box. According to the device, abandoned solid waste can be crushed, disinfectant is sprayed through a spray head before and after disposal, the interior and the exterior of the waste are effectively and preliminarily disinfected, and the waste is prevented from being recycled by lawbreakers.

Owner:唐建斌

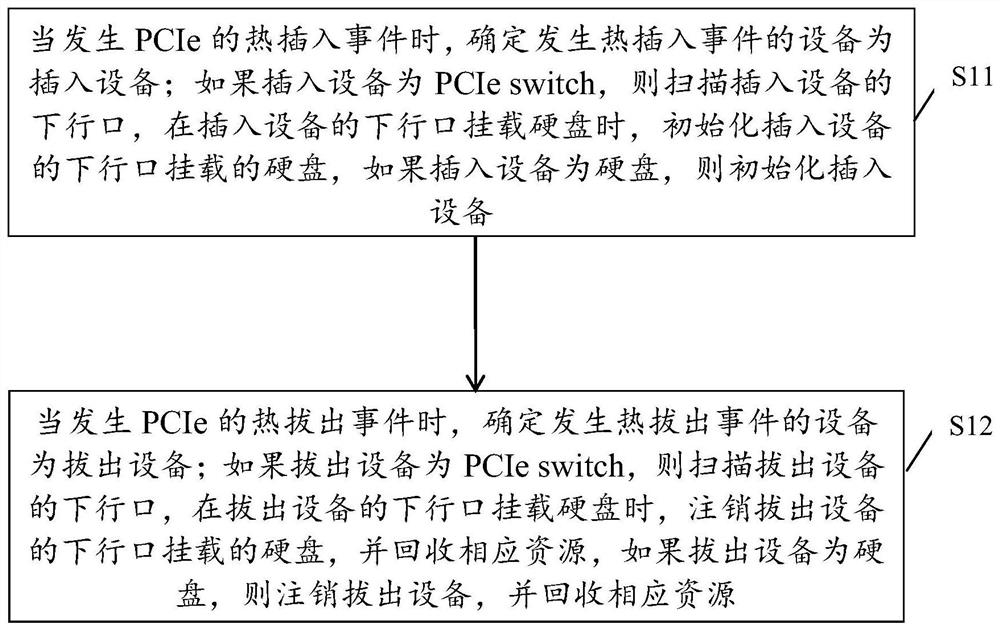

Hot plug processing method, device and equipment

PendingCN112445738AGood serviceabilityHot-swap support and ease of useElectric digital data processingHot swappingEmbedded system

The invention discloses a hot plug processing method, device and equipment, and the method comprises the steps: determining equipment with a hot plug-in event as plug-in equipment when a PCIe hot plug-in event occurs; if the plug-in equipment is a PCIe switch, scanning a downlink port of the plug-in equipment, initializing the hard disk mounted at the downlink port of the plug-in equipment when the hard disk is mounted at the downlink port of the plug-in equipment, and if the plug-in equipment is the hard disk, initializing the plug-in equipment; when a PCIe hot pull-out event occurs, determining the equipment in which the hot pull-out event occurs as a pull-out device; and if the pull-out equipment is a PCIe switch, scanning a downlink port of the pull-out device, when the hard disk is mounted at the downlink port of the pull-out device, cancelling the hard disk mounted on the downlink port of the pull-out device and recovering corresponding resources, and if the pull-out device is the hard disk, cancelling the pull-out device and recovering the corresponding resources. Good hot plug support usability and good serviceability of a corresponding storage system can be realized.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

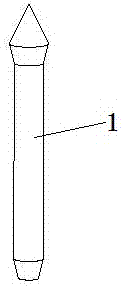

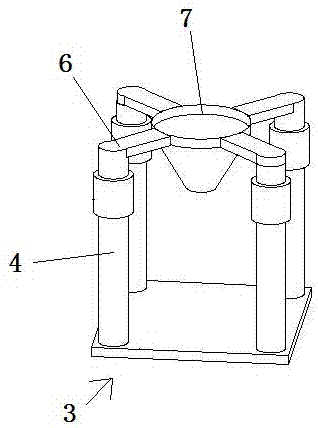

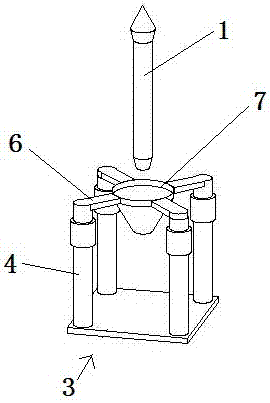

Rocket recycling device with funnel device

InactiveCN107478107ASolve the problem of easy to fall and cause explosionSimple structureSystems for re-entry to earthCosmonautic landing devicesRocketAerospace

A rocket recovery device with a support platform, which relates to the field of aerospace equipment recovery, including a rocket recovery platform and a rocket; the rocket recovery platform includes a funnel device, three or more support frames and a plurality of connecting rods; the connecting rods are installed On the upper end of the support frame, the other end of the connecting rod is connected to the funnel device, and the connecting rod is designed to surround the funnel device; the funnel device is in the shape of a funnel, and the cross-sectional area of the bottom of the funnel device is equal to the cross-sectional area of the rocket body. The rocket flies back to the sky above the rocket recovery platform, and then lands at the middle of the funnel device. During the landing process, because the upper opening of the funnel device is larger than the rocket, the rocket can easily pass through the funnel device until it reaches the lower end of the rocket. Touching the ground, the rocket completes its descent. The structure and principle of the present invention are very simple, and can be applied to sea and land, and the present invention also well solves the problem that the rocket is easy to fall and cause explosion during the early recovery process.

Owner:FOSHAN SHENHANG SCI & TECH CO LTD

Industrial rubber glove hot melting and recycling equipment

InactiveCN110450311AHigh degree of automationImprove recycling efficiencyPlastic recyclingHot meltSlide plate

The invention discloses industrial rubber glove hot melting and recycling equipment. The industrial rubber glove hot melting and recycling equipment comprises a base, a cleaning cavity with an upwardopening is formed in the base, and clear water is added into the cleaning cavity; a machine body is fixed to the top face of the base, and a melting cavity with a downward opening is formed in the machine body; and a sliding plate is slidably arranged in the cleaning cavity. According to the industrial rubber glove hot melting and recycling equipment, cleaned industrial rubber gloves can be heatedto form liquid rubber and then recycled, the overall automation degree of the equipment is high, and reaction is sensitive; meanwhile, the equipment conducts cleaning before recycling is conducted, the recycled liquid rubber is clean and has no impurities, standing is conducted before heating is conducted so as to remove most water on the industrial rubber gloves, the time needed by subsequent heating and melting is short, and the recycling efficiency is high; and in addition, when heating is conducted, new industrial rubber gloves can be immediately installed on the equipment, therefore, theinterval time between the two steps of heating and cleaning is greatly shortened, equipment operation is simple and clear, and the recycling efficiency is high.

Owner:绍兴上虞信道环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com