High-rigidity RV speed reducer for industrial robot

An industrial robot, high-rigidity technology, used in manipulators, manufacturing tools, mechanical equipment, etc., to achieve the effects of low cost, improved bearing rigidity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

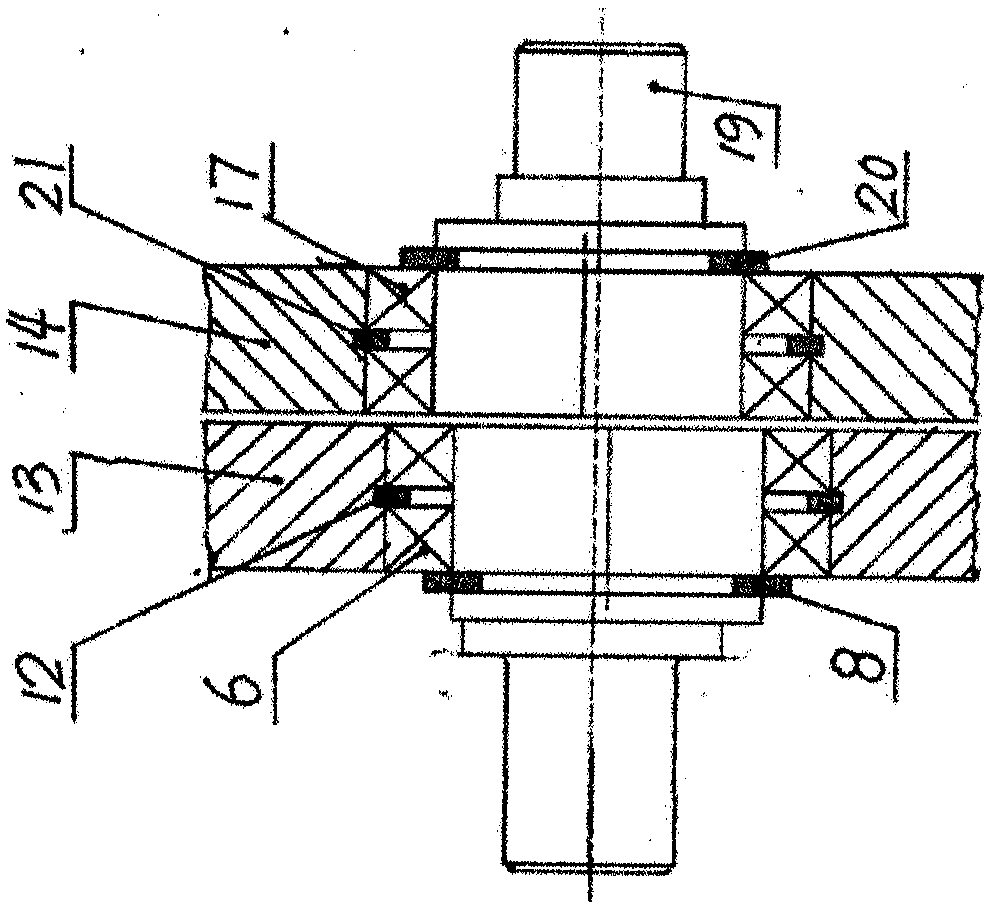

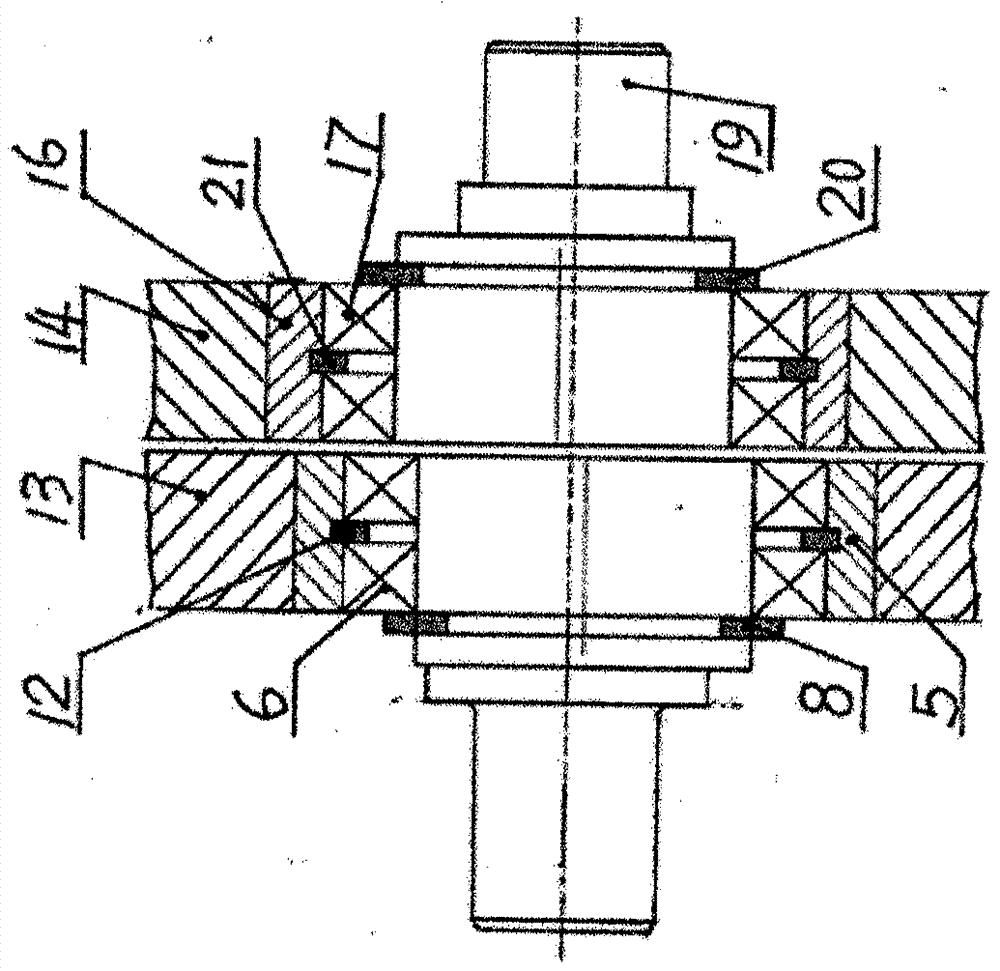

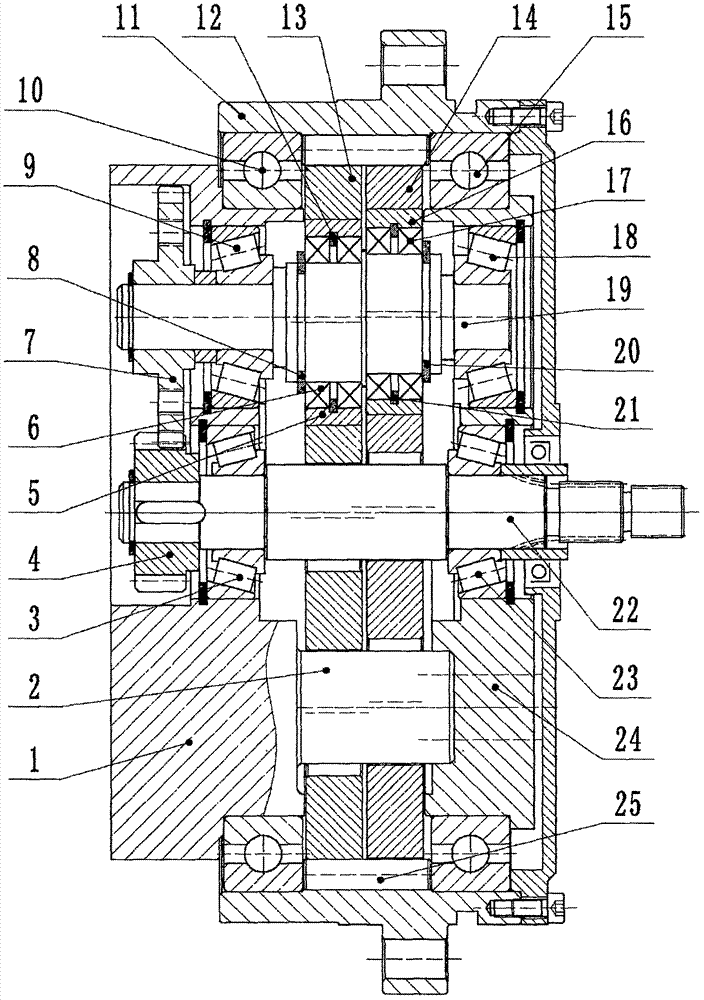

[0042] Such as Figure 1~3 As shown, a high-rigidity RV reducer for an industrial robot includes a cycloid and a planetary component, and the cycloid component includes left and right rigid discs 1, 24, pin gear housing 11, pins in the half-buried hole of the pin gear housing 25. The first and second cycloidal wheels 13, 14 and the uniformly distributed crankshaft 19, the uniformly distributed flange 2 on the end surface of the left rigid disc 1 passes through the corresponding The hole is connected with the right rigid disk 24 to form a rigid body. The left and right rigid disks 1, 24 are respectively supported by the first and second bearings 10, 15 in the inner holes on both sides of the pin gear housing 11. The planetary components include the sun gear 4 and the planetary gear 7, the sun gear 4 is arranged on the input shaft 22, and the input shaft 22 is supported in the center holes of the left and right rigid discs 1, 24 with the third and fourth bearings 3, 23 respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com