Artificial emulational ice

An artificial and simulated technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor hardness of polyethylene plastics, complicated manufacturing process, and poor experience, and achieve excellent load-bearing rigidity, simple and convenient construction, and ice surface The best effect of slip coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

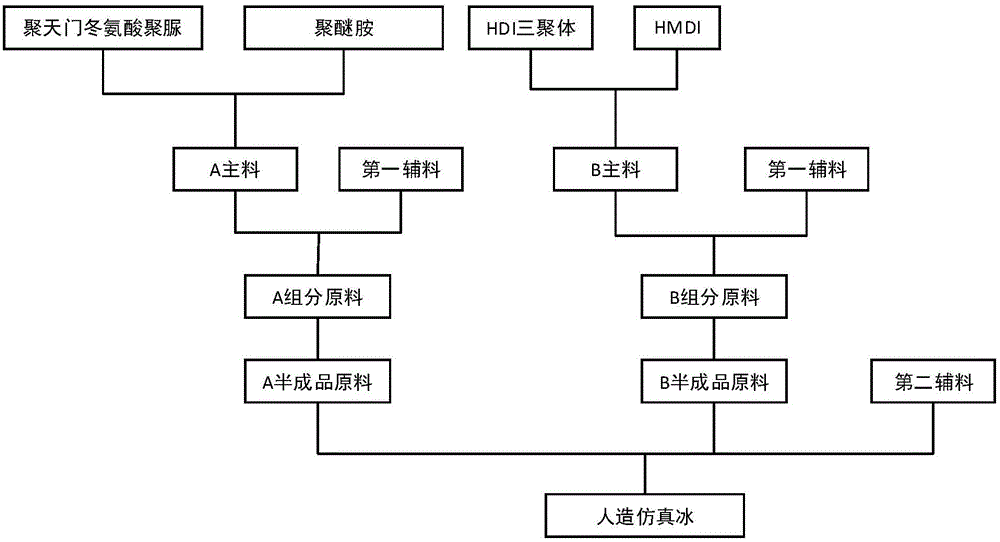

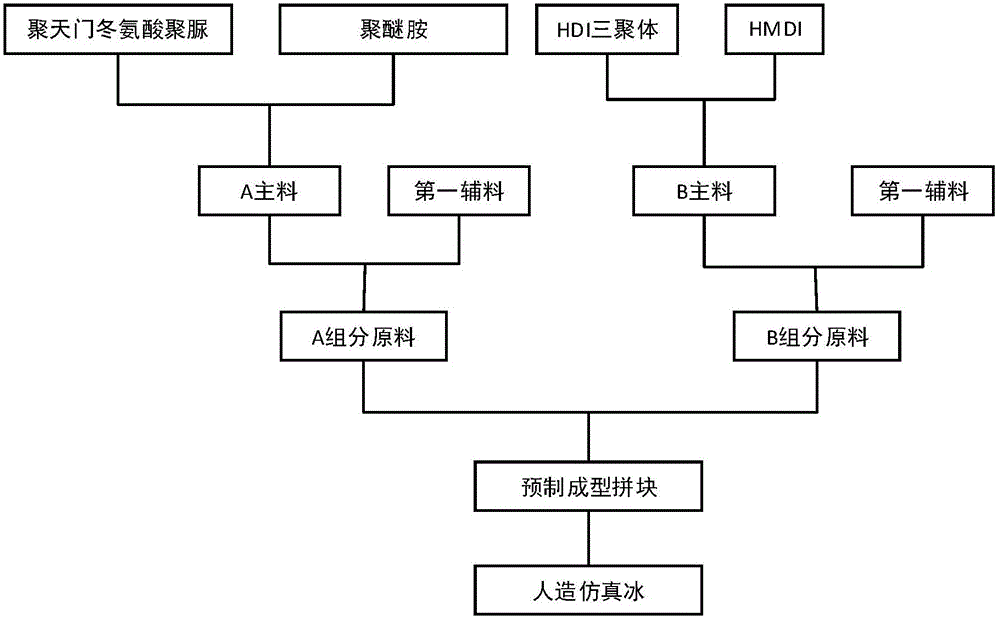

Method used

Image

Examples

Embodiment 1

[0046] Provide A main material, A main material includes: polyaspartate polyurea 15 parts, polyether amine 3 parts.

[0047] Provide B main material, B main material includes: HDI trimer 2 parts, HMDI 0.65 parts.

[0048] The main material A and the main material B pass through the reactor respectively, and the two raw materials are heated until the two materials fully react, and the heating temperature is 120 ° C.

[0049] Cool down to normal temperature after the A main material and the B main material are reacted;

[0050] Add the first auxiliary material to the main material A and the main material B to obtain the raw materials of component A and component B at a ratio of 1:1; the first auxiliary material includes nano-scale rigid solid fillers, environmentally friendly diluents, pigments and other auxiliary materials materials; wherein, the nanoscale rigid solid filler is corundum, white corundum and / or quartz sand powder; the environmentally friendly diluent can be sele...

Embodiment 2

[0054] Provide A main material, A main material includes: polyaspartate polyurea 15 parts, polyether amine 3 parts.

[0055] Provide B main material, B main material includes: HDI trimer 2 parts, HMDI 0.65 parts.

[0056] The main material A and the main material B pass through the reaction kettle respectively, and the two raw materials are heated until the two materials fully react, and the heating temperature is 140°C.

[0057] Cool down to normal temperature after the A main material and the B main material are reacted;

[0058] Add the first auxiliary material to the main material A and the main material B to obtain the A component raw material and the B component raw material with a ratio of 1:5; the first auxiliary material includes nano-scale rigid solid fillers, environmentally friendly diluents, pigments and other auxiliary materials materials; wherein, the nanoscale rigid solid filler is corundum, white corundum and / or quartz sand powder; the environmentally friendl...

Embodiment 3

[0062] Provide A main material, A main material includes: polyaspartate polyurea 15 parts, polyether amine 3 parts.

[0063] Provide B main material, B main material includes: HDI trimer 2 parts, HMDI 0.65 parts.

[0064] The main material A and the main material B pass through the reactor respectively, and the two raw materials are heated until the two materials fully react, and the heating temperature is 160°C.

[0065] Cool down to normal temperature after the A main material and the B main material are reacted;

[0066] Add the first auxiliary material to the A and B component raw materials to obtain the A component raw material and the B component raw material with a ratio of 1:7; the first auxiliary material includes nano-scale rigid solid fillers, environmentally friendly diluents, pigments and other auxiliary materials ; Wherein, the nanoscale rigid solid filler is corundum, white corundum and / or quartz sand powder; the environmentally friendly diluent can be selected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com