New energy automobile power battery pack shell stamping device

A technology for power battery packs and new energy vehicles, applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve problems such as mold damage, burrs, clamping and demoulding, and easy deformation, so as to prevent deviation and reduce burrs , the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

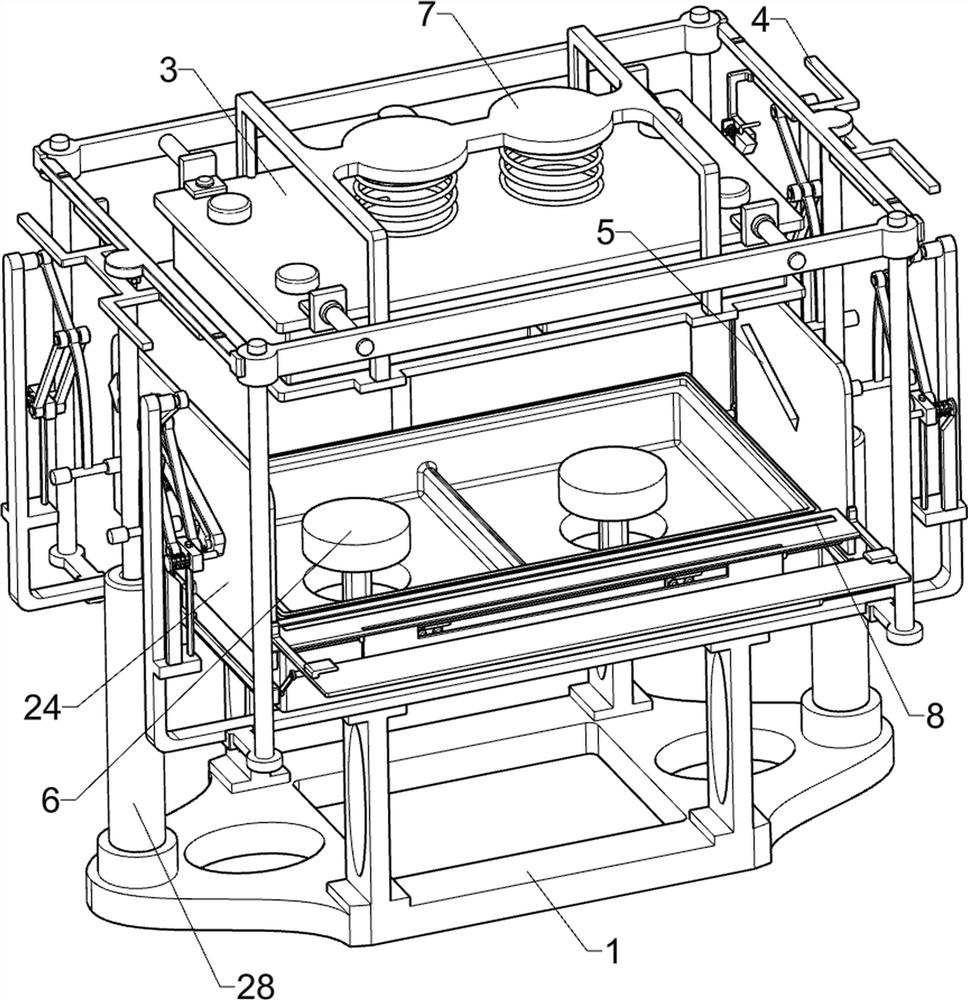

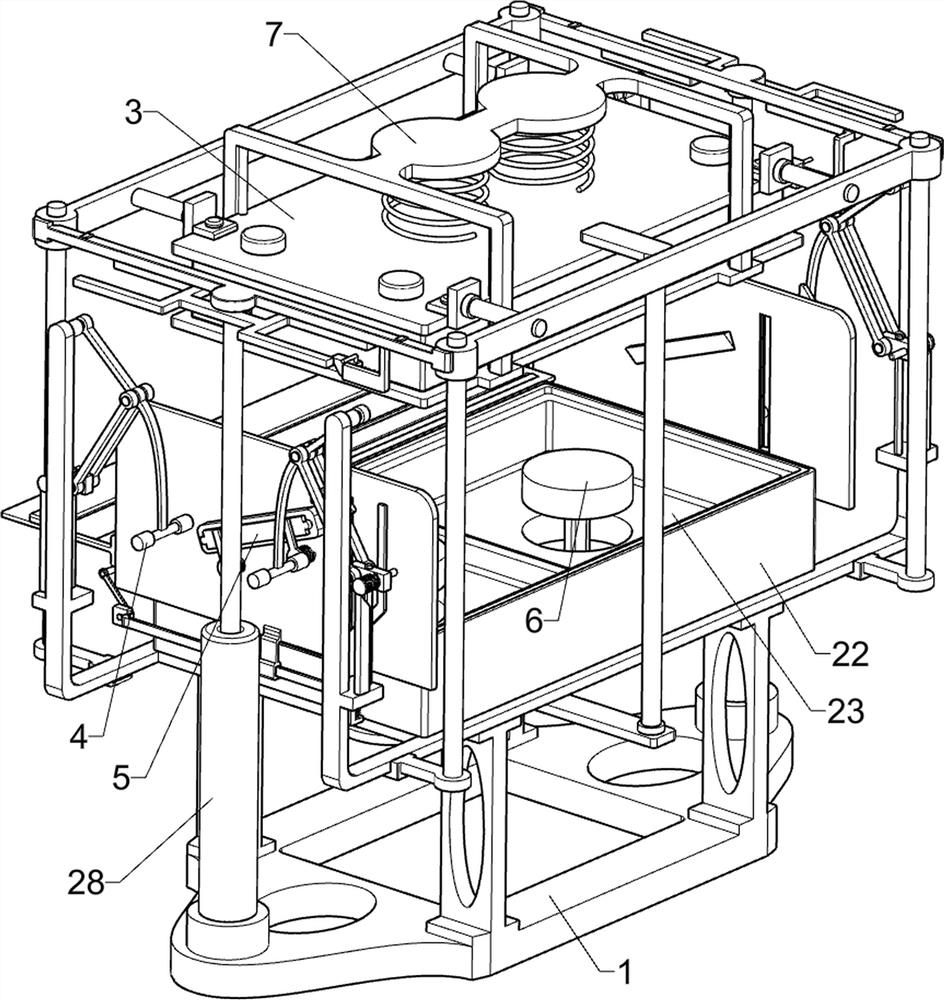

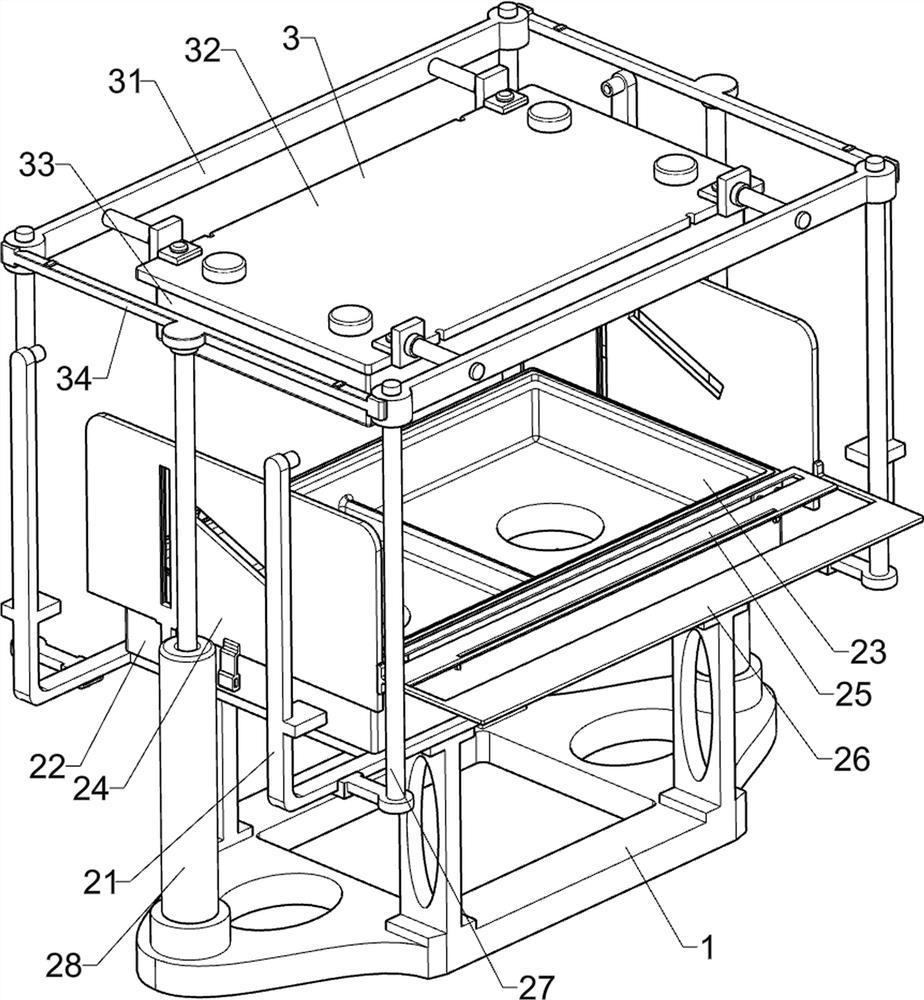

[0043] New energy vehicle power battery pack shell stamping device, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, it includes a support base 1, a special-shaped support frame 21, a mold support frame 22, a lower mold frame 23, a slotted limit plate 24, a slotted support plate 25, a U-shaped support plate 26, a limit sleeve rod 27, and a cylinder 28. Lifting component 3 and stamping component 4, the top of the support base 1 is fixedly connected with a special-shaped support frame 21, the top of the special-shaped support frame 21 is fixed with a mold support frame 22, and the inside of the mold support frame 22 is fixed with a lower mold frame 23. The left and right sides of the support frame 22 are fixedly connected with a slotted stop plate 24, the front side of the mold support frame 22 is fixedly connected with a slotted support plate 25, and the slotted support plate 25 is fixedly connected with the slotted limit ...

Embodiment 2

[0048] On the basis of Example 1, such as Figure 8 , Figure 9 , Figure 10 , Figure 11 with Figure 12 As shown, it also includes a leftover material separation assembly 5, which is used to separate the leftover material of the steel plate. Rod 53, transmission wedge frame 54, wedge-shaped slant plate 55, return spring 56, sliding clamp block 57, reciprocating spring 58, L-shaped support frame 59, wedge-shaped push block 510, return spring 511 and return frame 512, slotted support The plate 25 is slidably connected with a baffle frame 51, the baffle frame 51 is used to temporarily block the leftovers of the steel plate, a pair of tension springs 52 are connected between the baffle frame 51 and the slotted support plate 25, and the baffle frame 51 rotates A pair of swinging rods 53 are connected in the same way, and a drive wedge frame 54 is slidingly connected under the slotted limit plate 24. The drive wedge frame 54 is located on the side where the two slotted limit p...

Embodiment 3

[0051] On the basis of Example 2, such as Figure 13 with Figure 14 As shown, the demoulding assembly 6 is also included, and the demoulding assembly 6 for demoulding the stamped power battery casing is arranged on the mold support frame 22. The demoulding assembly 6 includes a push-out frame 61, a T-shaped Frame 62, compression spring 63 and second push rod 64, a pair of push-out frames 61 for pushing out the punched power battery case are slidably connected on the mold support frame 22, and a T-shaped frame is fixedly connected between the two push-out frames 61. Frame 62, T-shaped frame 62 is positioned at below mold support frame 22, is connected with a pair of compression springs 63 for driving T-shaped frame 62 and its upper device to move downwards between T-shaped frame 62 and mold support frame 22, T-shaped frame 62 top is fixedly connected with a second push rod 64, the second push rod 64 is located at the rear side of the mold support frame 22, and the second push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com