Fine sand recovery device

A recovery device and fine sand technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of coarse fineness modulus of finished sand and low stone powder content, and achieve the solution of coarse fineness modulus , the effect of reducing the amount of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

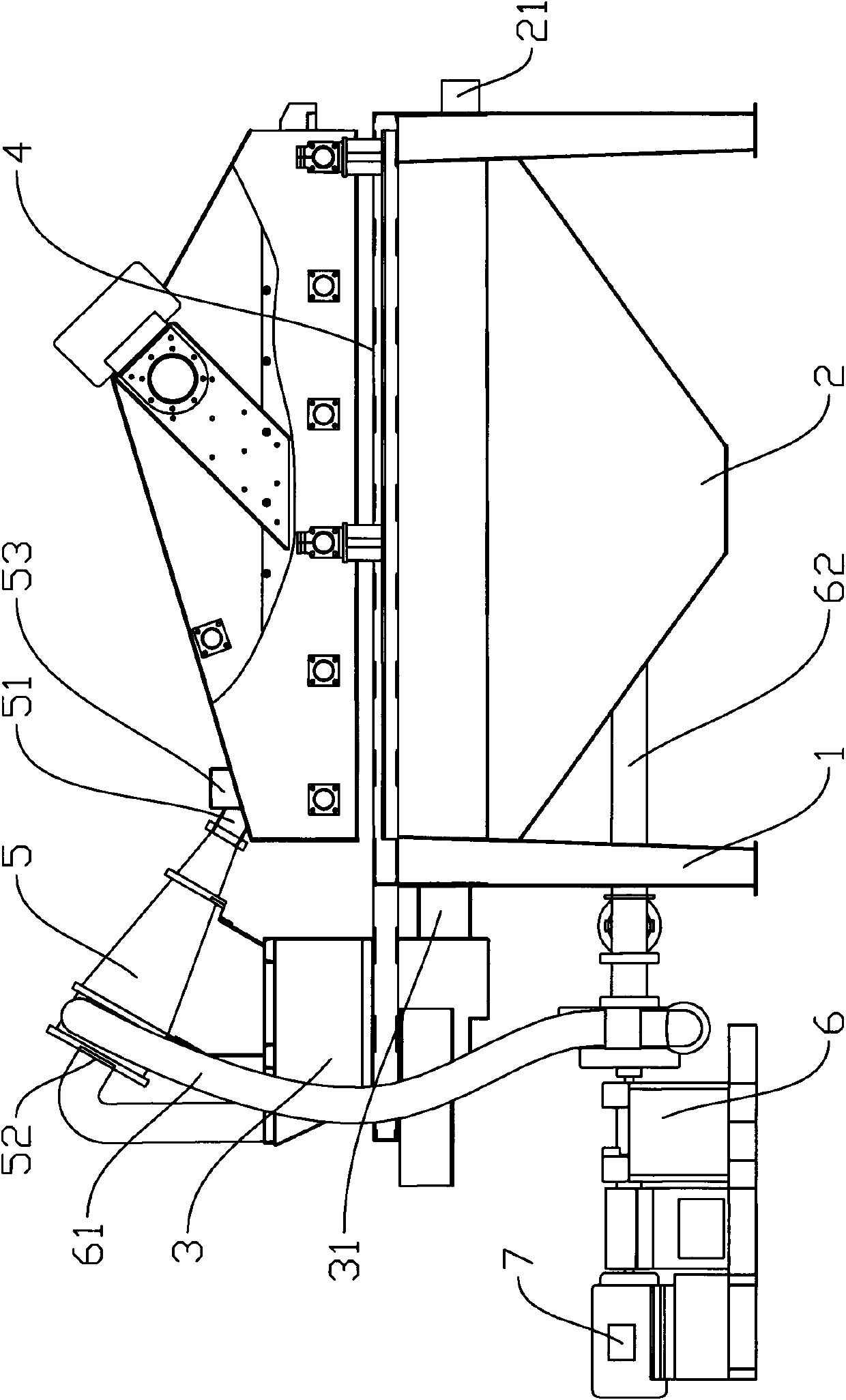

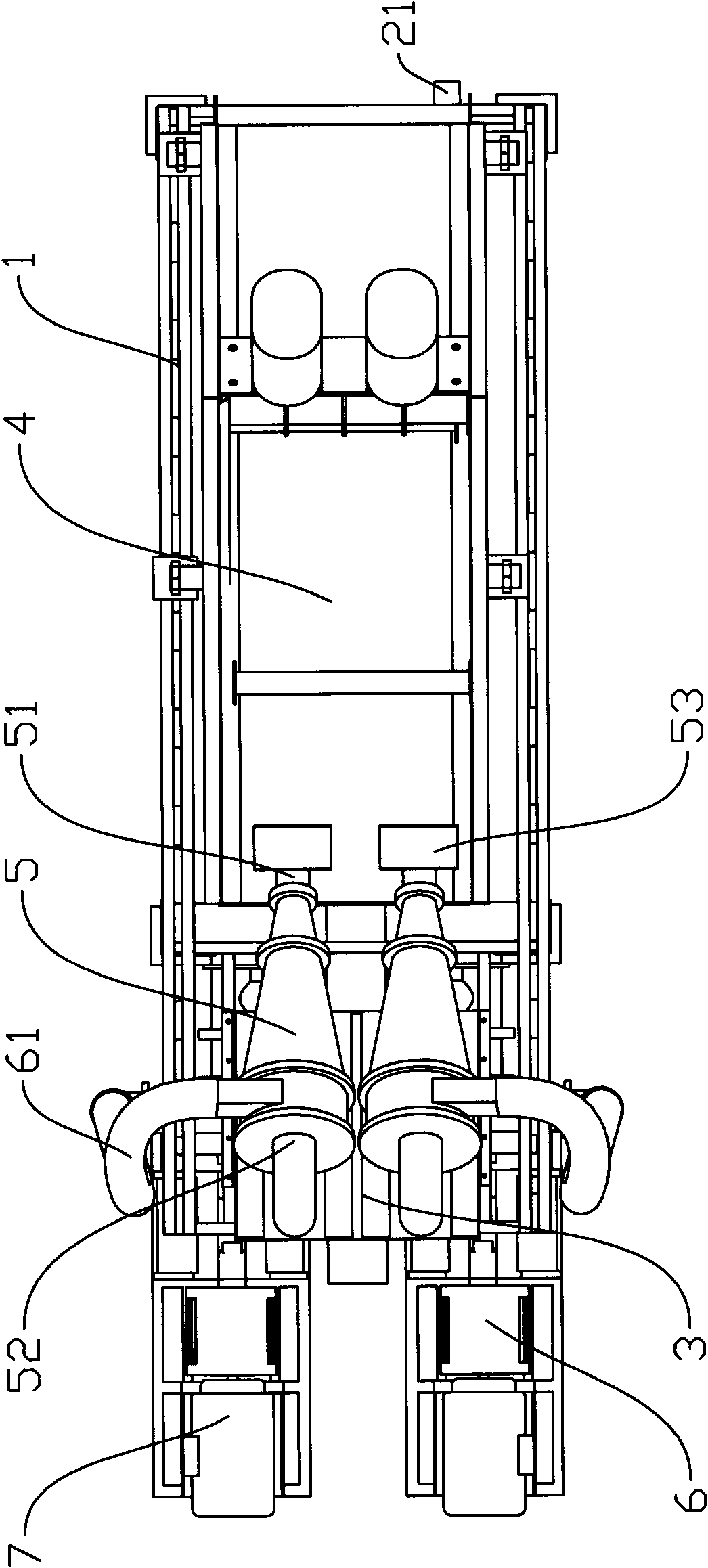

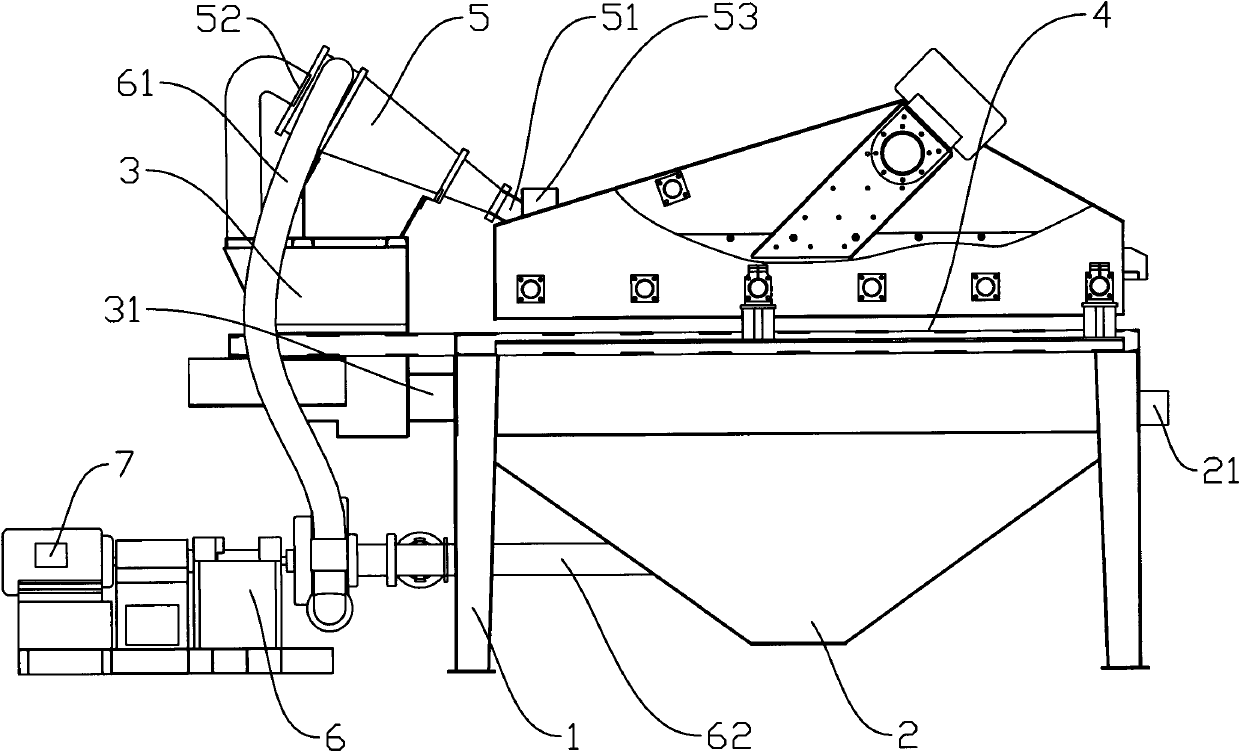

[0016] Such as Figures 1 to 2 Shown is a schematic structural view of an embodiment of the present invention, a fine sand recovery device, including a support 1, and a storage tank 2 that is respectively arranged on the support to store sewage and a return tank 3 that stores mortar after centrifugal classification. The upper part of the material box is provided with an overflow port 21, and the return material box is provided with a drainage pipe 31 to communicate with the material storage box. , the water inlet end is higher than the water outlet end; a sand-water separation device 4 is arranged above the material storage box, a cyclone 5 is arranged on the return material box, and the front end outlet 51 of the cyclone is arranged above the sand-water separation device, and the cyclone The rear end outlet 52 communicates with the return material box, and a polyurethane lining is provided inside the cyclone; a slurry machine 6 for conveying mortar is also provided below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com