Patents

Literature

46results about How to "Improve bearing rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

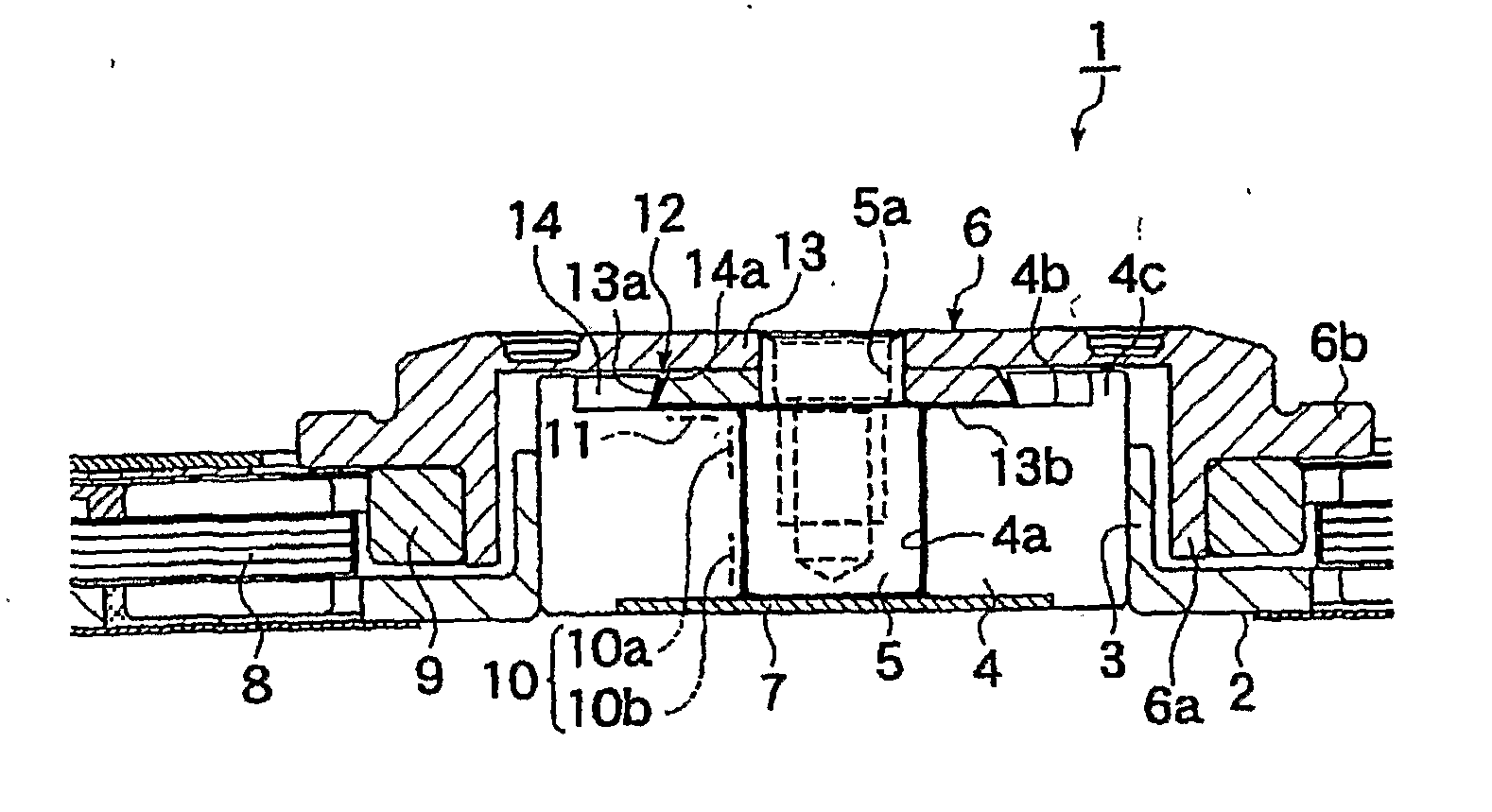

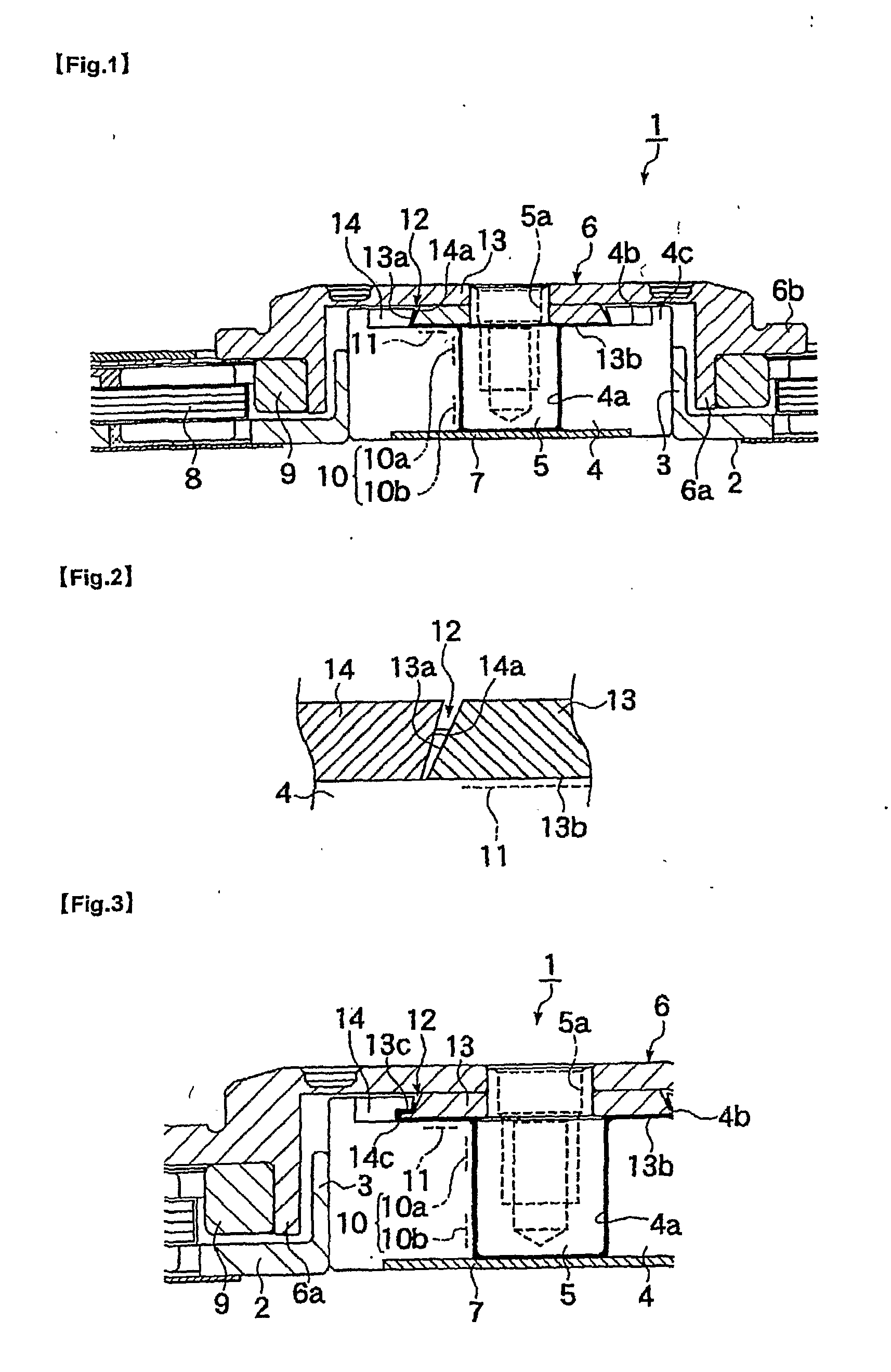

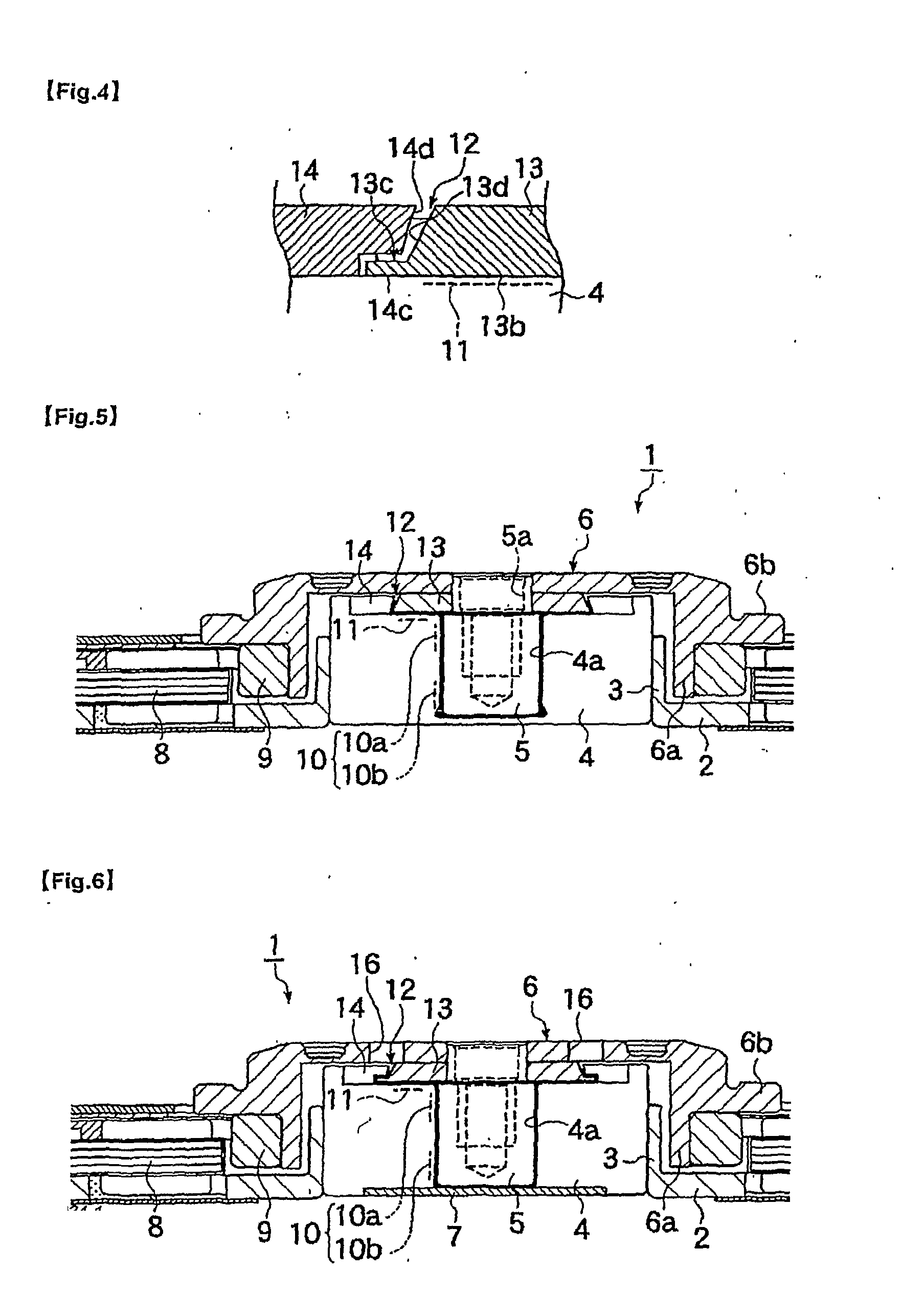

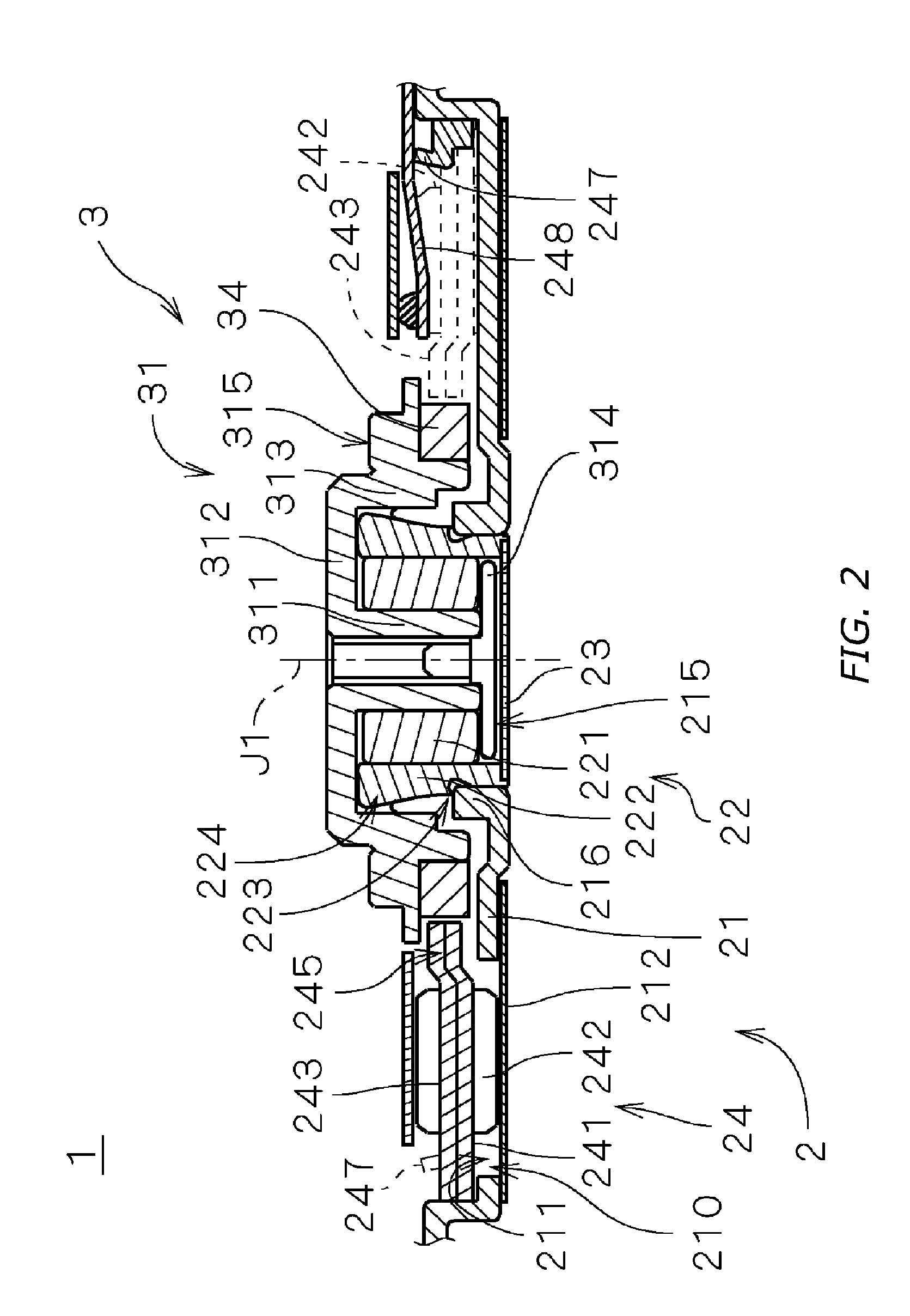

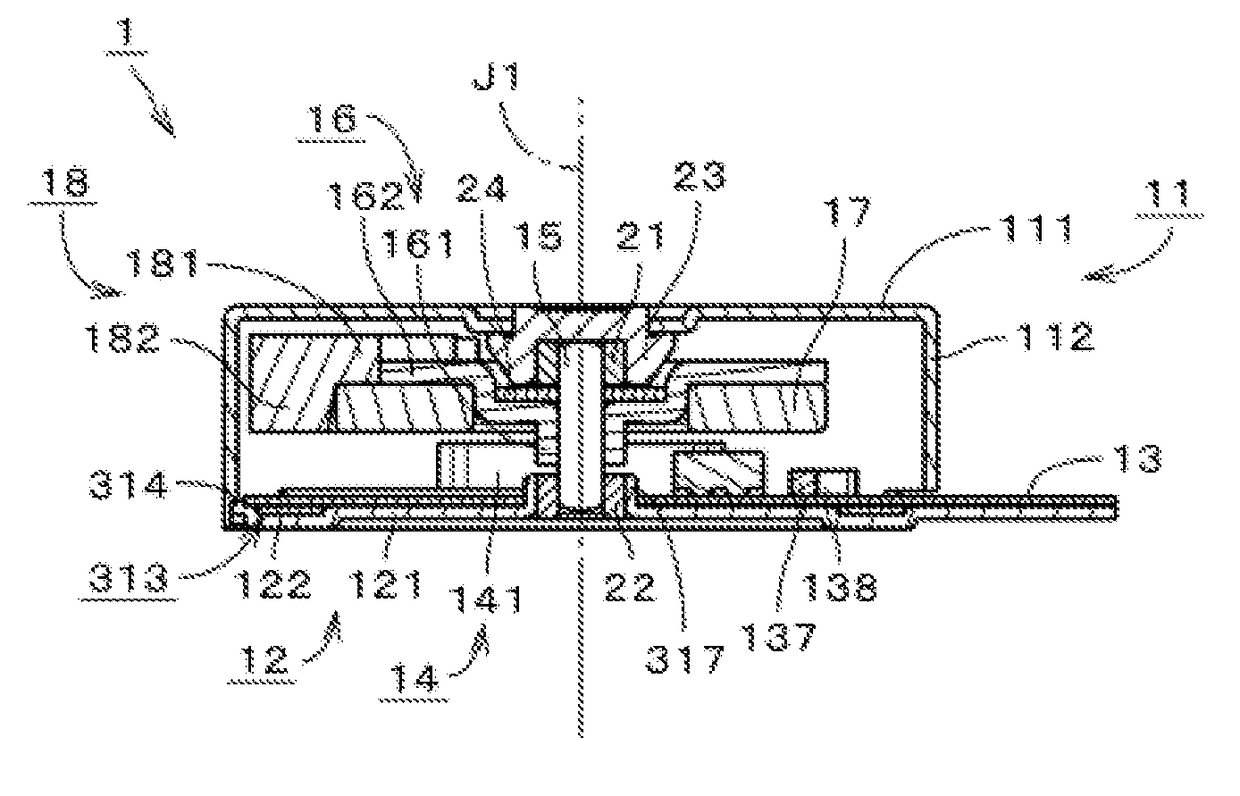

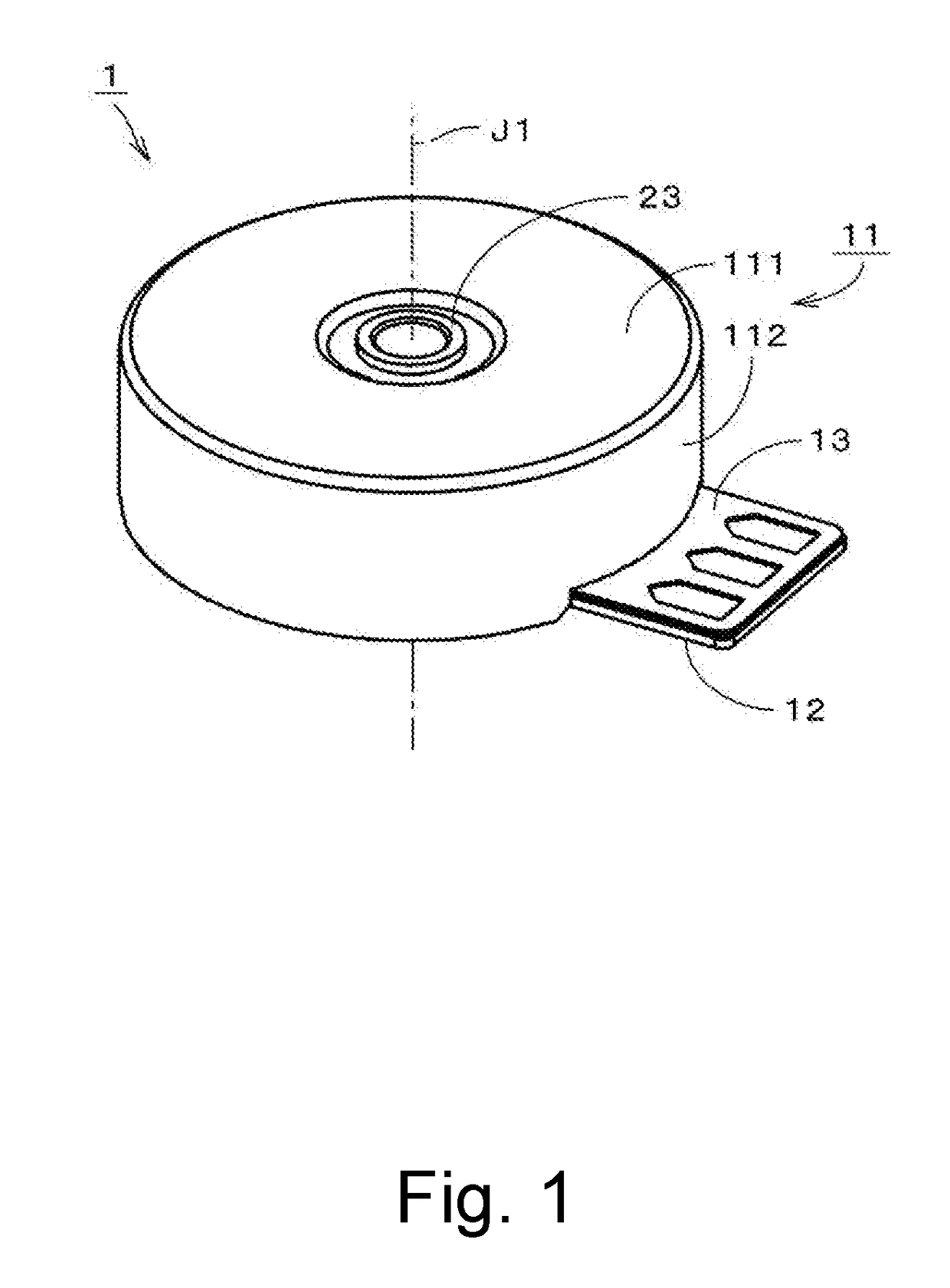

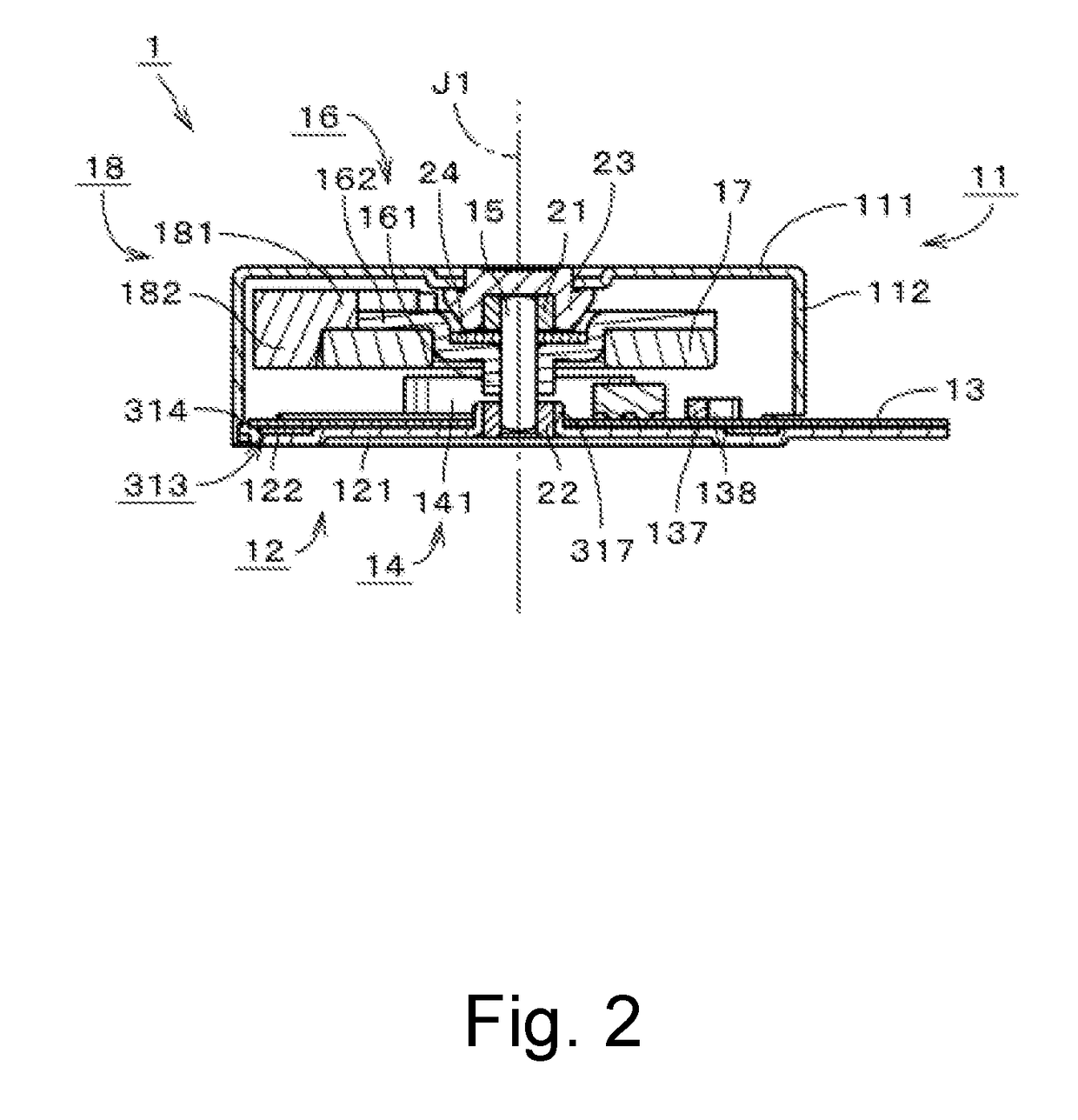

Fluid Dynamic Bearing Mechanism for a Motor

InactiveUS20070211971A1Improve bearing rigidityHigh rotation accuracyShaftsRecord information storageCapillaria obsignataDynamic pressure

A fluid dynamic bearing mechanism for a motor (1) suitable for use in a hard disk drive and having a compact and thin shape, high bearing rigidity, and high rotating accuracy, and which securely keeps the rotor member (6) in place against shocks, and allows the inspection of lubricant supply amount easily. A fluid dynamic bearing mechanism having a capillary seal part (12) on one end of lubricant supply part formed by a minute gap including dynamic pressure grooves (10) formed on a shaft member (5) or a bearing member (4) is provided. An annular member (13) is fitted on the shaft member at the location corresponding to the capillary seal part, another annular member (14) is fitted on the bearing member at the location corresponding to the capillary seal part, a taper or step (13a, 14a) is formed on the outer peripheral surface of the annular member on the shaft member side and the inner peripheral surface of the annular member on the bearing member side. These inner and outer peripheral surfaces are arranged to be close to and facing with each other so that the rotor member is prevented from disengaging from the bearing member, and the capillary seal part can be formed at the same time. An axial dynamic pressure bearing unit (1) is formed between the annular member on the shaft member side and one end of the bearing member.

Owner:MINEBEA CO LTD

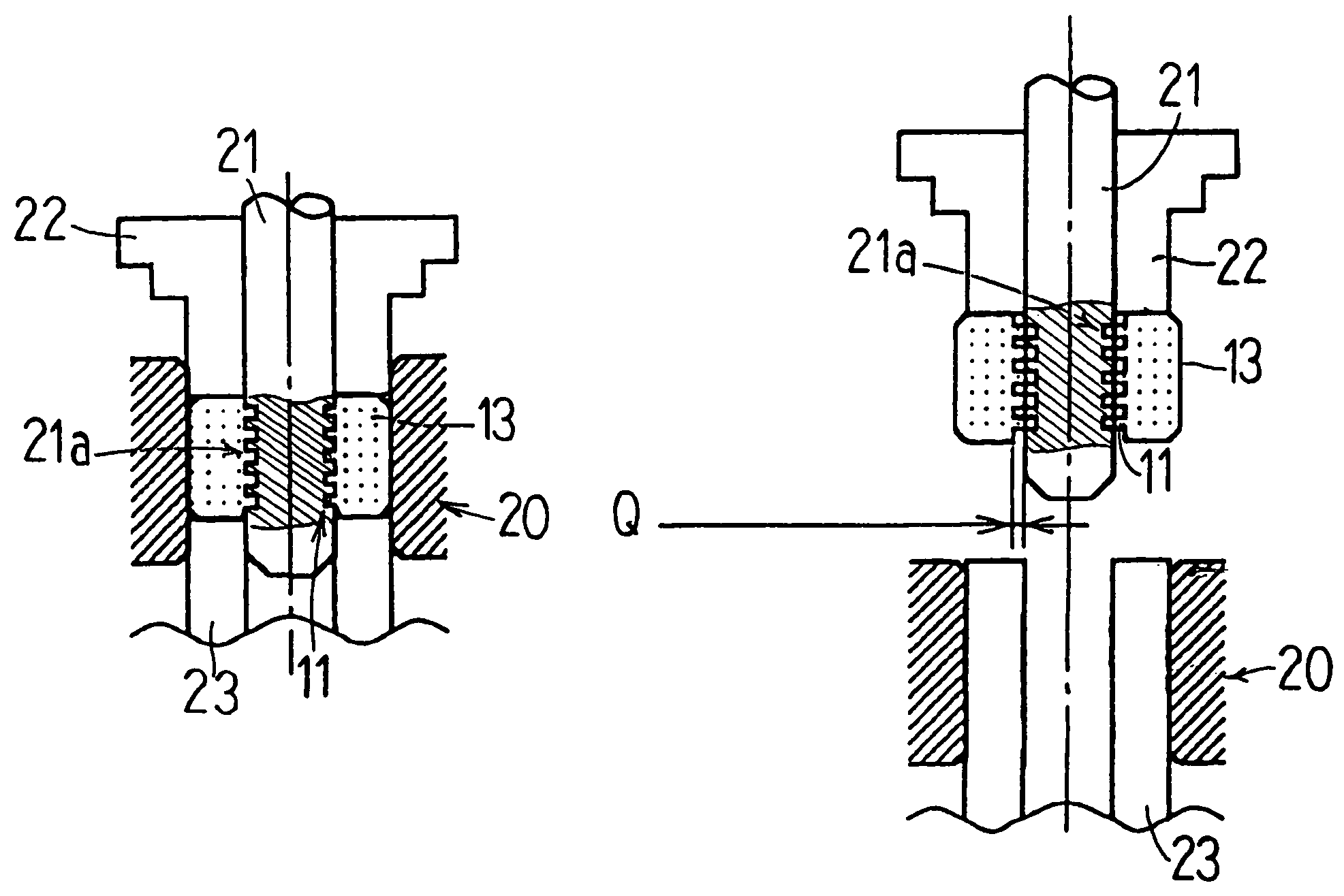

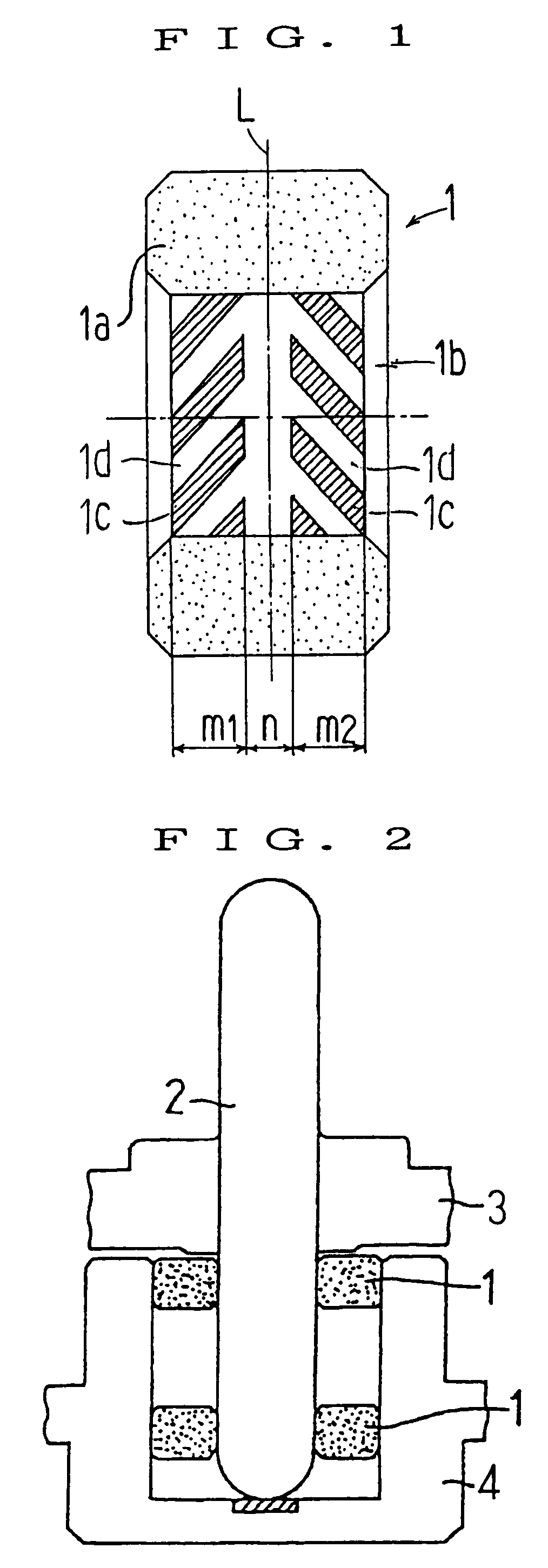

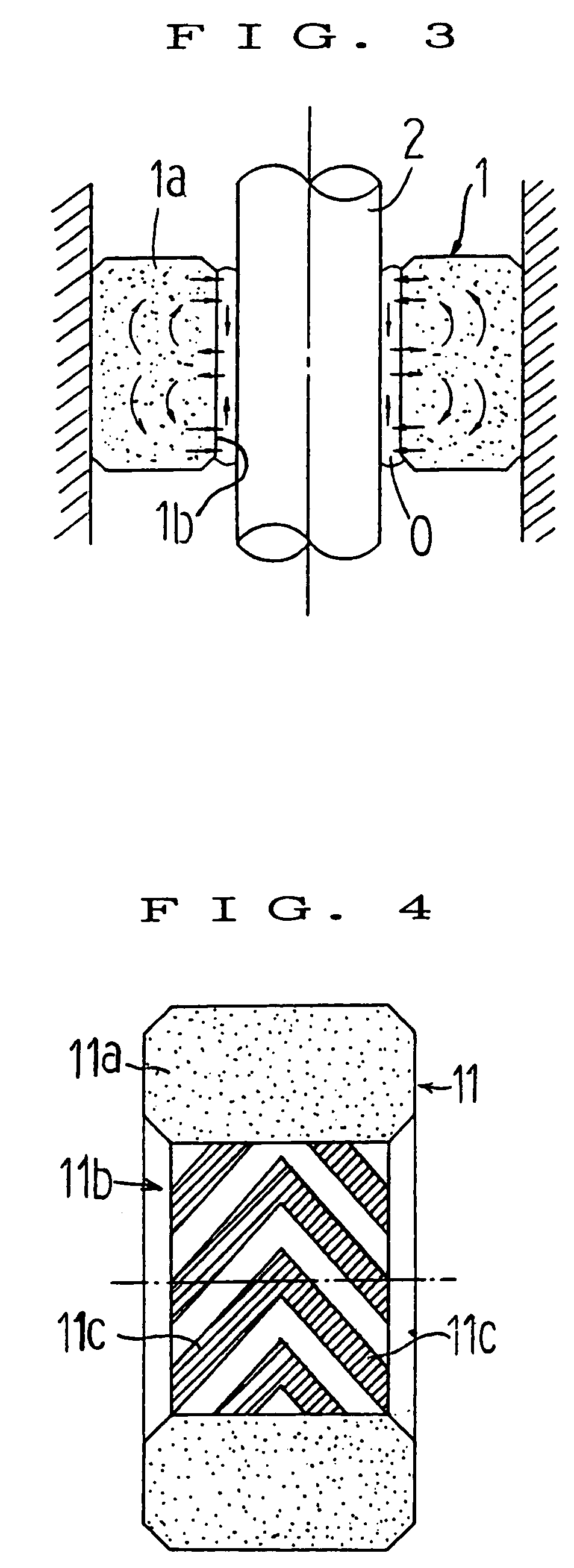

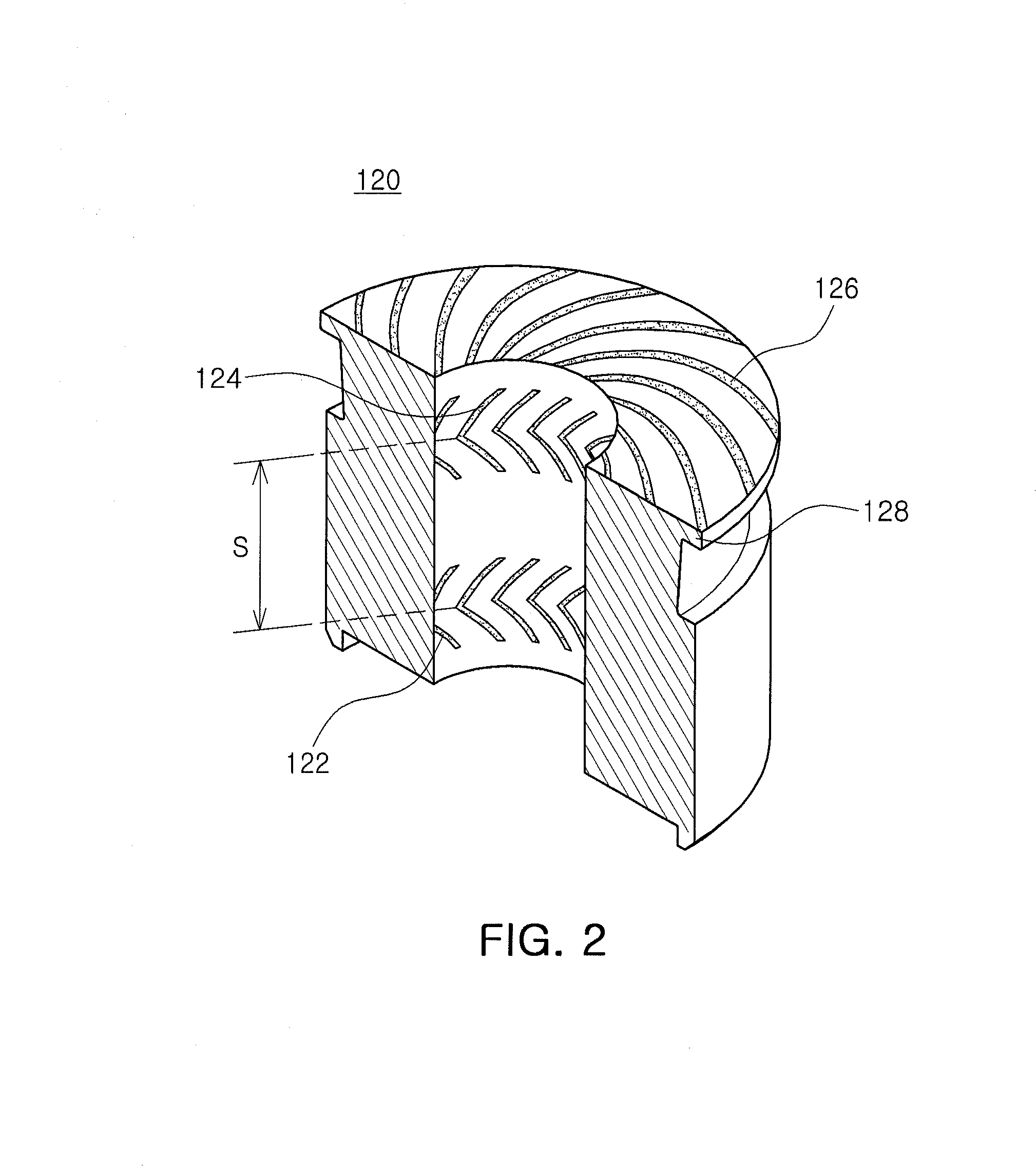

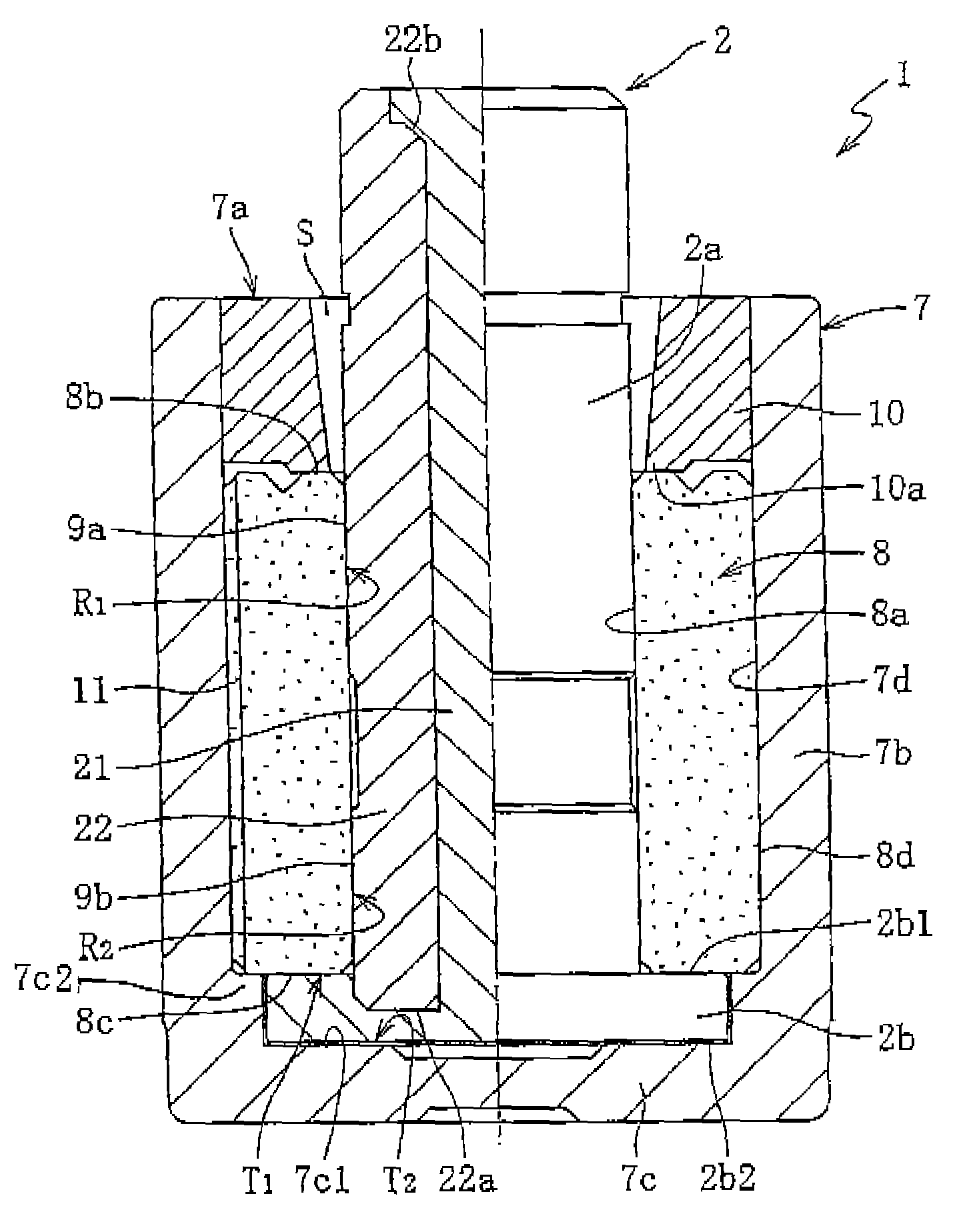

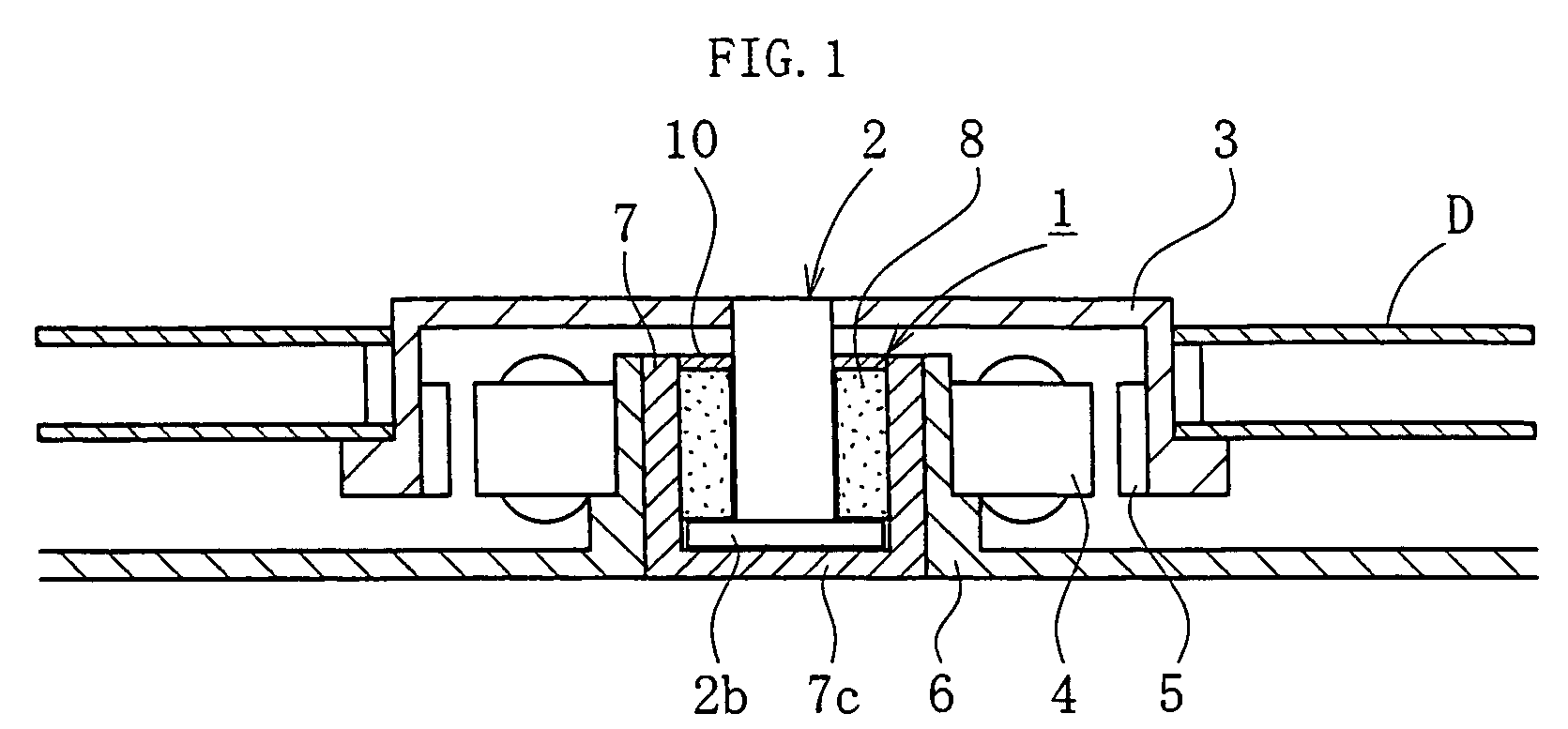

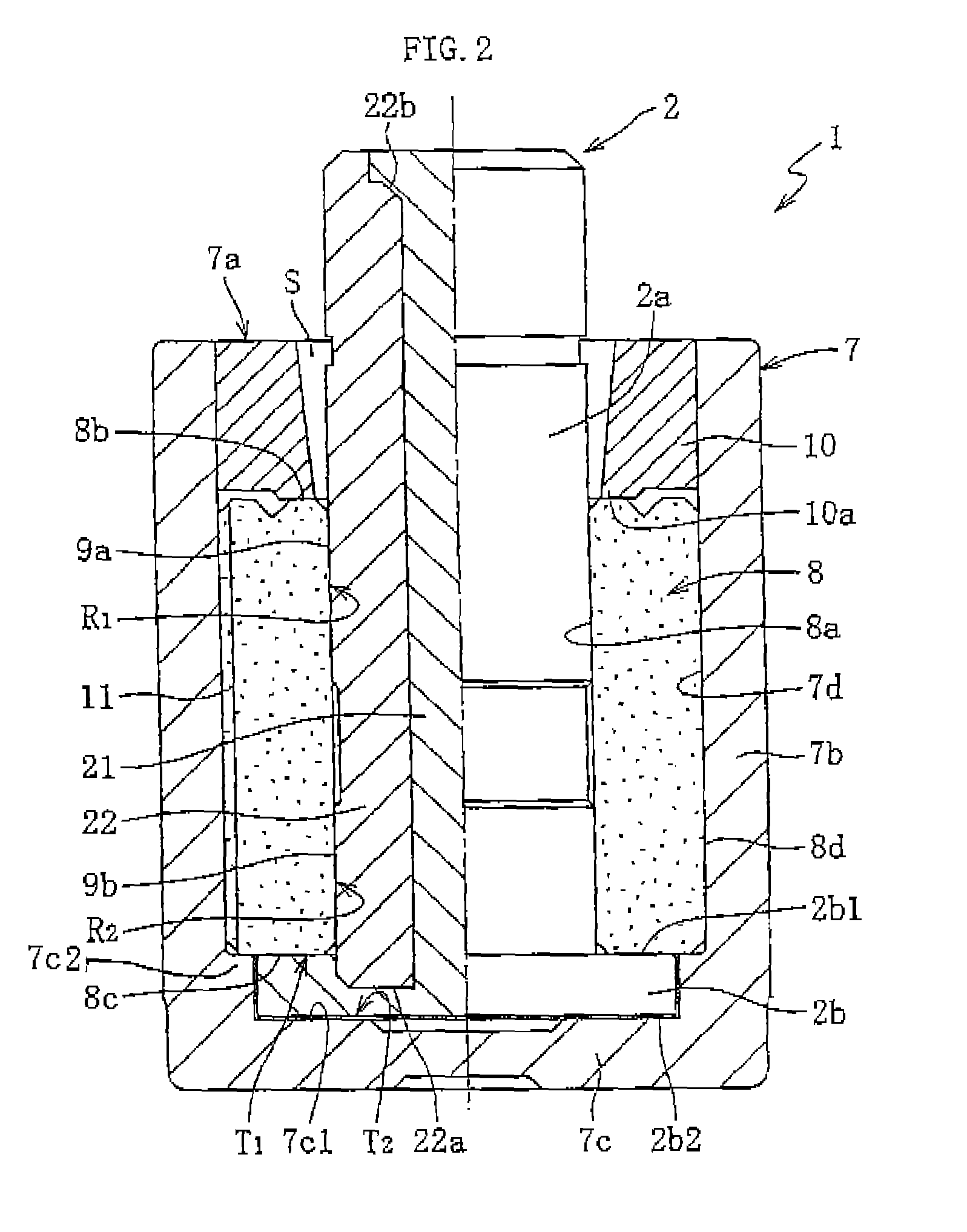

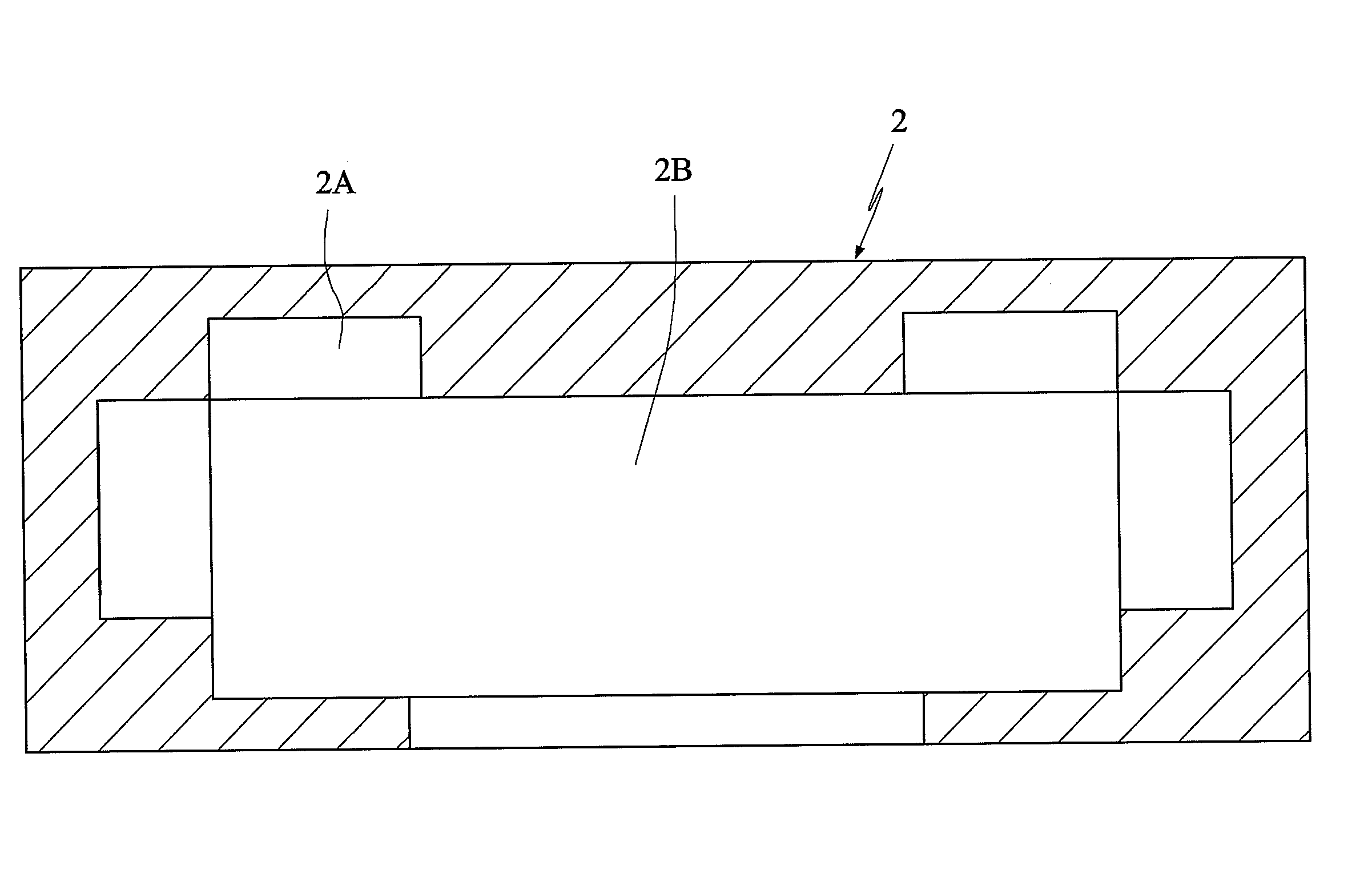

Hydrodynamic type porous oil-impregnated bearing

InactiveUS7059052B2Inhibit deteriorationGood effectMetal-working apparatusBearing componentsEngineeringBearing surface

The porous oil-impregnated bearing 1 comprises a bearing body 1a made of a porous material, and oil retained in the pores of the bearing body 1a by impregnation with lubricating oil or lubricating grease. The inner peripheral surface of the bearing body 1a is formed with a bearing surface 1b opposed to an outer peripheral surface of a shaft to be supported, with a bearing clearance defined therebetween. The bearing surface 1b has a first region m1 in which a plurality of hydrodynamic pressure generating grooves 1c inclined in one direction with respect to the axial direction are circumferentially disposed, a second region m2 which is axially spaced from said first region m1 and in which a plurality of hydrodynamic pressure generating grooves 1c inclined in the other direction with respect to the axial direction are circumferentially disposed, and an annular smooth region n disposed between the first and second regions m1 and m2.

Owner:NTN CORP

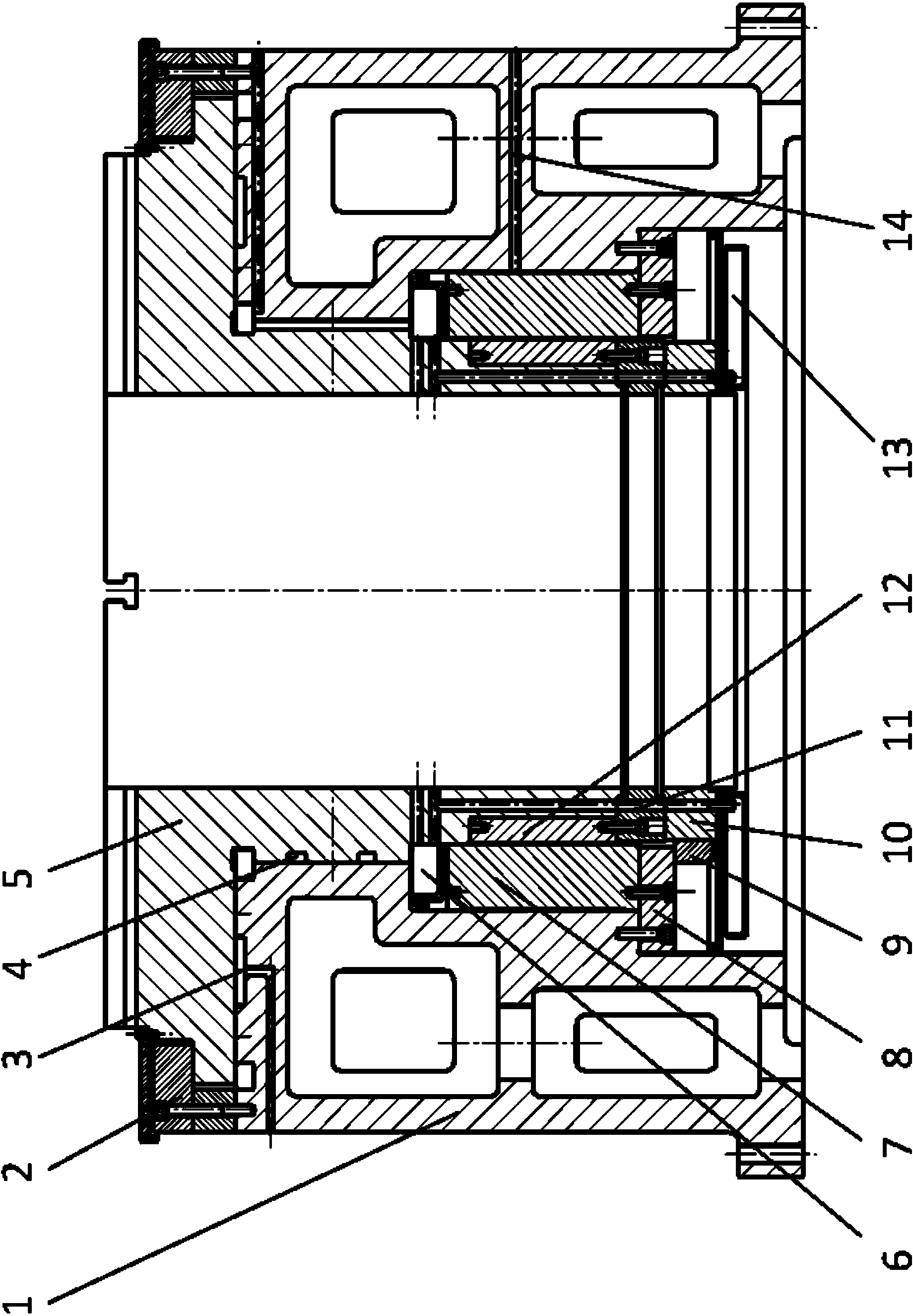

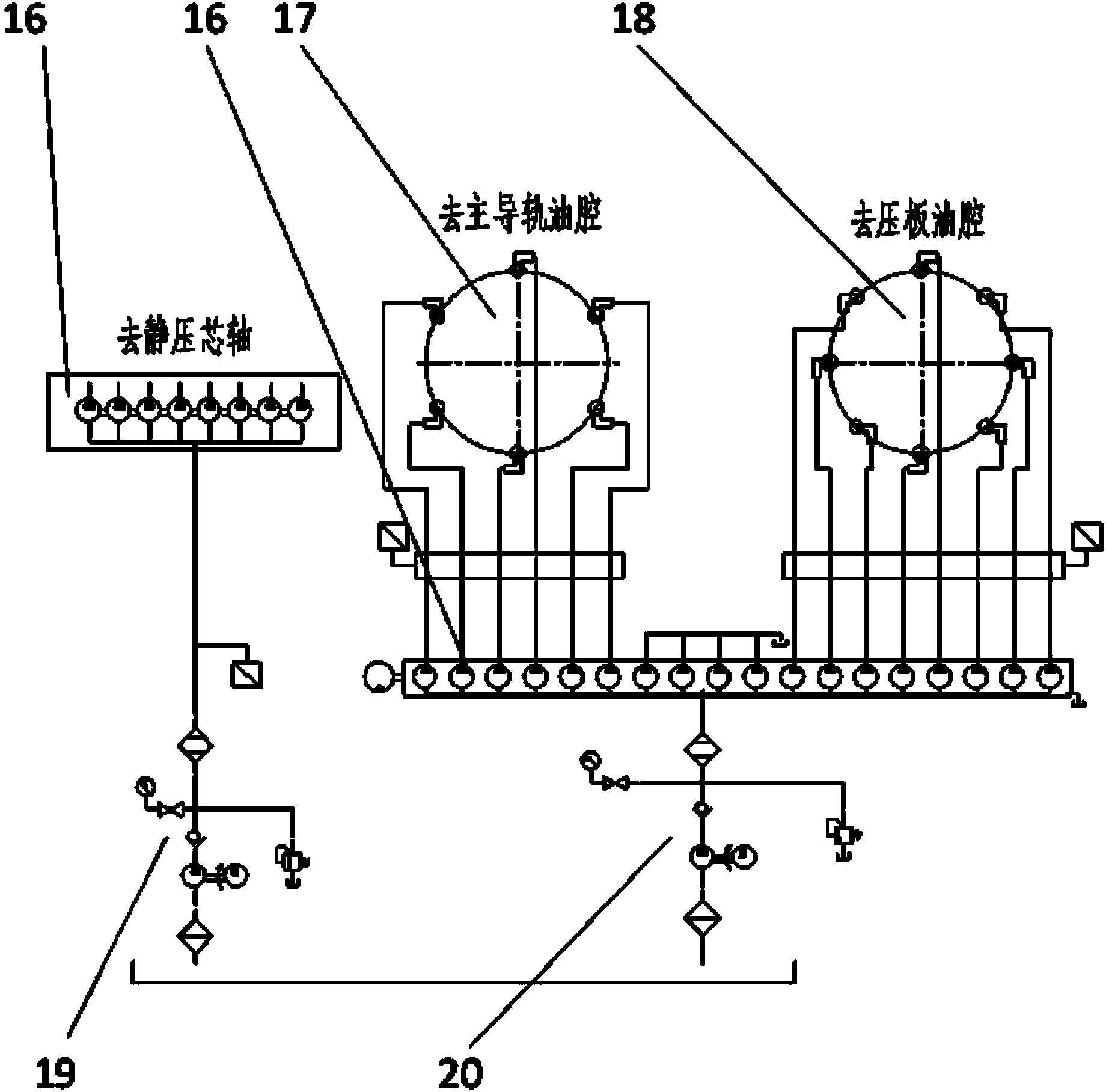

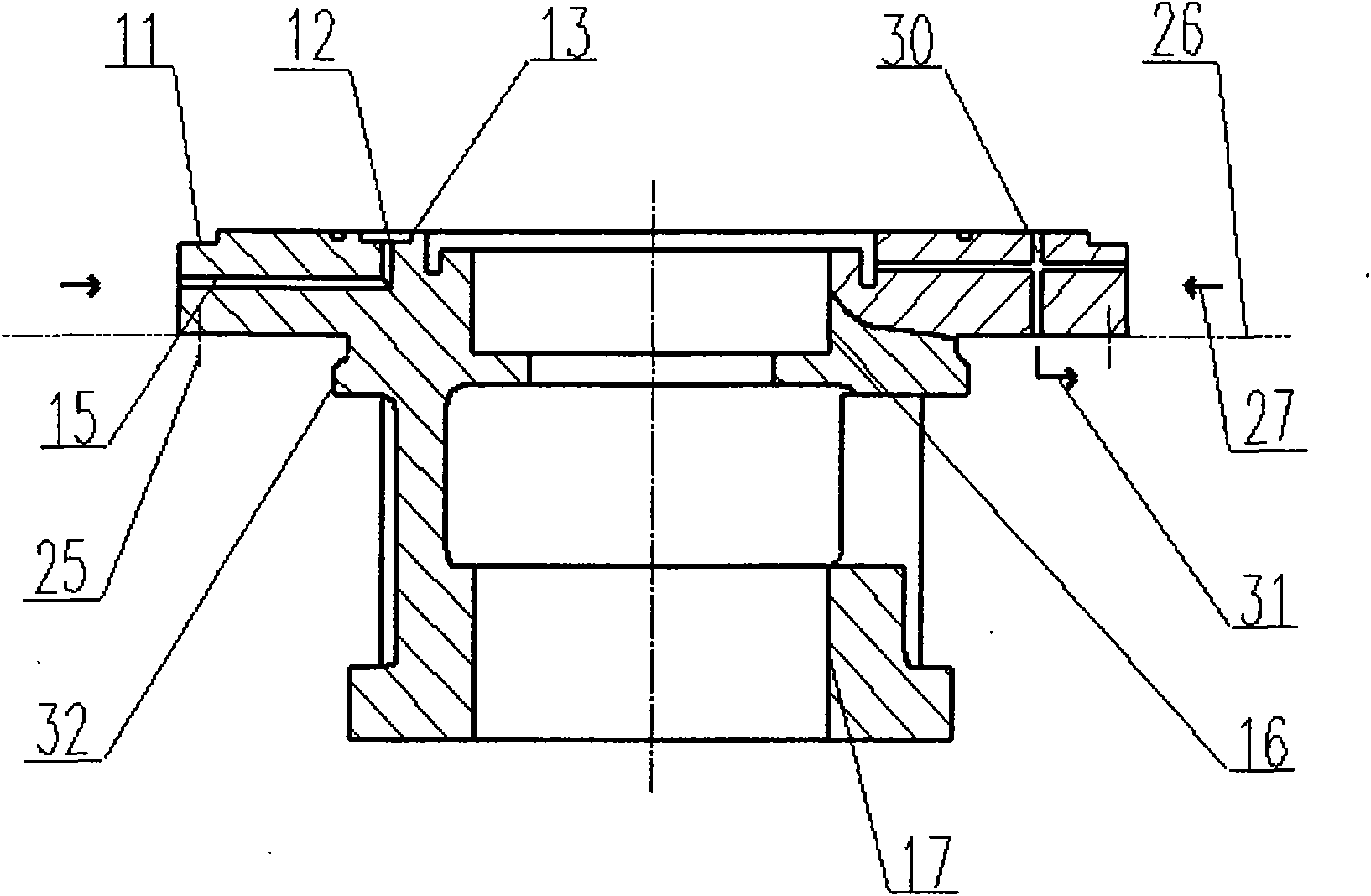

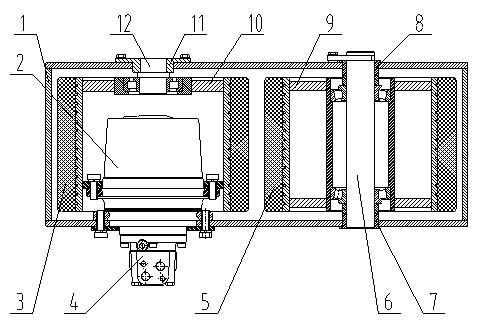

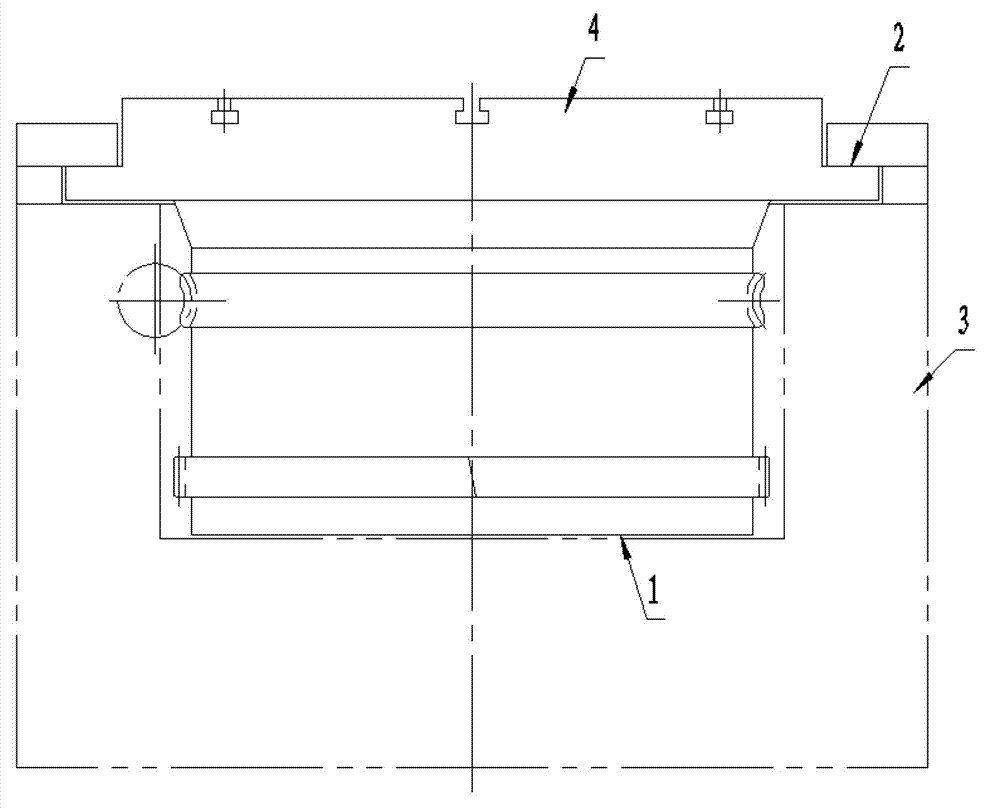

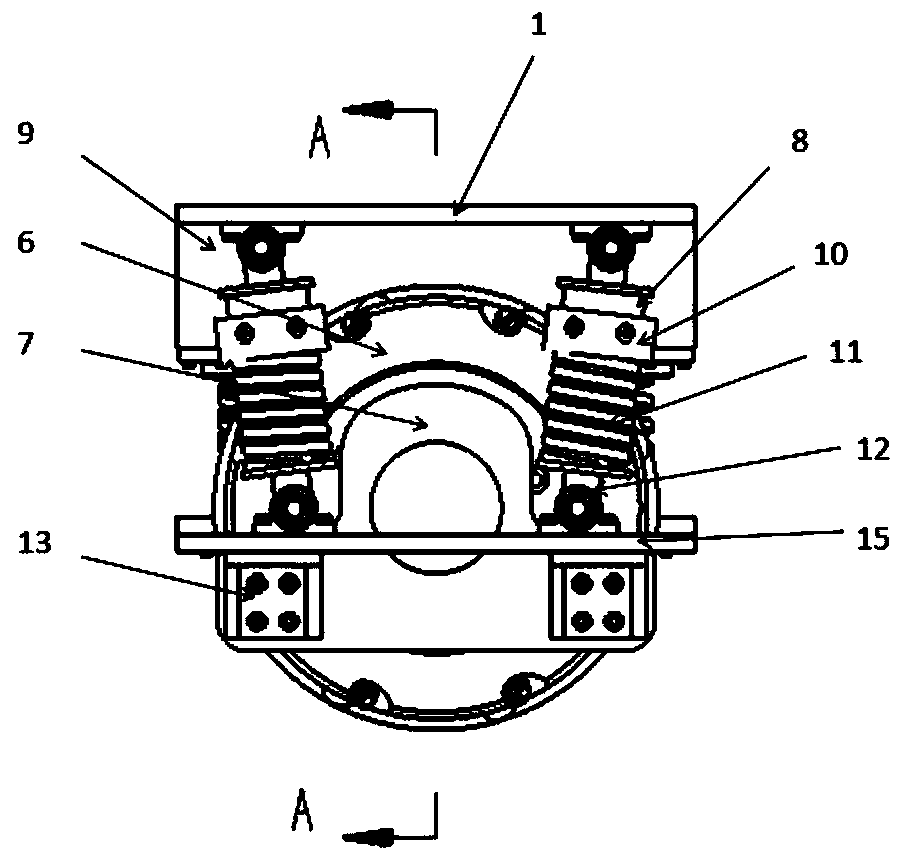

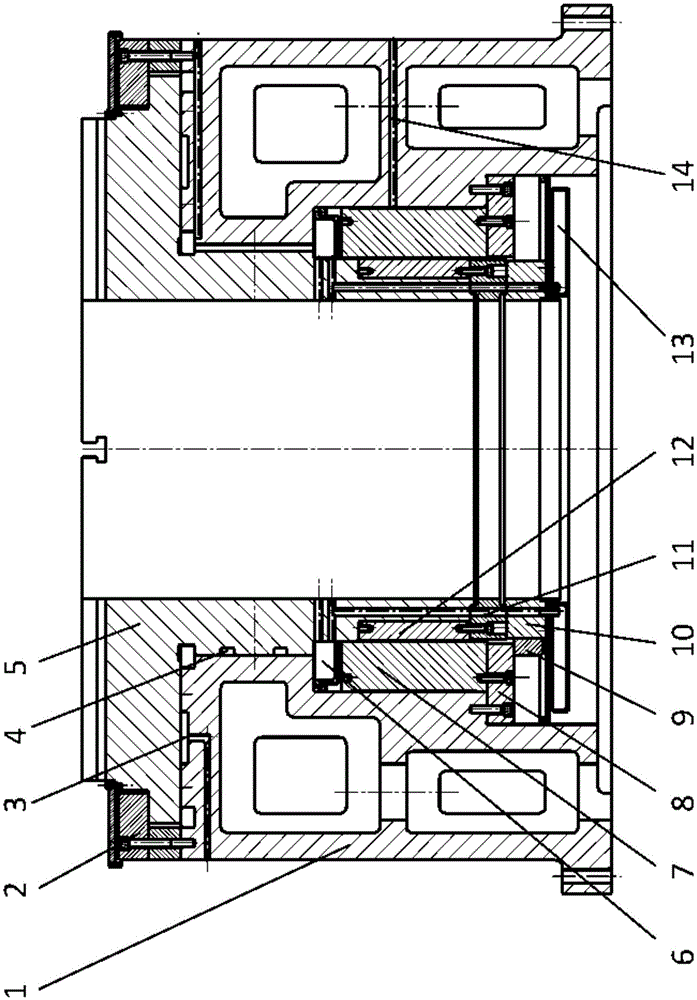

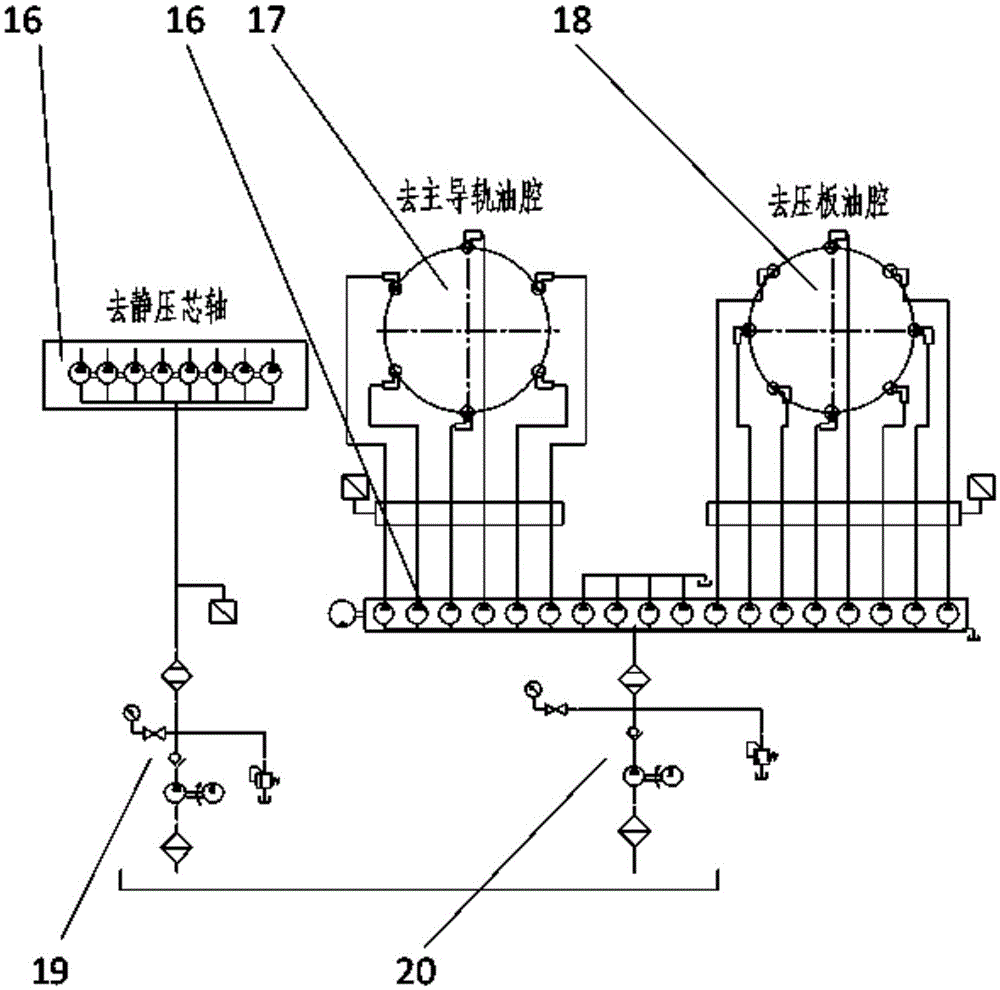

Static pressure heavy-load direct-drive high-accuracy rotating table

ActiveCN103624555AReduce skew errorLarge viaMeasurement/indication equipmentsFeeding apparatusGratingFrictional coefficient

A static pressure heavy-load direct-drive high-accuracy rotating table comprises a rotating platform composed of a base (1), a pressing board (2), a main guide rail static pressure oil cavity (3), a static pressure core shaft oil cavity (4), a work table top (5), a static pressure oil return system (6), a torque motor stator (7), a stator fixing support (8), a reading head (9), a steel belt type optical grating installation support (10), a rotor installation support (11), a torque motor rotor (12), an oil collection pot (13), a water cooling system (14), a gear distributor (15), a multi-head pump (16), a main guide rail oil cavity (17), a pressing board oil cavity (18), a core shaft pump station system (19), a guide rail pump station system (20), an oil supply system and an oil return system. The static pressure heavy-load direct-drive high-accuracy rotating table is directly driven by the large-torque motor rotor, achieves zero transmission, and is compact in structure and reliable in work; a very low frictional coefficient characteristic of a hydrostatic guide rail is combined, and the rotating table is high in servo rigidity, high in dynamic response speed and small in static difference.

Owner:NANJING GONGDA CNC TECH

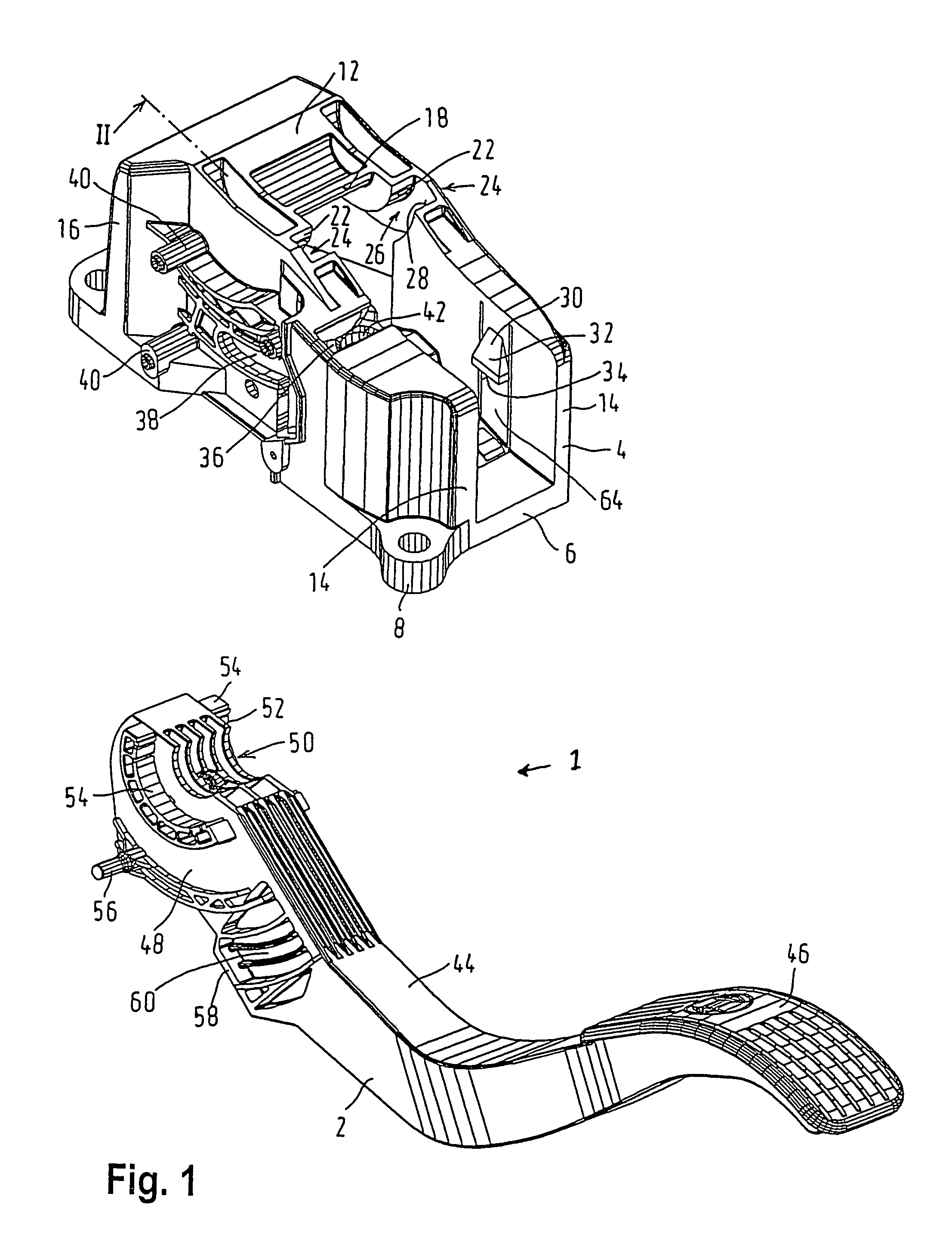

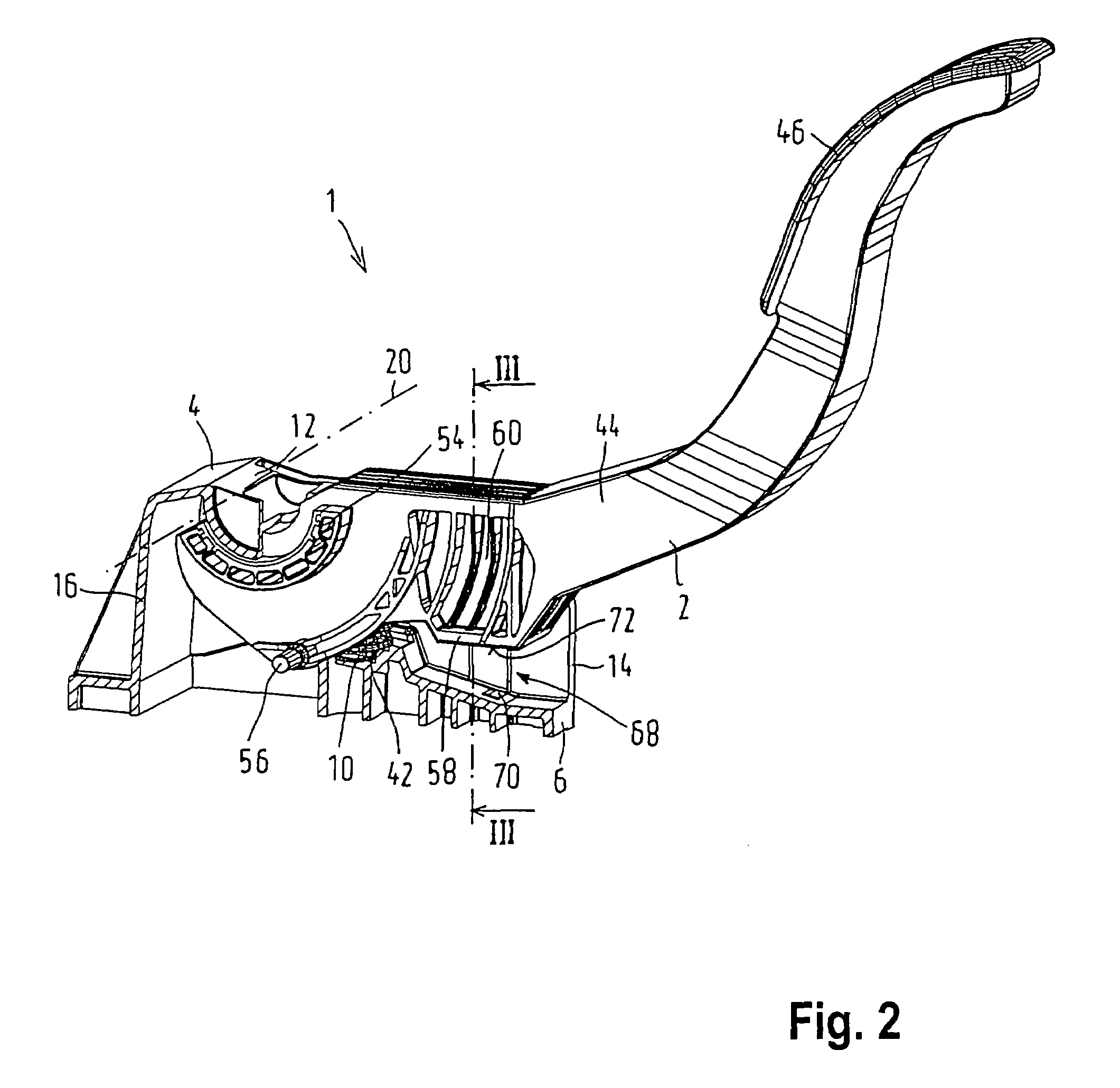

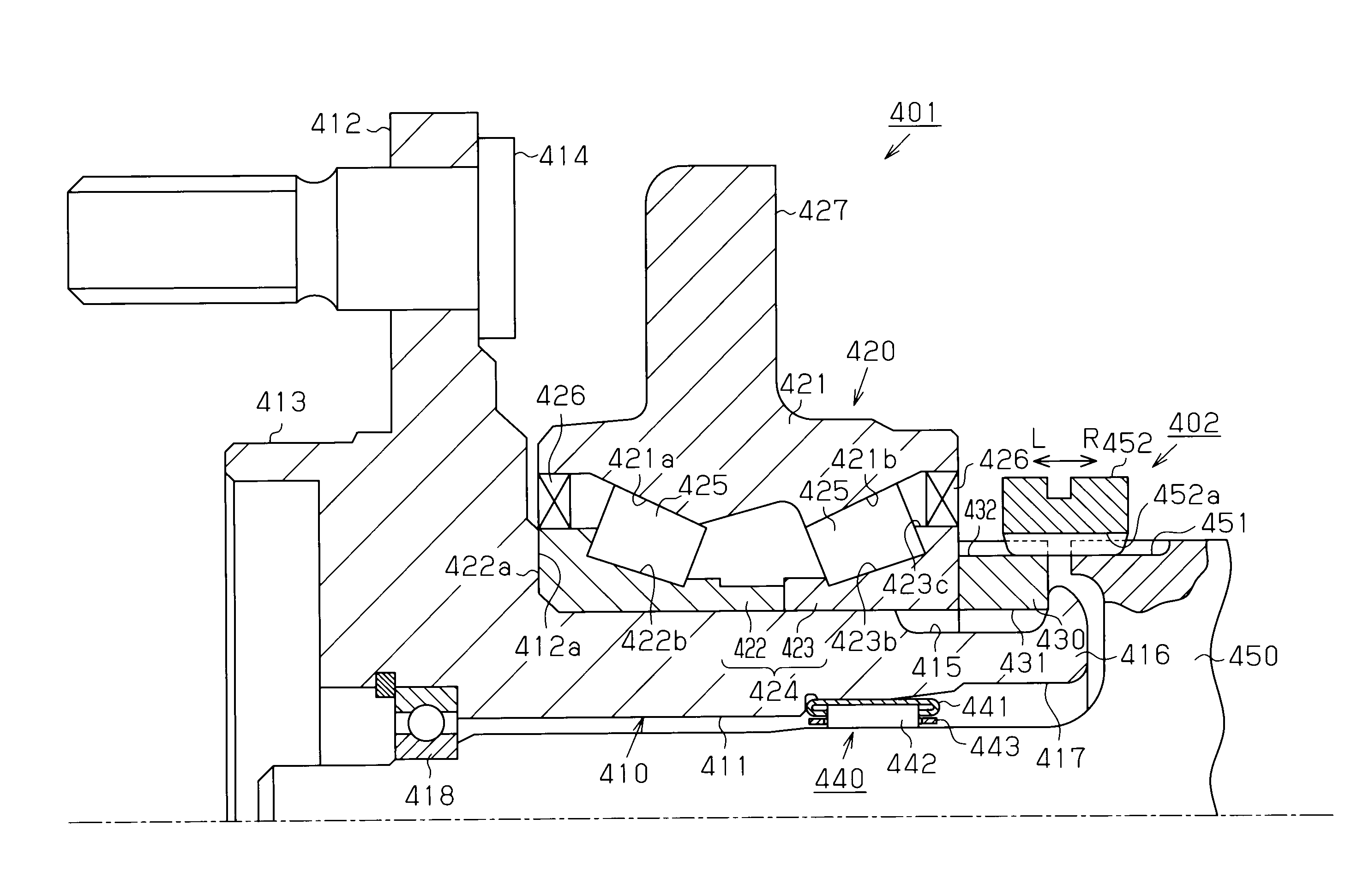

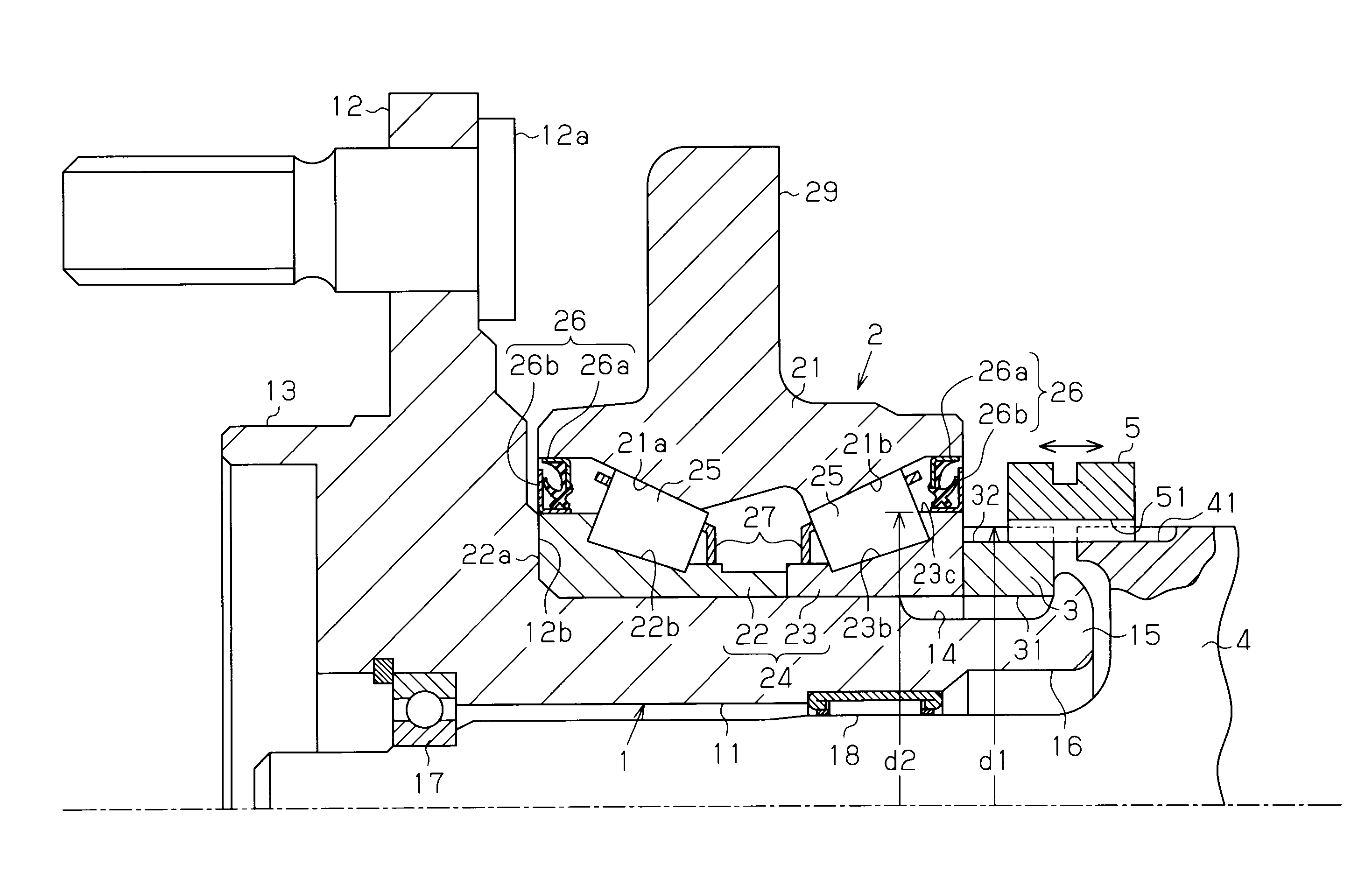

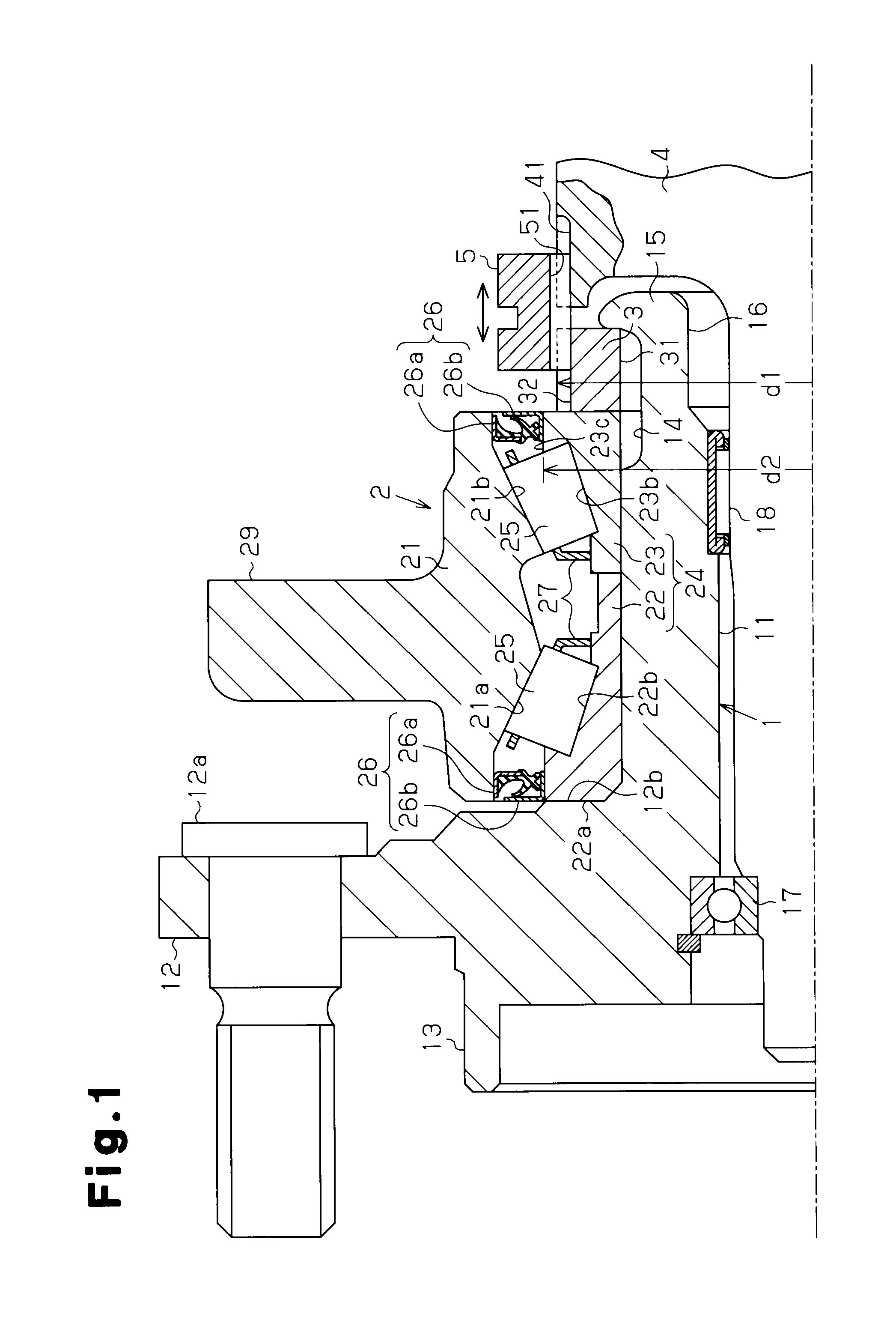

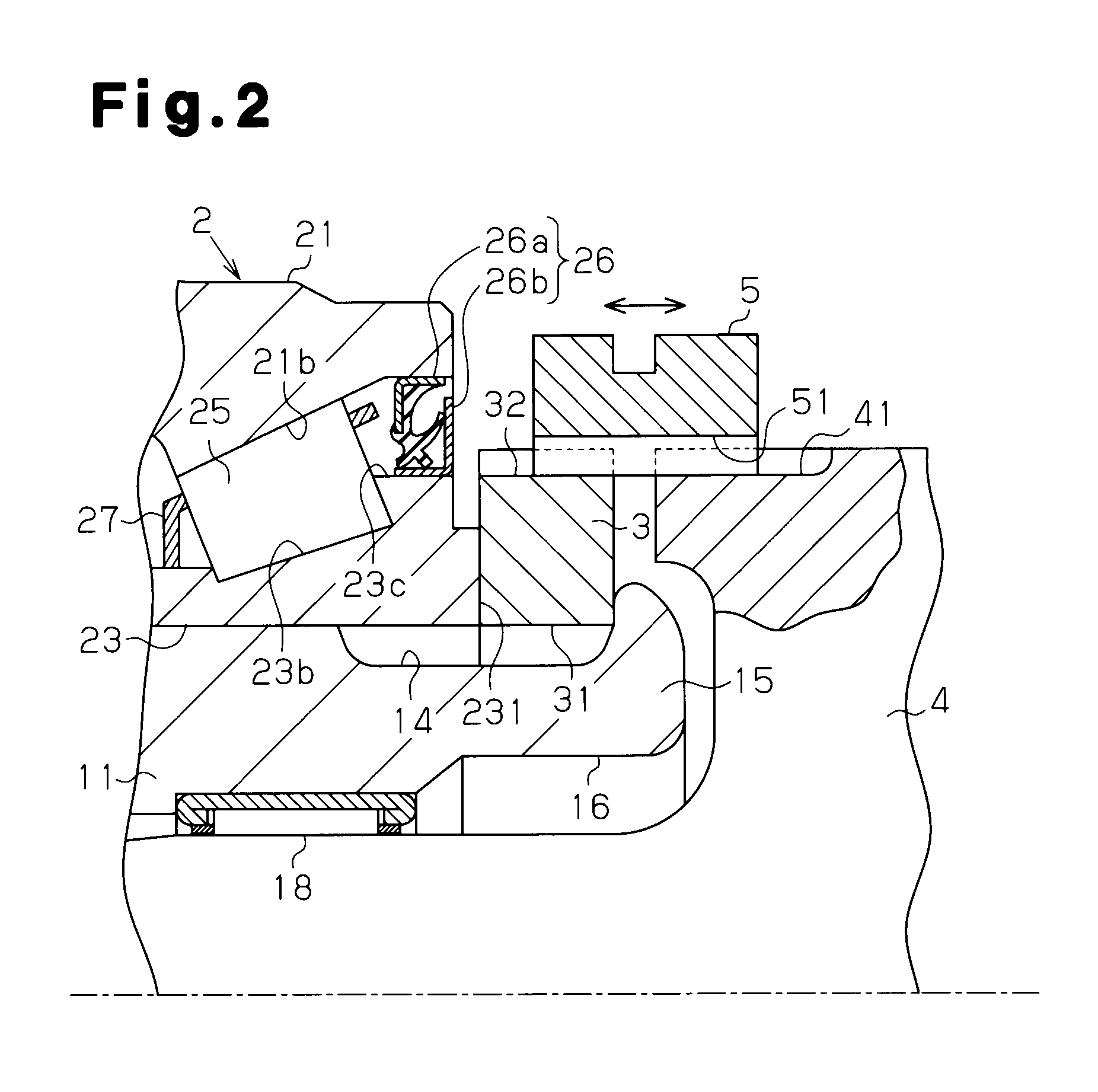

Accelerator pedal module

InactiveUS7278337B2Favorable effect on the measurement accuracy of the rotation sensorImprove bearing rigidityControlling membersLimiting/preventing/returning movement of partsComputer moduleEngineering

The invention relates to an accelerator pedal module for controlling the power of a driving engine having a pedal lever which is retained rotatably about a pivot axis on a bearing block and which actuates a sensor shaft of a rotation sensor, the sensor shaft being coaxial with the pivot axis. At least a part of the sensor shaft is directly supported rotatably in a bearing bore of a bearing region that is integral with the bearing block, of which bearing region at least a part of the radially outer circumferential surface forms at least one bearing face for the pedal lever.

Owner:ROBERT BOSCH GMBH

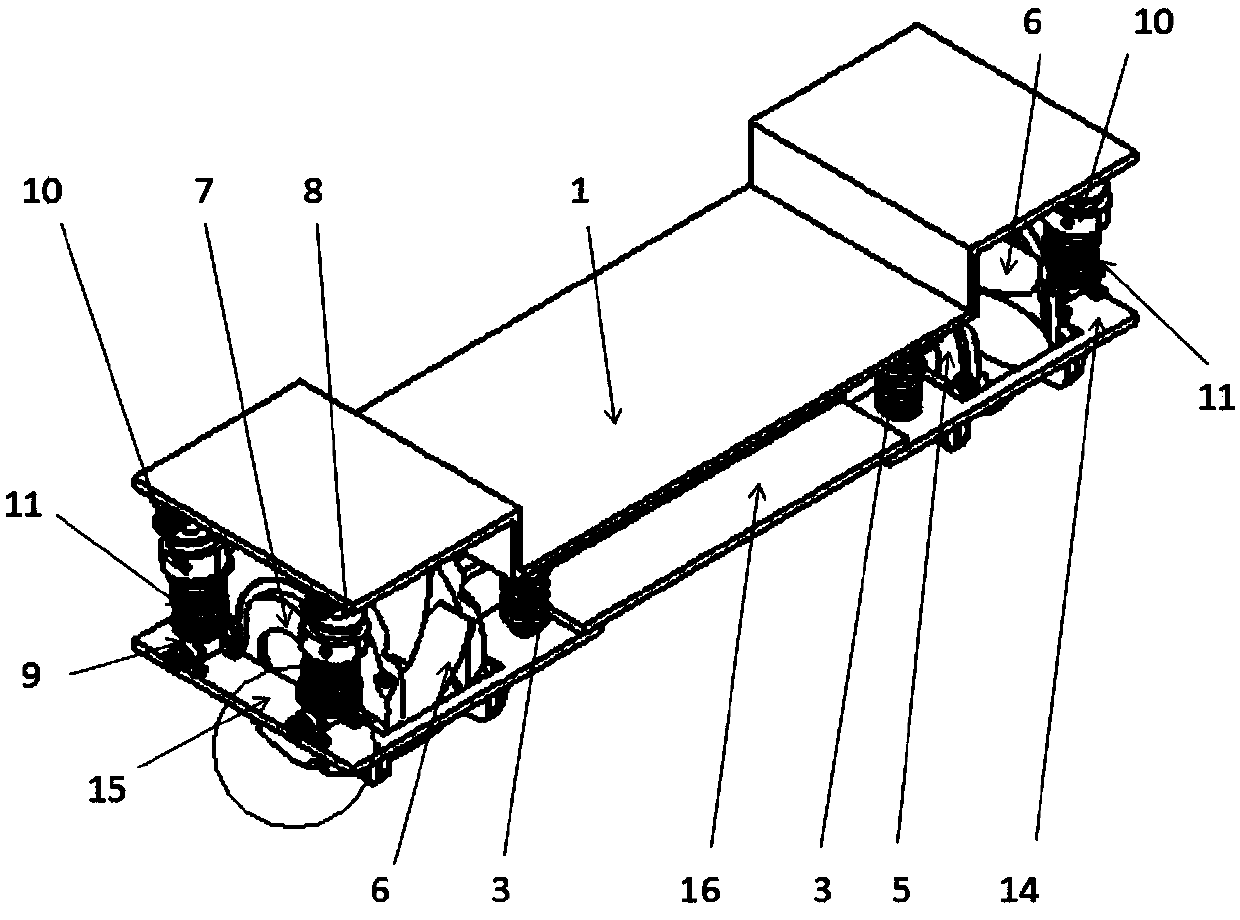

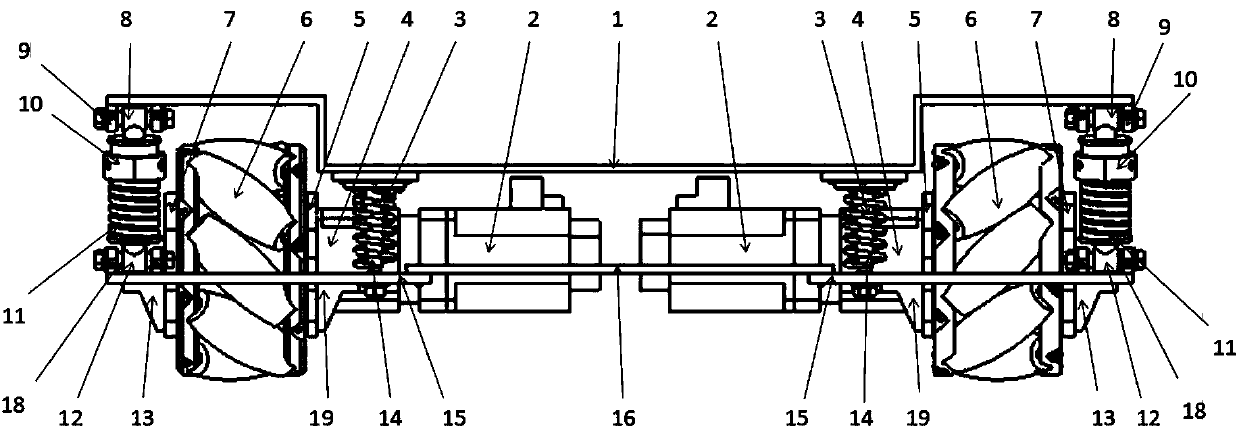

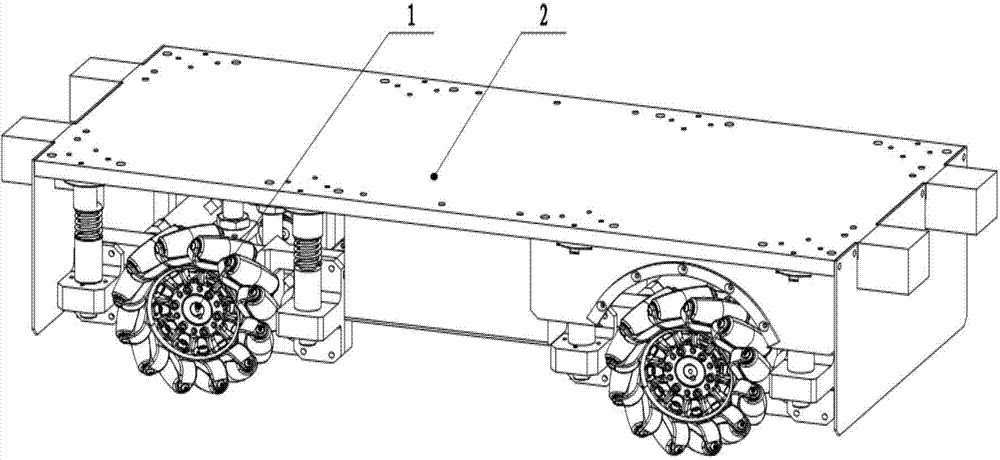

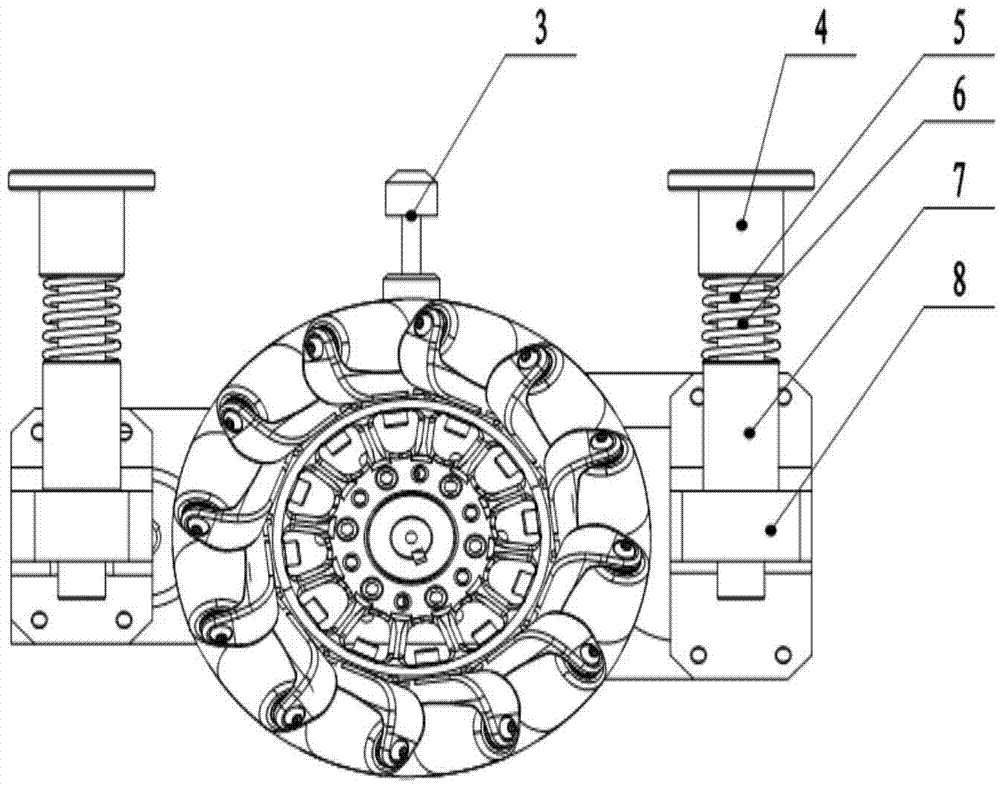

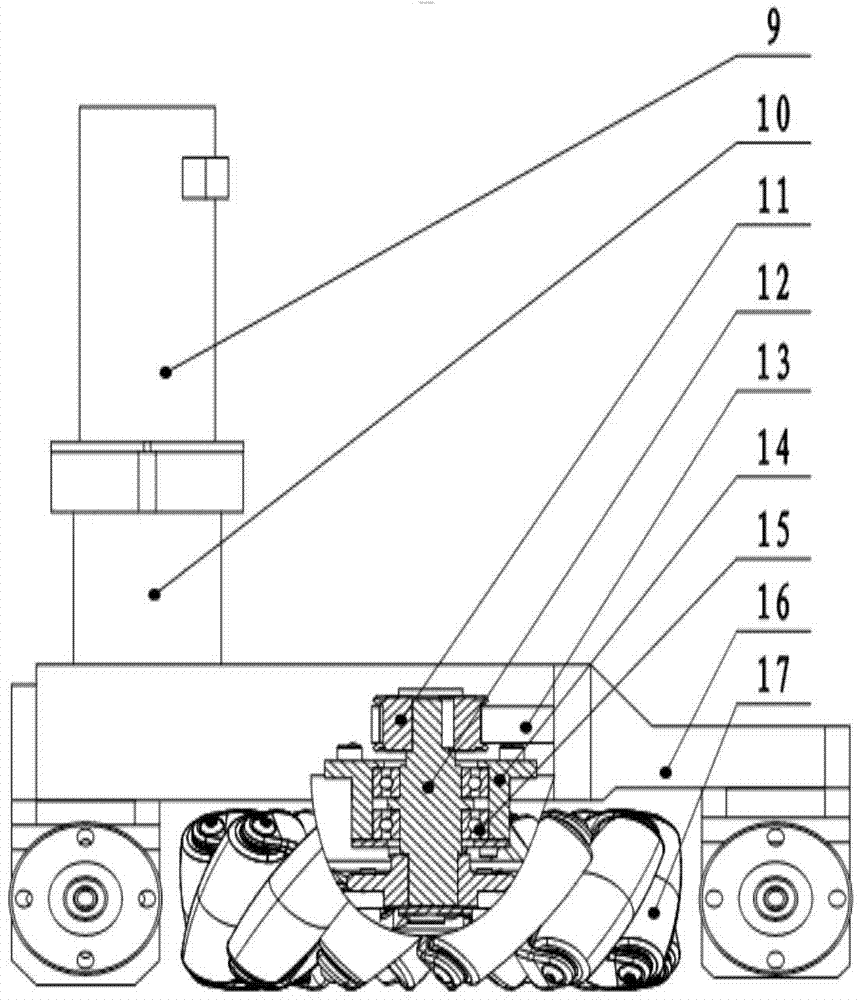

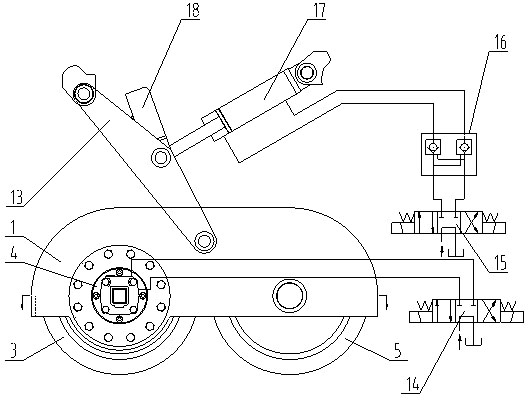

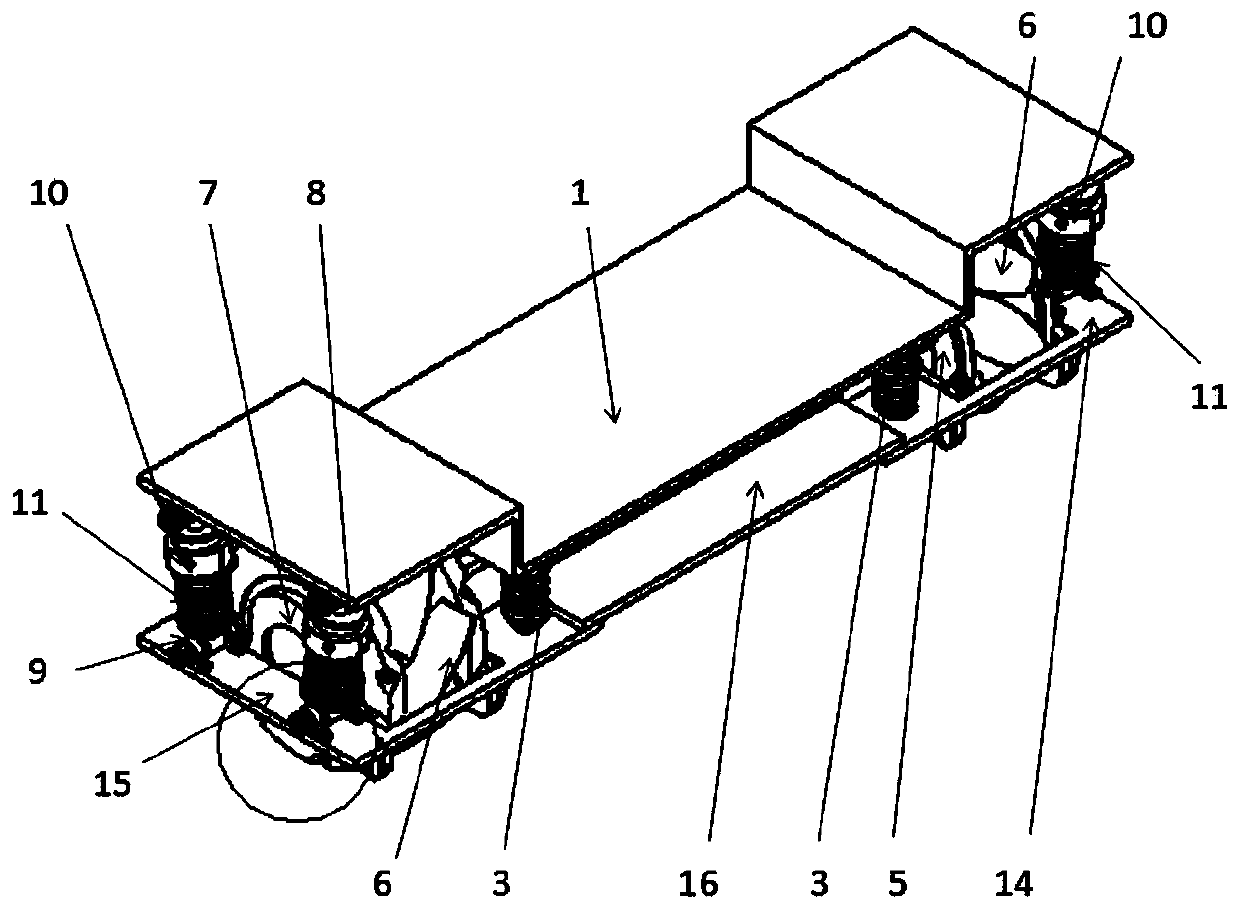

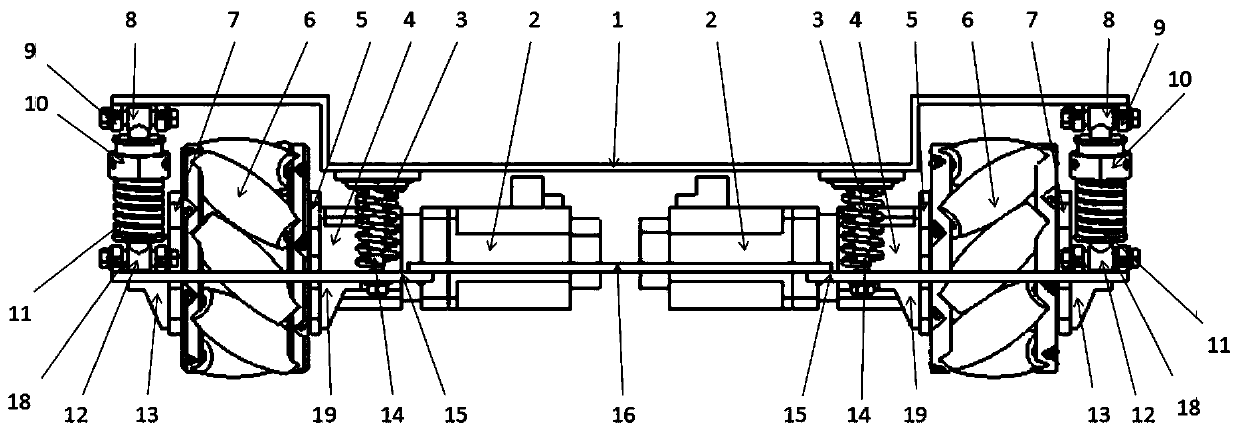

Independent suspension mechanism for omni-directional mobile platform

An independent suspension mechanism for an omni-directional mobile platform includes two symmetrically arranged mecanum wheels, driving devices are connected to the inner sides of the mecanum wheels,and damping mechanisms are connected to mounting brackets at the outer sides of the mecanum wheels; spring guide rods are arranged at both sides of reduction gears, the top portions of the spring guide rods are connected with a car body mounting plate, and the bottom portions of the spring guide rods are connected with the mounting brackets, and the middle of the spring guide rods are sleeved withfirst rectangular cross-section springs; and a closed structure is formed by the two mecanum wheels through the car body mounting plate, the mounting brackets, and a connecting plate. According to the independent suspension mechanism for the omni-directional mobile platform, the pressure can be adjusted according to the load and ground conditions under multiple different environmental conditions,the influence of the ground on the running process of the mecanum wheels can be reduced, and the phenomenon of suspension of a certain group of wheels due to the unevenness of the ground is avoided;and the independent suspension mechanism for the omni-directional mobile platform has the advantages of stable operation of the platform, strong ability to overcome obstacles, and high bearing capacity.

Owner:XIJING UNIV

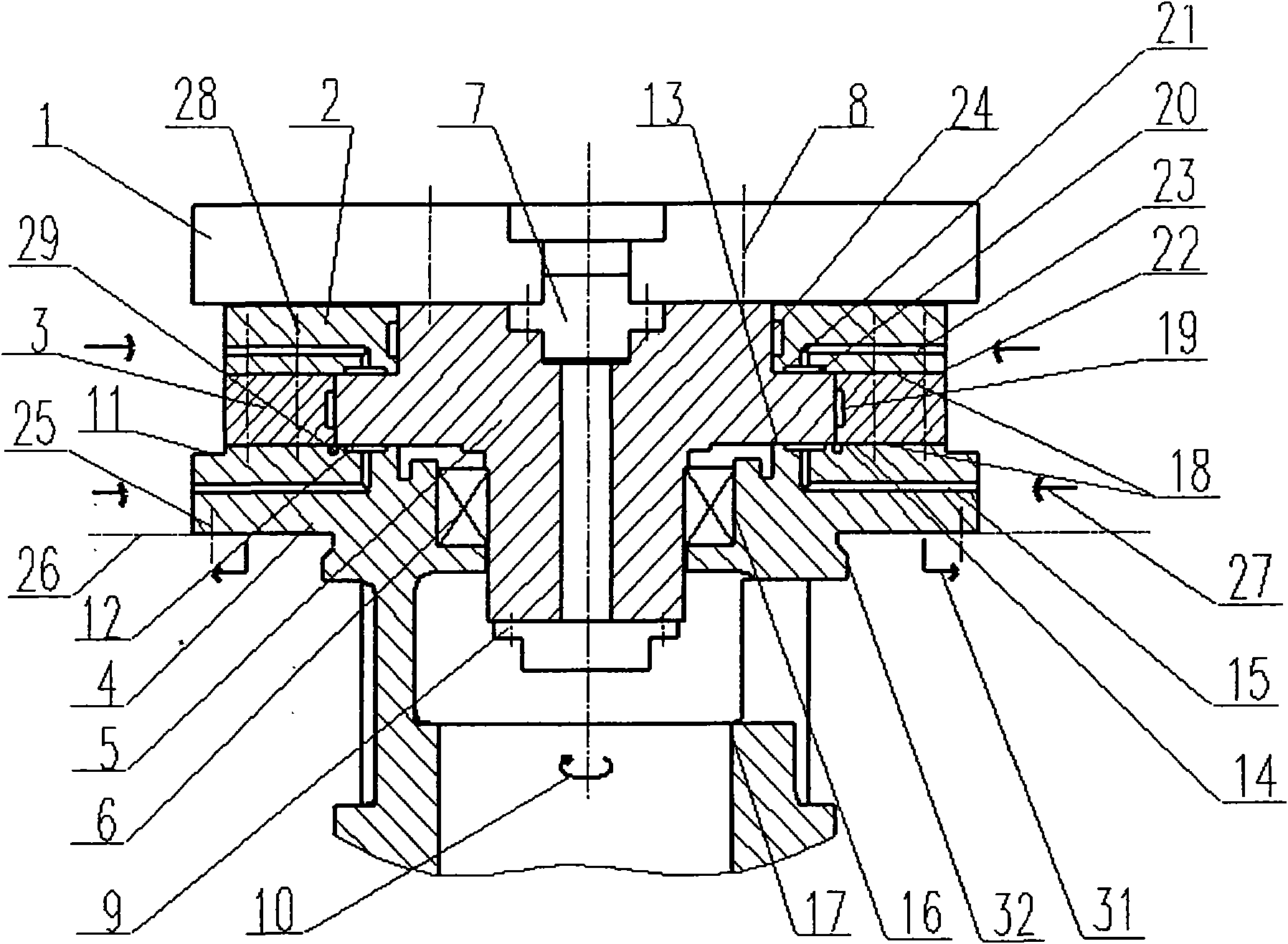

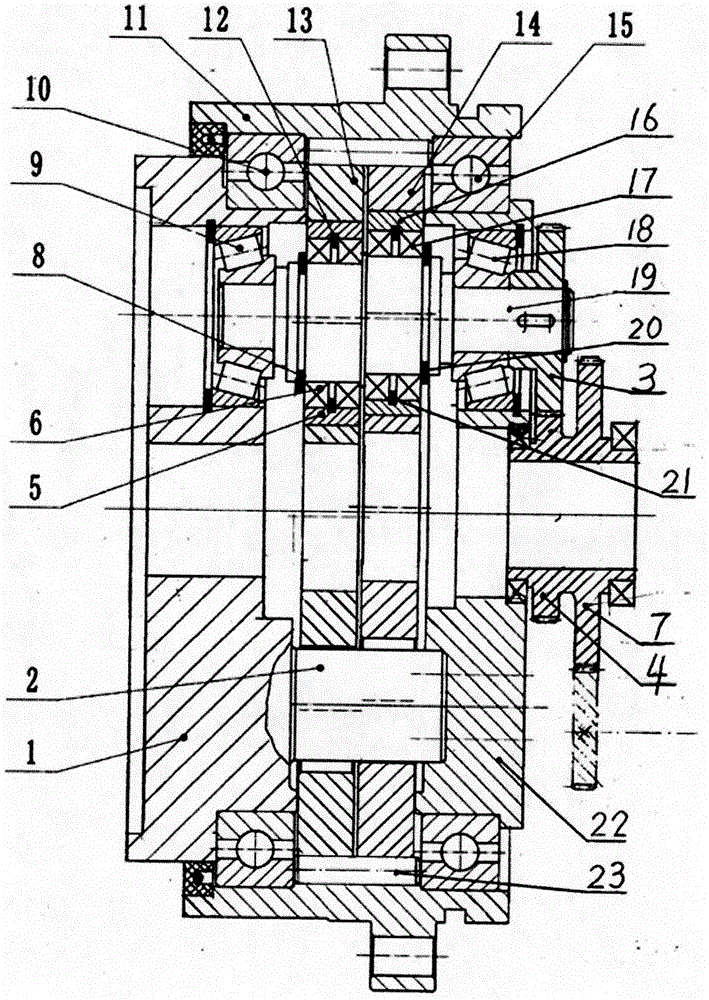

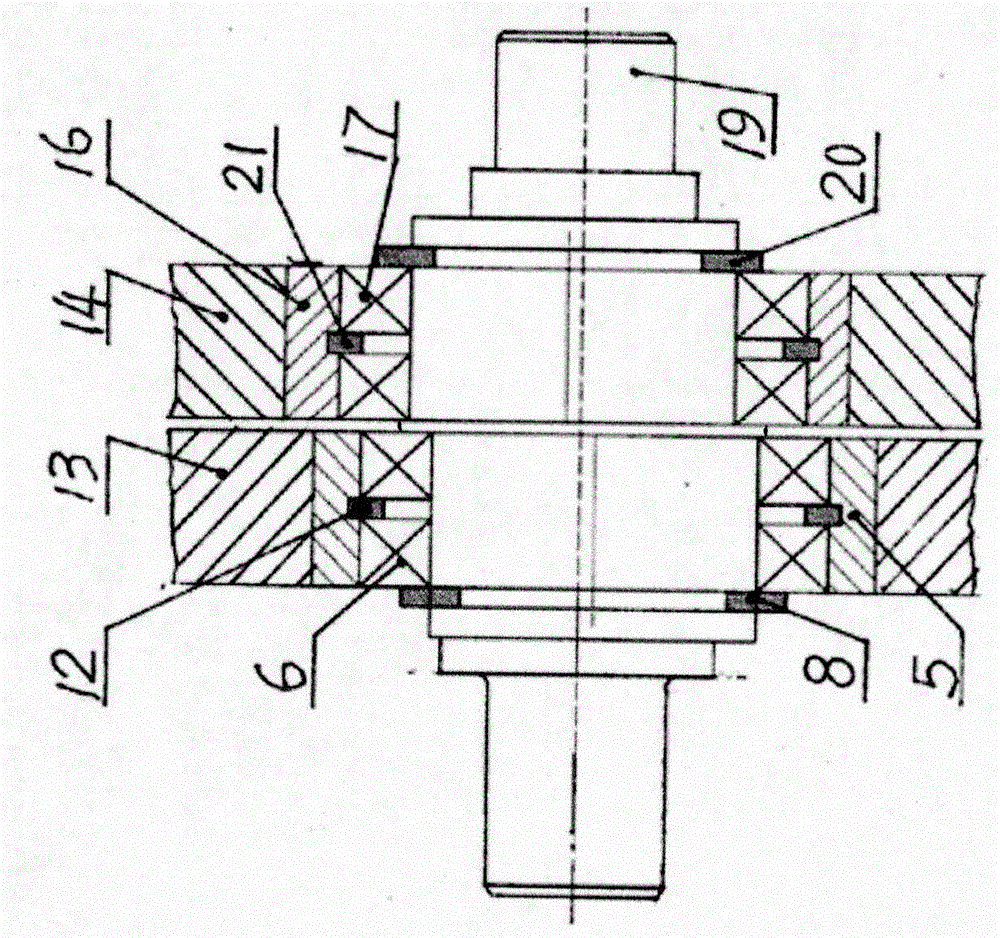

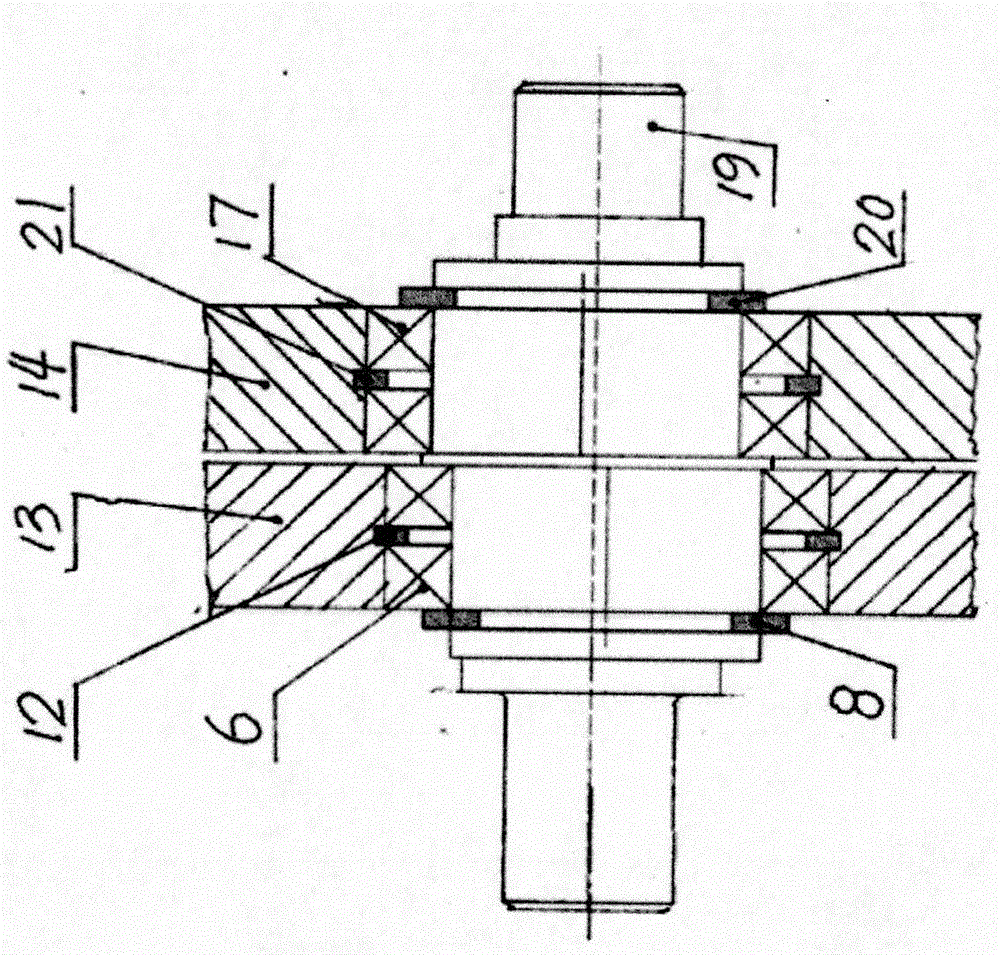

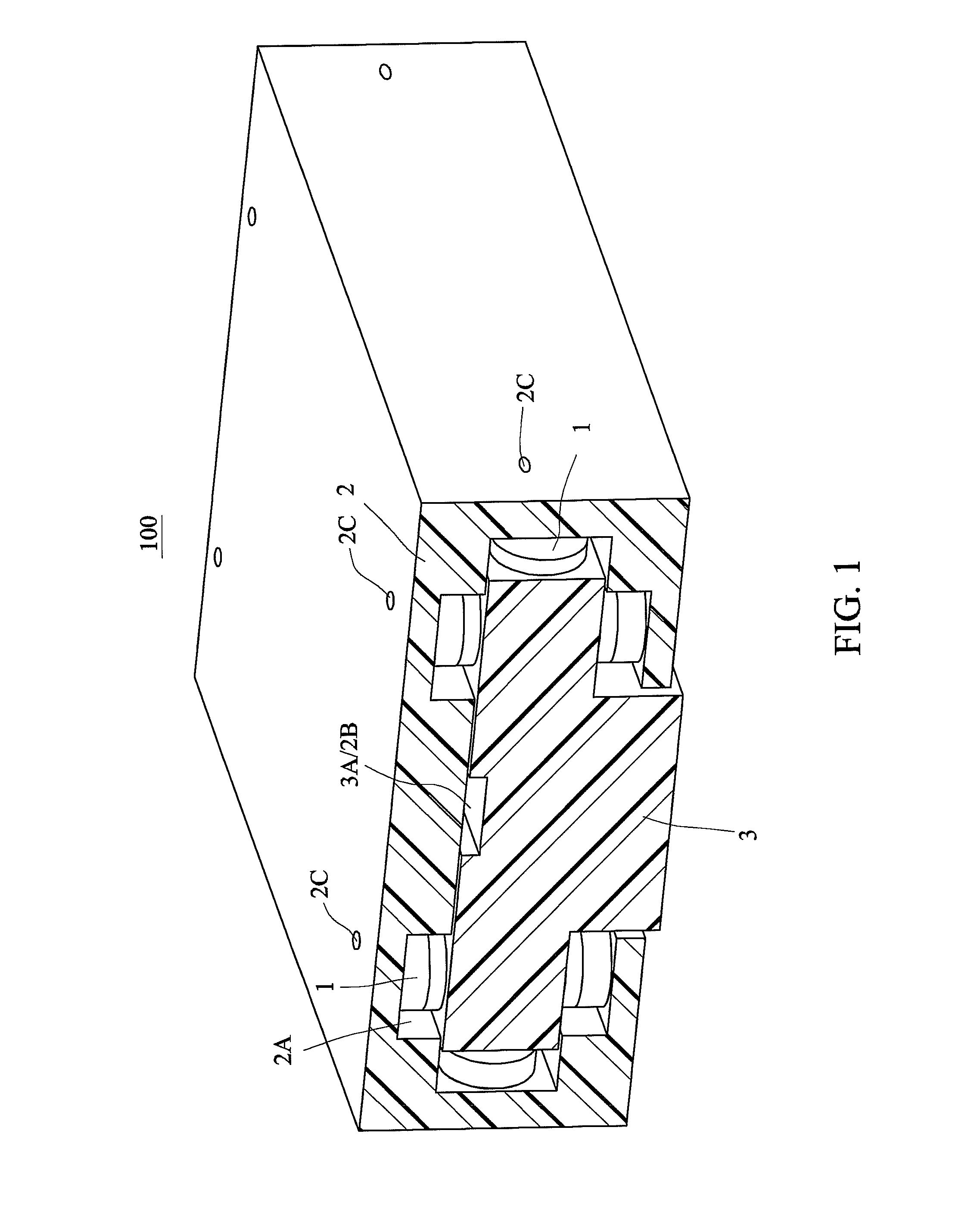

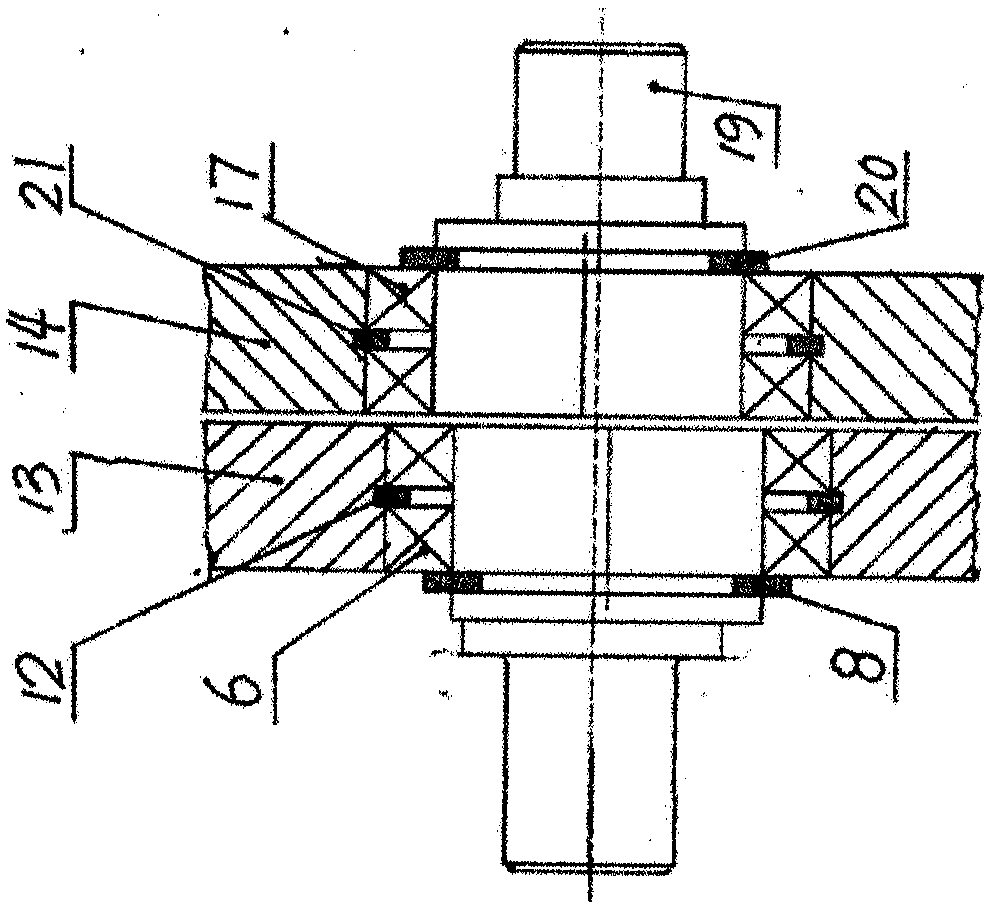

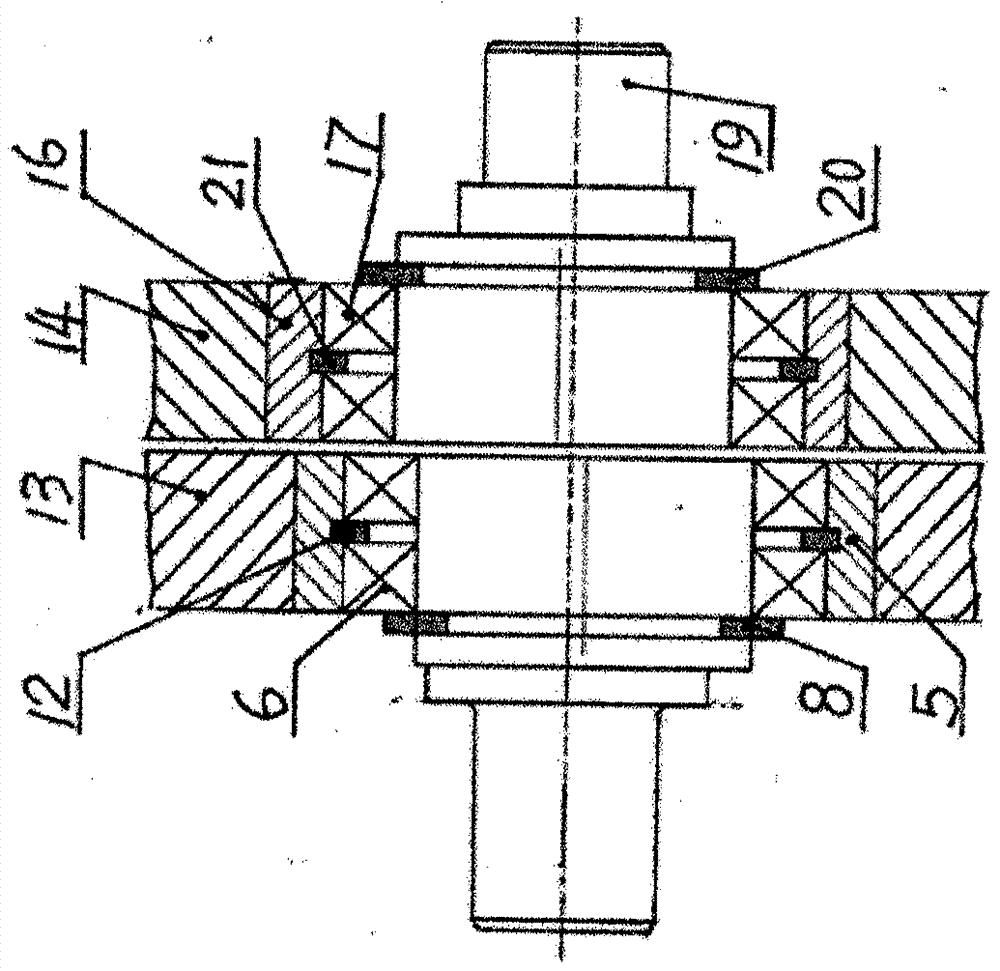

Compound type rotary supporting device for machine tool round workbench

ActiveCN101549461ALarge bearing capacityImprove bearing rigidityLarge fixed membersRolling-element bearingEngineering

The invention discloses a compound type rotary supporting device for a machine tool round workbench, which comprises a workbench, a rotary main shaft, an axial static-pressure supporting component and a rolling bearing. The compound type rotary supporting device is characterized in that the upper part of the rotary main shaft is provided with an axial plane annular closed static-pressure round guide rail support which bears axial loads, the middle part of the rotary main shaft is provided with the rolling bearing which bears radial loads, and both the guide rail support and the rolling bearing form a static-pressure and rolling compound type rotary support; the closed static-pressure round guide rail support comprises an upper press ring, a middle spacing ring arranged below the upper press ring and a lower shell arranged below the middle spacing ring, and the upper press ring, the middle spacing ring and the lower shell are connected into a whole; the lower plane of the upper press ring and the upper plane of the lower shell form an upper sealing combination surface and a lower sealing combination surface with the middle spacing ring, and a pressure bearing surface of the guide rail support which corresponds to the rotary main shaft is provided with a static-pressure oil cavity; the rolling bearing is a rolling bearing of a cylinder roller or an equivalent combination of the rolling bearing. The compound type rotary supporting device has the advantages of large bearing capacity, high moving precision and long service life and has short rotary main shaft, simple and compact structure, low manufacturing and using cost, convenient maintenance and high supporting rigidity.

Owner:浙江杭机股份有限公司

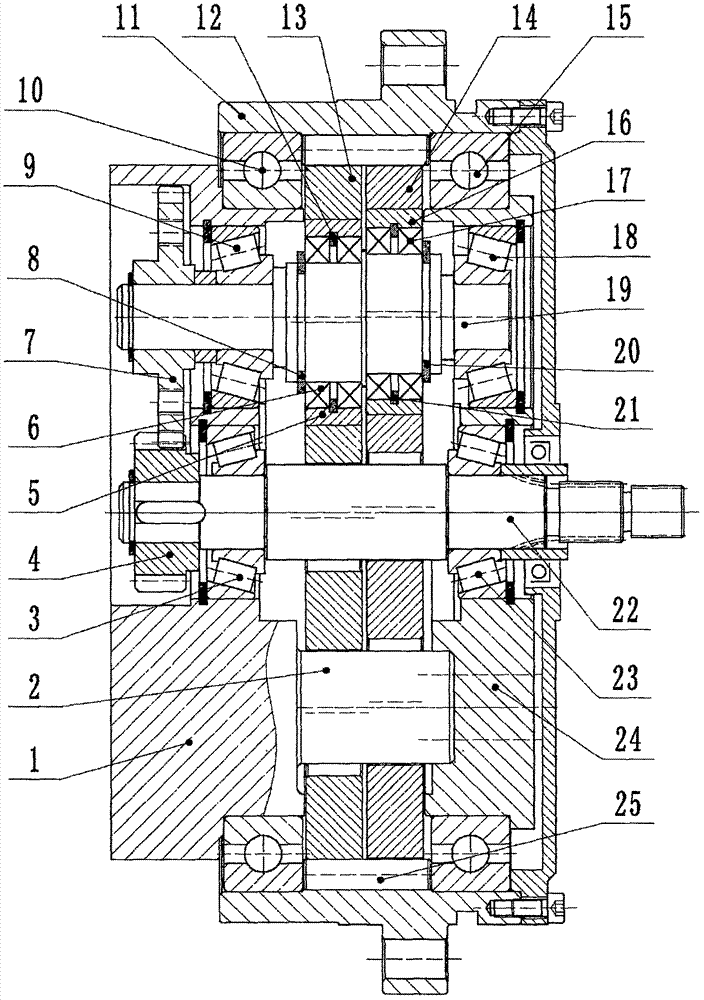

High-rigidity hollow RV speed reducer for industrial robot

InactiveCN106641110AImprove bearing rigiditySimple processToothed gearingsGearing detailsDouble rowEngineering

The invention relates to the technical field of speed reducers and provides a high-rigidity hollow RV speed reducer for an industrial robot. The high-rigidity hollow RV speed reducer comprises a left rigid disc, a right rigid disc, a pin wheel housing, a pin, a cycloidal wheel, a cycloid part of a crankshaft, and planet parts of a sun wheel and a planet wheel. The high-rigidity hollow RV speed reducer is characterized in that the rigid discs, the cycloidal wheel, a driven gear and the sun wheel are each provided with a center hole, shaft elastic retainer rings are arranged on the eccentric sections of the two sides of a crankshaft barrier, a rotating arm bearing assembly is arranged between the retainer ring and the barrier and comprises a loop, an elastic retainer ring and a radial bearing, the radial bearing is located on an axial pretightening structure, the loop is matched with a corresponding hole of the cycloidal wheel or melt into the hole, and the radial bearing is a deep groove ball bearing or a radial thrust ball bearing or a single-row tapered roller bearing or a single double-row tapered roller bearing. The high-rigidity hollow RV speed reducer has the beneficial effects that by means of the axial pretightening structure for the rotating arm bearing, the bearing rigidity is improved, and it is ensured that the total return difference caused by elastic deformation of the bearing is no more than 6 arc min, for the domestic machine tool, the conventional manufacturing precision is high, the technology is simple, and the cost is low and is reduced by 55-70%.

Owner:吴小杰

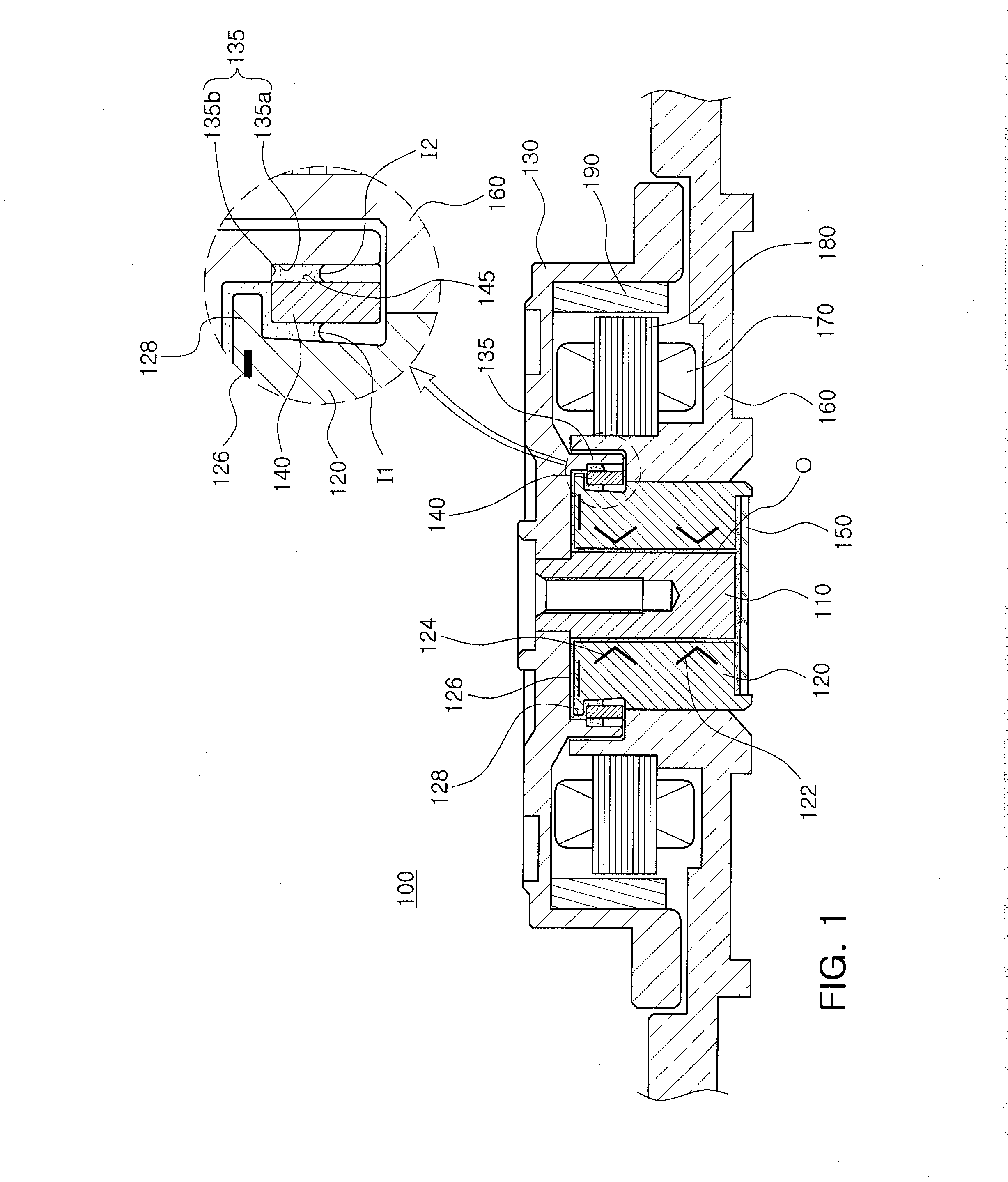

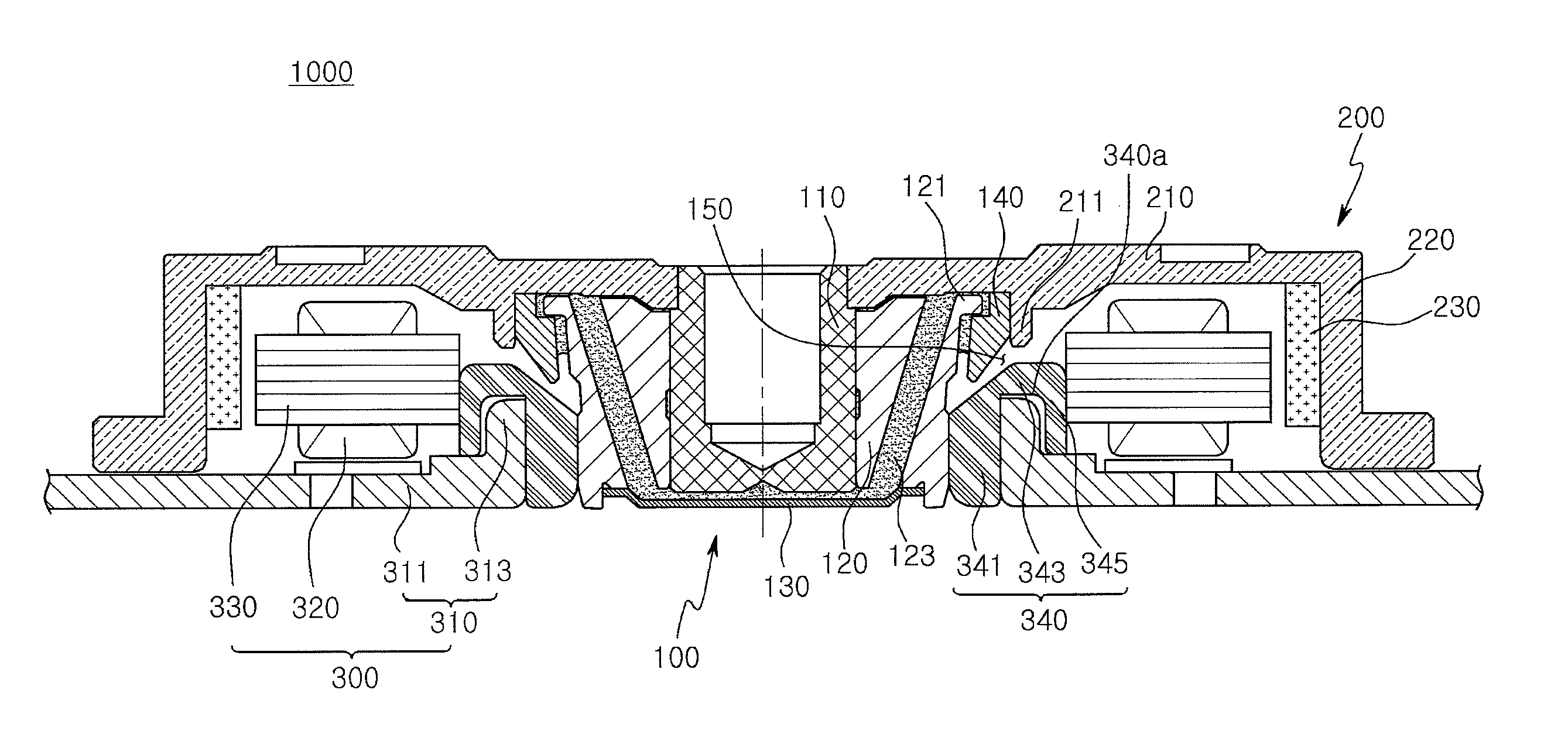

Bearing device for wheel

InactiveUS8047724B2Avoid interferenceAvoid deformationRoller bearingsHubsEngineeringMechanical engineering

A wheel bearing apparatus includes a roller bearing, an inner shaft having an outer circumferential surface to which an inner ring of the roller bearing is installed, a coupler ring attached to an end portion of the inner shaft, and a caulked portion provided in an end portion of the inner shaft so as to fix the coupler ring and the roller bearing to the inner shaft so as to be immovable in an axial direction of the inner shaft. An outer diameter of the coupler ring is set smaller than a diameter of a shoulder portion of the inner ring. Alternatively, a protruding portion is provided in any one of opposing end surfaces of the coupler ring and the inner ring, whereby the coupler ring is arranged away from a seal member. Accordingly, it is possible to avoid an interference of the coupler ring with the seal member.

Owner:JTEKT CORP

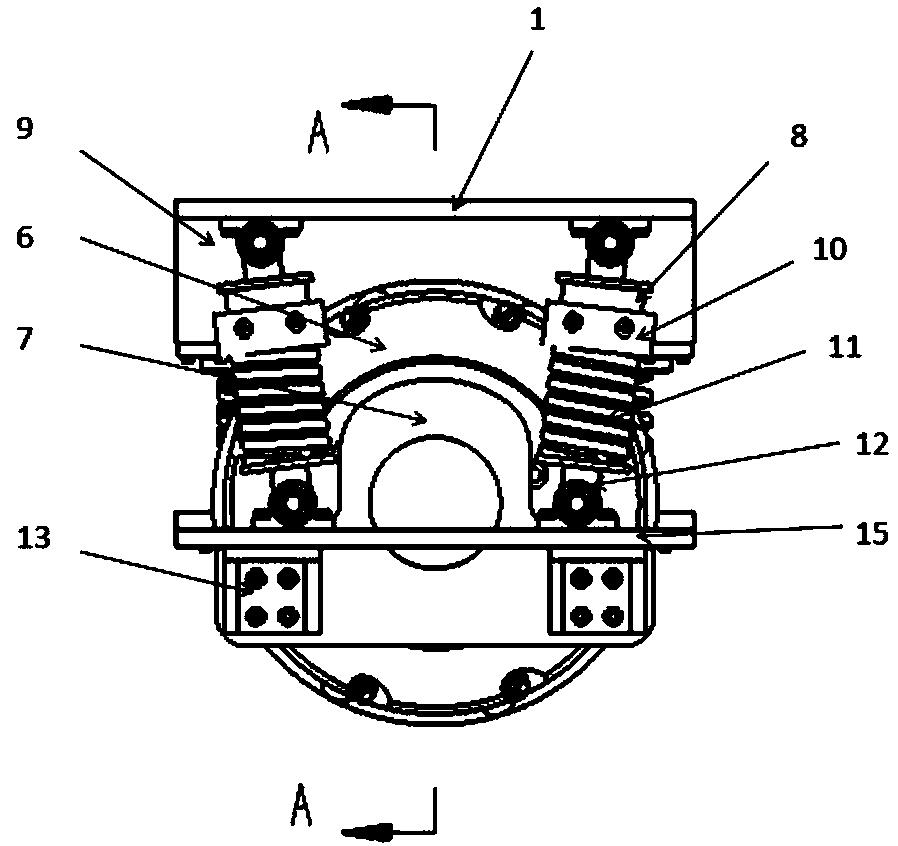

Independent suspension mechanism of intelligent Mecanum wheel movement platform

InactiveCN104494382AGuaranteed uptimeImprove bearing rigidityMotor depositionResilient suspensionsTerrainEngineering

The invention relates to an independent suspension mechanism of an intelligent Mecanum wheel movement platform. The independent suspension mechanism is arranged below the movement platform and on the radial side of a Mecanum wheel and comprises a feed rod, a linear bearing, springs, a feed rod flange and an installation frame, wherein one end of the feed rod is connected with the movement platform through the feed rod flange, the other end of the feed rod is connected to the installation frame through a feed rod seat, the feed rod penetrates the linear bearing to be connected with the feed rod seat, and the springs sleeve the feed rod and are arranged between the feed rod flange and the linear bearing respectively. According to the independent suspension mechanism of the intelligent Mecanum wheel movement platform, advantages of the independent suspension mechanism and the Mecanum wheel movement platform are organically combined, the platform is stably operated, a high adaptive capability to uneven terrains and a high obstacle crossing capability are achieved, and the platform is good in bearing rigidity.

Owner:LIAONING XINHAI HONGYE AVIATION TECH CO LTD

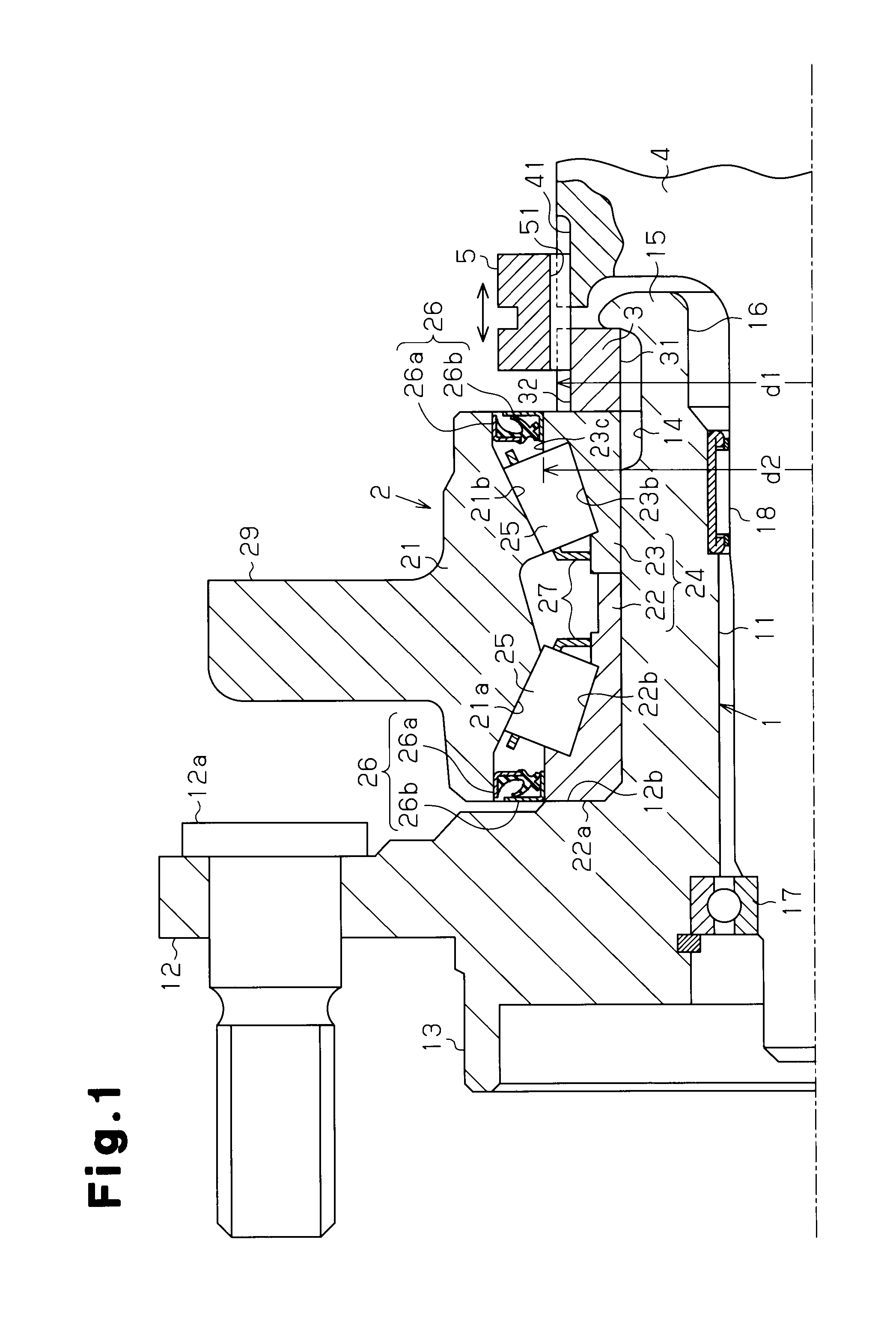

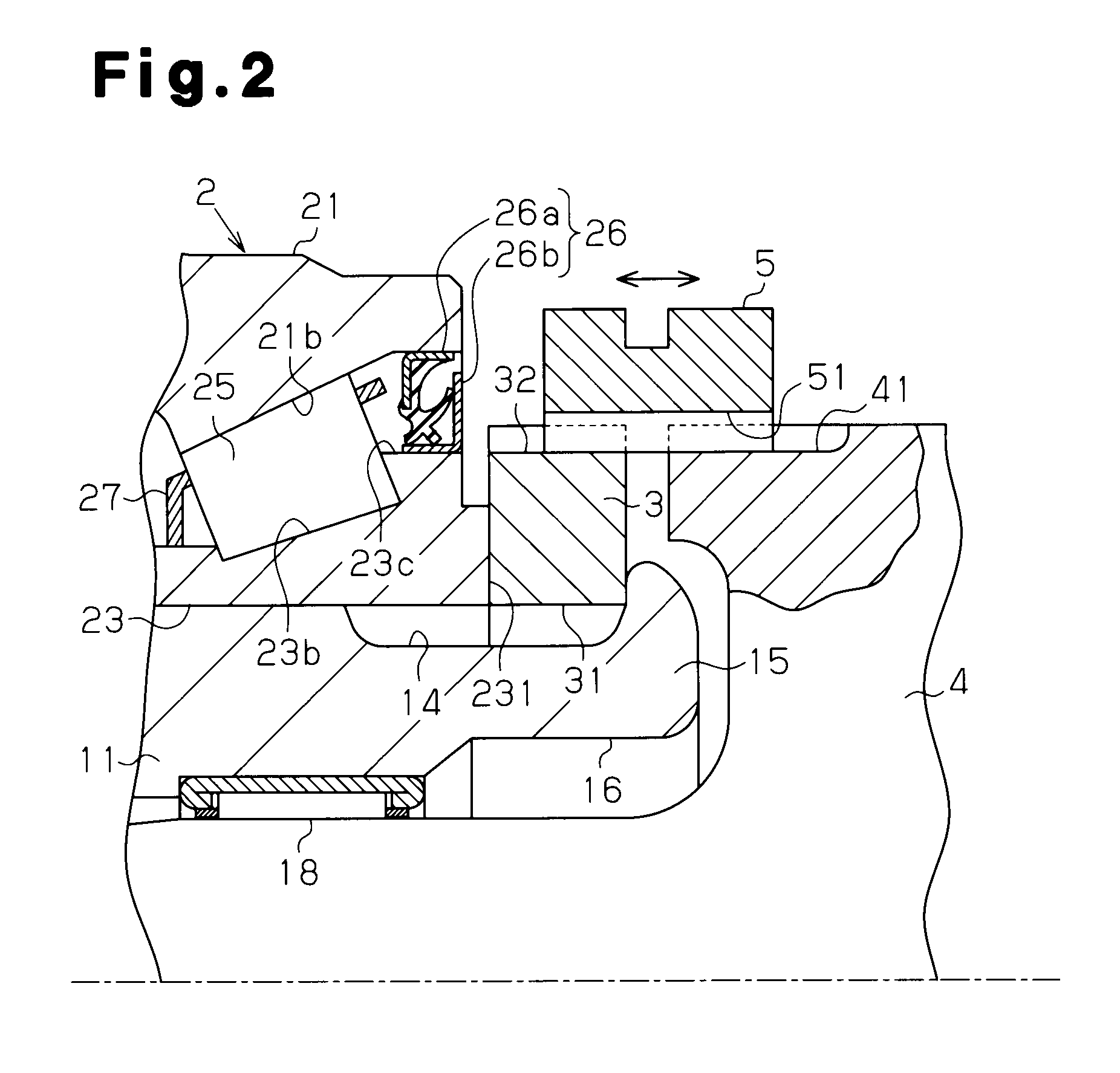

Bearing Device for Wheel

ActiveUS20080258541A1Avoid interferenceAvoid deformationRoller bearingsBearing assemblyEngineeringMechanical engineering

A wheel bearing apparatus includes a roller bearing, an inner shaft having an outer circumferential surface to which an inner ring of the roller bearing is installed, a coupler ring attached to an end portion of the inner shaft, and a caulked portion provided in an end portion of the inner shaft so as to fix the coupler ring and the roller bearing to the inner shaft so as to be immovable in an axial direction of the inner shaft. An outer diameter of the coupler ring is set smaller than a diameter of a shoulder portion of the inner ring. Alternatively, a protruding portion is provided in any one of opposing end surfaces of the coupler ring and the inner ring, whereby the coupler ring is arranged away from a seal member. Accordingly, it is possible to avoid an interference of the coupler ring with the seal member.

Owner:JTEKT CORP

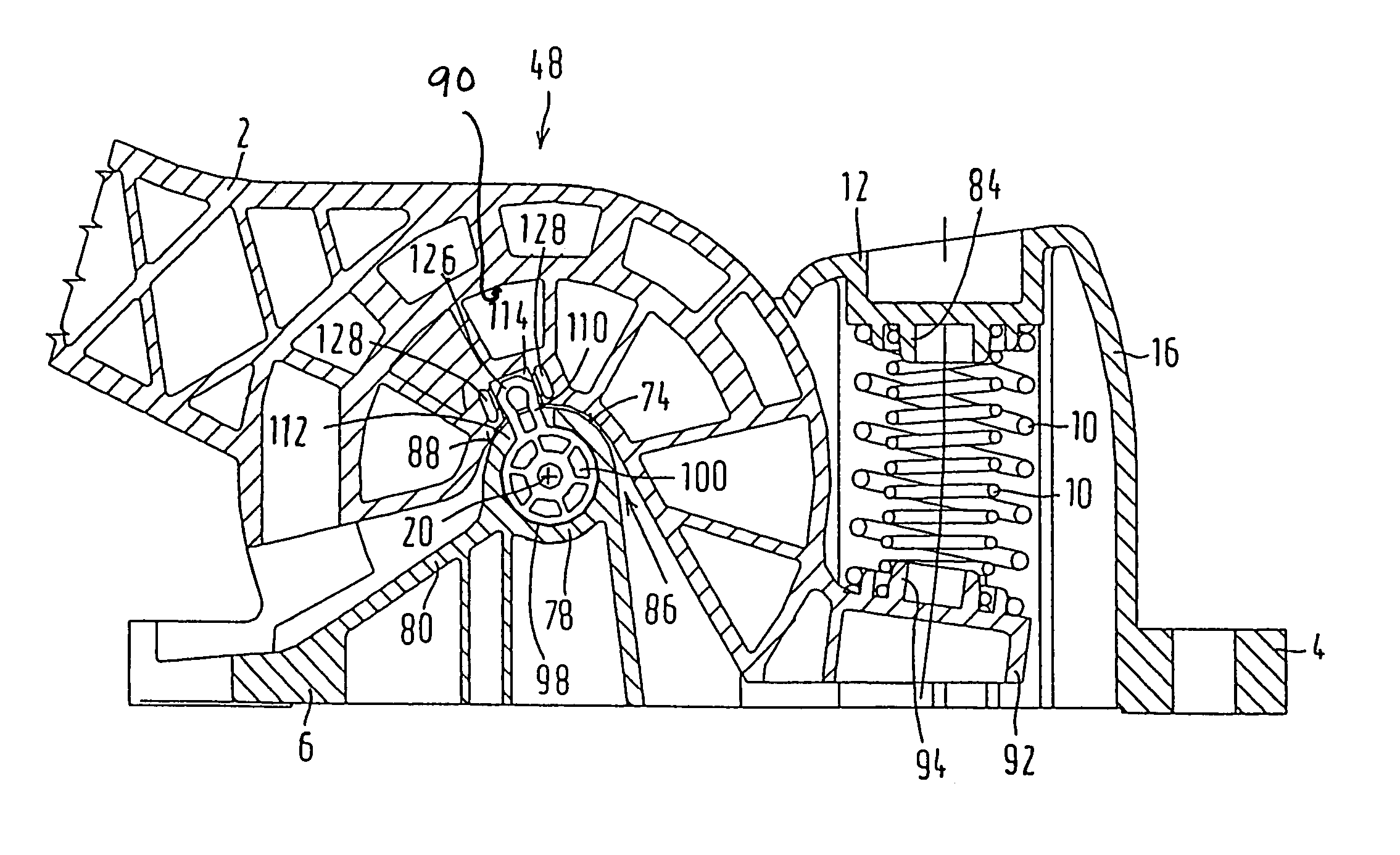

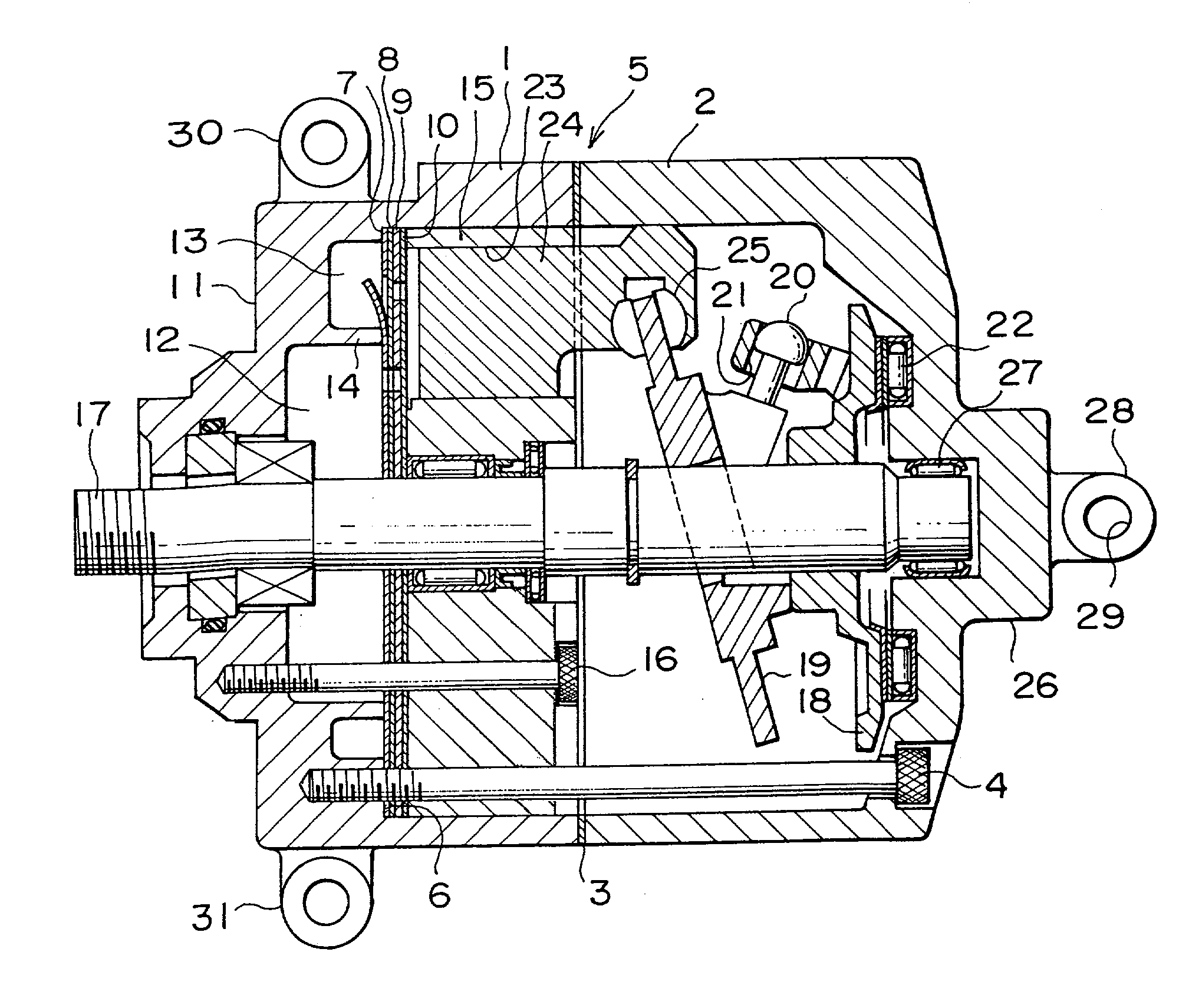

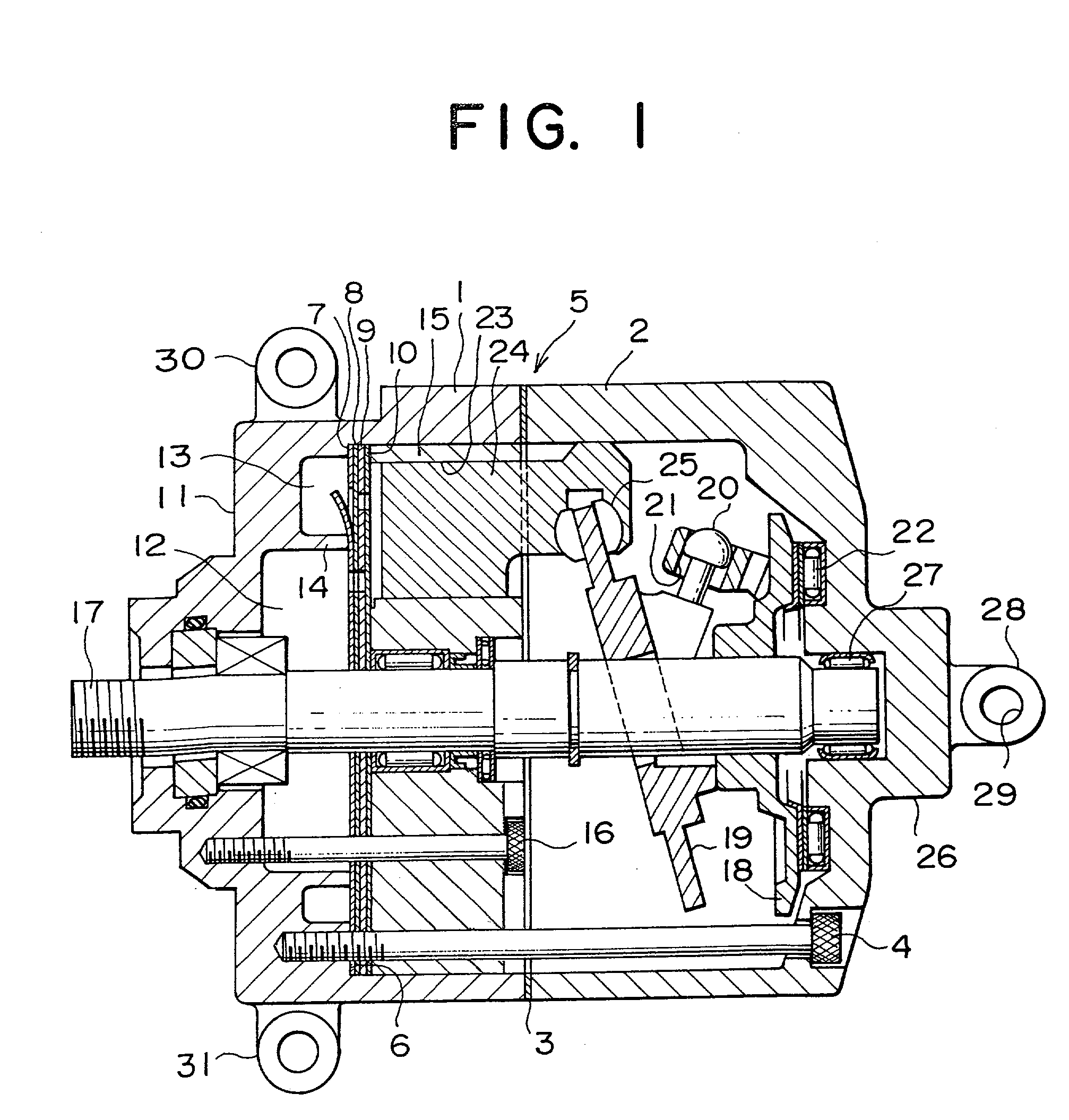

Compressor

InactiveUS20020127118A1Reduce vibrationSuppress increase in weightPositive displacement pump componentsMulti-stage pumpsPistonRefrigerant

A compressor includes a housing having a hollow projection portion, a rotary shaft provided rotatably within the housing, a piston reciprocating in accordance with rotation of the rotary shaft for sucking and discharging refrigerant, a bearing disposed within the projection portion of the housing for rotatably supporting one end of the rotary shaft and an attaching leg portion formed on an outer surface of the projection portion of the housing. The attaching leg portion is fastened to an engine block, a bracket or the like by using a bolt or the like.

Owner:TOYOTA IND CORP

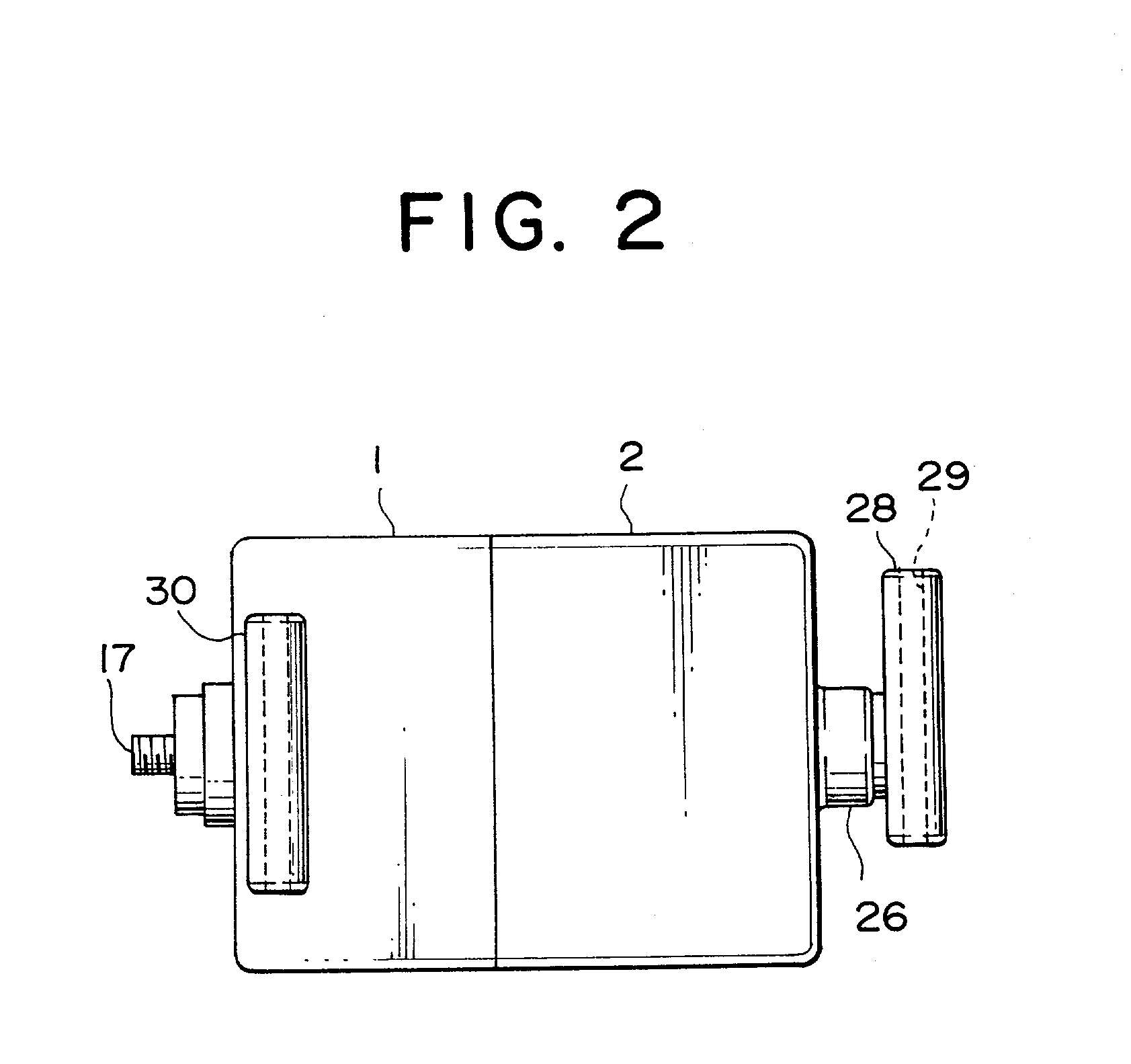

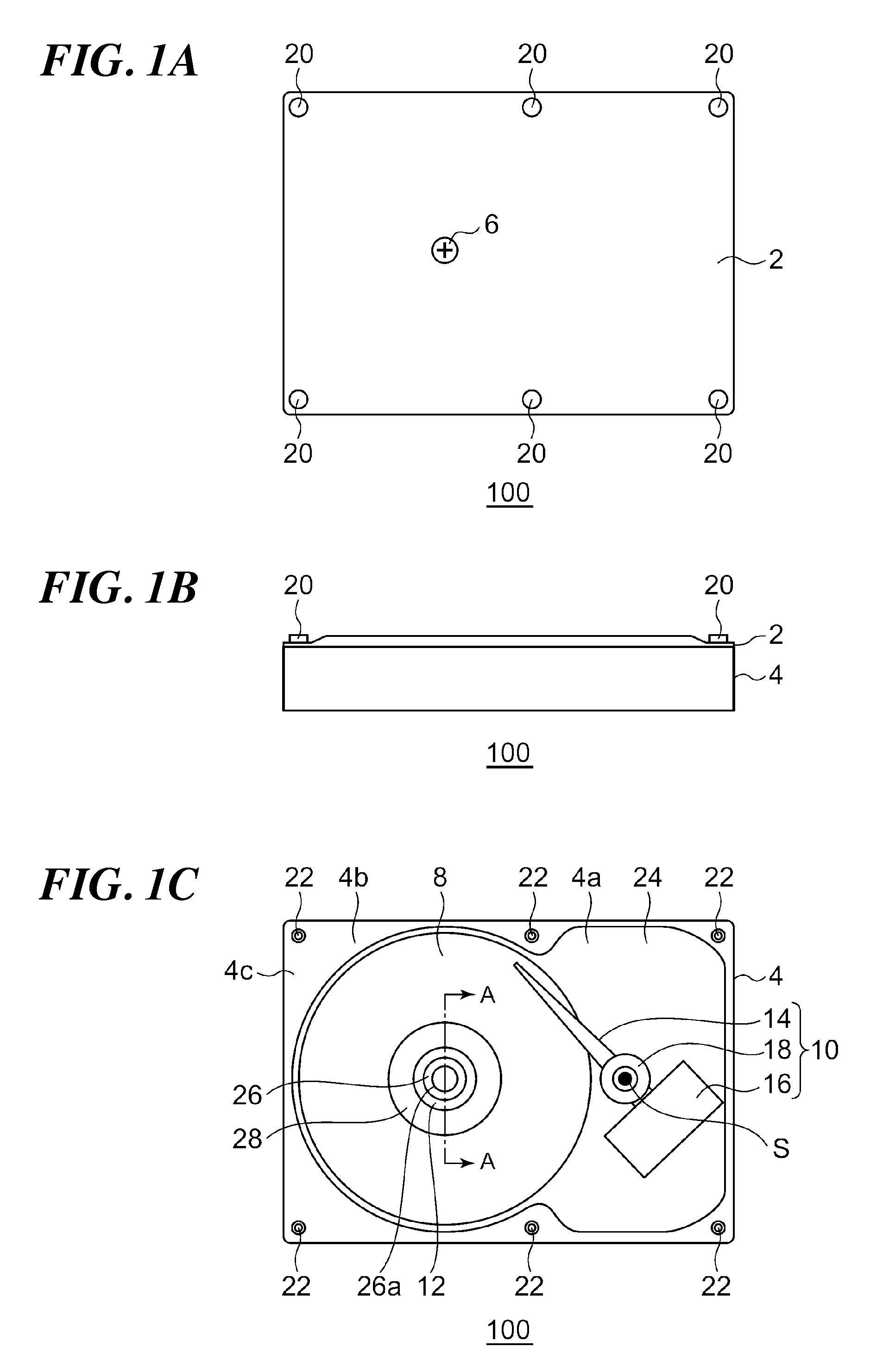

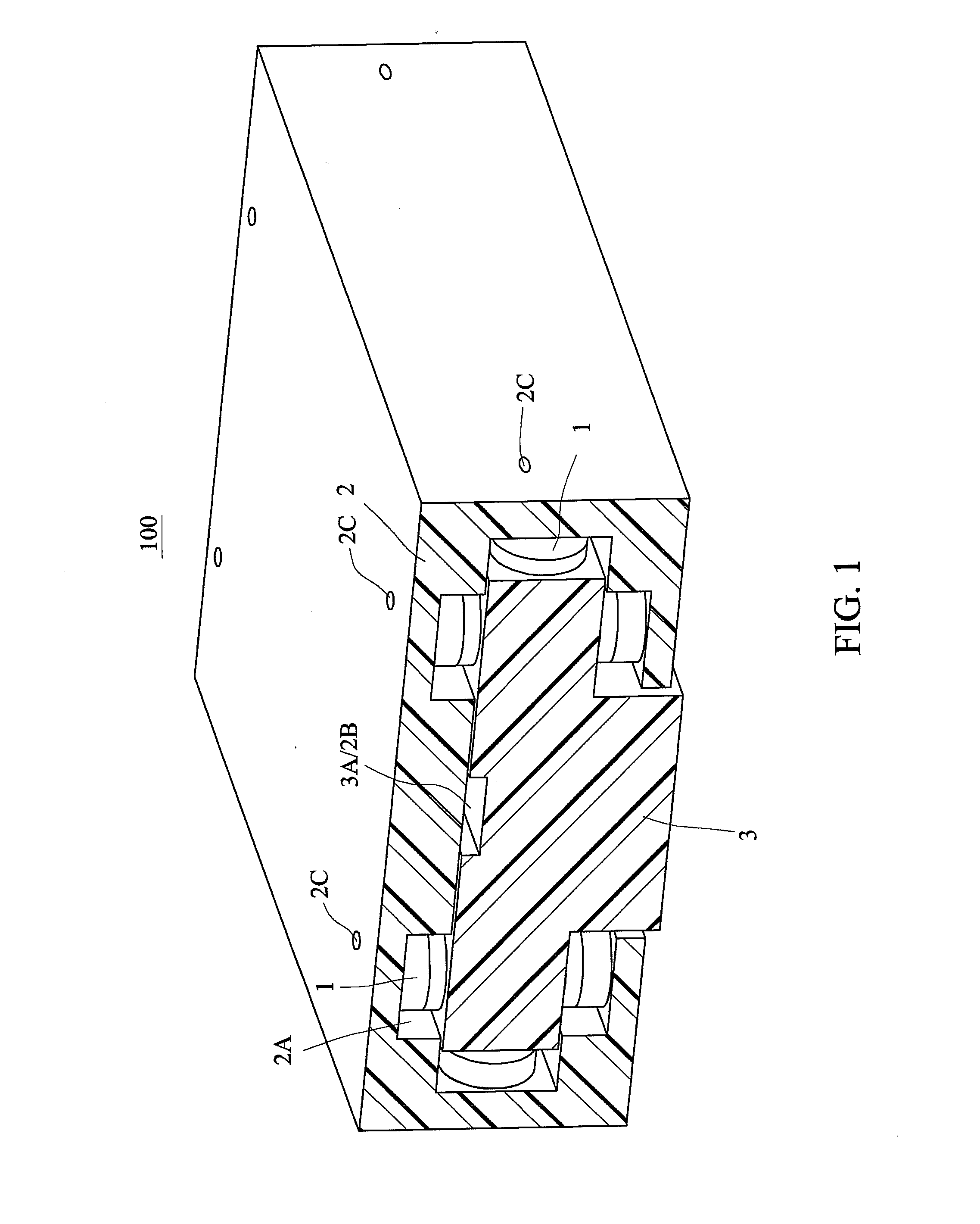

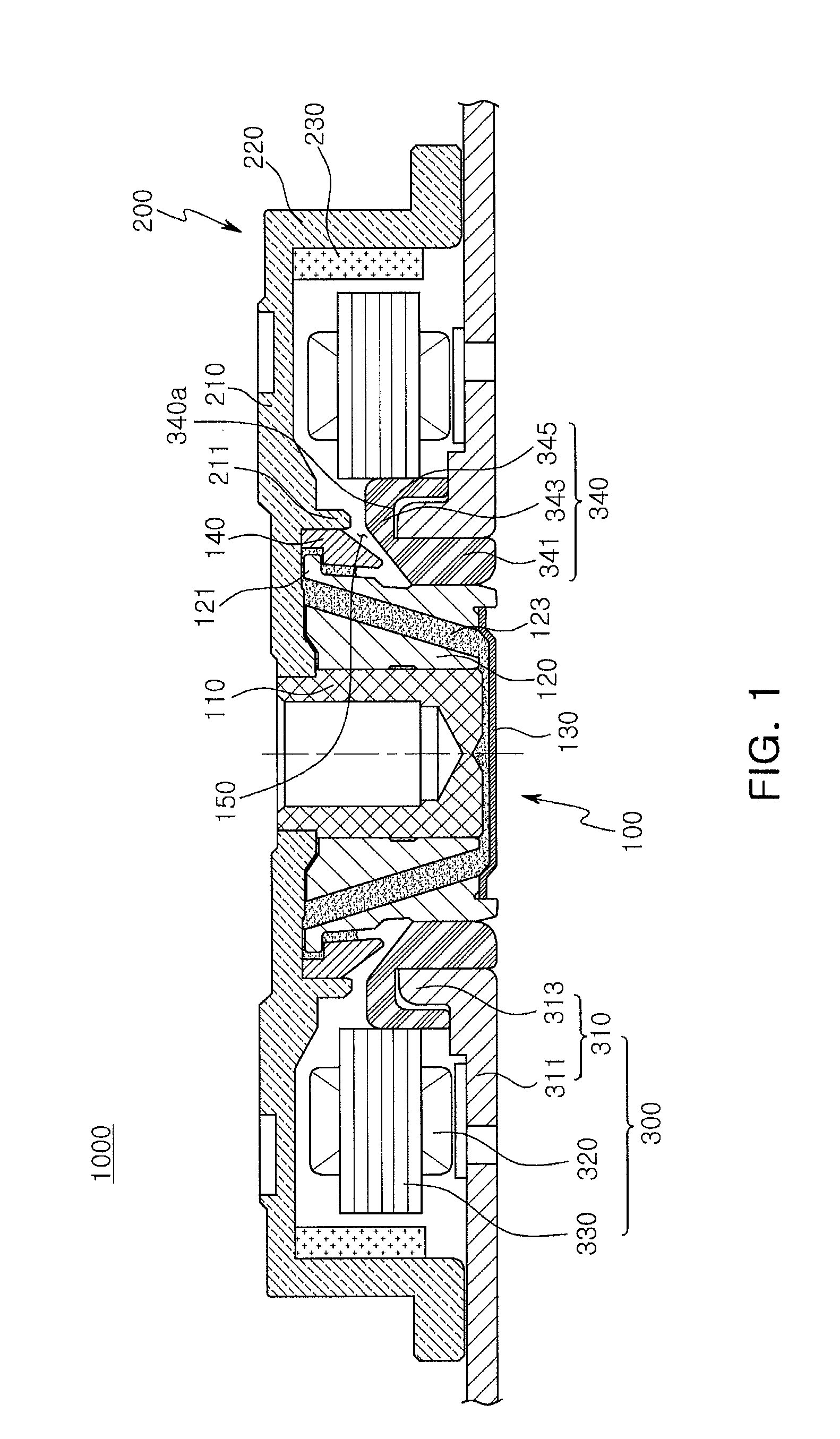

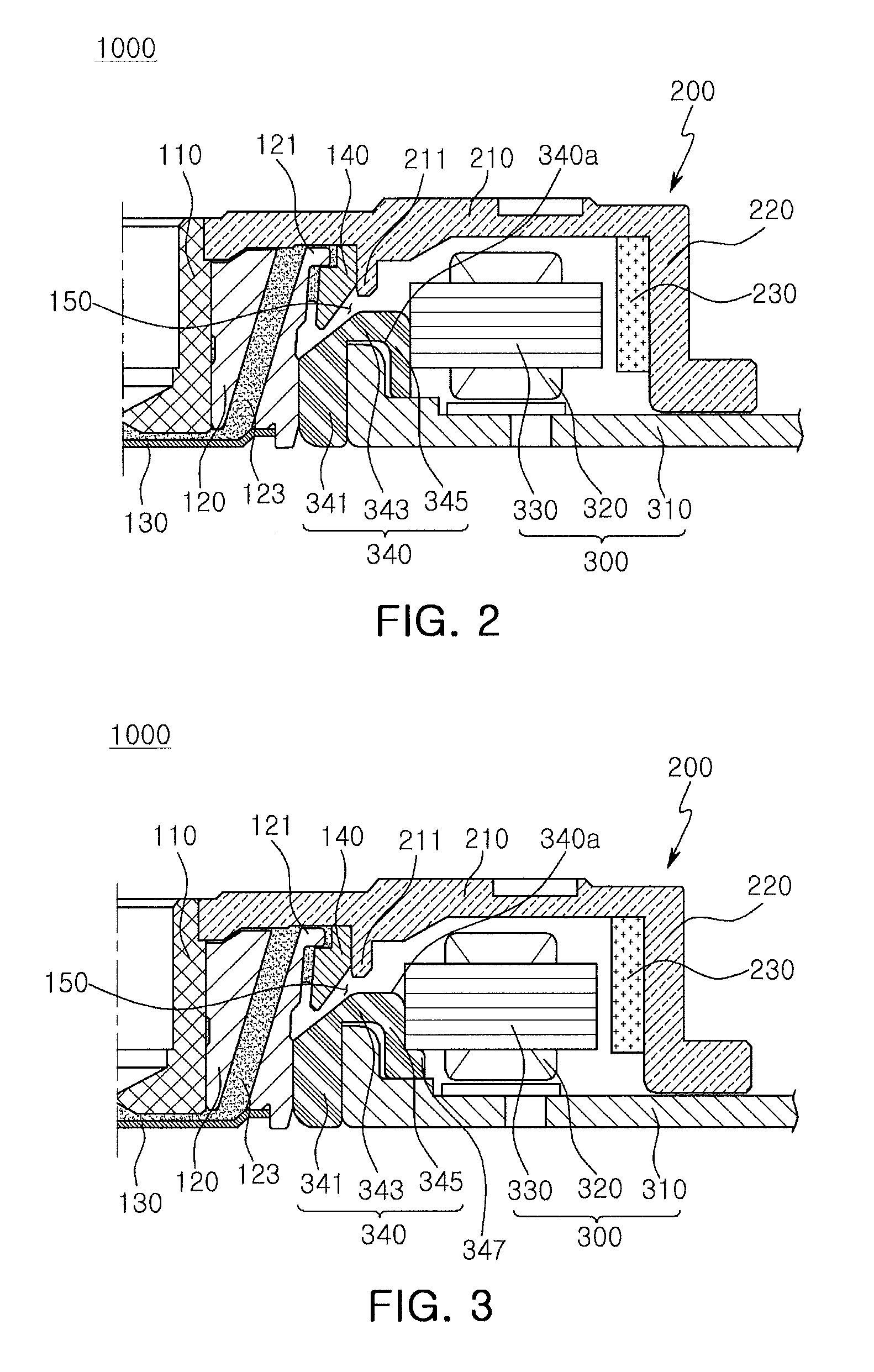

Recording disk driving device motor unit having a sheet member attached to a base

InactiveUS7593182B2Precise positioningImprove efficiencySynchronous machine detailsRecord information storageEngineeringDevice Motor

In a motor of a motor unit, a base plate includes a raised portion protruding from a surrounding portion on a side of the stator portion opposite to a rotor portion. A raised face of the raised portion is perpendicular to a central axis and is formed in an annular shape around the central axis. The raised face of the raised portion protrudes lower than a lower surface of a sticker member stuck around the raised portion to thereby close a hole portion formed around the raised portion.

Owner:NIDEC CORP

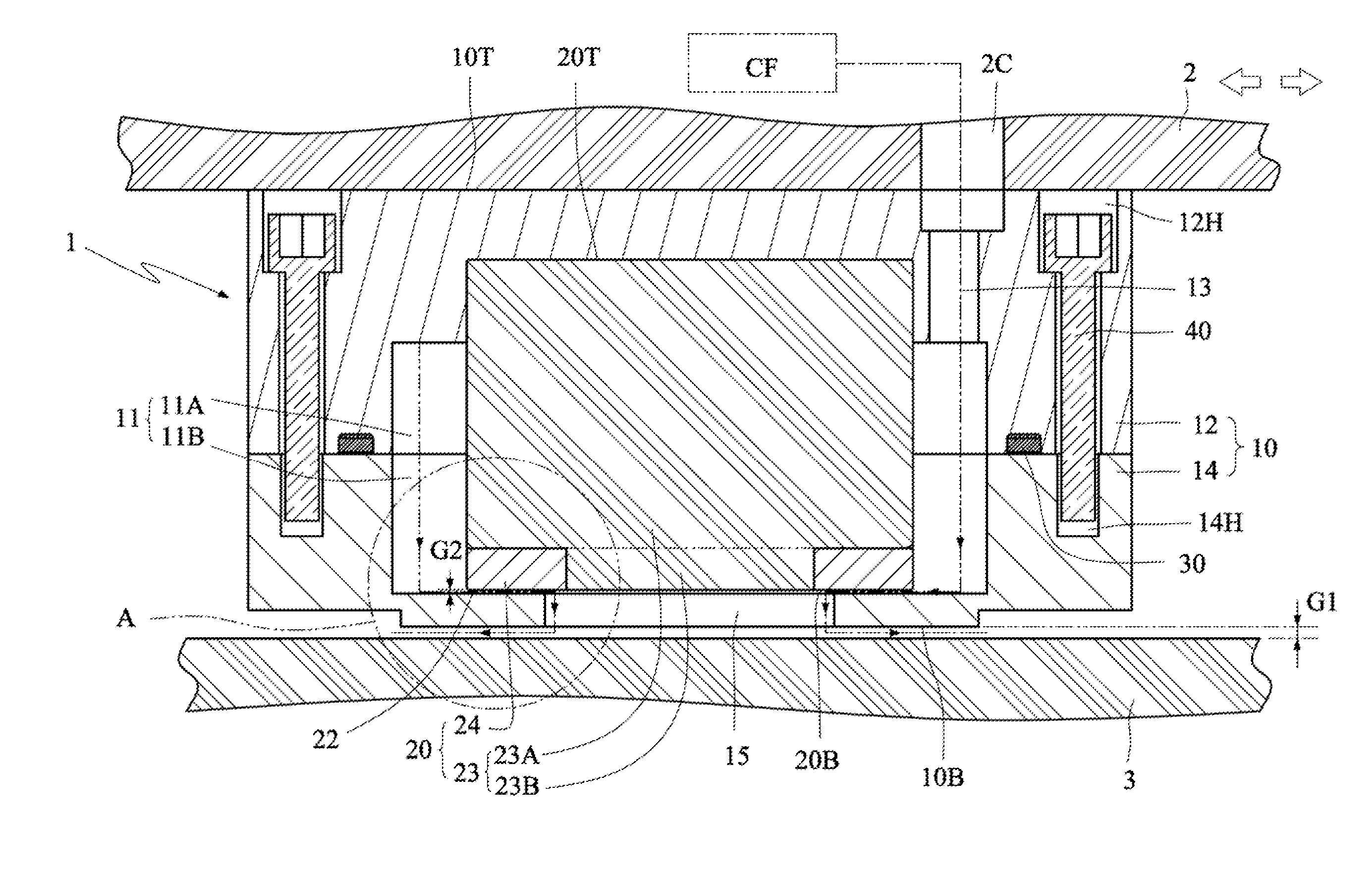

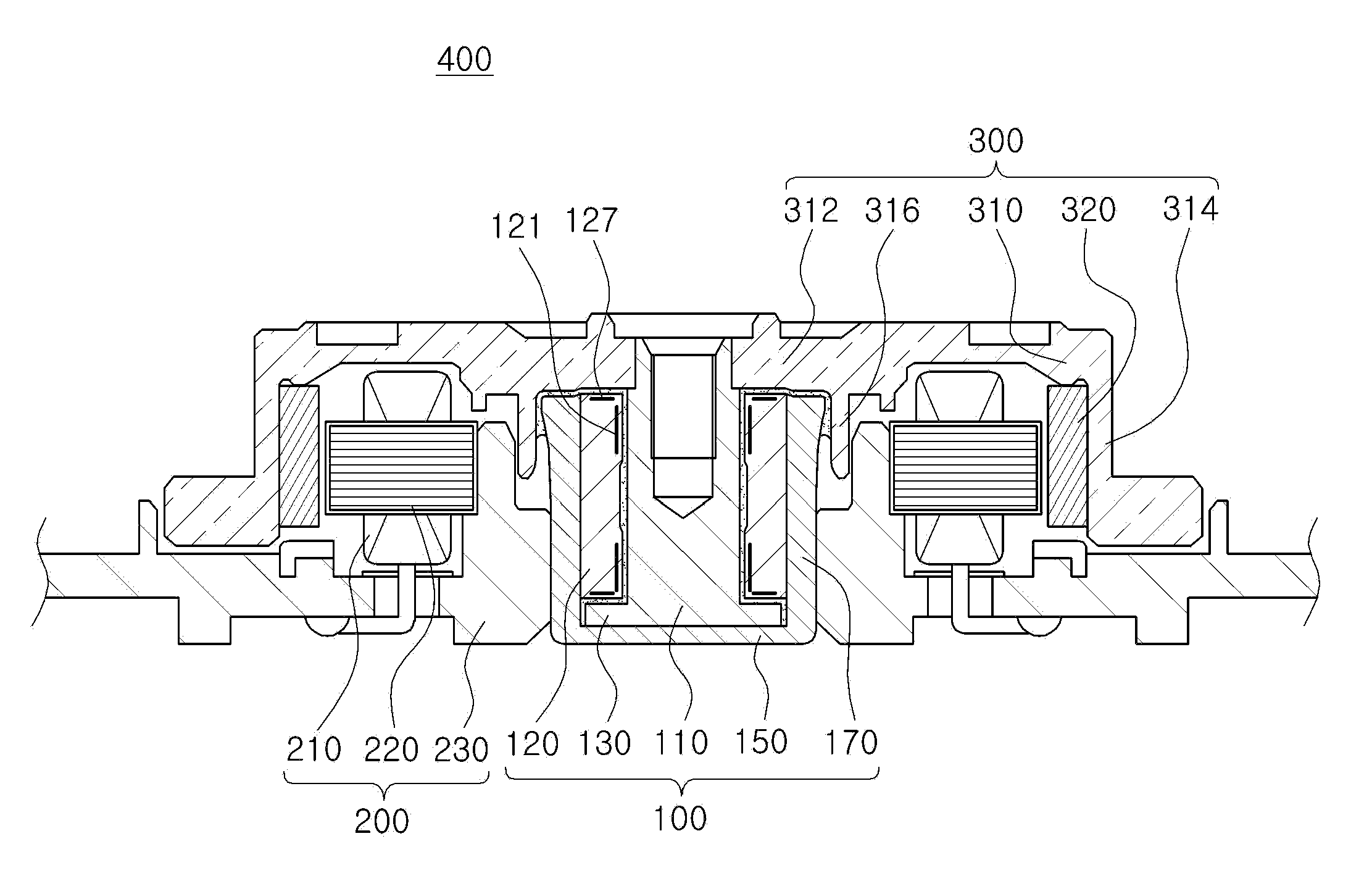

Active compensating hydrostatic bearing and hydrostatic bearing module using the same

ActiveUS8556509B2Improve rigidityMaintain stability and rigidityLinear bearingsShaftsEngineeringSelf sensing

Owner:NATIONAL TSING HUA UNIVERSITY

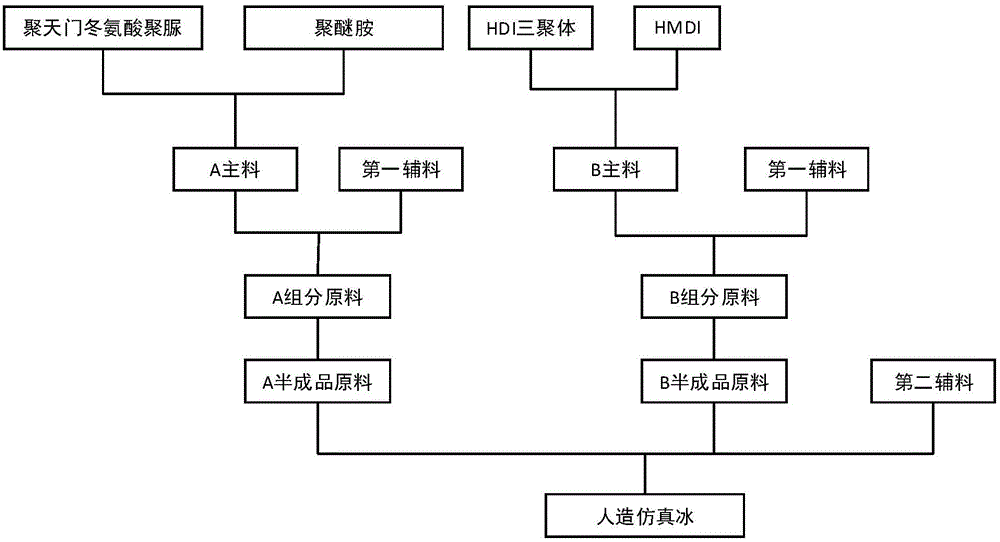

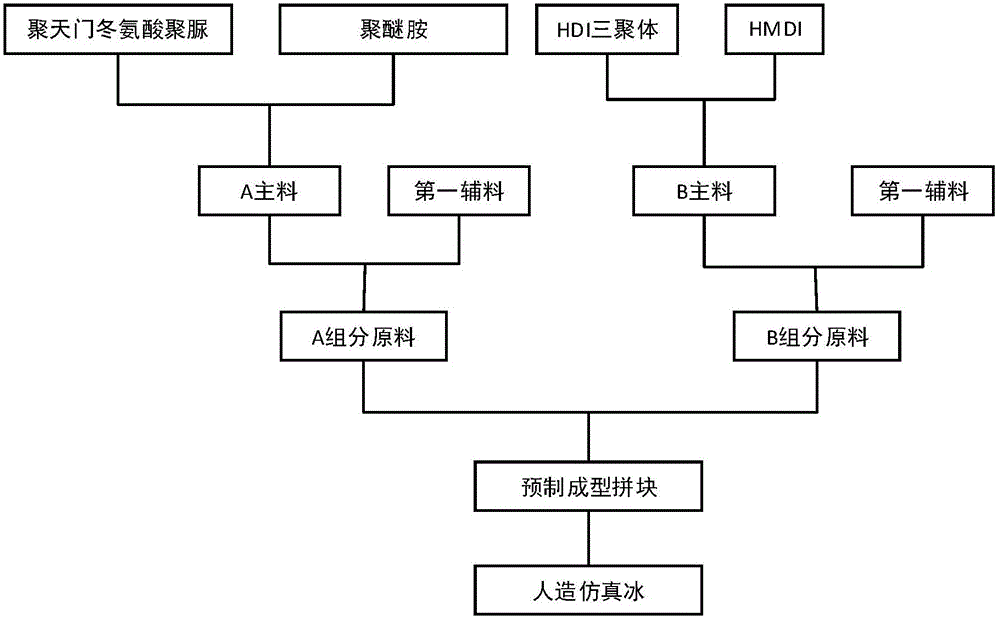

Artificial emulational ice

ActiveCN106634496AImprove bearing rigidityAll-weather sports performancePolyurea/polyurethane coatingsMetallurgyDiluent

The invention provides artificial emulational ice which comprises raw materials of a component A and raw materials of a component B, wherein the raw materials of the component A comprise a main material A, nano-grade rigid solid packing and a diluent; the main material A comprises 15 parts of polyaspartic acid ester polyurea and 3 parts of polyether amine; the raw materials of the component B comprise a main material B, the nano-grade rigid solid packing and the diluent; the main material B comprises 2 parts of HDI trimer and 0.65 part of HMDI; the ratio of the raw materials of the component A to the raw materials of the component B ranges from 1:1 to 1:10. Compared with an ice stadium in the prior art, the artificial emulational ice is excellent in ice surface loading rigidity, optimal in ice surface sliding resistance coefficient, good in all-weather sports performance, very rich in sports color and simple, convenient and rapid to construct and can meet the top international environmental-friendly standards.

Owner:牛长安

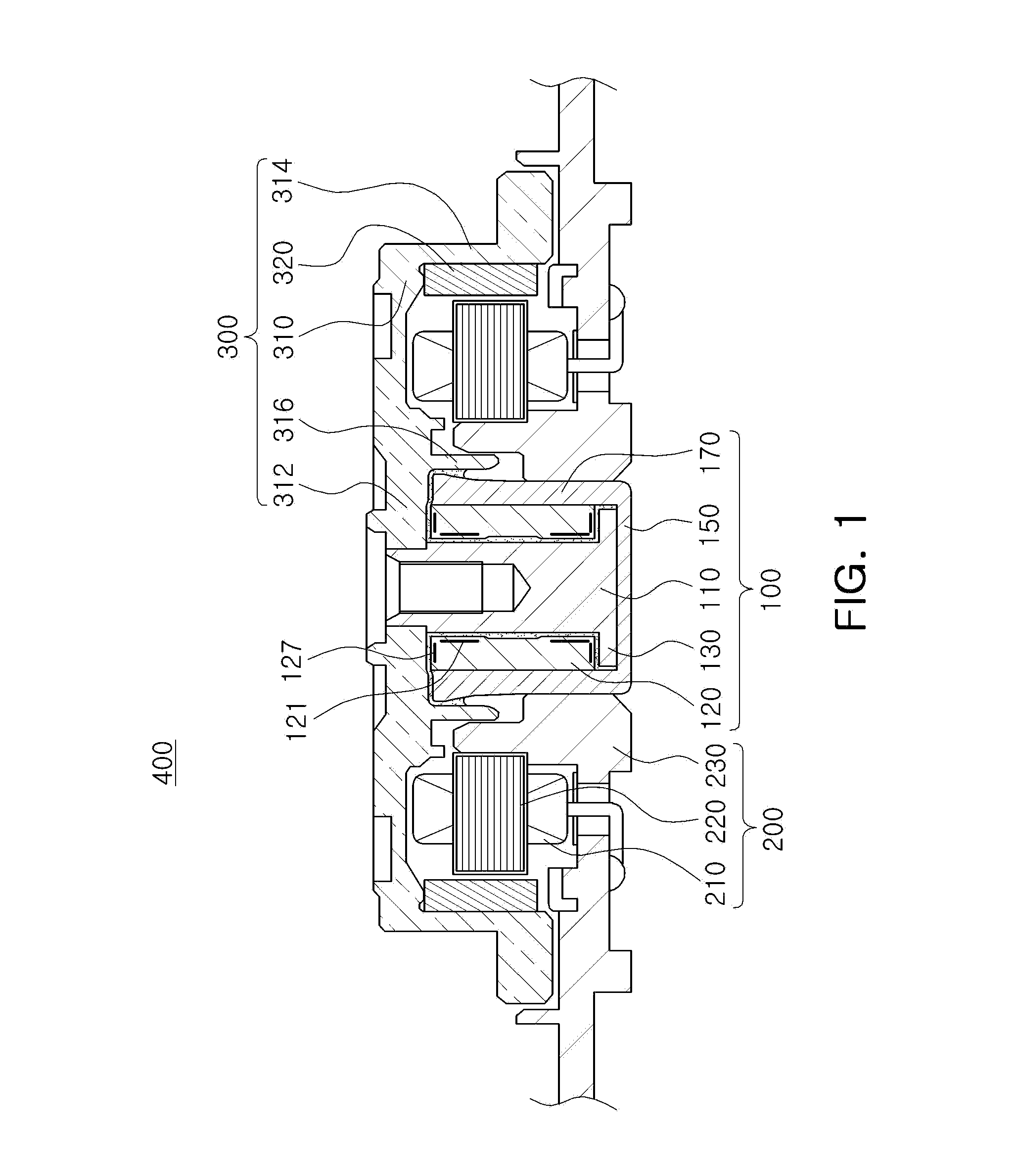

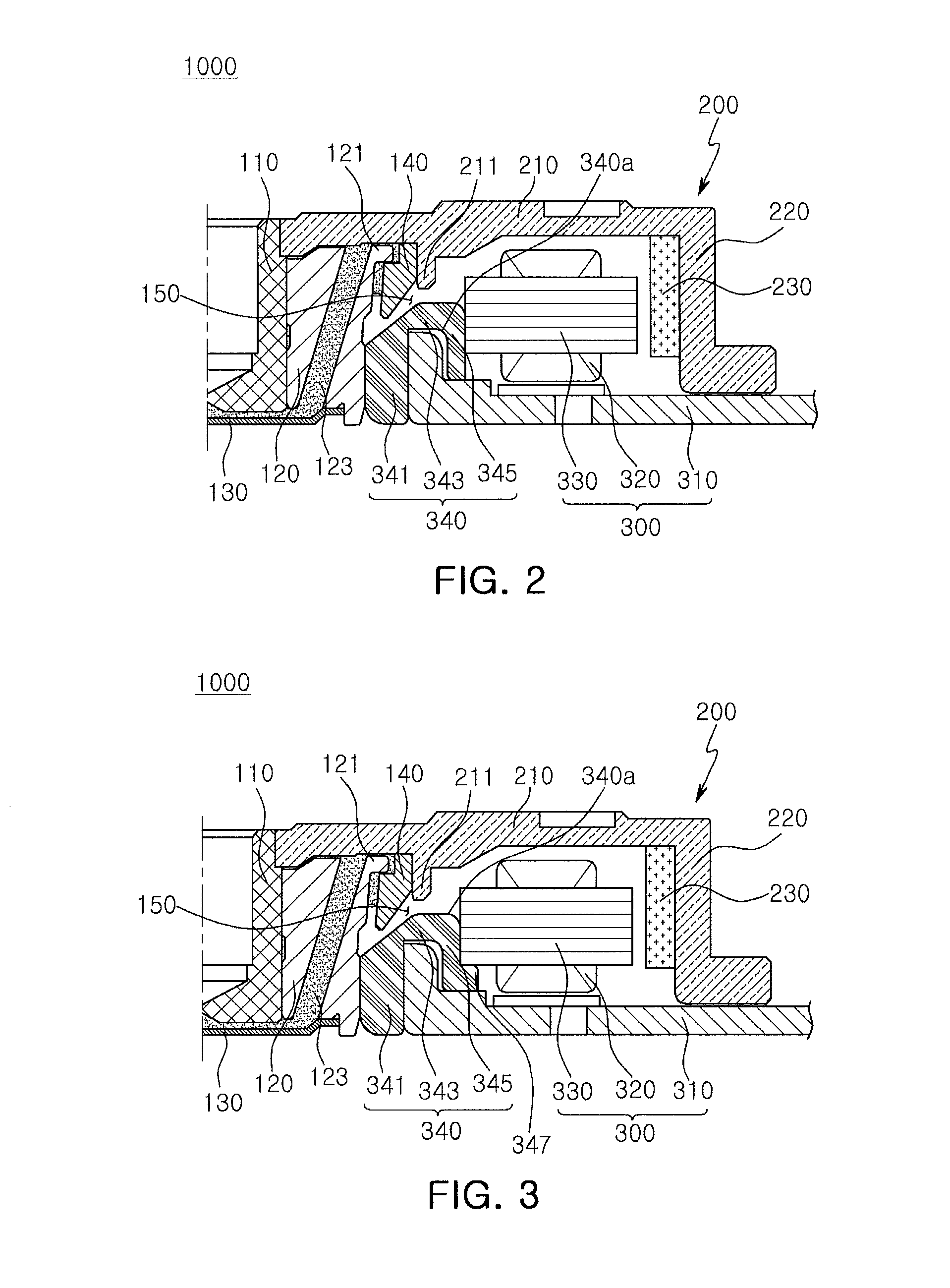

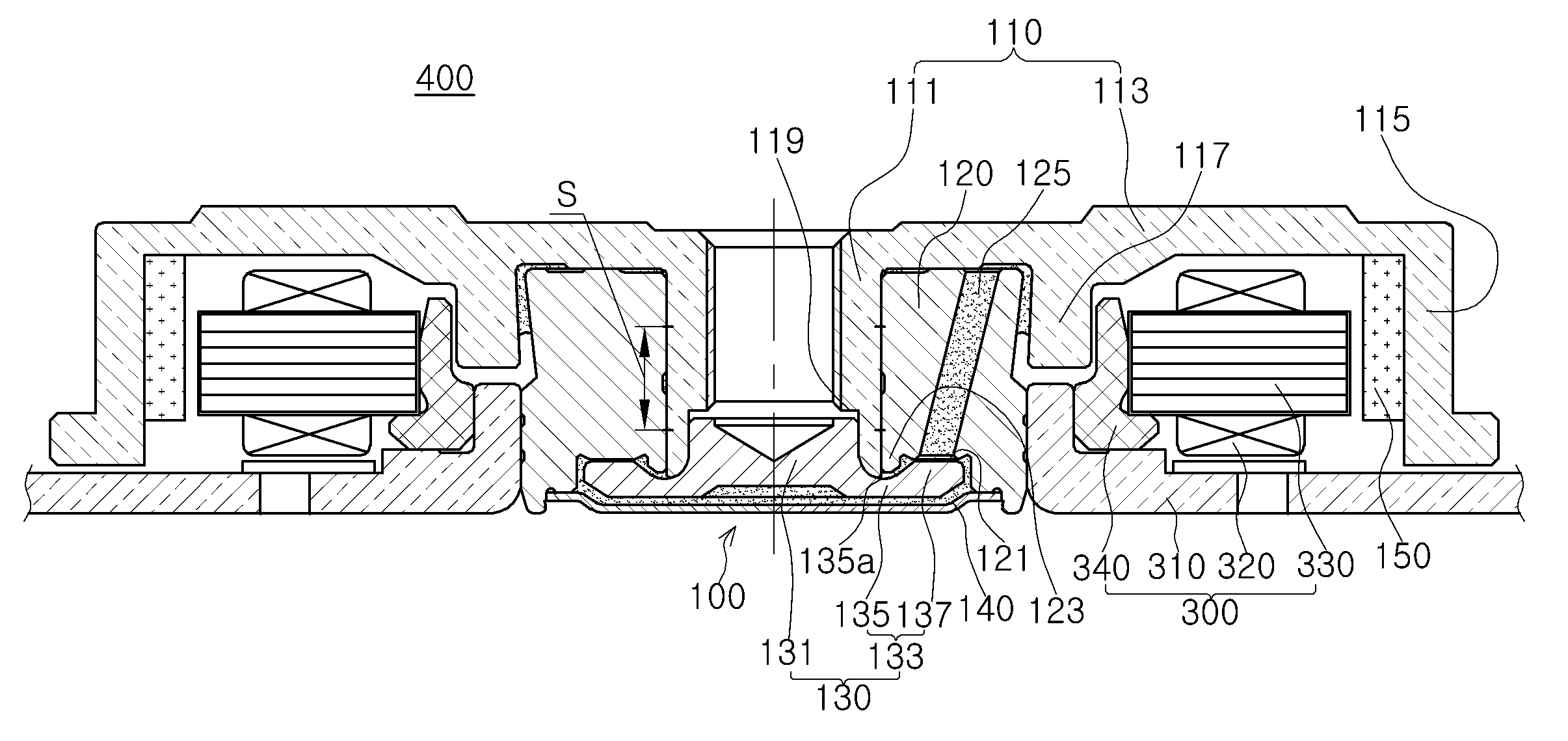

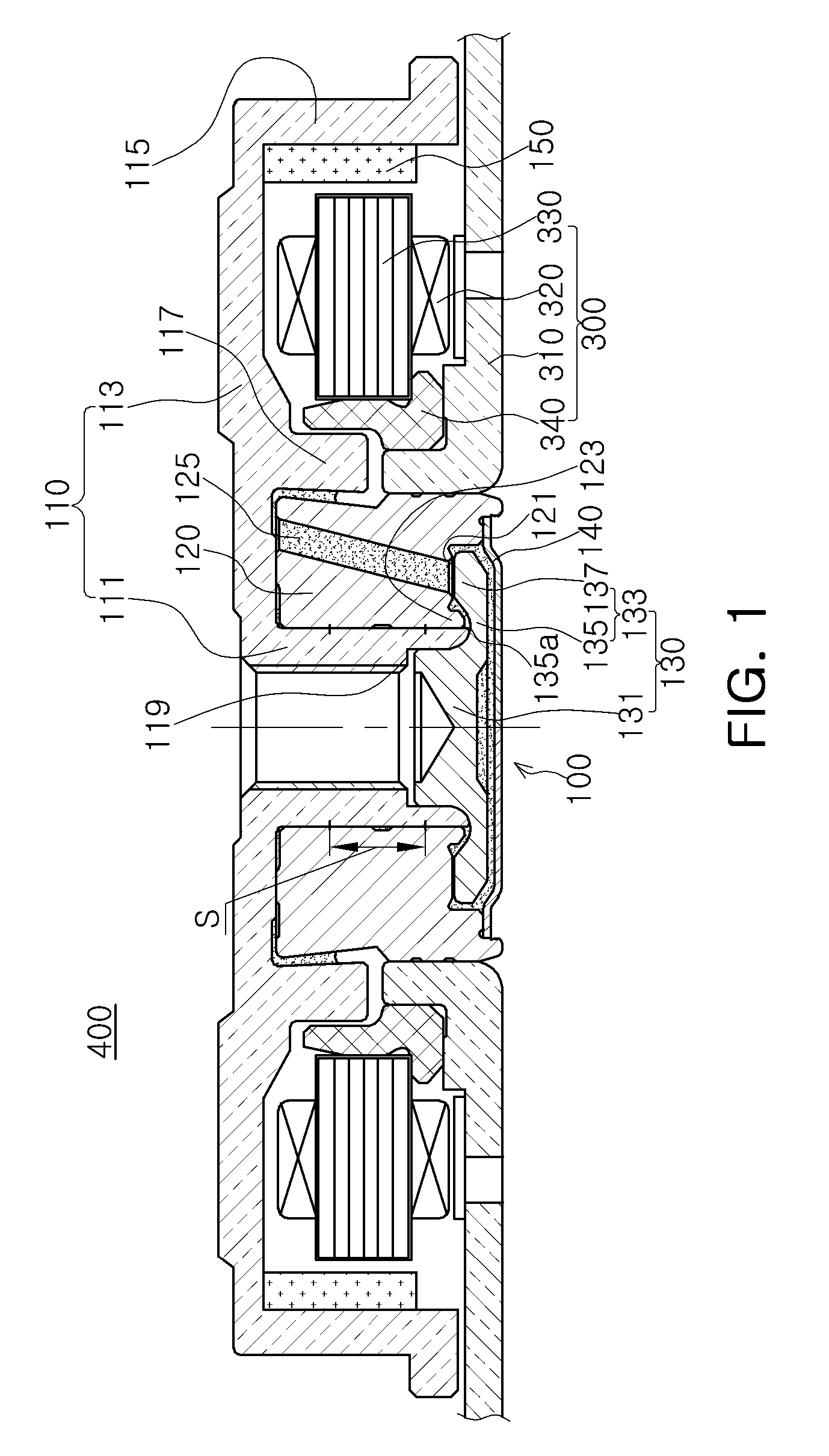

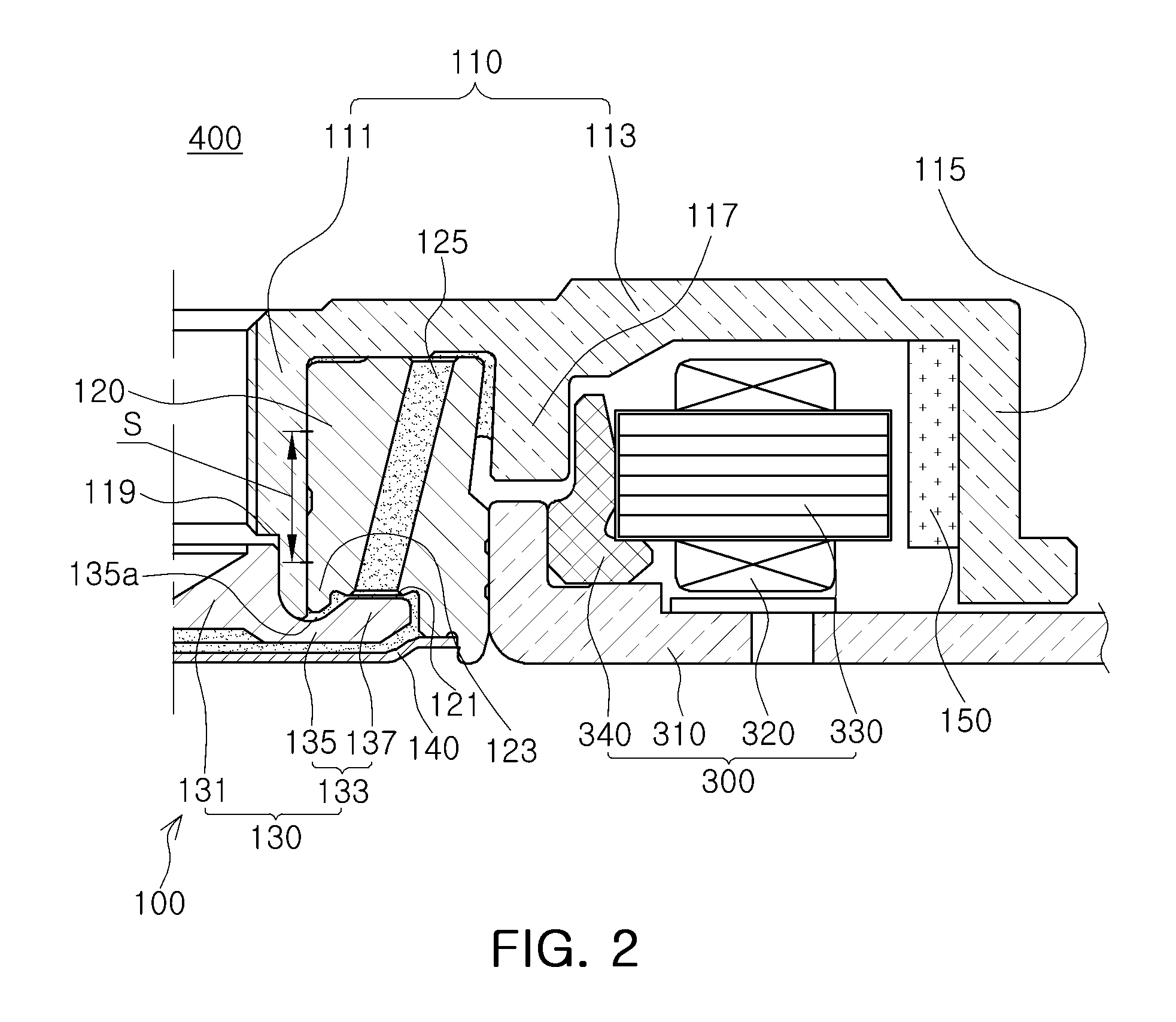

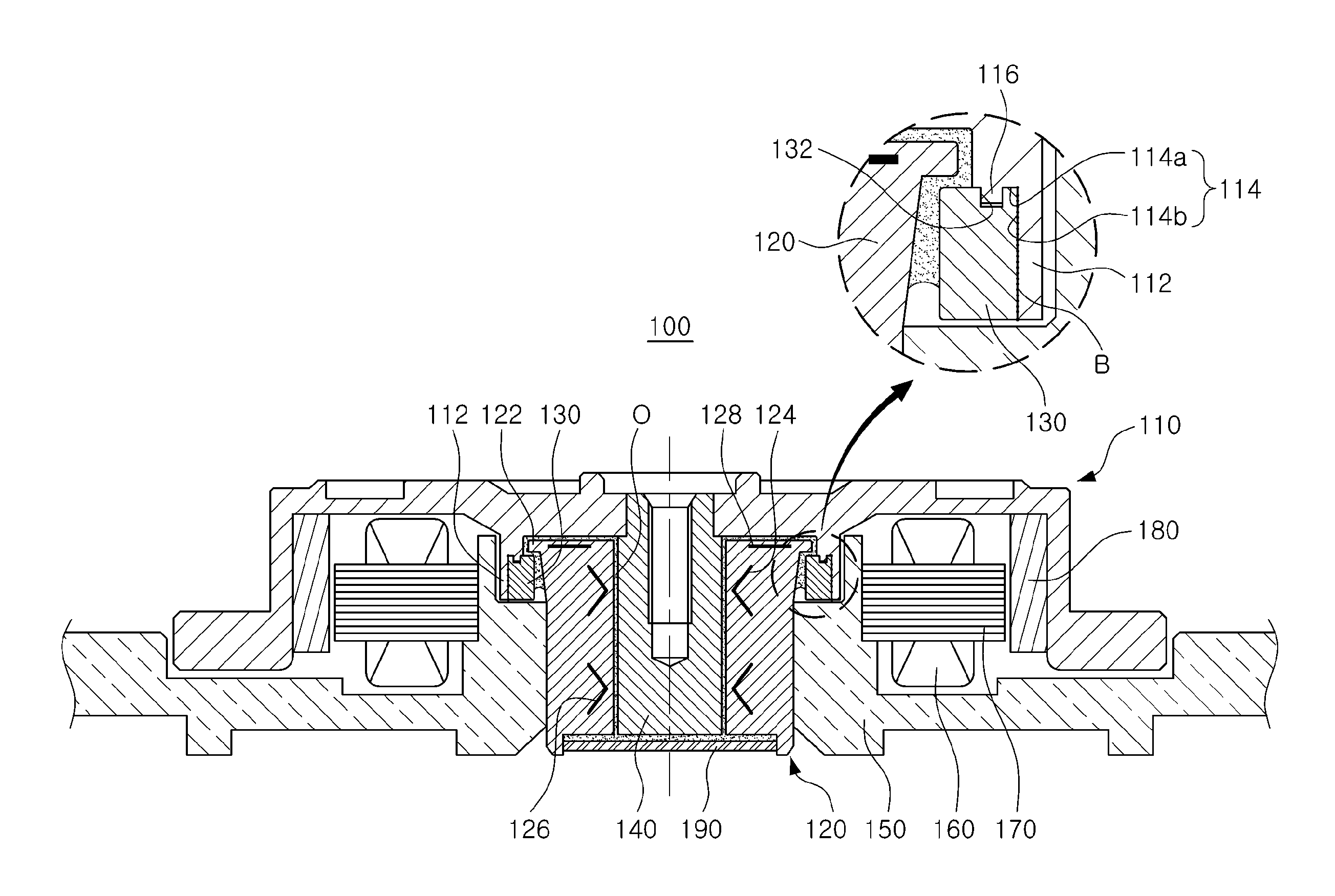

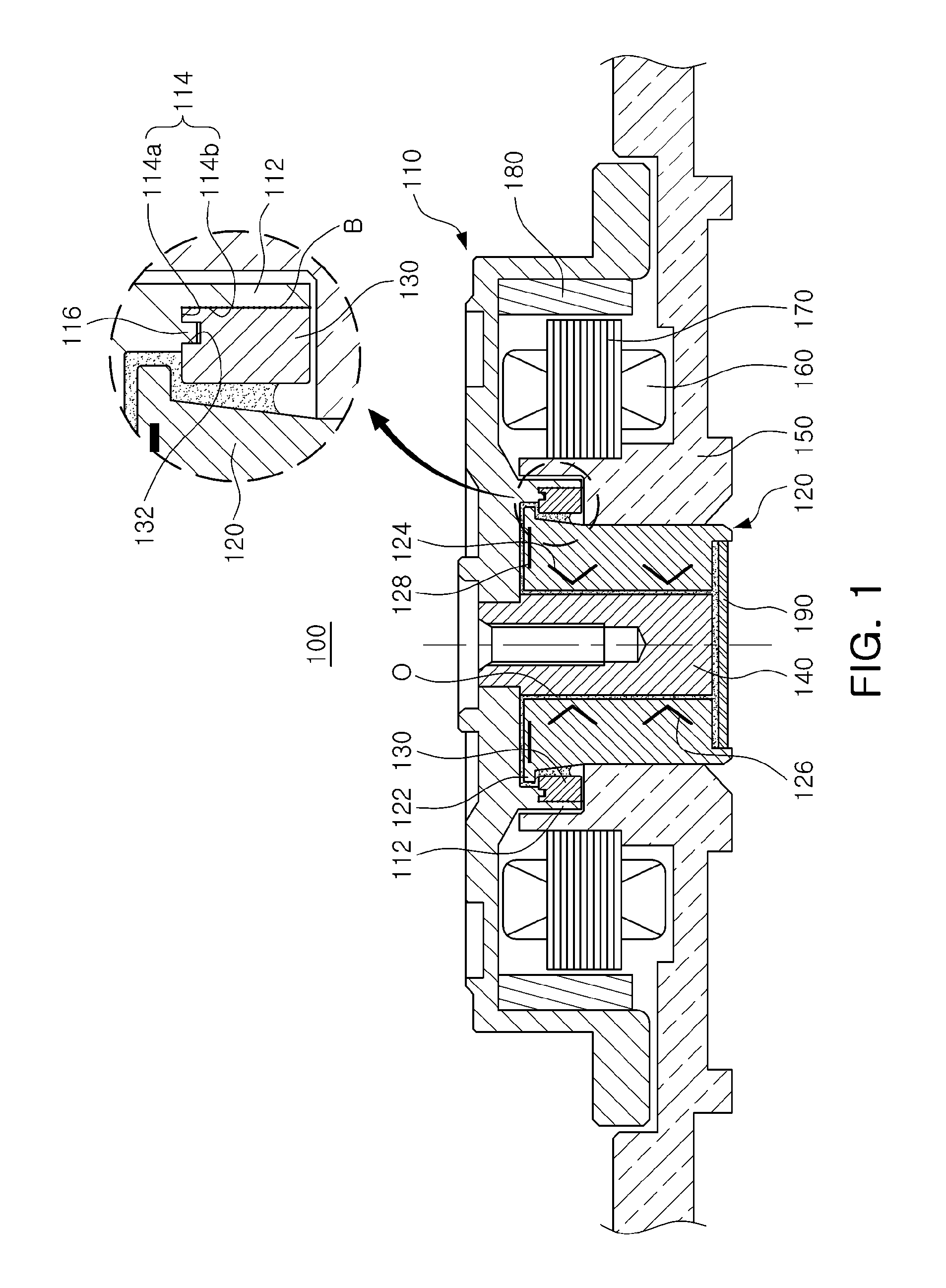

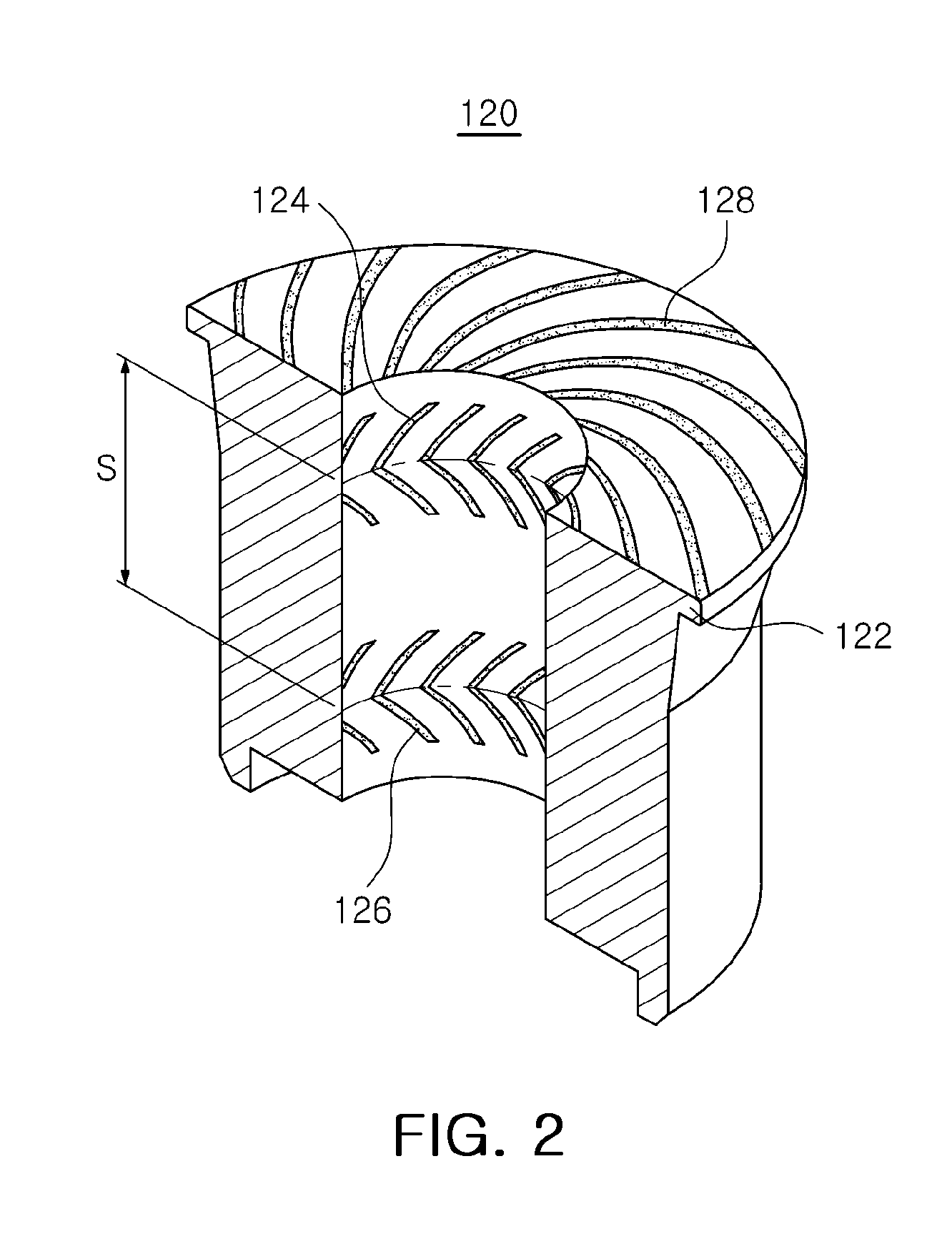

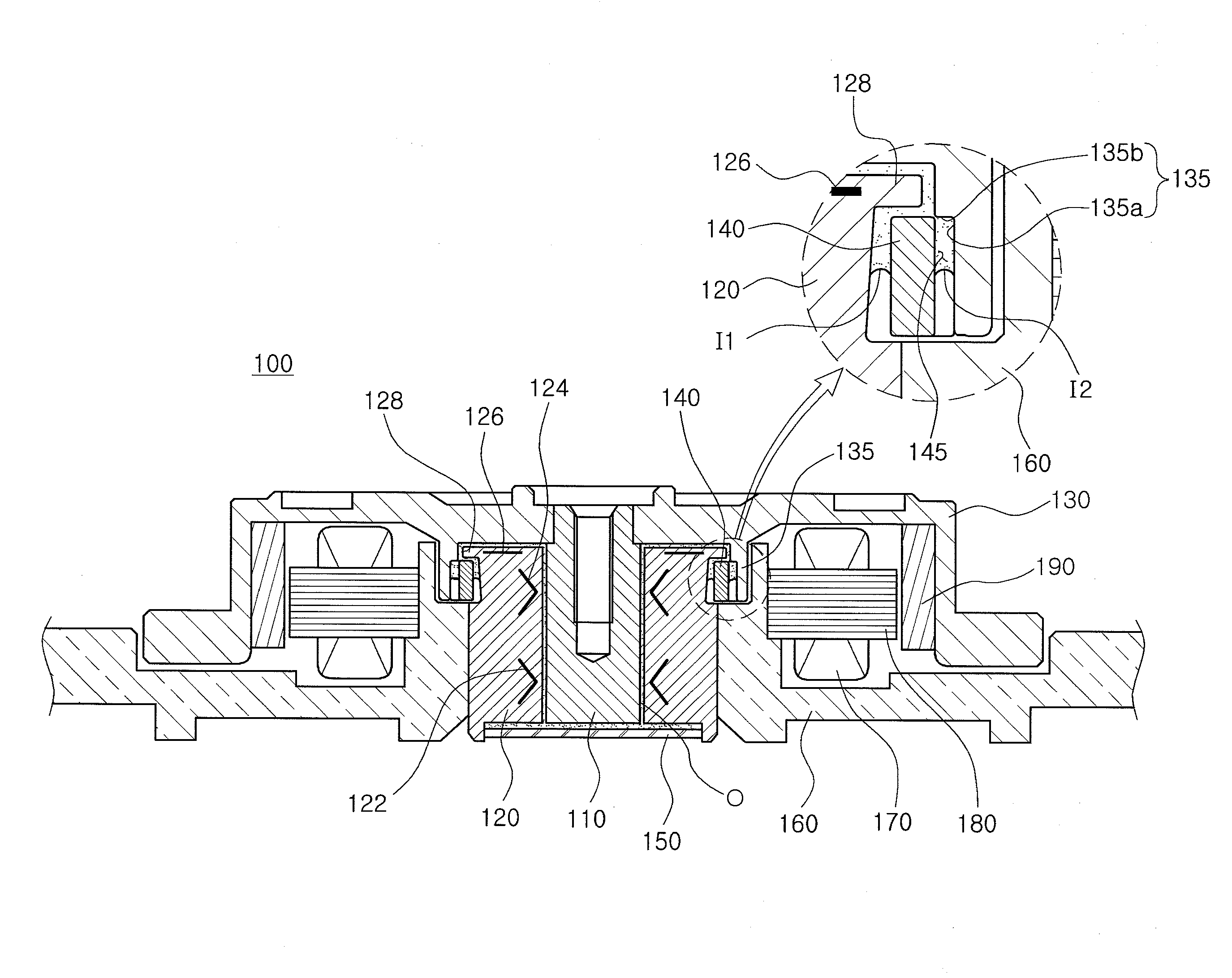

Hydrodynamic bearing assembly and spindle motor including the same

InactiveUS20130121627A1Improve bearing rigidityBearing componentsSliding contact bearingsPorosityMechanical engineering

The hydrodynamic bearing assembly includes: a sintered sleeve having a shaft hole formed therein such that a shaft is rotatably inserted thereinto and including at least one dynamic pressure bearing part to generate dynamic pressure in a lubricating fluid filled in a bearing clearance at the time of rotation of the shaft; and a housing provided to enclose an outer peripheral surface of the sintered sleeve, wherein a bottom surface of a dynamic pressure groove of the at least one dynamic pressure bearing part has a porosity higher than that of a protrusion surface thereof.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

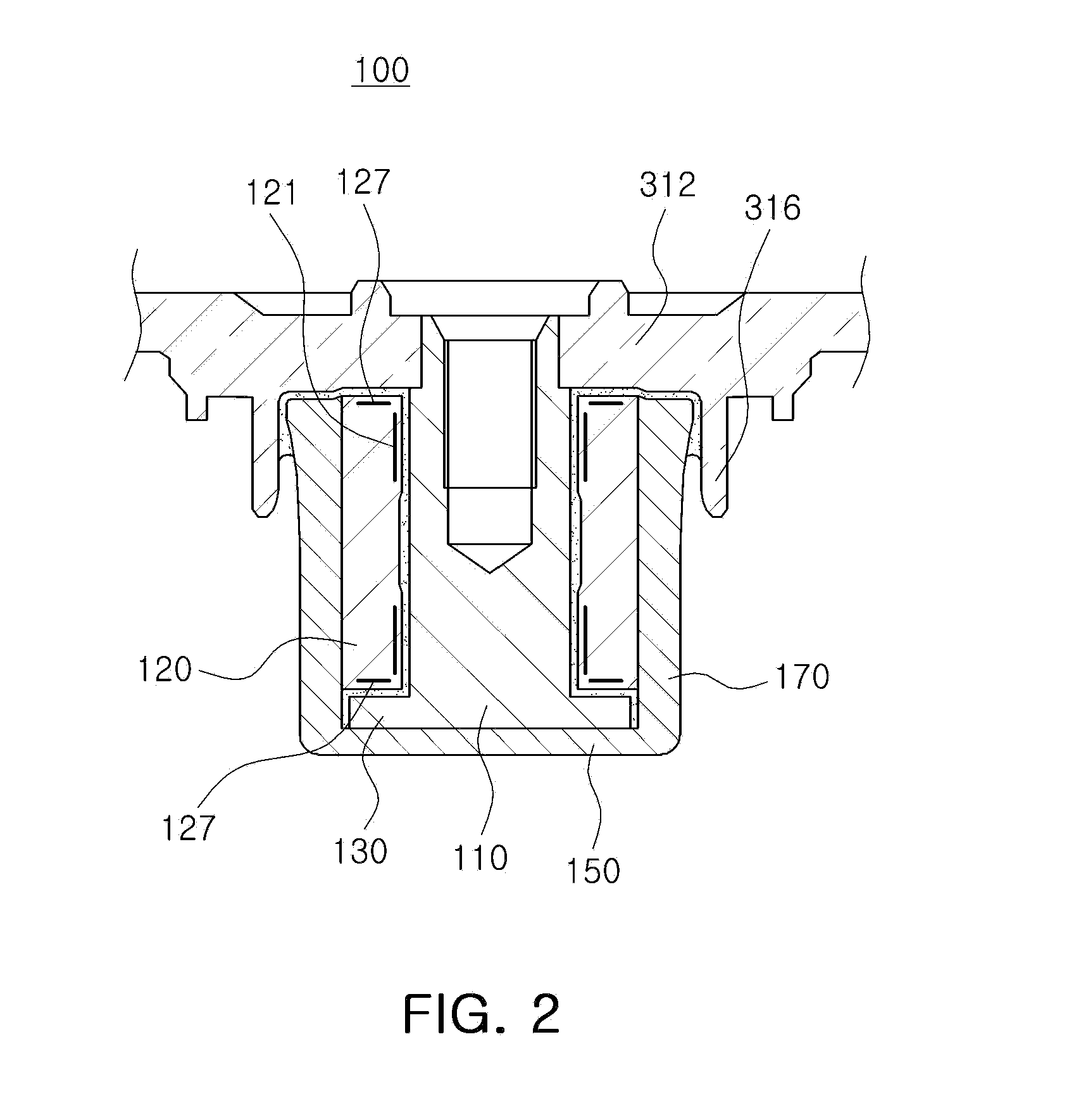

Spindle motor

InactiveUS8928196B2Improve bearing rigidityPrevent leakageMagnetic circuitRecord information storageEngineeringMechanical engineering

There is provided a spindle motor including: a sleeve rotatably supporting a shaft; a rotor coupled to an upper end of the shaft and rotating in conjunction with the shaft; a stopper portion coupled to a main wall portion protruded from one surface of the rotor and facing an outer circumferential surface of the sleeve; a stator holder having a fixed portion coupled to an outer circumferential surface of the sleeve, an installation portion to which a core having a coil wound therearound is fixed, and a connection portion connecting an upper end of the fixed portion and an upper end of the installation portion; and a base member fixedly coupled to the stator holder.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

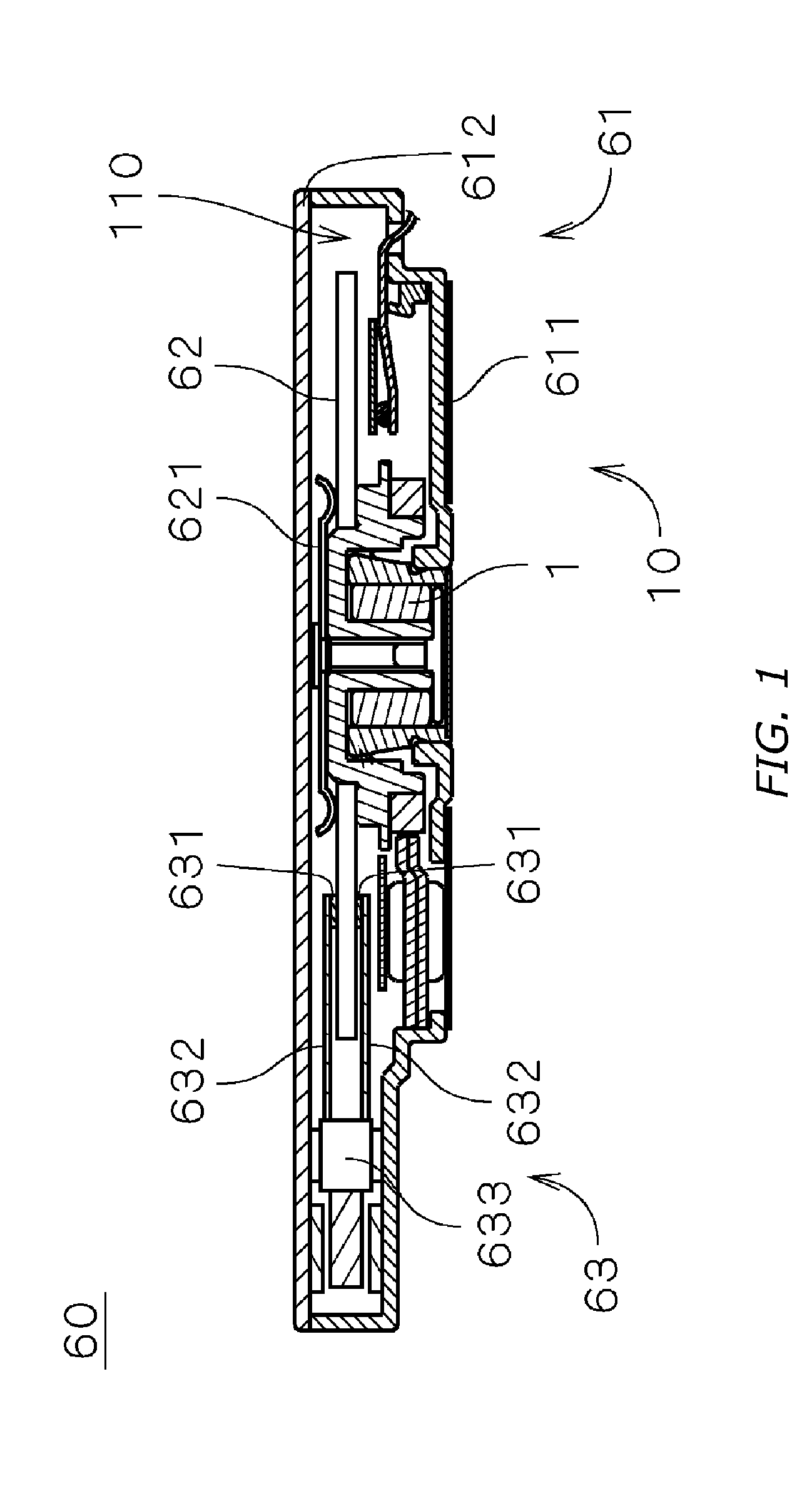

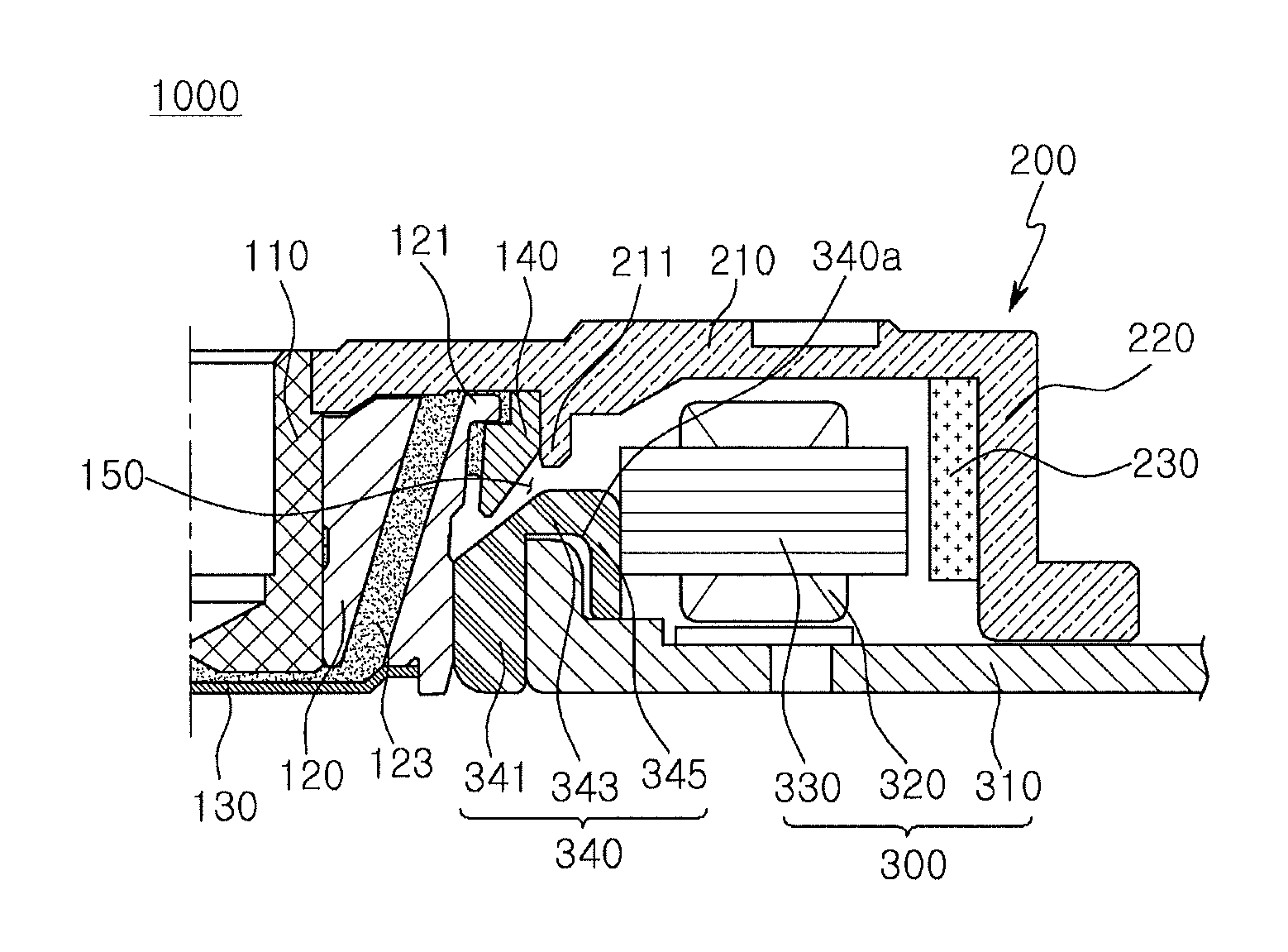

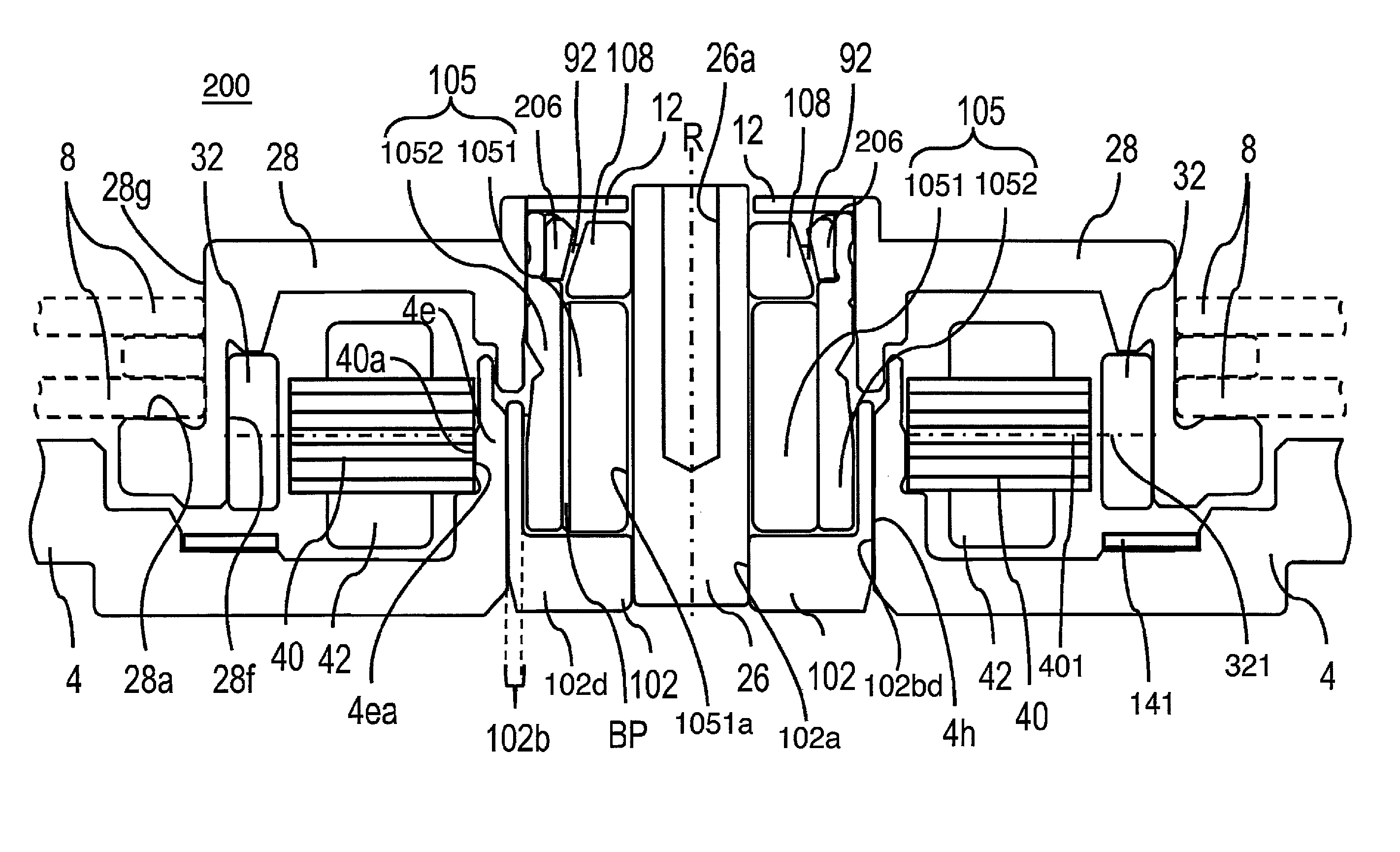

Rotating device and component for fluid dynamic bearing unit thereof

InactiveUS8858084B2Improve bearing rigidityLeak-out of a lubricant can be reducedGas cushion bearingsShaftsAir liquid interfaceDynamic pressure

A rotating device includes a fixed body having a base and a shaft, a hub, and a rotating body having a rotating-body-side encircling member fixed to the hub and encircling the shaft. A lubricant is present between the fixed body and the rotating body. The rotating-body-side encircling member and the shaft are each formed with a radial dynamic pressure generating groove. The fixed body includes a base-side encircling member having a disk part encircling the base-side portion of the shaft and a cylinder part encircling the rotating-body-side encircling member. The base-side encircling member has the disk part fixed to the shaft by interference fitting, and has the cylinder part fixed to the base. An air-liquid interface is located in a gap in the radial direction between the inner periphery of the cylinder part and the outer periphery of the rotating-body-side encircling member.

Owner:SAMSUNG ELECTRO MECHANICS JAPAN ADVANCED TECHNOLOGY CO LTD

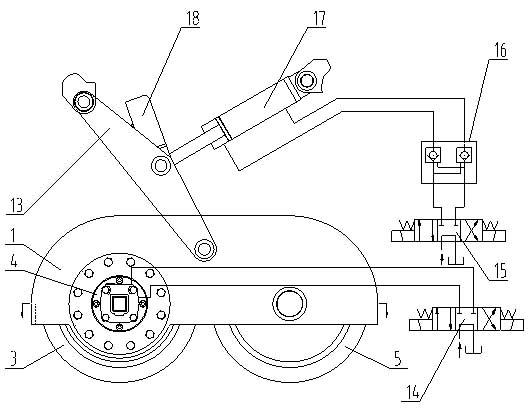

Walking driving and supporting device for bridge detection operating vehicle

ActiveCN102101437AImprove wear resistanceImprove carrying capacityBridge structural detailsControl devicesHydraulic motorDrive wheel

The invention discloses a walking driving and supporting device for a bridge detection operating vehicle. The walking driving and supporting device mainly comprises a bracket assembly, a hydraulic driving and bearing device, a driving wheel assembly and a driven wheel assembly, wherein the bracket assembly comprises a supporting bracket, a groove-shaped bracket and a groove-shaped wheel carrier; the groove-shaped wheel carrier is a groove-shaped frame with a downward notch; the hydraulic driving and bearing device mainly comprises a hydraulic motor, a supporting hydraulic oil cylinder, a bidirectional hydraulic lock, a motor control valve and an oil cylinder control valve; a driving wheel assembly is arranged on a left side inside the groove-shaped wheel carrier and mainly comprises a driving wheel hub, a driving wheel sleeve, a short shaft, an end cover and a planetary gear reducer; and the driven wheel assembly is arranged on a right side inside the groove-shaped wheel carrier and mainly comprises a driven wheel hub, a driven wheel shaft and a driven wheel sleeve. Supporting and stabilizing effects can be achieved, and driving force can be supplied to a movable machine needed byoperation. The walking driving and supporting device has high bearing rigidity, high bearing capability, high wear resistance, a simple structure and long service life, and is safe and reliable.

Owner:XCMG XUZHOU TRUCK MOUNTED CRANE +1

Vibration motor

InactiveUS20170246664A1Increase bearing rigidityImprove bearing rigidityAssociation with control/drive circuitsMechanical vibrations separationEngineeringVibration motor

A vibration motor includes a base portion arranged to extend perpendicularly to a central axis extending in a vertical direction; a cover portion arranged above the base portion, and fixed to an outer edge portion of the base portion; a lower bearing portion fixed to the base portion; an upper bearing portion fixed to the cover portion; a shaft arranged to extend along the central axis, and having a lower end portion and an upper end portion rotatably supported by the lower bearing portion and the upper bearing portion, respectively; a rotor holder attached to the shaft; a magnet portion including a plurality of magnetic poles, and attached to the rotor holder; an eccentric weight attached to the rotor holder; a circuit board arranged above the base portion; and a coil portion attached onto the circuit board, and arranged vertically opposite to the magnet portion with a space therebetween.

Owner:SANYO SEIMITSU

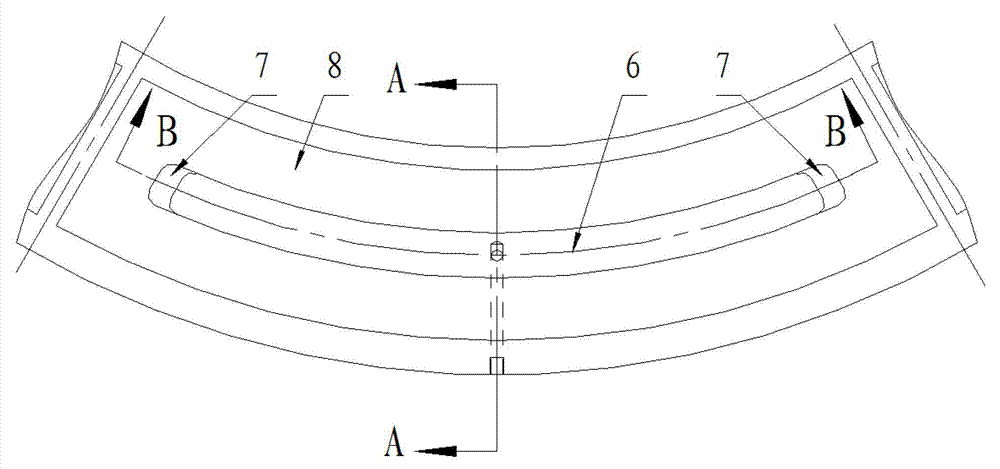

Constant-current and constant-voltage composite type floating hydrostatic guide rail and control method thereof

ActiveCN103028954AMeet high and low speed motion requirementsFunctionalLarge fixed membersLow speedEngineering

The invention relates to a constant-current and constant-voltage composite type floating hydrostatic guide rail, which comprises a main guide rail (1), a reverse preloading guide rail (2), a base (3) and a worktable surface (4), wherein the main guide rail (1) and the reverse preloading guide rail (2) form a closed type hydrostatic guide rail to realize a supporting function, the main guide rail (1) is a constant-current hydrostatic guide rail, and consists of a movable guide rail and a fixed guide rail, the main guide rail (1) on the worktable surface (4) is the movable guide rail, the main guide rail (1) on the base (3) is the fixed guide rail, and the reverse preloading guide rail (2) is the constant-current and constant-voltage composite type floating hydrostatic guide rail. The constant-current and constant-voltage composite type floating hydrostatic guide rail has the advantages that a high-speed and low-speed indexing function of a rotary table is met, and an assembly process and a control method are simple and reliable.

Owner:NANJING GONGDA CNC TECH

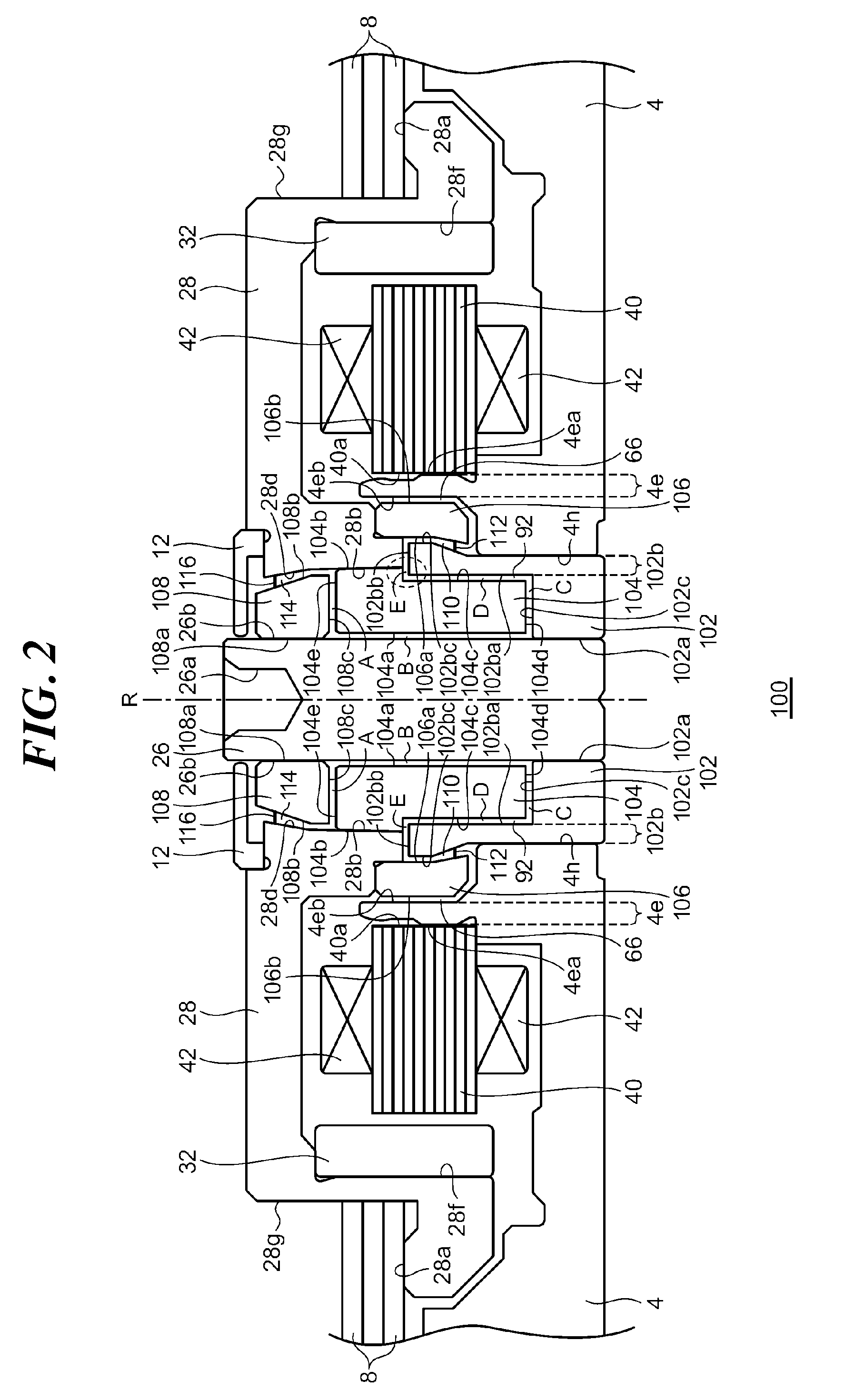

Spindle motor and hard disk drive including the same

InactiveUS8837079B1Improve rigidityStorage spaceShaftsRecord information storageHard disc driveMagnet

There is provided a spindle motor, including: a rotating member including a shaft having a fixing groove disposed in a lower portion thereof, a hub base extending from an upper end of the shaft in an outer radial direction, and a magnet support part extending from an outer edge of the hub base downwardly in an axial direction; a sleeve rotatably supporting the rotating member; and a stopper including a fixed part inserted into the fixing groove and a flange part extending from an end of the fixed part in the outer radial direction, wherein the flange part includes a groove part formed by being recessed inwardly and an extension part extending from the groove part in the outer radial direction.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Spindle motor

InactiveUS20130154418A1Improve bearing rigidityExtend the lifespanRecord information storageMechanical energy handlingEngineeringMechanical engineering

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

An Independent Suspension Mechanism for an Omnidirectional Mobile Platform

An independent suspension mechanism for an omni-directional mobile platform includes two symmetrically arranged mecanum wheels, driving devices are connected to the inner sides of the mecanum wheels,and damping mechanisms are connected to mounting brackets at the outer sides of the mecanum wheels; spring guide rods are arranged at both sides of reduction gears, the top portions of the spring guide rods are connected with a car body mounting plate, and the bottom portions of the spring guide rods are connected with the mounting brackets, and the middle of the spring guide rods are sleeved withfirst rectangular cross-section springs; and a closed structure is formed by the two mecanum wheels through the car body mounting plate, the mounting brackets, and a connecting plate. According to the independent suspension mechanism for the omni-directional mobile platform, the pressure can be adjusted according to the load and ground conditions under multiple different environmental conditions,the influence of the ground on the running process of the mecanum wheels can be reduced, and the phenomenon of suspension of a certain group of wheels due to the unevenness of the ground is avoided;and the independent suspension mechanism for the omni-directional mobile platform has the advantages of stable operation of the platform, strong ability to overcome obstacles, and high bearing capacity.

Owner:XIJING UNIV

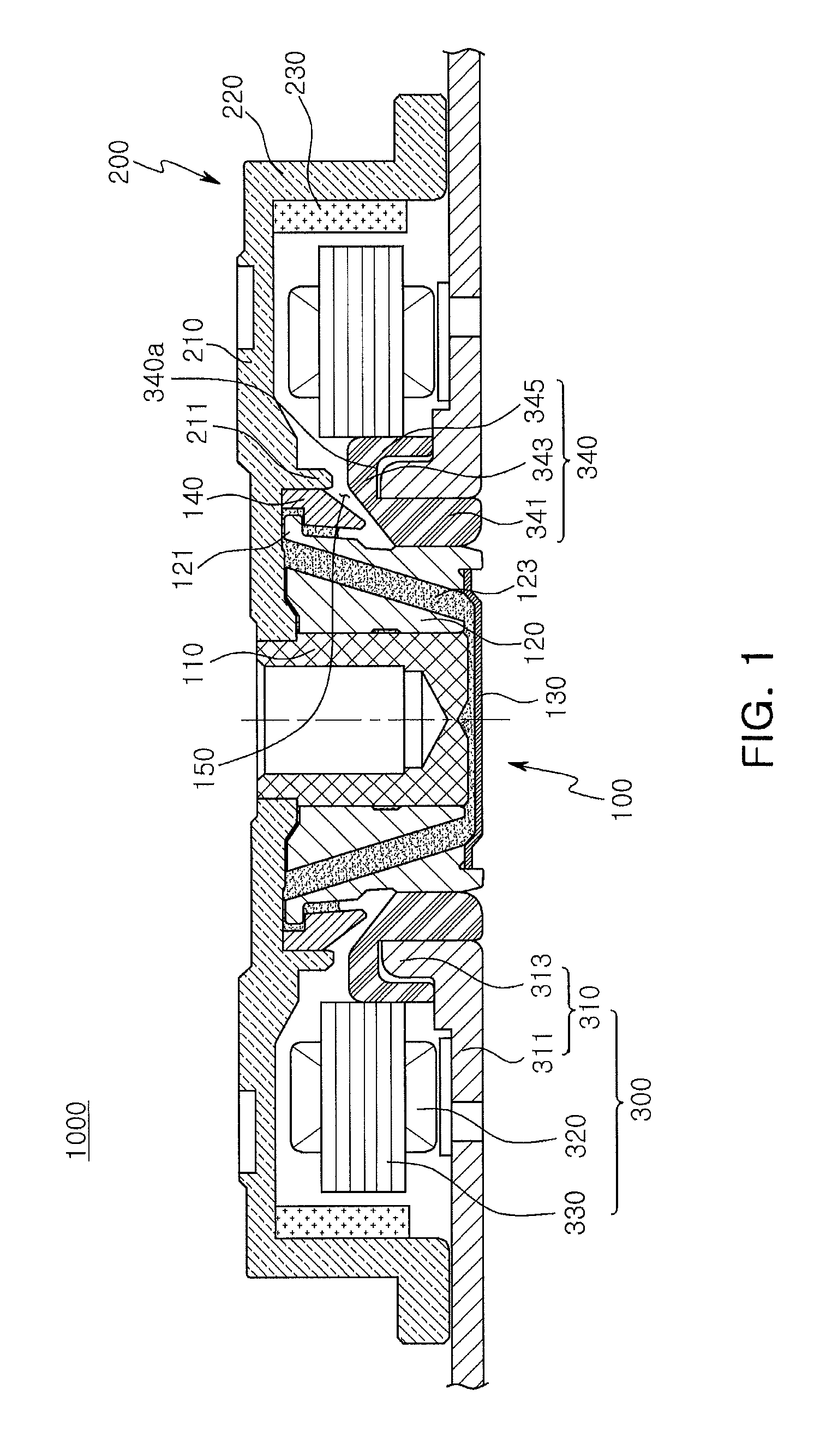

Spindle motor

InactiveUS20130058603A1Improve bearing rigidityMaximize storageShaftsRecord information storageEngineeringBung

There is provided a spindle motor including: a hub moving together with a shaft; a sleeve supporting the shaft with oil; a stopper provided in the hub to thereby prevent excessive floating of the shaft; and oil storage parts formed on the stopper so as to be in communication with the outside, providing a storage space for the oil, and allowing an oil interface to be formed therein.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

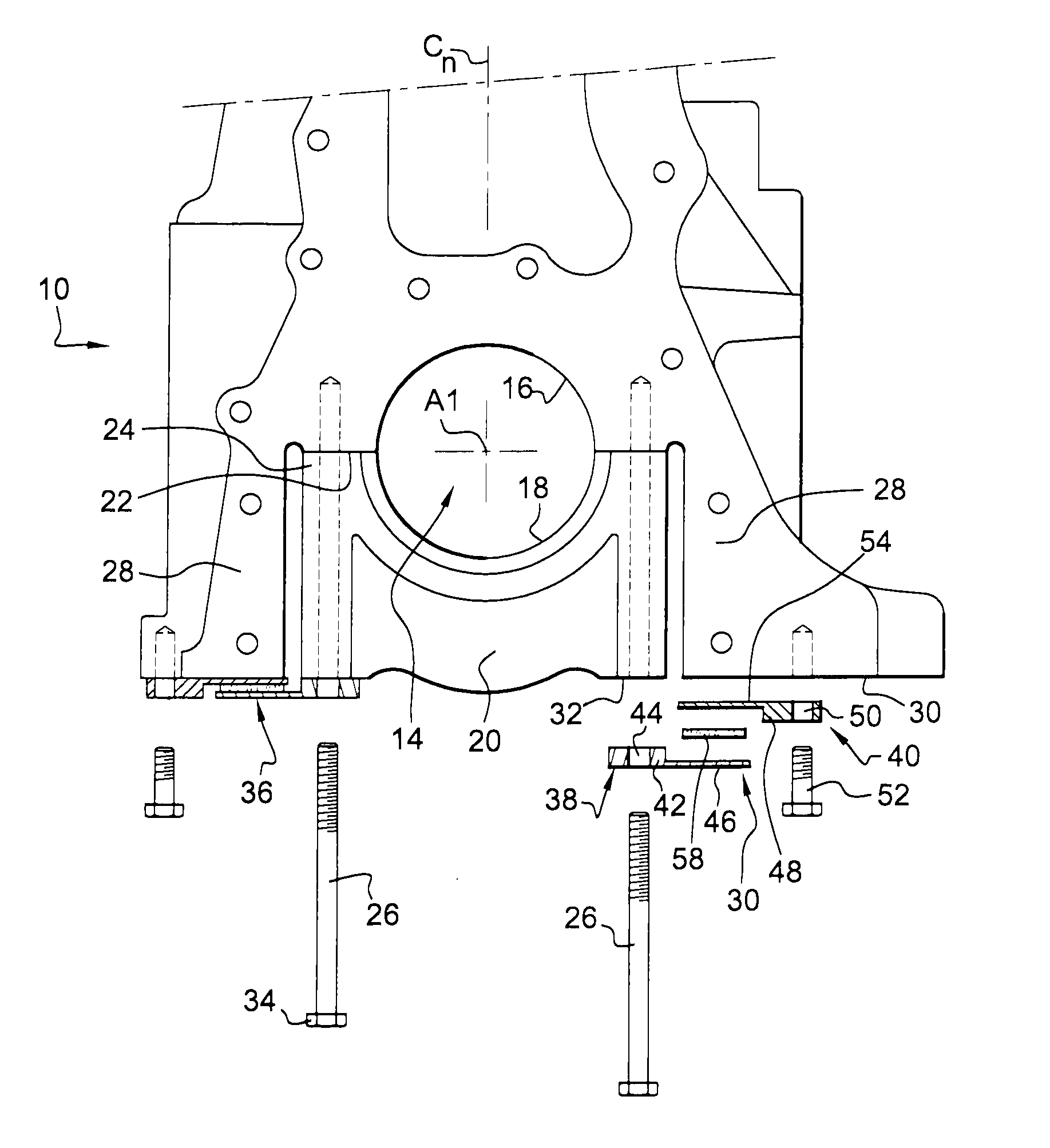

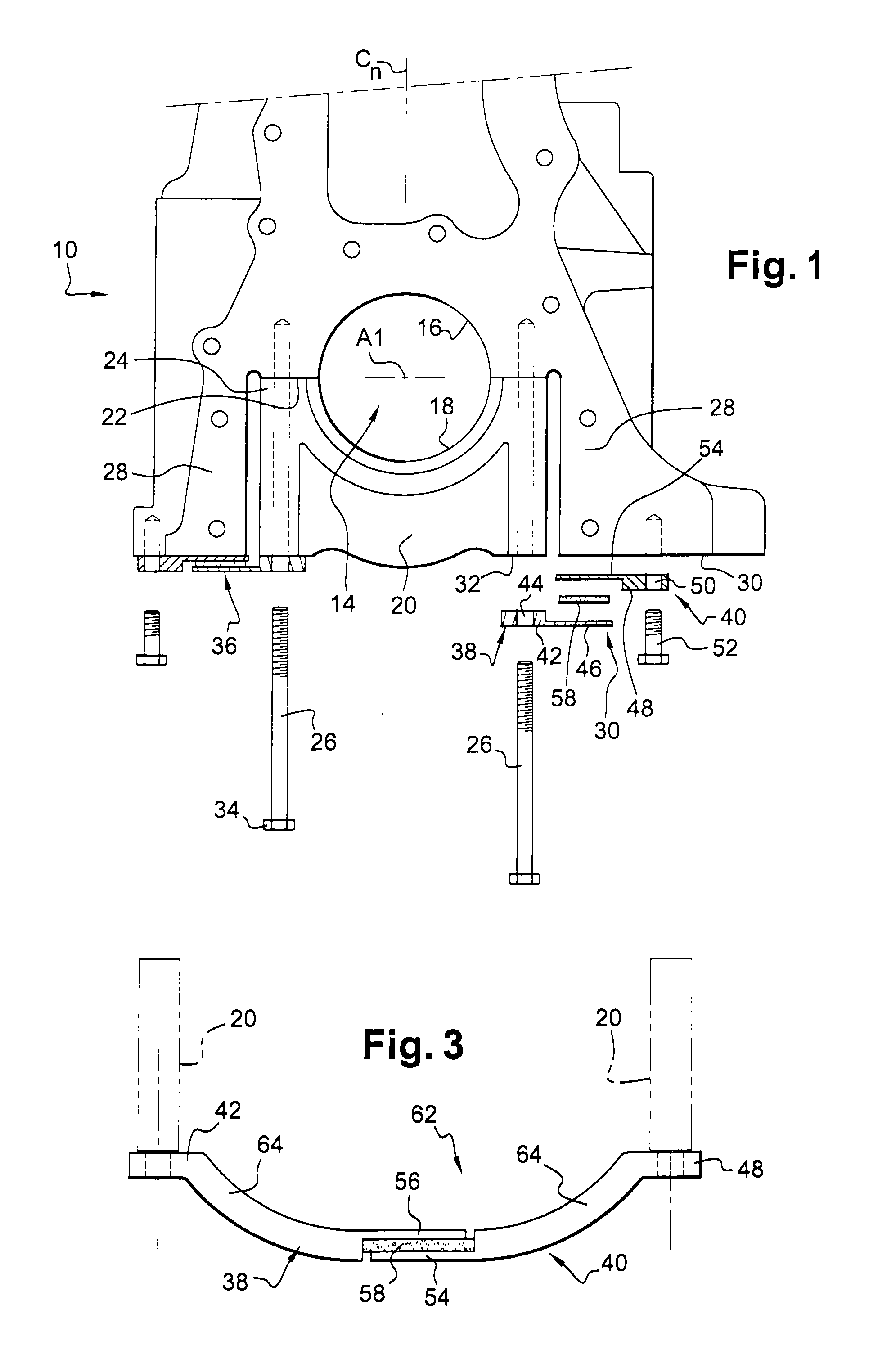

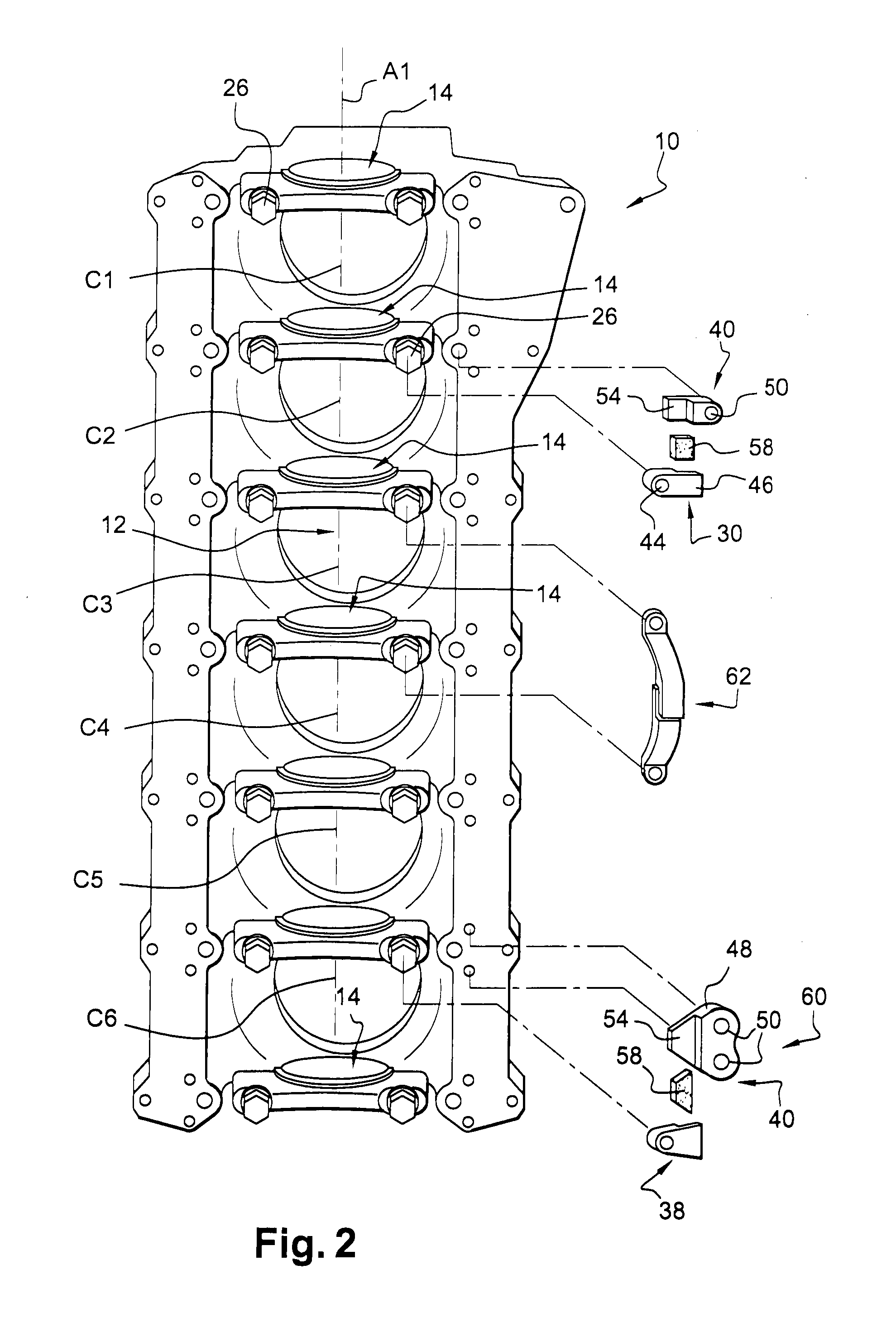

Improved internal combustion engine with bearing cap dampening

InactiveUS20100059014A1Low costReduce vibrationCasingsMachines/enginesExternal combustion engineEngineering

An internal combustion engine has an engine block including a crankshaft which is mounted on the engine block by at least a first and a second main bearings, wherein the main bearings each include a first bearing portion and a second bearing portion, the second bearing portion being part of a bearing cap, wherein at least the first bearing cap is connected to the engine block or to the second bearing cap by at least one dampening structure, the structure including a first support portion fixed on the bearing cap, a second support portion fixed on the engine block or on an adjacent bearing cap, and a dampening portion including an elastomeric material which connects the two support portions.

Owner:VOLVO LASTVAGNAR AB

High-rigidity RV speed reducer for industrial robot

InactiveCN107053247AImprove bearing rigiditySimple processGearboxesToothed gearingsDouble rowMachine tool

The invention relates to the technical field of a speed reducer for an industrial robot, in particular to a high-rigidity RV speed reducer for the industrial robot. The high-rigidity RV speed reducer comprises a left rigid disk, a right rigid disk, a pin gear housing, a pin, two cycloidal wheels, a cycloidal component and a planetary component, wherein the cycloidal component is uniformly distributed with crankshafts, and the planetary component comprises a sun wheel and a planet wheel. The high-rigidity RV speed reducer is characterized in that two shaft circlips are arranged on eccentric sections of the two sides of a crankshaft spacer, and two turning arm bearing assemblies are arranged between the circlips and the spacer; each turning arm bearing assembly comprises a ferrule, a circlip and a radial bearing; the two radial bearings are in an axial pretension structure, and the two ferrules are matched with corresponding holes of the cycloidal wheels or are melted into the holes; and the two radial bearings are deep groove ball bearings, or radial-thrust ball bearings, or single-row tapered roller bearings or single double-row taper roller bearings. The high-rigidity RV speed reducer has the beneficial effects that the turning arm bearings on the crankshafts adopt the axial pretension structure, thus the bearing rigidity is improved, and the total return difference including the return difference caused by elastic deformation of the turning arm bearings is no more than 6arc min; and the high-rigidity RV speed reducer is a domestic machine tool and adopts normal manufacturing accuracy and a simple process, and the cost is reduced by 55-70%.

Owner:SUZHOU HUAZHEN IND RV REDUCER CO LTD

Dynamic bearing device

InactiveUS7591591B2Improve bearing rigidityReduce torqueShaftsRecord information storageThrust bearingEngineering

It is an object to improve bearing rigidity in a thrust direction at high temperatures and reduce a torque at low temperatures. An axial member is arranged in such a manner that an outer circumferential surface of an axial part is opposed to an inner circumferential surface of a bearing sleeve with a radial bearing gap interposed therebetween, and both end faces of a flange part are opposed to one end face of the bearing sleeve and a bottom face of a housing with thrust bearing gaps interposed therebetween, respectively. In this manner, the axial member is supported by dynamic pressures generated in the respective bearing gaps in the thrust direction in a non-contact manner. The flange part of the axial member is formed of a resin in such a manner that its linear expansion coefficient in its axial direction is equal to or larger than that of the housing.

Owner:NTN CORP

Active compensating hydrostatic bearing and hydrostatic bearing module using the same

ActiveUS20130016927A1Improve rigidityMaintain stability and rigidityLinear bearingsShaftsEngineeringSelf sensing

Owner:NATIONAL TSING HUA UNIVERSITY

Static pressure heavy load direct drive high precision rotary table

ActiveCN103624555BOptimum working oil film thicknessImprove carrying capacityMeasurement/indication equipmentsFeeding apparatusGratingFrictional coefficient

A static pressure heavy-load direct-drive high-accuracy rotating table comprises a rotating platform composed of a base (1), a pressing board (2), a main guide rail static pressure oil cavity (3), a static pressure core shaft oil cavity (4), a work table top (5), a static pressure oil return system (6), a torque motor stator (7), a stator fixing support (8), a reading head (9), a steel belt type optical grating installation support (10), a rotor installation support (11), a torque motor rotor (12), an oil collection pot (13), a water cooling system (14), a gear distributor (15), a multi-head pump (16), a main guide rail oil cavity (17), a pressing board oil cavity (18), a core shaft pump station system (19), a guide rail pump station system (20), an oil supply system and an oil return system. The static pressure heavy-load direct-drive high-accuracy rotating table is directly driven by the large-torque motor rotor, achieves zero transmission, and is compact in structure and reliable in work; a very low frictional coefficient characteristic of a hydrostatic guide rail is combined, and the rotating table is high in servo rigidity, high in dynamic response speed and small in static difference.

Owner:NANJING GONGDA CNC TECH

Spindle motor

InactiveUS20140184000A1Improve bearing rigidityPrevent leakageMagnetic circuitRecord information storageEngineeringMechanical engineering

There is provided a spindle motor including: a sleeve rotatably supporting a shaft; a rotor coupled to an upper end of the shaft and rotating in conjunction with the shaft; a stopper portion coupled to a main wall portion protruded from one surface of the rotor and facing an outer circumferential surface of the sleeve; a stator holder having a fixed portion coupled to an outer circumferential surface of the sleeve, an installation portion to which a core having a coil wound therearound is fixed, and a connection portion connecting an upper end of the fixed portion and an upper end of the installation portion; and a base member fixedly coupled to the stator holder.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com