Method and device for recycling rubber from waste radial tire

A radial tire and rubber recycling technology, applied in the field of reclaimed rubber processing equipment, can solve the problem of the efficiency of steel wire not being able to be completely removed, and achieve the effect of small footprint, simple structure and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

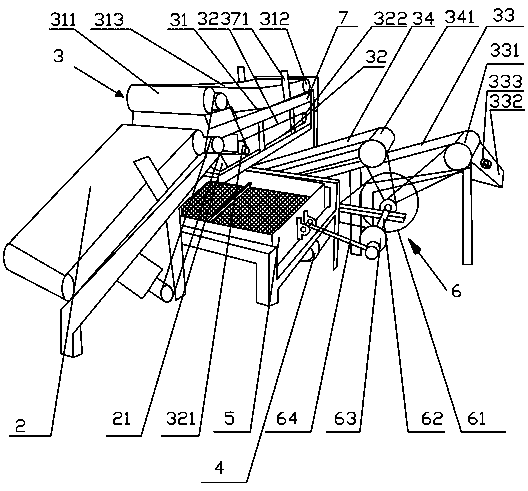

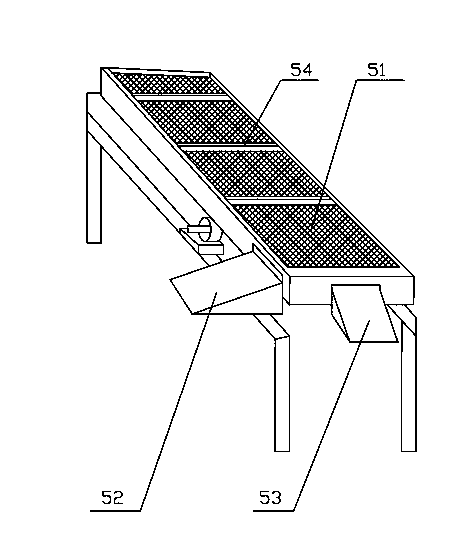

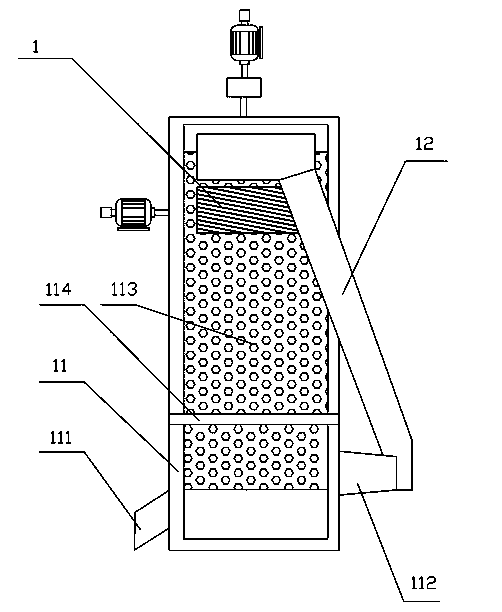

[0018] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0019] Depend on figure 1 combine figure 2 , 3 As shown, a device for recovering rubber from waste radial tires includes a frame 7, a rubber cutter, a rubber pulverizer 1, a feeding device 2, a multi-stage separation device 3 and a driving device 4. Radial tires are crushed, cut into strips, and then cut into block rubber. The rubber cutting machine is a prior art, and will not be described in detail here. The rubber pulverizer is to process block rubber into powder. The rubber pulverizer 1 is provided with a vibrating sieve 11, and the vibrating sieve 11 is provided with a first vibrating sieve outlet 111, a second vibrating sieve outlet 112 connected with the rubber pulverizer conveyor belt 12, The vibrating screen 113 and the gantry 114, the vibrating sieve 11 is driven by the gantry and the drive motor to separate block rubber and powdered rubber th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com