Compound type rotary supporting device for machine tool round workbench

A technology of rotating support and workbench, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc. It can solve the problems of high manufacturing cost, low motion precision, and less rigidity than rolling bearings, and achieves low manufacturing and use costs. The effect of simple and compact, large load-bearing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

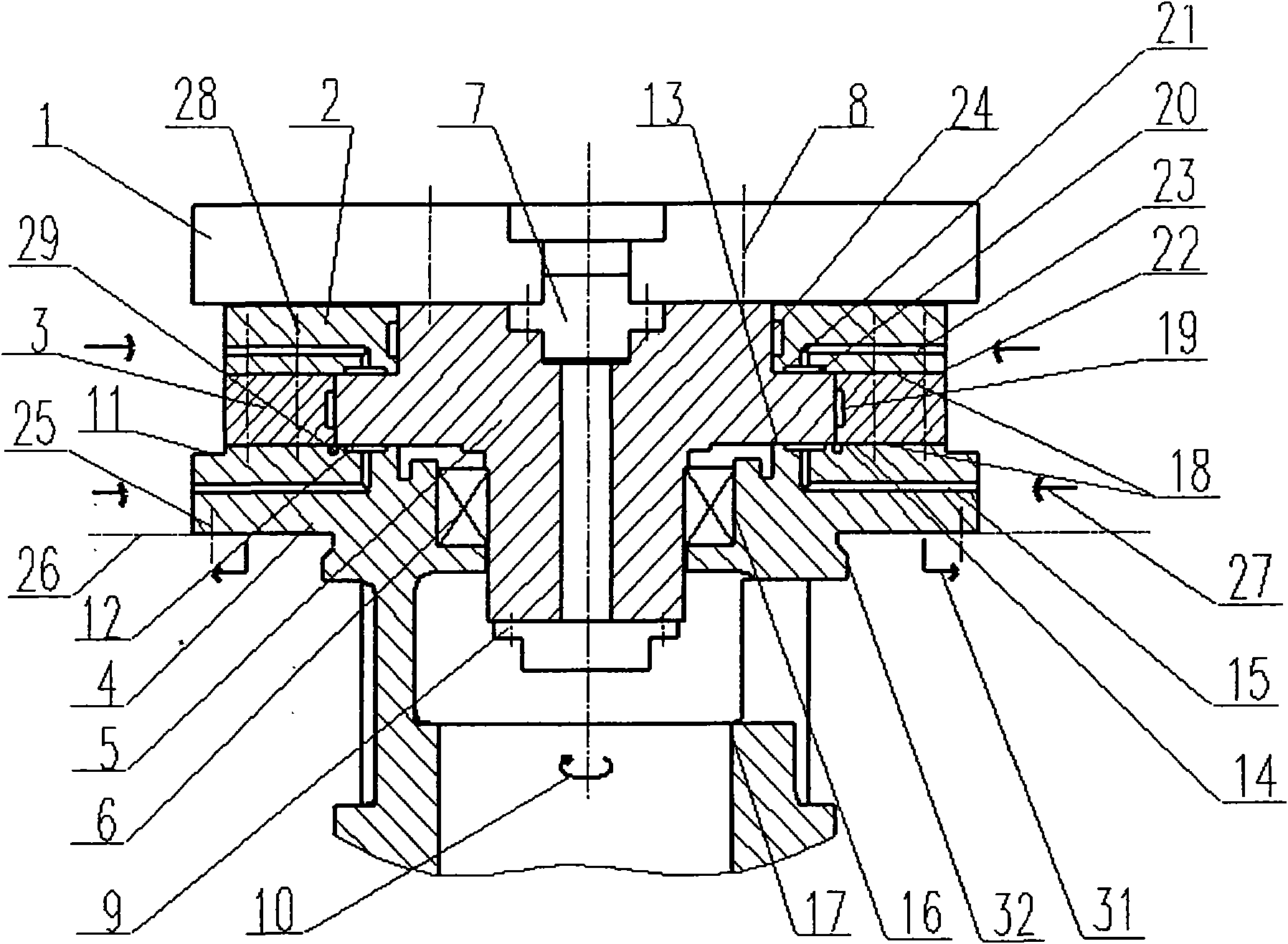

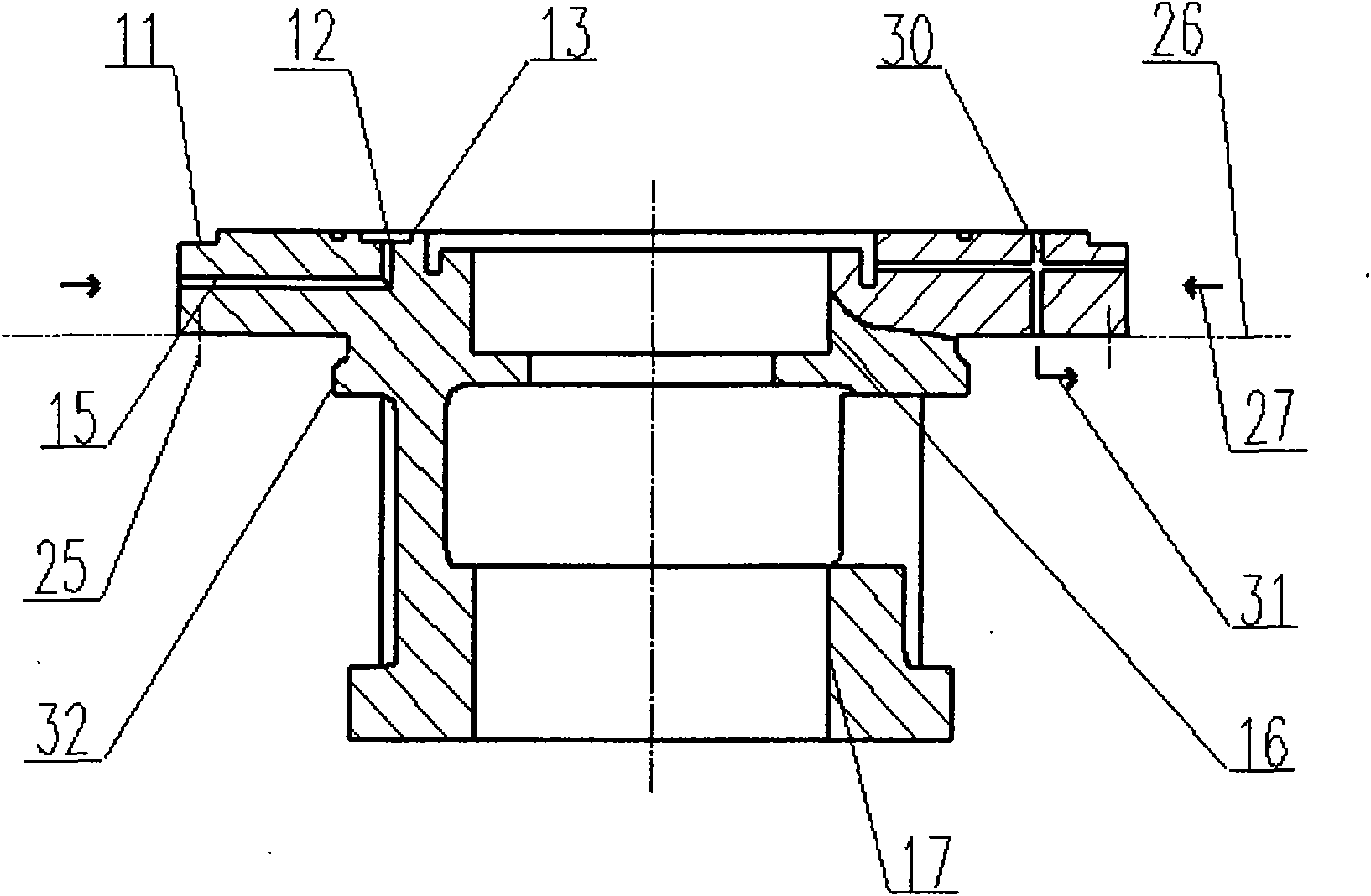

[0020] Example: such as figure 1 , figure 2 As shown in the rotary support device of the round worktable of the machine tool, there are 4 M12 screw holes on the counterbore on the top surface of the rotating spindle 5 to install the centering sleeve 7, and there are 6 M16 screw holes on the top surface, and the bolt 8 and the centering sleeve 7 are used to connect with the centering sleeve 7. The worktables 1 are connected; the bottom end surface of the rotating main shaft 5 is equipped with a coupling 9 connected with the circular worktable rotation drive mechanism 10 .

[0021] An upper pressure ring 2 is installed on the outer diameter of the top end of the rotating main shaft 5, and a septum ring 3 is installed on the outer side of the large diameter; both sides of the large diameter are axially rigid bearing surfaces of a hydrostatic oil film, which bear oil on the upper pressure ring 2 of the axial static pressure supporting member. The static pressure system pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com