Patents

Literature

510results about How to "Stable handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubber composition containing resinous nanoparticle

InactiveUS7347237B2Deteriorate controllabilityDeteriorate stabilitySpecial tyresInflatable tyresElastomerEngineering

Owner:THE GOODYEAR TIRE & RUBBER CO

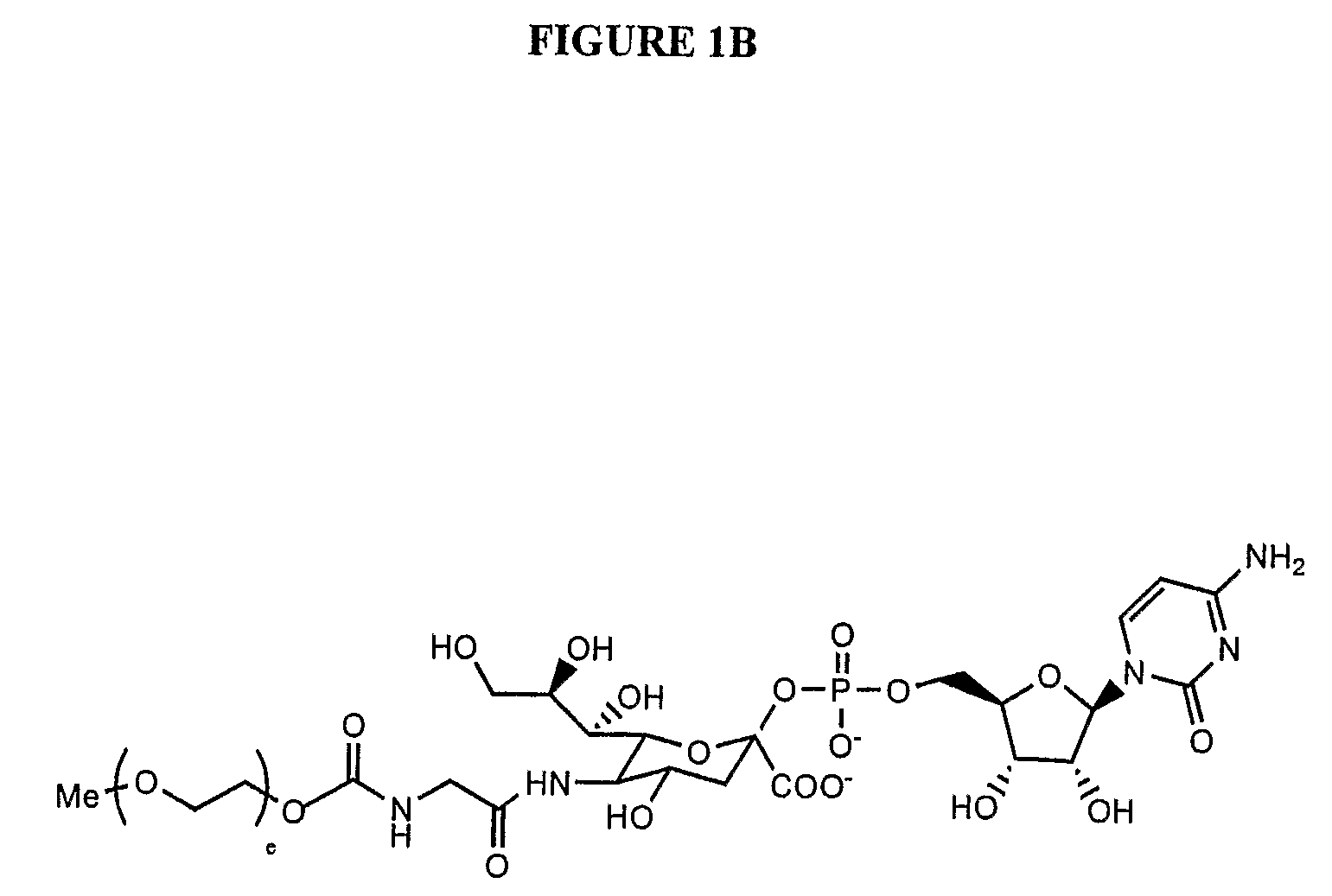

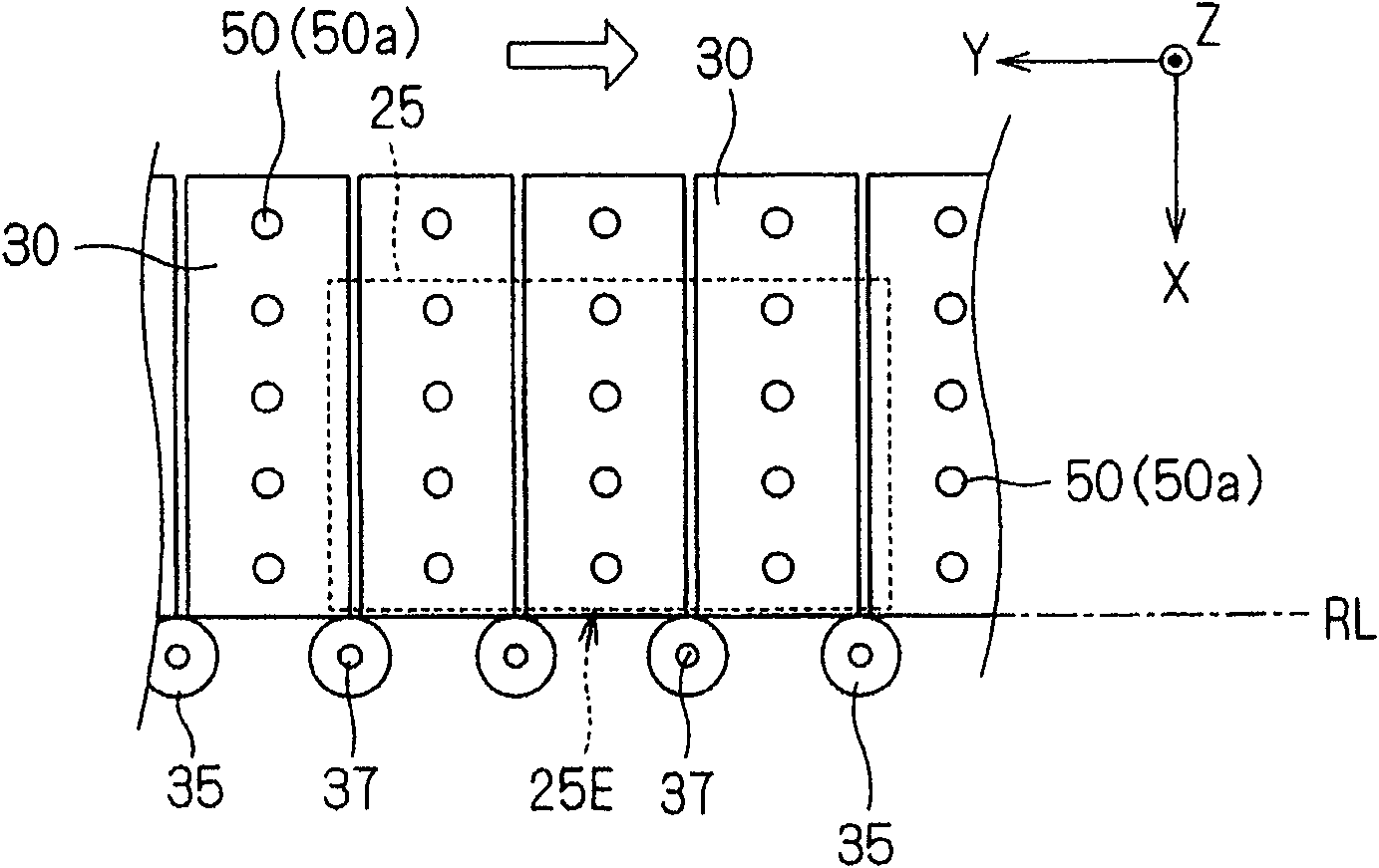

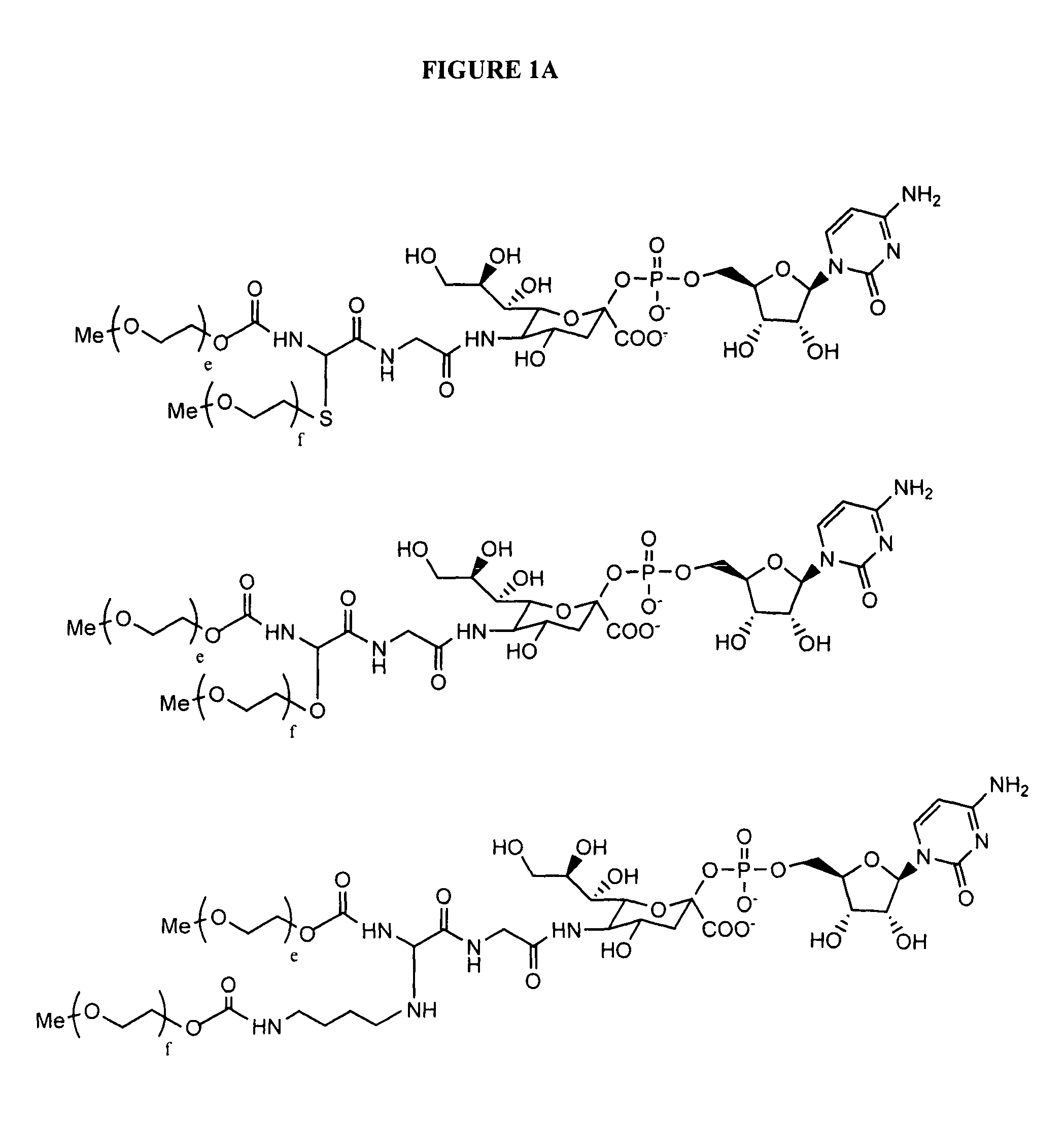

Glycopegylated erythropoietin formulations

InactiveUS20060287224A1Improved pharmacokinetic propertiesCost effectiveOrganic active ingredientsBiocideDiseasePharmaceutical formulation

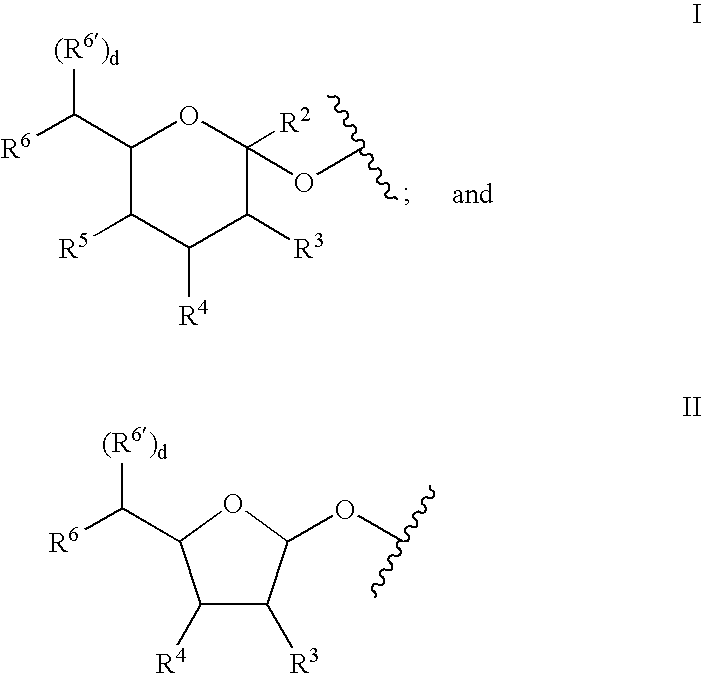

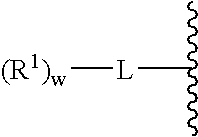

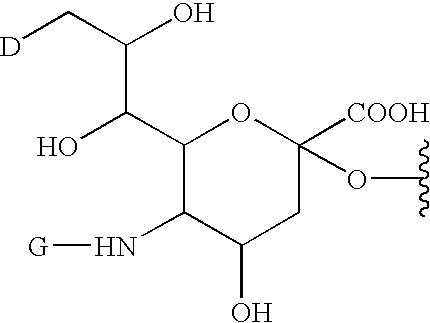

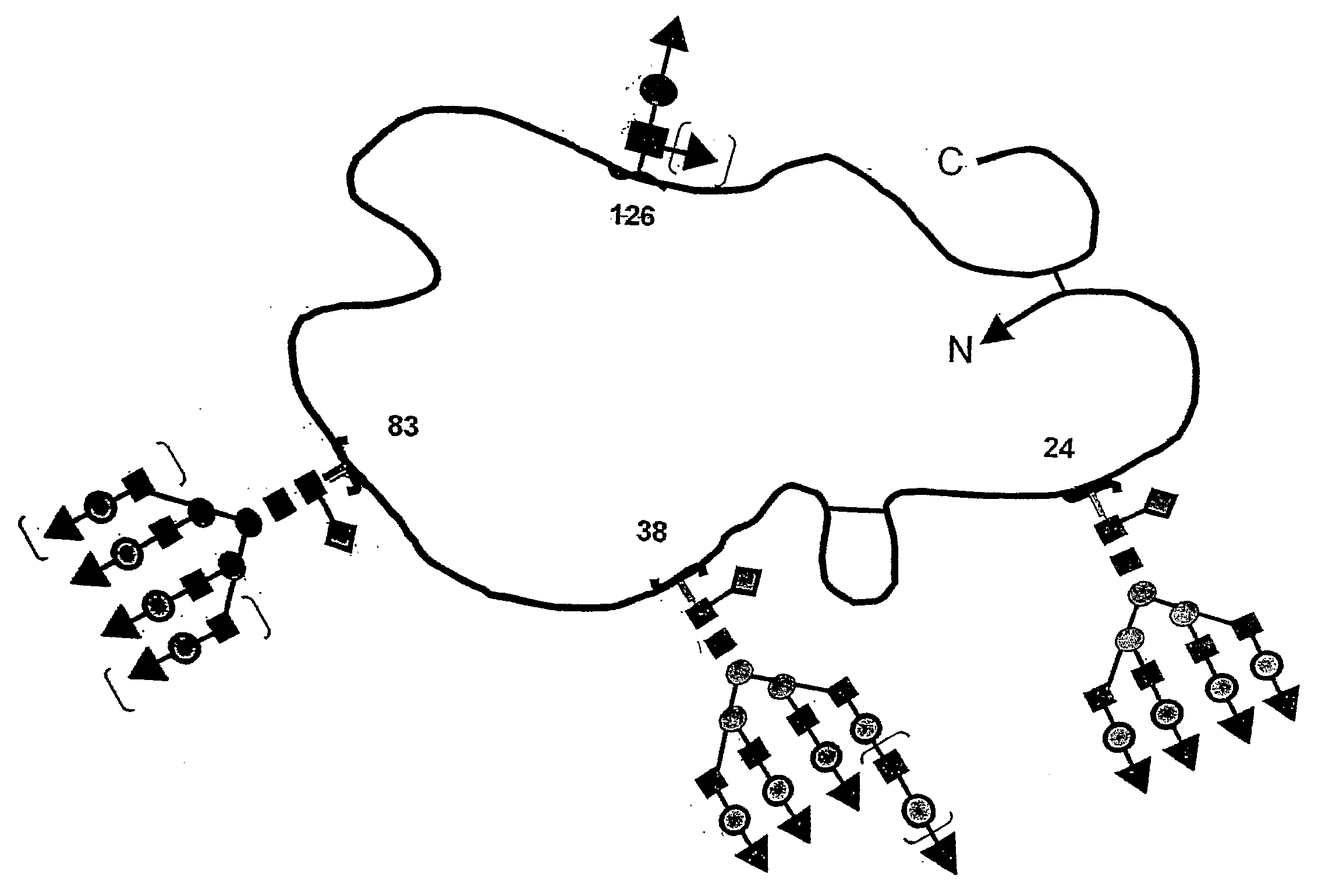

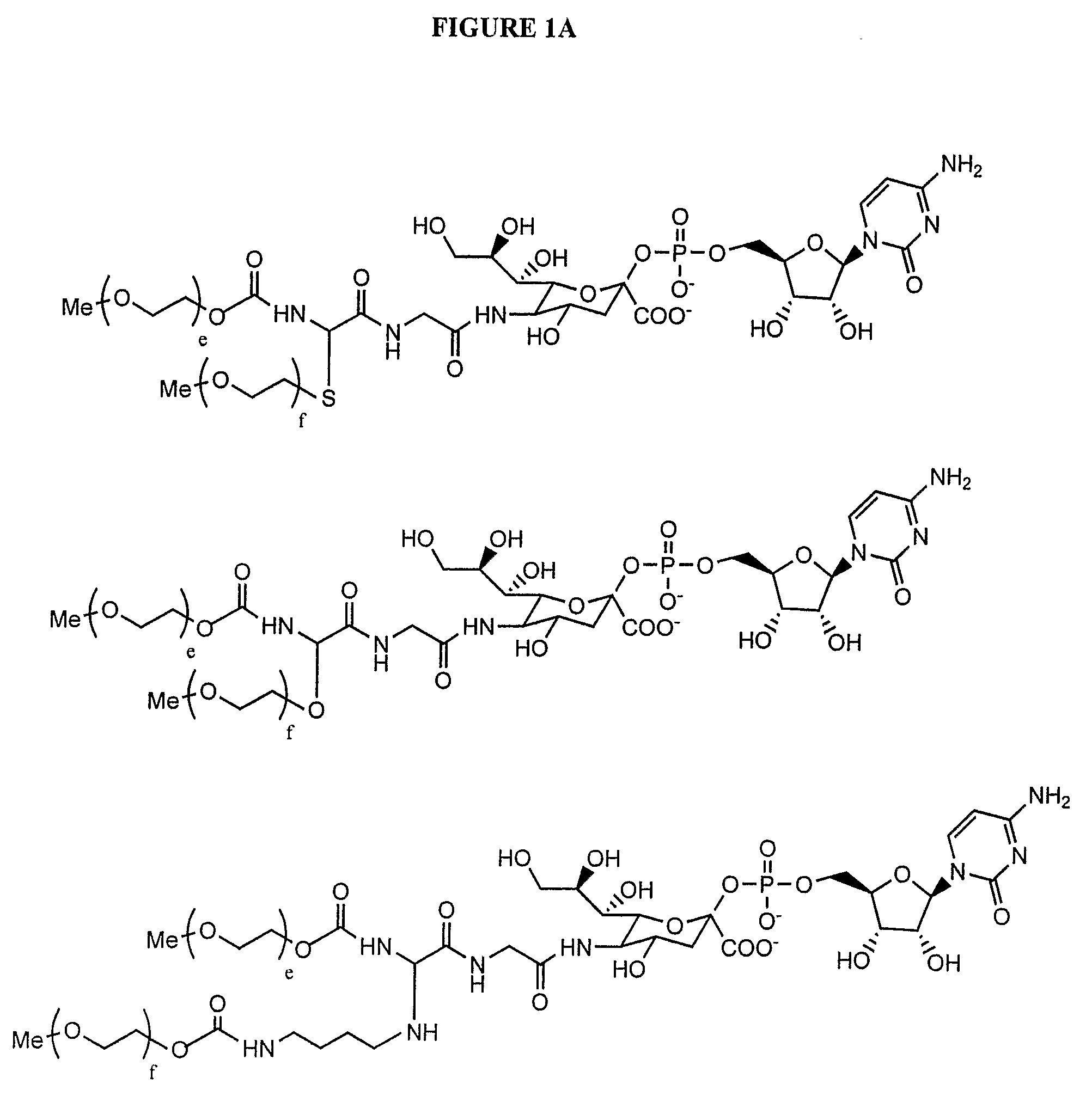

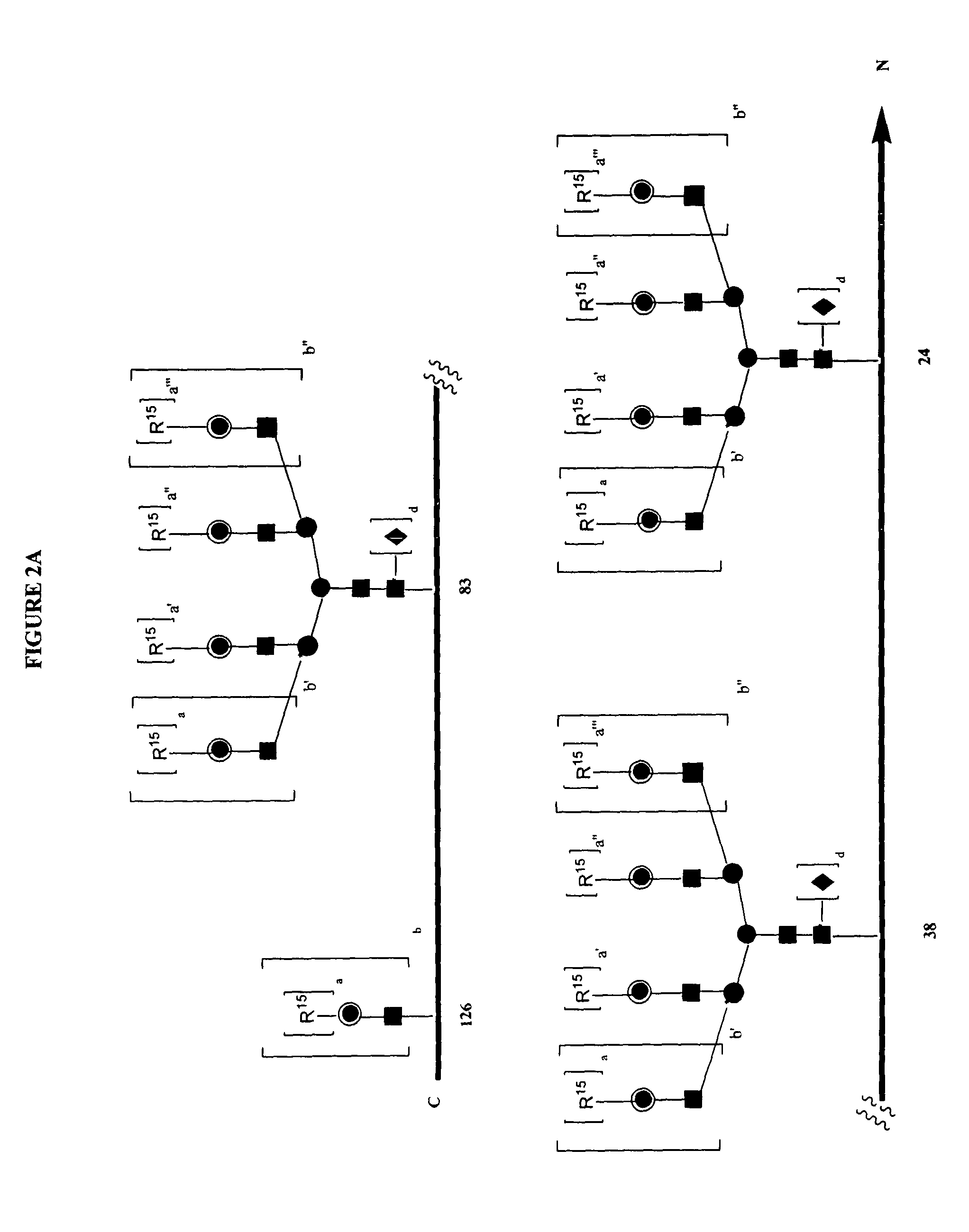

The present invention provides conjugates between erythropoietin and PEG moieties. The conjugates are linked via an intact glycosyl linking group interposed between and covalently attached to the peptide and the modifying group. The conjugates are formed from glycosylated peptides by the action of a glycosyltransferase. The glycosyltransferase ligates a modified sugar moiety onto a glycosyl residue on the peptide. Also provided are methods for preparing the conjugates, methods for treating various disease conditions with the conjugates, and pharmaceutical formulations including the conjugates.

Owner:NOVO NORDISK AS

Glycopegylated Erythropoietin Formulations

InactiveUS20110003744A1Improved pharmacokinetic propertiesCost effectivePeptide/protein ingredientsPharmaceutical delivery mechanismDiseaseSugar moiety

The present invention provides conjugates between erythropoietin and PEG moieties. The conjugates are linked via an intact glycosyl linking group interposed between and covalently attached to the peptide and the modifying group. The conjugates are formed from glycosylated peptides by the action of a glycosyltransferase. The glycosyltransferase ligates a modified sugar moiety onto a glycosyl residue on the peptide. Also provided are methods for preparing the conjugates, methods for treating various disease conditions with the conjugates, and pharmaceutical formulations including the conjugates.

Owner:NOVO NORDISK AS

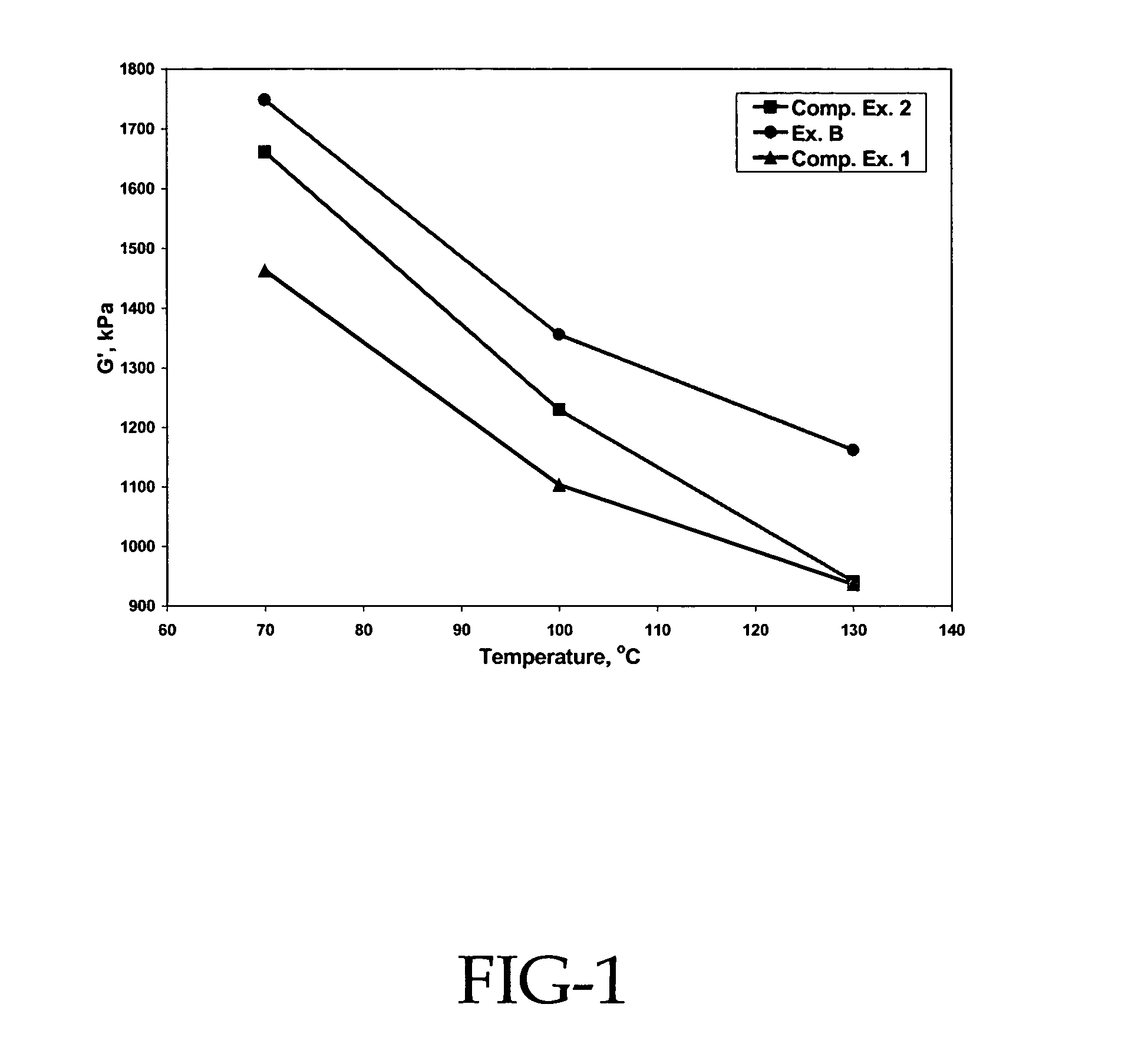

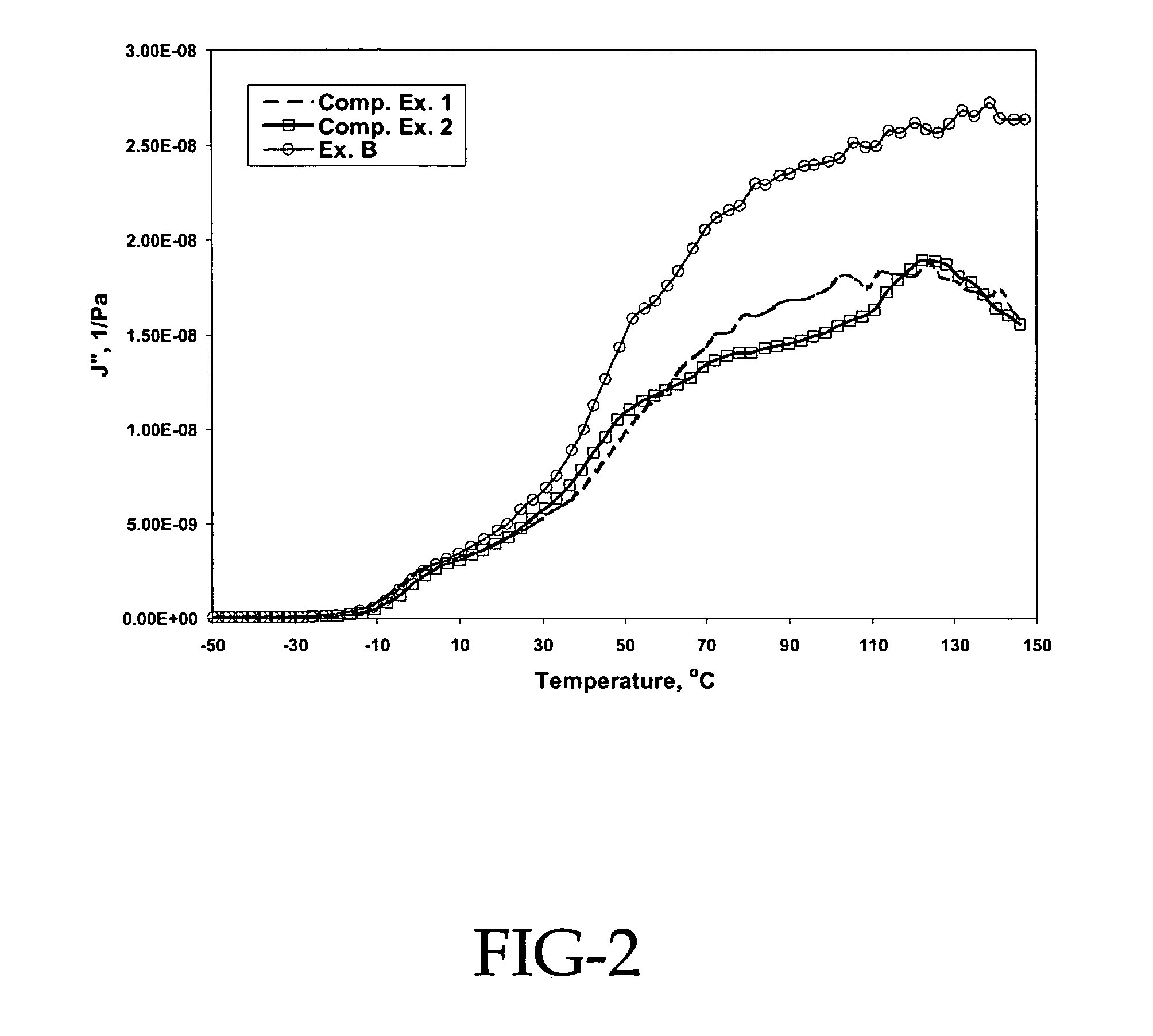

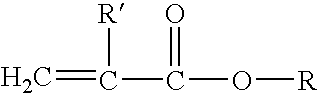

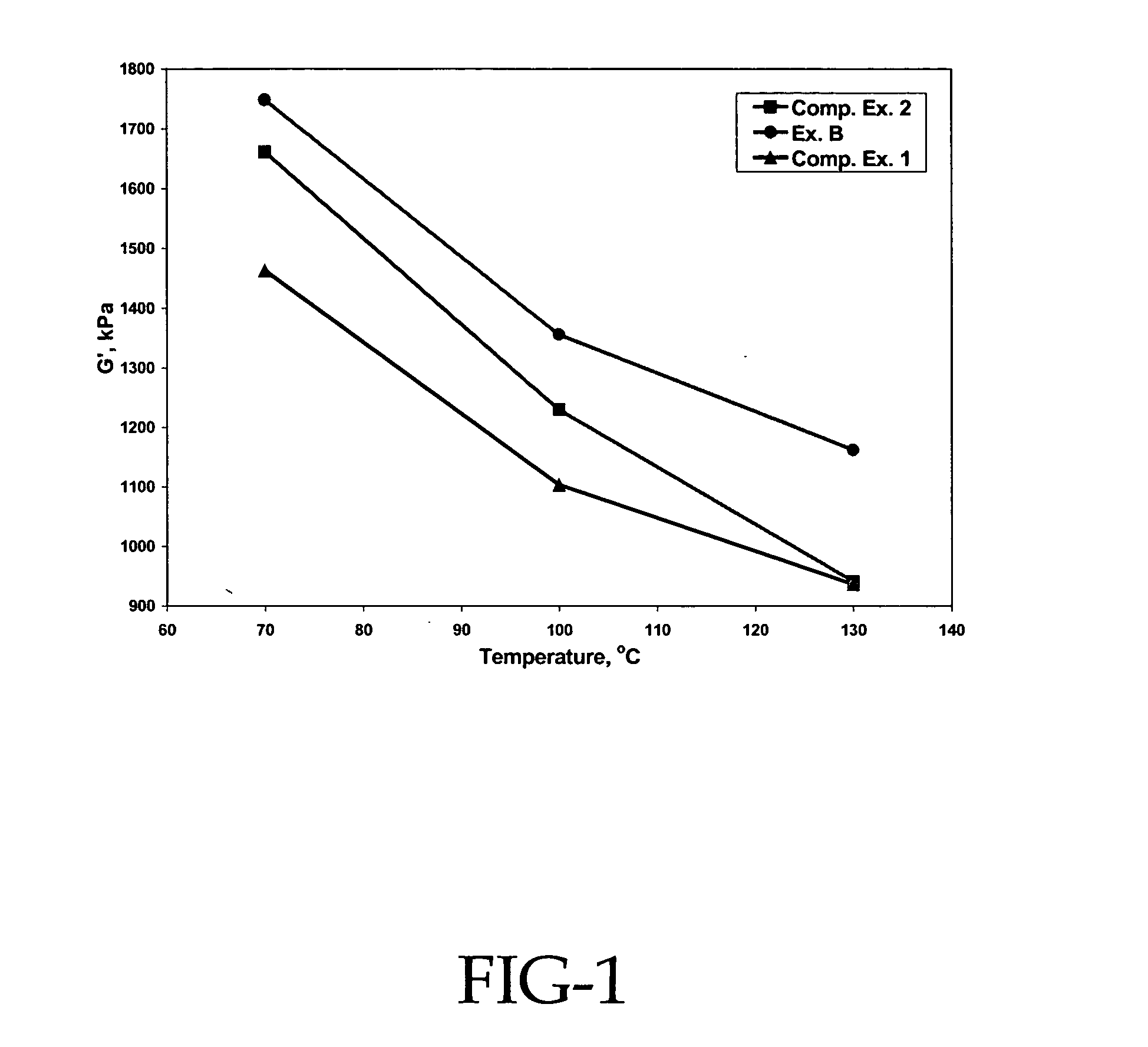

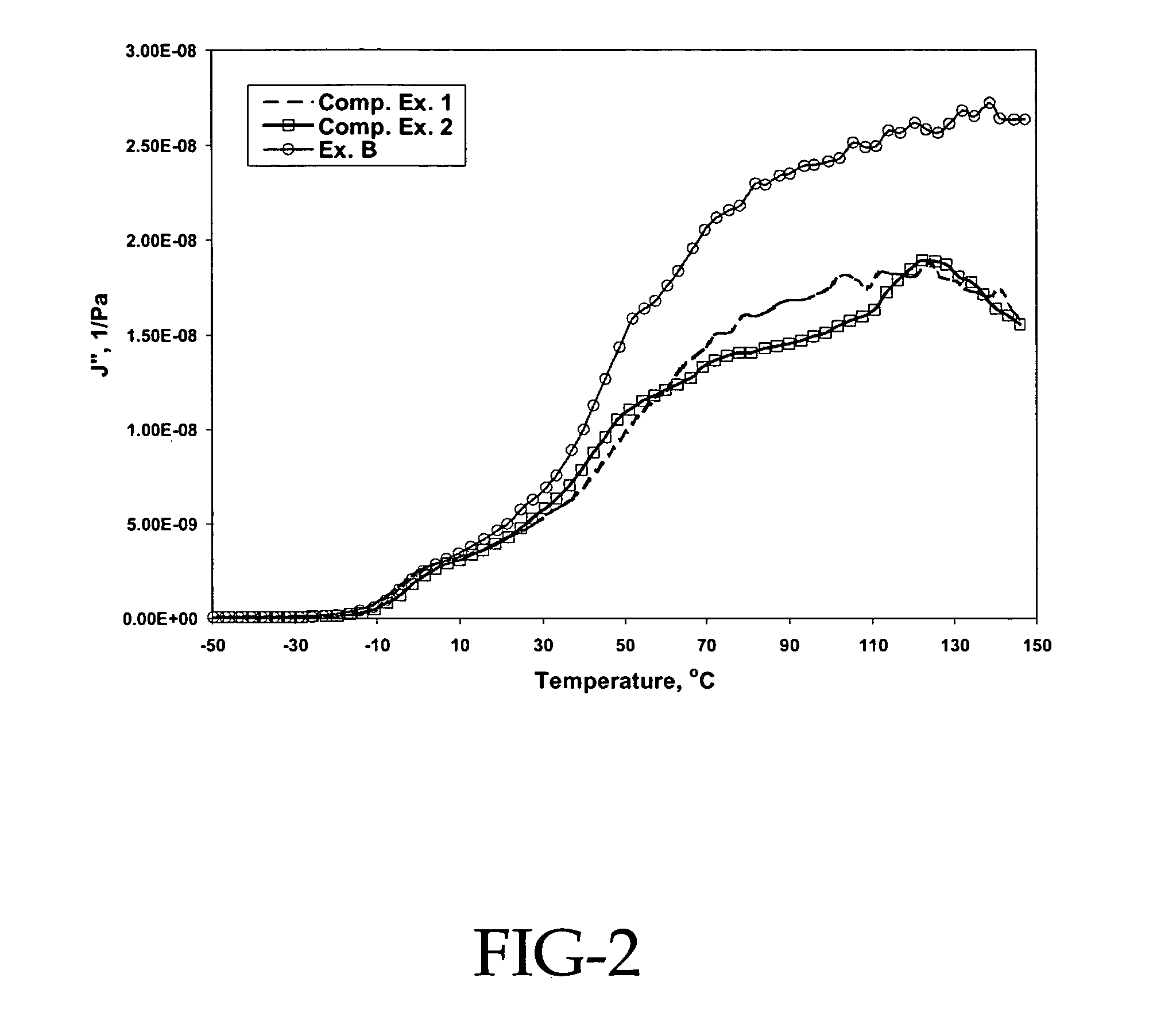

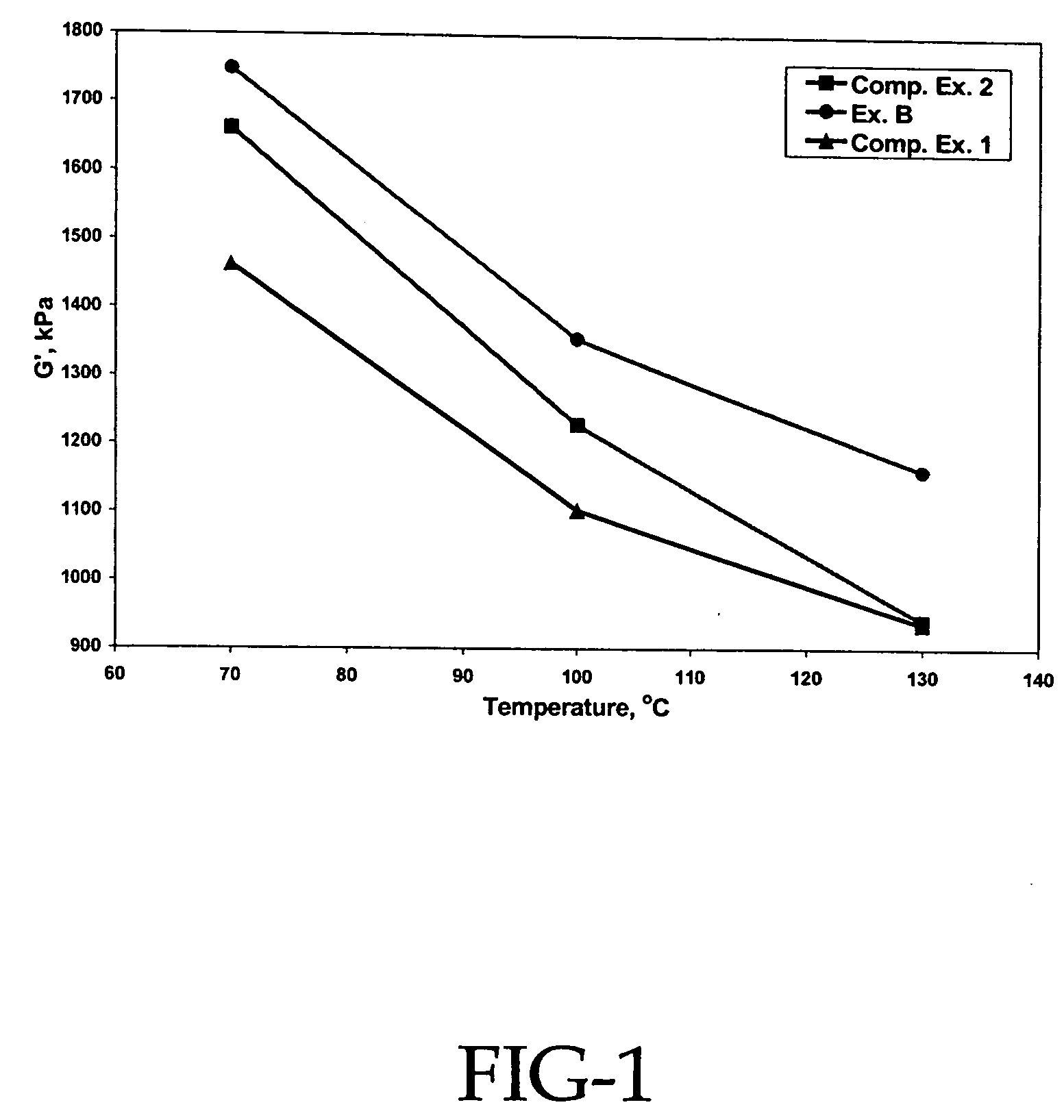

Rubber composition containing resinous nanopractice

InactiveUS7071246B2Deteriorate controllabilityDeteriorate stabilitySpecial tyresCoatingsElastomerPolymer science

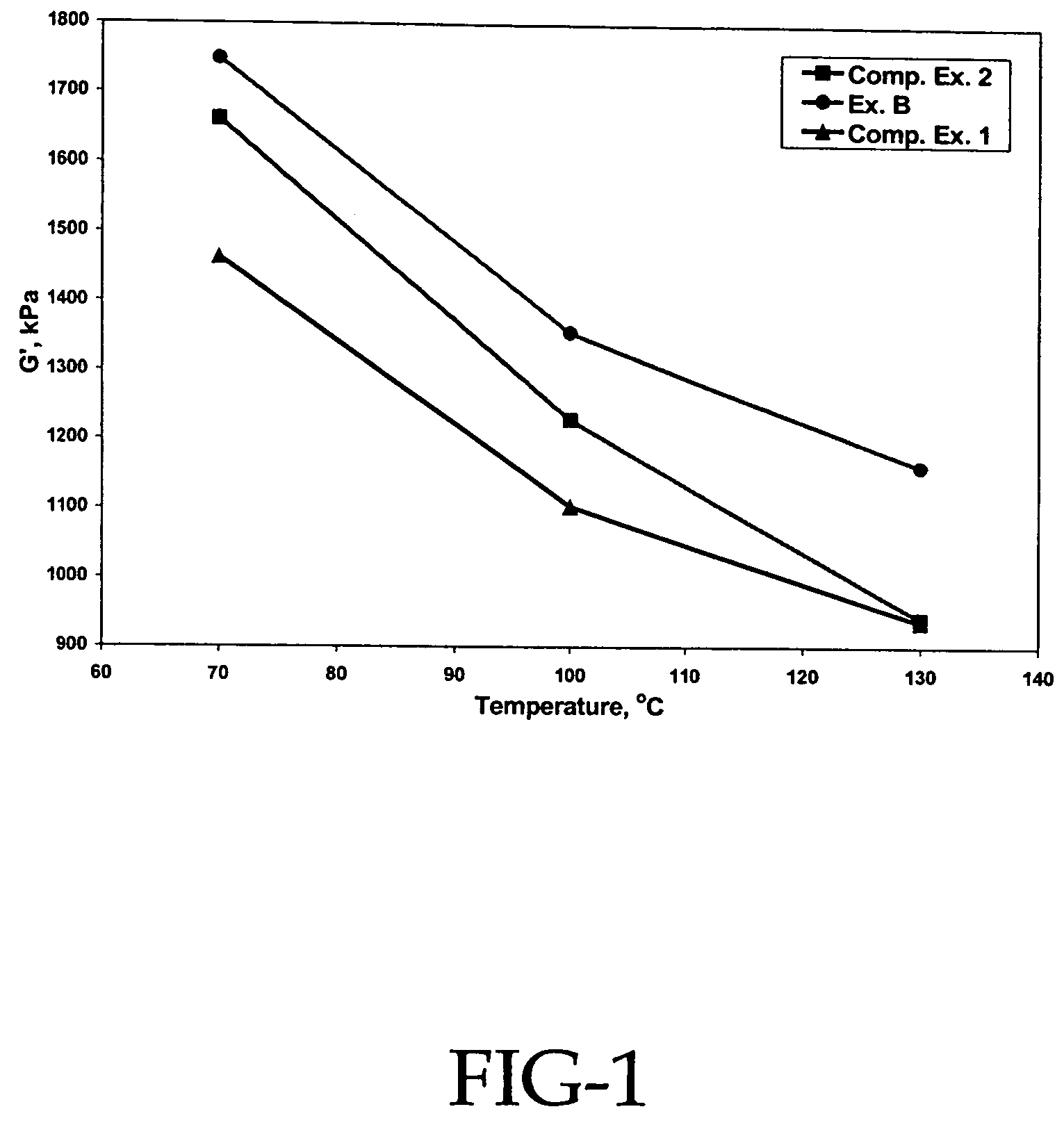

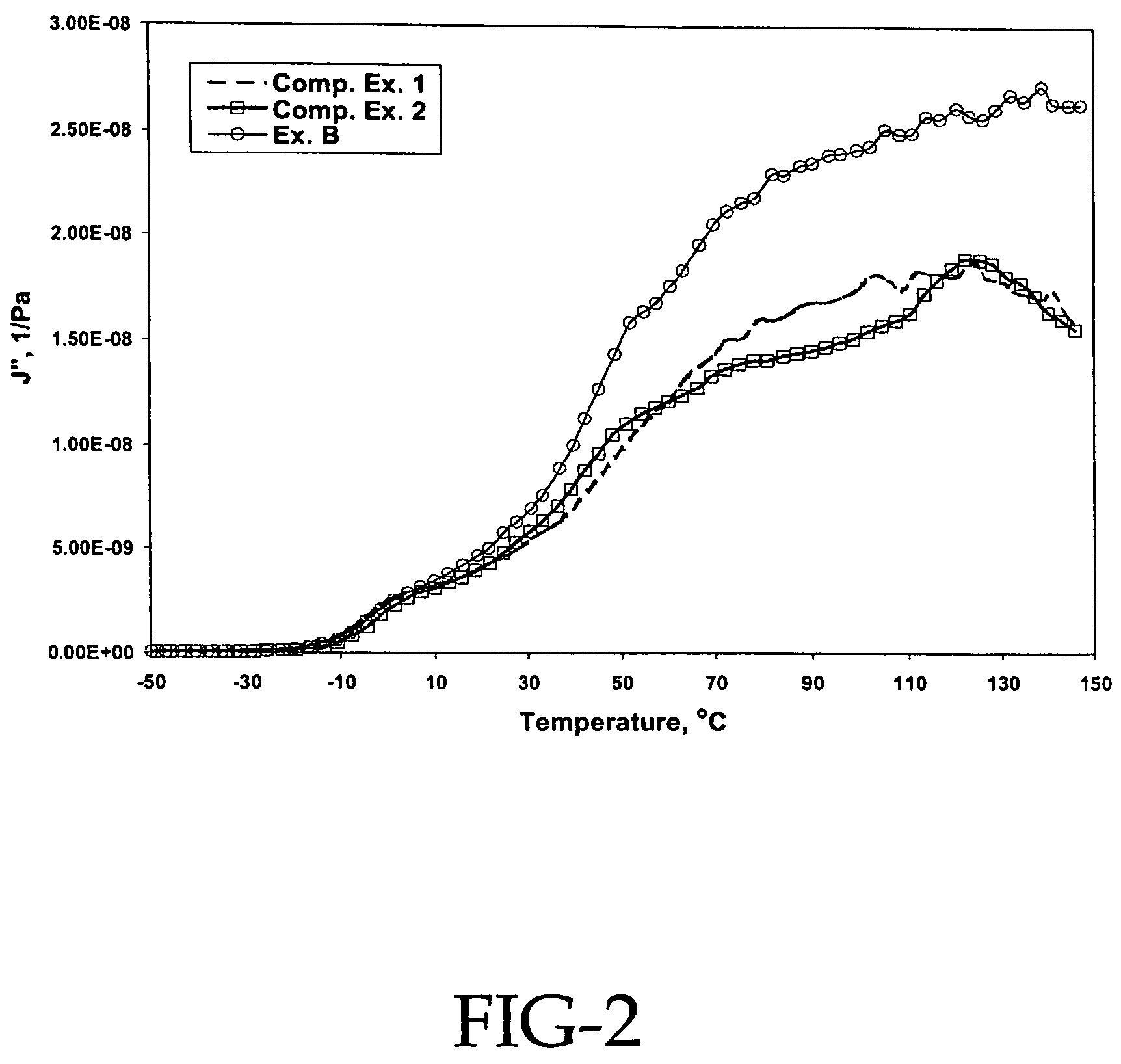

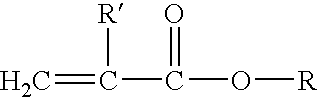

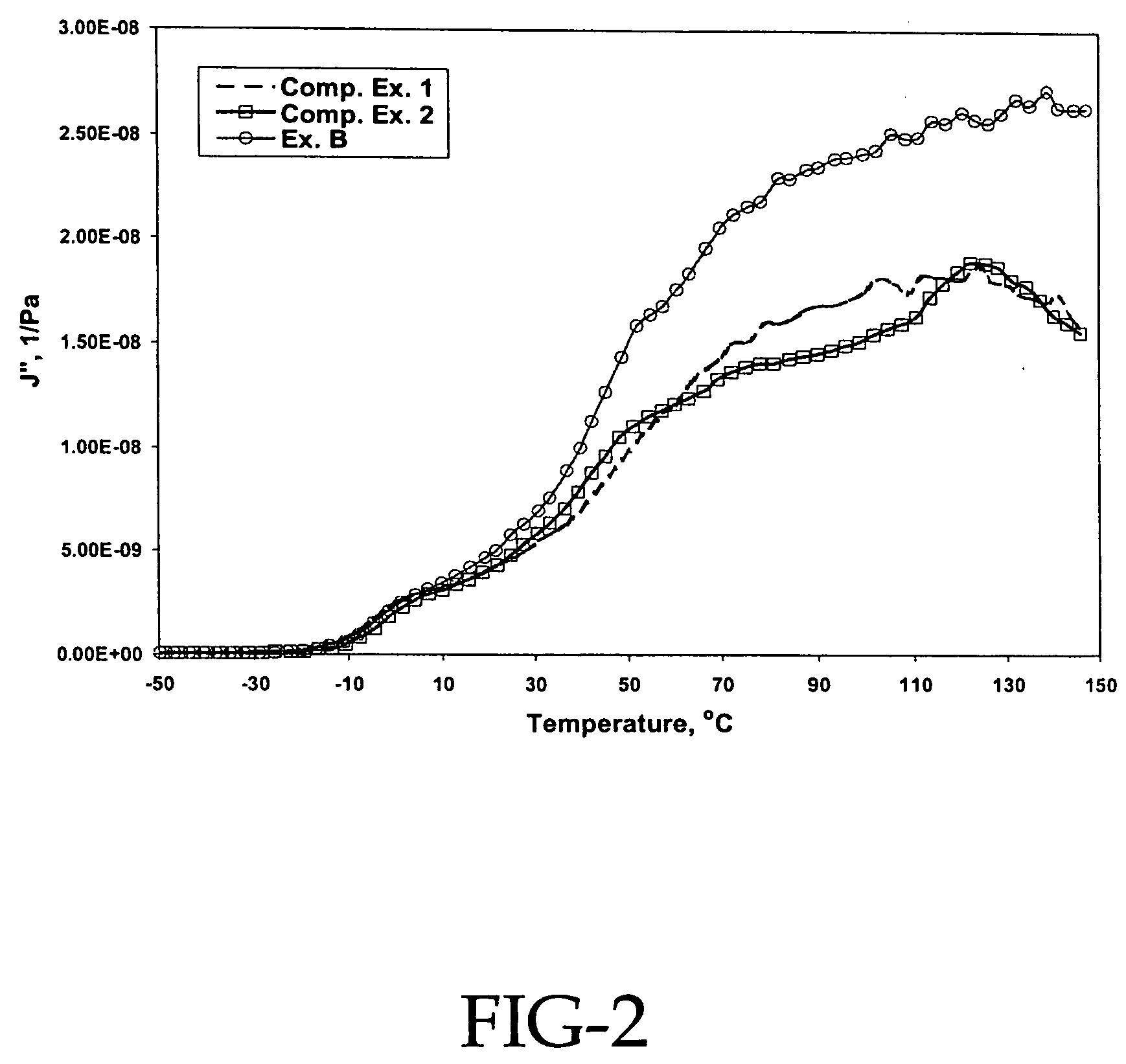

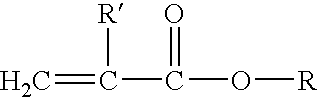

This invention relates to a tread rubber composition for tires with the addition of crosslinked resinous nanoparticles having a high glass transition temperature (Tg) into elastomeric base polymers. The invention demonstrates greatly improved handling performance without deteriorating controllability and stability during high-speed running. The present invention discloses a rubber composition comprising: (1) a rubbery polymer and (2) from 1 to 30 parts per hundred parts of rubber by weight (phr) of pre-crosslinked polymer particles, wherein the pre-crosslinked polymer particles have a particle size which is within the range of 30 nm to 500 nm, wherein the pre-crosslinked polymer is comprised of repeat units that are derived from at least one monomer selected from the group consisting of acrylate monomers, vinyl aromatic monomers, acrylonitrile monomer, and vinyl halide monomers, and wherein the pre-crosslinked polymer has a glass transition temperature which is within the range of 30° C. to 200° C.

Owner:THE GOODYEAR TIRE & RUBBER CO

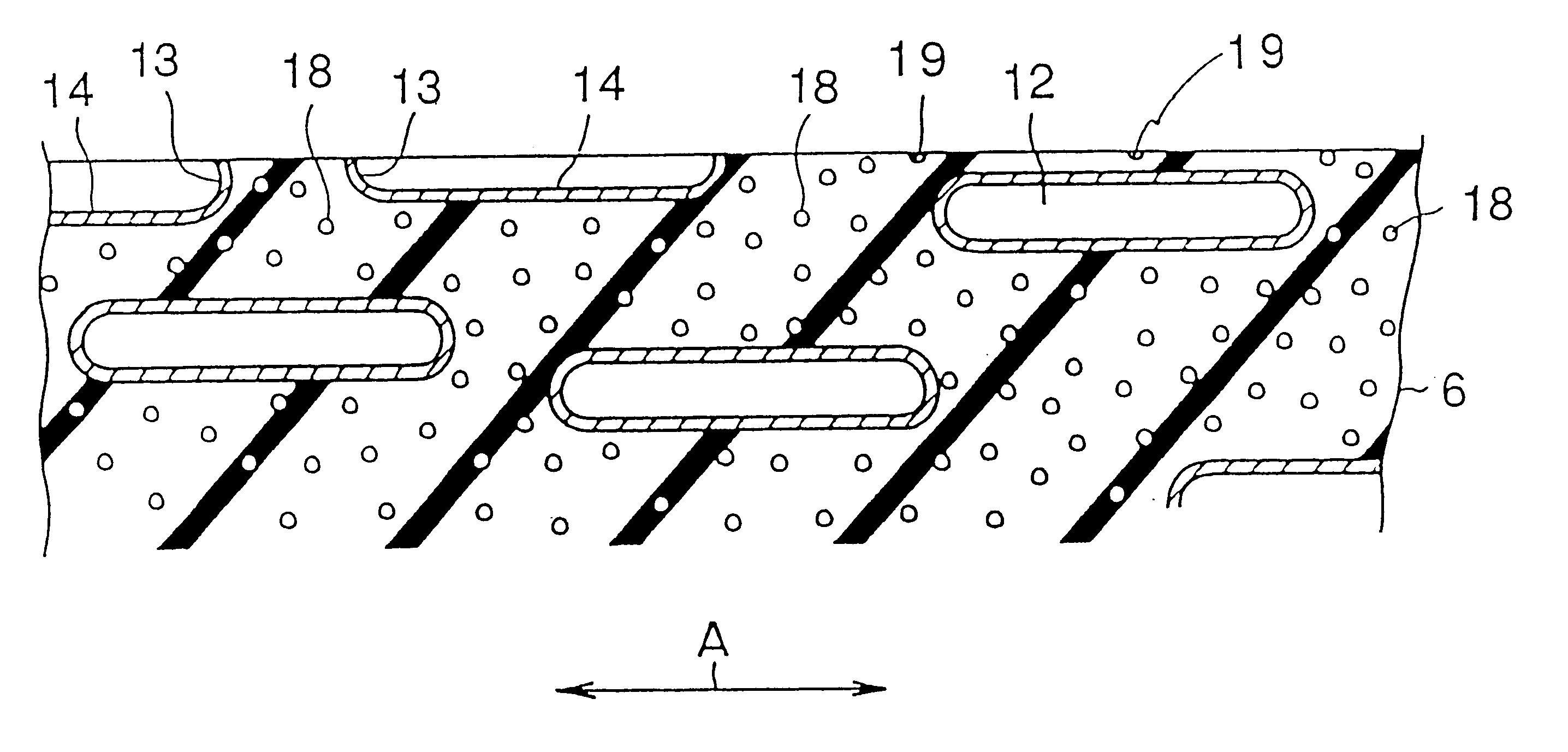

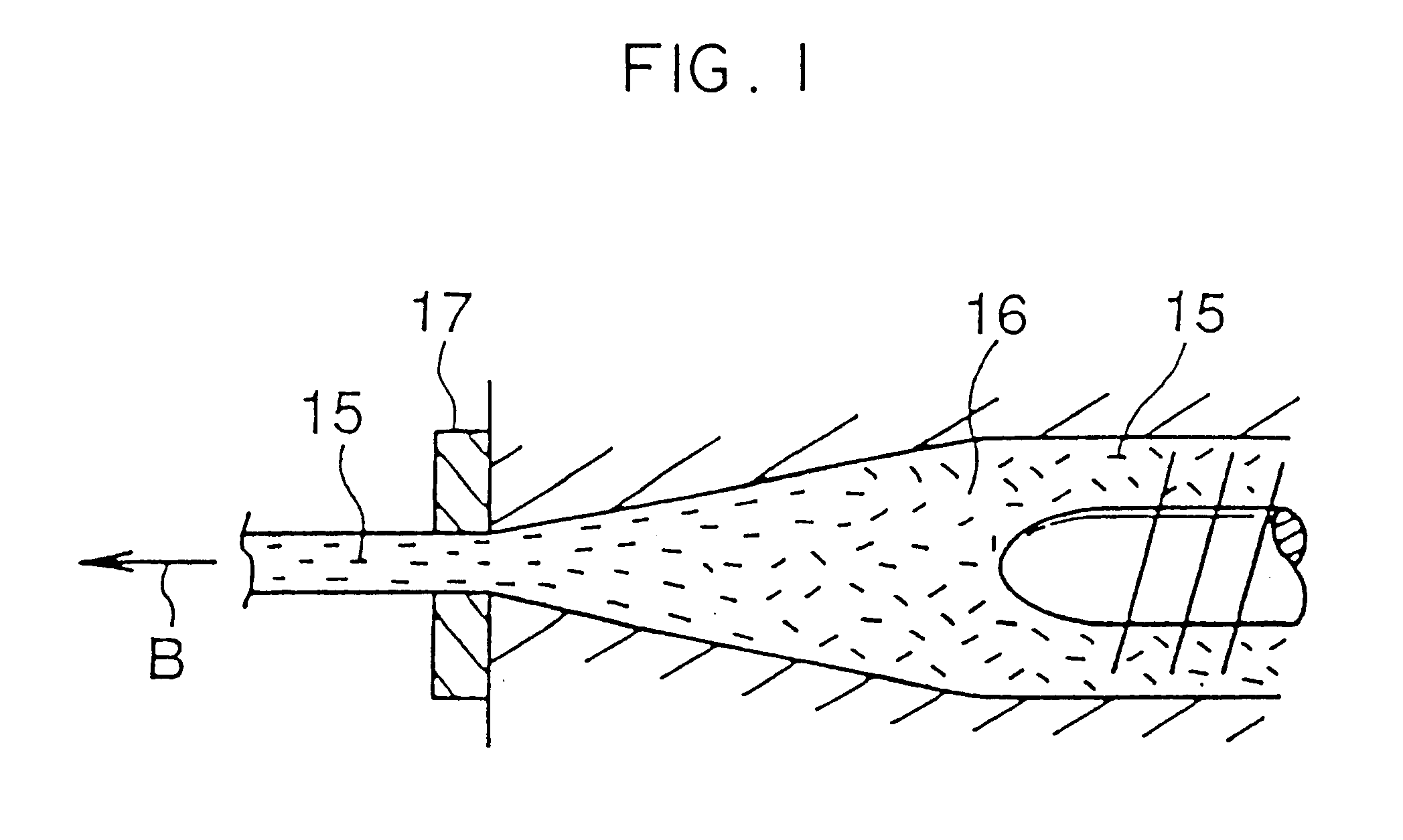

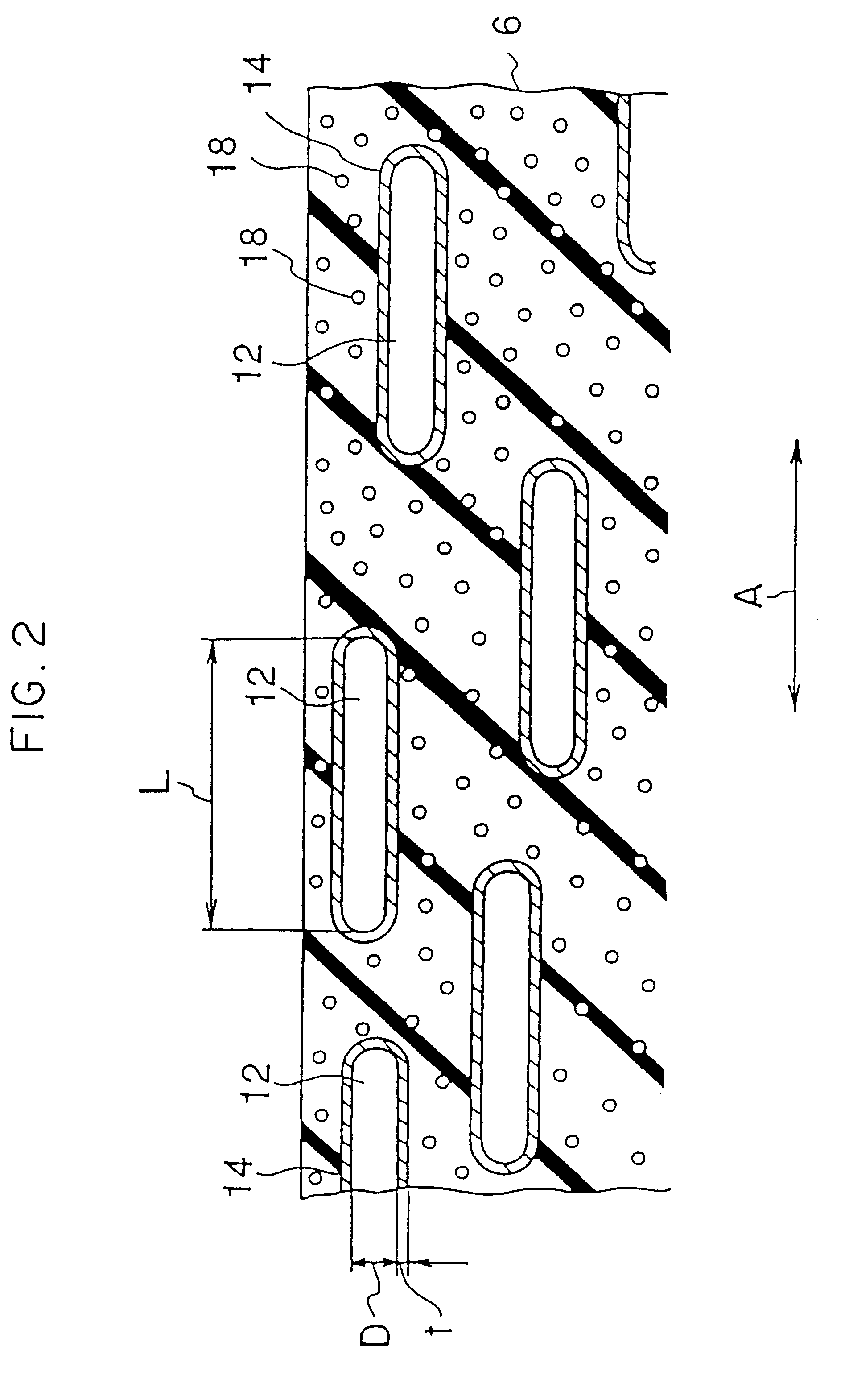

Tire and vulcanized rubber including elongated cells

InactiveUS6427738B1Good removal effectIncrease coefficient of frictionLayered productsSpecial tyresPolymer scienceWear resistance

A vulcanized rubber comprising a rubber component containing natural rubber, in an amount of 20 to 70 parts by weight, and polybutadiene, in an amount of 30 to 80 parts by weight; a rubber matrix containing 5 to 55 parts by weight of carbon black and 5 to 55 parts by weight of silica per 100 parts per weight of the rubber component; a resin, and resin coated elongated cells having a length (L) to diameter (D) ratio (L / D) of at least 3. The vulcanized rubber can be used in the tread of tires to improve on-ice performance, wet properties and wear resistance in a well balanced manner.

Owner:BRIDGESTONE CORP

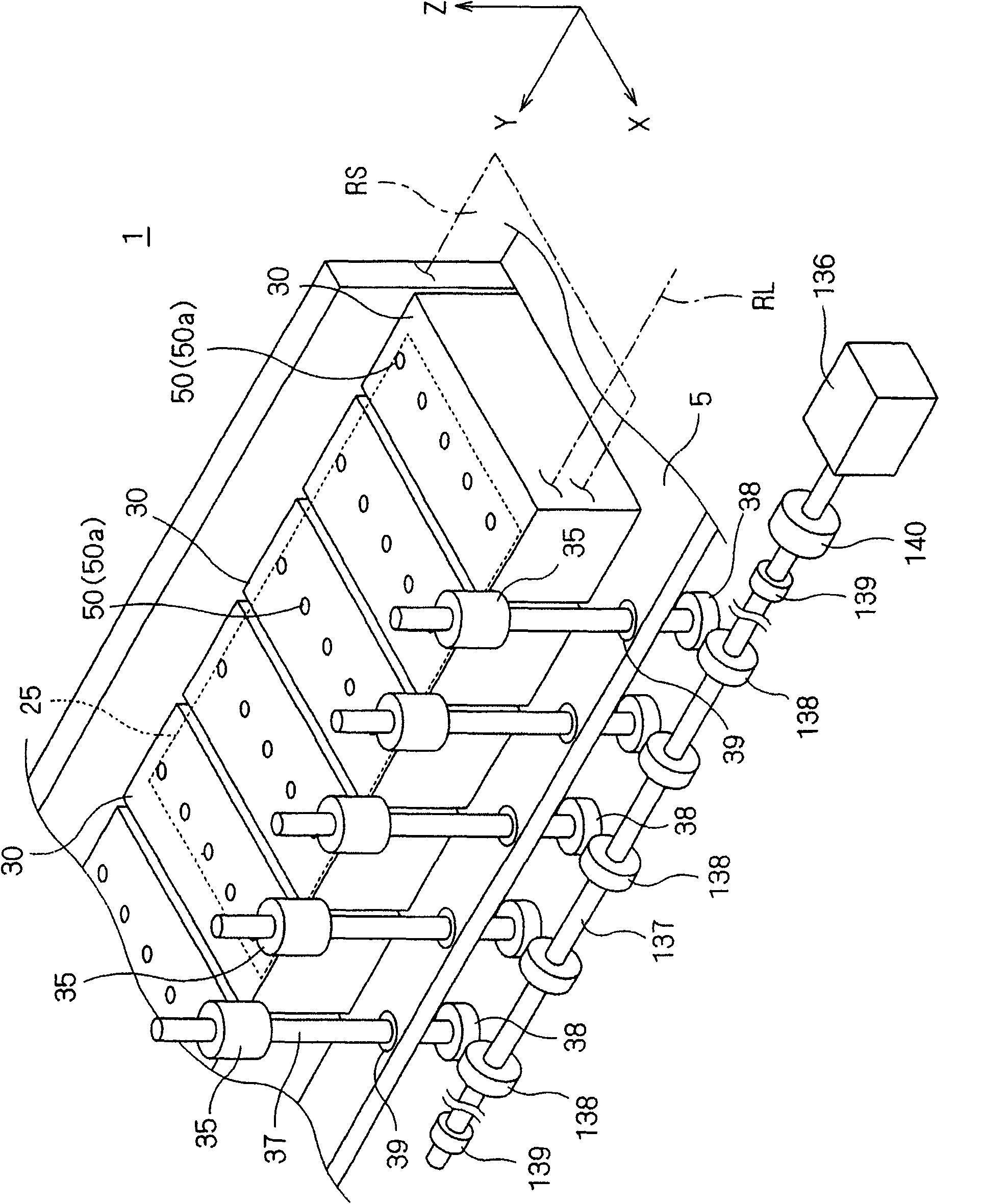

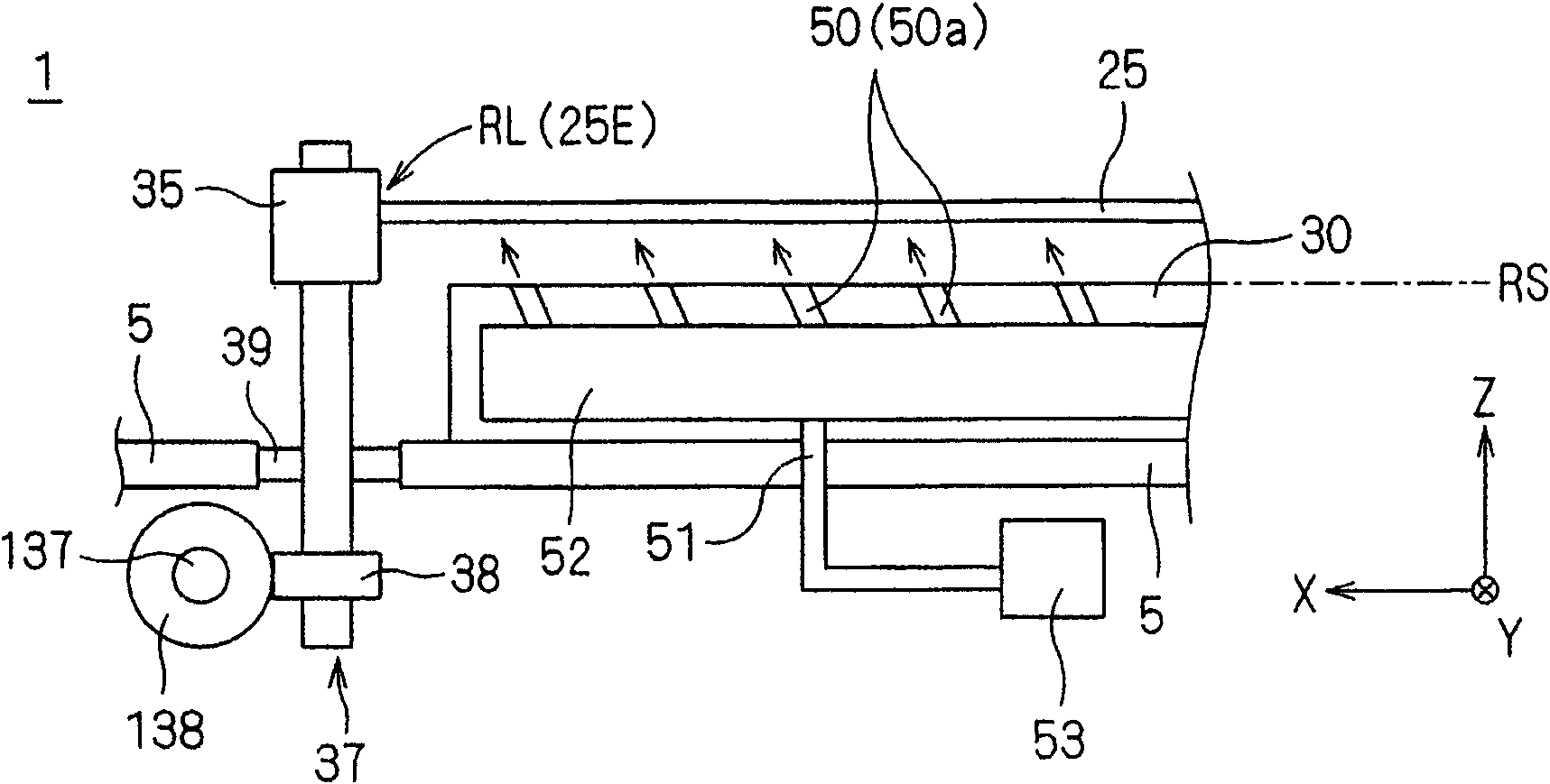

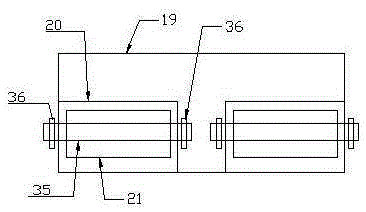

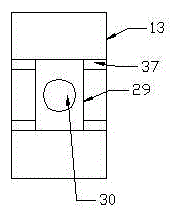

Apparatus for conveying substrates, method and apparatus for locating substrates

InactiveCN101676181ASimple structureStrong buoyancyConveyorsSemiconductor/solid-state device manufacturingEngineeringCompressed air

The present invention provides an apparatus for conveying substrates, capable of preventing the substrates from deformation or damage due to flexibility of the substrates and conveying the substrateswithout contact. Compressed air for spraying to a lower surface of a horizontal substrate (25) is applied in a face manner from the lower of the substrate (25). Thus, the substrate (25) is floated upward and is subjected to an action force toward a baseline (RL) side, such that a fiducial edge (25E) of the substrate (25) which is subjected to the action force by the compressed air is contacted toan array of conveying rollers (35) arranged along the baseline (RL). By means of the drive of the conveying rollers (35), the substrate (25) is conveyed horizontally in a floating mode that the fiducial edge (25E) and the conveying rollers (35) are contacted mutually.

Owner:DAINIPPON SCREEN MTG CO LTD

Glycopegylated erythropoietin formulations

InactiveUS7842661B2Improved pharmacokinetic propertiesCost effectiveOrganic active ingredientsBiocideDiseaseSugar moiety

The present invention provides conjugates between erythropoietin and PEG moieties. The conjugates are linked via an intact glycosyl linking group interposed between and covalently attached to the peptide and the modifying group. The conjugates are formed from glycosylated peptides by the action of a glycosyltransferase. The glycosyltransferase ligates a modified sugar moiety onto a glycosyl residue on the peptide. Also provided are methods for preparing the conjugates, methods for treating various disease conditions with the conjugates, and pharmaceutical formulations including the conjugates.

Owner:NOVO NORDISK AS

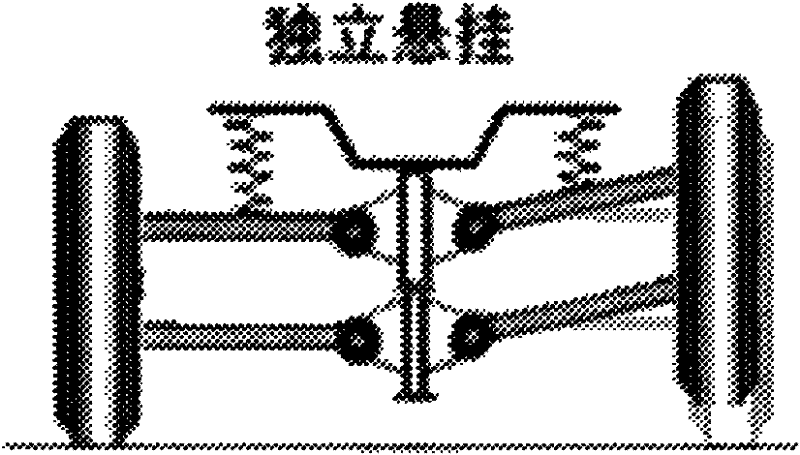

Self compensation floating swing arm independent suspension system

ActiveCN102363408AIdeal handlingIdealized securityInterconnection systemsResilient suspensionsAnti-roll barCamber angle

The invention provides a self compensation floating swing arm independent suspension system, comprising a self compensation floating swing arm independent suspension device and a centrifugal force control scissors-type anti-roll bar device. The two mechanisms can be used in combination or independently and are applicable to both front wheels and rear wheels. The self compensation floating swing arm independent suspension system guarantees that wheels perform line bounce along a vertical direction of a car body on various kinds of road surfaces when a car runs at a low speed or at a high speed or makes turns and guarantees maximum contact area between the wheels and the road surfaces, with the parameters of king pin angle, toe-in angle, camber angle, wheel track, and axle base being maintained the same as original parameters; and, when the car makes turns, the centrifugal force control scissors-type anti-roll bar device works automatically, offsets a roll force with a force equal to the roll force in magnitude and opposite to the roll force in direction, and enables the car body to lower automatically, thereby improving anti-roll capacity and realizing idealization of controllability, safety, stability and comfort of the car. The self compensation floating swing arm independent suspension system has a simple structure, excellent performance, and low cost, and is easy to realize.

Owner:侯贺

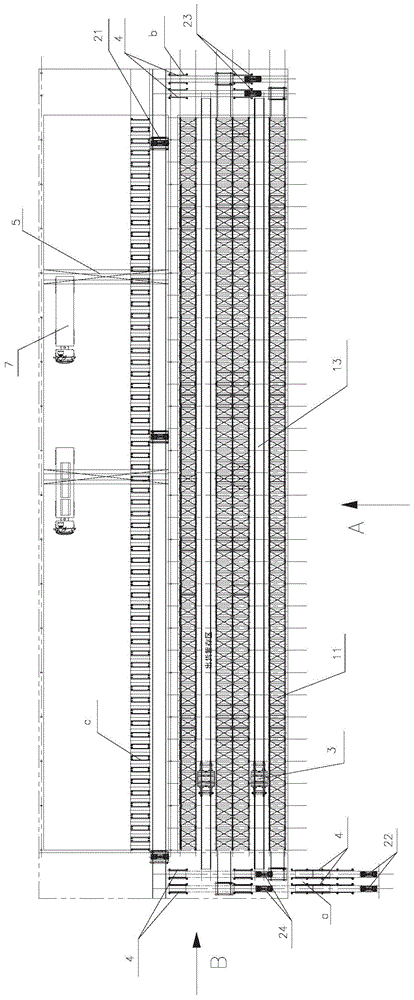

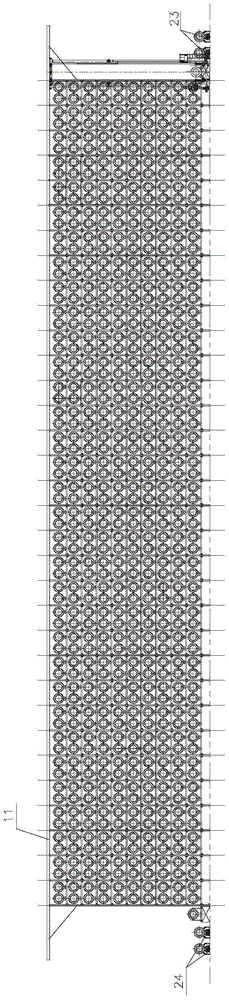

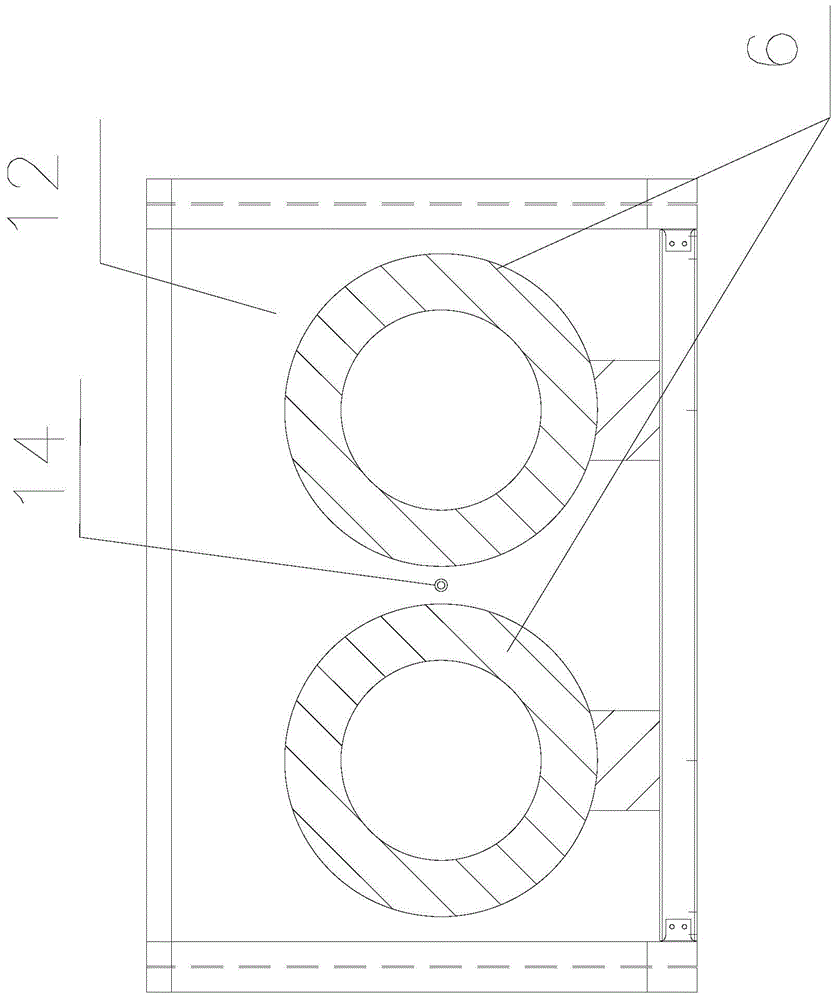

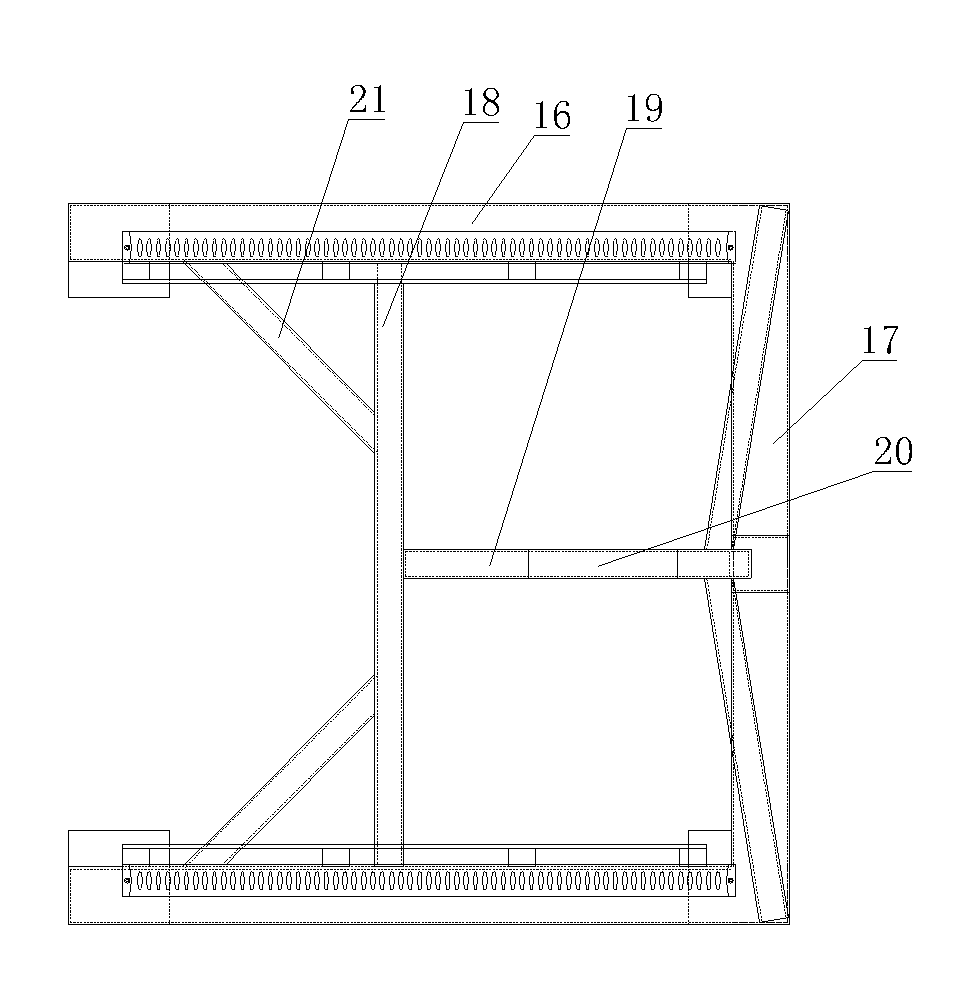

Automated three-dimensional warehouse for placing round goods and goods incoming and outgoing method thereof

The invention discloses an automated three-dimensional warehouse for placing round goods and a goods incoming and outgoing method thereof. The automated three-dimensional warehouse comprises a stereoscopic godown which includes one or more rows of goods shelves and is provided with one or more alleys, carrying carts which include outgoing carts, incoming carts, outgoing transfer carts and incoming transfer carts, wherein the outgoing / incoming carts are arranged on the exit / entrance of the warehouse, the outgoing / incoming transfer carts are arranged on the exit / entrance of the alleys, and the moving track of the outgoing / incoming carts is connected to the moving track of the outgoing / incoming transfer cart, and stacking machines, wherein the stacking machines are four-pillar stacking machines which are arranged in each alley, the stacking machines can lift perpendicularly and move along the alleys, and the stacking machines are provided with inclined-plane fork mechanisms thereon. The automated three-dimensional warehouse is good in strength and stable in structure; by virtue of the inclined-plane fork mechanisms, the automated three-dimensional warehouse can be used for effectively solving the problem that fork arms become deformed under inclined force when forking round goods, so that the goods can be forked rapidly and stably.

Owner:苏州怡丰自动化装备有限公司

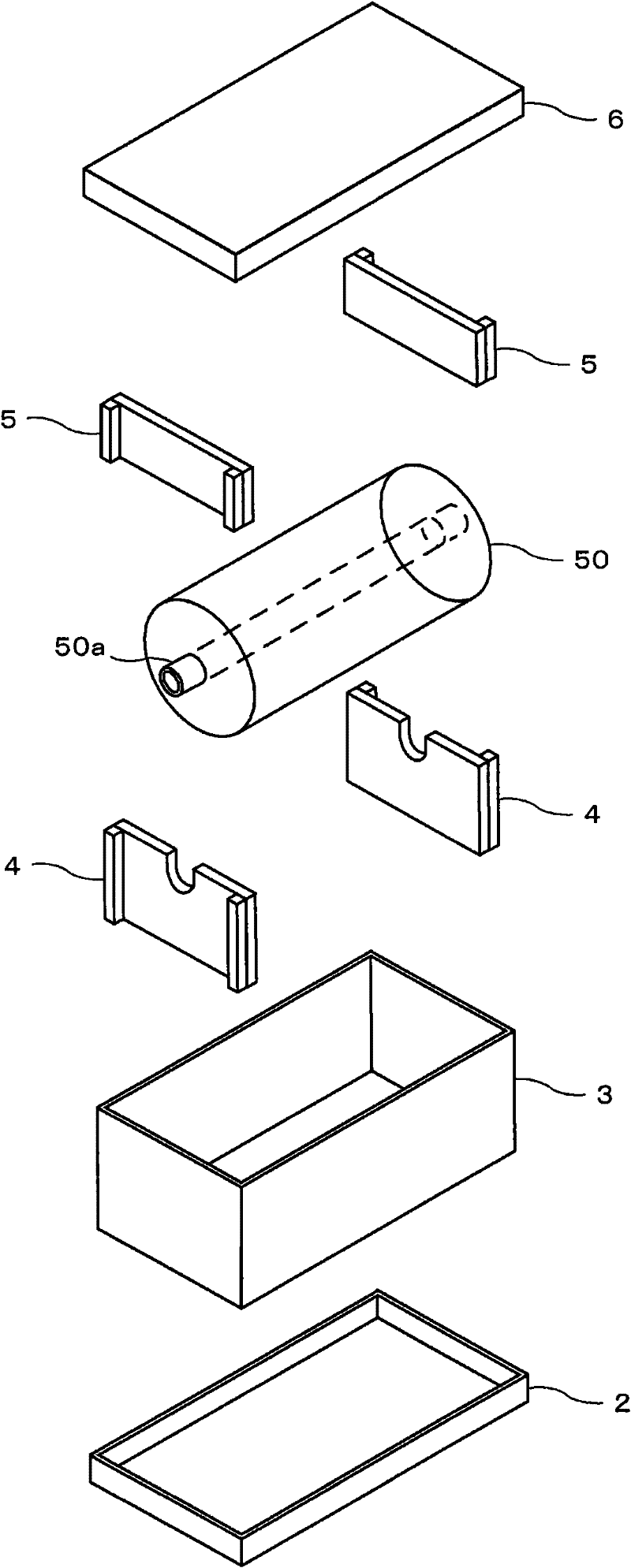

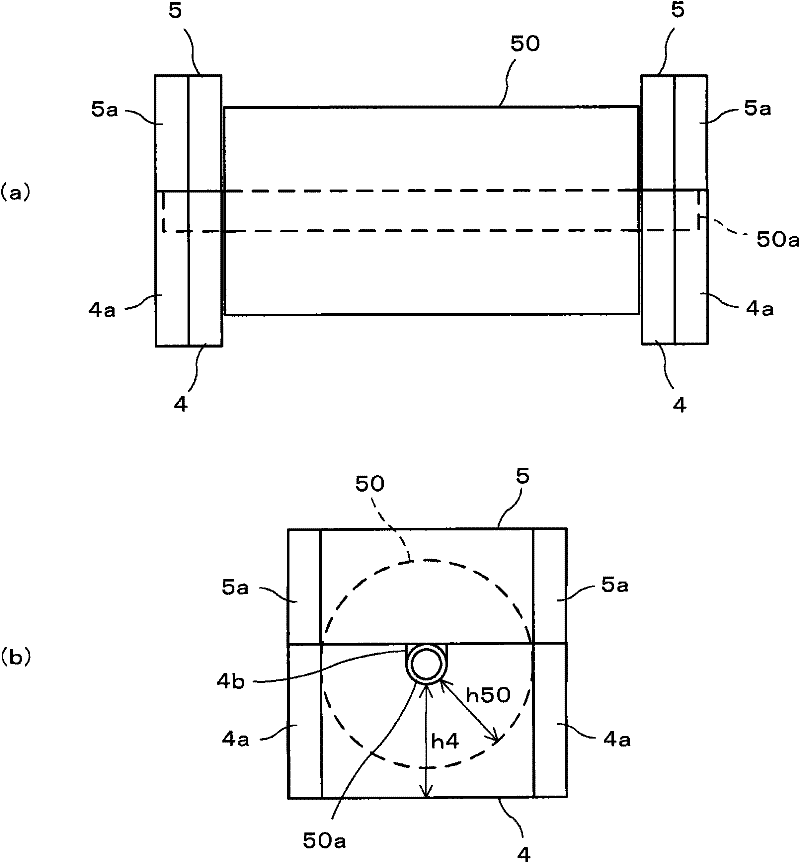

Packing container for roll article

InactiveCN102556524APrevent independent swingStable handlingContainers to prevent mechanical damagePlastic containersEngineeringMechanical engineering

Owner:ASAHI GLASS CO LTD

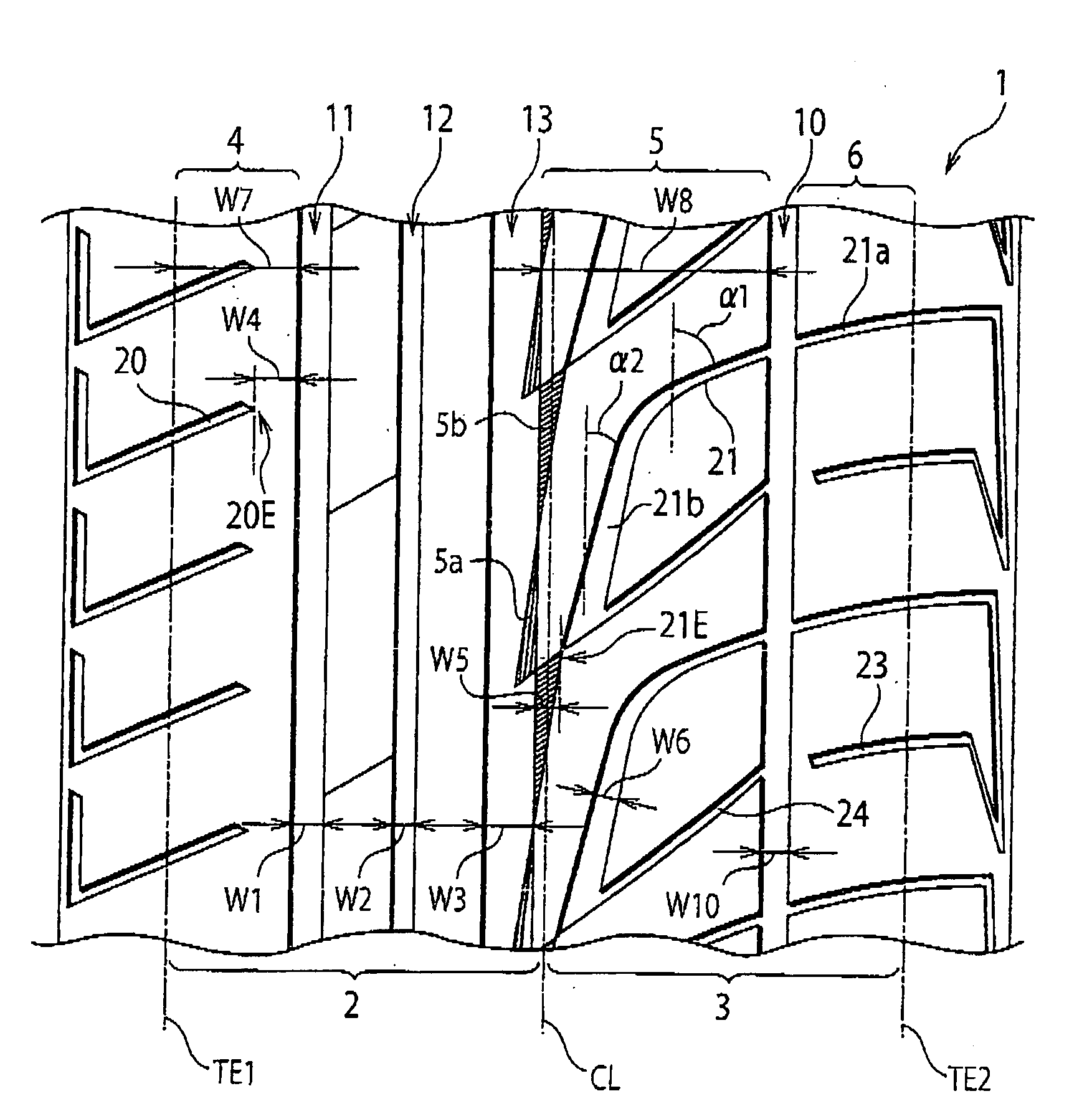

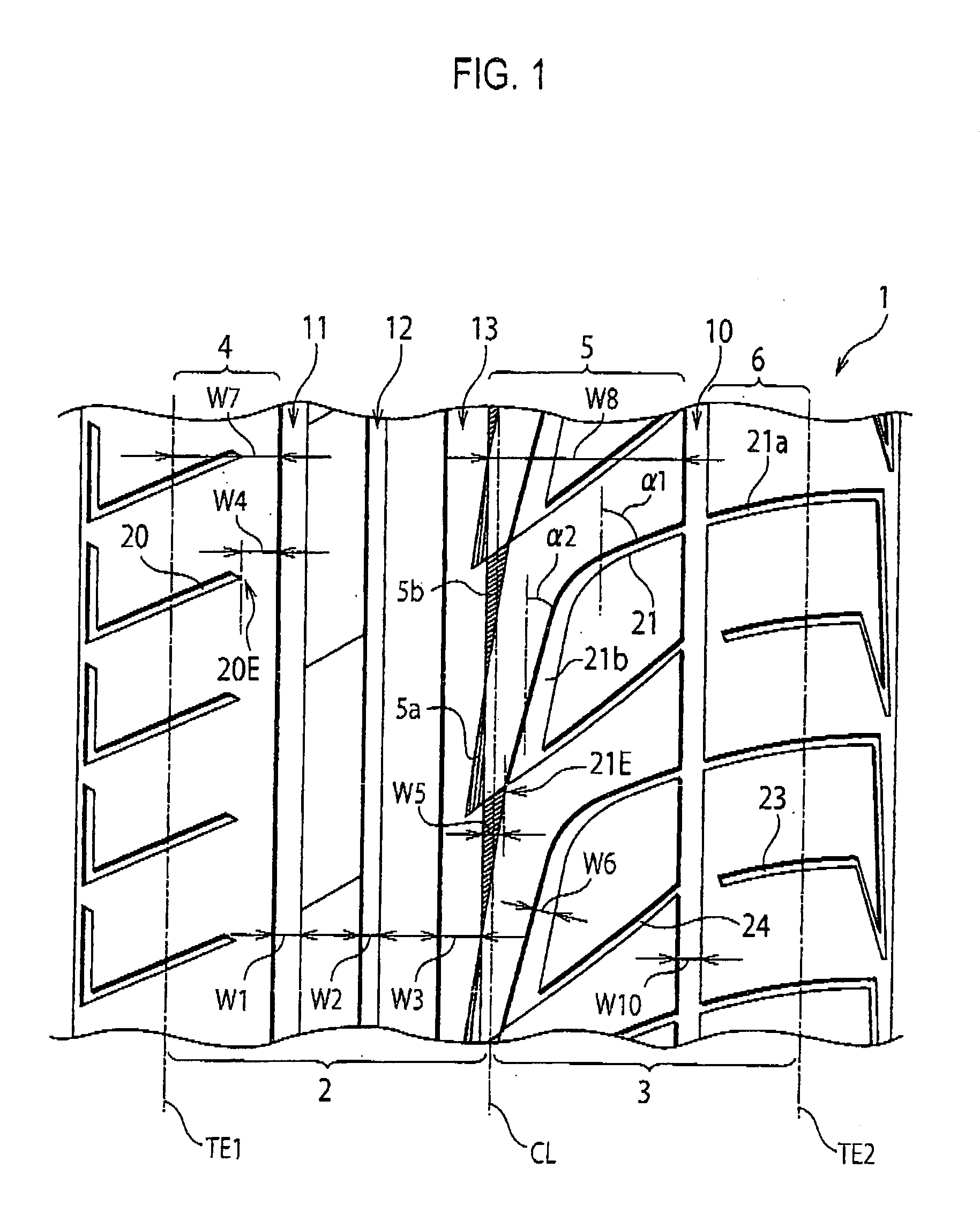

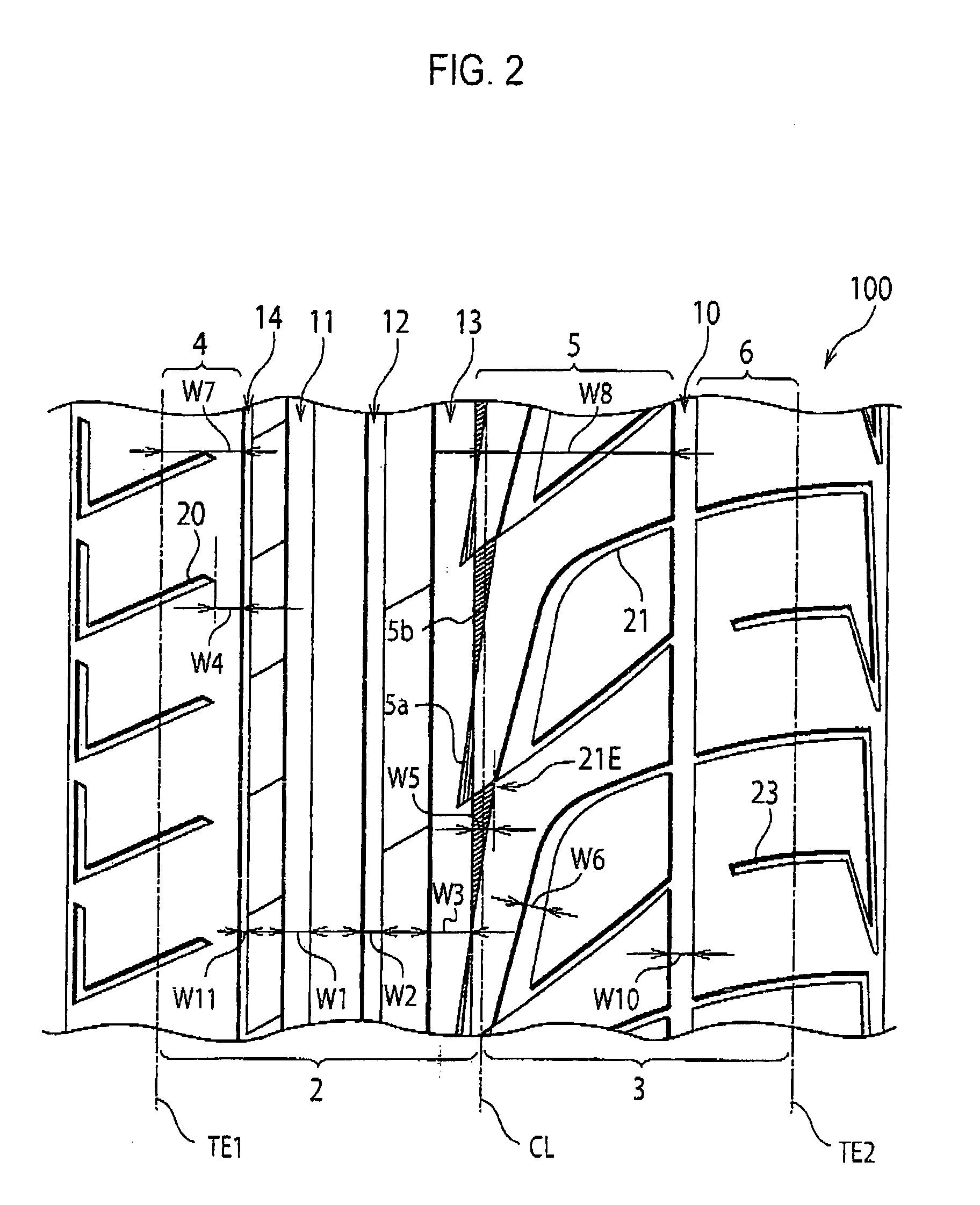

Pneumatic Tire

InactiveUS20080142133A1Effective divisionMinimal drainage performanceTyre tread bands/patternsNon-skid devicesEngineeringTread

On a tread surface 1 of a pneumatic tire, at least one circumferential groove is formed on an outer-side region 3 in a vehicle width direction, at least three circumferential, which number is two or more larger than the outer-side region 3, grooves are formed on an inner-side region 2 in the vehicle width direction. A plurality of lug grooves 20 are formed on the tread surface 1, open to a tread edge TE1 of the inner-side region 3, extend in a direction toward circumferential groove 11, and terminate without opening to circumferential groove 11. A plurality of continuous lug grooves 21 are formed on the tread surface 1, open to a tread edge TE2 of the outer-side region 3, extend in a direction toward the circumferential groove 13, continue to the central land portion 5 intersecting the circumferential groove 10, and terminate without opening to the circumferential groove 13 which borders the central land portion 5, among the three second-region circumferential grooves 11, 12, 13.

Owner:BRIDGESTONE CORP

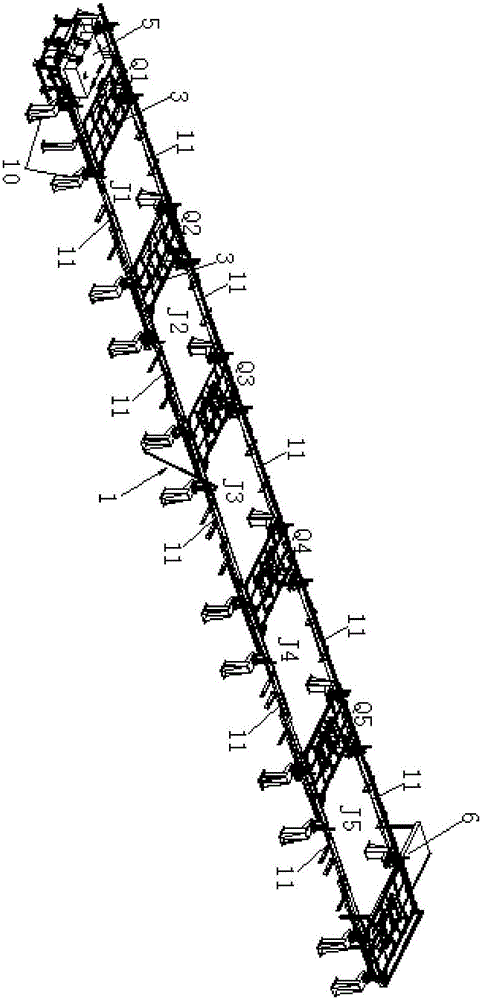

Intelligent carrying line

ActiveCN105923369AImprove handling flexibilityEasy to operateConveyor partsElectrical and Electronics engineering

The invention discloses an intelligent carrying line. The intelligent carrying line runs throughout a plurality of machining stations arranged linearly in a matched mode so that machined workpieces can be conveyed to the machining stations to be subjected to various processes. The intelligent carrying line comprises a line body rack and a plurality of material taking trolleys. The line body rack comprises a lifting device and two linear tracks transversely arranged on the lifting device side by side. The two linear tracks also can synchronously conduct mobile positioning up and down under driven of the lifting device. The multiple material taking trolleys are in bridge connection with the position between the two linear tracks in the length direction of the linear tracks at intervals and can also conduct mobile positioning back and forth in the length direction of the linear tracks. Thus, the positioning accuracy of workpiece grabbing of the material taking trolleys and the control flexibility of quickly conveying the machined workpieces to the designated machining stations to be subjected to process treatment can be greatly improved, and the working efficiency is enormously improved; and meanwhile, the manpower consumption amount is effectively reduced, and the labor intensity is effectively relieved.

Owner:昆山威创自动化科技有限公司

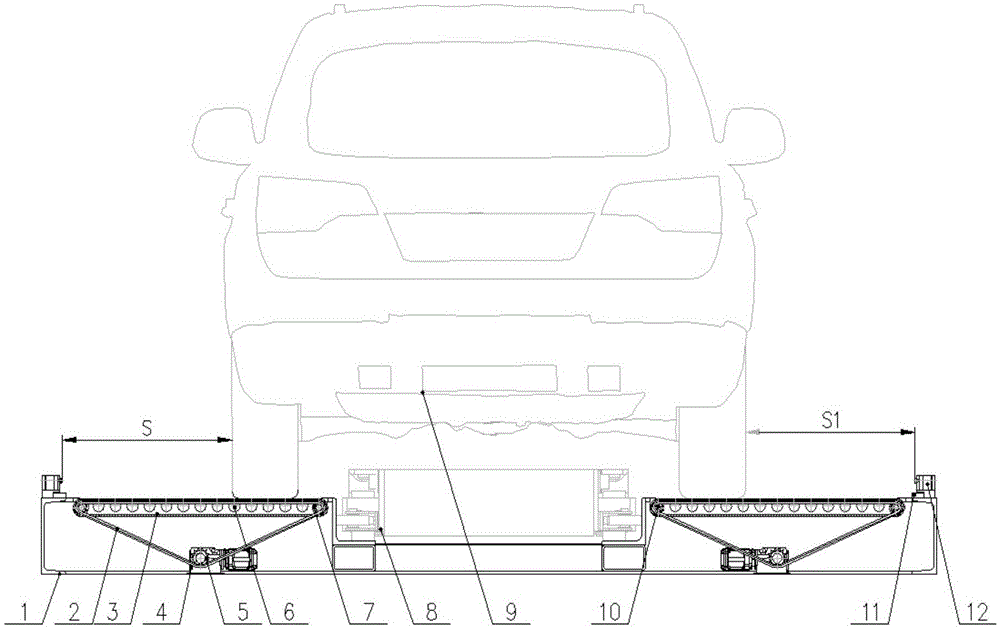

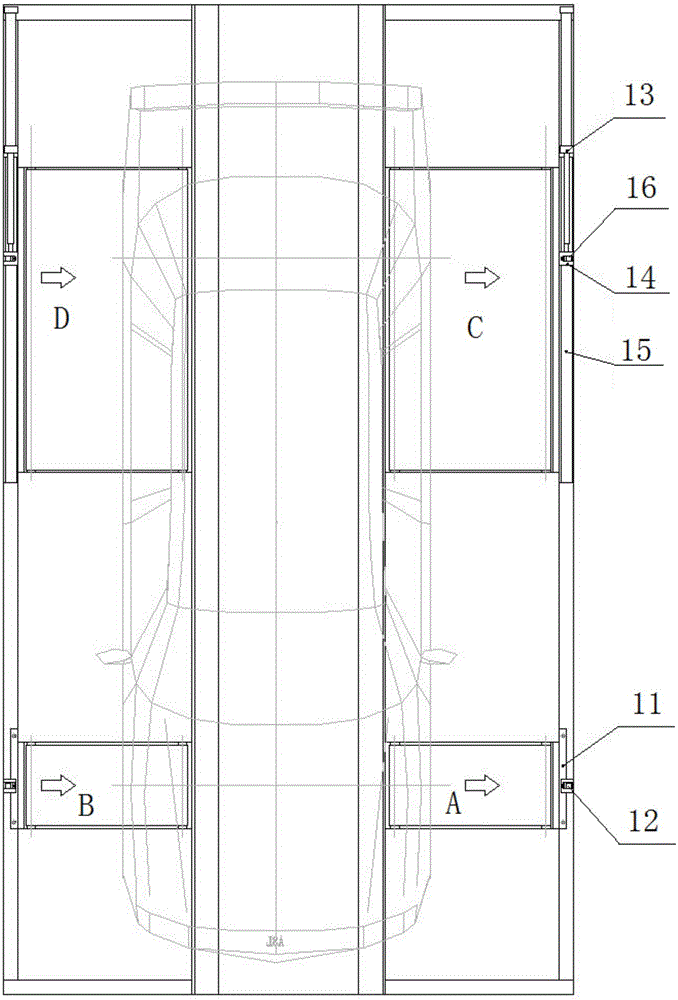

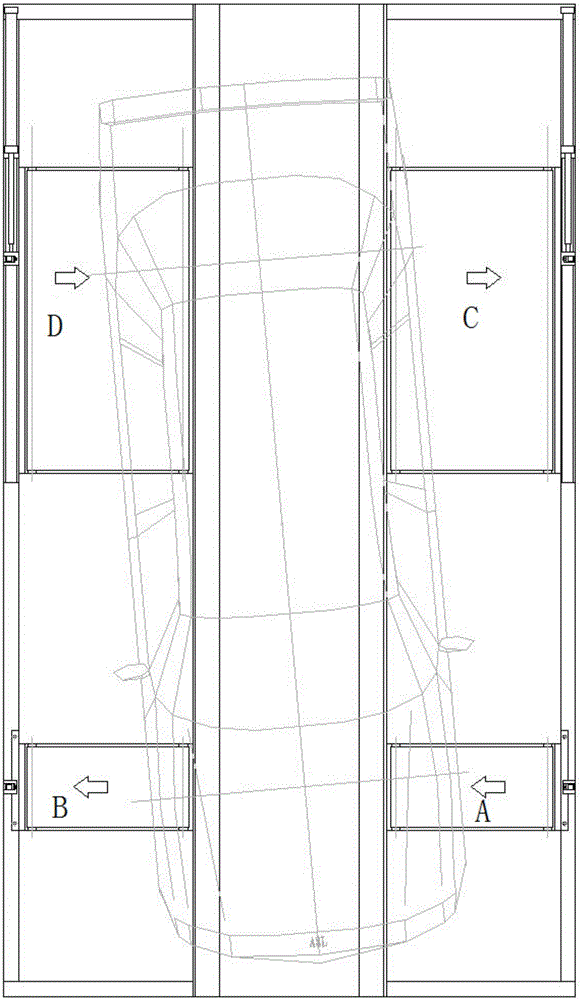

Automatic vehicle alignment device and method

The invention discloses an automatic vehicle alignment device and method. The device comprises a rack, windows corresponding to vehicle wheels are formed in the parking surface of the rack, a transverse moving mechanism is arranged in each window, and the parking surface of the rack is provided with a front wheel location detecting mechanism, a front wheel distance measurement mechanism and a back wheel distance measurement mechanism; each transverse moving mechanism comprises a motor, a driving chain wheel, a roller chain, driven chain wheels, synchronous belt rollers, synchronous belts and a carrier roller assembly, wherein the vehicle wheels are placed on the synchronous belts; the front wheel location detecting mechanism comprises a pair of region detecting light curtains; the front wheel distance measurement mechanism comprises a pair of front wheel distance measurement sensors; the back wheel distance measurement mechanism comprises a pair of back wheel distance measurement sensors. According to the automatic vehicle alignment device and method, the vehicle parking time can be shortened, and the problem that a vehicle cannot be transferred due to the vehicle is not parked rightly is solved.

Owner:WISDRI ENG & RES INC LTD

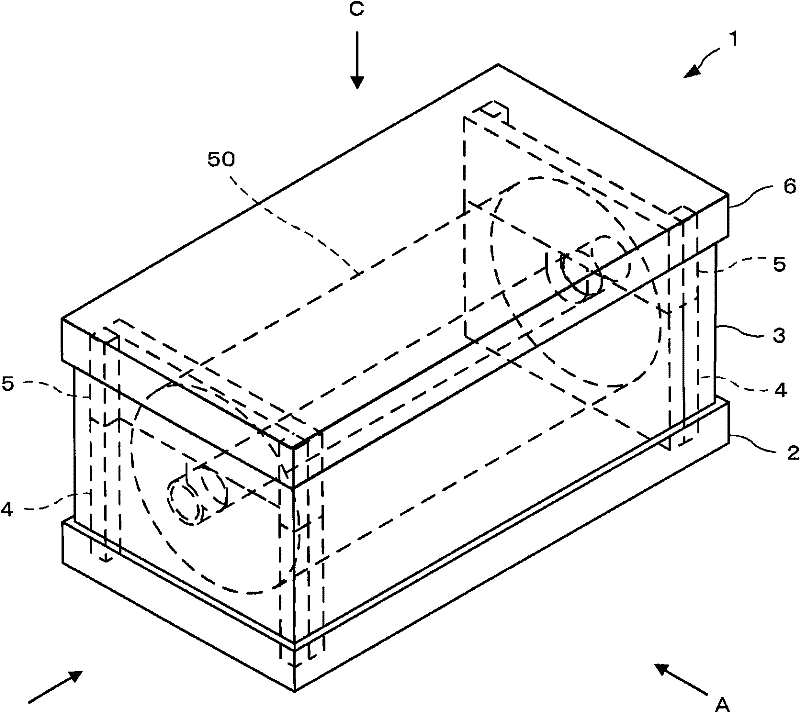

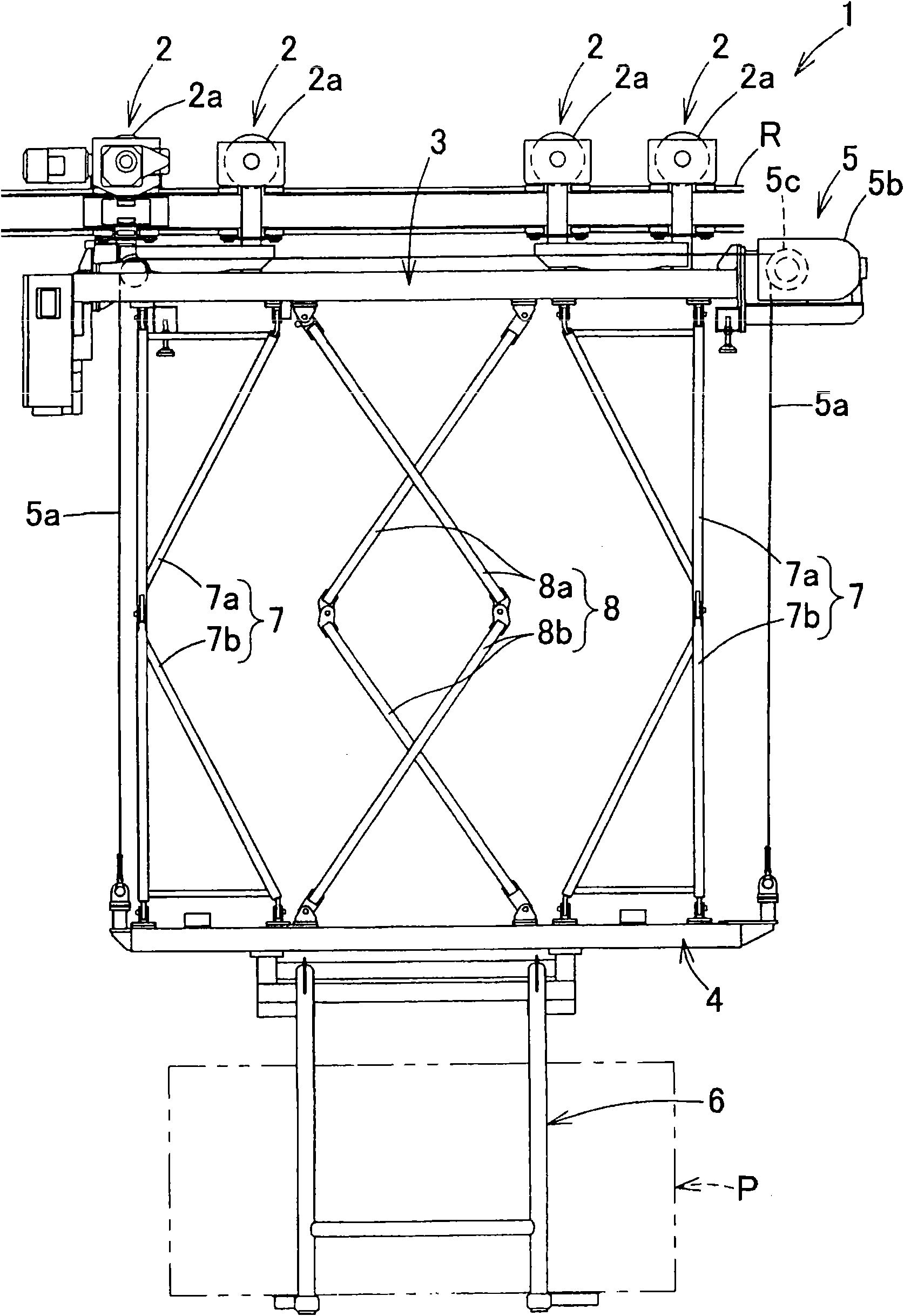

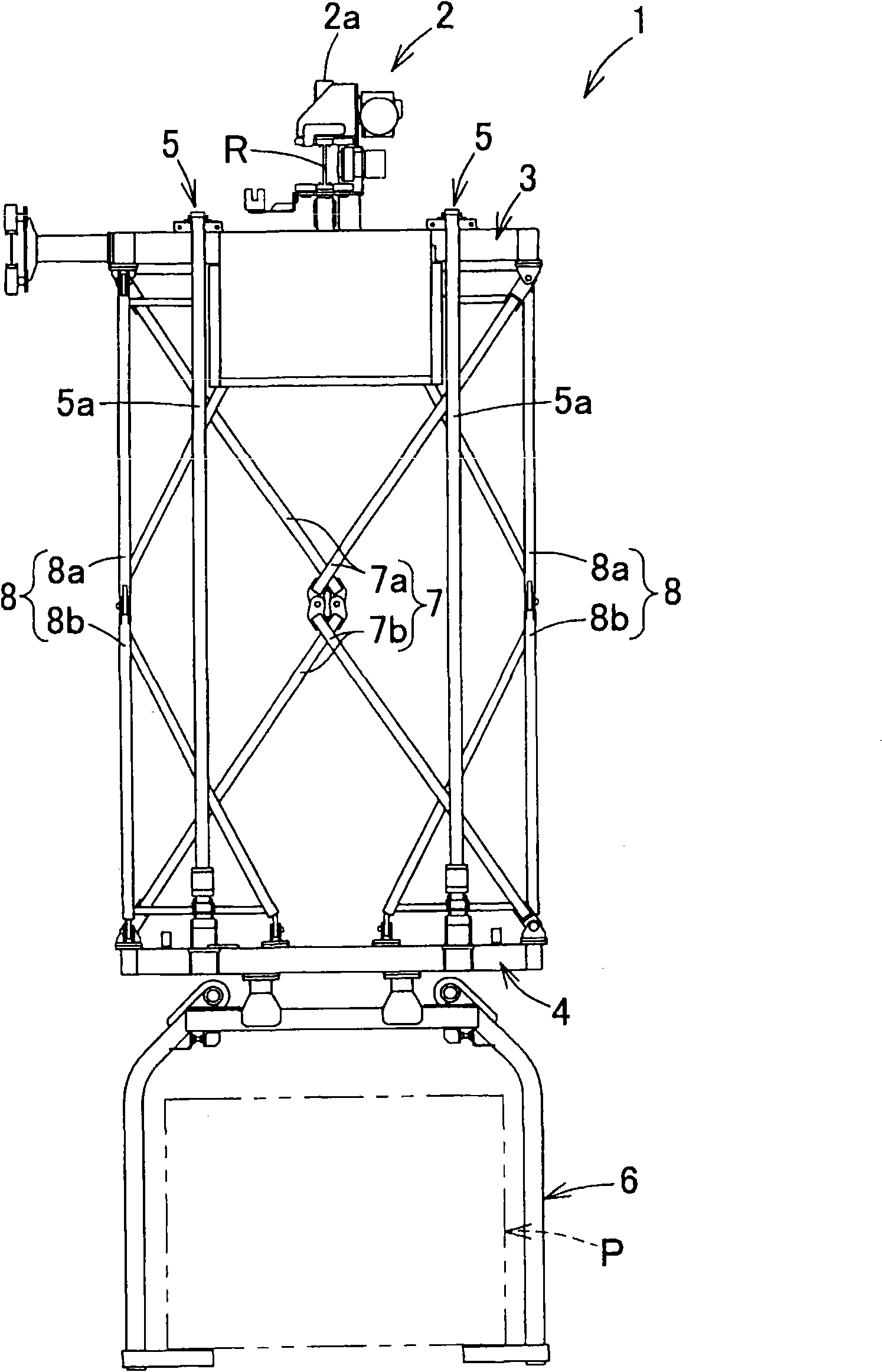

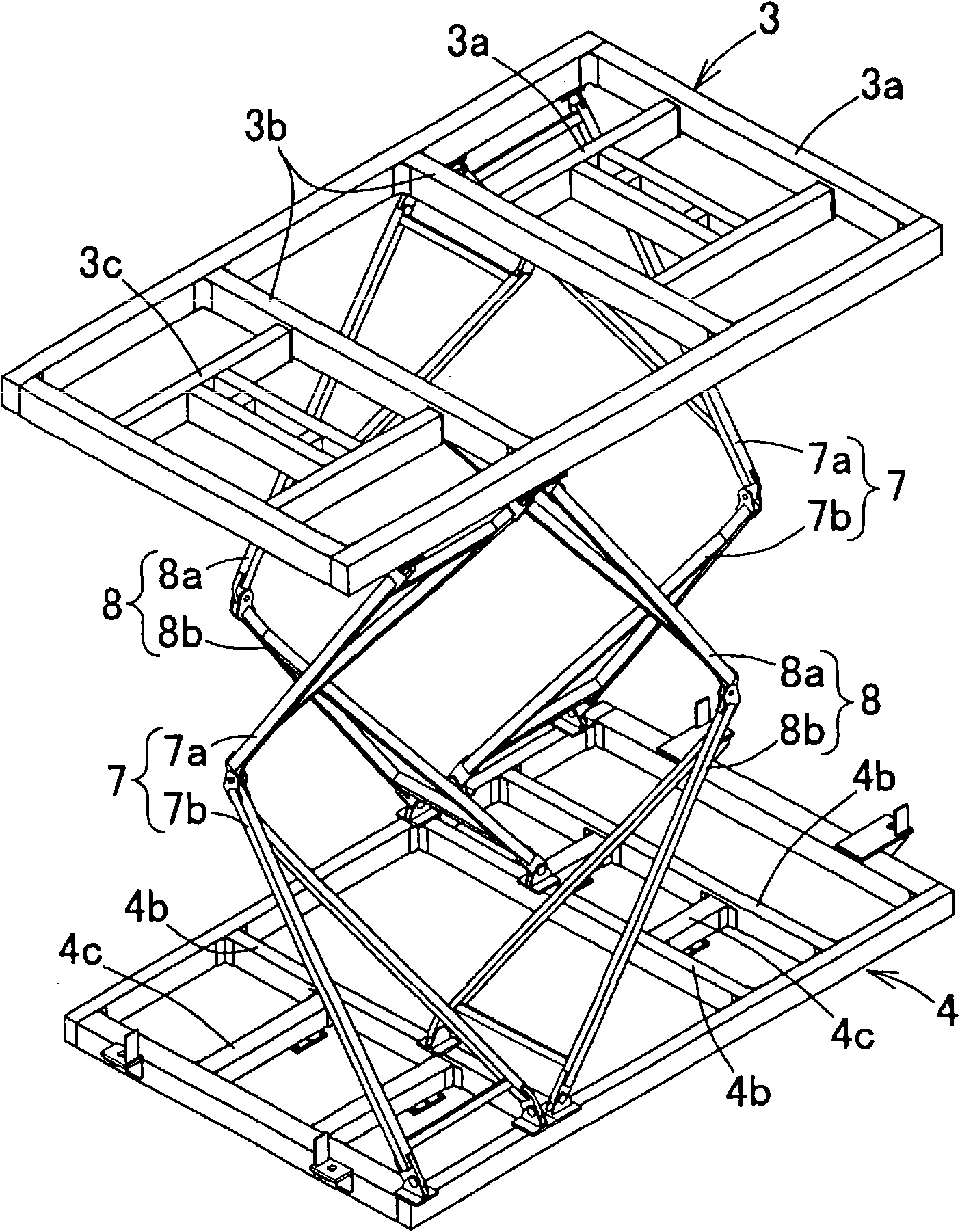

Lifting type conveyor

The invention provides a lifting type conveyer (1) capable of preventing the sway of the load (P) and safely conveying the load (P) and increasing the lifting range of the load (P). The lifting type conveyer (1) comprises an upper frame (3) suspended on a carriage running on a conveying trail ( R ), a lower frame (4) liftably mounted below the upper frame (3) with a hanging frame (6); a first sway prevention frame (7) with a first upper frame (7a) and a first lower frame (7b) and capable of correspondingly folding or extending along with the lifting of the lower frame (4), wherein the first upper frame (7a) is approximately of upside-down triangle and in axle suspension on the upper frame (3) and the first lower frame (7b) is longitudinal symmetry with the first upper frame (7a) and the lower end of the first upper frame is in axle connection with the upper end; and a second sway prevention frame (8) longitudinal symmetry with the first sway prevention frame (7) and vertically extending on the horizontal plane opposite to the upper border of the first upper frame (7a).

Owner:NAKANISHI METAL WORKS CO LTD

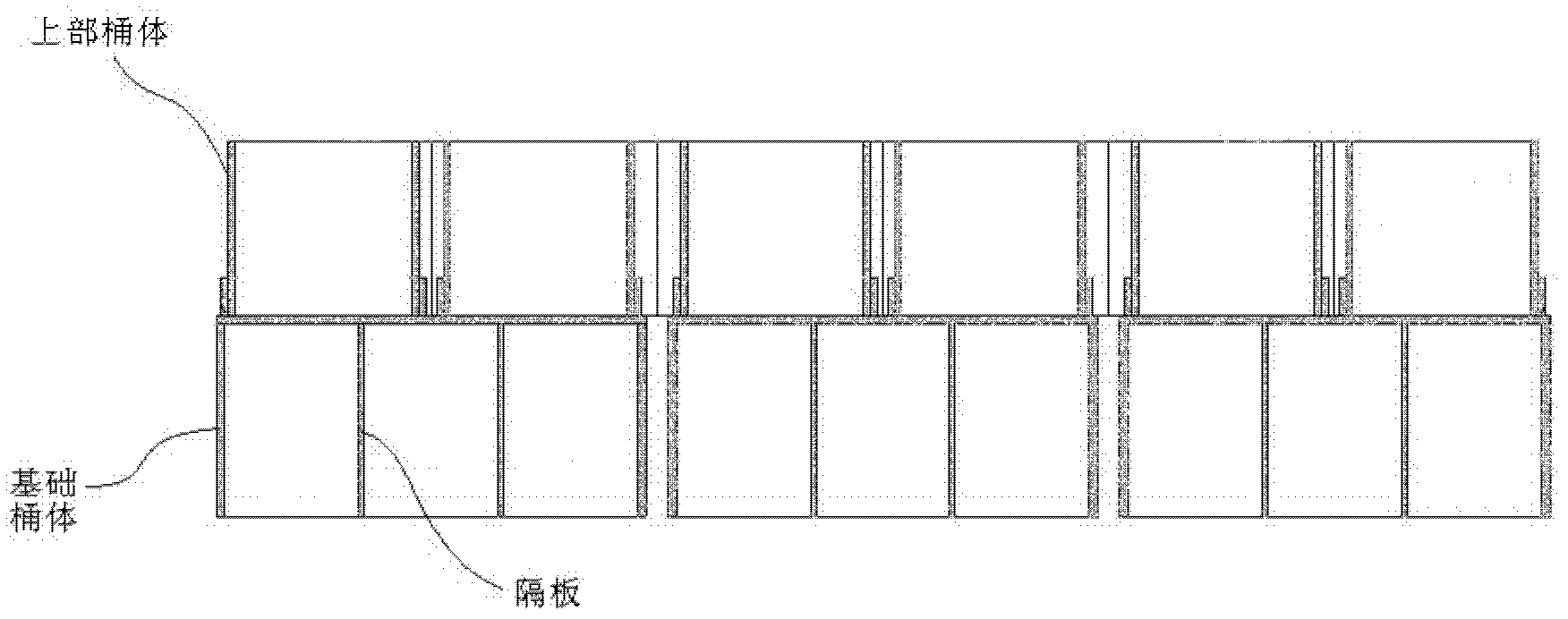

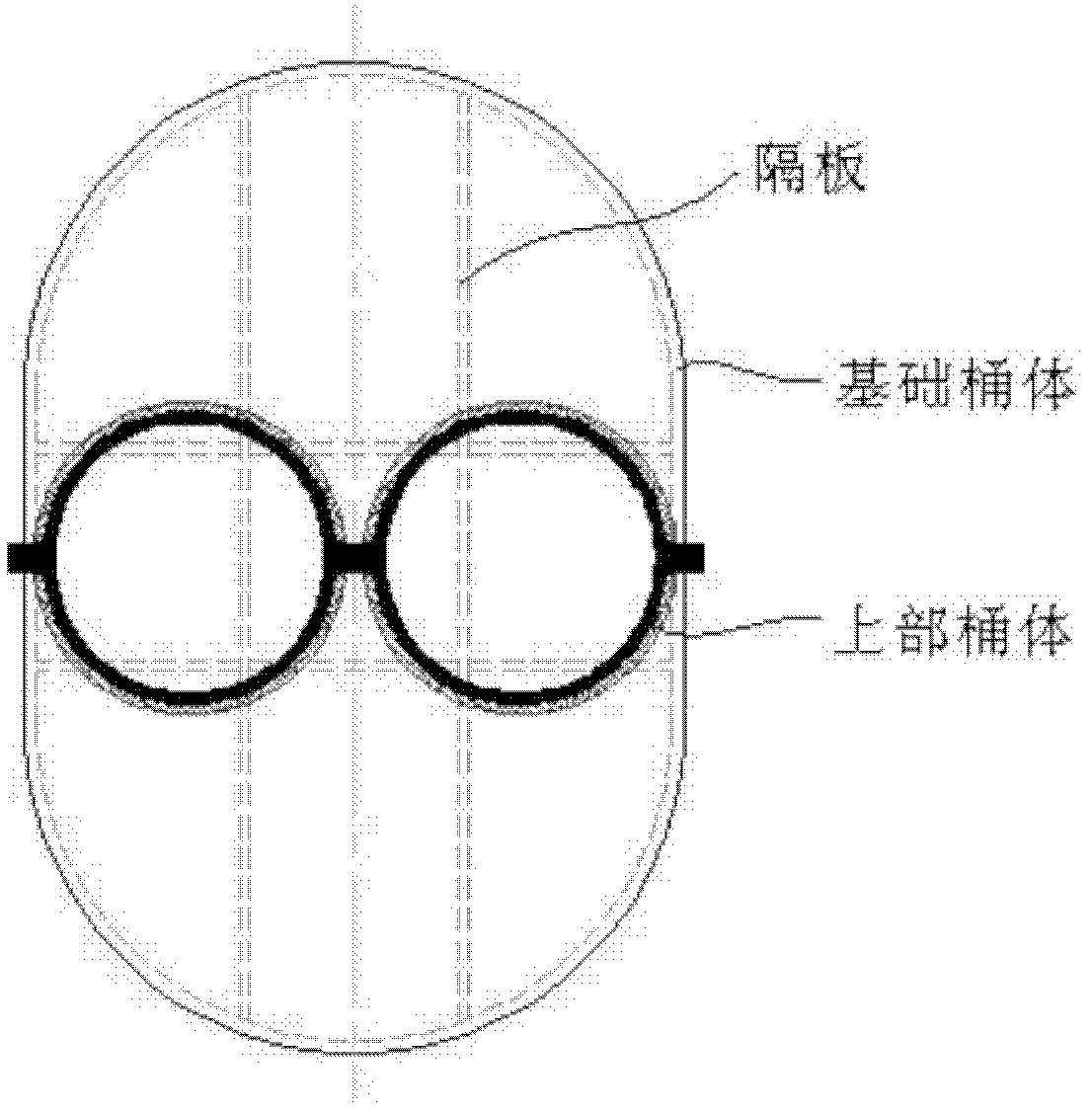

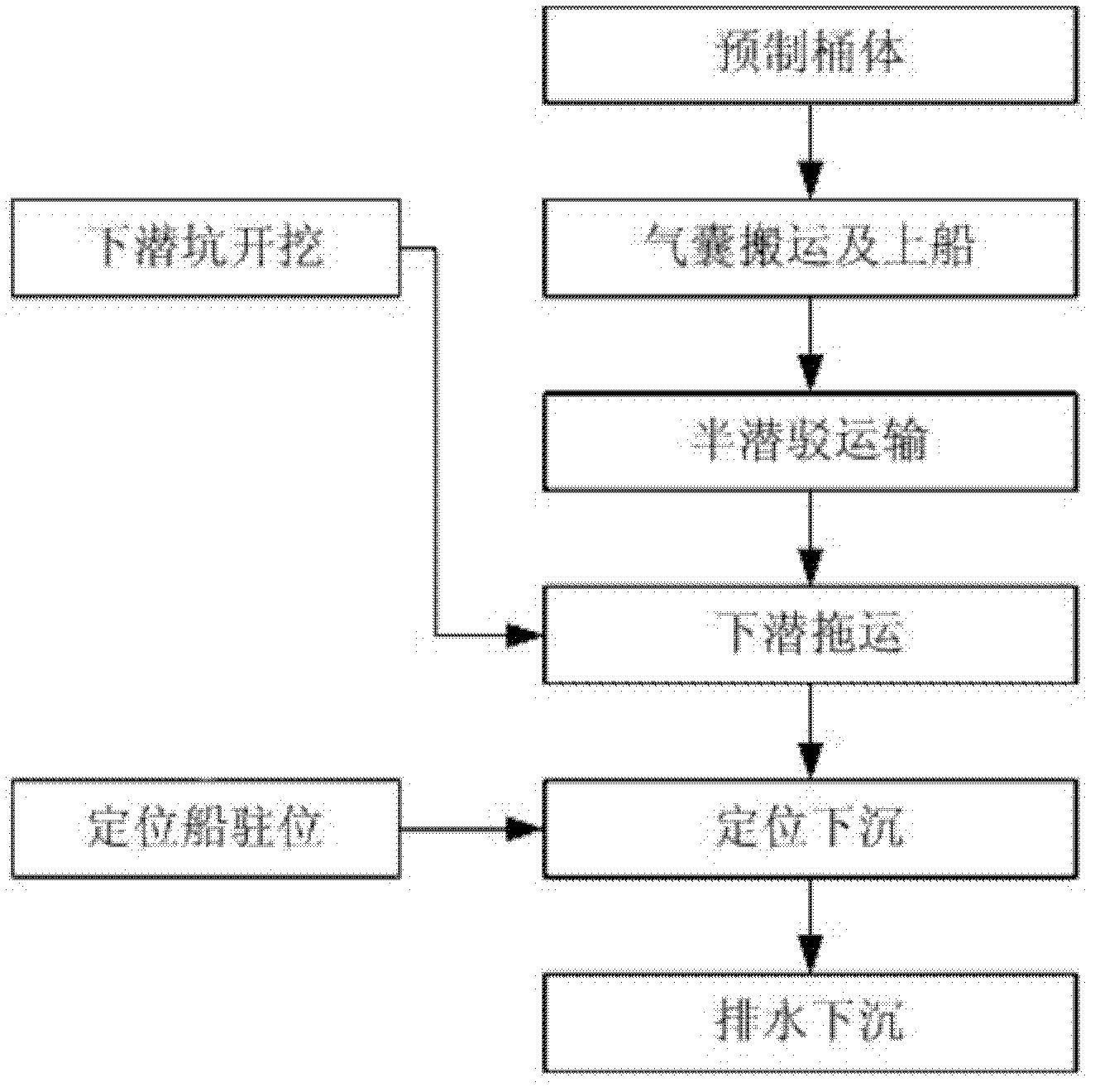

Transportation and installation process of base barrel body of barrel type breakwater

The invention discloses a transportation and installation process of a base barrel body of a barrel type breakwater, wherein the base barrel body is hauled to a construction field through a tugboat and a semi-submerged barge; a floating air bag is arranged on the base barrel body; the balance of the base barrel body is adjusted by inflating the floating air bag; and the base barrel body is sunk by deflating the floating air bag. After the technical scheme is adopted, because the semi-submerged barge is adopted to transport the base barrel body, the base barrel body is transported more stably and quickly; because of the large tonnage semi-submerged barge, the base barrel body can be transported under the condition with large stormy waves; and due to the floating air bag, the processes of the floating, the installation and the positioning of the base barrel body can be effectively controlled and kept balanced all the time.

Owner:CCCC THIRD HARBOR ENG

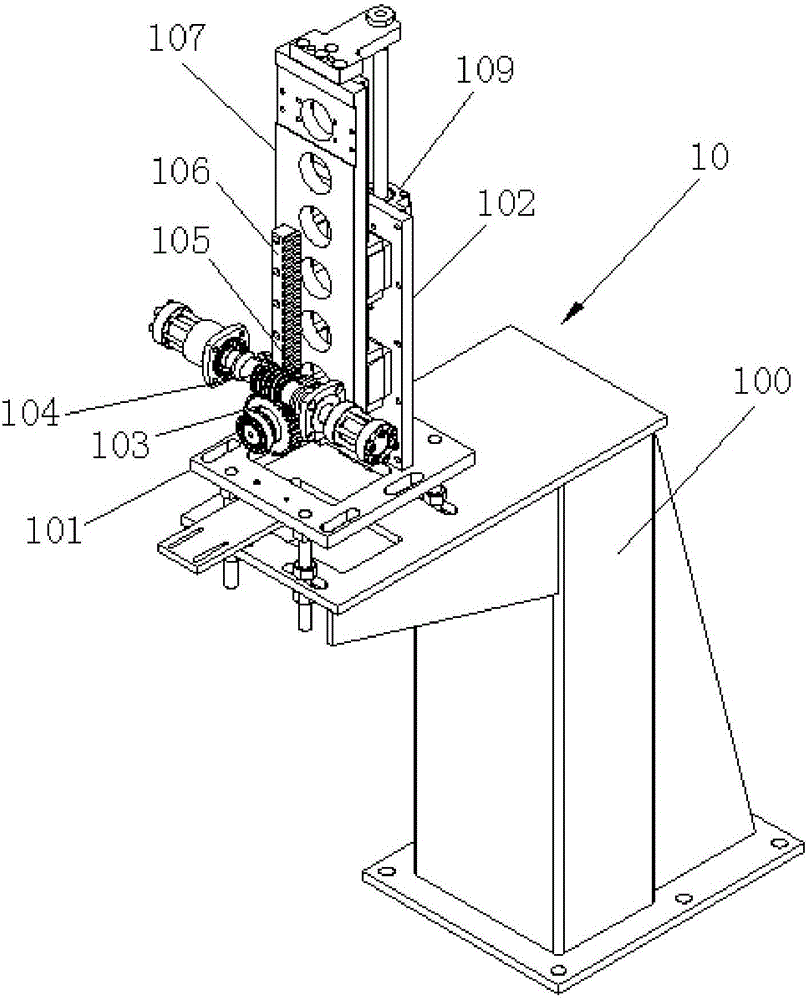

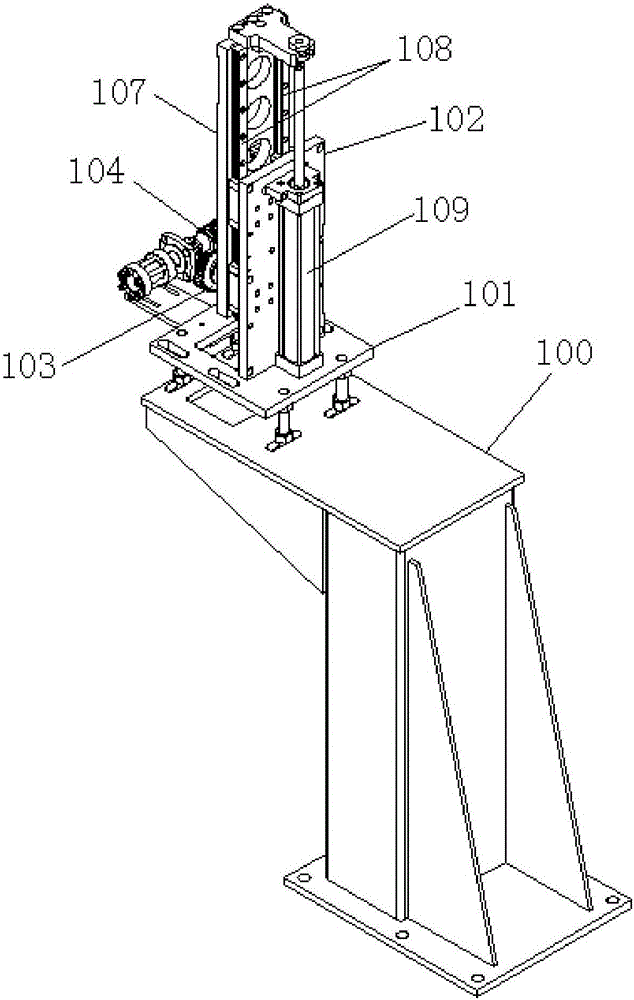

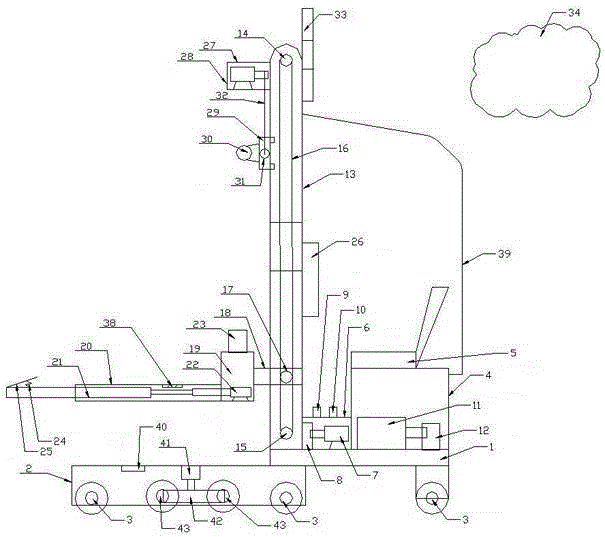

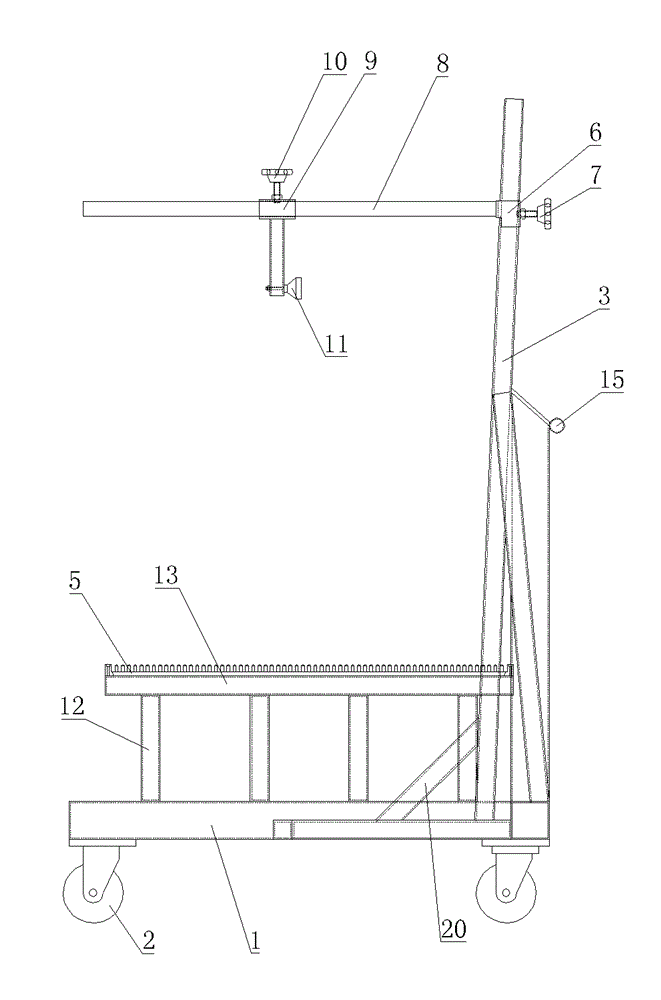

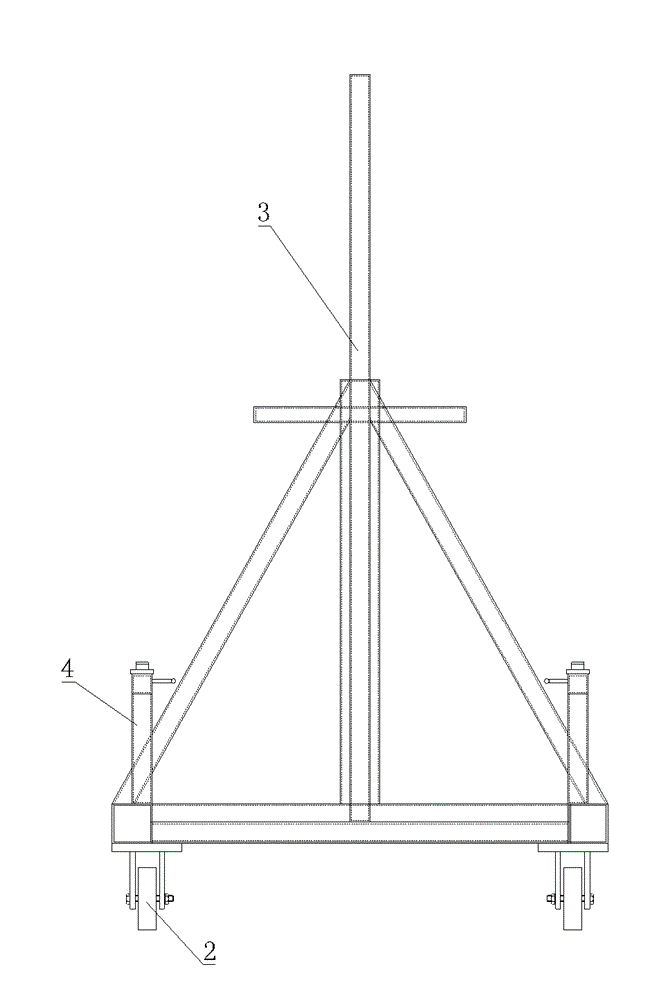

Efficient stacking device for carrying goods

ActiveCN105036003AEfficient handlingRelieve physical fatigueLifting devicesComputer moduleTransportation technology

The invention belongs to the technical field of goods transportation and particularly discloses an efficient stacking device for carrying goods. The efficient stacking device for carrying goods comprises a base, a fork body base connected with one side of the base, a guiding beam frame arranged on the base, a first motor arranged on the base, a gear transmission box connected with the first motor, a first chain wheel, a second chain wheel, a third chain wheel arranged between the first chain wheel and the second chain wheel and connected with a transmission chain, a first fork body, a second fork body, a protective cover and an auxiliary assembly arranged in the fork body base. The first chain wheel and the second chain wheel are arranged at the upper end and the lower end of the guiding beam frame respectively. The first fork body and the second fork body are arranged on the two sides of a fork body box respectively. The protective cover is arranged above a seat. The two ends of the protective cover are connected with the guiding beam frame and a seat installing frame respectively. When the efficient stacking device is used for carrying goods and performing stacking operation and the size of the goods is too large, a second cylinder is controlled to be pressed downwards through a monitoring module, an auxiliary running wheel makes contact with the ground, and stable carrying is completed; and the visible range is wide due to the full-transparent protective cover, and meanwhile injuries to operators caused when the goods slide can be effectively prevented.

Owner:米亚斯物流设备(昆山)有限公司

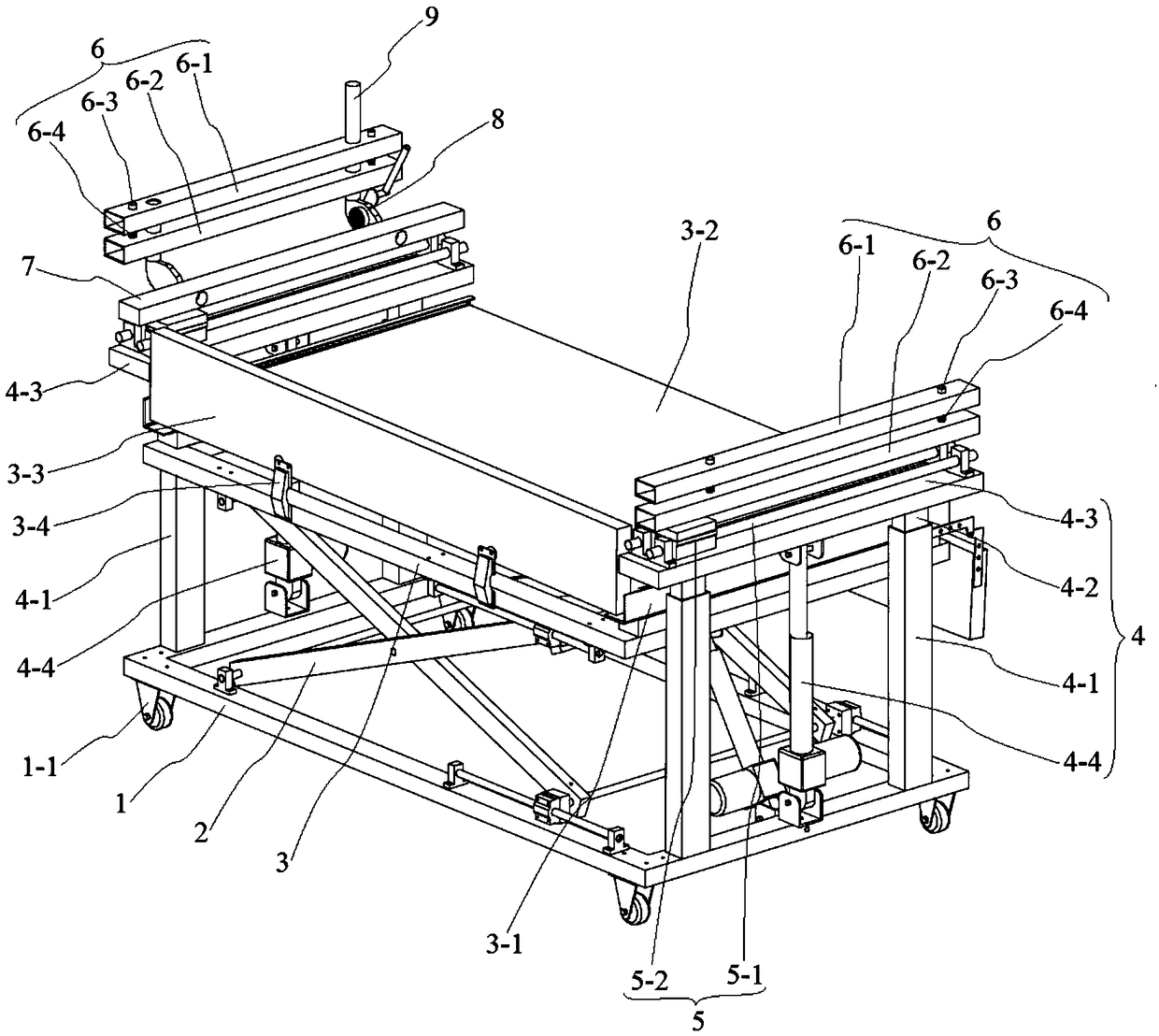

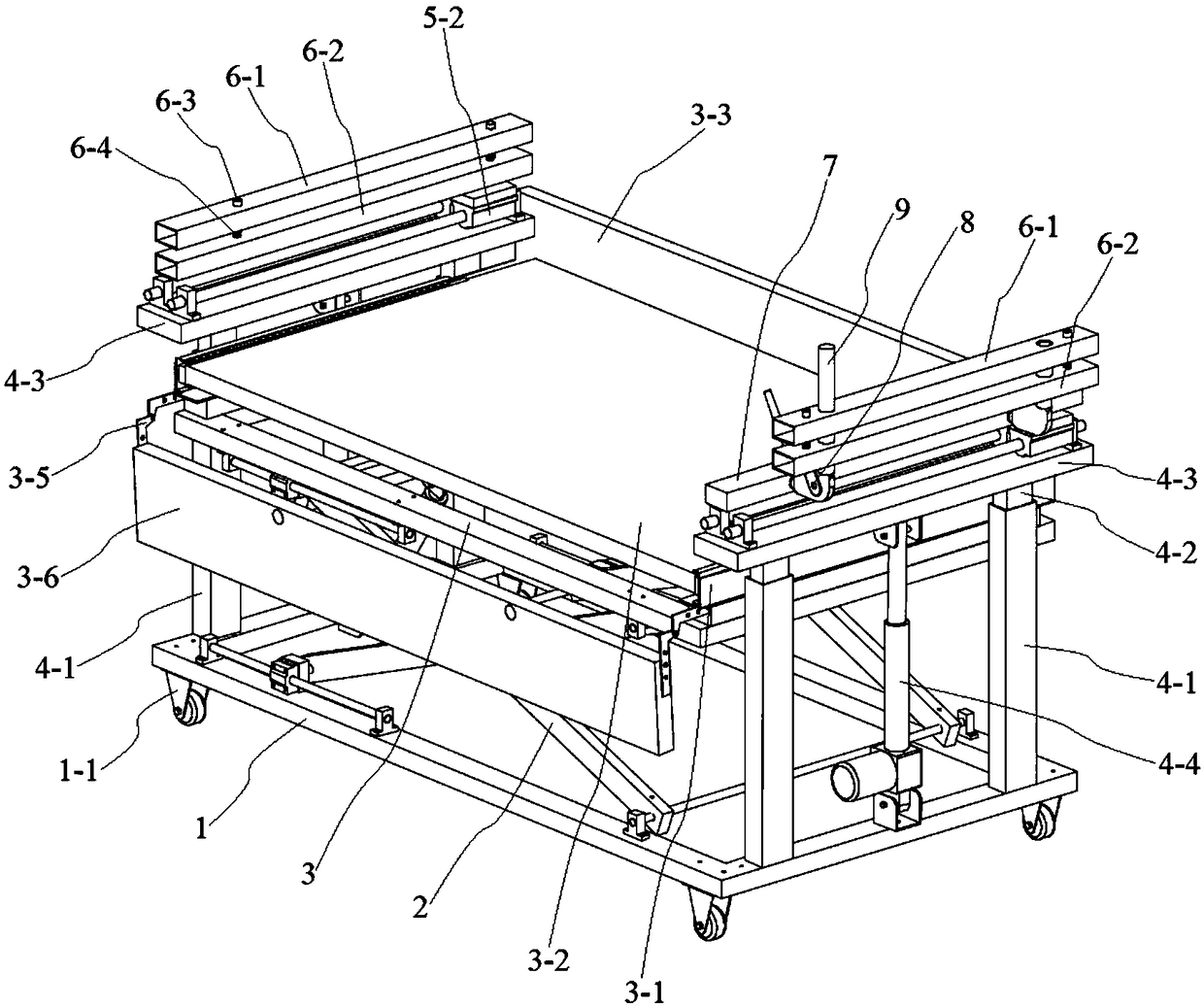

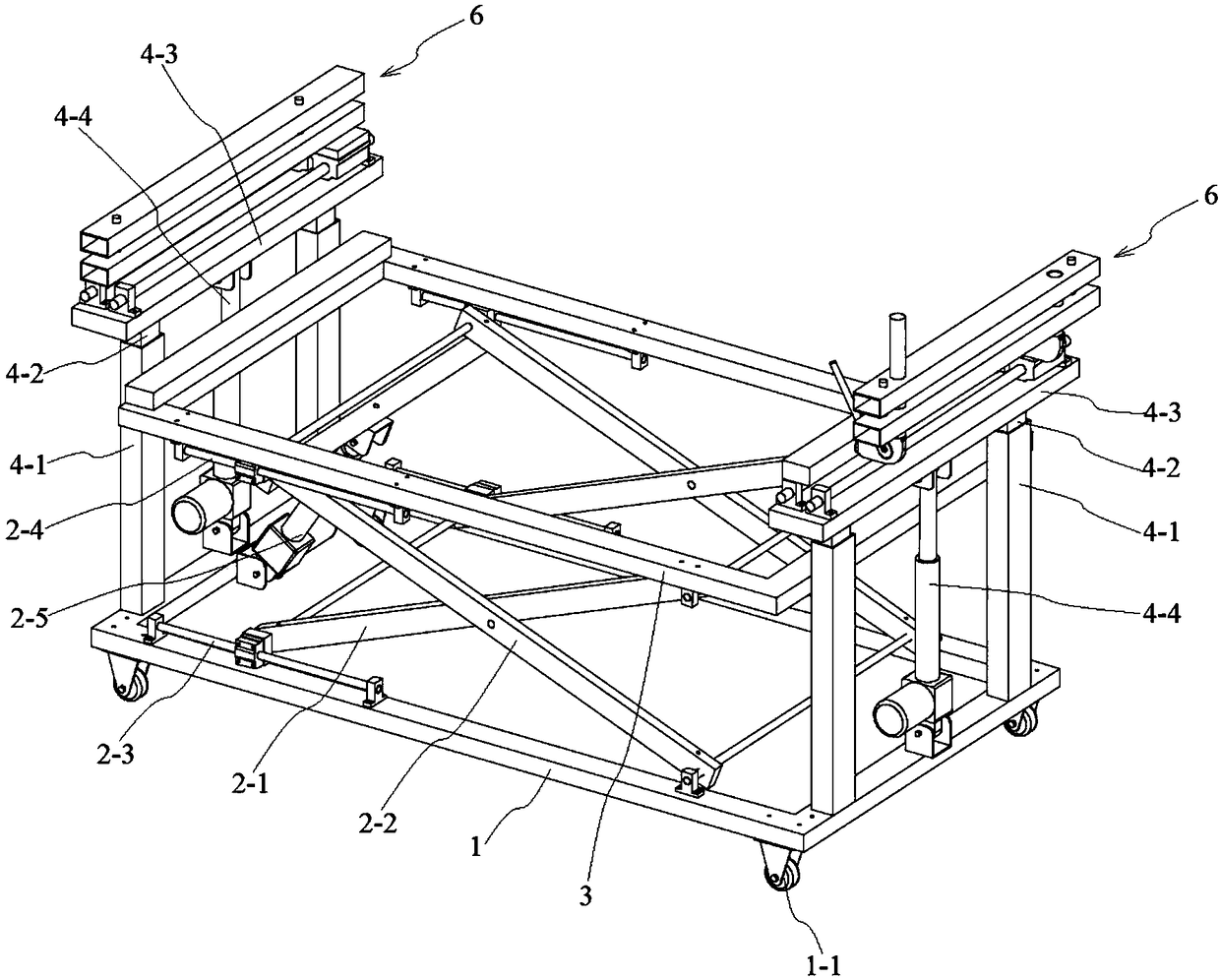

Critical-patient transfer bed with carrying function and application method thereof

The invention discloses a critical-patient transfer bed with a carrying function and an application method thereof and belongs to the field of medical equipment. The critical-patient transfer bed hasthe advantages that the critical-patient transfer bed is provided with a bed board which can ascend and descend and extend outwardly, sheet clamping mechanisms which can ascend and descend and extendoutwardly are arranged at the head and the tail of the transfer bed, the sheet clamping mechanism at one end has a turning function, a patient can be stably transferred between the transfer bed and ahospital bed by the coordination of the two sheet clamping mechanisms and the telescoping bed board, simple and reliable patient carrying is achieved, high carrying safety is achieved, the secondary damage problem during patient carrying is solved, and high carrying efficiency is achieved; in addition, first and second guard boards are arranged on two sides of an upper bed frame and can be horizontally spread to form expansion bed surfaces, the critical-patient transfer bed can be used as the hospital bed which can be used by the patient for a long time, and the critical-patient transfer bed is simple in structure, convenient to use, flexible to operate, low in manufacturing cost, good in market popularization value and the like.

Owner:CHANGZHOU INST OF TECH

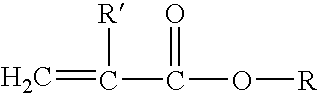

Rubber composition containing resinous nanopractice

InactiveUS20050228134A1Deteriorate controllabilityDeteriorate stabilitySpecial tyresCoatingsElastomerPolymer science

This invention relates to a tread rubber composition for tires with the addition of crosslinked resinous nanoparticles having a high glass transition temperature (Tg) into elastomeric base polymers. The invention demonstrates greatly improved handling performance without deteriorating controllability and stability during high-speed running. The present invention discloses a rubber composition comprising: (1) a rubbery polymer and (2) from 1 phr to 30 phr of pre-crosslinked polymer particles, wherein the pre-crosslinked polymer particles have a particle size which is within the range of 30 nm to 500 nm, wherein the pre-crosslinked polymer is comprised of repeat units that are derived from at least one monomer selected from the group consisting of acrylate monomers, vinyl aromatic monomers, acrylonitrile monomer, and vinyl halide monomers, and wherein the pre-crosslinked polymer has a glass transition temperature which is within the range of 30° C. to 200° C.

Owner:THE GOODYEAR TIRE & RUBBER CO

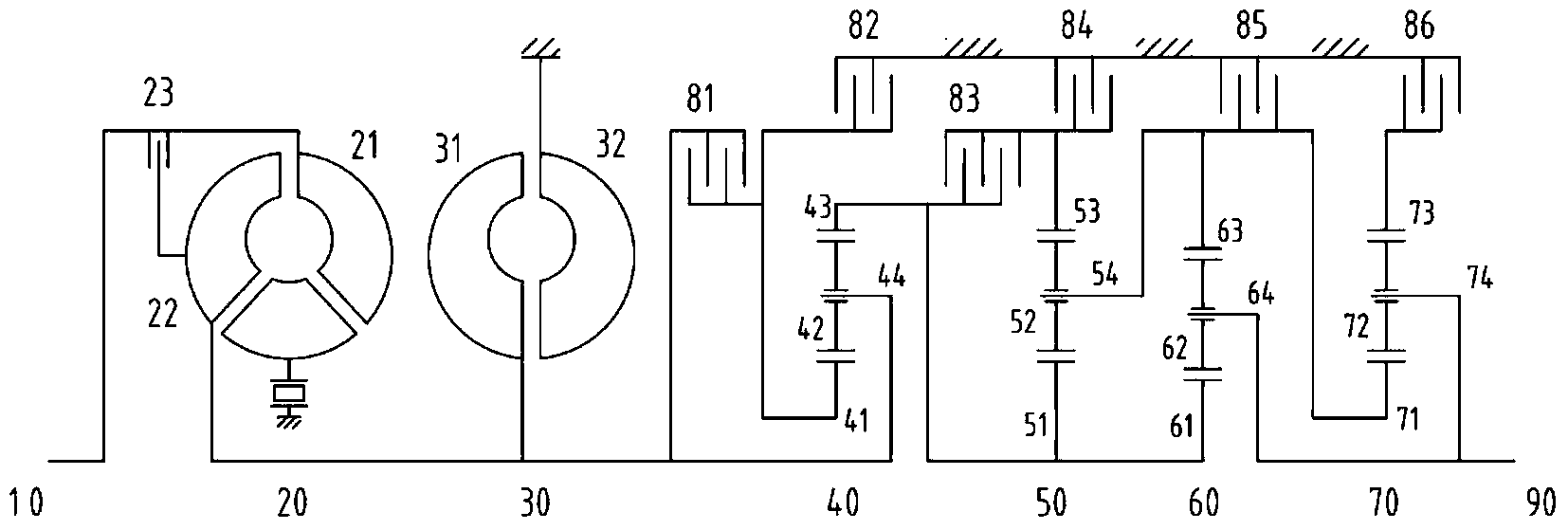

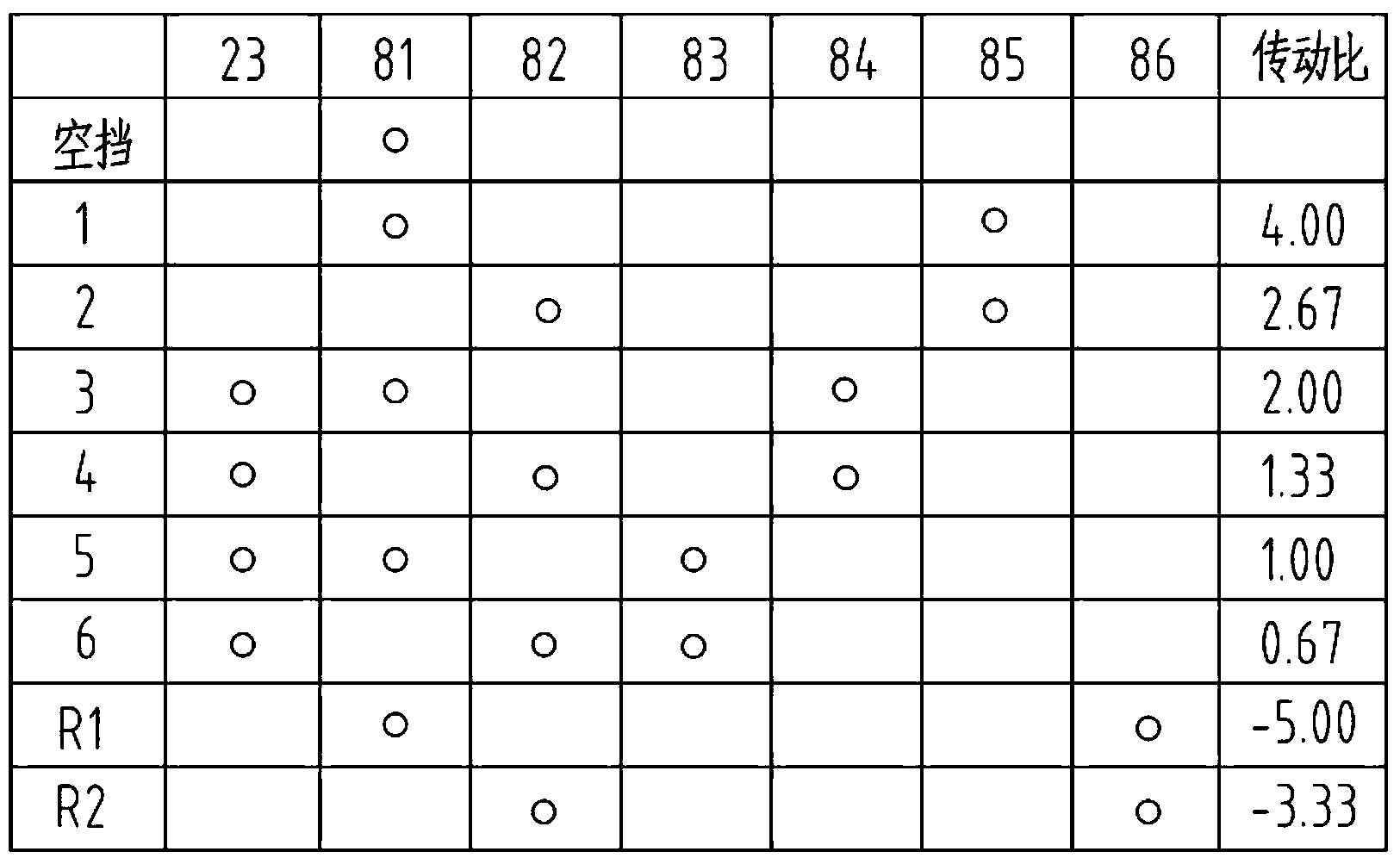

Planetary automatic transmission

InactiveCN103591248AStable handlingEasy to operateTransmission elementsFluid gearingsImpellerAutomatic transmission

The invention relates to a transmission, in particular to a planetary automatic transmission. The planetary automatic transmission comprises the input end, a torque converter, a lockup clutch, a hydraulic retarder, four planetary rows, two clutches, four brakes and the output end, wherein the input end is connected with a torque converter pump impeller, a torque converter worm wheel and a rotor of the hydraulic retarder are connected with a first planetary frame, a first gear ring and a second solar gear are connected with a third solar gear, a second planetary frame and a third gear ring are connected with a fourth solar gear, a third planetary frame and a fourth planetary frame are connected with the output end, the two ends of the lockup clutch are connected with the torque converter worm wheel and the torque converter pump impeller respectively, the two ends of the first clutch are connected with the first planetary frame and a first solar gear respectively, the two ends of the second clutch are connected with the first gear ring and the second solar gear respectively, one ends of the brakes are fixed, and the other ends of the brakes are respectively connected with the first solar gear, the second gear ring, the third gear ring and the fourth gear ring. According to the planetary automatic transmission, six forward gears and two backward gears can be achieved, the structure is simple, and machining is conveniently carried out.

Owner:UNIV OF SCI & TECH BEIJING

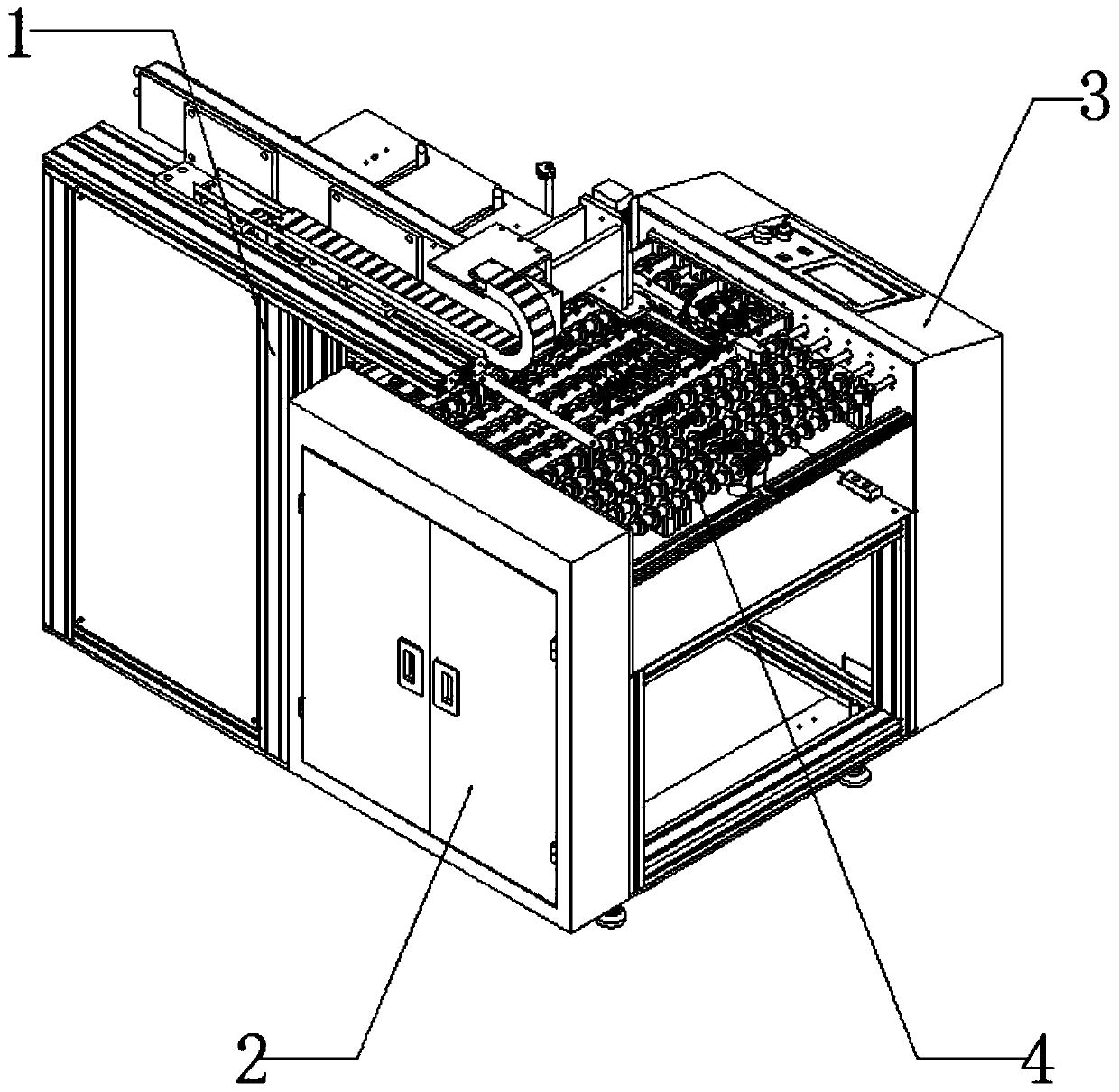

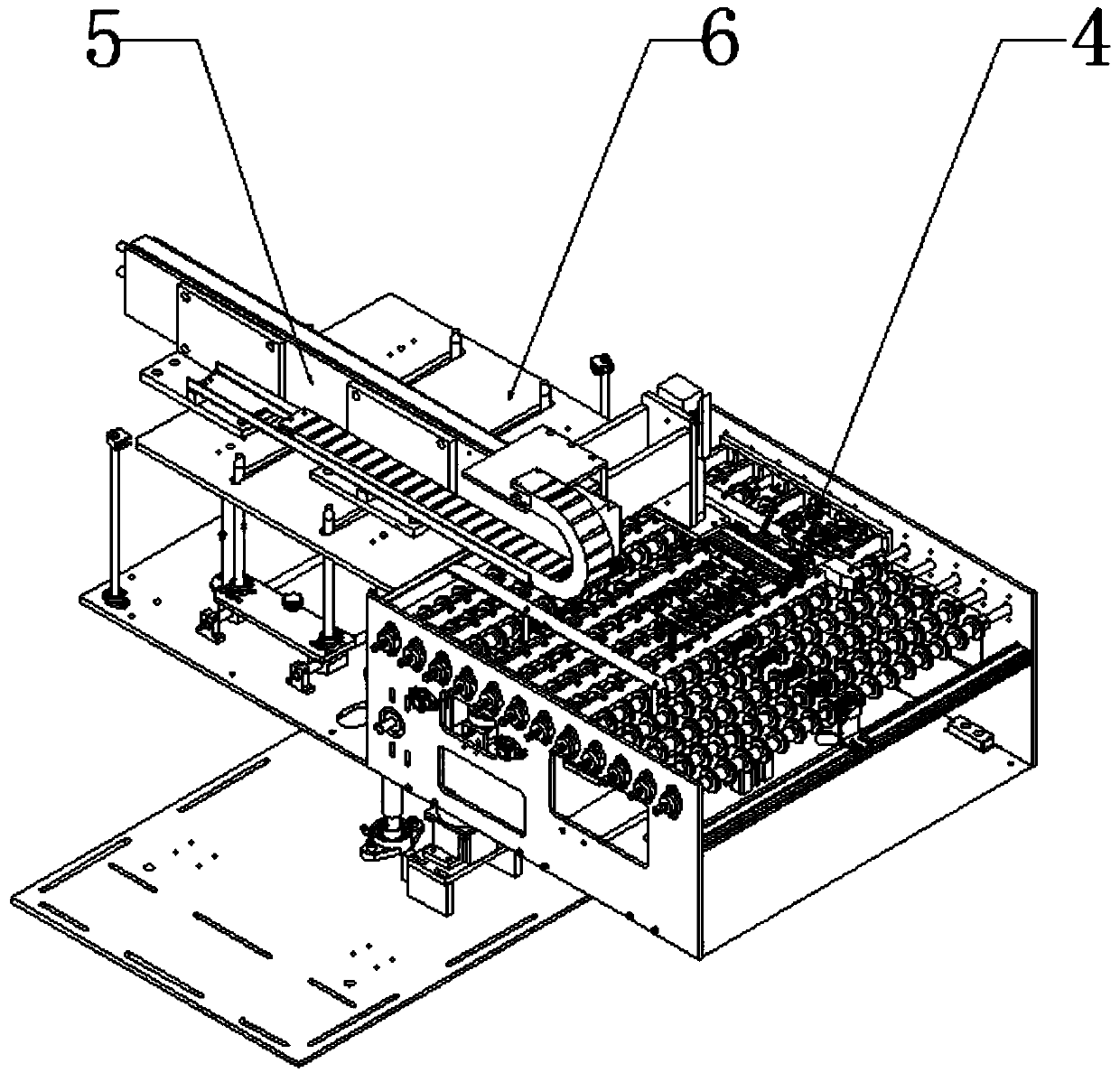

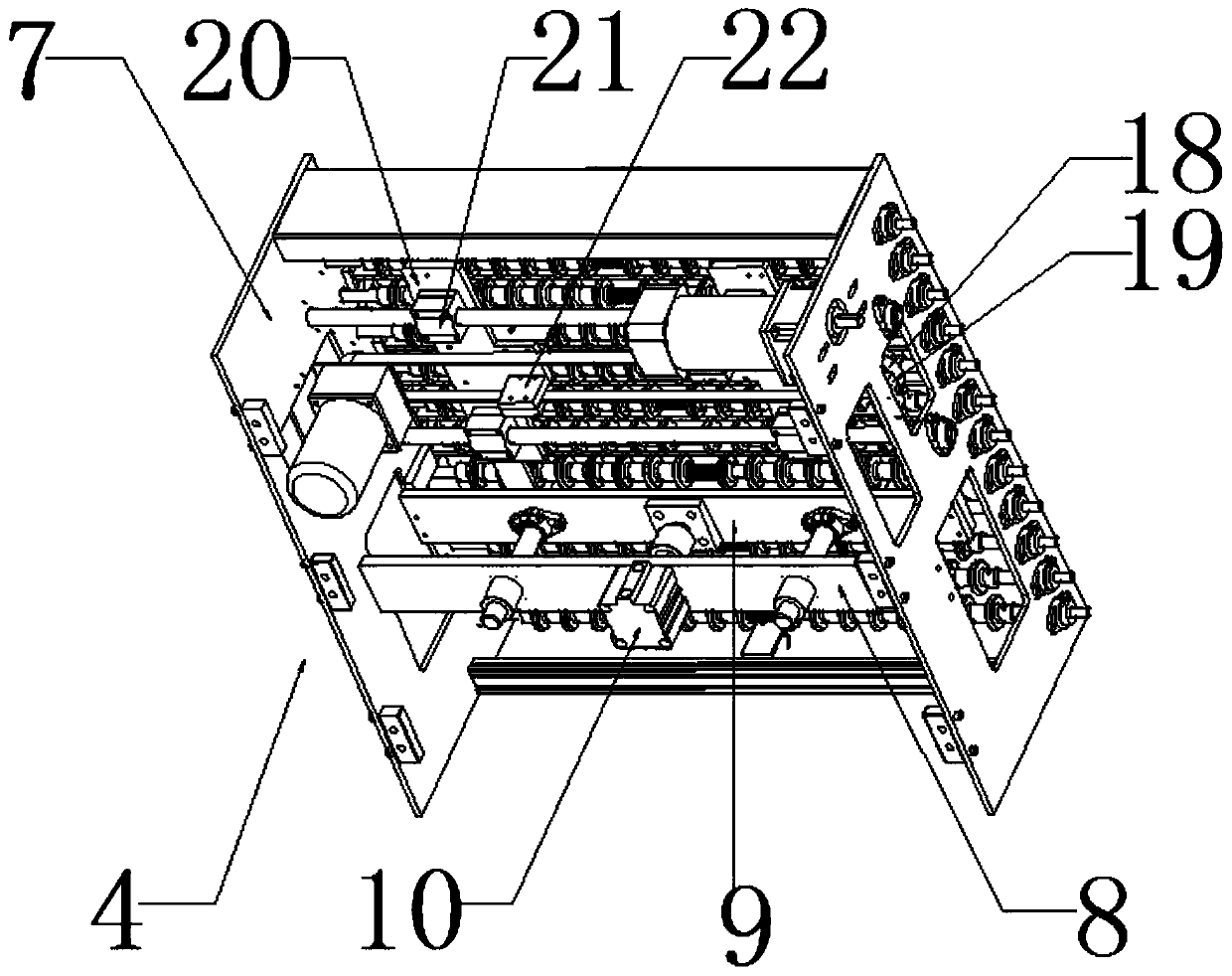

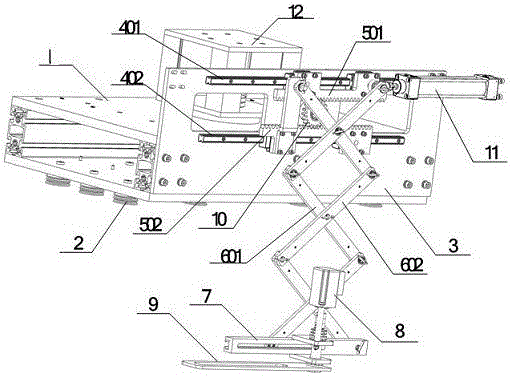

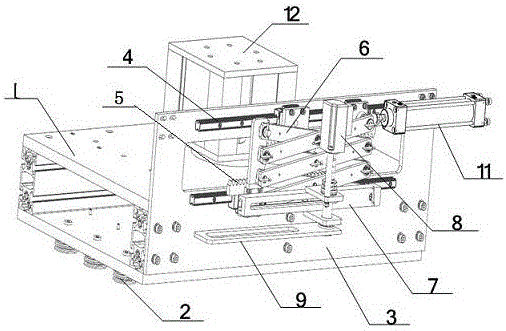

Automatic loading and unloading device for PCBA manufacturing and production and operation method thereof

ActiveCN109795880APlay a protective roleHigh degree of automationControl devices for conveyorsStacking articlesAutomationEngineering

The invention discloses an automatic loading and unloading device for PCBA manufacturing and production. The automatic loading and unloading device for the PCBA manufacturing and production comprisesa frame, an electric cabinet box, an electric cabinet, a discharging mechanism, a suction hanging mechanism and a stacking mechanism, wherein one side of the frame is provided with the electric cabinet box, the other side of the frame is provided with the electric cabinet, one side of the top of the frame is provided with the suction hanging mechanism, the inner side of the frame is provided withthe discharging mechanism, and one side adjacent to the frame is provided with the stacking mechanism; According to the invention, the piled PCBA is regulated on the whole, so that the transportationcan be carried out directly through positioning and adsorption of the suction hanging mechanism in each transportation process, and the automation degree is high; meanwhile, according to different sizes and areas of different PCBA, the position of a sucking disc can be planned and adjusted before the suction hanging mechanism is used, and when the suction carrying is carried out, the stable conveying can be completed by using the least sucking disc; the PCBA on a transmission mechanism is well calibrated and positioned to ensure that the subsequent manufacturing process can be directly operated.

Owner:广东中晨电子科技有限公司

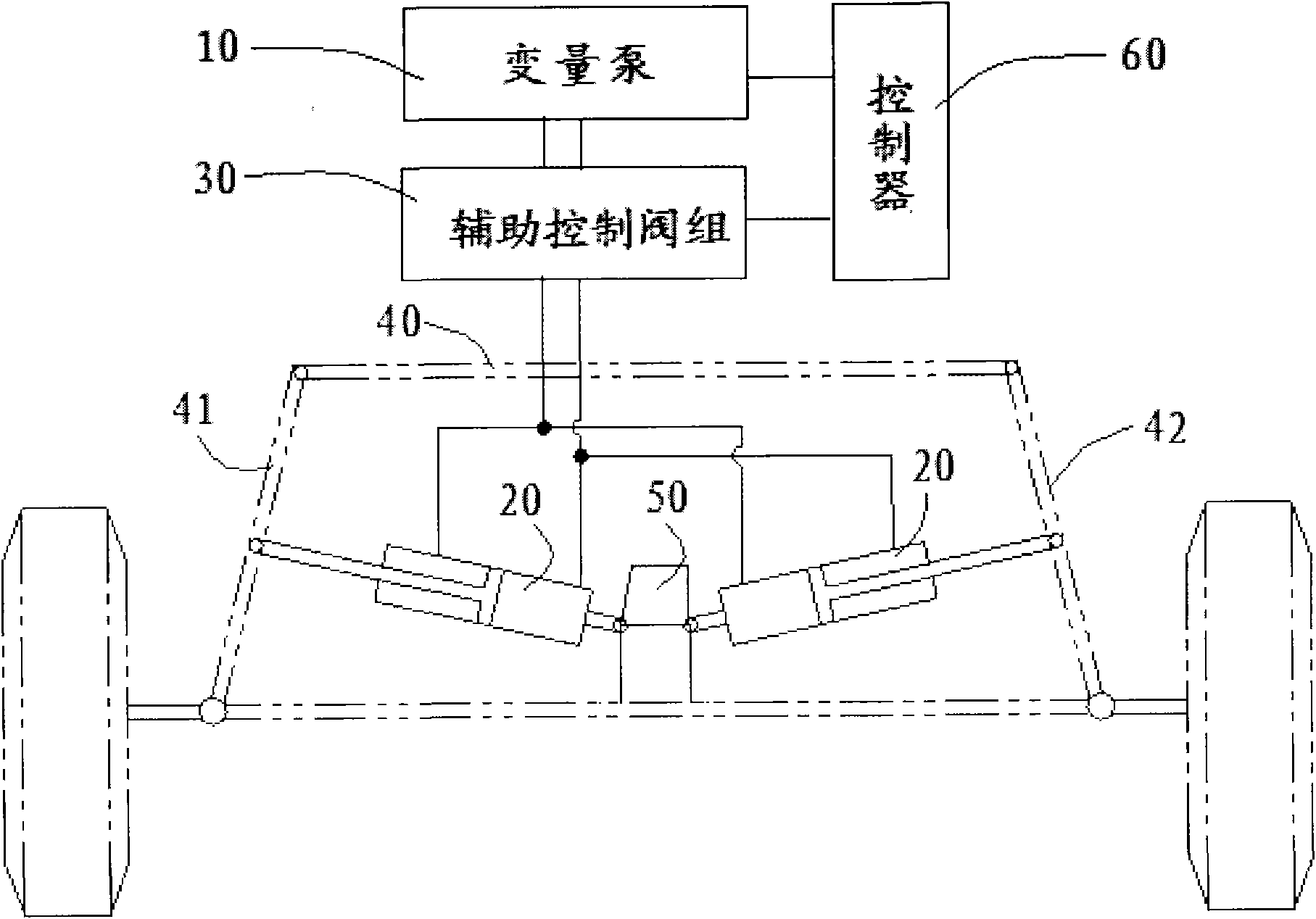

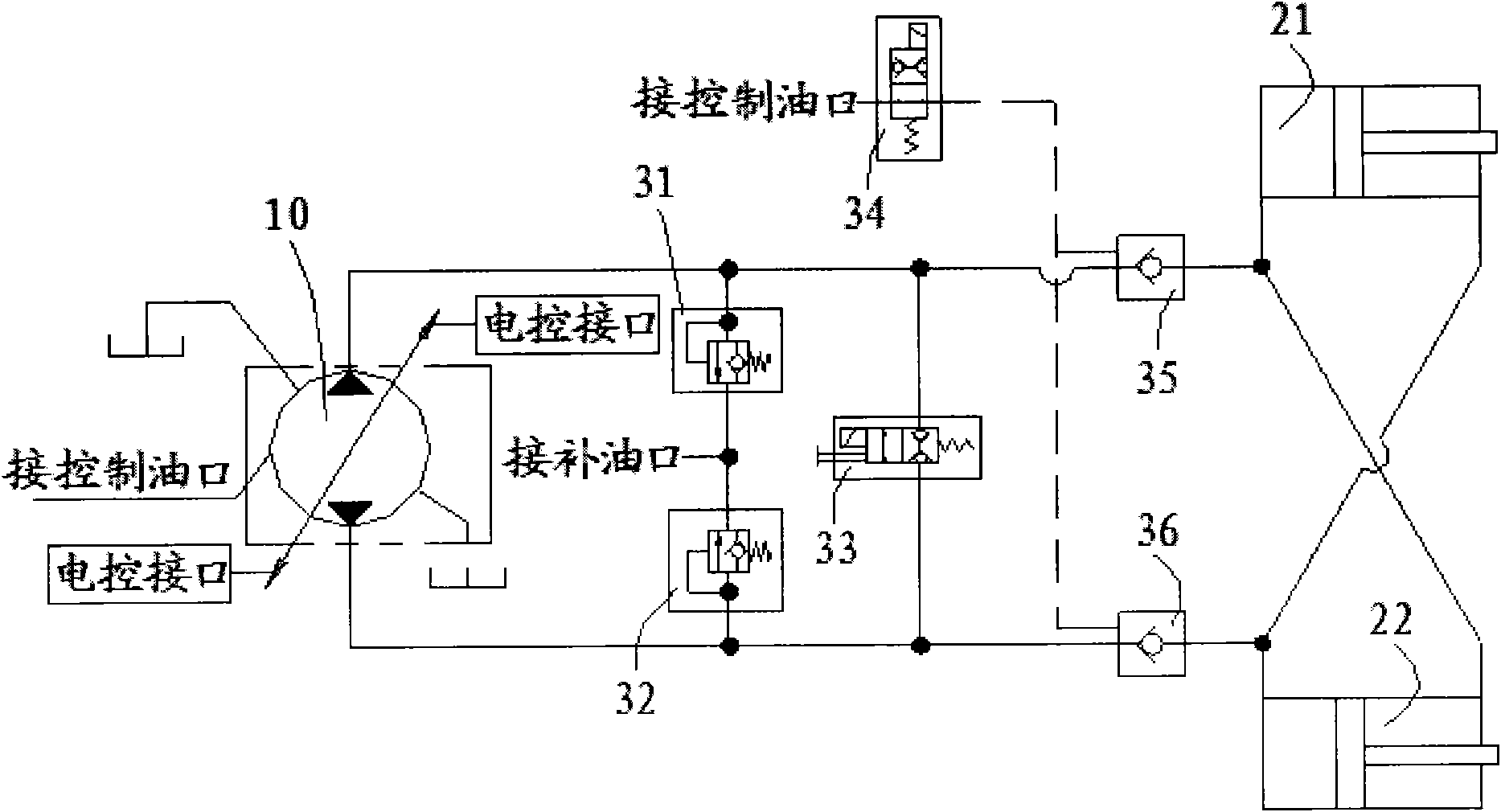

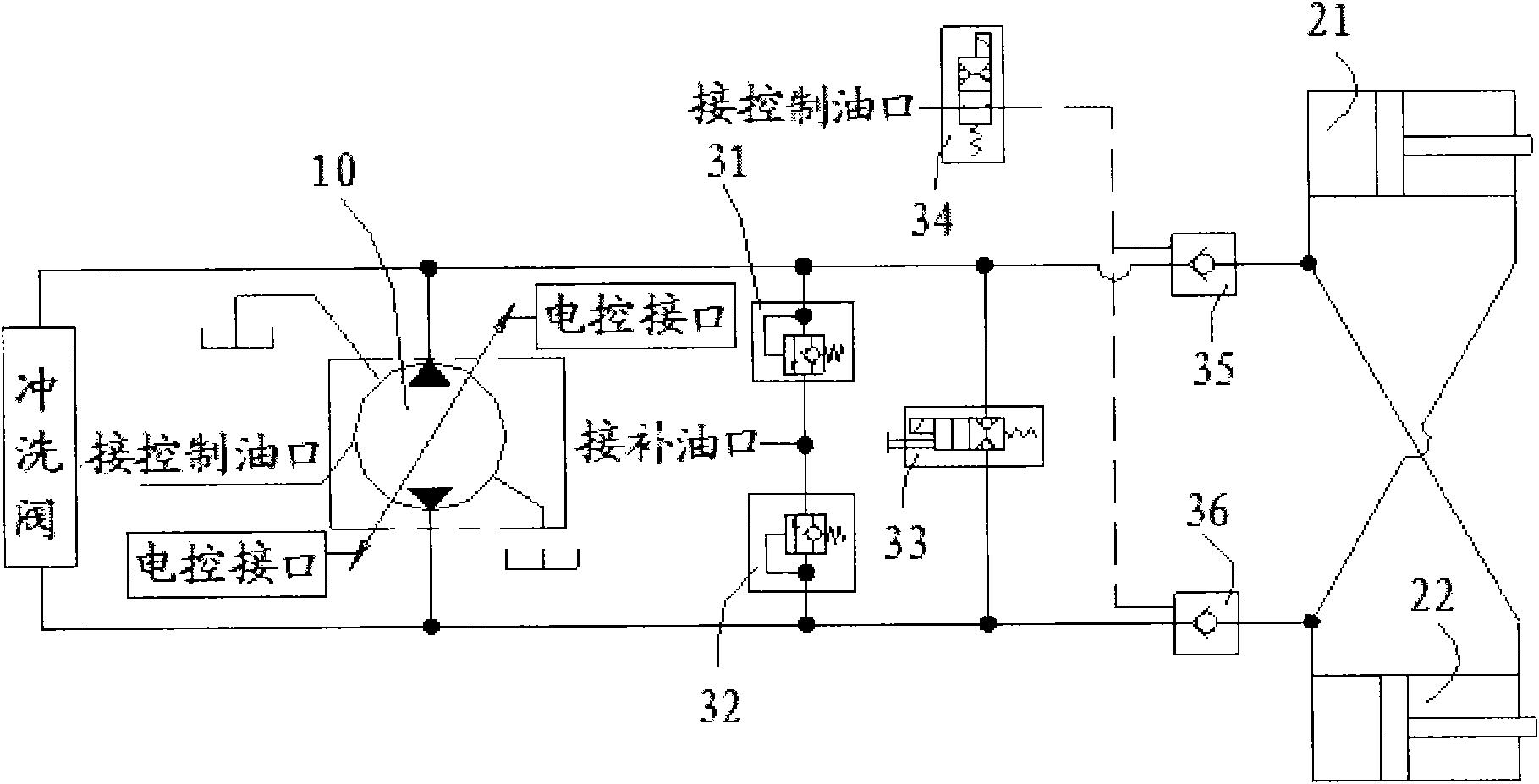

Electric control closed type hydraulic steering system, control method and vehicle having system

ActiveCN102372025ASave energySave power consumptionSteering linkagesFluid steeringElectricitySteering control

The invention discloses an electric control closed type hydraulic steering system and a vehicle having the system. The hydraulic steering system comprises a hydraulic steering device, a variable pump and a controller, wherein the hydraulic steering device comprises a power-assisted steering cylinder; the variable pump is used for directly supplying hydraulic oil to the power-assisted steering cylinder through a main oil path; an output flow of the variable pump and a direction of the oil path are controlled by an electric signal; and the controller is in signal connection with the variable pump and is used for calculating the output flow of the variable pump and confirming the direction of the oil path according to the working condition of the vehicle and a steering requirement signal of a wheel and accordingly outputting the electric signal used for controlling the variable pump. According to a pump-control-cylinder principle, the steering closed type hydraulic control of the vehicleis realized by the hydraulic steering system. The hydraulic steering system is used for supplying a hydraulic power according to a steering requirement and fully utilizing an output power of an engine or a transmission element thereof, thereby meeting an energy-saving requirement, reducing system elements, being beneficial to optimizing and lightening the configuration of the vehicle and being suitable for the steering control of various engineering mechanical vehicles or special vehicles.

Owner:ZOOMLION HEAVY IND CO LTD

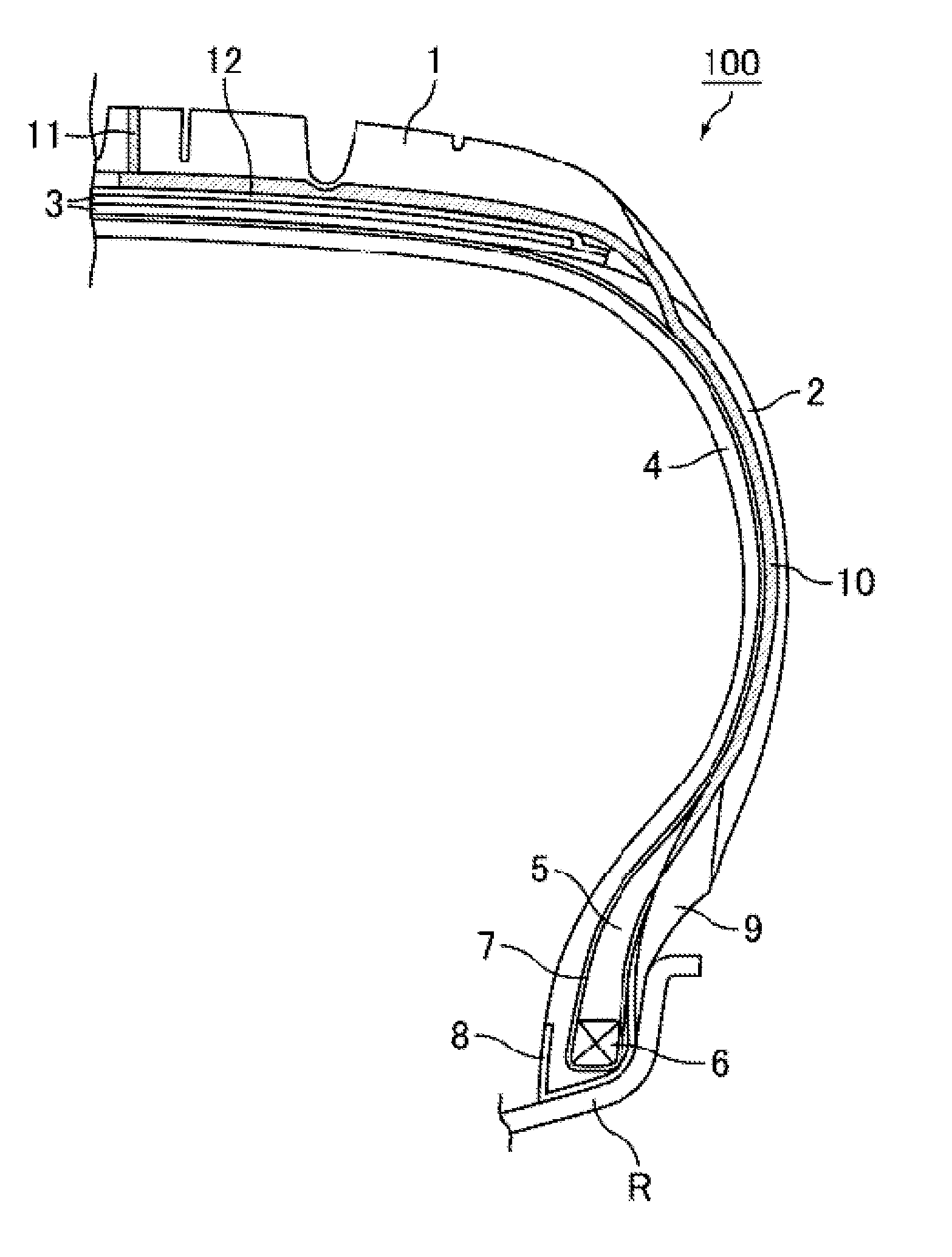

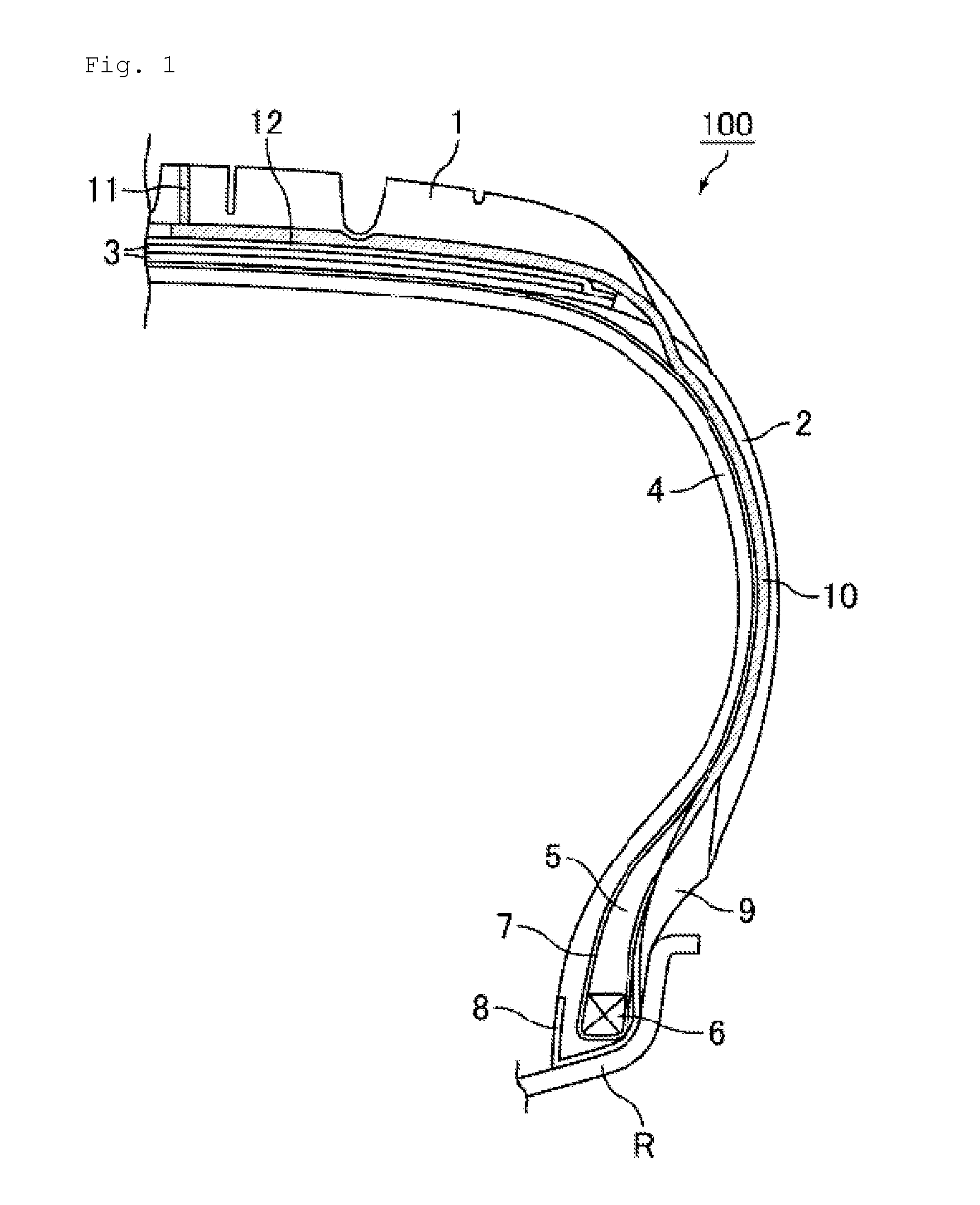

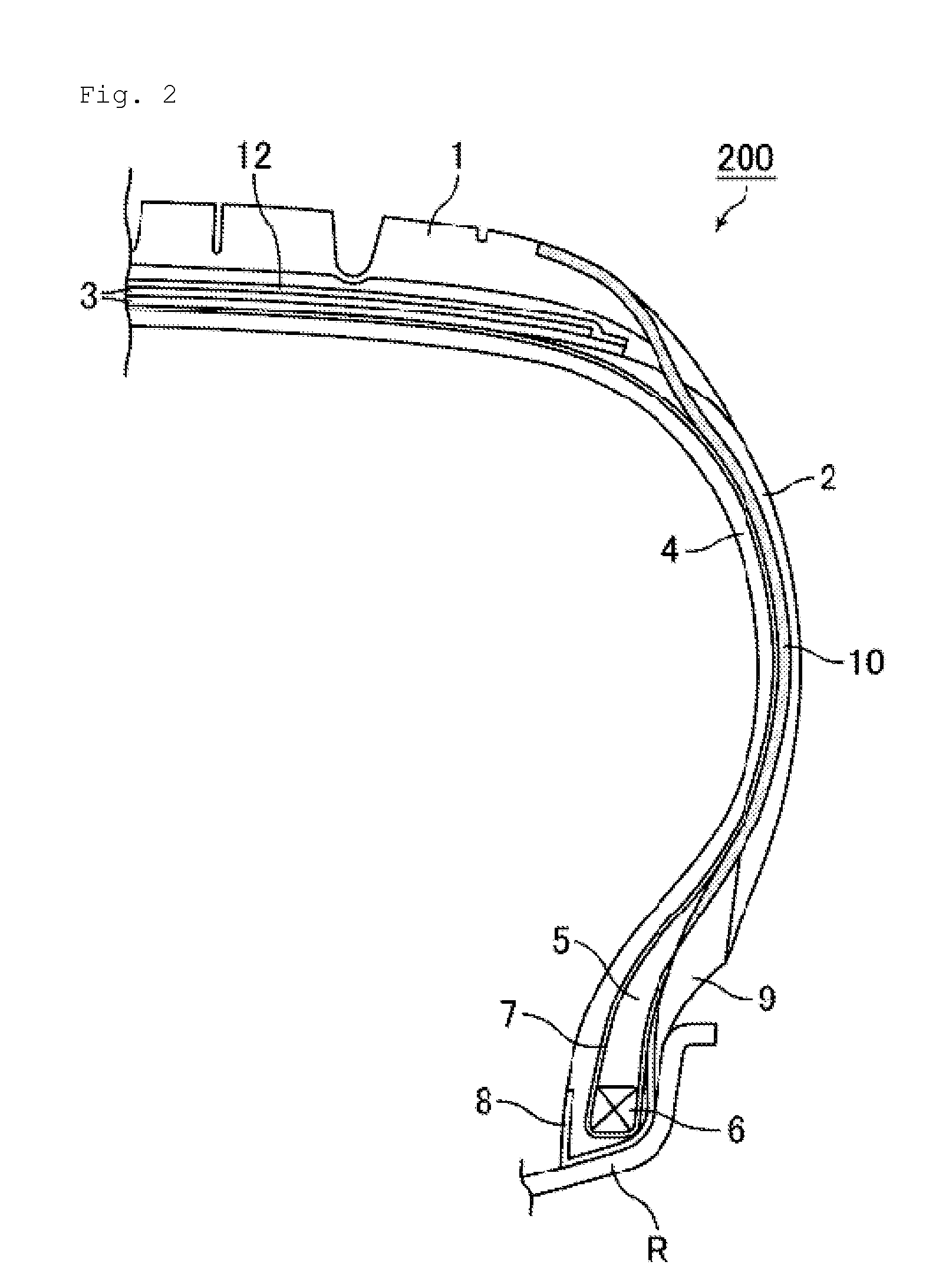

Pneumatic tire

ActiveUS20140326386A1Reduce weightGood fuel efficiencySpecial tyresPneumatic tyre reinforcementsEngineeringFuel efficiency

Provided is a pneumatic tire ensuring conductivity while being reduced in weight, and having good fuel efficiency and handling stability. The tire includes a sidewall and a carcass, the sidewall including a laminate of two or more rubber layers including an inner sidewall layer (1) located closest to the carcass, and an outer sidewall layer (2) constituting an outer surface of the tire; the layer (1) including a rubber composition for (1); the layer (2) including a rubber composition for (2); the carcass including a carcass cord topped with a rubber composition for a carcass cord topping (3); the sidewall having a thickness of 3.0 mm or less; the layer (1) having a thickness of 0.2-1.0 mm; the composition for (1) having a volume resistivity of 5.0×107 Ω·cm or less; the compositions for (1) and for (2), and the compositions for (3) and for (1) satisfying specific relations.

Owner:SUMITOMO RUBBER IND LTD

Anti-collision transfer box for ceramic tiles

PendingCN107902209AStable handlingSolve the instabilityContainers to prevent mechanical damageRigid containersSlide plateIndustrial engineering

The invention discloses an anti-collision transfer box for ceramic tiles. The anti-collision transfer box comprises a bottom plate, wherein the two sides of the top of the bottom plate are fixedly connected with supporting rods; the top ends of the supporting rods are fixedly connected with slide plates; a movable plate is in sliding connection between the two slide plates; the middle part of thetop of the movable plate is fixedly connected with a box body through a base; the middle part of the bottom of the inner cavity of the box body is fixedly connected with a fixed rod; the top end of the fixed rod is fixedly connected with the top of the inner cavity of the box body; the middle parts of the two sides of the fixed rod are fixedly connected with mobile plates; and one side of each mobile plate is fixedly connected with the inner wall of the box body. The invention relates to the technical field of ceramic tile transfer. According to the anti-collision transfer box for the ceramictiles disclosed by the invention, the two sides of the top of the bottom plate are fixedly connected with the supporting rods, so that the ceramic tiles can be stably transferred, are especially stable during transfer, are not liable to shake, and not liable to have position changes, and therefore, the problem that an existing anti-collision transfer box for the ceramic tiles does not have stability is solved.

Owner:WUXI HUIOU CERAMIC CO LTD

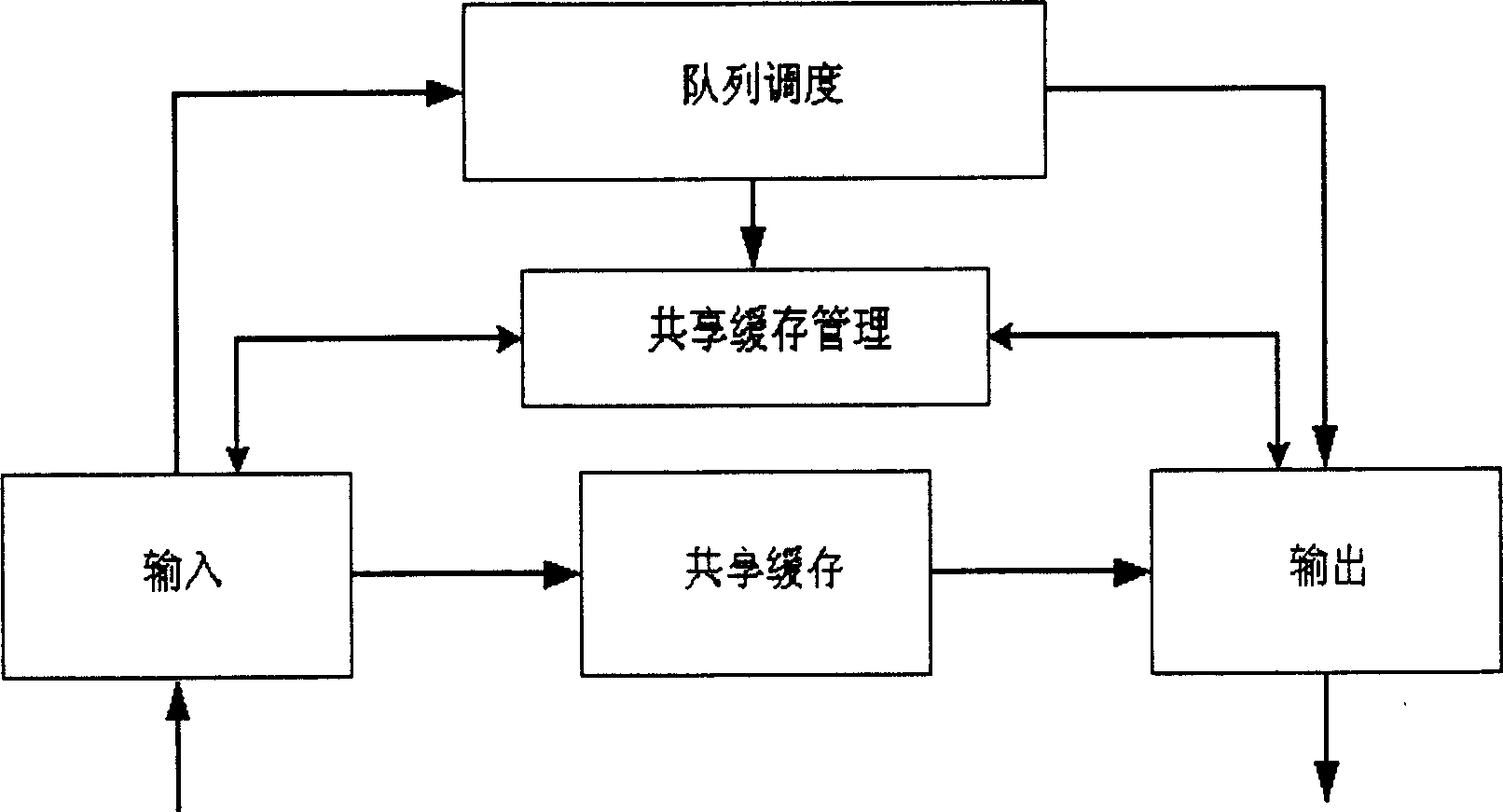

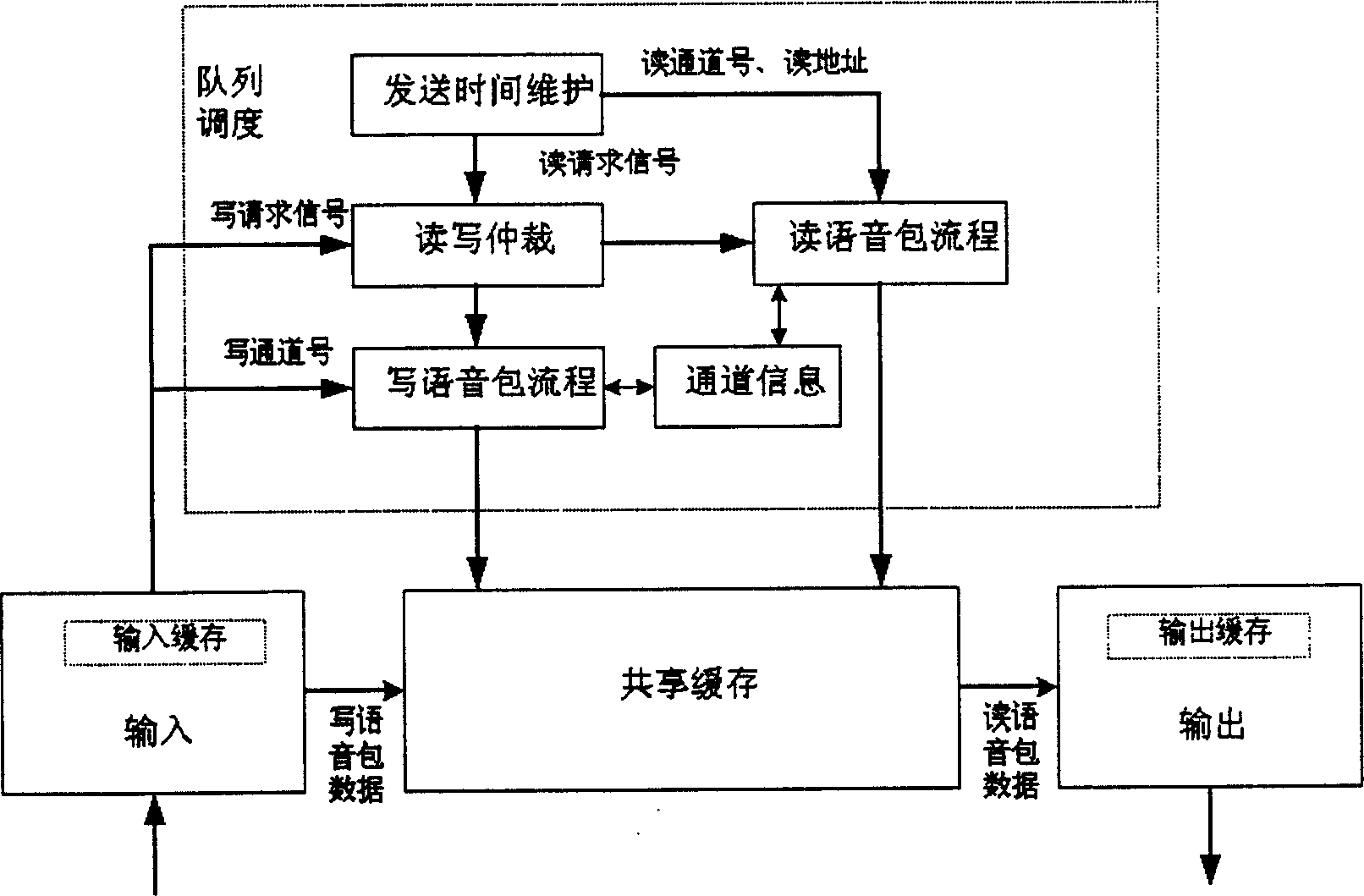

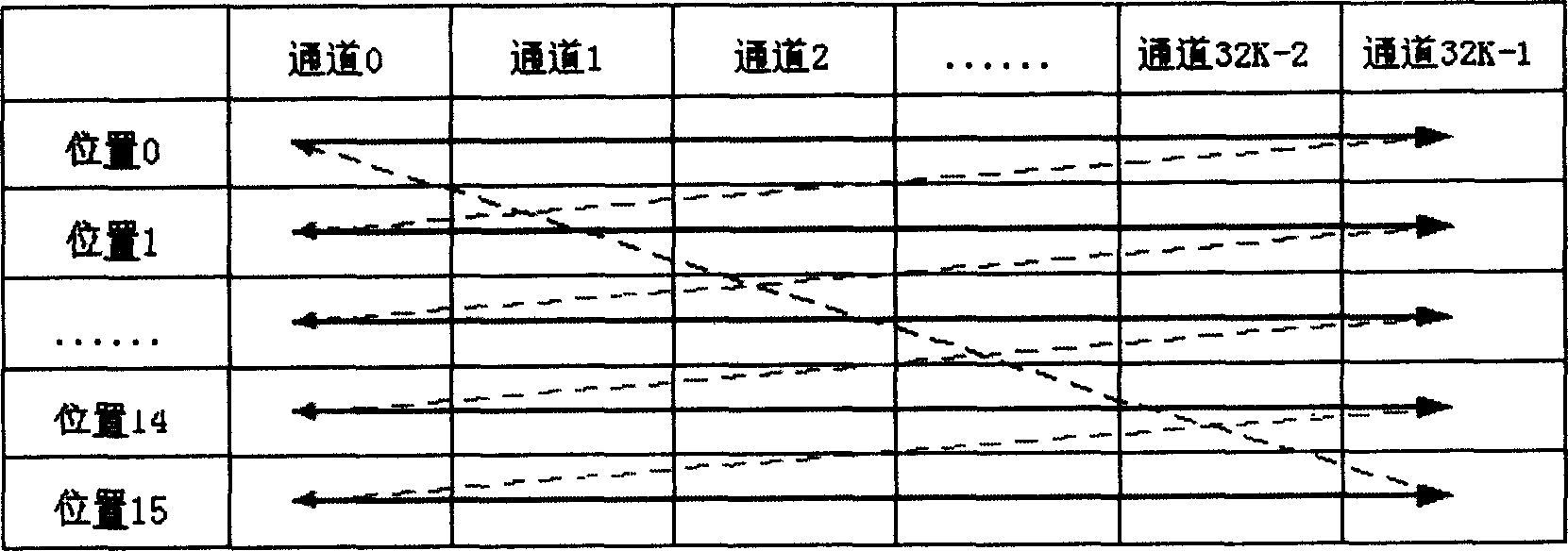

Large capacity realtime stream processing method for removing dithering in using buffer memory

InactiveCN1463125AAvoid additional jitterProcessing time differenceData switching networksStreaming dataNetwork packet

First, with real time stream data packet being received, write request is sent to the dispatching queue and request for reading packets is sent at fixed time interval. Read / write arbitrator arbitrates the writing and reading requests and starts-up reading and writing flows. The reading flow reads channel information, fetching packet data from shared buffer and stores them in output buffer. The writing flow reads channel information and writes data packet to shared buffer. In the invention, the buffered de-dithering chain table is omitted so as to prevent the additional dither inducted by requests of reading voice packets put forward from multiple channel at same time. Since allocation mode of fixed position and average capacity is utilized, thus the processing performance is stable. The processing is carried out in parallel so as to increase de-dithering channels.

Owner:HUAWEI TECH CO LTD

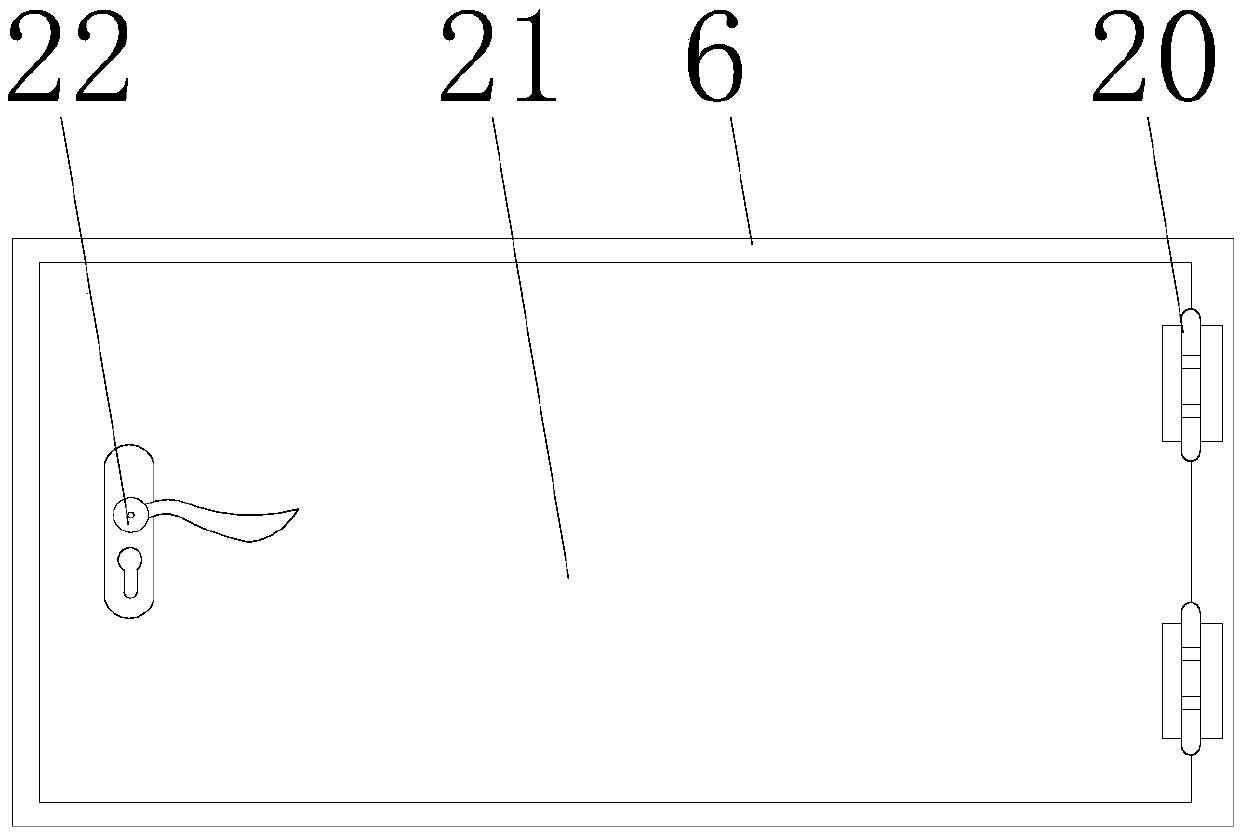

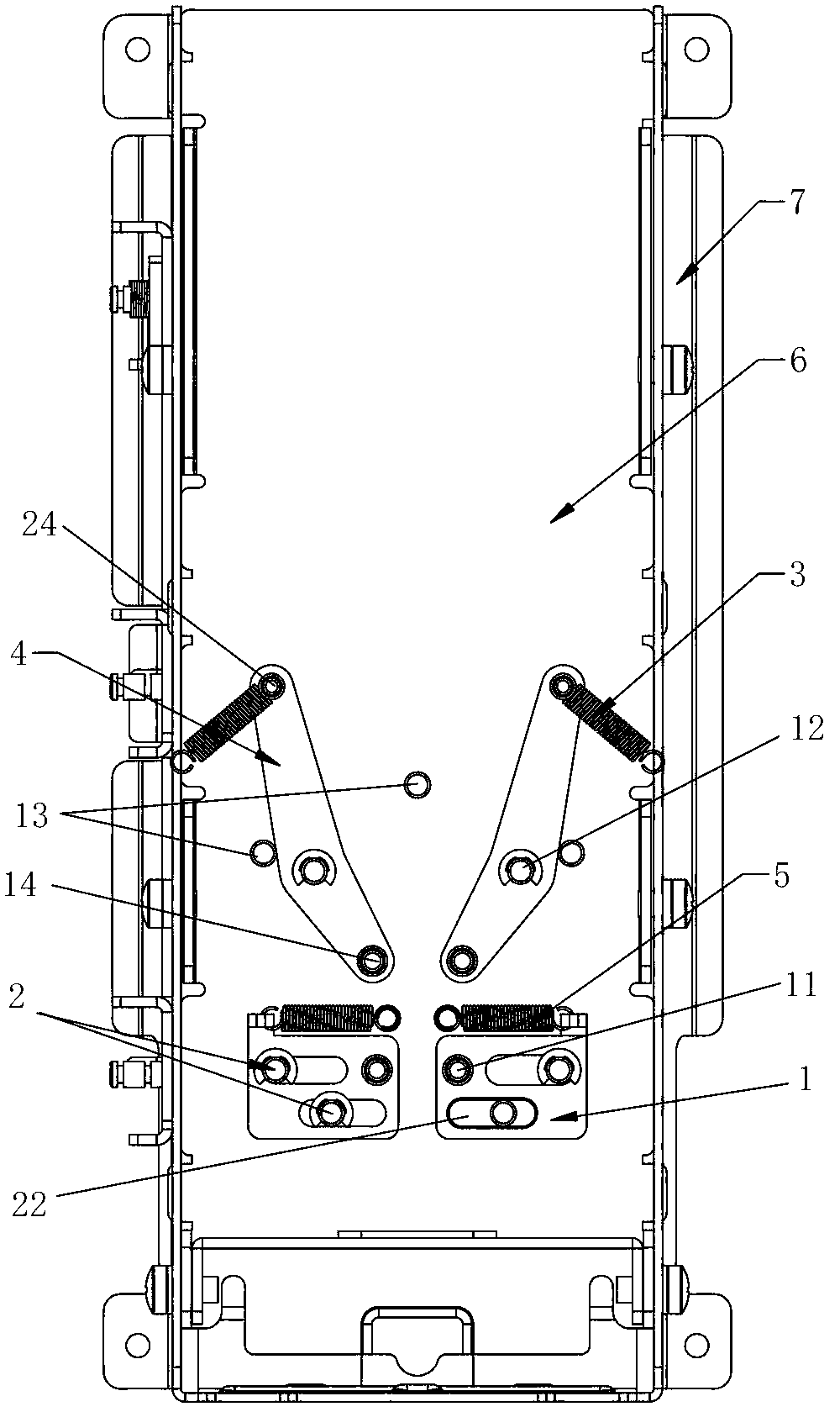

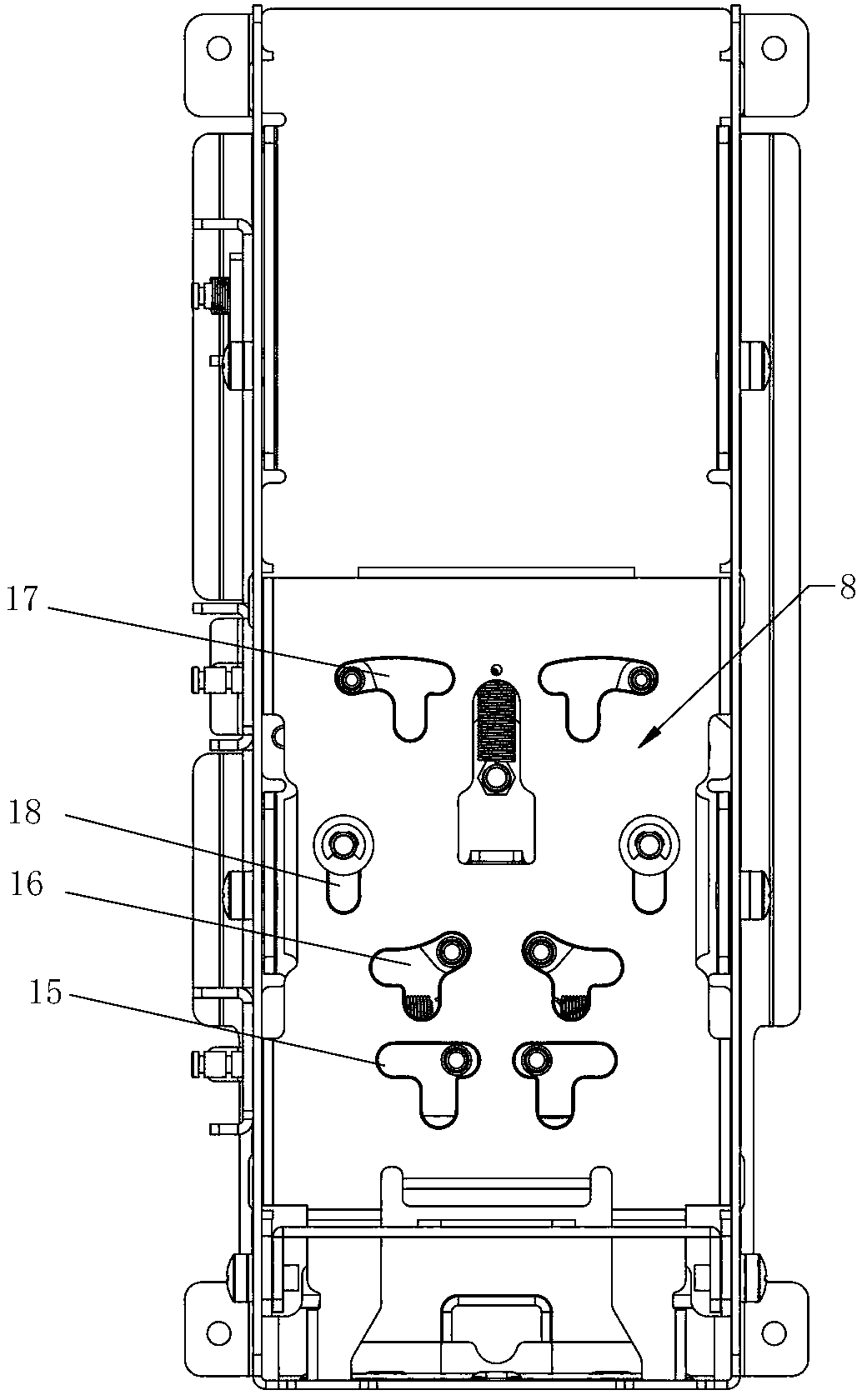

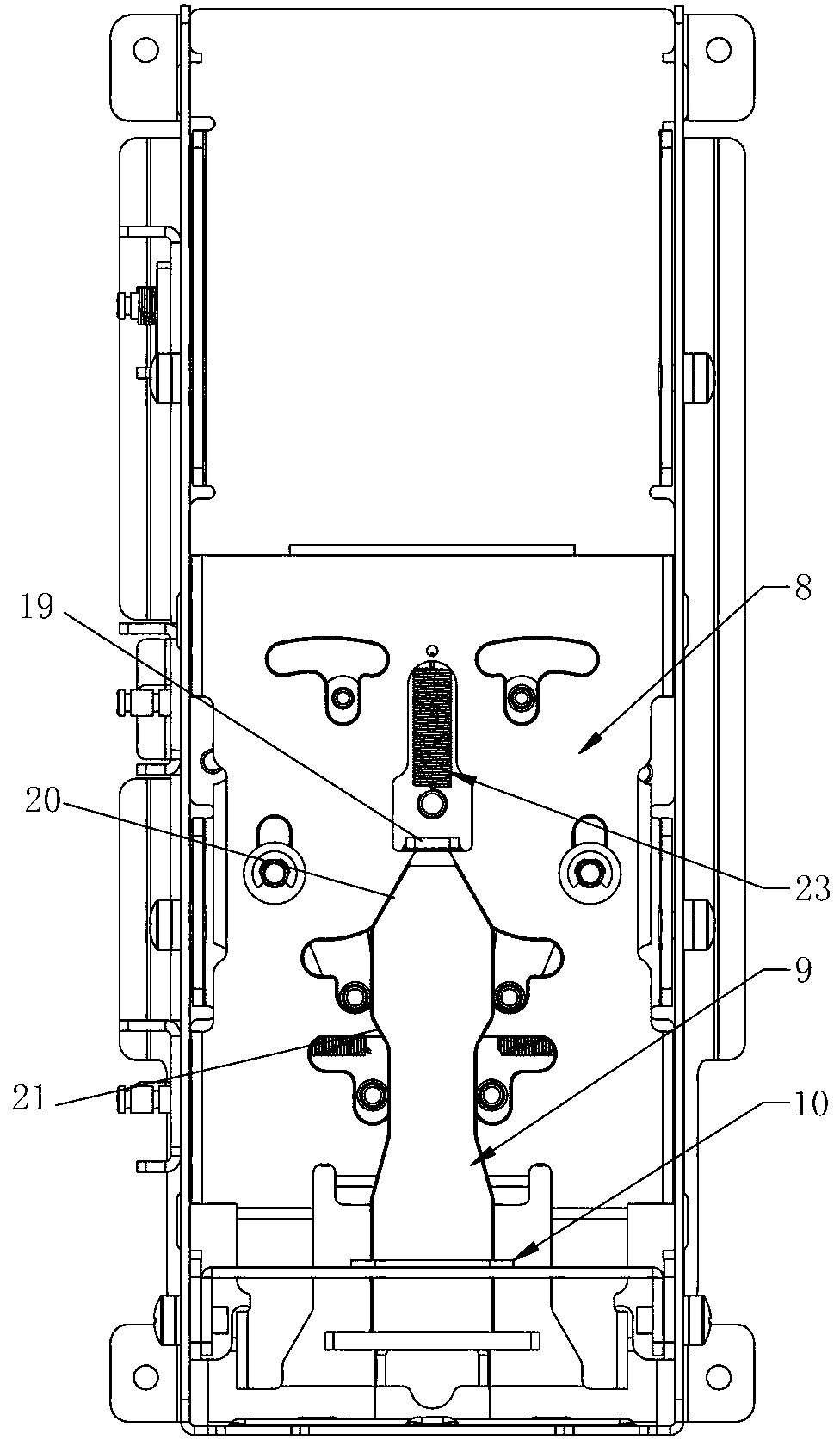

Control mechanism of card box gate

ActiveCN102938079AEasy to operateImprove reliabilityConveying record carriersLocking mechanismEngineering

The invention discloses a control mechanism of a card box gate. The control mechanism is characterized by comprising an unlocking sheet (9) and a stopper block (19). The control mechanism further comprises at least one locking mechanism of a transverse locking mechanism and a rotational locking mechanism; the stopper block (19) is arranged on a movable gate (8); a first return spring (23) is arranged between the movable gate (8) and a card box inner shell stopper plate (6); a lock sheet inlet plate (10) is arranged on the card box inner shell stopper plate (6); and the unlocking sheet (9) is inserted into an inlet in the lock sheet inlet plate (10) so as to prop up the stopper block (19) and open the movable gate (8). The control mechanism of the card box gate adopts a mechanical locking mechanism with smart structure, convenience in operation and high security reliability.

Owner:HUNAN GREATWALL INFORMATION FINANCIAL EQUIP

A sheet glass carrying rack

InactiveCN105800156AAvoid collisionEasy accessExternal framesContainers to prevent mechanical damageFlat glassArchitectural engineering

Owner:WUXI XIDA FRICTION MATERIAL FACTORY

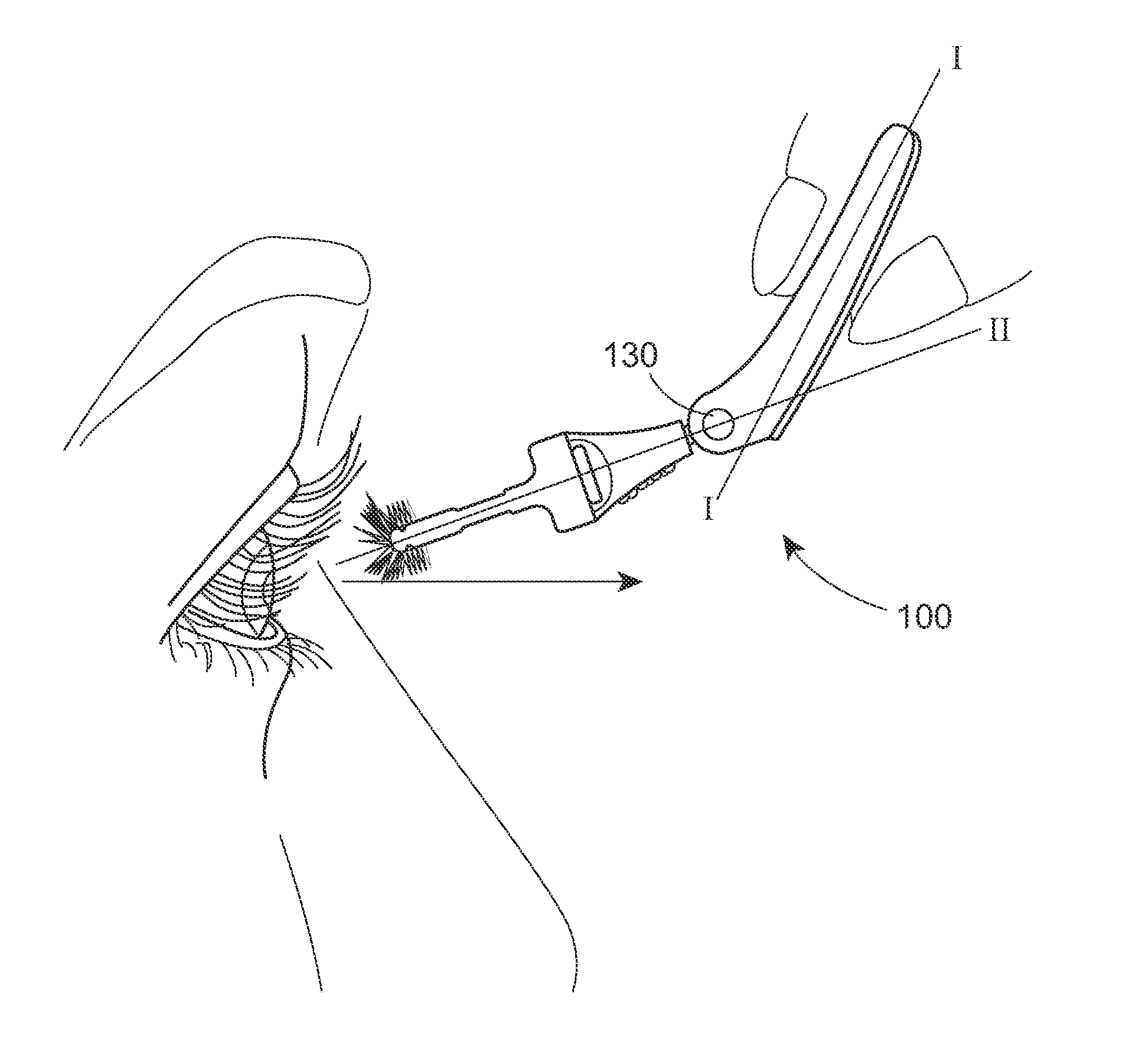

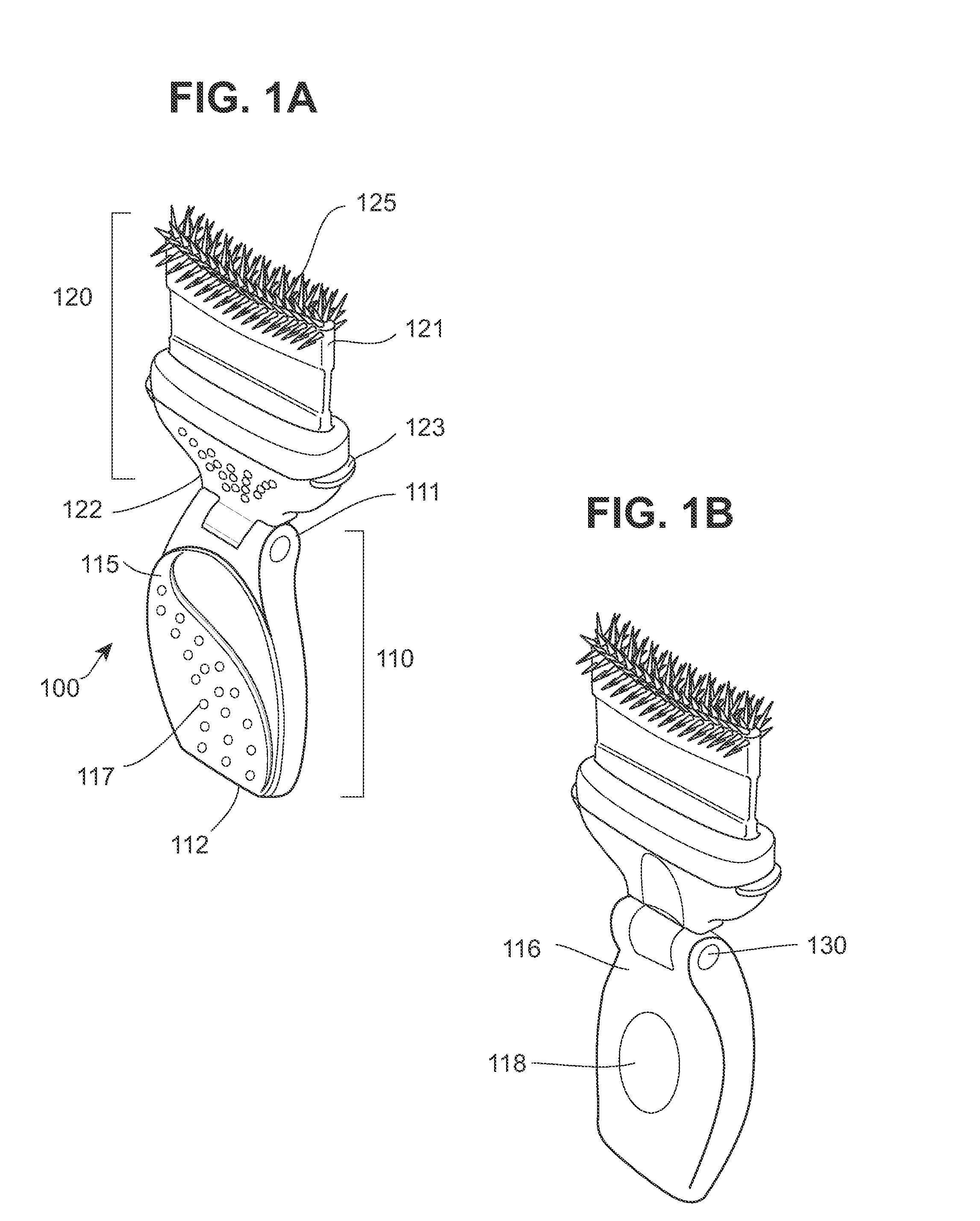

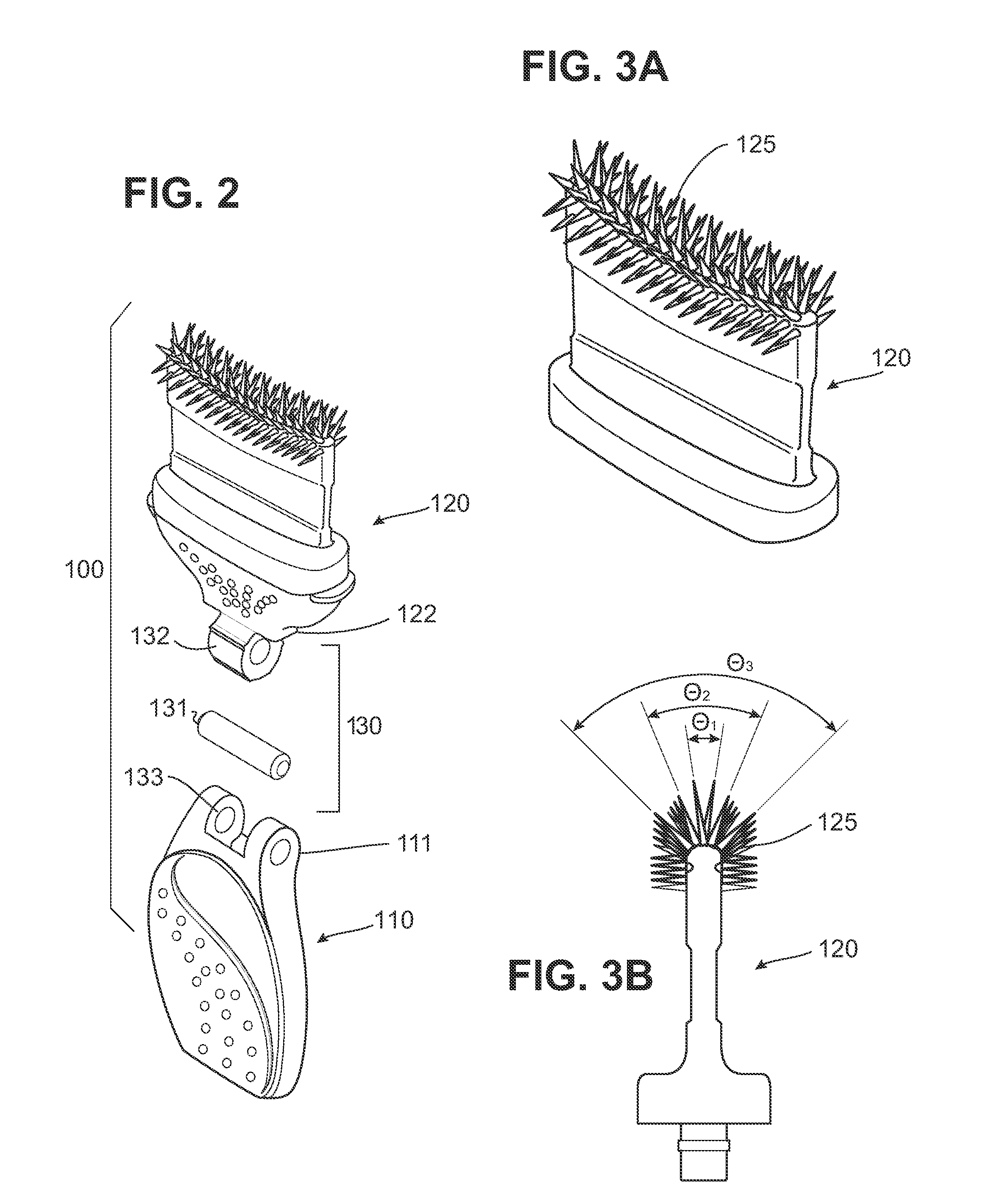

Ergonomic Cosmetic Groomer

An ergonomic groomer is provided for use with a human integument. The groomer comprises a handle portion and a head portion wherein the longitudinal axis of the head portion is positioned or can be rotatably positioned with respect to the longitudinal axis of the handle. The handle being suitably dimensioned for holding between the thumb and fingers without rotation of the handle. The head portion having at its distal end means for optionally holding a charge of cosmetic composition and transferring it to the eyelashes or another integument on contact therewith, such as but not limited to bristles.

Owner:AVON PROD INC

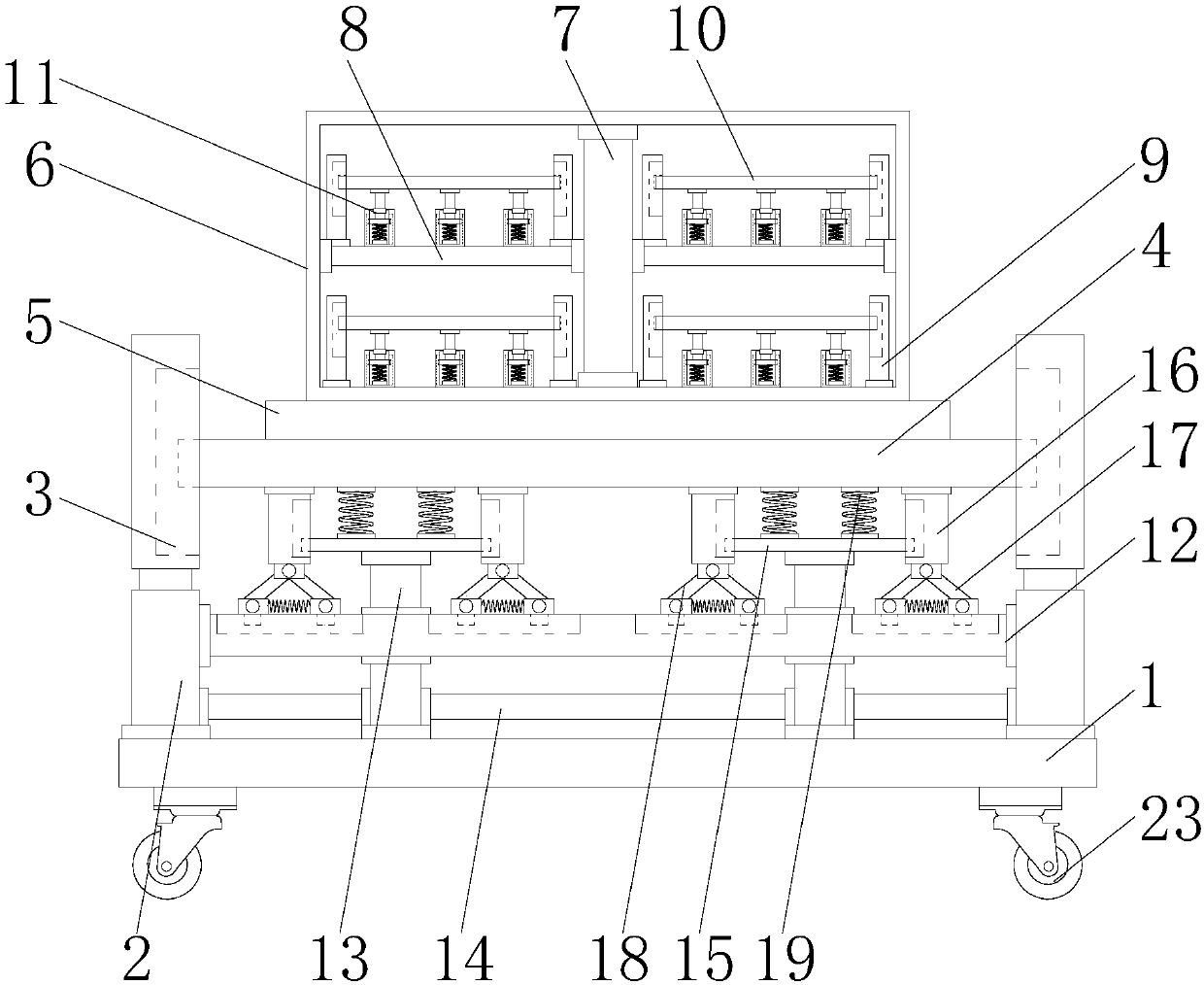

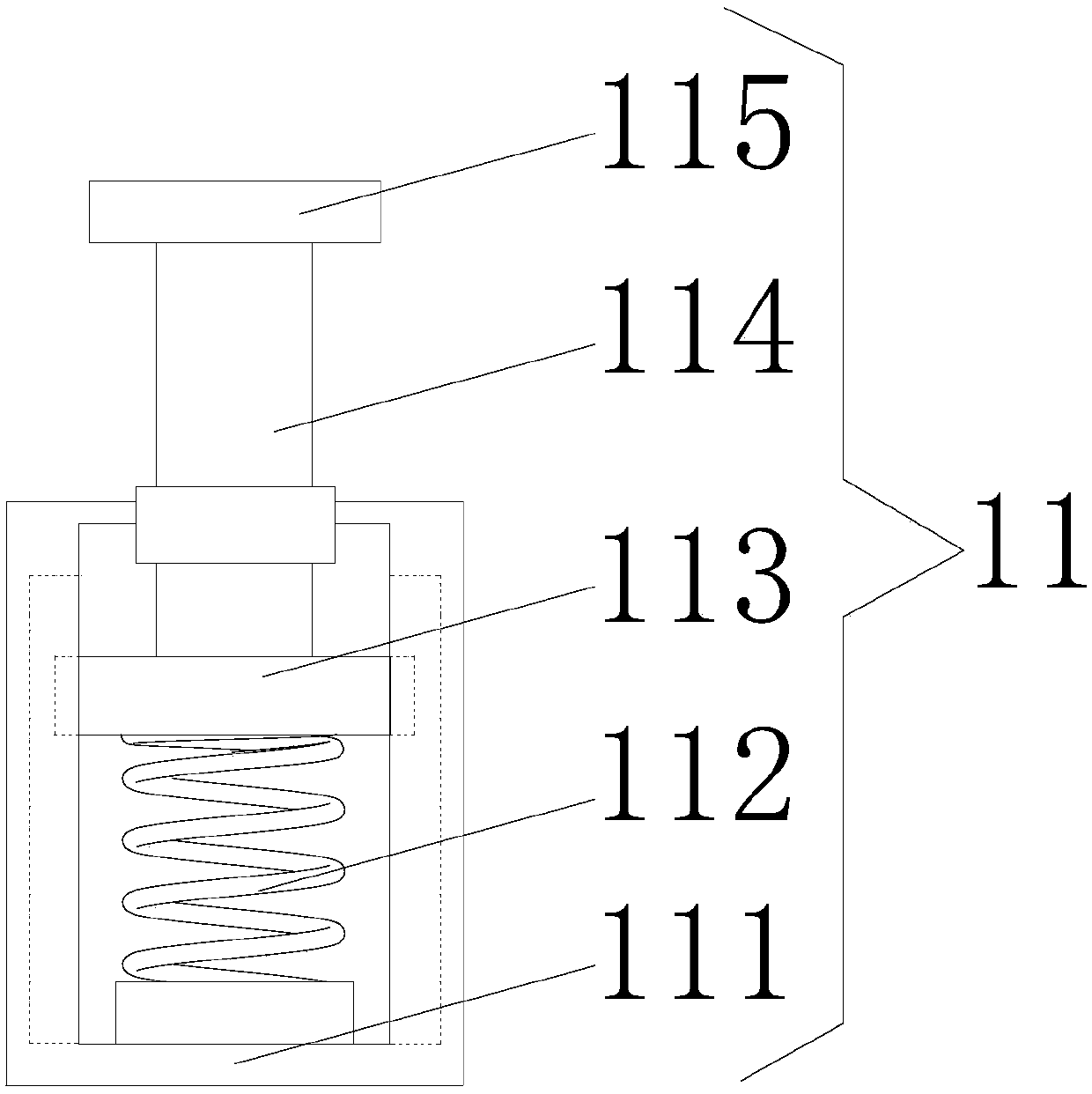

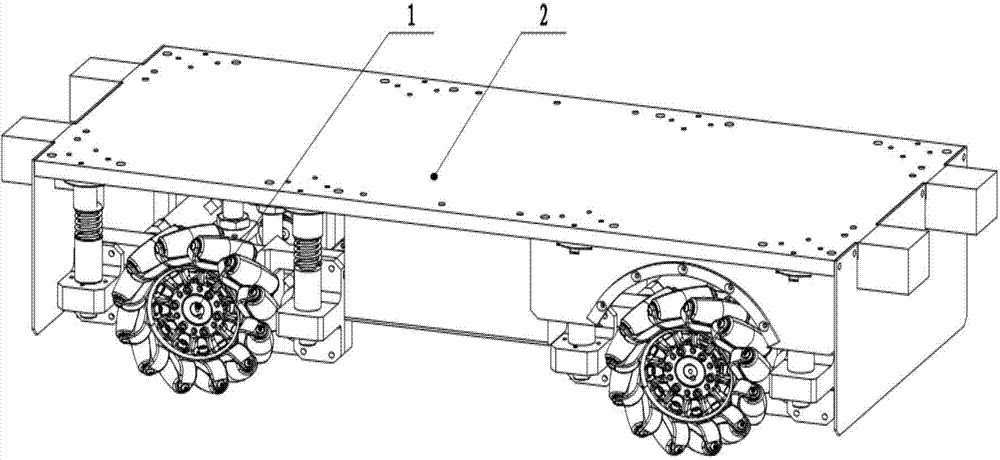

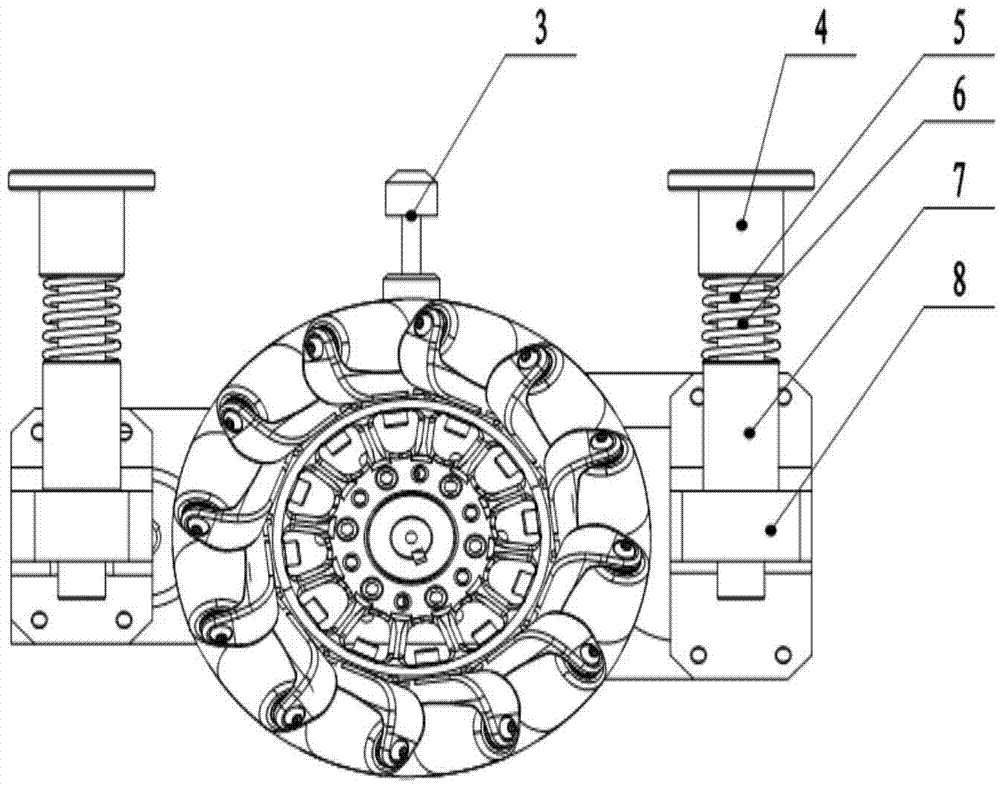

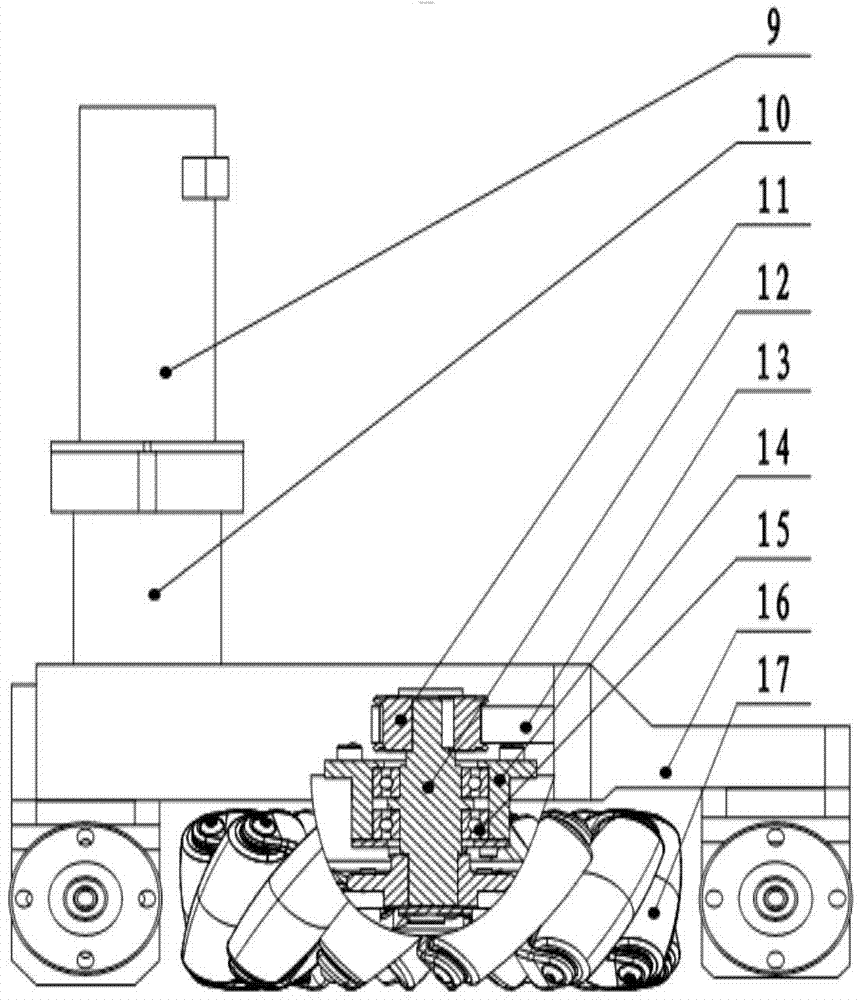

Independent suspension mechanism of intelligent Mecanum wheel movement platform

InactiveCN104494382AGuaranteed uptimeImprove bearing rigidityMotor depositionResilient suspensionsTerrainEngineering

The invention relates to an independent suspension mechanism of an intelligent Mecanum wheel movement platform. The independent suspension mechanism is arranged below the movement platform and on the radial side of a Mecanum wheel and comprises a feed rod, a linear bearing, springs, a feed rod flange and an installation frame, wherein one end of the feed rod is connected with the movement platform through the feed rod flange, the other end of the feed rod is connected to the installation frame through a feed rod seat, the feed rod penetrates the linear bearing to be connected with the feed rod seat, and the springs sleeve the feed rod and are arranged between the feed rod flange and the linear bearing respectively. According to the independent suspension mechanism of the intelligent Mecanum wheel movement platform, advantages of the independent suspension mechanism and the Mecanum wheel movement platform are organically combined, the platform is stably operated, a high adaptive capability to uneven terrains and a high obstacle crossing capability are achieved, and the platform is good in bearing rigidity.

Owner:LIAONING XINHAI HONGYE AVIATION TECH CO LTD

Rubber composition containing resinous nanoparticle

InactiveUS20060148931A1Improve handlingHigh glass transition temperatureSpecial tyresInflatable tyresTire beadPolymer science

This invention relates to a tread rubber composition for tires with the addition of crosslinked resinous nanoparticles having a high glass transition temperature (Tg) into elastomeric base polymers. The invention demonstrates greatly improved handling performance without deteriorating controllability and stability during high-speed running. The present invention more specifically discloses a tire which is comprised of a generally toroidal-shaped carcass with an outer circumferential tread, two spaced beads, at least one ply extending from bead to bead and sidewalls extending radially from and connecting said tread to said beads; wherein said tread is adapted to be ground-contacting; and wherein the tread is comprised of a rubber composition comprising: (1) a rubbery polymer; (2) from 1 to 30 parts per hundred parts of rubber by weight of pre-crosslinked polymer particles, wherein the pre-crosslinked polymer particles have a mean number average particle size as determined by light scattering which is within the range of 30 nm to 500 nm, wherein the pre-crosslinked polymer is comprised of repeat units that are derived from at least one monomer selected from the group consisting of acrylate monomers, acrylonitrile monomer, and vinyl halide monomers, wherein the pre-croslinked polymer is in the form of core-shell particles having a core and a shell, and wherein the pre-crosslinked polymer has a glass transition temperature which is within the range of 30° C. to 200° C.; and (3) 10 to 150 parts per hundred parts of rubber by weight of at least one filler selected from the group consisting of carbon black and silica.

Owner:THE GOODYEAR TIRE & RUBBER CO

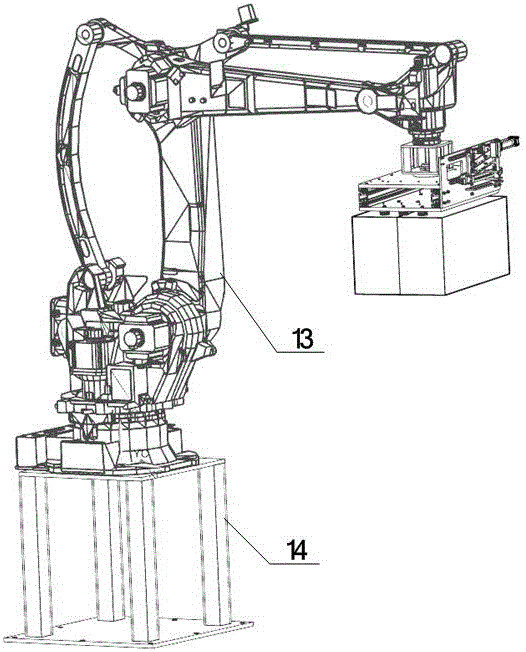

Underpinning carrying manipulator

ActiveCN105945931AStable handlingPalletizing process is stableProgramme-controlled manipulatorEngineeringManipulator

The invention provides an underpinning carrying manipulator, which comprises a mechanical arm, and an underpinning carrying device fixedly connected to the mechanical arm. The underpinning carrying device is composed of a grabbing device and an underpinning device. The underpinning device comprises a shear type lifting support, an electric cylinder, a gear, a rack, and a motor. The underpinning carrying manipulator provided by the present invention allows automatic grabbing and underpinning operations. After a sucker connected to the mechanical arm grabs a box, an expansion link of the electric cylinder extends to drive the shear type lifting support to extend downwards; after the shear type lifting support extends to a predetermined stroke, the motor acts to drive a supporting plate to rotate to be under the box, and then the electric cylinder reverses to support the box; the mechanical arm drives the box to move or be stacked steadily and quickly; as a result, the probability of occurrence of box dropping and box opening accidents is greatly reduced; the stability during carrying and stacking is guaranteed, and the production efficiency is improved.

Owner:QINGDAO WANLONG INTELLIGENT CONTROL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com