Compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

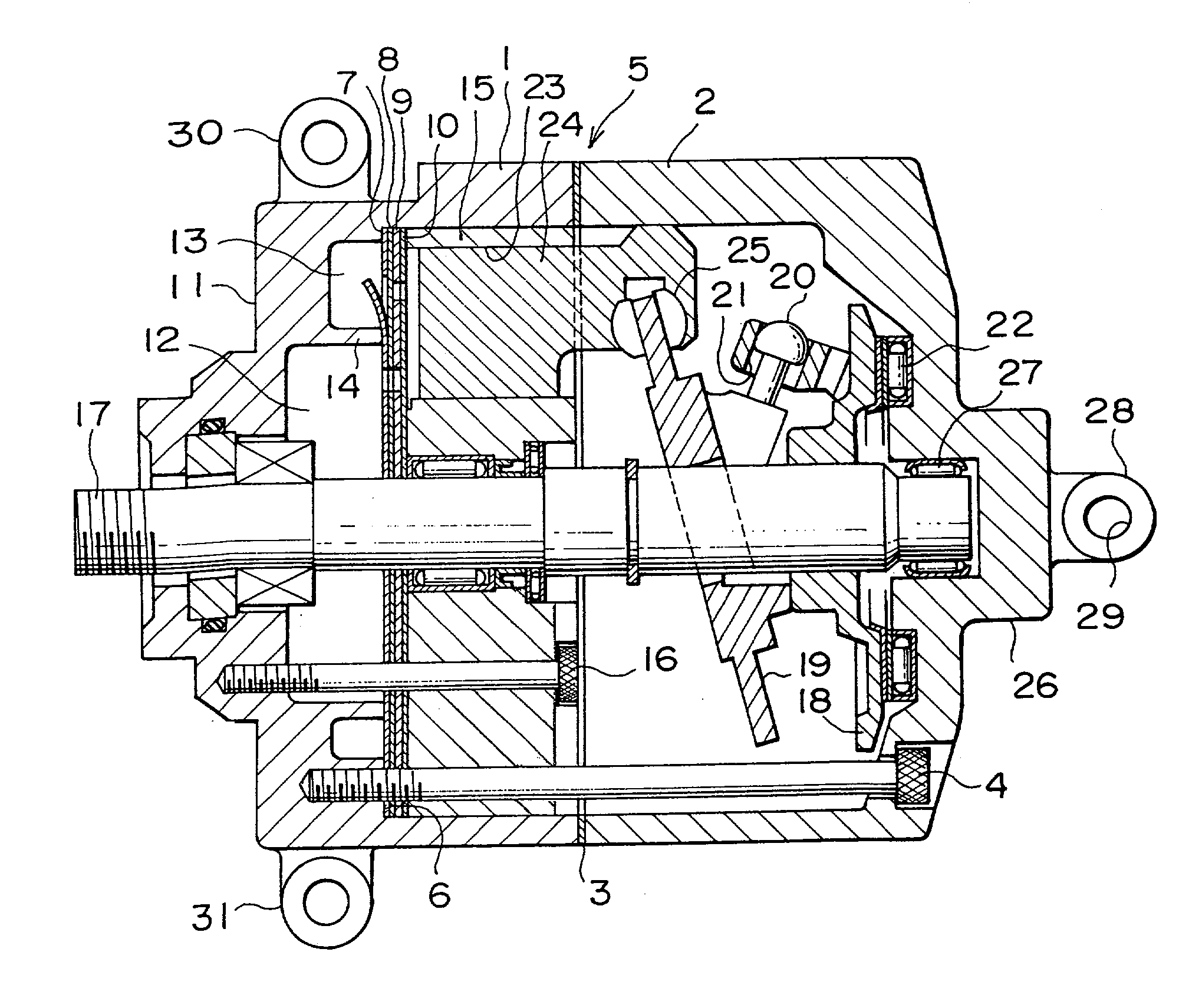

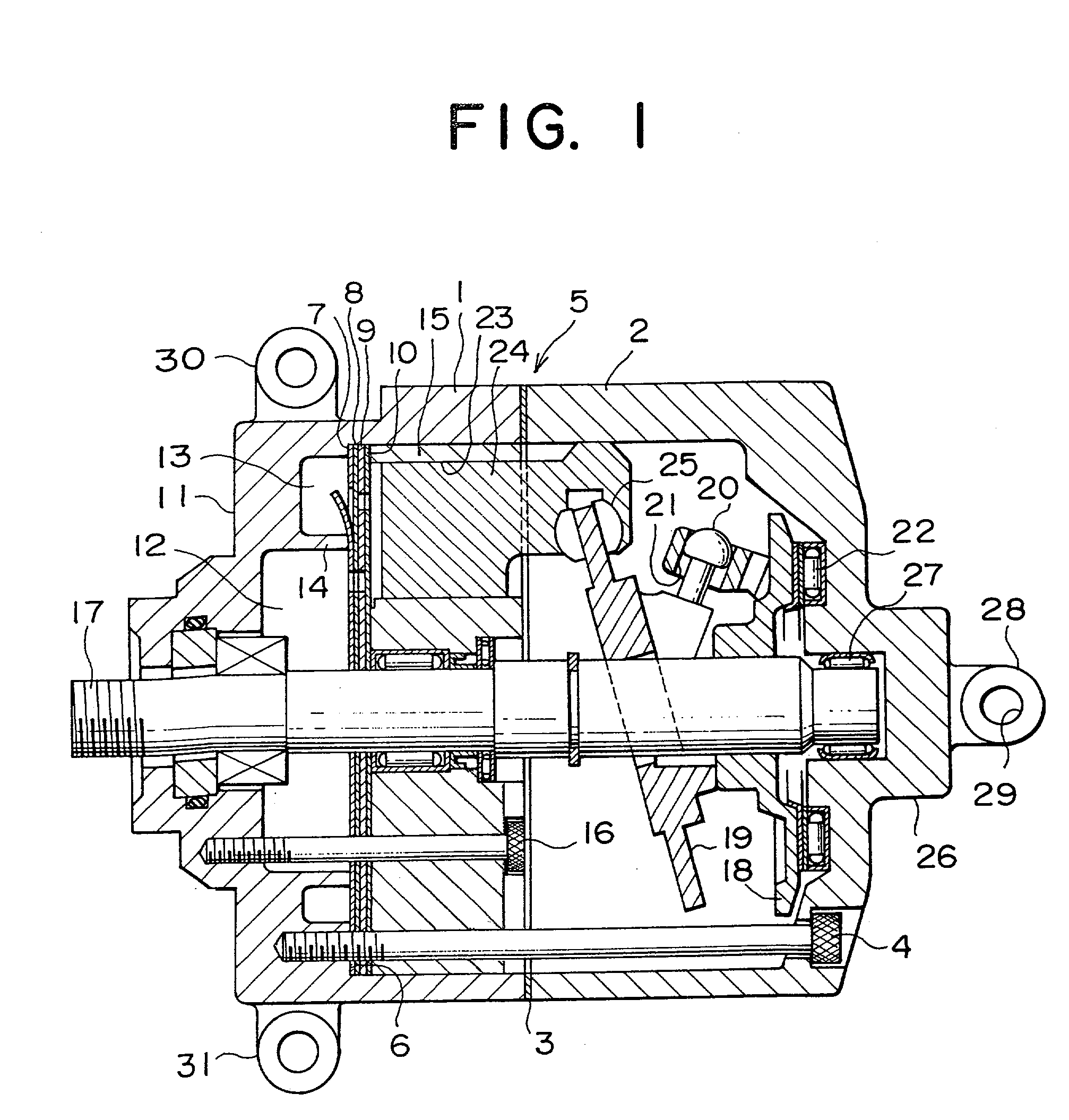

[0013] Embodiments of the present invention will now be described with reference to the accompanying drawings.

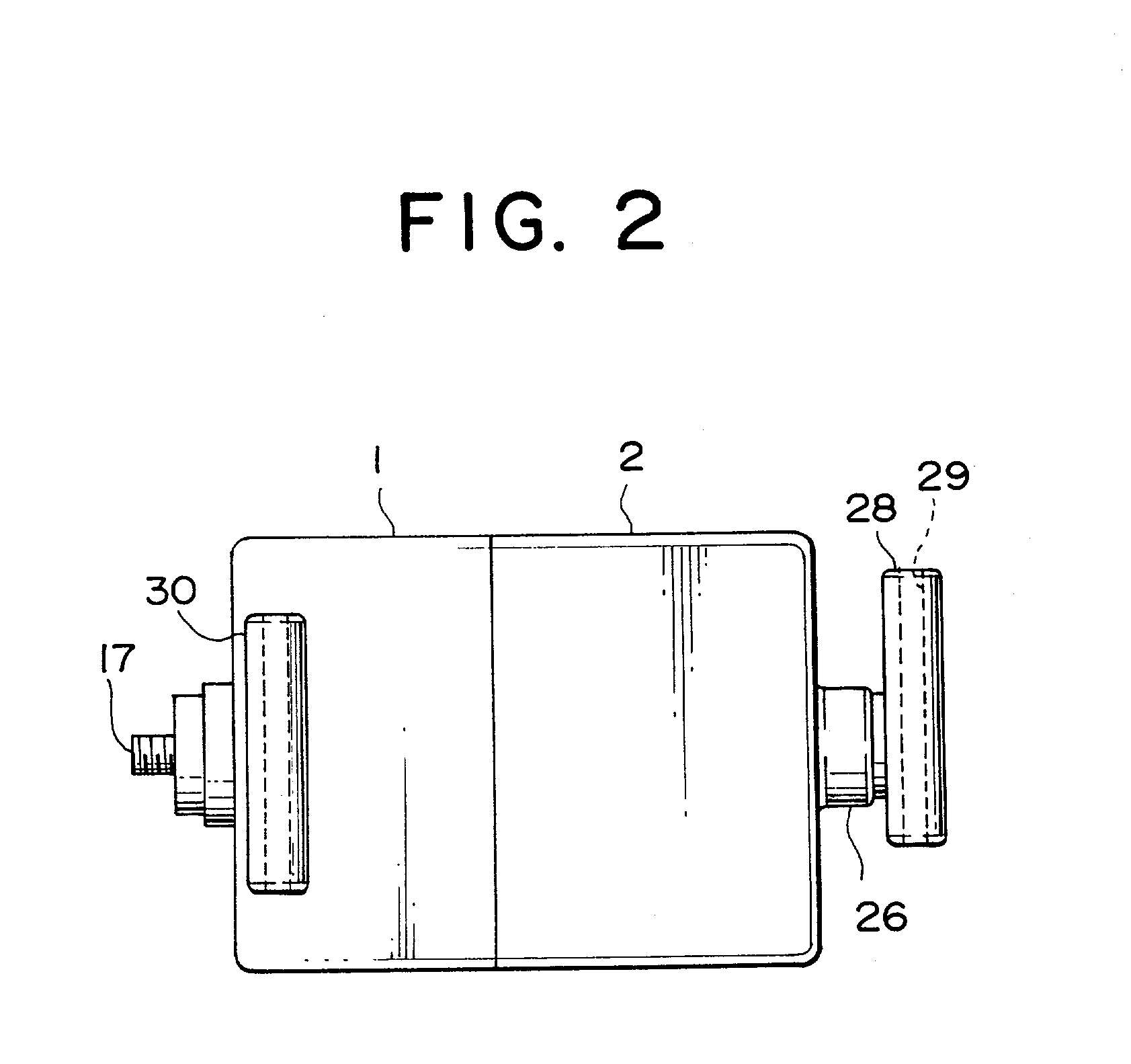

[0014] FIG. 1 shows a structure of a swash plate type variable capacity compressor in accordance with an embodiment of this invention. A front housing 1 and a rear housing 2 are fastened together by means of bolts 4 under the condition that they are coupled with each other through a gasket 3 to thereby form a whole housing 5. A stepped portion 6 is formed within the front housing 1. A retainer forming plate 7, a valve forming plate 8, a valve plate 9 and a valve forming plate 10 are fitted so as to be jointed to this stepped portion 6. An intake chamber 12 and a discharge chamber 13 are defined between the retainer forming plate 7 and a rear end wall portion 11 of the front housing 1 so as to be apart from each other through a partitioning wall 14.

[0015] Also, a cylinder block 15 is fitted so as to be jointed to the valve forming plate 10 within the front housing 1 and is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com