A stamping equipment for panoramic sunroof beam mold

A technology of stamping equipment and panoramic sunroof, which is applied in the field of stamping equipment, can solve the problems of declining product competitiveness, increased production cost of sunroof beams, troubles, etc., to improve the stamping pressure and stamping speed, facilitate finishing and later maintenance, and complicate the mechanism structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

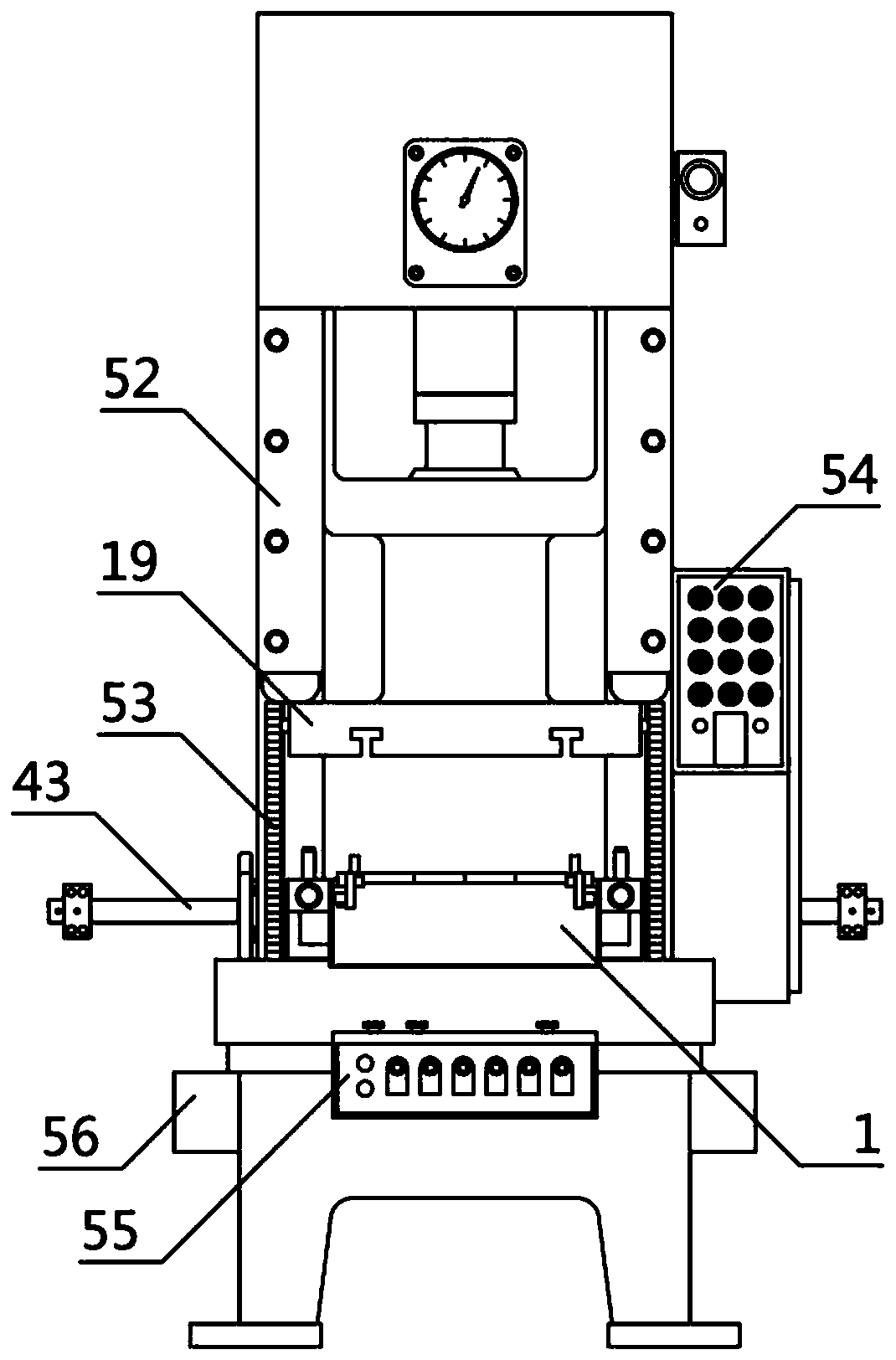

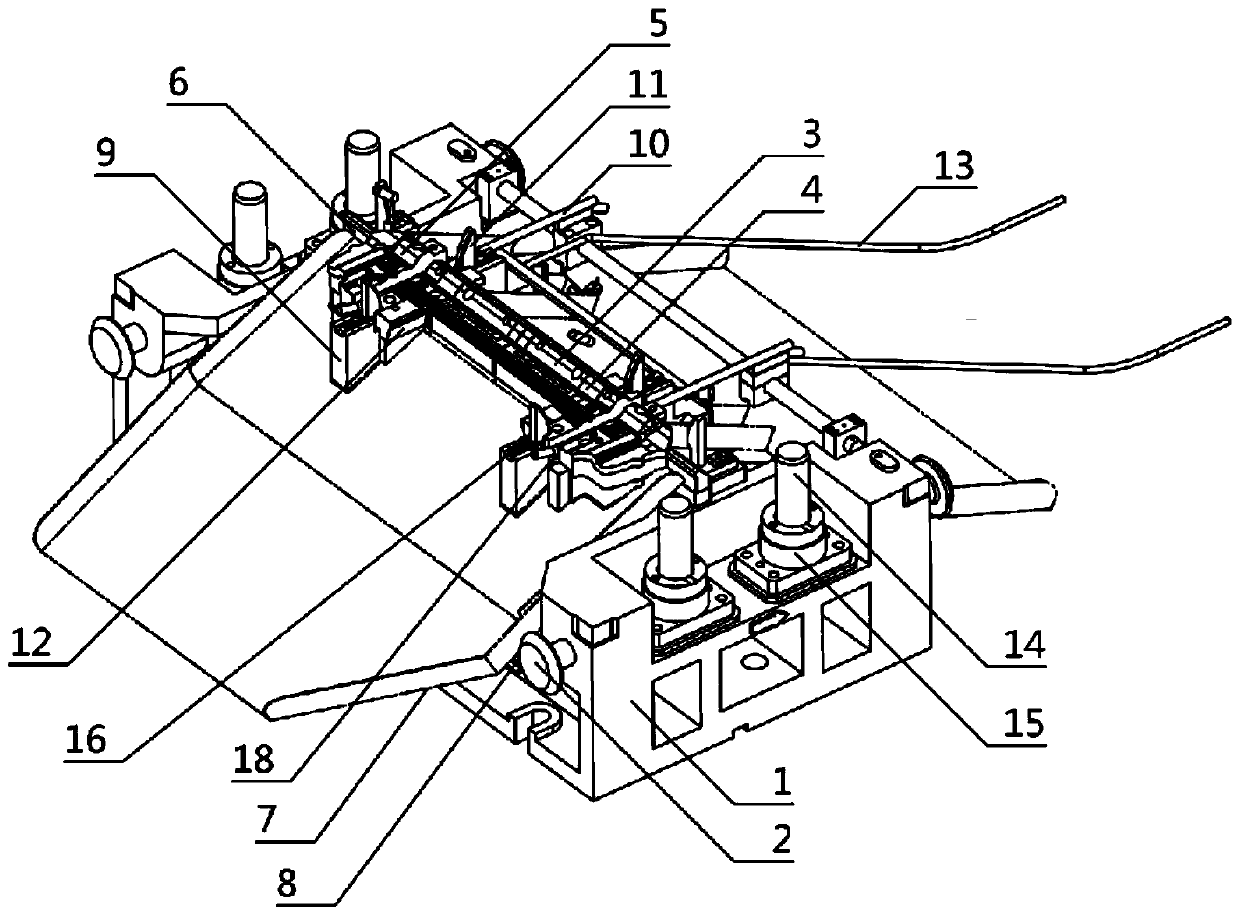

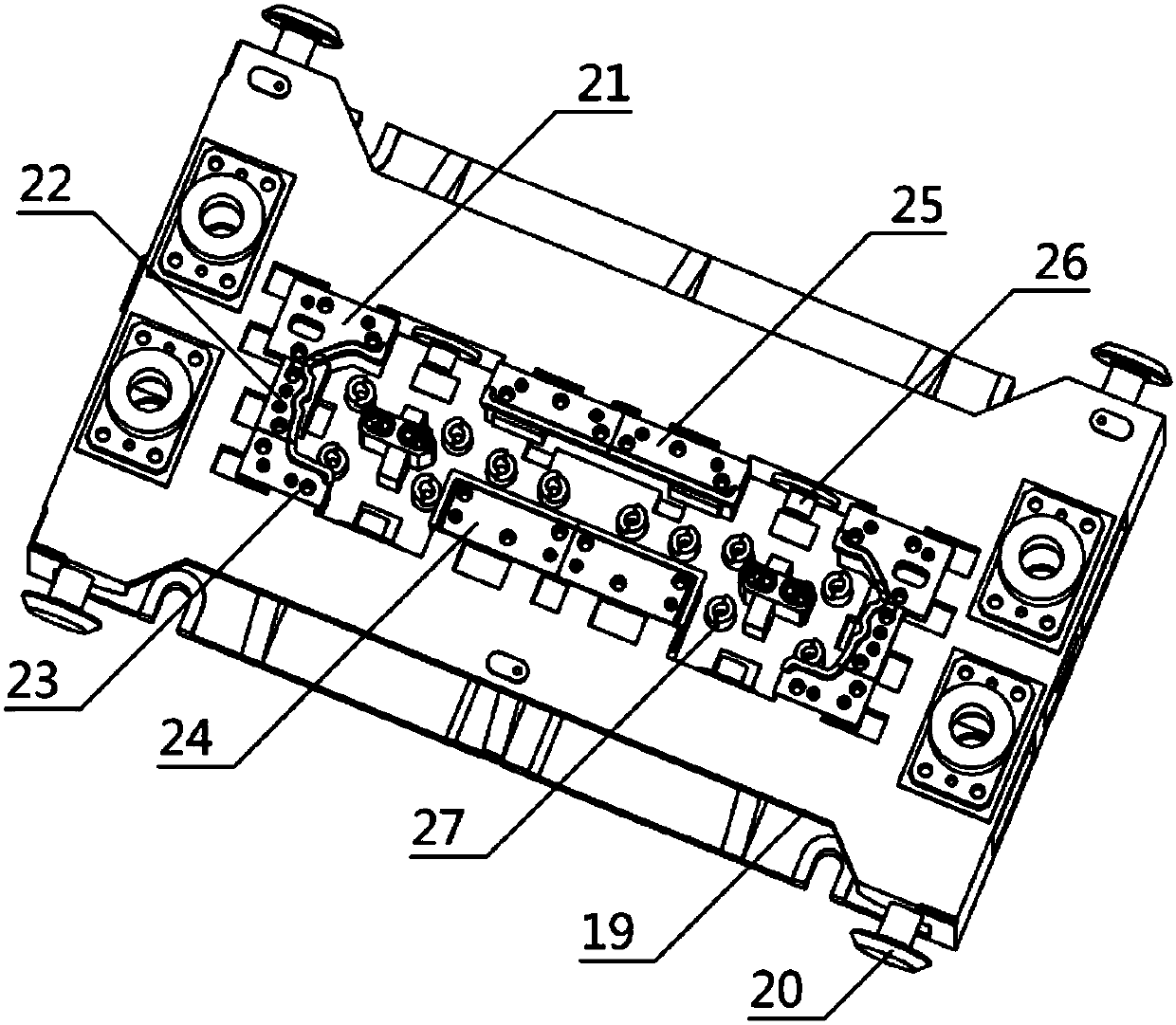

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7Shown is a stamping device for a panorama sunroof beam mold, which is characterized in that it includes a lower mold body 1, an upper mold body 19, a pressing core 28, a single air path system 32, a bracket 43 and a stamping device 52. The lower die body 1, the upper die body 19 and the pressing core 28 are all located inside the punching device 52, the lower die body 1 and the upper die body 19 are fixedly connected to the punching device 52, and the lower die body 1 is located The lower part of the upper die body 19, the lower die body 1 is movably connected with the upper die body 19, and the binder core 28 is positioned at the inside of the lower die body 1, and the binder core 28 and the lower die body 1 are fixed connected, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com