Underpinning carrying manipulator

A manipulator and backing technology, which is applied in the field of manipulators, can solve the problems of package drop or broken package height, and packaging boxes with unstandardized finished packages, so as to reduce package drop, stabilize the palletizing process, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

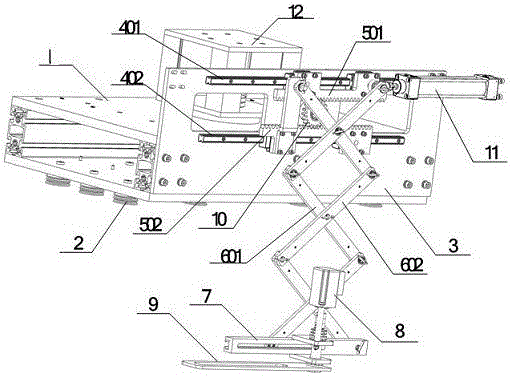

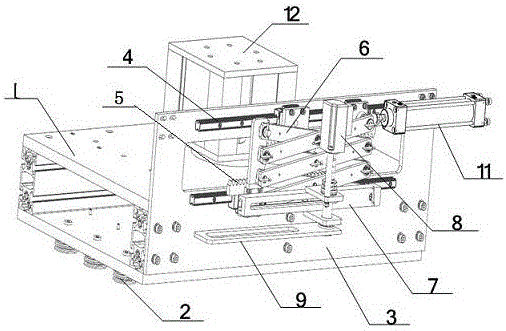

[0035] A preferred embodiment is shown in Fig. 1 and Fig. 2. The sliding guide rail 4 includes an upper guide rail 401 and a lower guide rail 402; The gear 10 for meshing is set between the upper rack 501 and the lower rack 502; the scissor lift bracket 6 includes a left bracket 601 and a right bracket 602 that are scissor-type cross-connected; the head end of the left bracket 601 is connected to The telescopic rod of the electric cylinder 11 is connected and fixed on the upper rack 501; the fixed bar 7 is provided with a chute, and the end of the left bracket 601 is connected in the chute; the head end of the right bracket 602 is connected to the lower The rack 502; the end of the right bracket 602 is fixedly connected with the side of the fixed bar 7 away from the chute. The head end of the right bracket 602 is connected to the lower rack 502 through a connecting plate, so that the head end of the right bracket 602 is equal to the head end of the left bracket 601 .

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com