Patents

Literature

643results about "Engines with rotating cylinders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

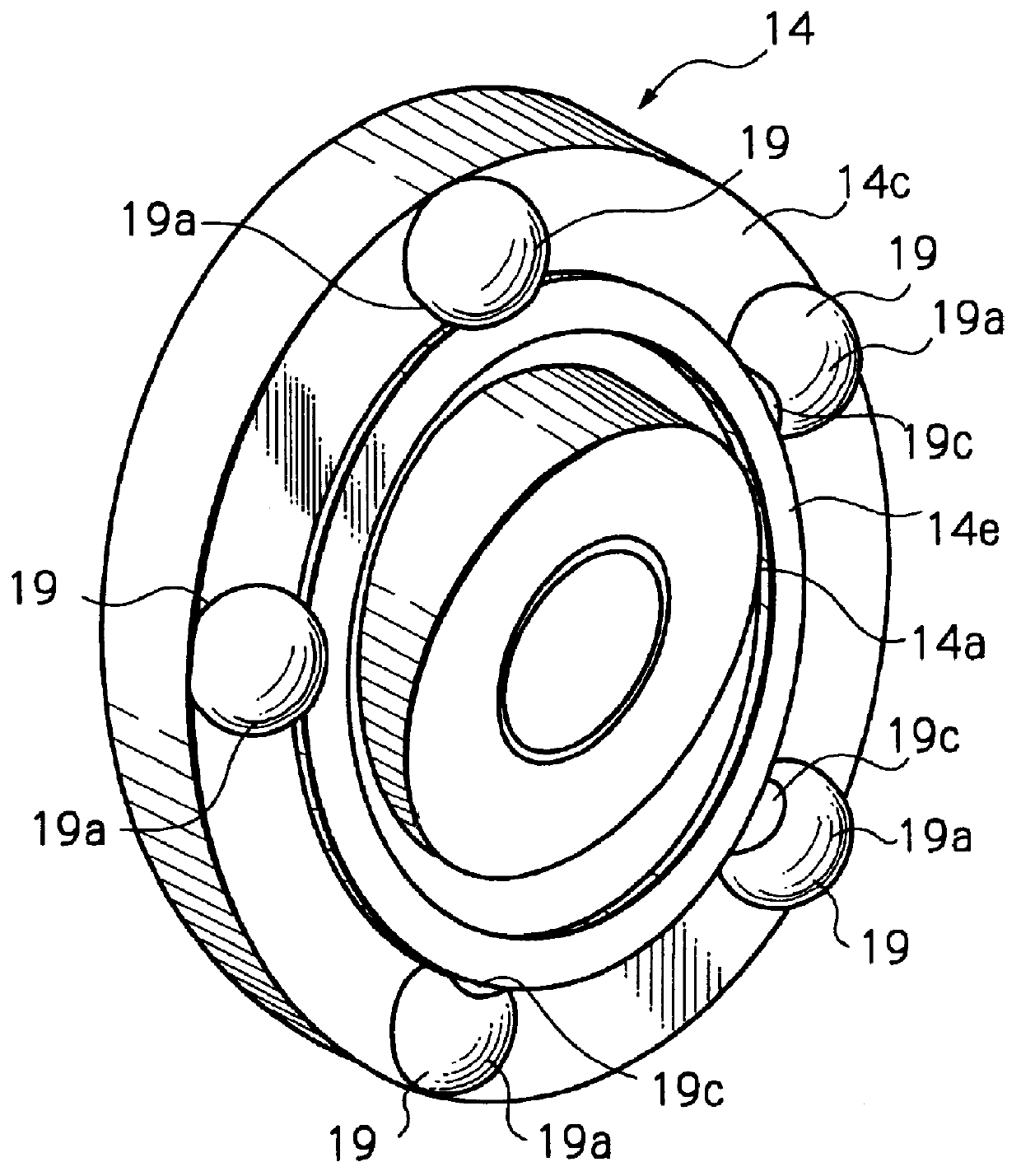

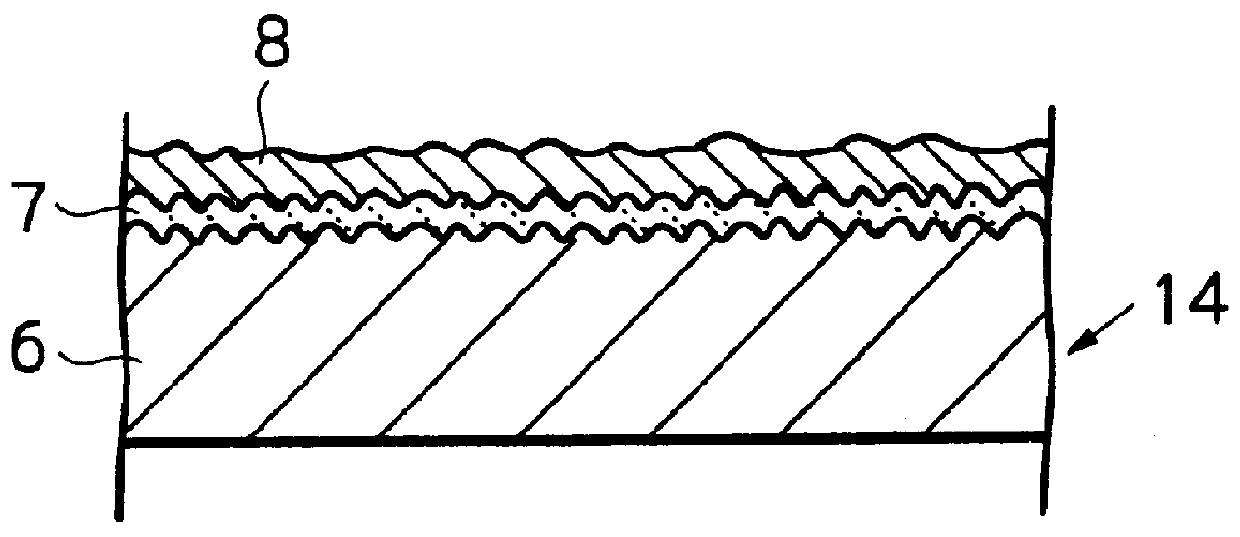

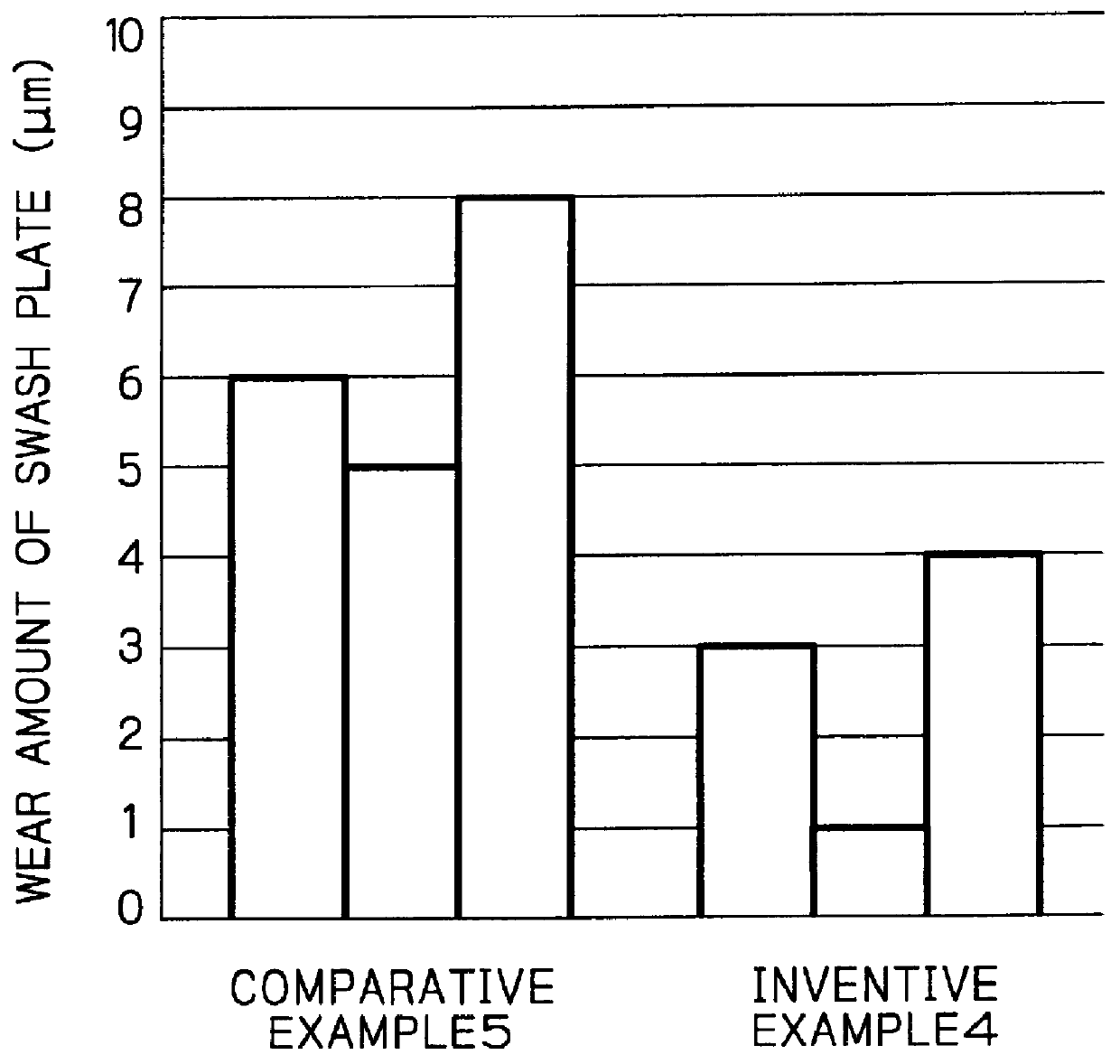

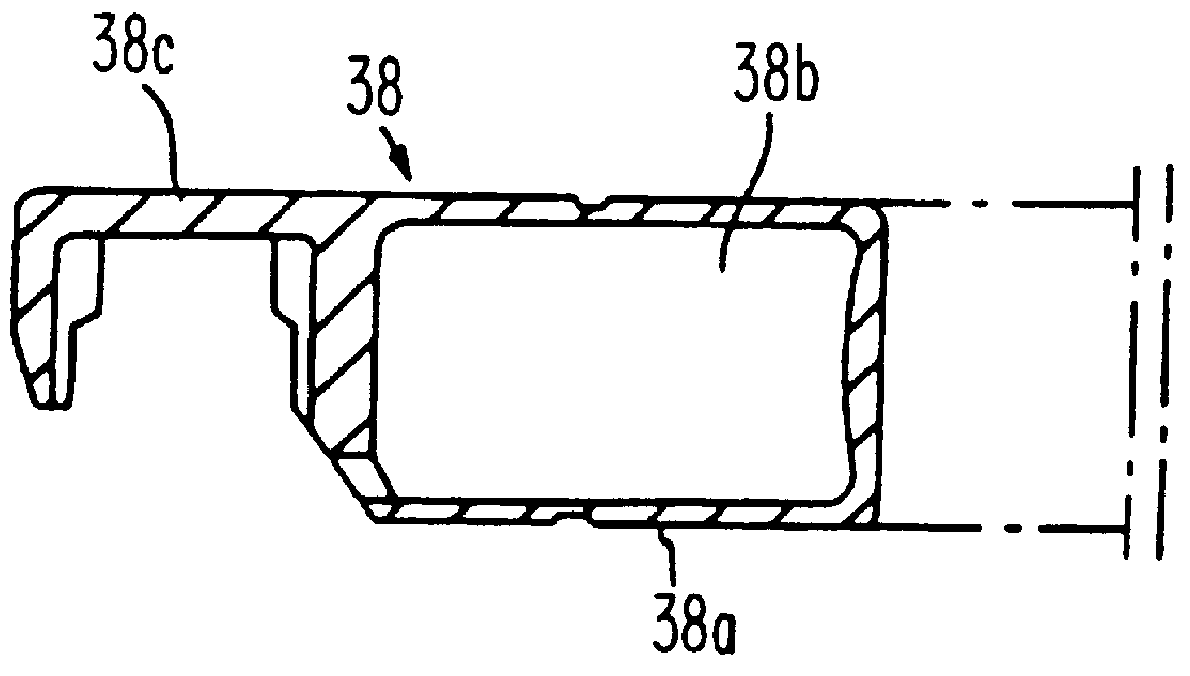

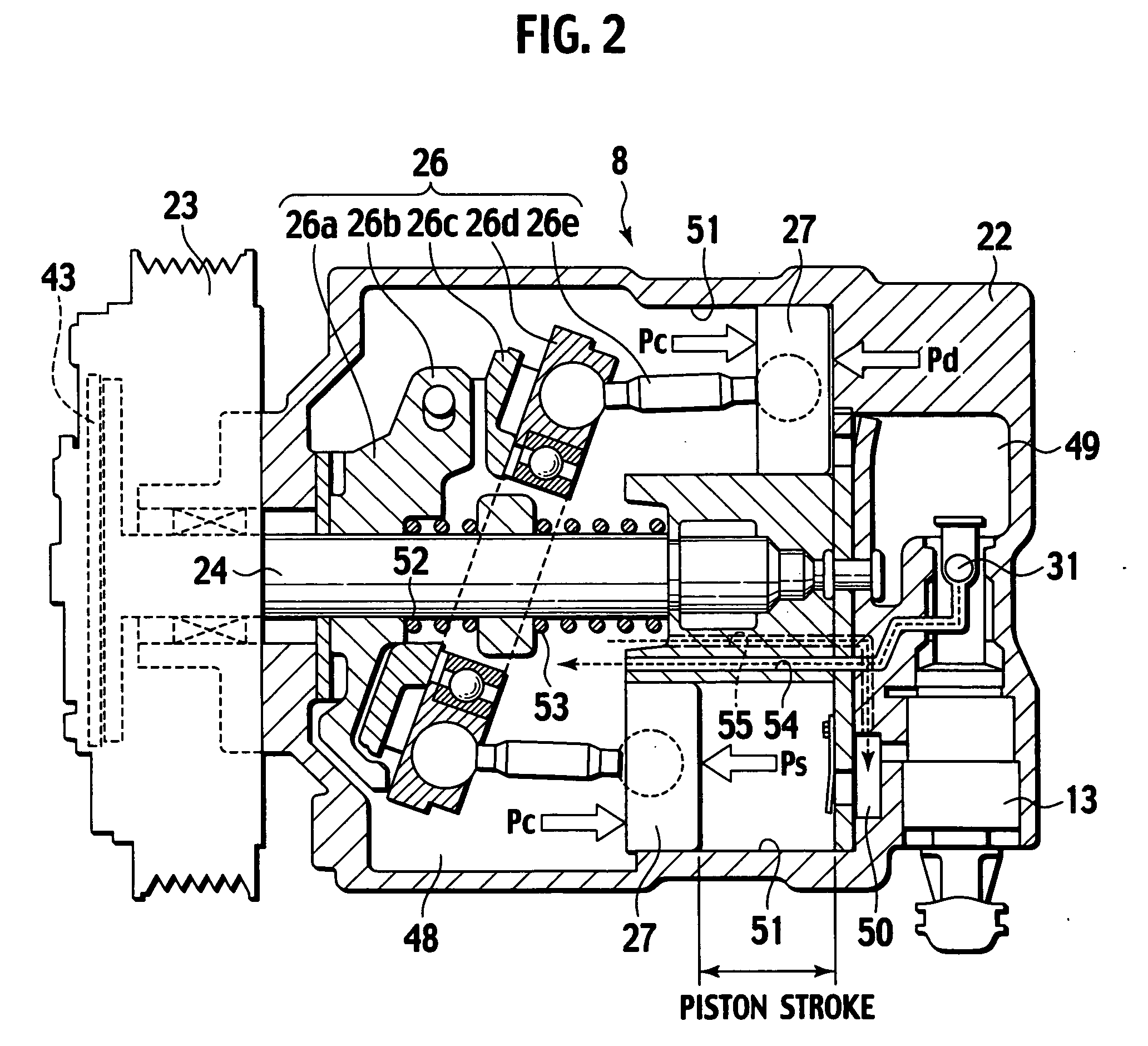

Swash plate of swash-plate compressor

InactiveUS6123009AReduce coating thicknessReduce loadPositive displacement pump componentsAdditivesGas compressorGraphite

A swash plate of a swash-plate compressor is subjected to sliding on shoes and is required to have excellent seizure resistance and wear resistance under the dry lubricating condition. The swash plate according to the present invention is provided with the surface-treated layer, i,e., the intermediate layer consisting of Cu, Sn or metal phosphate, and a sliding contact layer consisting of MoS2 and / or graphite and thermosetting resin.

Owner:TAIHO INDUSTRIES CO LTD +1

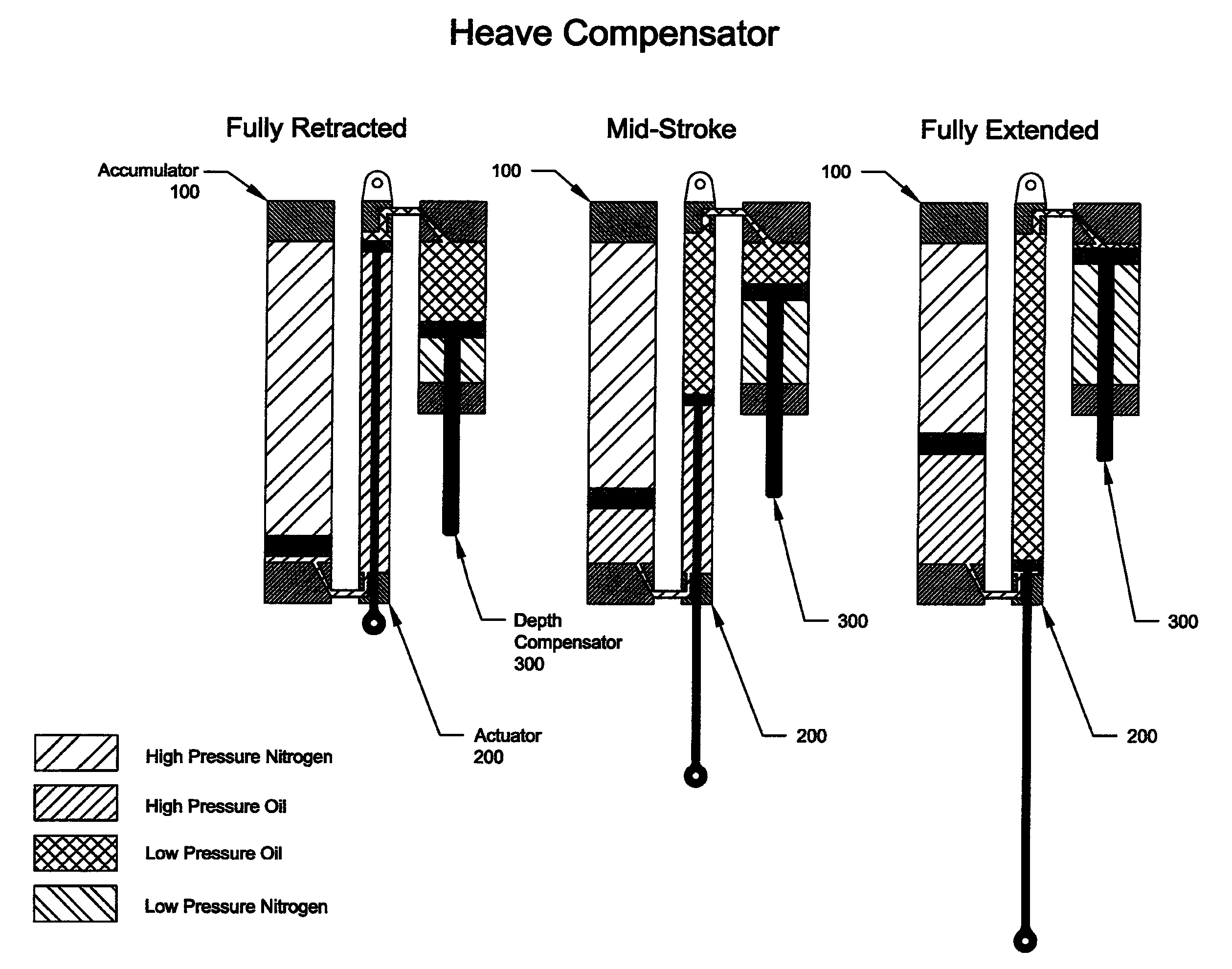

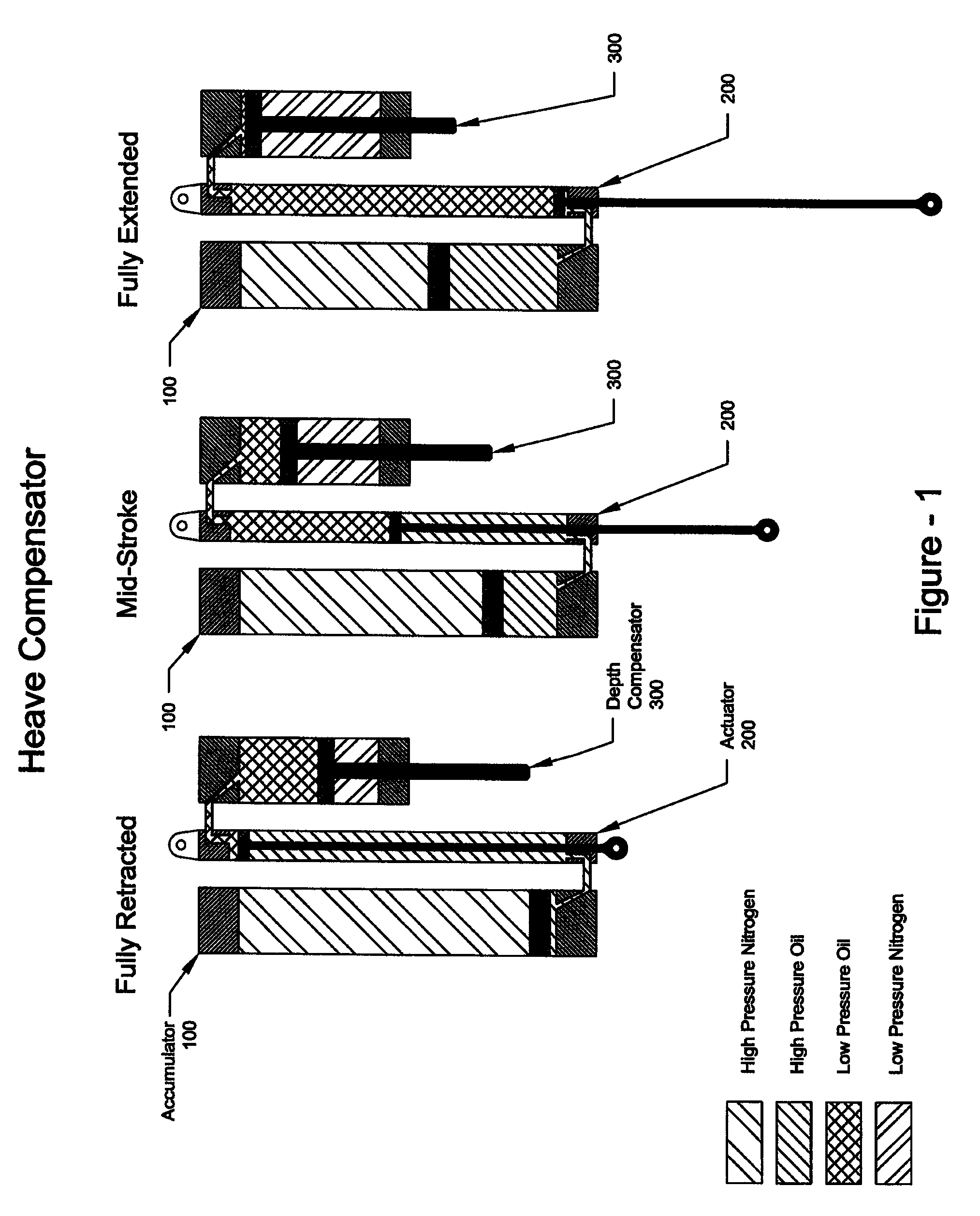

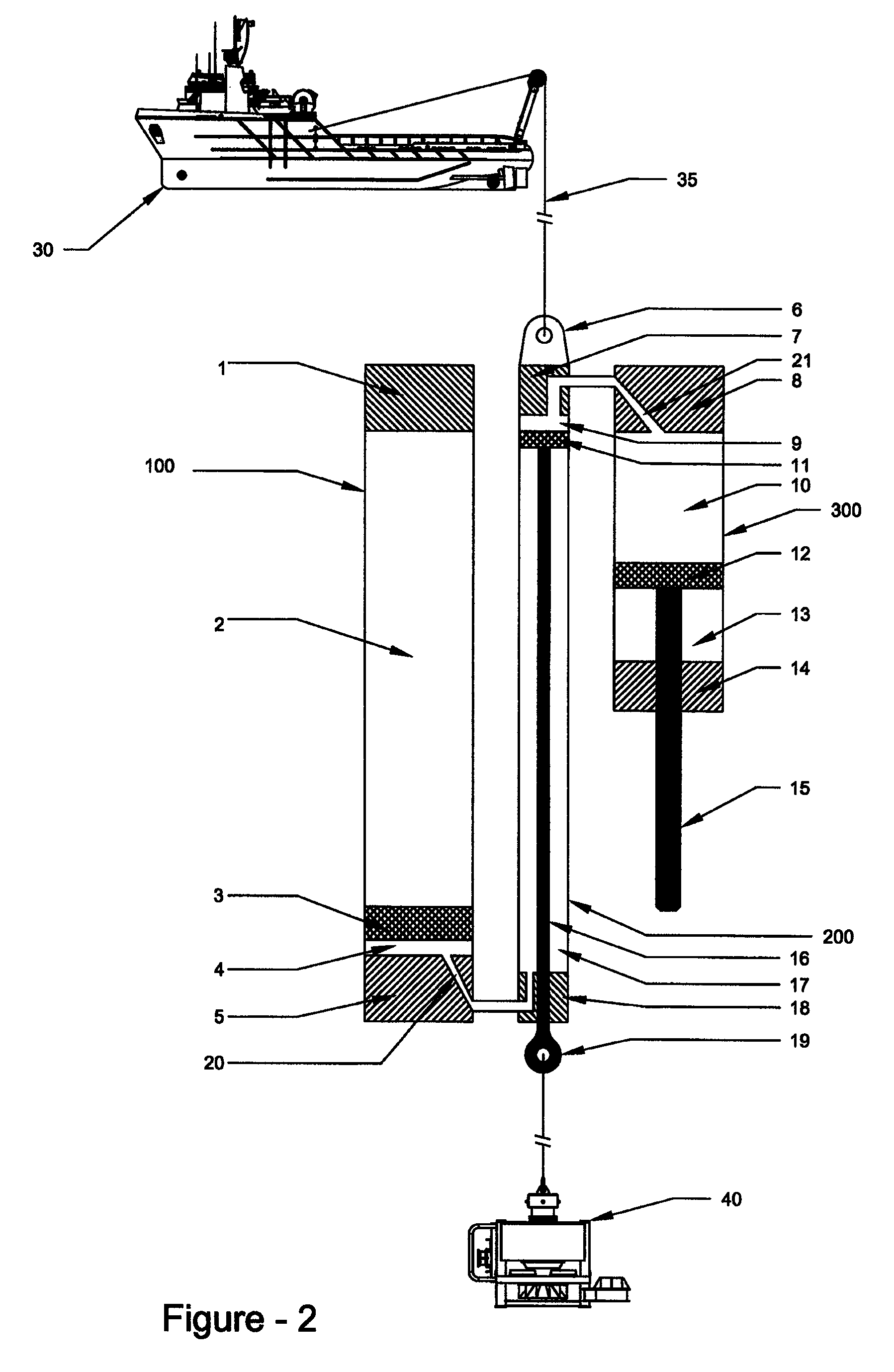

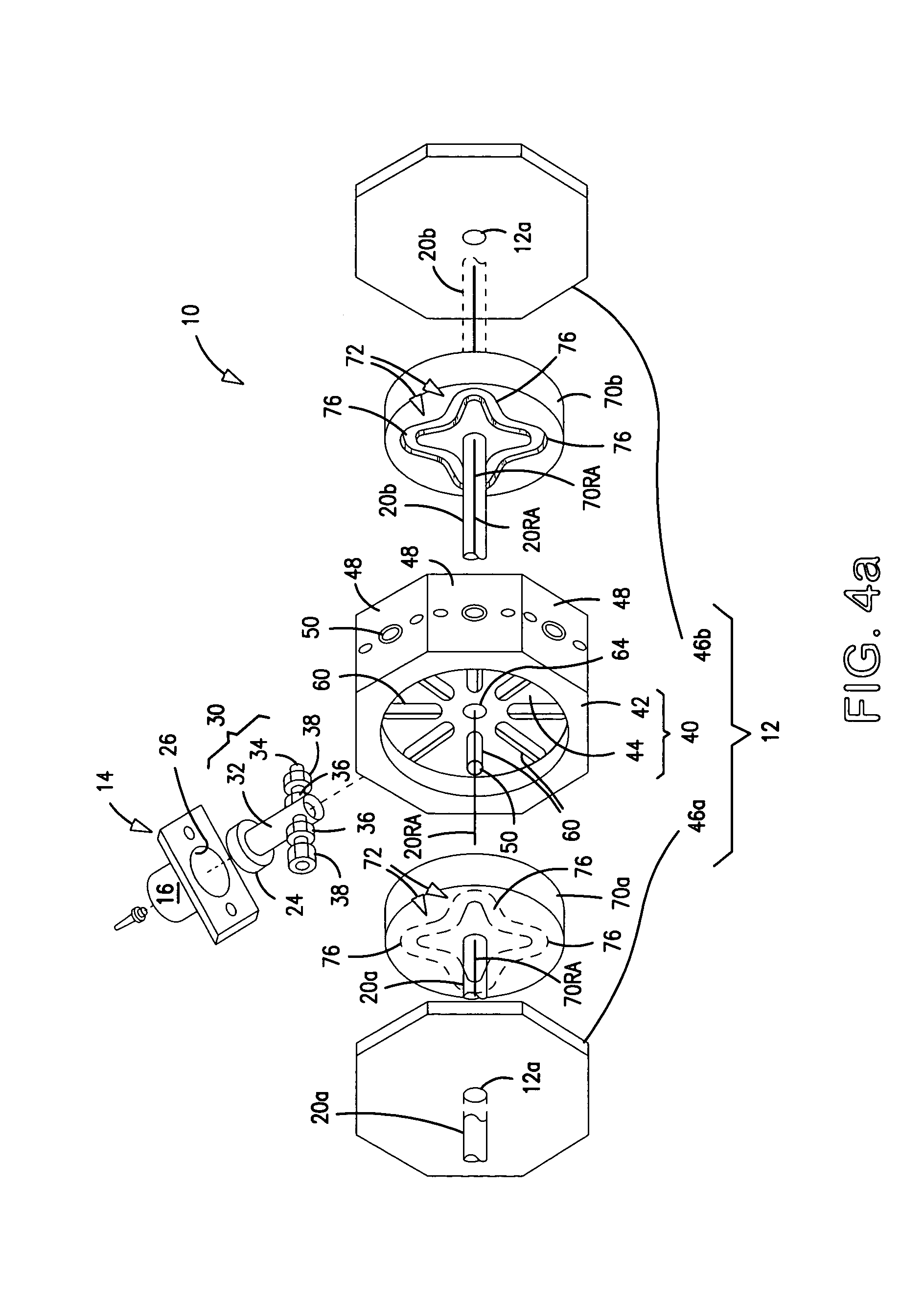

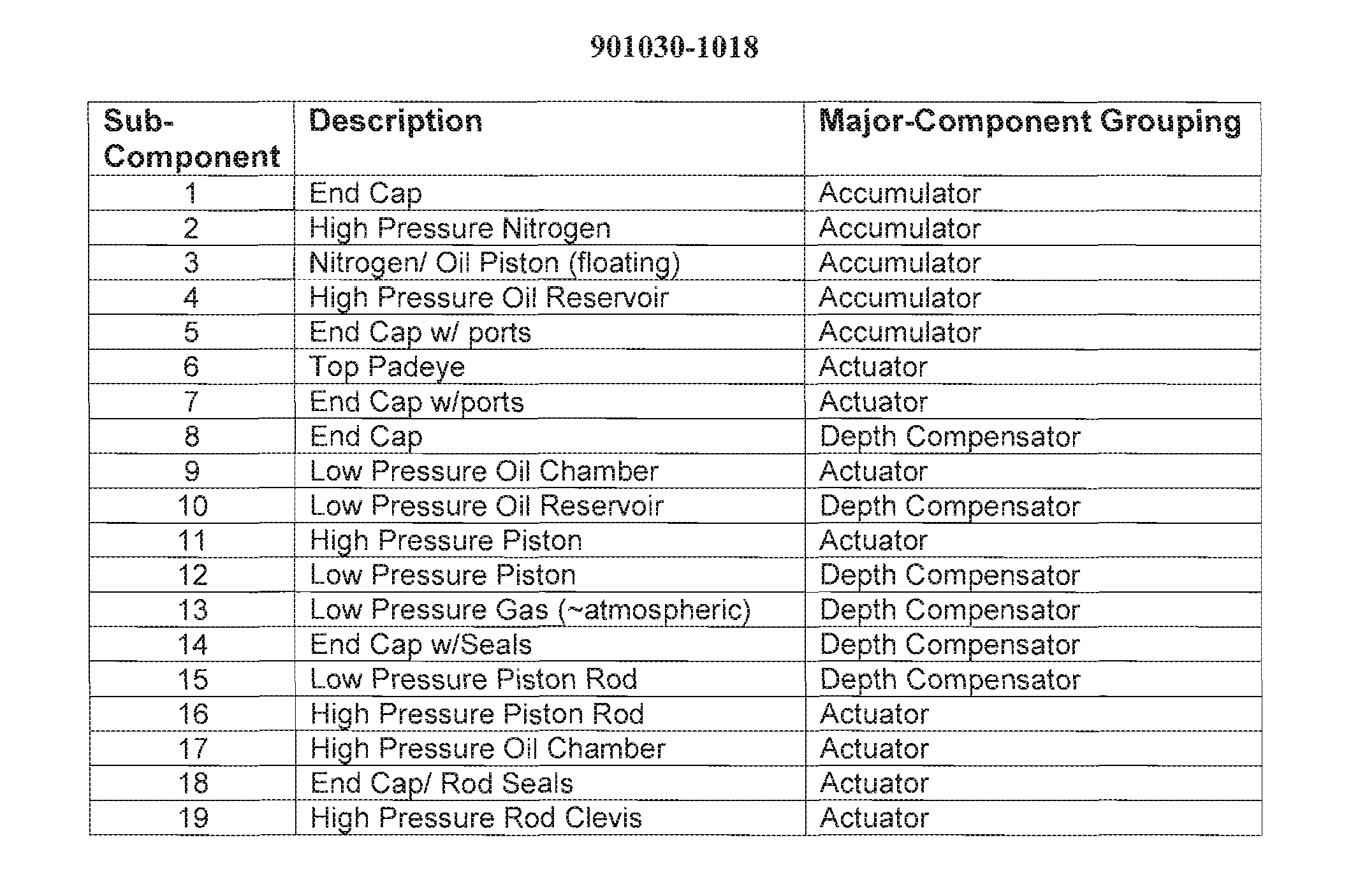

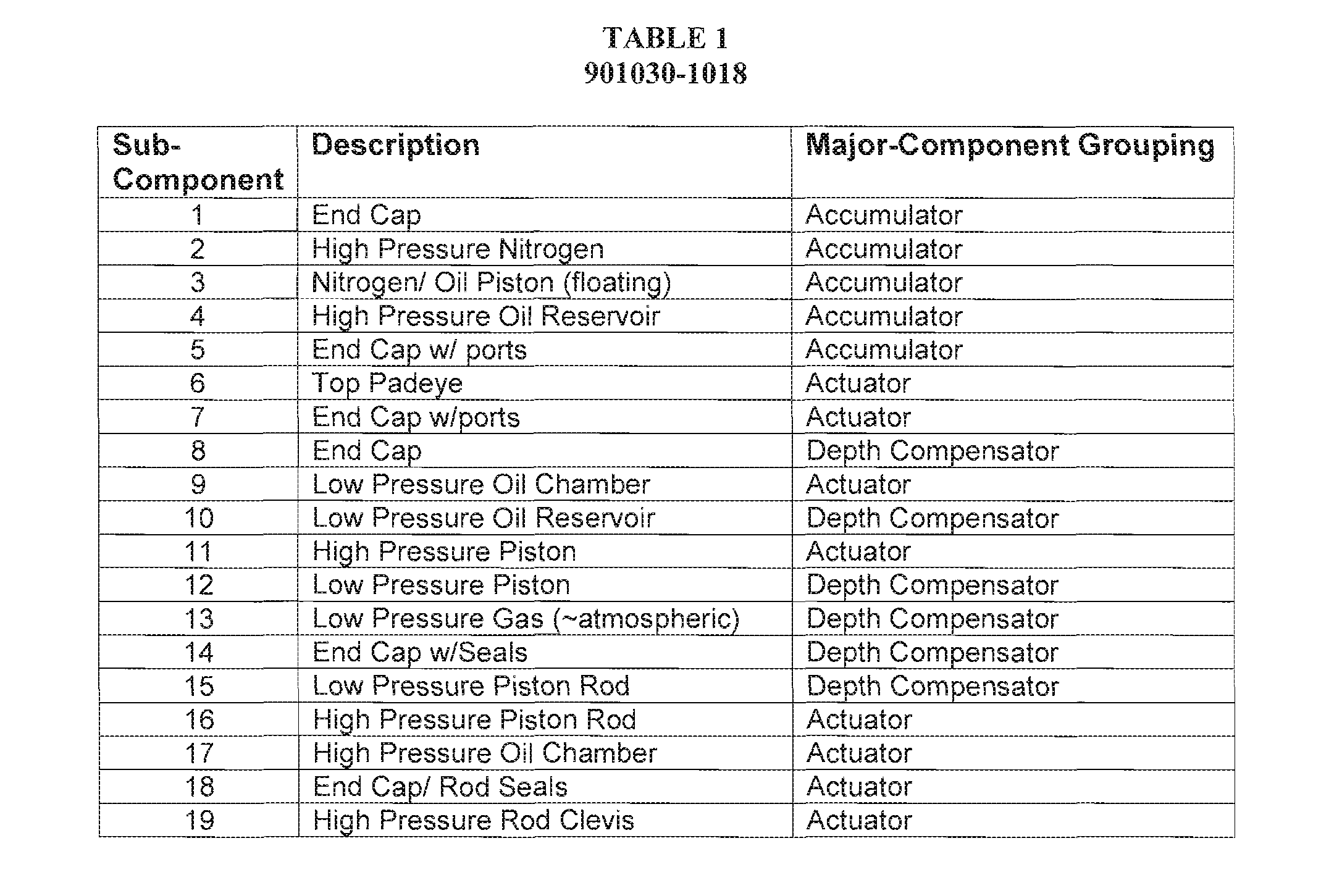

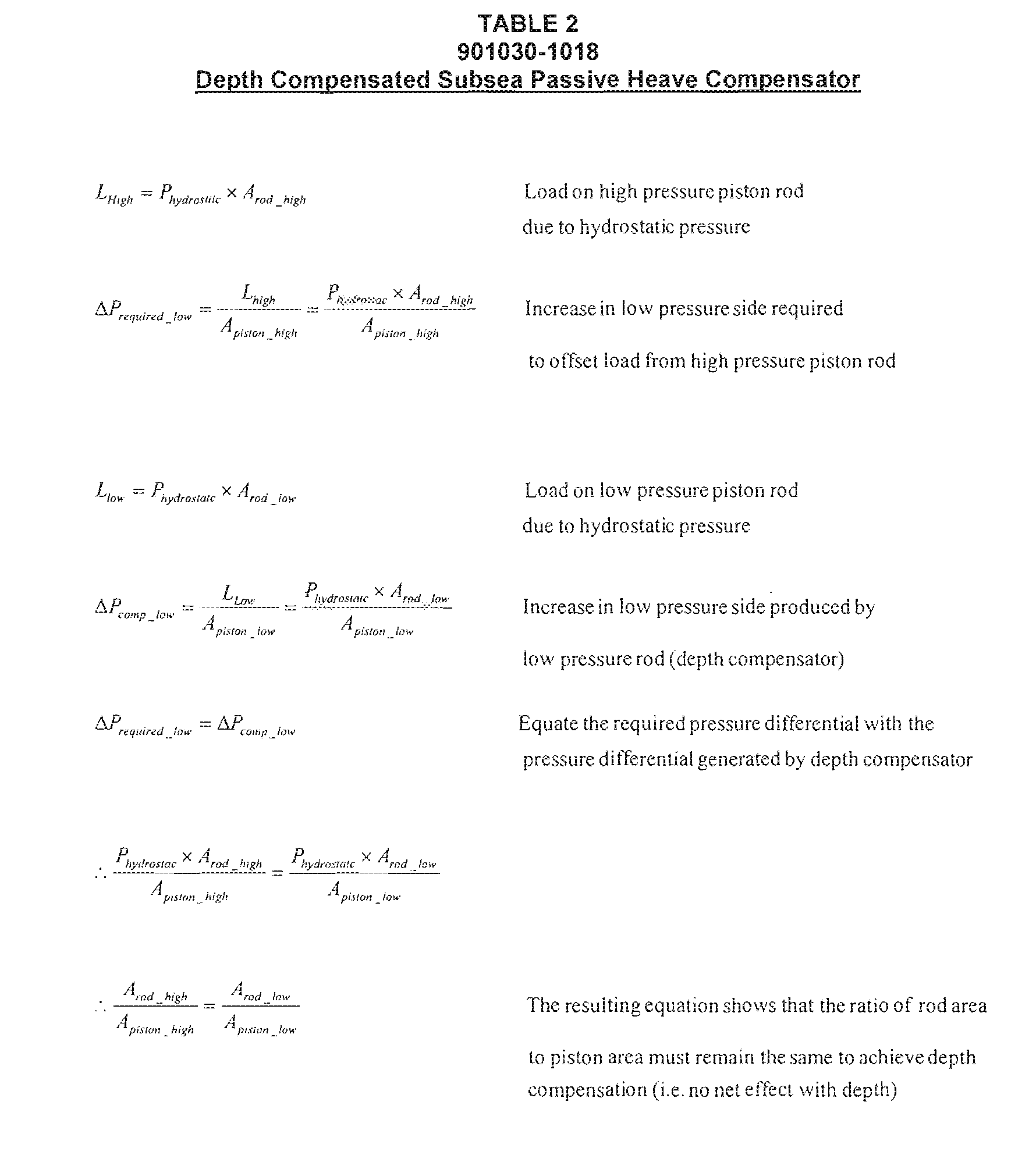

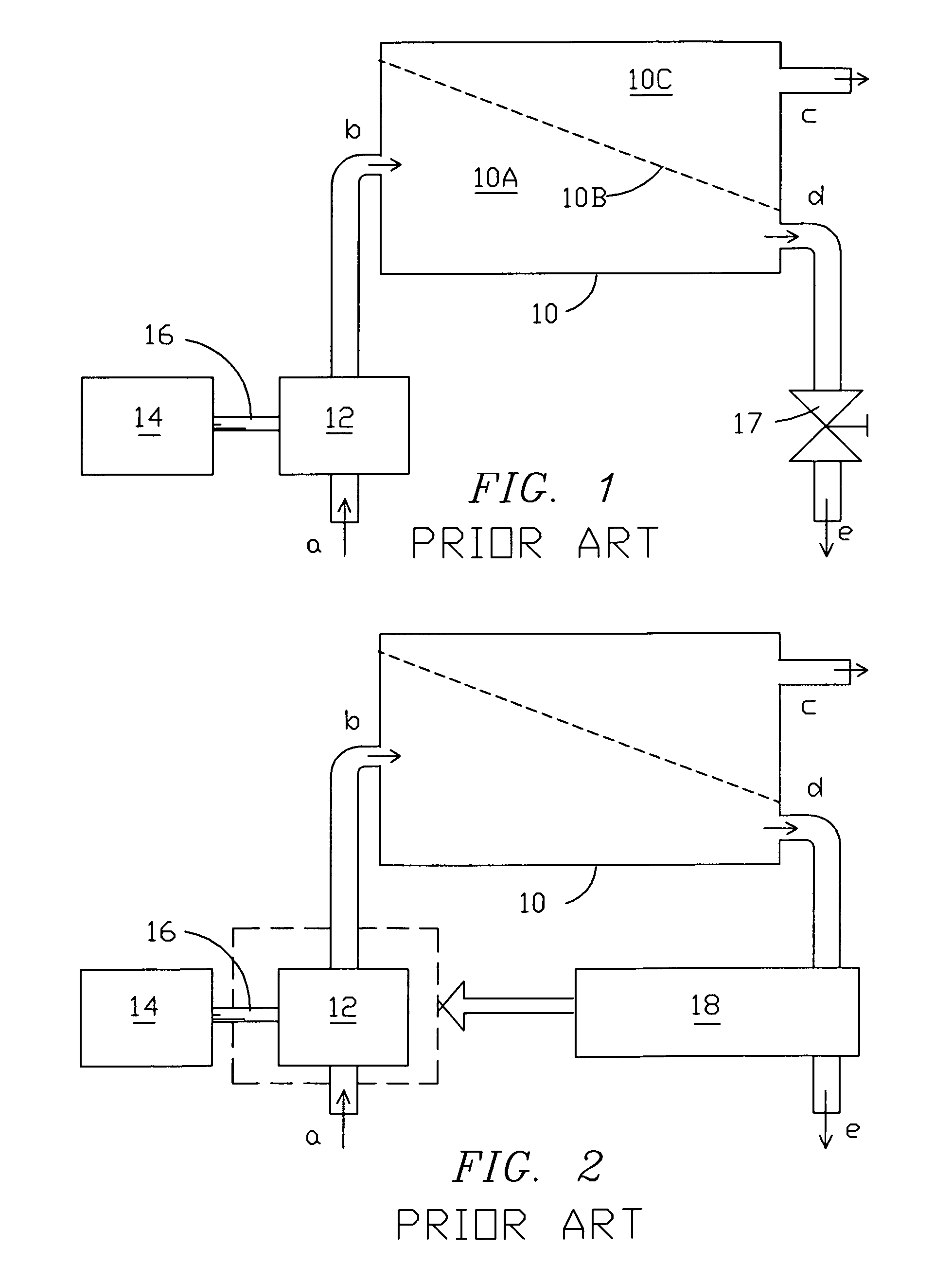

Depth compensated subsea passive heave compensator

ActiveUS7934561B2Mitigate/eliminate the depth effectEliminate the effects ofDrilling rodsDerricks/mastsEngineeringPiston rod

A depth compensated passive eave compensator comprises a first cylinder connected at its upper end to a vessel. A piston rod extends from a piston located within the first cylinder through the lower end thereof and is connected to subsea equipment. A second cylinder contains a compressed gas which maintains pressure beneath the piston of the first cylinder. The upper end of the first cylinder is connected to the upper end of a third cylinder having a piston mounted therein. A piston rod extending from the piston of third cylinder extends through the lower end thereof thereby applying the pressure of the sea to the piston of the third cylinder.

Owner:INTERMOOR

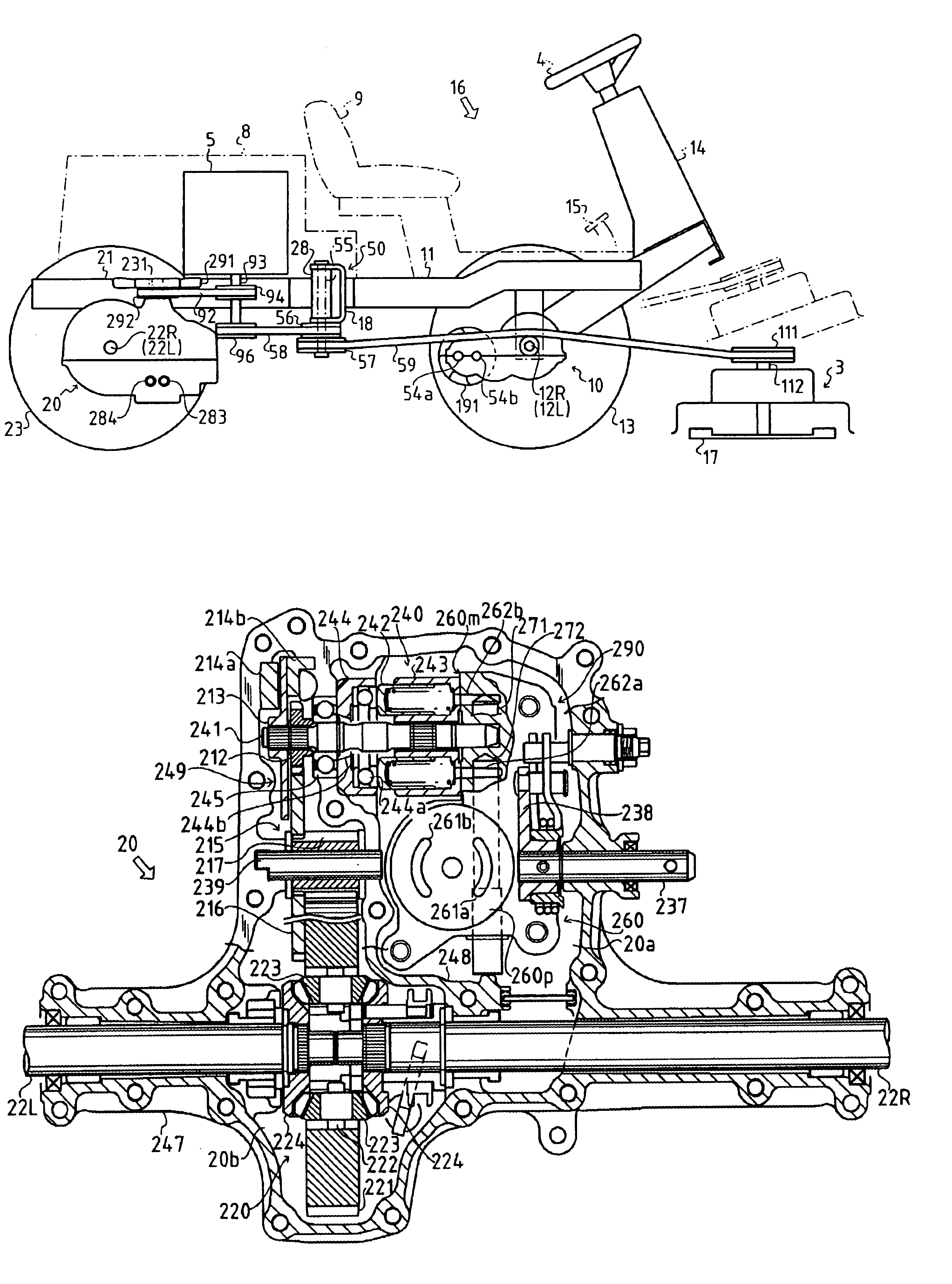

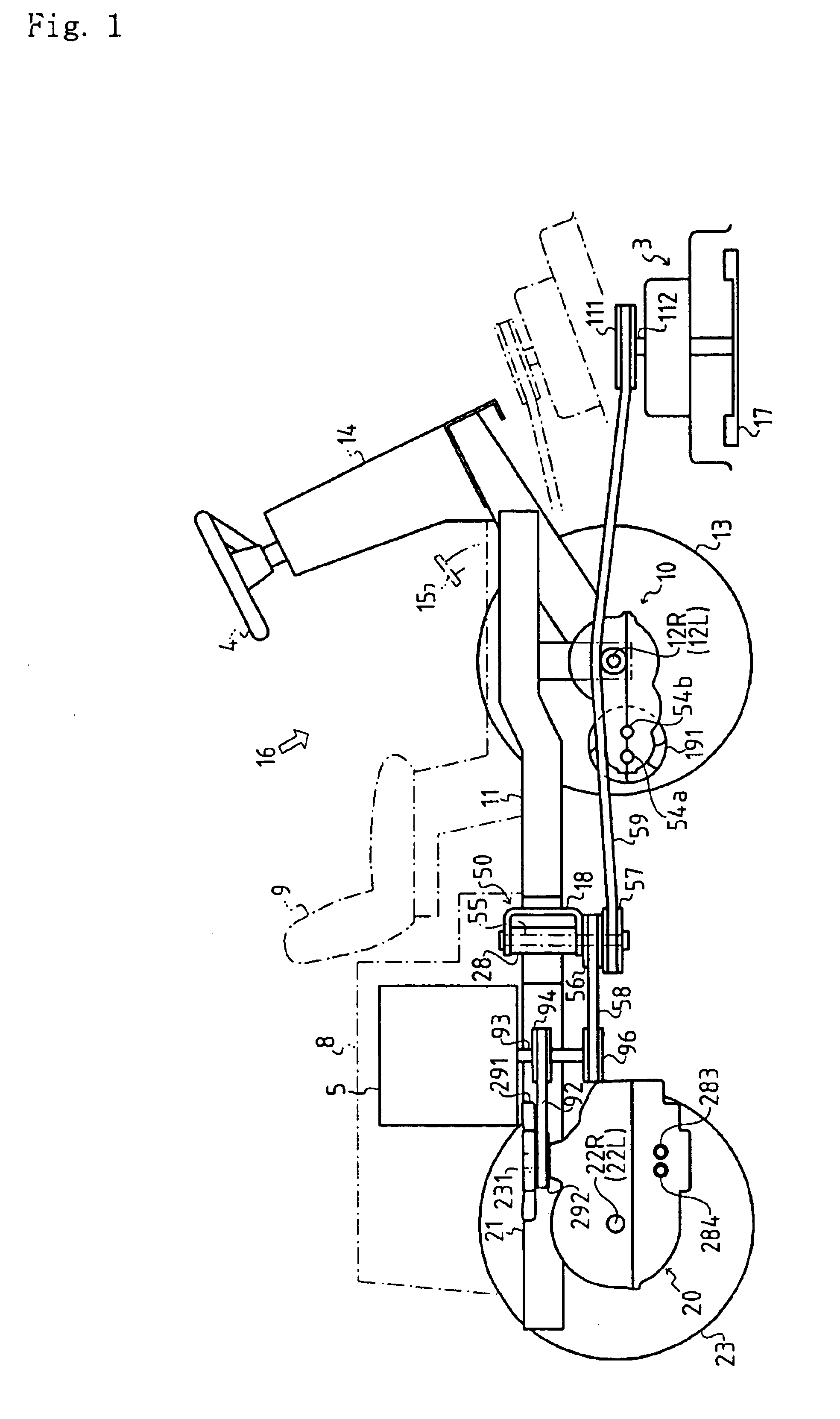

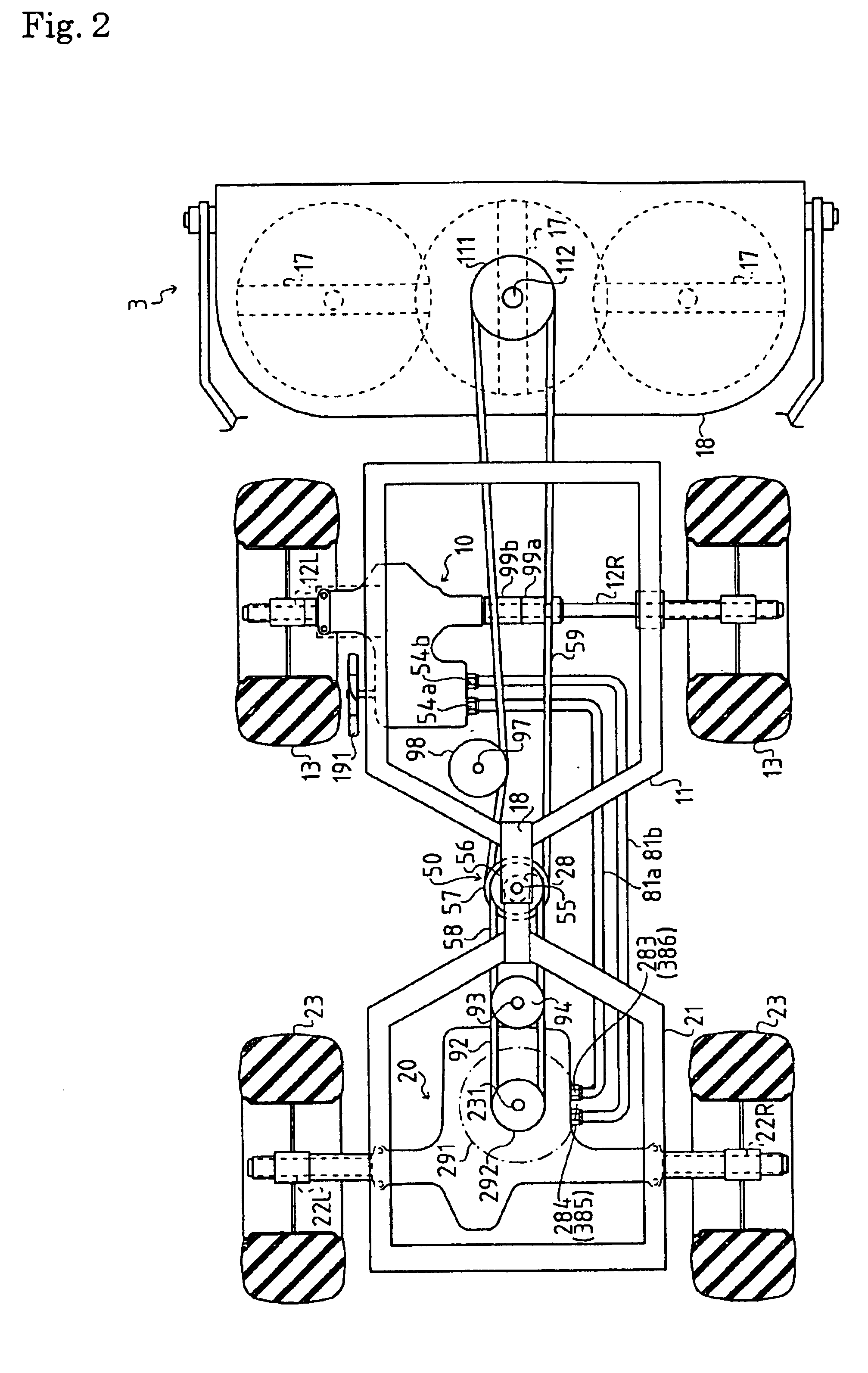

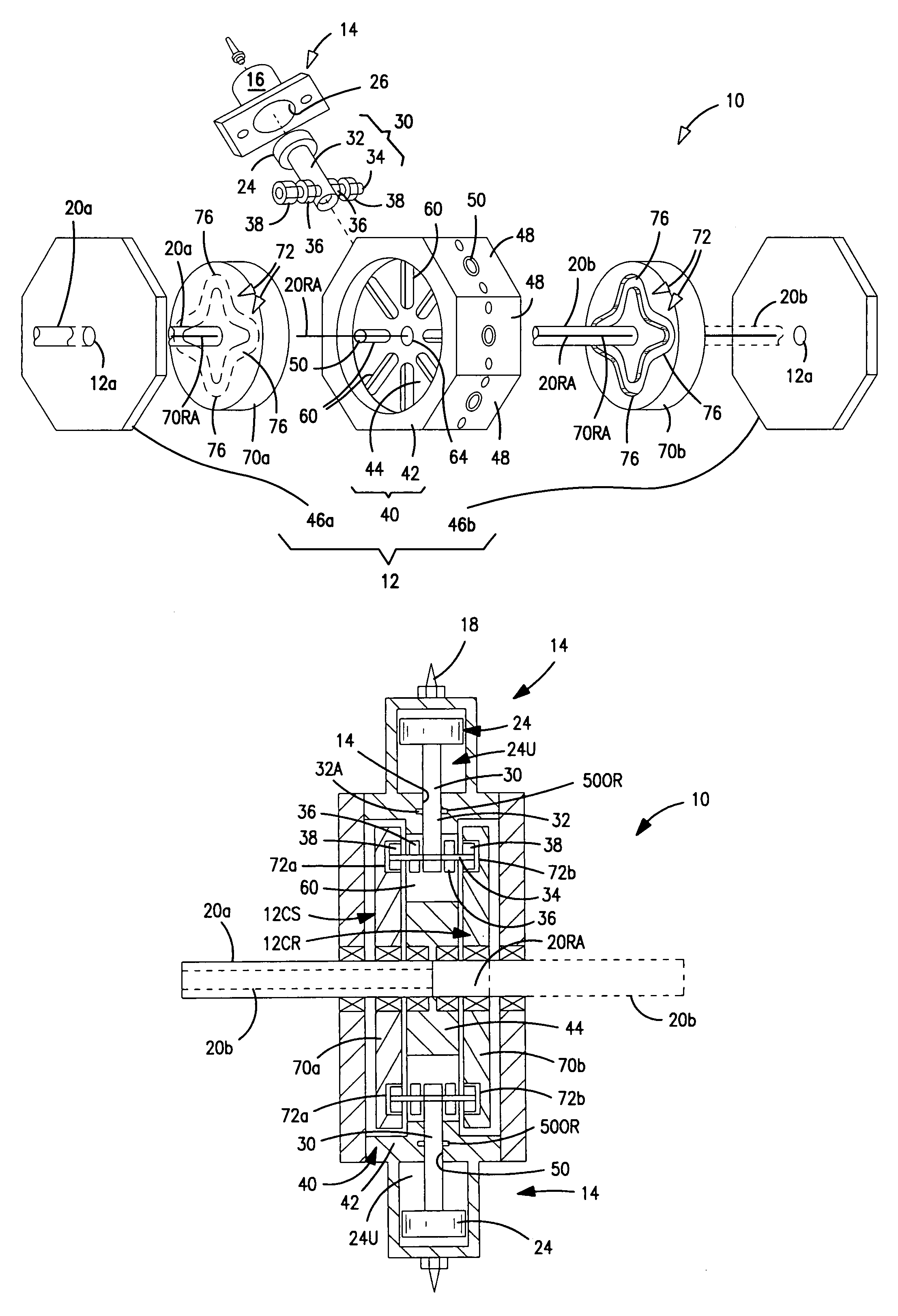

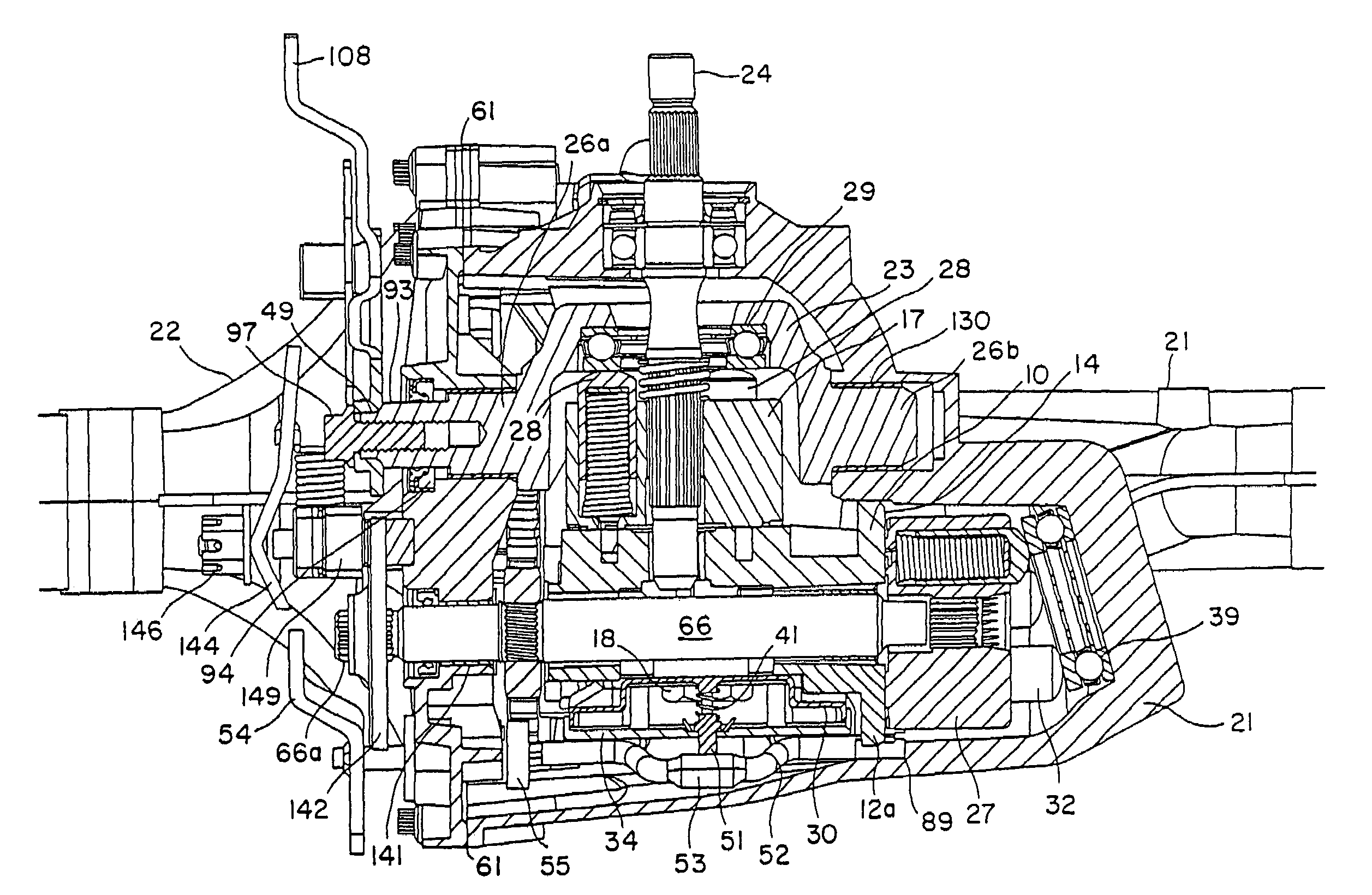

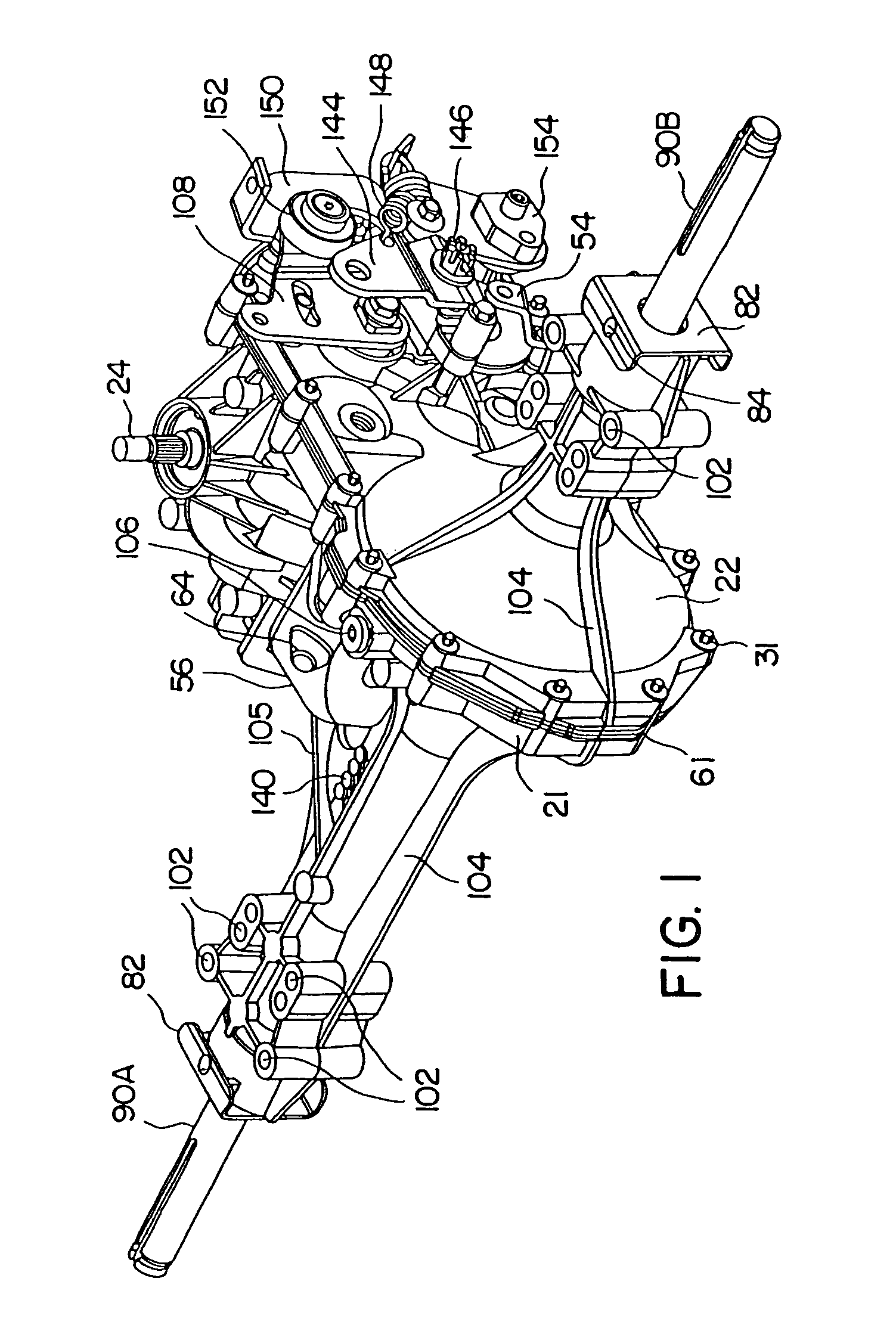

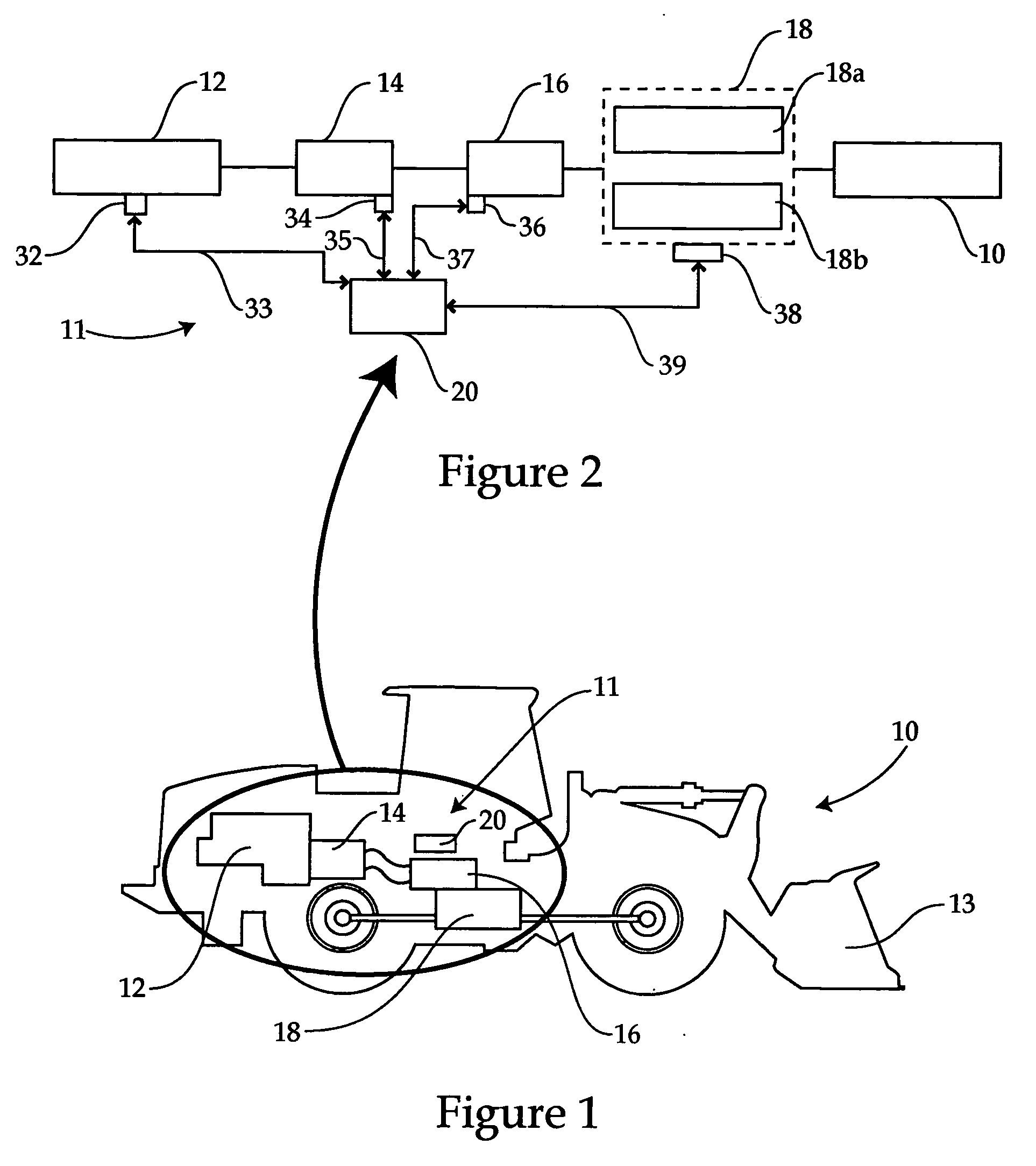

Hydraulic transaxle apparatus for a four-wheel driving vehicle and four-wheel driving vehicle using the apparatus

InactiveUS6845837B2Prevent liquid leakageEasy to manufactureFluid couplingsElectric devicesHydraulic pumpArticulated vehicle

An articulated vehicle with a working device has a first frame having a prime mover mounted thereon and supporting a first transaxle apparatus. The first transaxle apparatus includes an input shalt receiving power from the prime mover, a pair of first axles, and a hydrostatic transmission. The hydrostatic transmission comprises a variable hydraulic pump, a first hydraulic motor fluidly connected to the hydraulic pump via a fluid passage, and a housing with a port fluidly connected to the fluid passage. The second transaxle apparatus includes a pair of second axles having different lengths and a second hydraulic motor. The second hydraulic motor is fluidly connected to the port. Proximal ends of the first and second frames with respect to the vehicle are coupled to each other so that the first and second flames are rotatable around a vertical axis relative to each other when steered.

Owner:KANZAKI KOKYUKOKI MFG

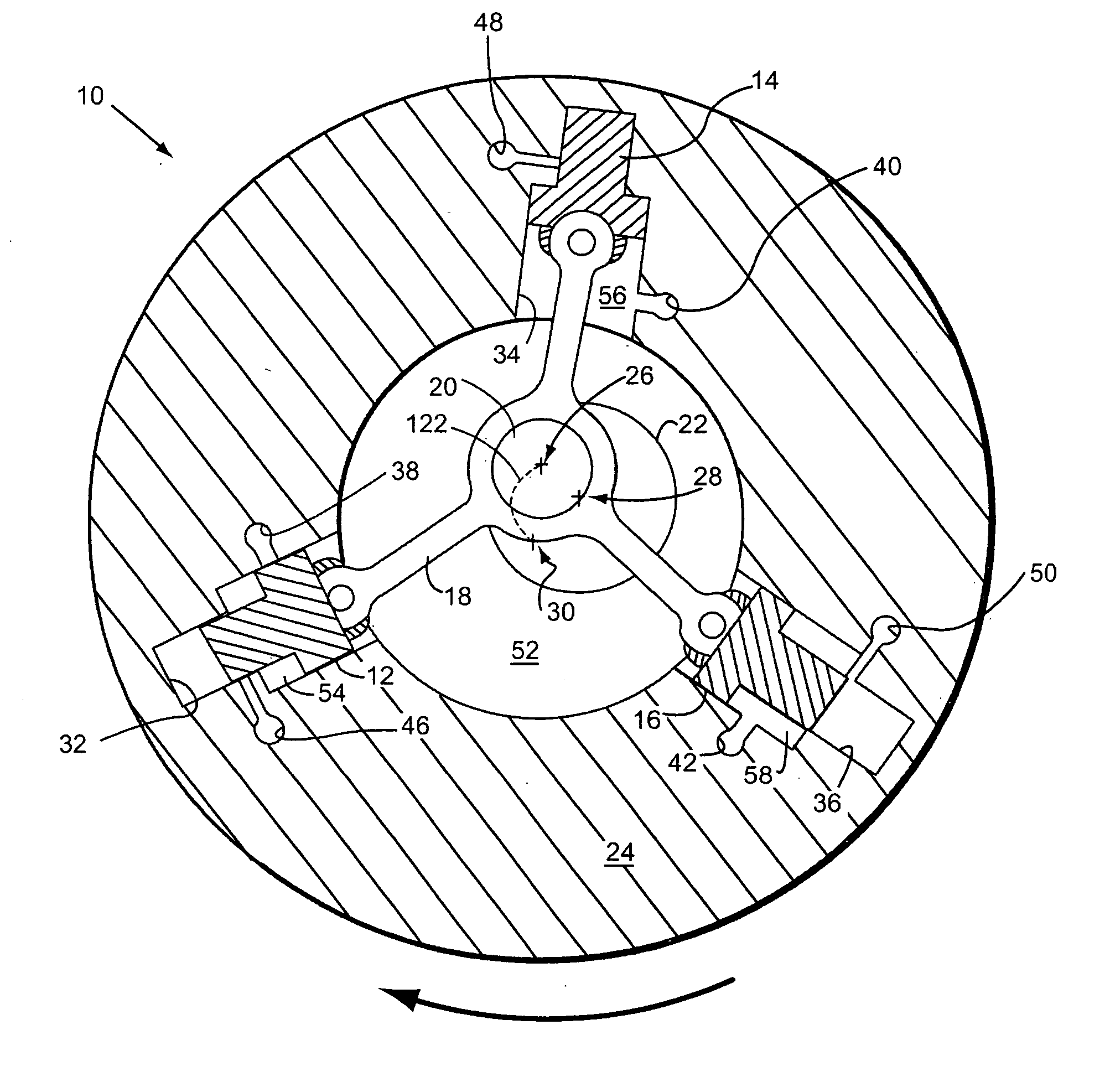

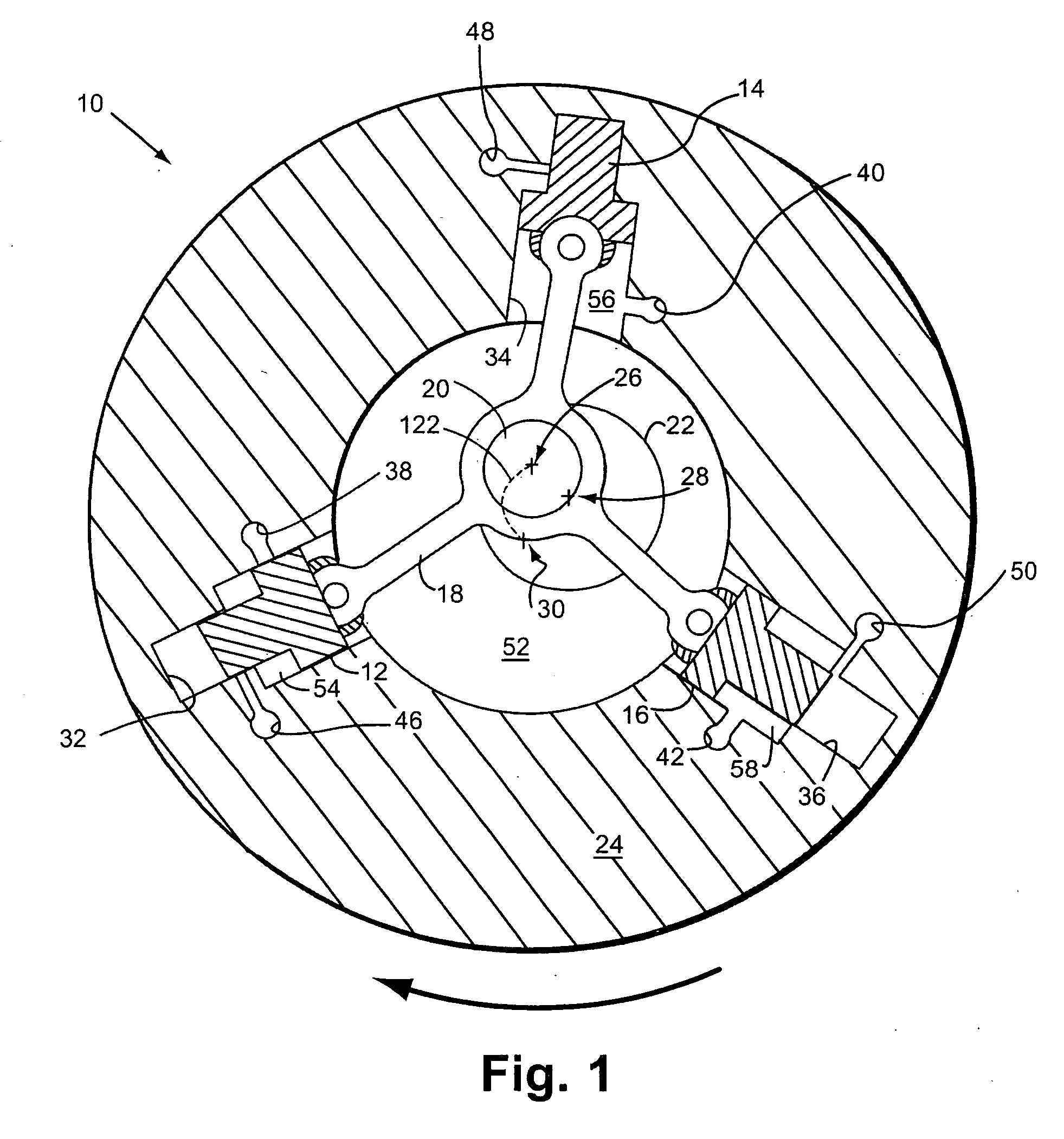

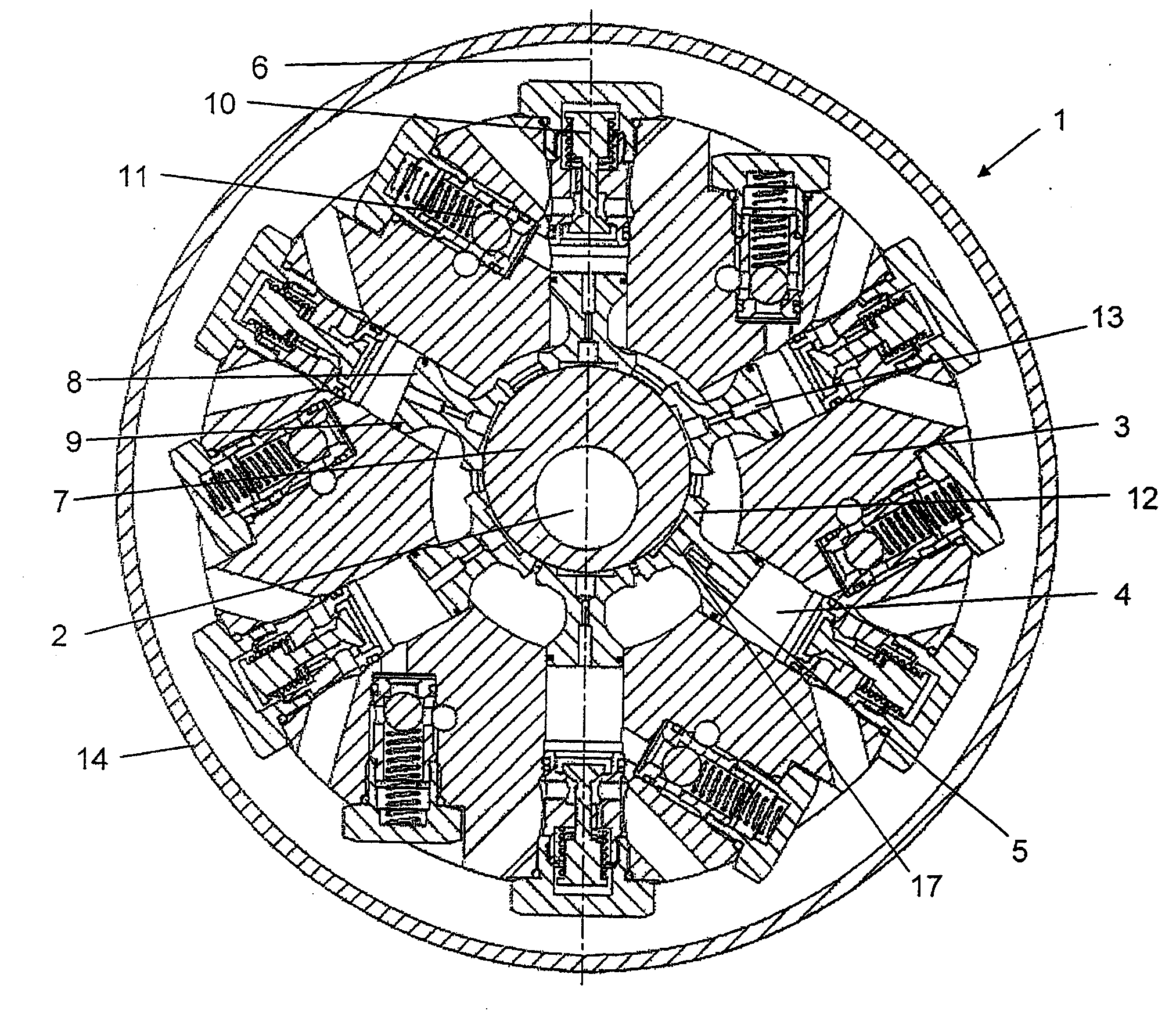

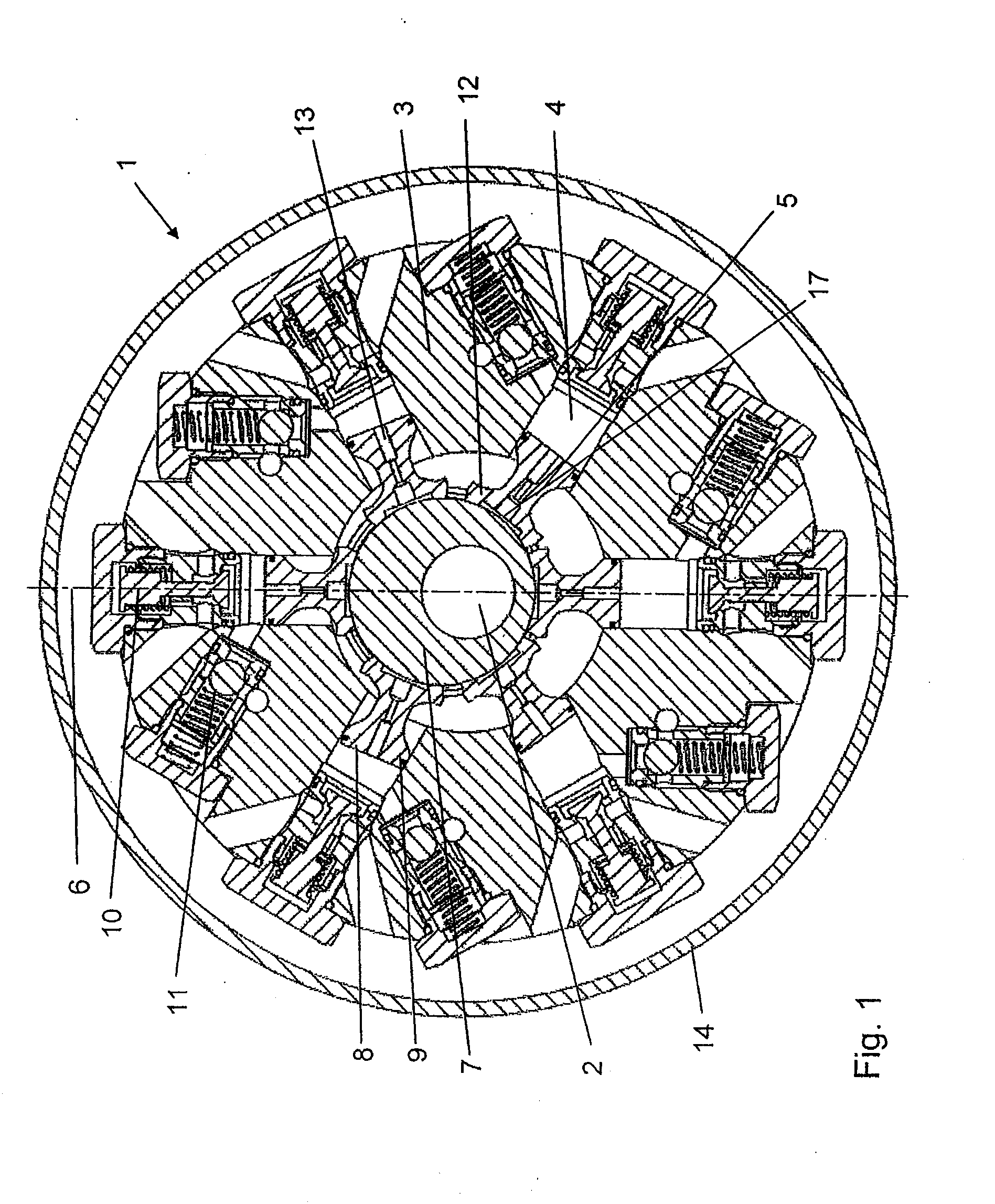

Radial engine power system

InactiveUS20070137595A1Improve efficiencyInternal combustion piston enginesEngines with rotating cylindersFlywheel effectEngineering

A power plant utilizing a radial rotary engine and incorporating onboard energy storage. The engine is of the type utilized in pre-World War I aircraft, but with certain modifications. The energy storage system exploits the flywheel effect inherent in these engines and optionally also includes auxiliary energy storage in other forms, such as compressed air or electrical. Using a continuously variable transmission enables advantageous use of engine inertia in a coast down mode of driving.

Owner:GREENWELL GARY A

Positive-displacement machine

InactiveUS20110041681A1High trafficLarge idle volumePump controlPositive-displacement liquid enginesMechanical engineeringPiston

A hydraulic positive-displacement machine includes at least two radially or axially spaced-apart groups of cylinder-piston units. The cylinders of the primary group can be made to communicate fluidically with cylinders of the secondary group via intermediate valves. At least two intermediate valves can be switched independently of one another.

Owner:ROBERT BOSCH GMBH

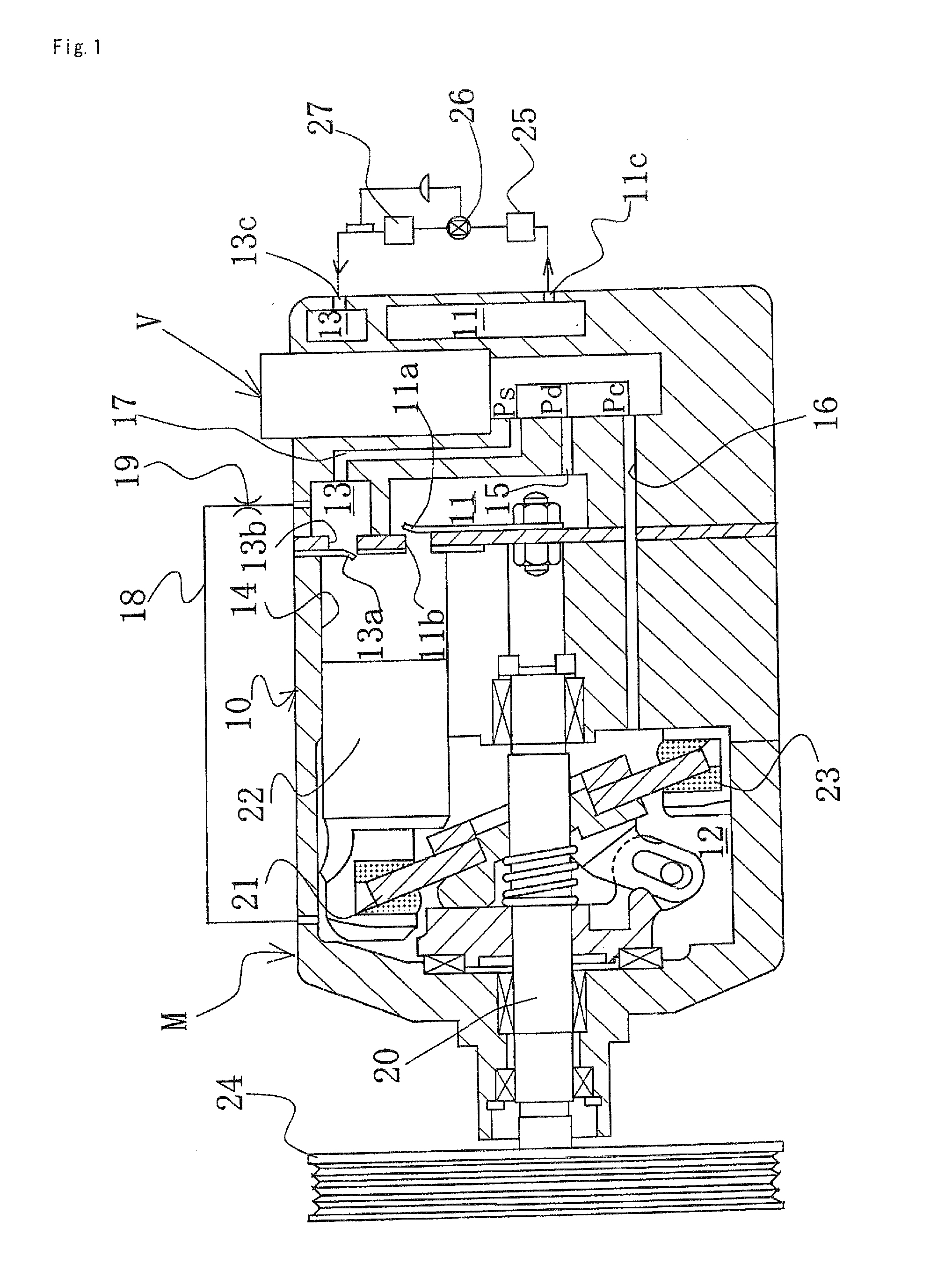

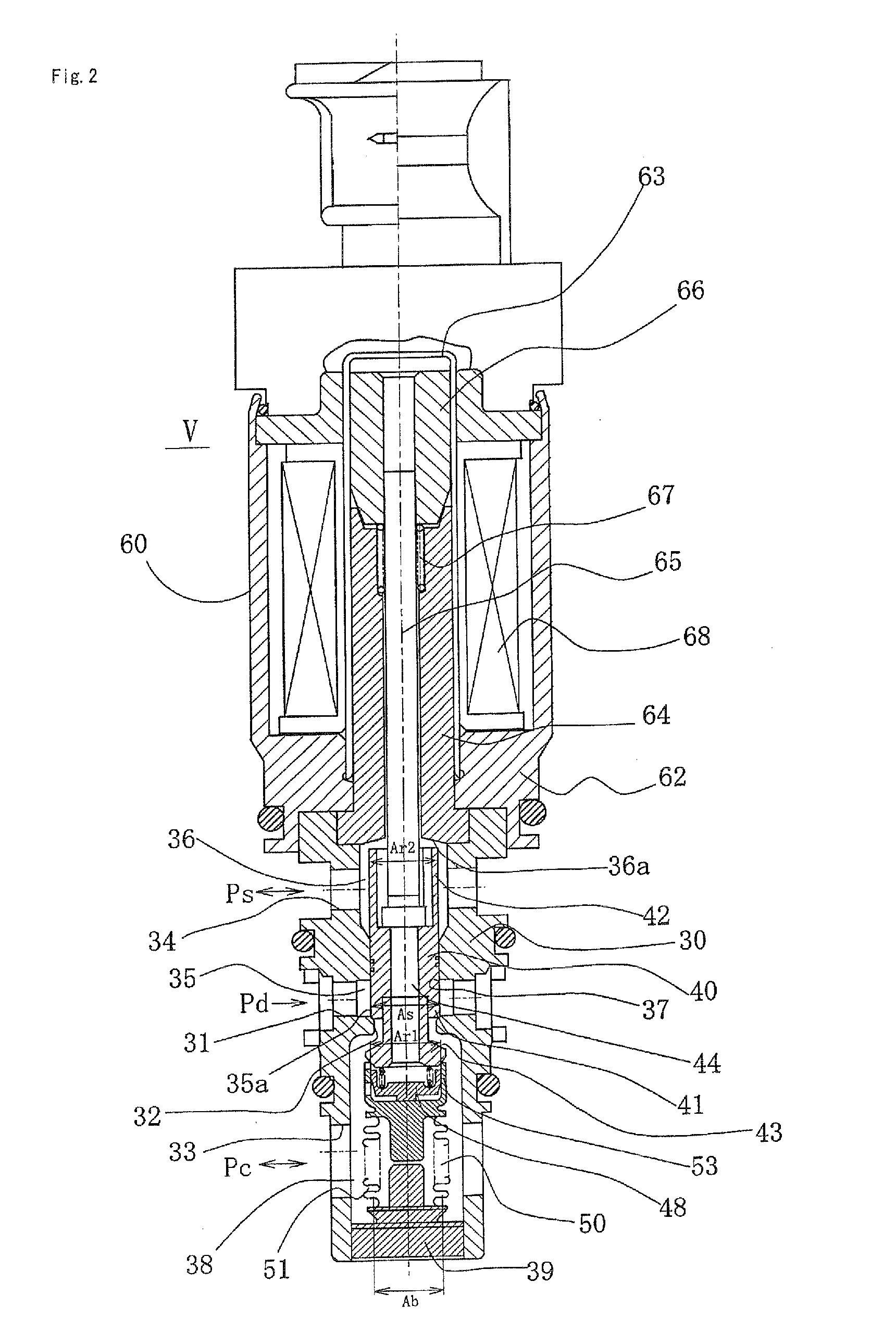

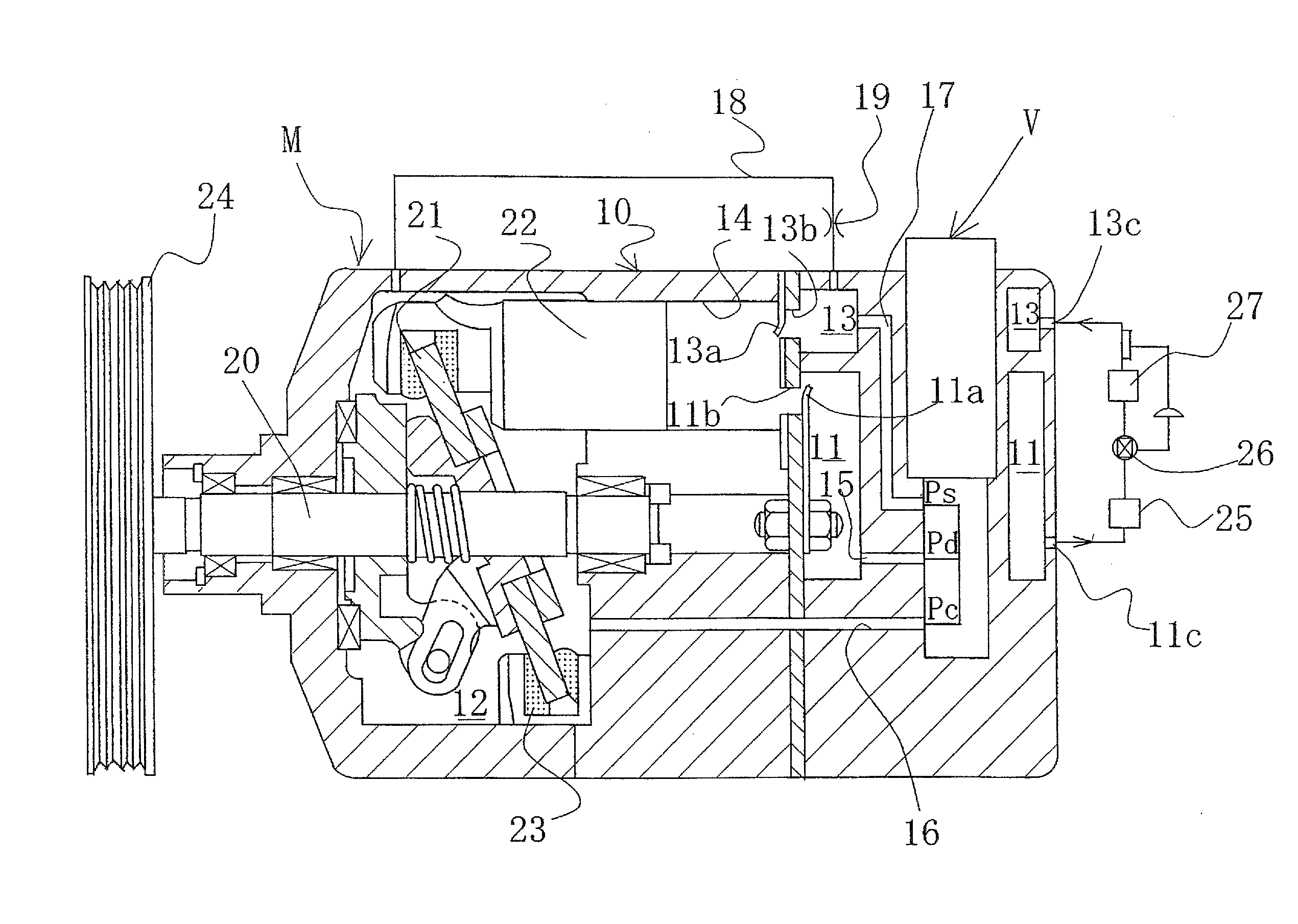

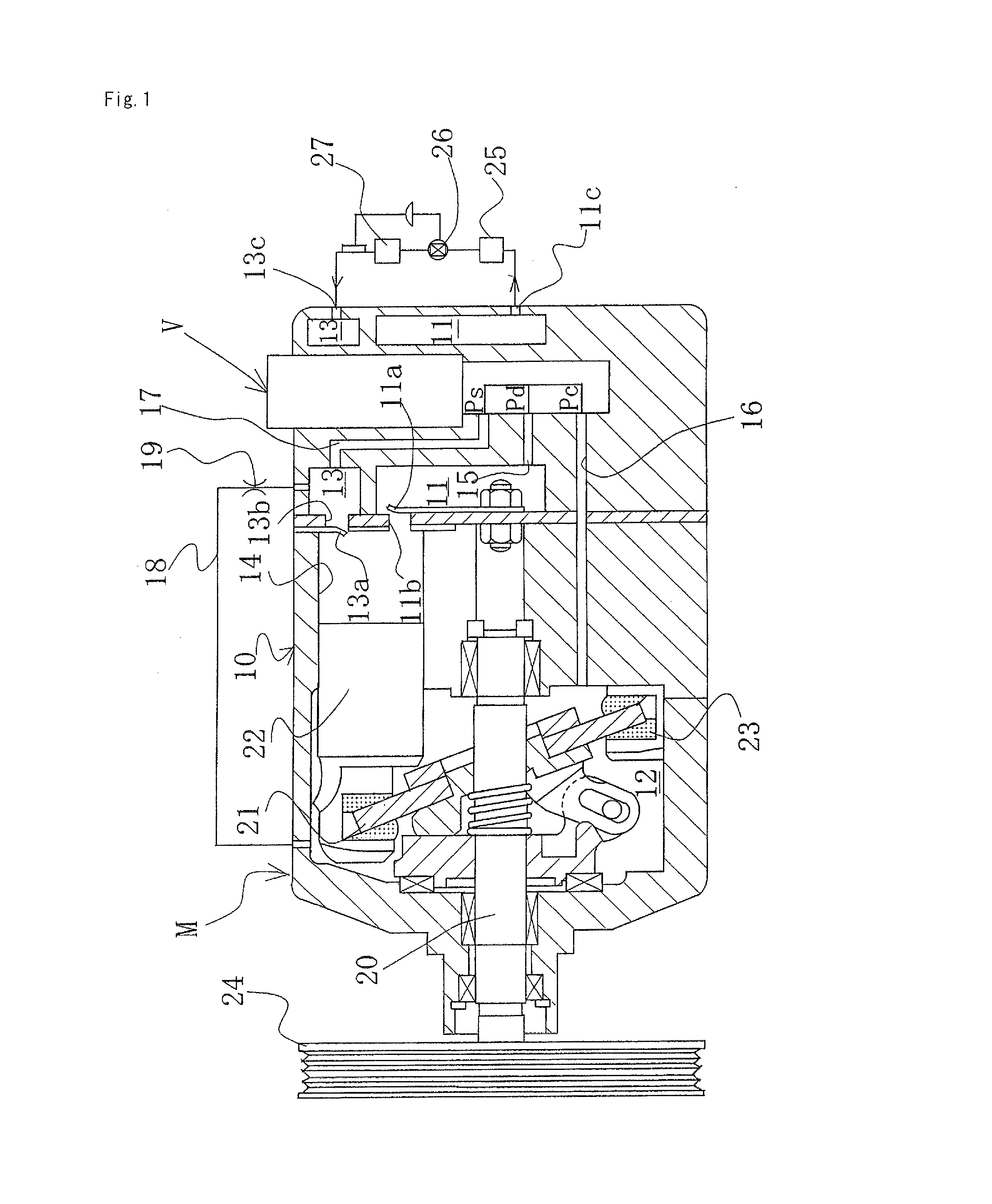

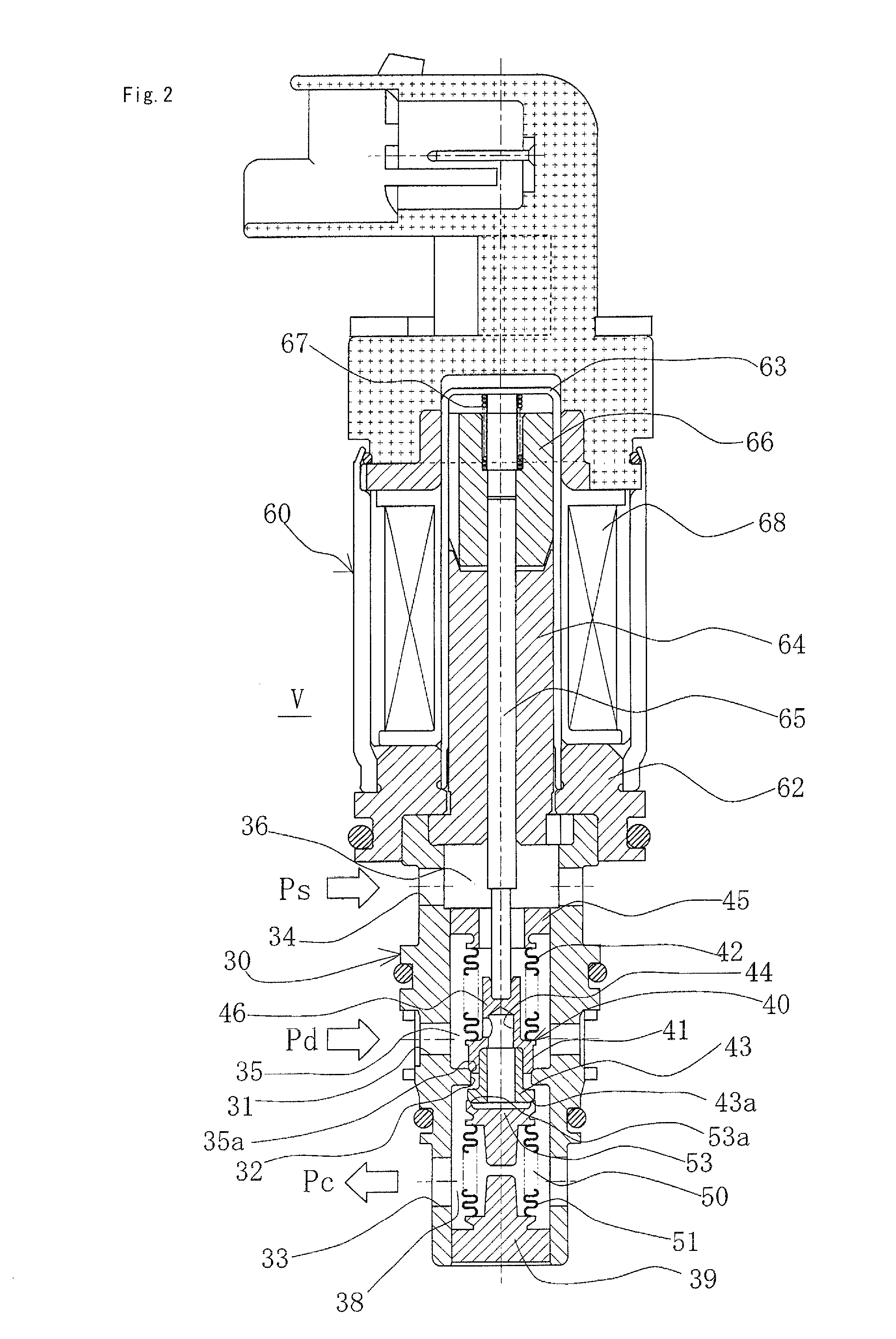

Volume control valve

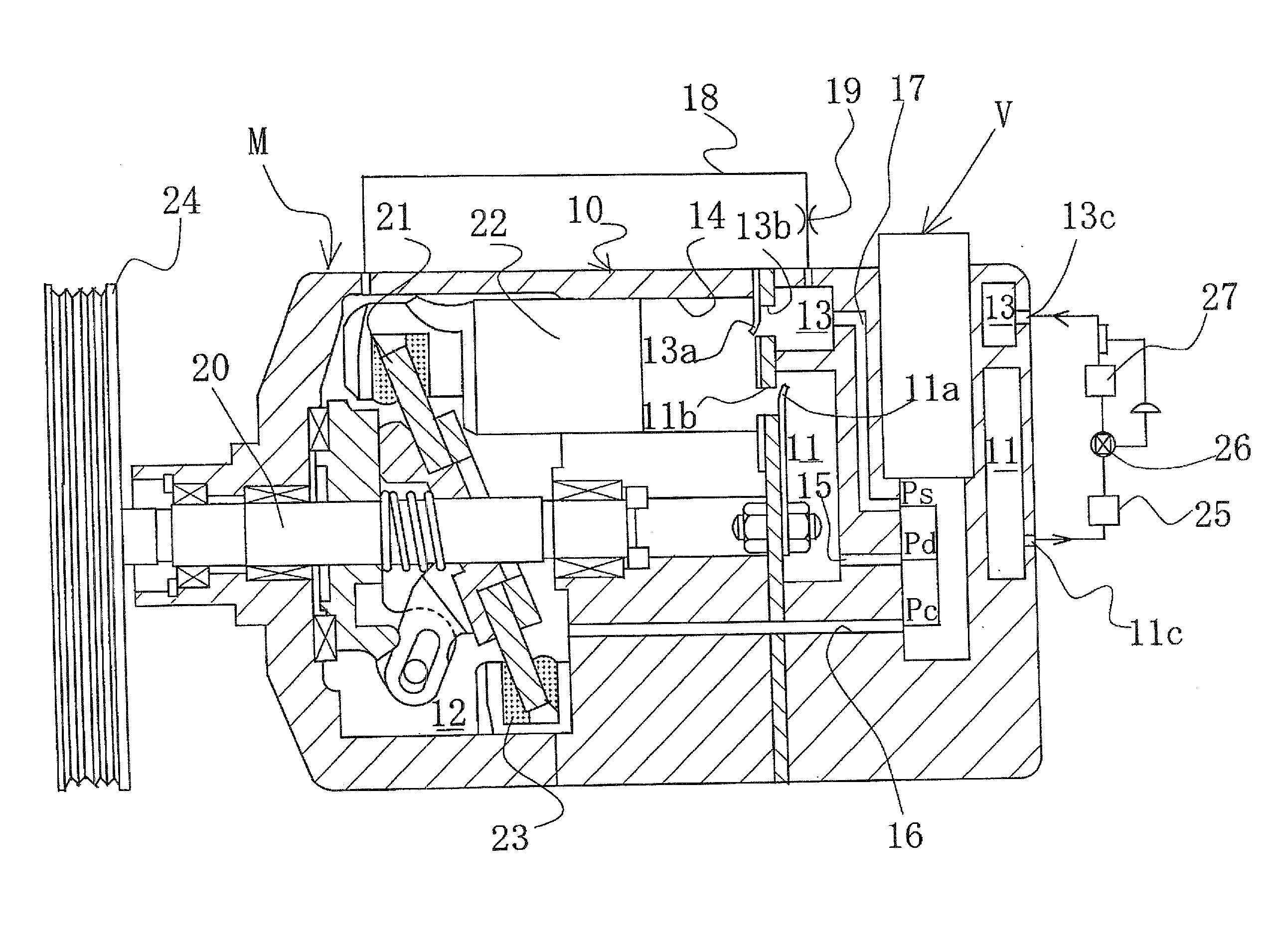

ActiveUS20120198992A1Minimum capacityGood conditionMulti-stage pumpsPositive-displacement liquid enginesControl valvesBearing surface

A capacity control valve capable of enhancing the function of discharging liquid refrigerant in a control chamber during startup of a variable capacity compressor, and improving the control speed of a swash plate during control is provided. The valve has an adapter that has an annular bearing surface and is provided to a free end of a pressure-sensitive body in the elongation and constriction direction, and a valve body for discharging liquid refrigerant, moveably provided inside the adapter. A slit is provided to an engaging part of the adapter with a third valve part, and an introduction hole for causing the control chamber pressure to act on a bottom surface of the valve body for discharging the liquid refrigerant is provided to the base part side, and an urging force is provided whereby the valve body for discharging the liquid refrigerant is urged in a valve-opening direction away from the third valve part.

Owner:EAGLE INDS

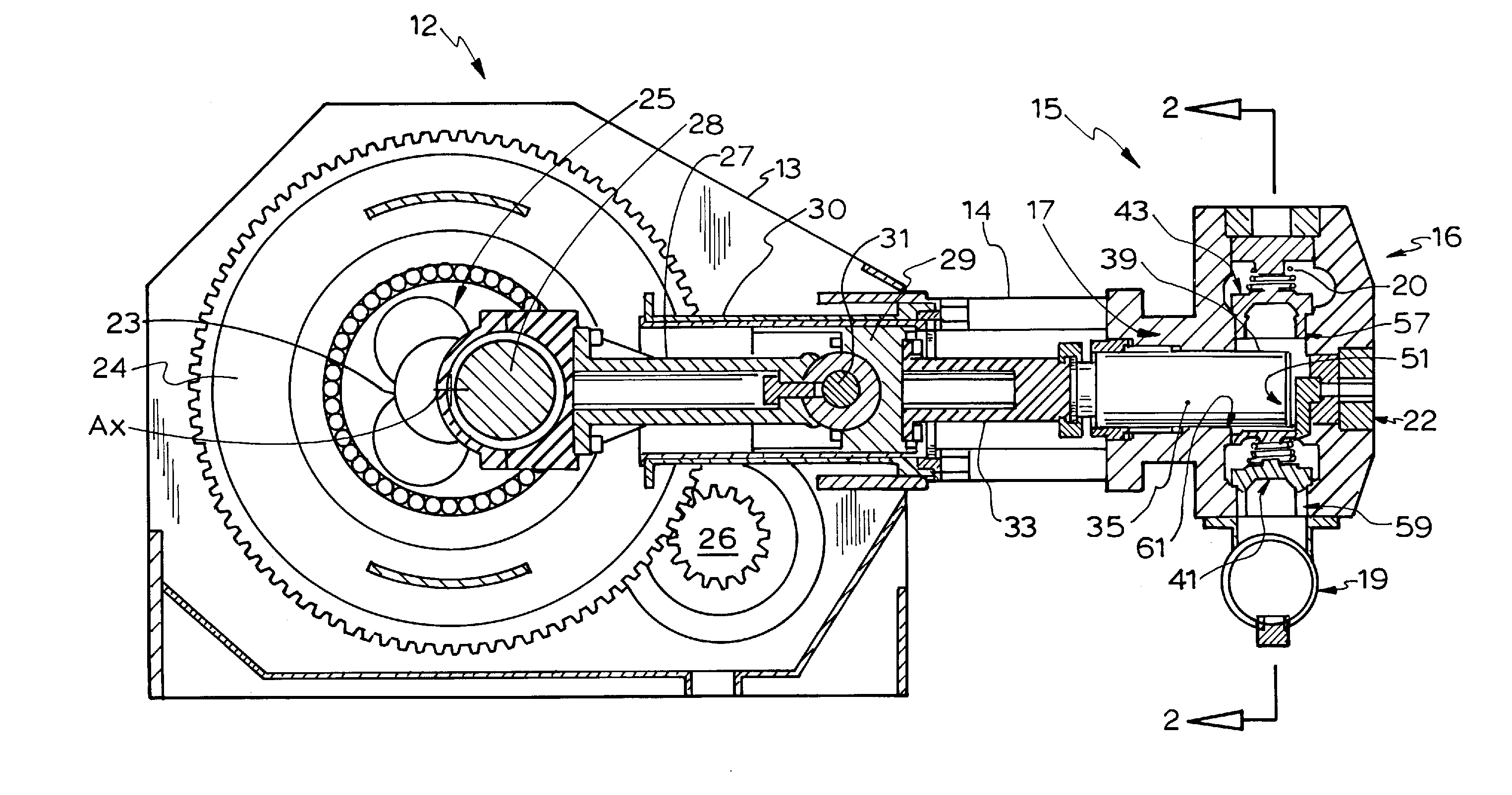

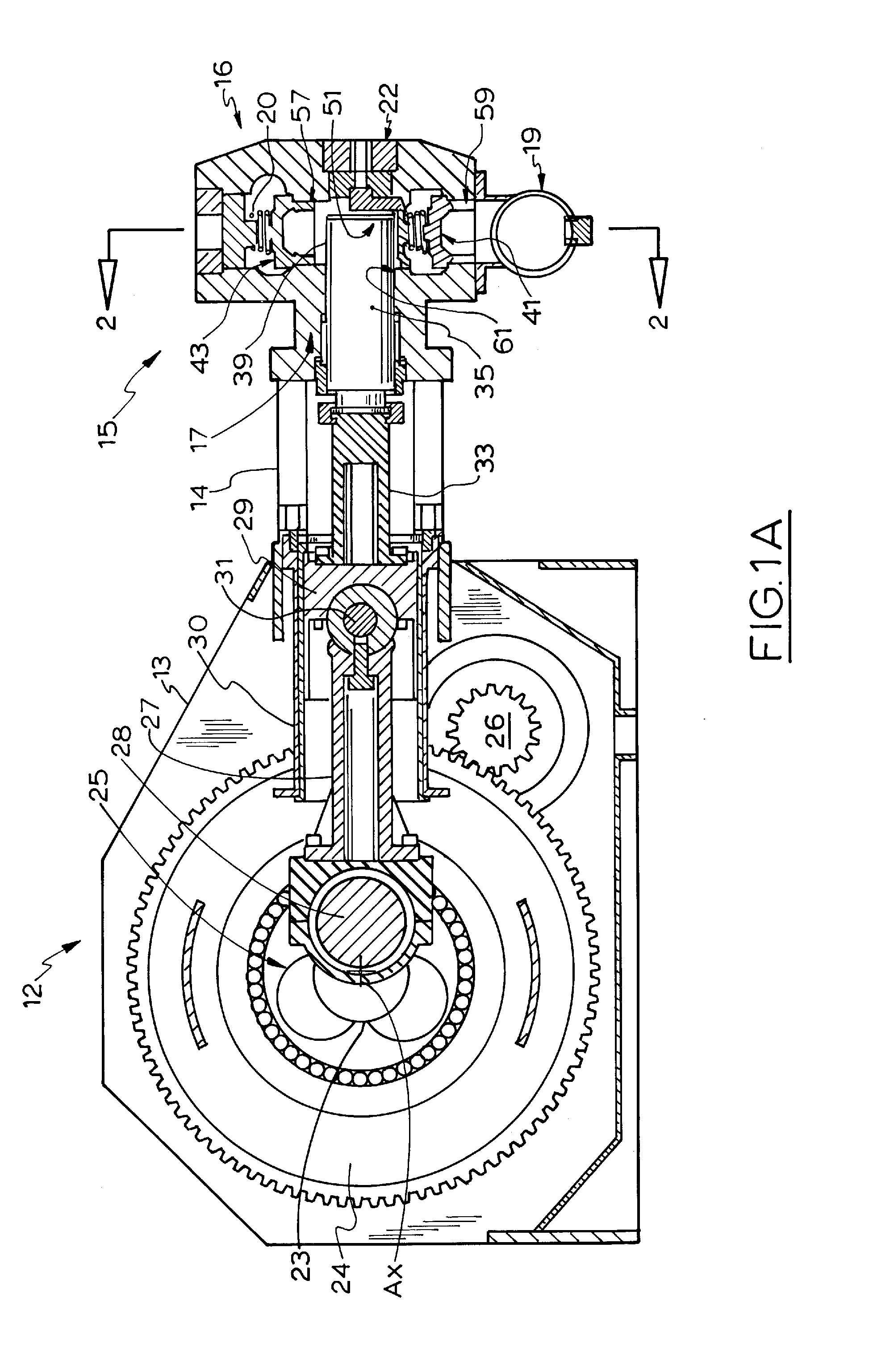

High torque, low velocity, internal combustion engine

ActiveUS7219631B1Increased torque outputReduce eliminateInternal combustion piston enginesGearingAxial displacementGear wheel

An Internal Combustion Engine including a plurality of reciprocating pistons disposed about the periphery of a central housing, and a pair of drive cams responsive to the displacement of the pistons for driving one or more output drive shafts. A piston rod cross member engages cam raceways of a pair of drive cams. Each raceway comprises a plurality of lobes defining power and compression stroke surfaces. Axial displacement of the cross member within the raceway effects rotation of the drive cams and output drive shafts which are rotational coupled to each drive cam. The drive cams and output drive shafts may rotate in the same or opposite directions, delivering high torque at low rotational speeds and, in one embodiment providing a torque-balanced output. Furthermore, the drive cams may include peripheral teeth for driving a timing gear which is timed relative to the output drive shafts for driving auxiliary equipment.

Owner:ONEILL JAMES LEO

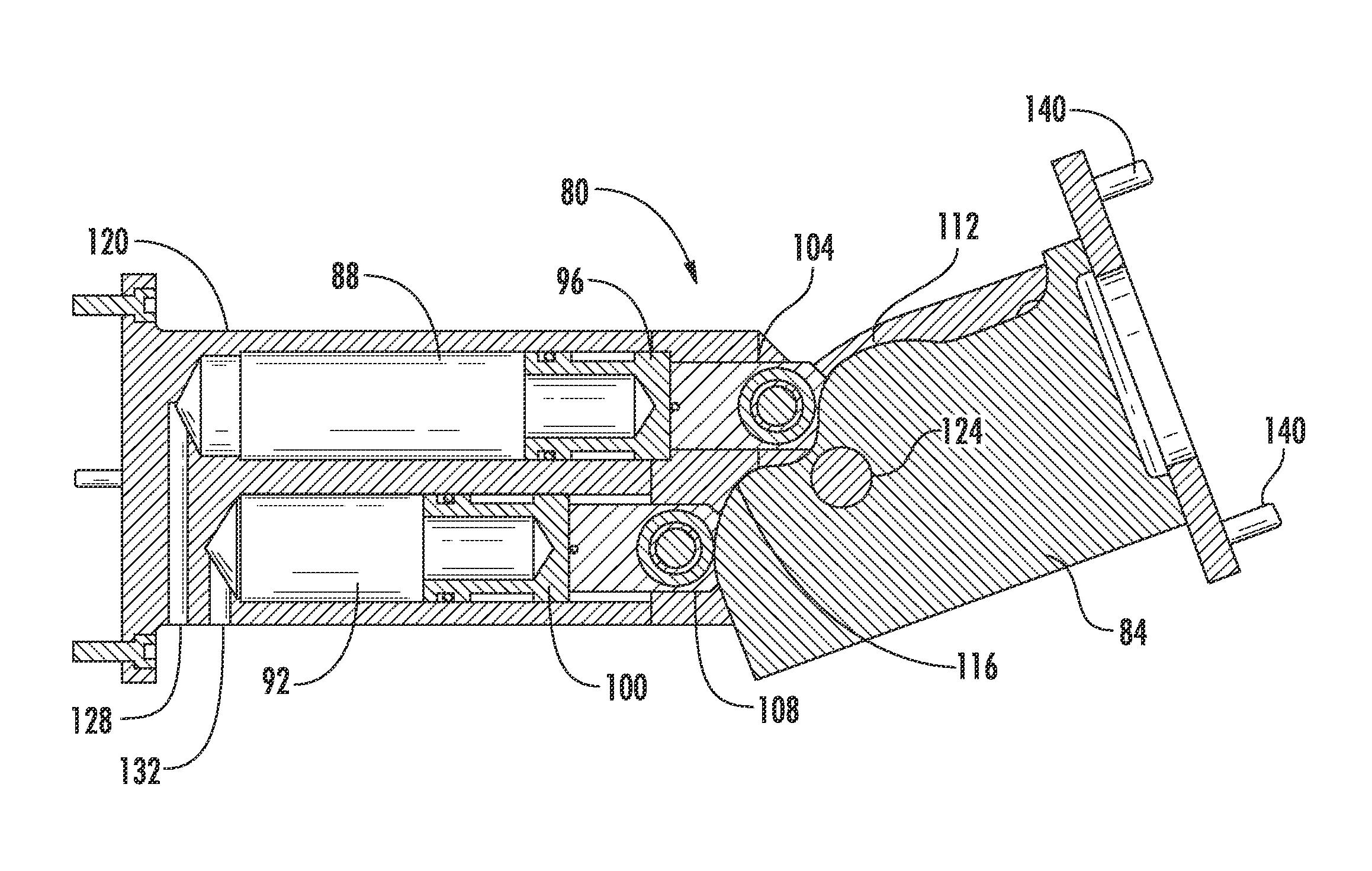

Depth compensated subsea passive heave compensator

ActiveUS20080251980A1Extended maintenance periodGreat spring isolationDrilling rodsDerricks/mastsOcean bottomEngineering

A depth compensated passive eave compensator comprises a first cylinder connected at its upper end to a vessel. A piston rod extends from a piston located within the first cylinder through the lower end thereof and is connected to subsea equipment. A second cylinder contains a compressed gas which maintains pressure beneath the piston of the first cylinder. The upper end of the first cylinder is connected to the upper end of a third cylinder having a piston mounted therein. A piston rod extending from the piston of third cylinder extends through the lower end thereof thereby applying the pressure of the sea to the piston of the third cylinder.

Owner:INTERMOOR

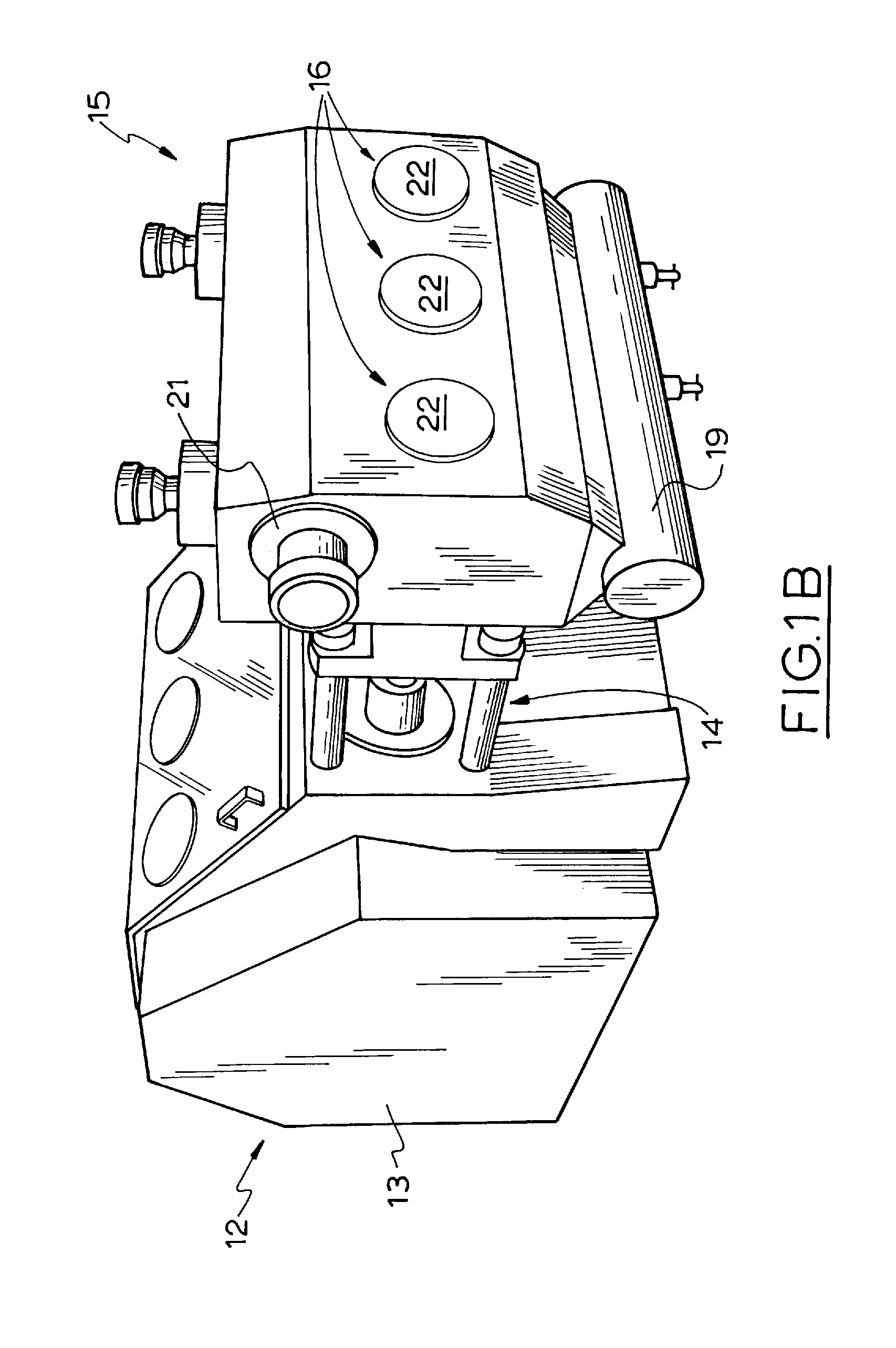

Offset valve bore in a reciprocating pump

InactiveUS20120144995A1Easy maintenanceEasy to manufacturePositive displacement pump componentsFlexible member pumpsEngineeringMechanical engineering

A fluid end 15 for a multiple reciprocating pump assembly 12 comprises at least three plunger bores 61 or 91 each for receiving a reciprocating plunger 35, each plunger bore having a plunger bore axis 65 or 95. Plunger bores being arranged across the fluid head to define a central plunger bore and lateral plunger bores located on either side of the central plunger bore. Fluid end 15 has suction valve bores 59 or 89, each suction valve bore receiving a suction valve 41 and having a suction valve bore axis 63 or 93. Discharge valve bores 57 or 87, each discharge valve bore receiving a discharge valve 43 and having a discharge valve bore axis 63 or 93. The axes of at least one of suction and discharge valve bores is inwardly offset in the fluid end from its respective plunger bore axis.

Owner:S P M FLOW CONTROL

Hydraulic apparatus with direct torque control

A hydraulic apparatus has a cam body rotatable about an axis and with at least two mirror image involute cam surfaces on opposing sides of the axis. Hydraulic actuators on opposing sides of the axis have a linearly extendable ram and a hydraulic cylinder. A fluid supply line is provided for delivering a pressurized fluid equally to each of the cylinders. A pressure relief or flow control valve is associated with each of the hydraulic cylinders and is operable to selectively assume a closed position to retain fluid or assume an open position to release fluid from the hydraulic cylinders. A control can operate the pressure relief valves between at least the closed and open positions, to move the rams out of and in to the cylinders to rotate the cam body about the axis with controlled torque. A robotic, prosthetic or orthotic and a method for applying torque to a body are also disclosed.

Owner:UT BATTELLE LLC

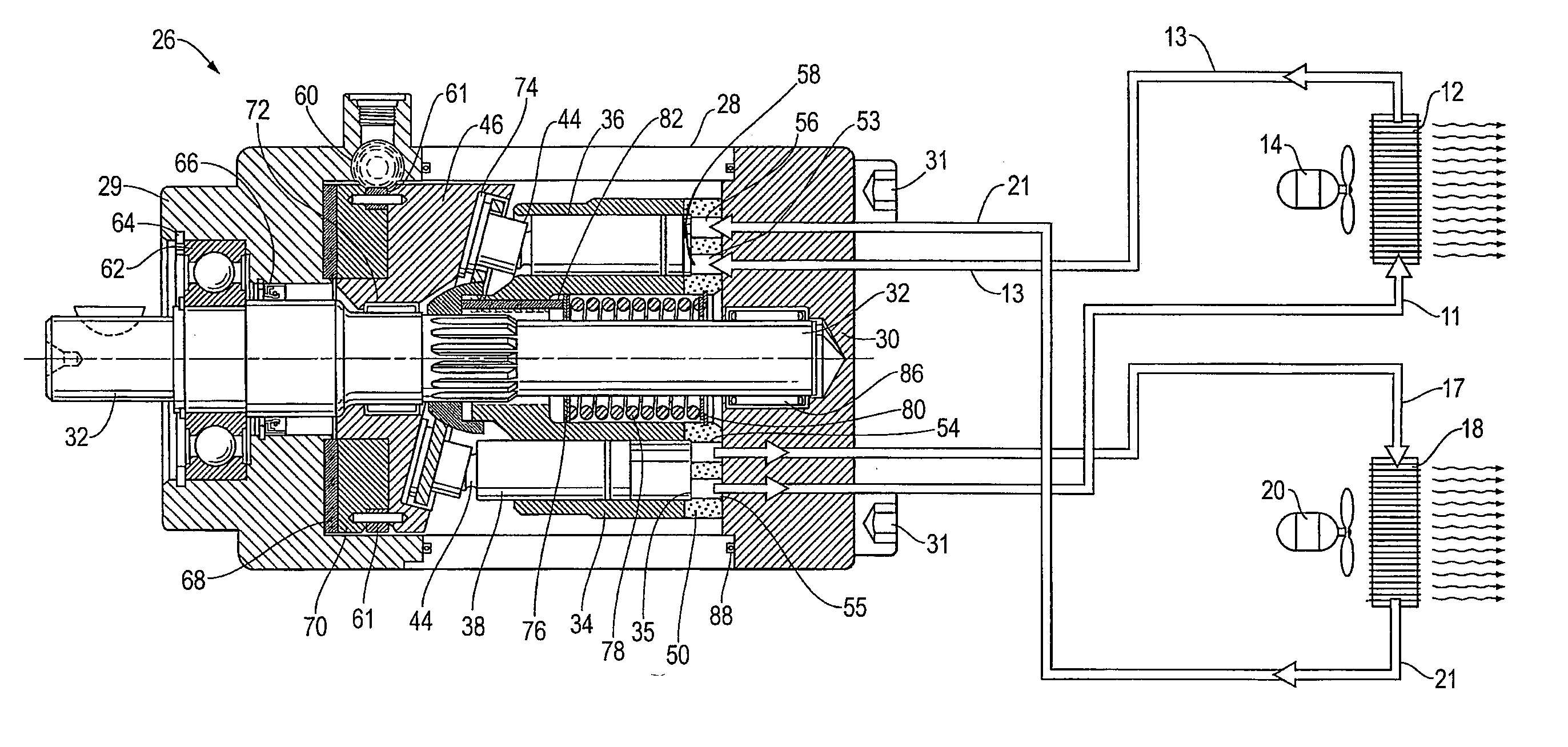

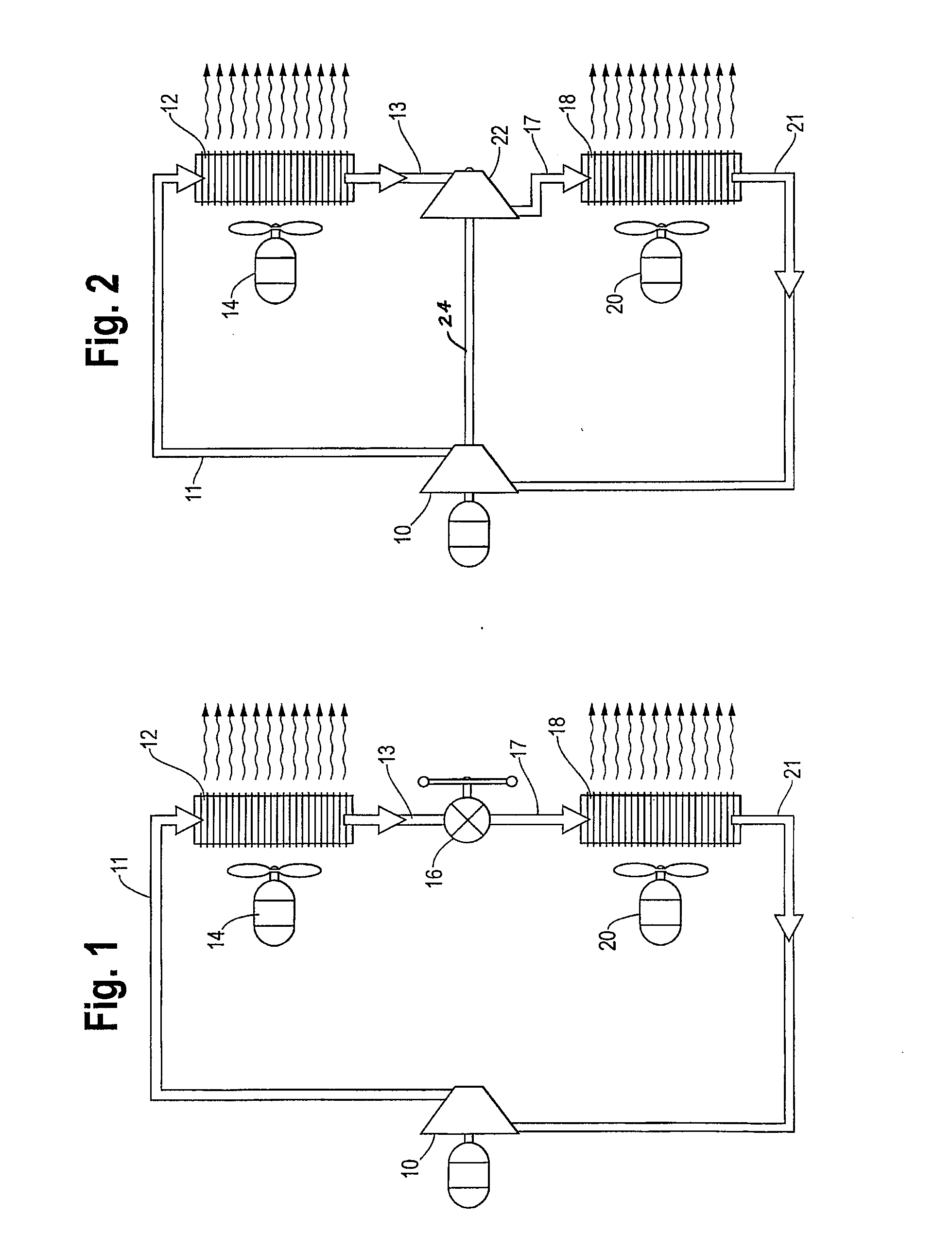

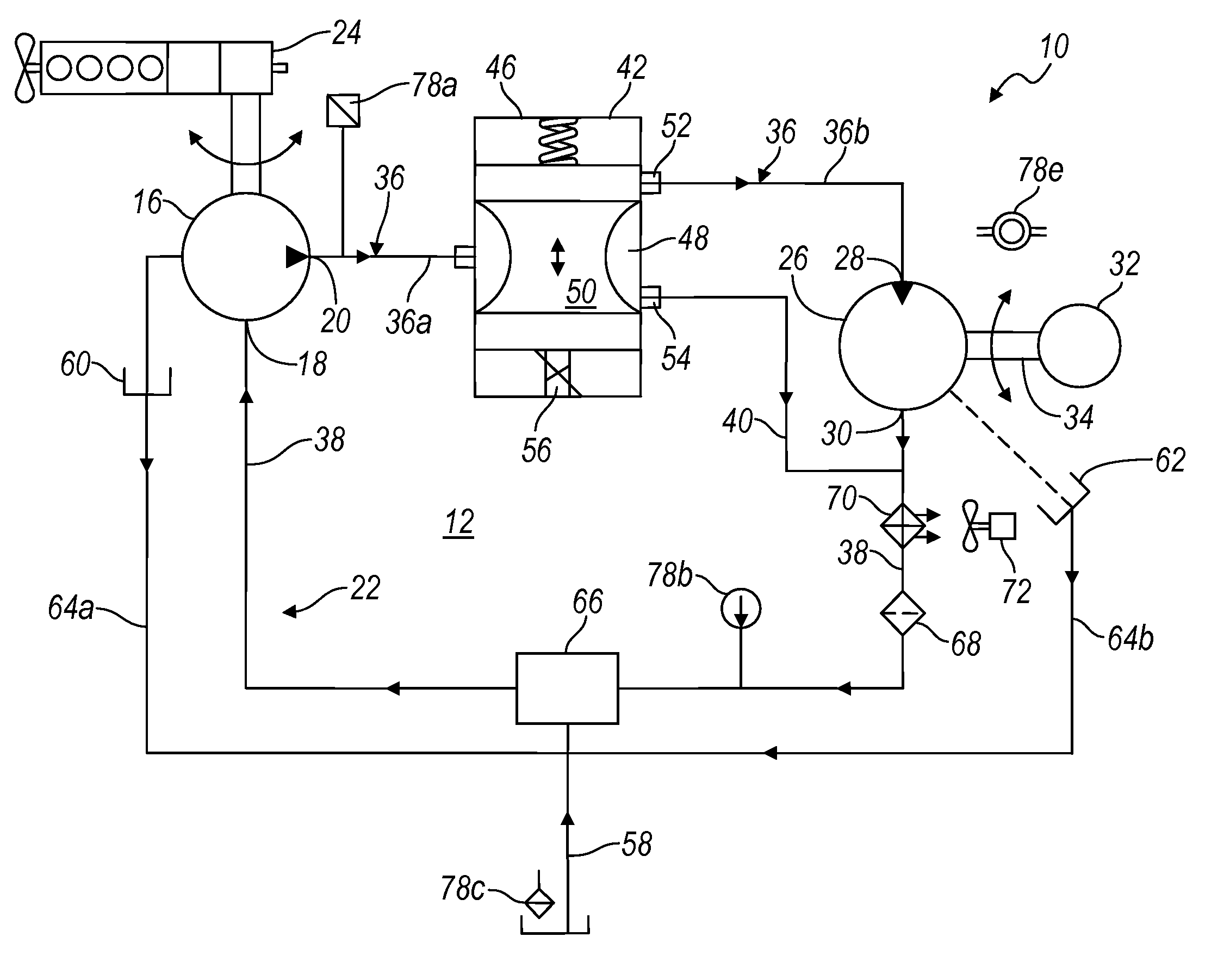

Integrated compressor/expansion engine

InactiveUS20090249826A1Retaining compressor compactnessRetaining configurationDomestic cooling apparatusCompression machines with non-reversible cycleDrive shaftHigh pressure

A multi cylinder compressor / expansion engine having a centrally mounted drive shaft. A cylinder barrel is mounted on the drive shaft and both the cylinder barrel and the drive shaft rotate about a common axis. There is a plurality of cylinders in the cylinder barrel with pistons disposed in each of the cylinders. Some of the cylinders are compression cylinders and some of the cylinders are expansion cylinders. The compression cylinders discharge a fluid at a first high pressure from the engine. The expansion cylinders receive fluid at a second pressure which provides energy to the engine thereby reducing the energy required for the engine to rotate the drive shaft.

Owner:WHITEMOSS

CO2 compressor

InactiveUS6129532ASmall sizeStable, reliable lubricant supply unitRotary/oscillating piston combinations for elastic fluidsCompressorForeign matterDifferential pressure

A CO2 compressor is disclosed for forcing and moving a lubricant under discharge pressure. If the oil path is reduced in size or a pressure reducing part is inserted to handle the large differential pressure caused between the discharge pressure and the intake pressure, the oil path would become liable to be easily clogged by foreign matter. In view of this, an intermittent oil supply mechanism is formed in the oil path using the sliding contact portion between a fixed member of the compressor body and a movable member. Thus, the substantial lubrication time period is shortened and the amount of oil supplied is limited.

Owner:DENSO CORP

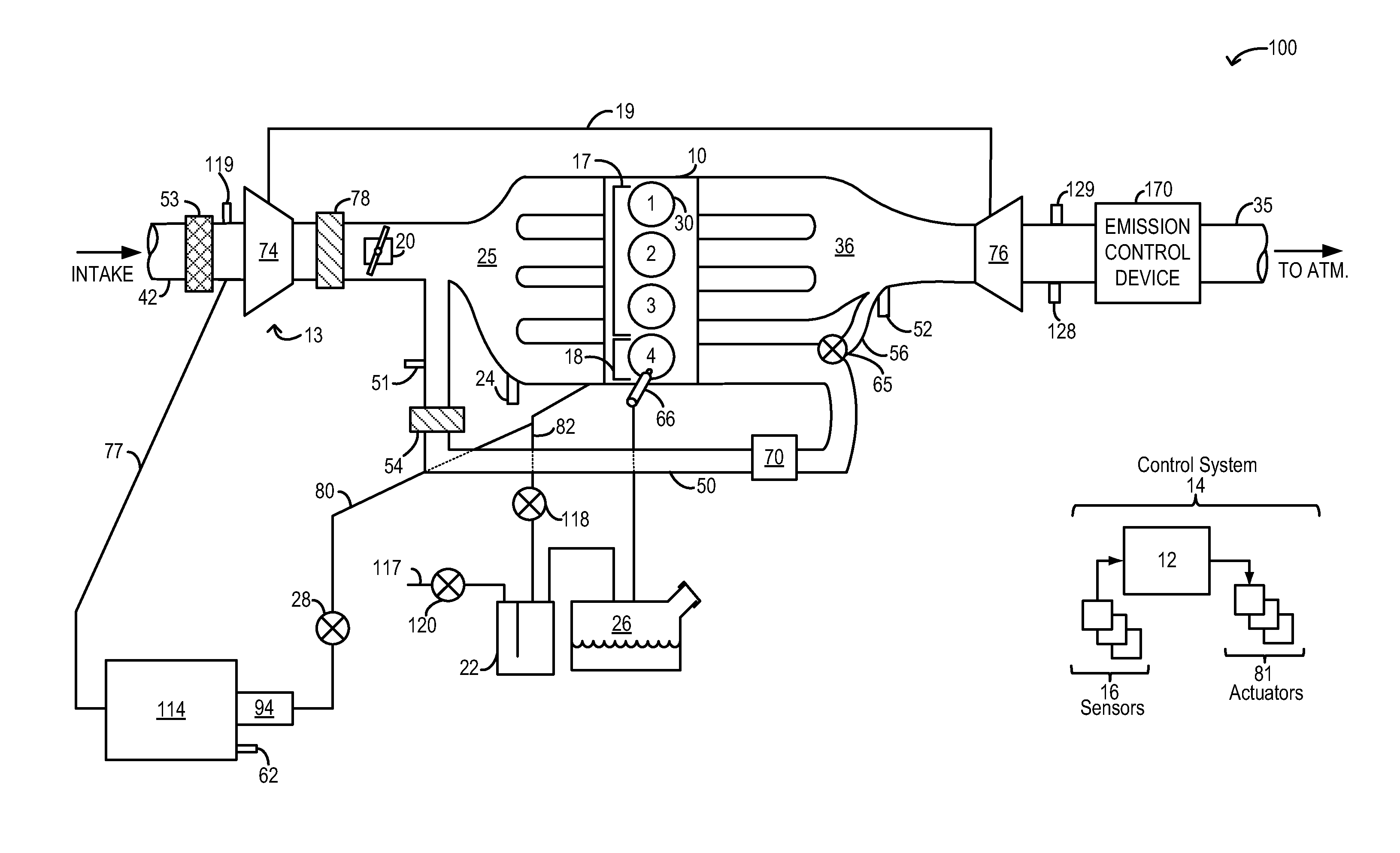

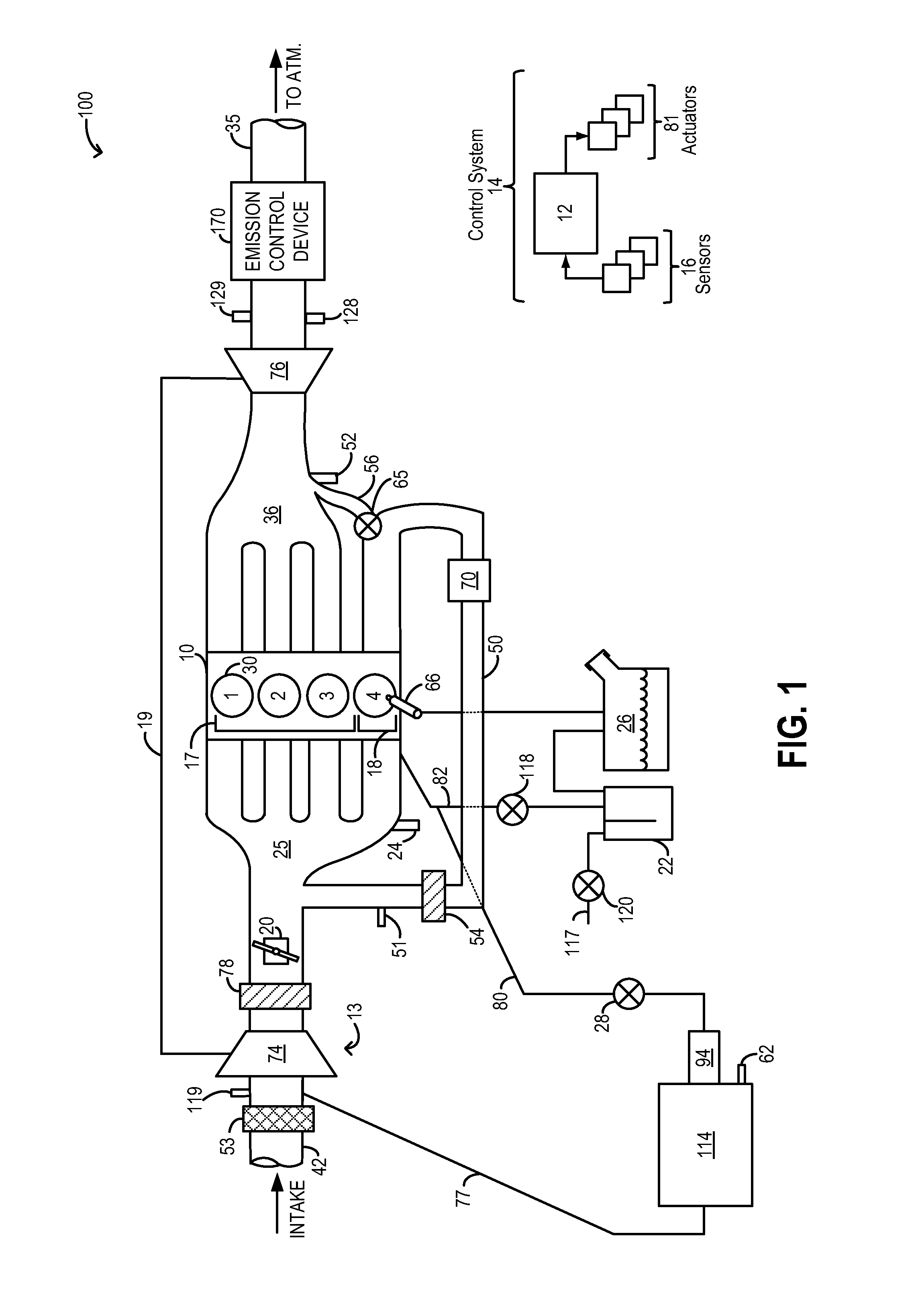

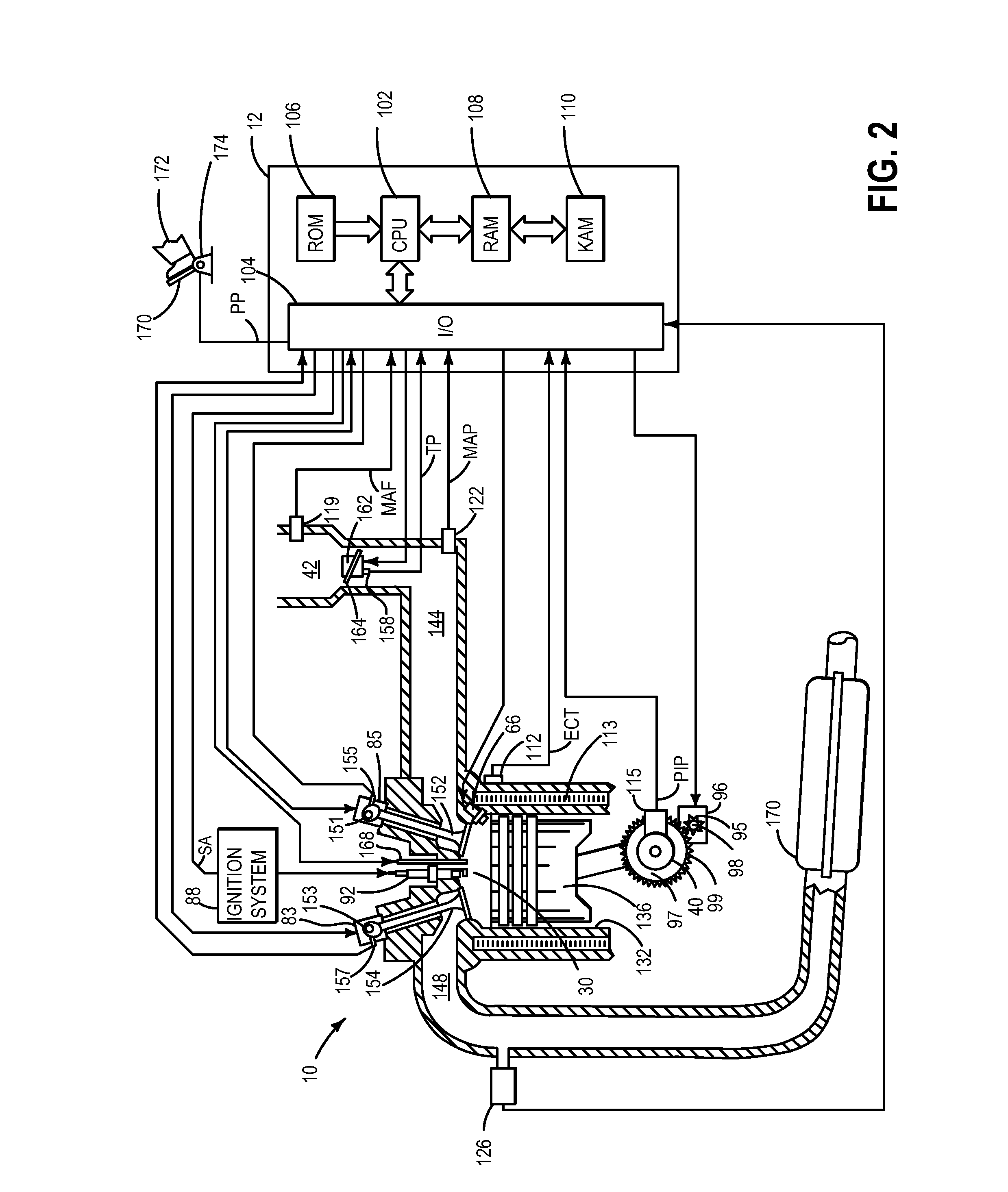

Systems and methods for purge and pcv control

ActiveUS20150337696A1Reliable air-fuel ratio controlImprove toleranceElectrical controlInternal combustion piston enginesEngineeringCrankcase

Methods and systems are provided for improving purge air-fuel ratio control. Fuel vapors from a canister and the crankcase are selectively purged to a group of cylinders and not to remaining engine cylinders. Exhaust is recirculated from the selected group of cylinders to the engine intake wherefrom the EGR is ingested in the remaining engine cylinders and the selected group of cylinders.

Owner:FORD GLOBAL TECH LLC

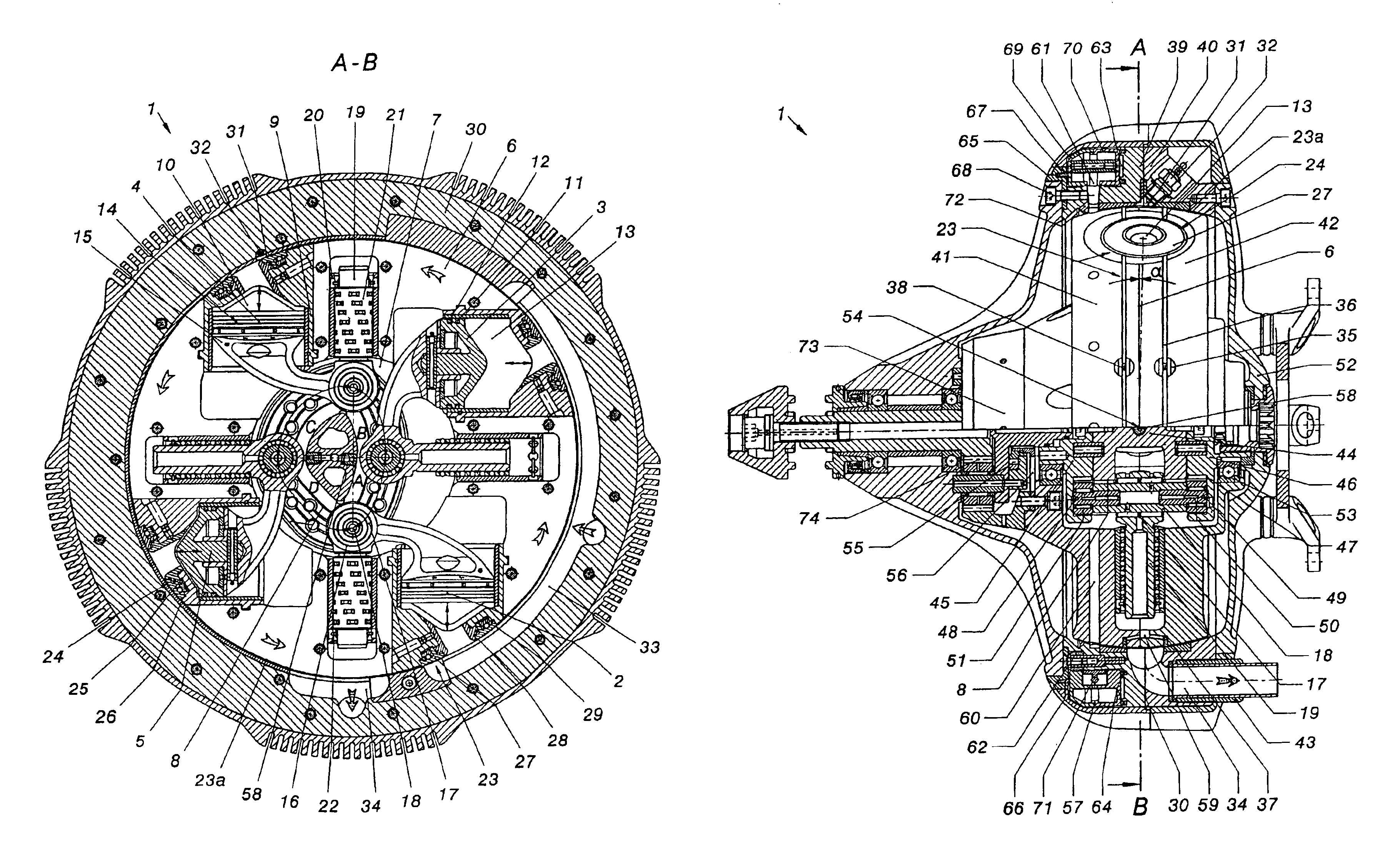

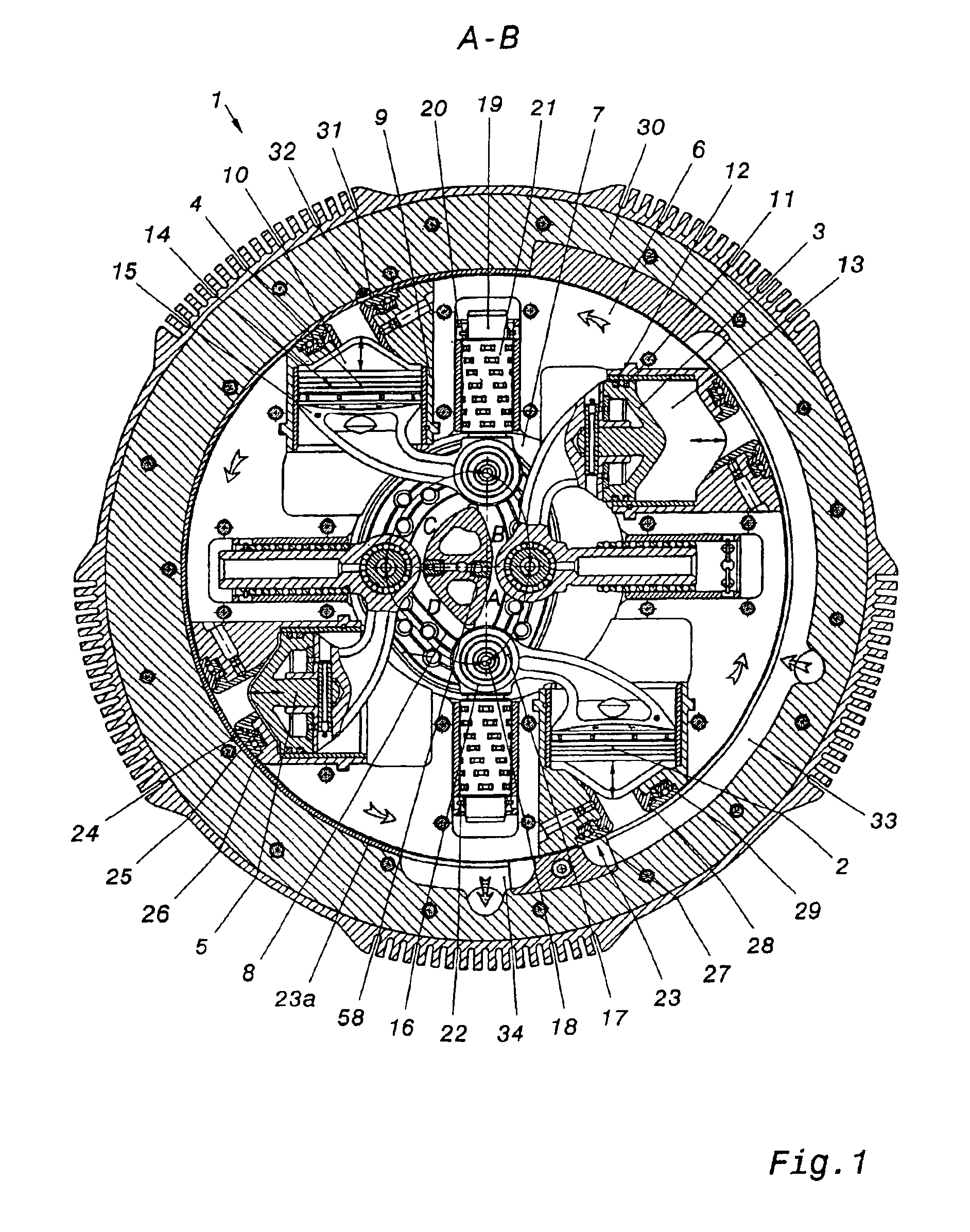

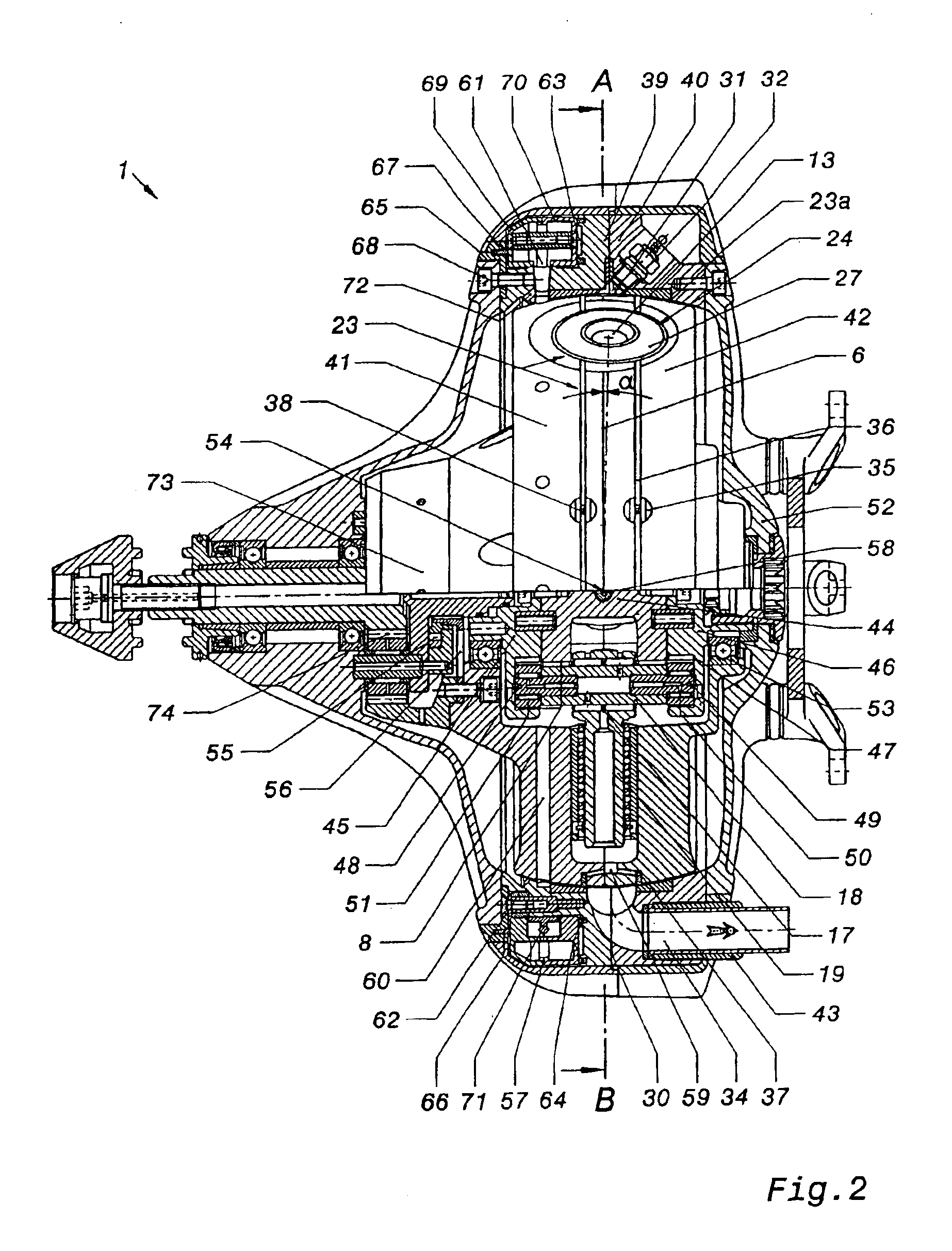

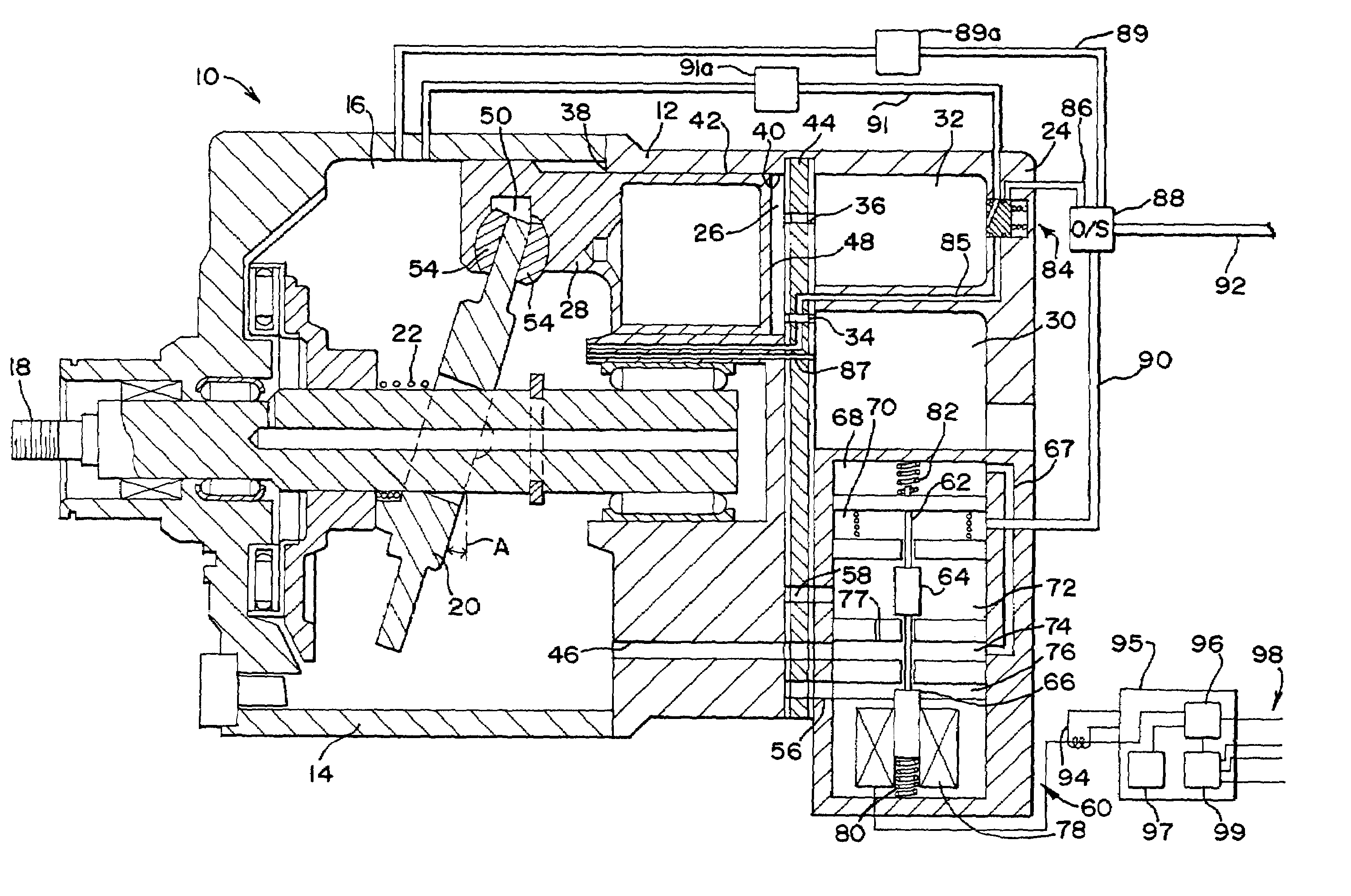

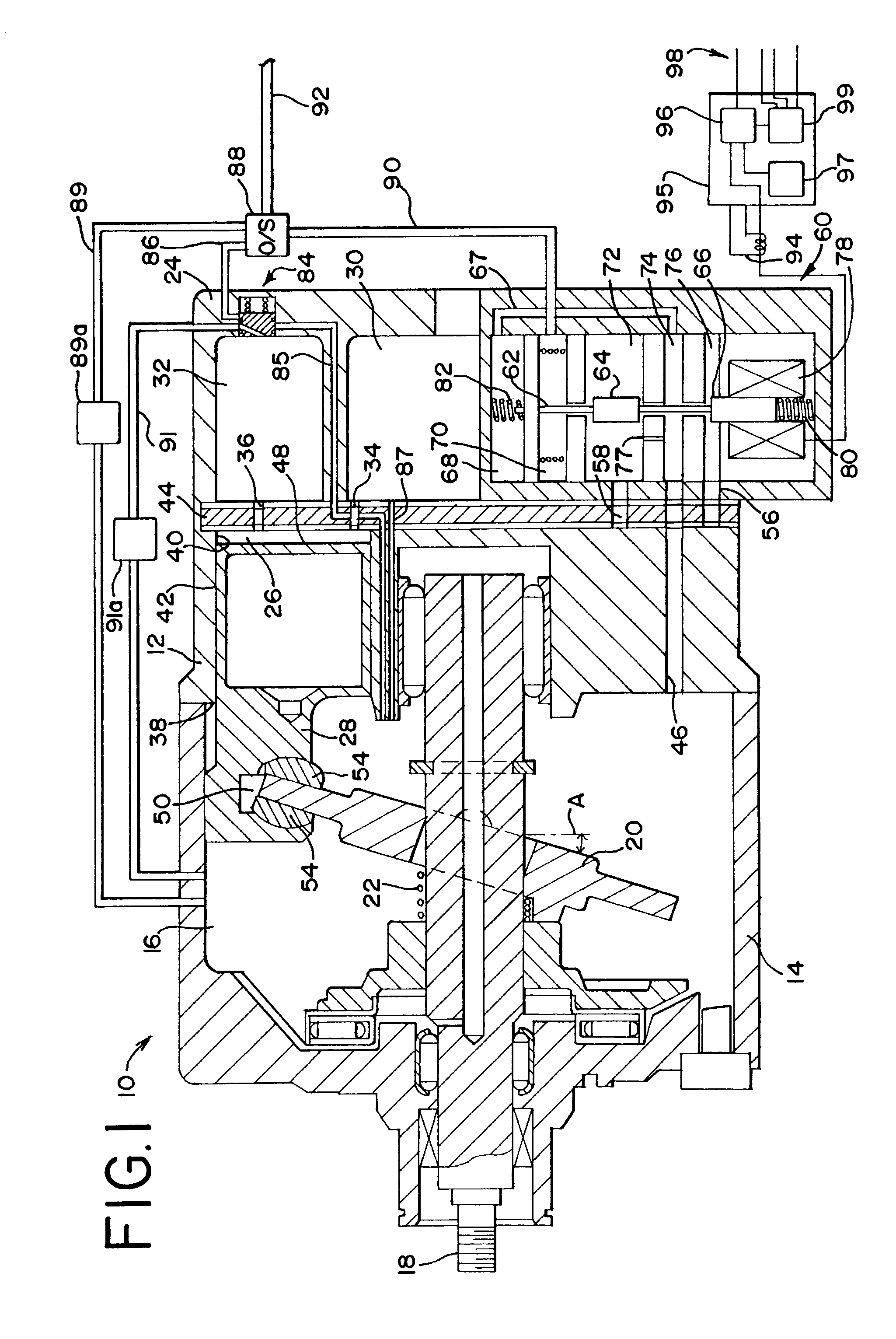

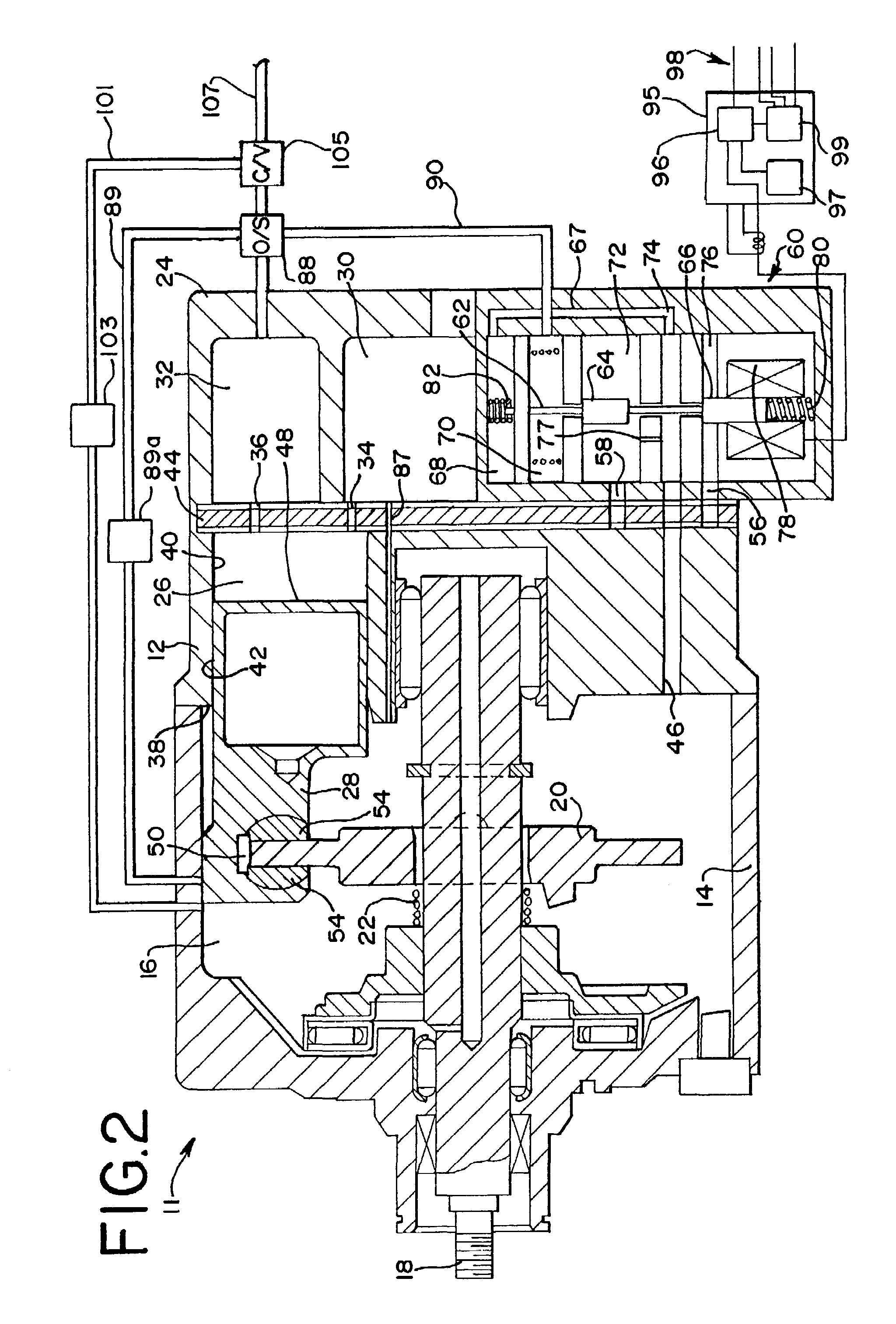

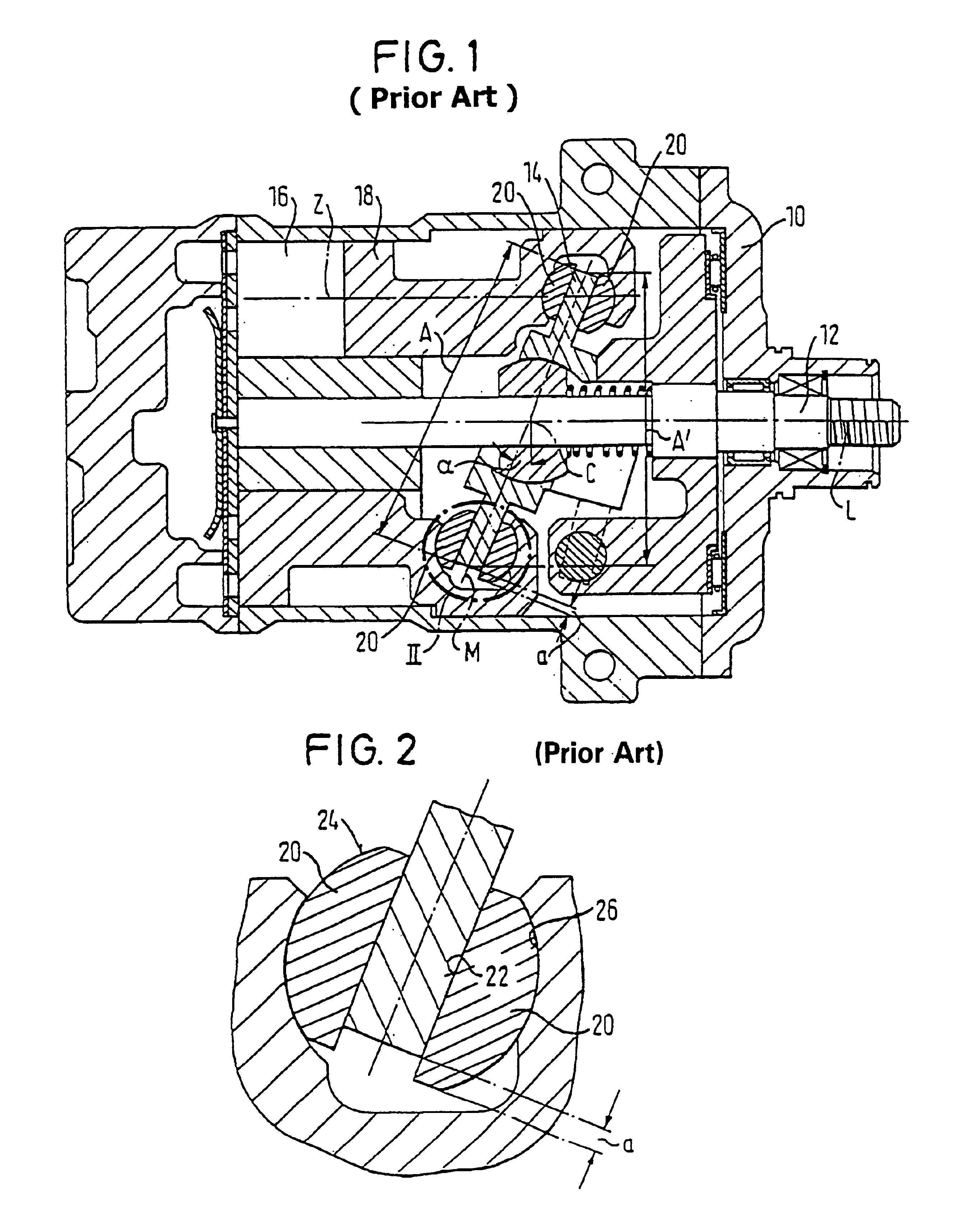

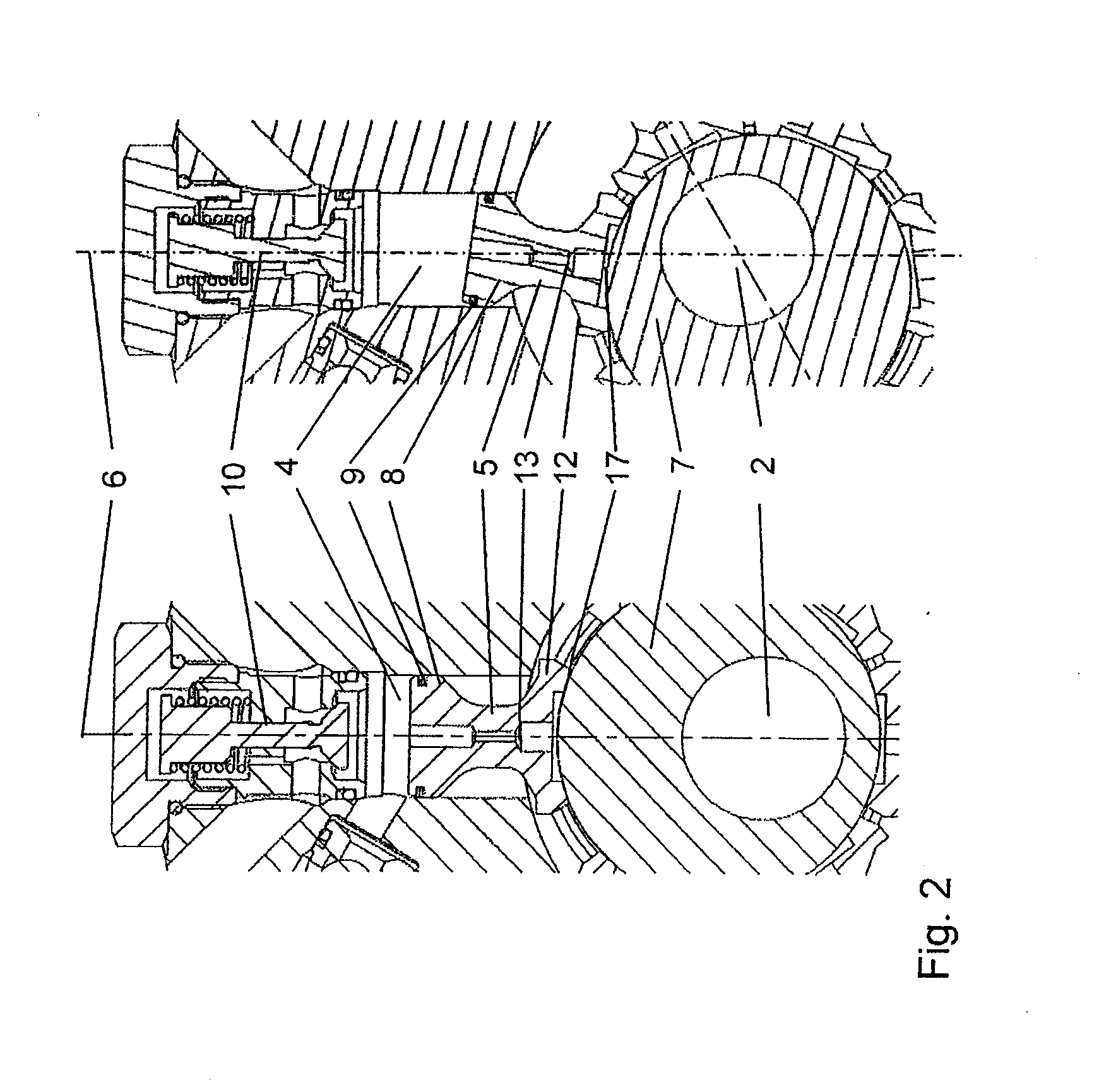

Reciprocating piston engine comprising a rotative cylinder

InactiveUS6928965B2Improve efficiencyRaise the ratioCasingsInternal combustion piston enginesLine of actionMotion transfer

A reciprocating piston engine includes a rotor housing for transferring torque to an engine output drive; a contoured guide element in the rotor housing, having a closed, curvilinearly contoured shape, around which the rotor housing is rotatable; at least one compression unit in the rotor housing, each unit including a piston and a cylinder, with the piston having a straight line of action in a plane perpendicular to the axis of rotation of the rotor housing; a connecting rod, rigidly coupled to the piston, movable along a path determined by the contoured guide element, for transferring controlled movement specified by the contoured guide element to the piston; and a guide part, joined to the connecting rod, and movable along a separate guide in the rotor housing, with the connecting rod, the piston, and the guide part each performing a single stroke along a straight line in the rotor housing.

Owner:TEUFL ERICH

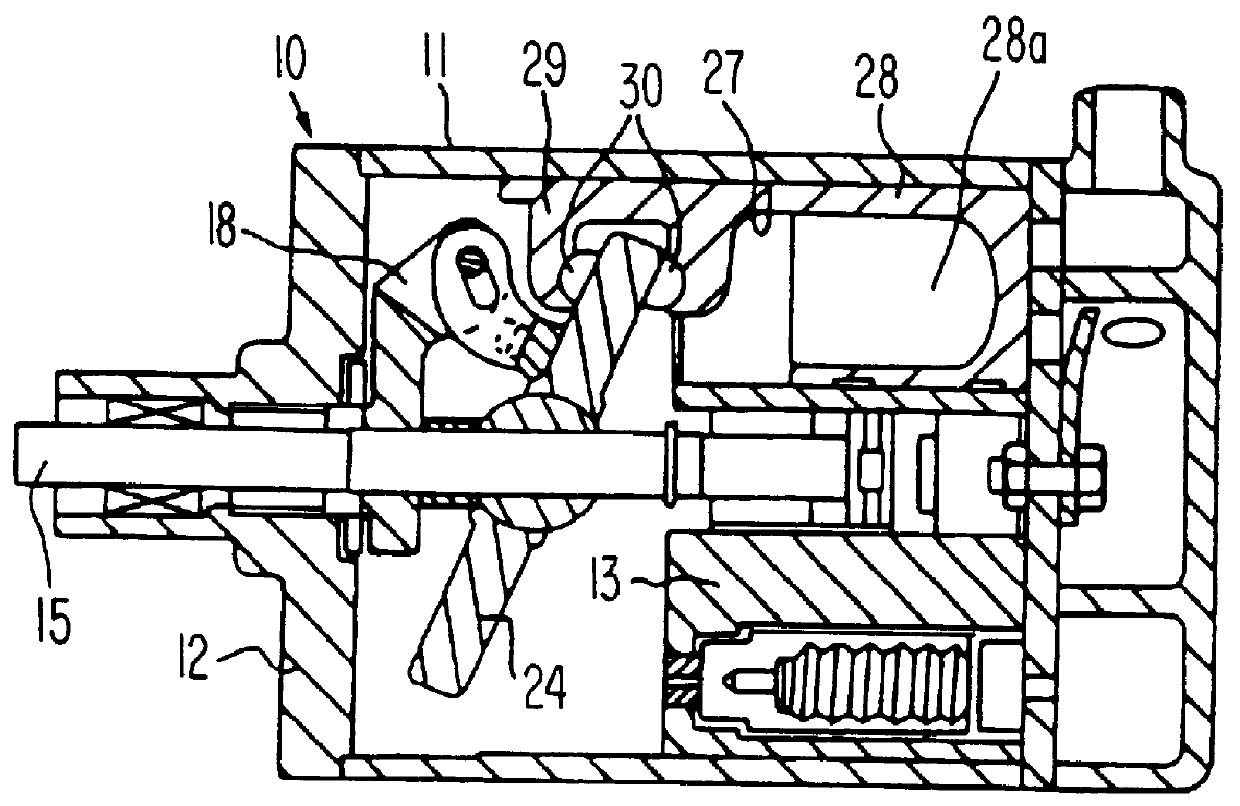

Hydrostatic transmission

InactiveUS6986406B1Reduce the overall heightAvoid less flexibilityFluid couplingsGearboxesThrust bearingEngineering

An axle driving apparatus having a housing having two members joined along a joint surface and a hydraulic axial piston pump and motor mounted on a center section located in the housing, wherein the pump and motor are mounted perpendicular to one another. The motor is engaged to a fixed thrust bearing located in the housing and the center section is located entirely between the joint surface and the thrust bearing.

Owner:HYDR0 GEAR

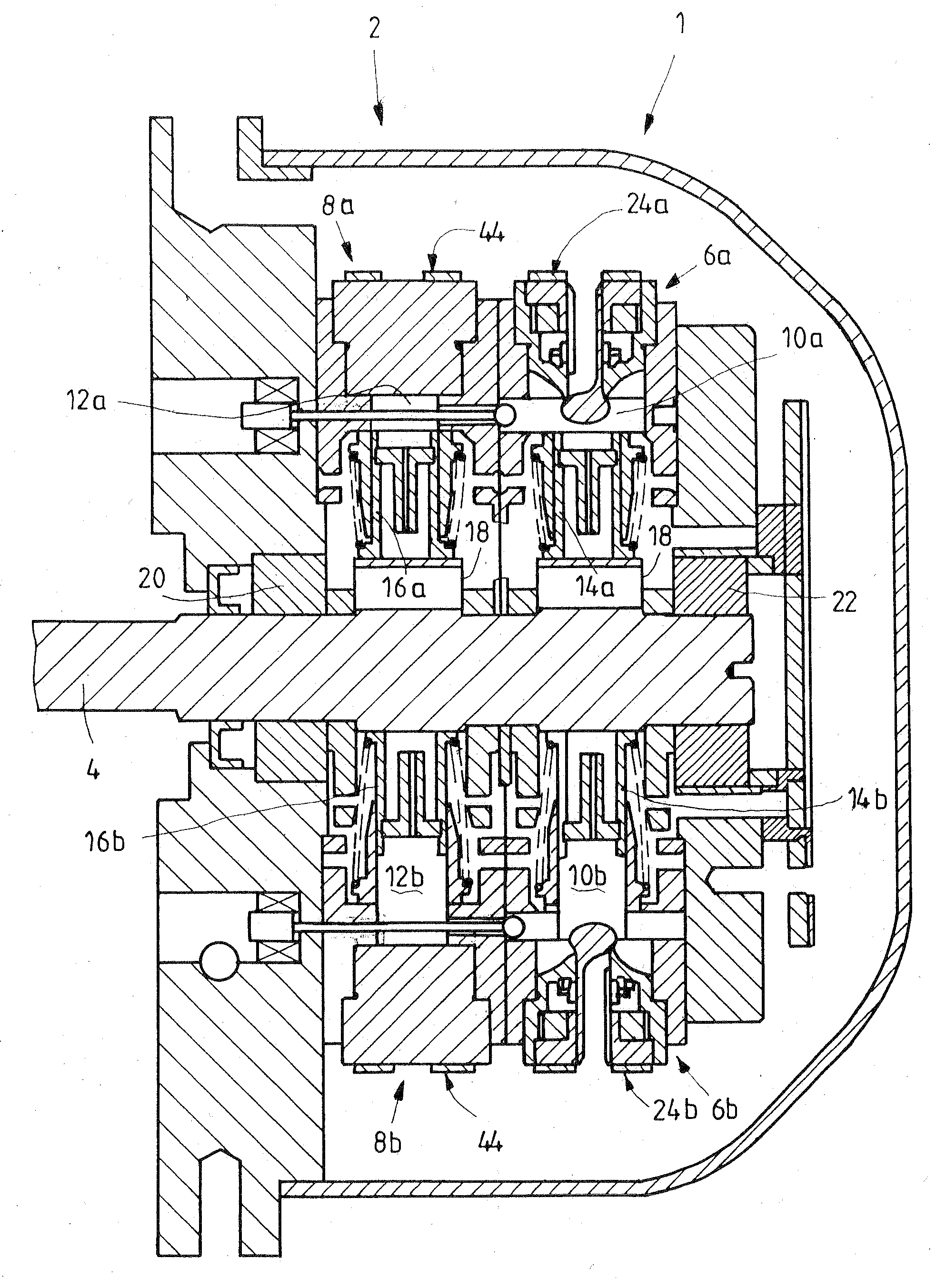

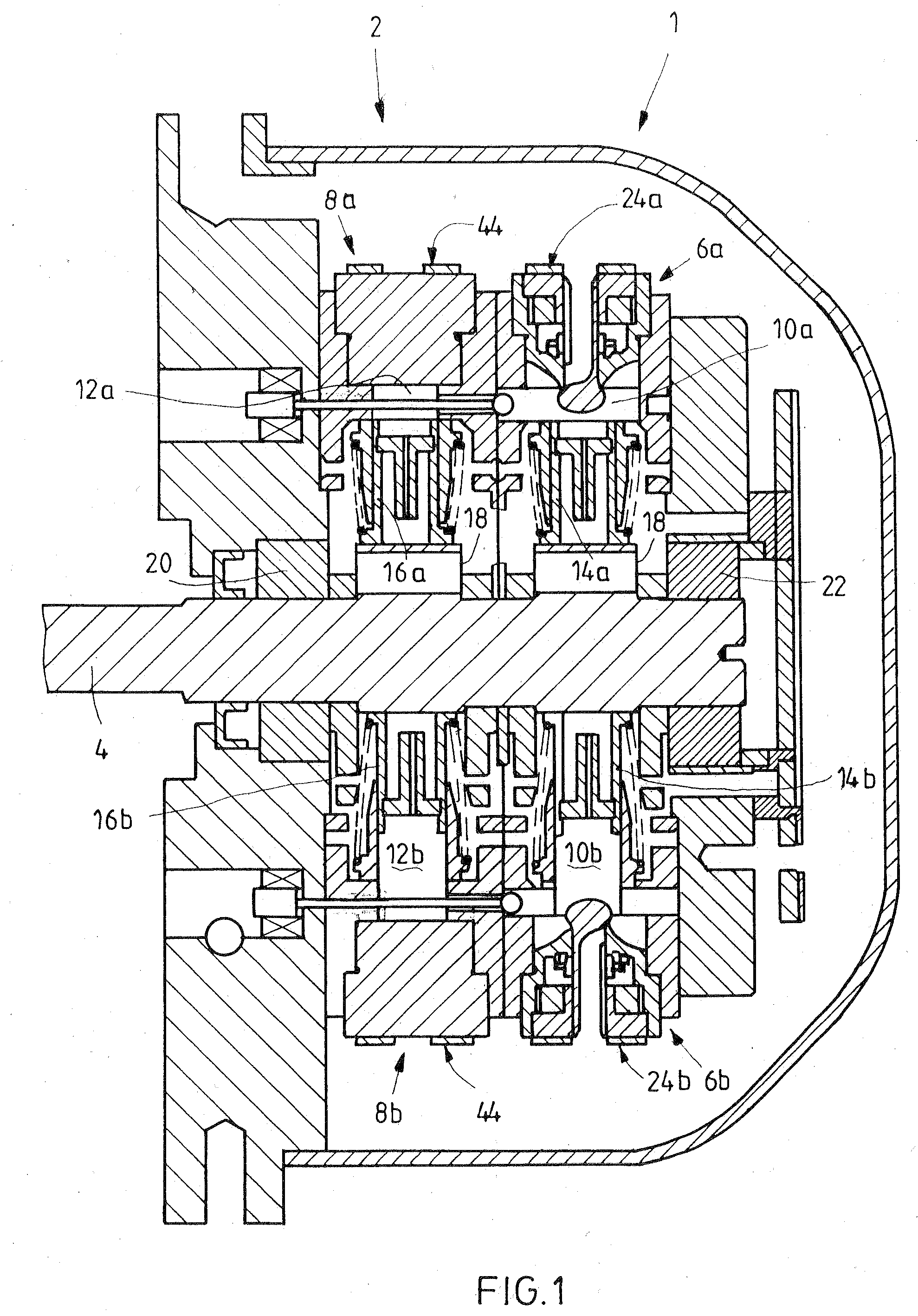

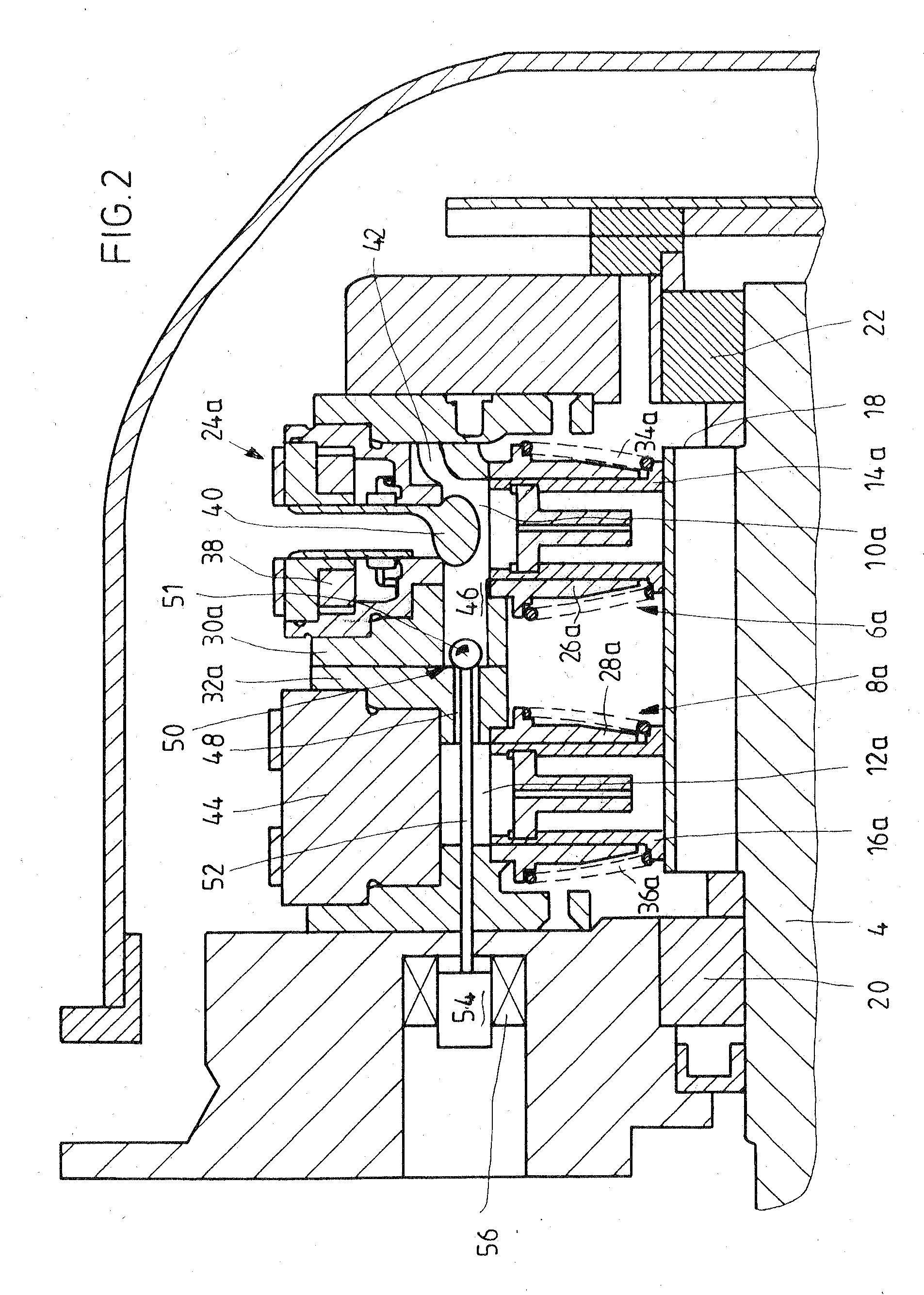

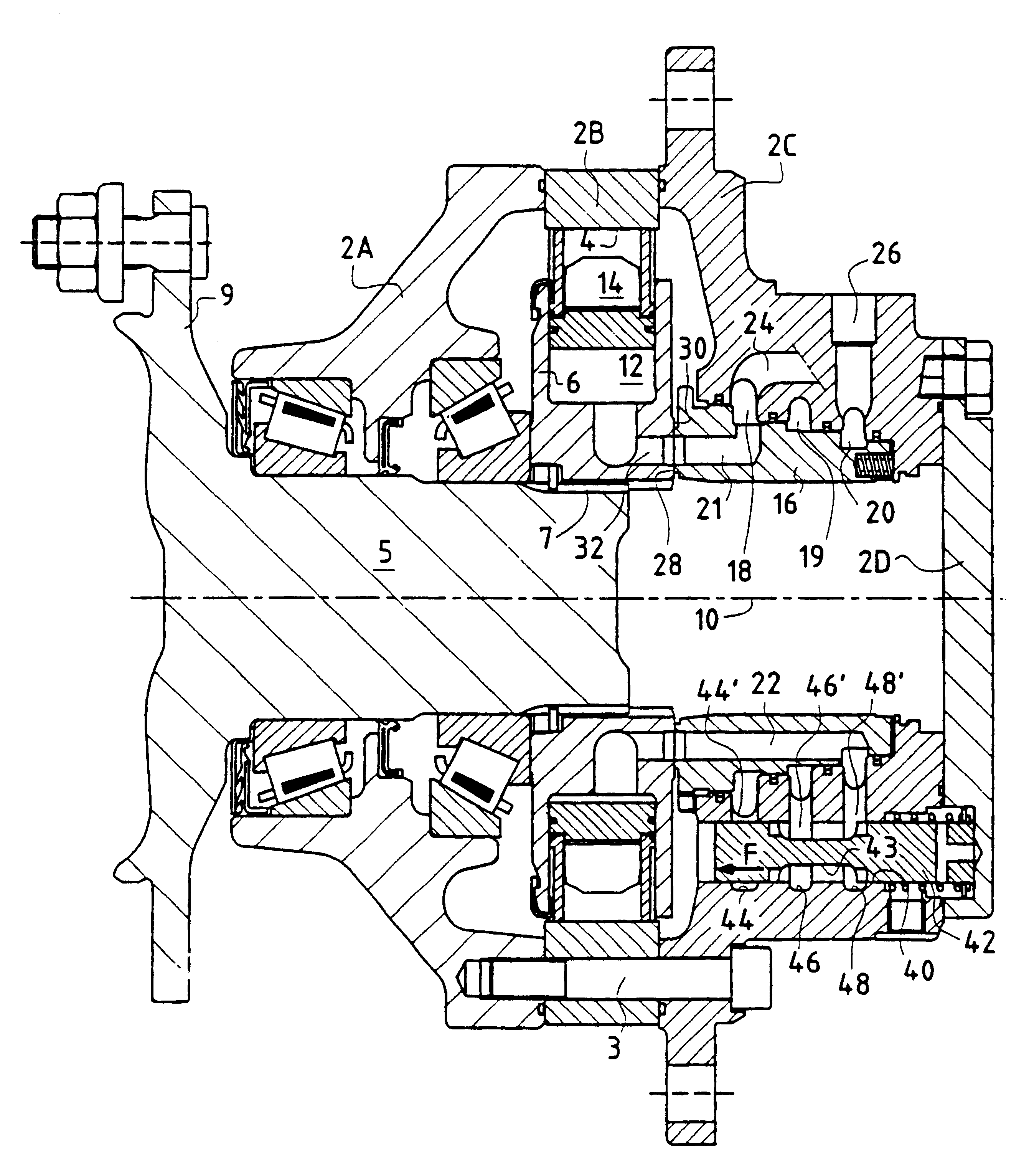

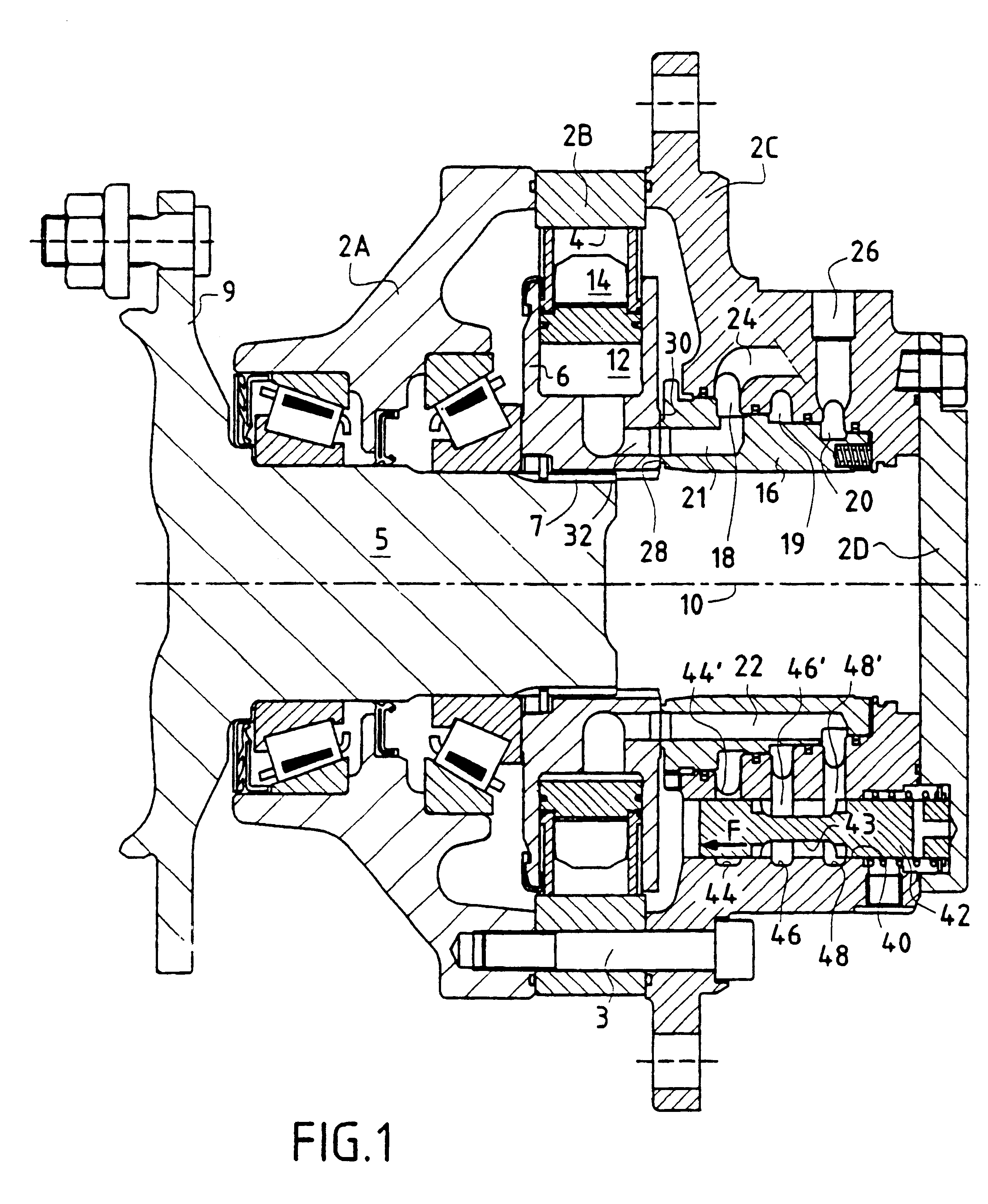

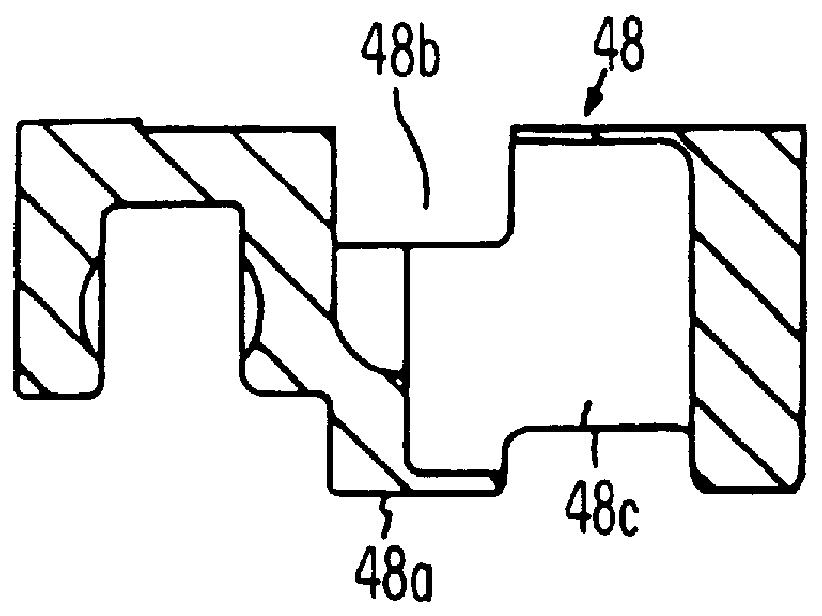

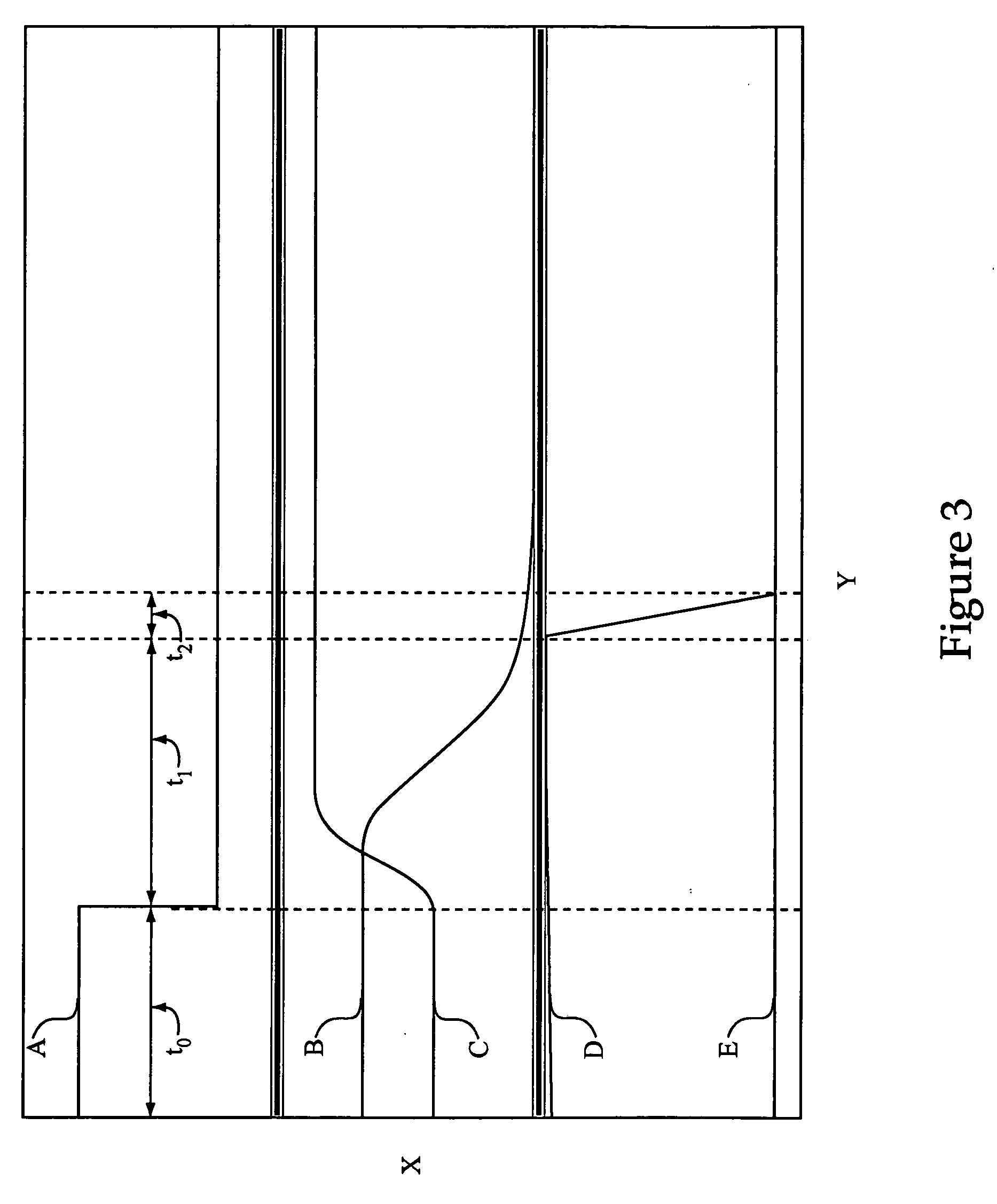

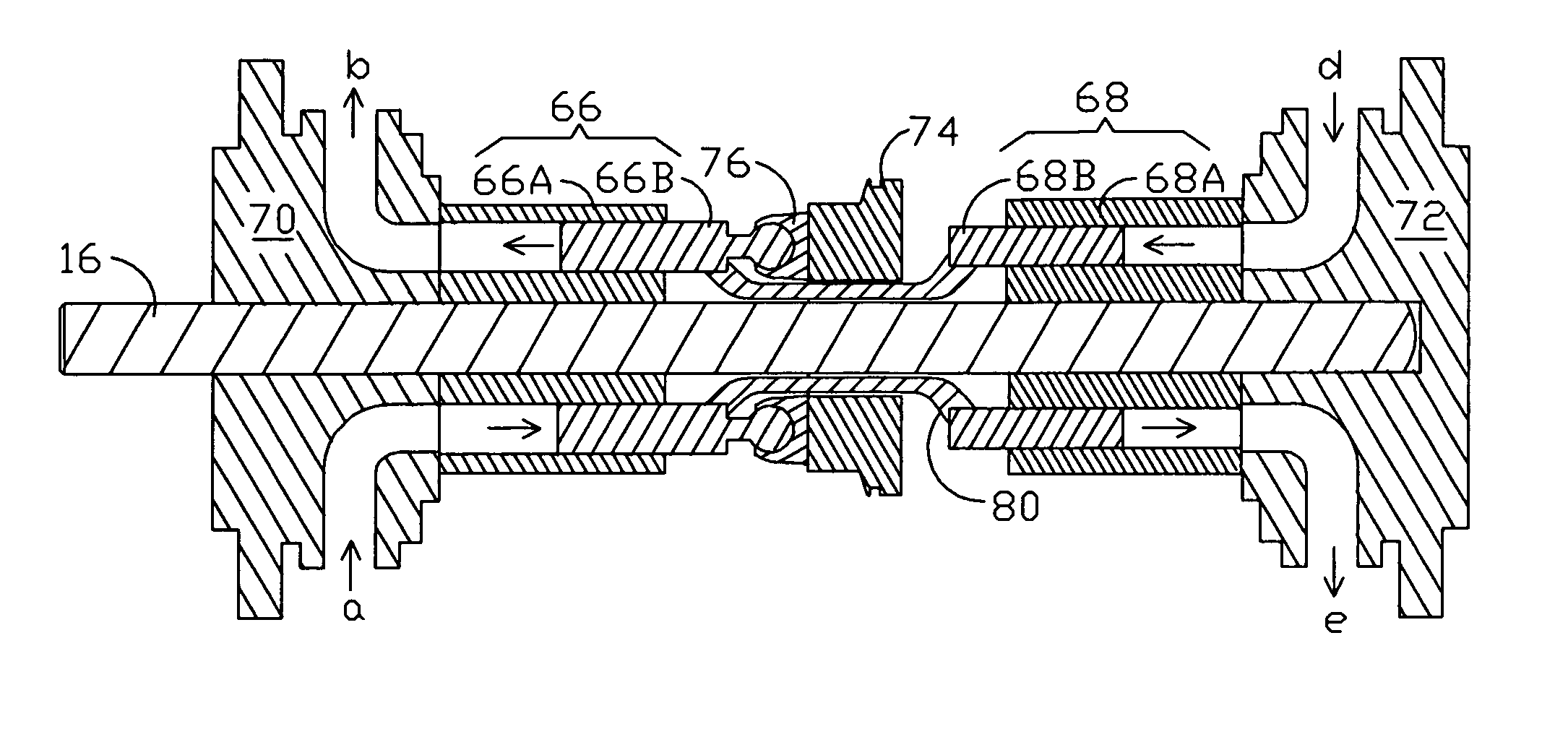

Hydraulic motor cylinder-capacity selector for avoiding jarring when switching from one cylinder capacity to another

InactiveUS6318235B1Reduce vibration effectsReduce impactFluid couplingsServomotor componentsHydraulic motorHydraulic cylinder

A cylinder-capacity selector for a hydraulic motor having at least two active operating cylinder capacities and comprising having at least two main ducts. The selector includes three ports and distribution ducts of the motor to establish selective communication between the main ducts and the cylinders of the motor. When the selector passes between its first and second stable positions, in at least one displacement direction, an intermediate stage exists that is maintained for a lapse of time, during which all three ports are in communication and the section of at least one of the passages between the first and second ports and between the second and third ports of the selector is constricted.

Owner:POCLAIN HYDRAULICS IND

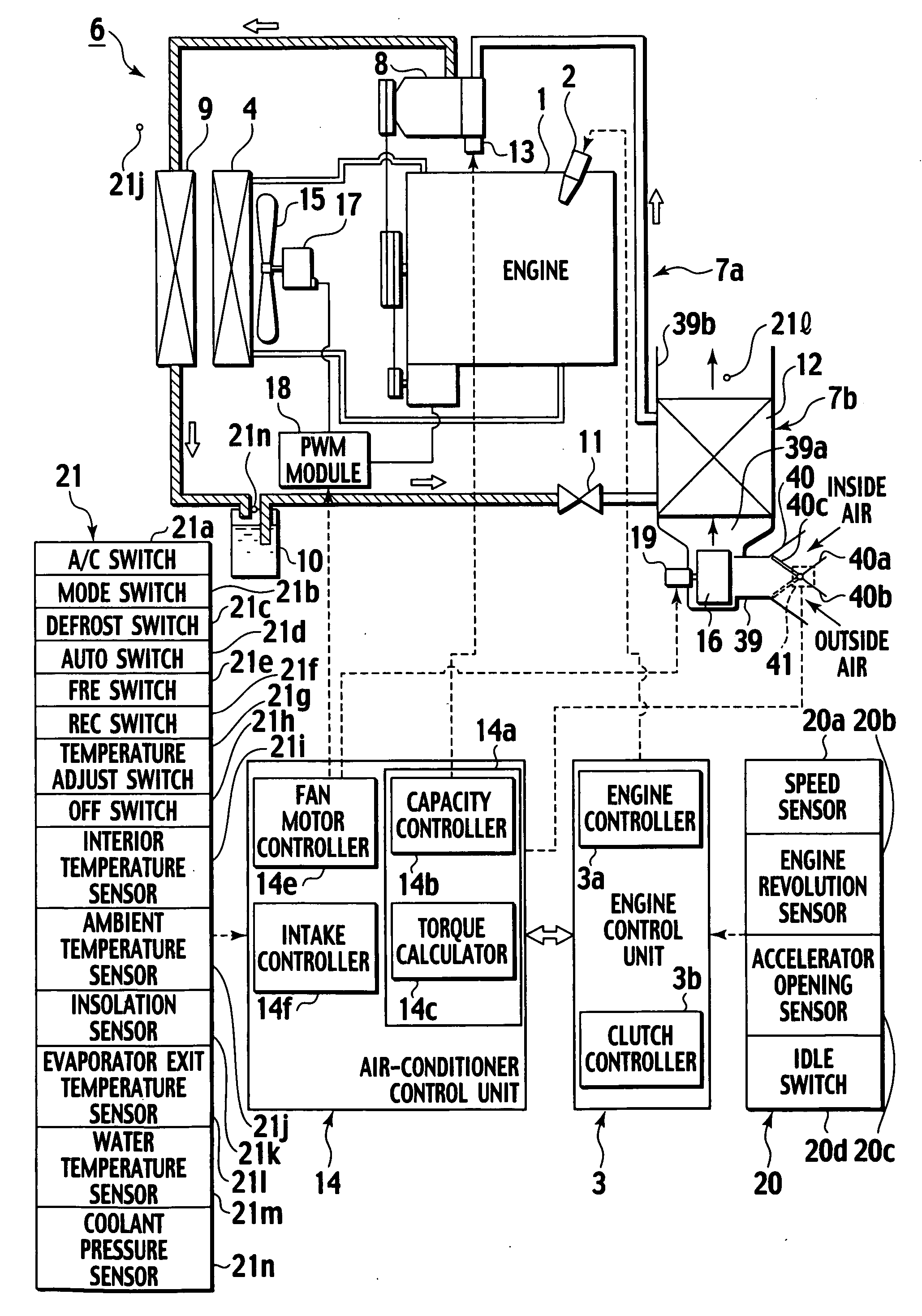

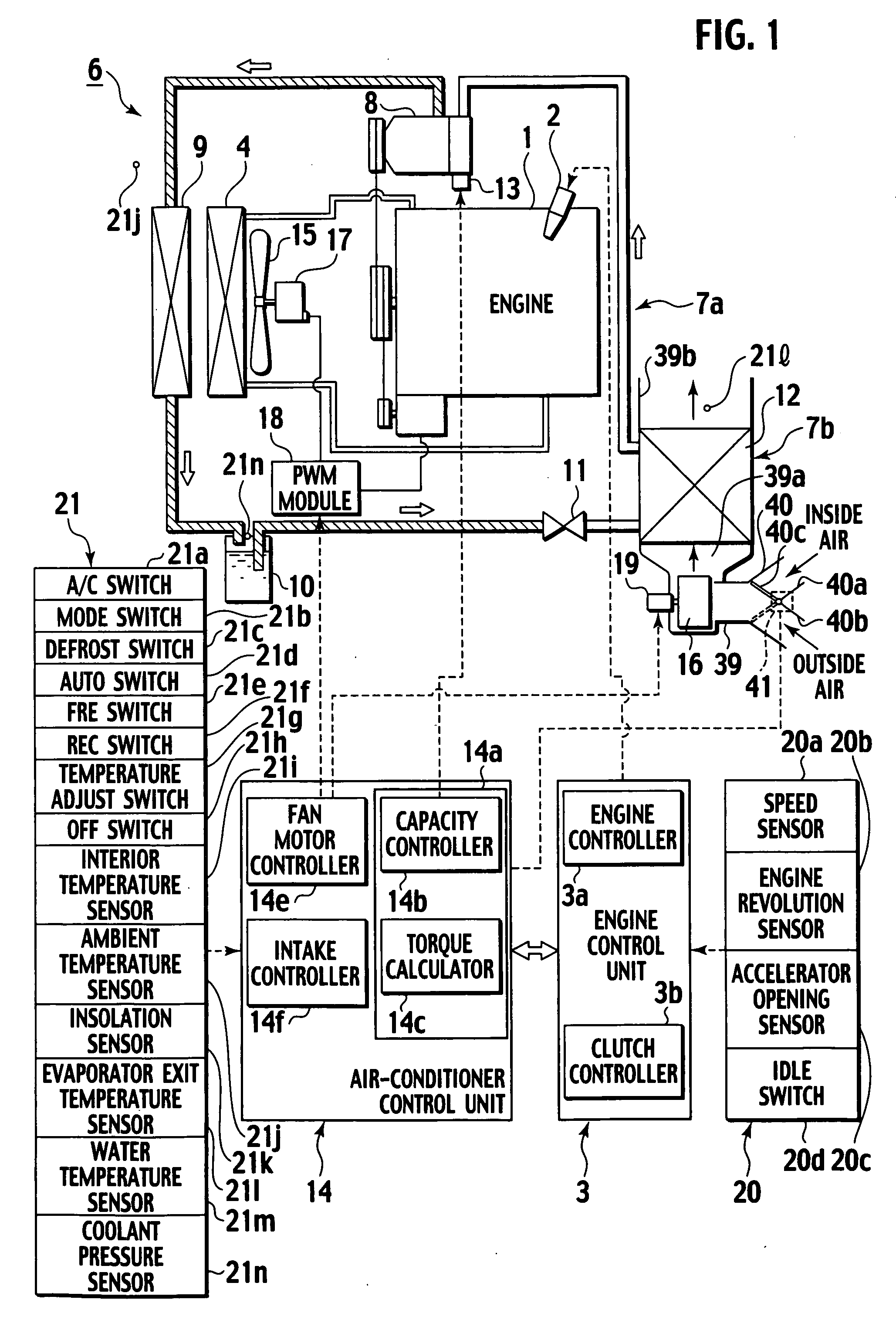

Controls for variable displacement compressor

A control system for a variable displacement compressor uses a mechanical valve to minimize energy consumption in an air conditioning system. The control system can also provide instantaneous indications to the vehicle controller of air conditioning power consumption to avoid engine loading. Controls are also used to contain oil within the compressor and to minimize its presence downstream of the compressor into the gas cooler and evaporator parts of the system.

Owner:HANON SYST

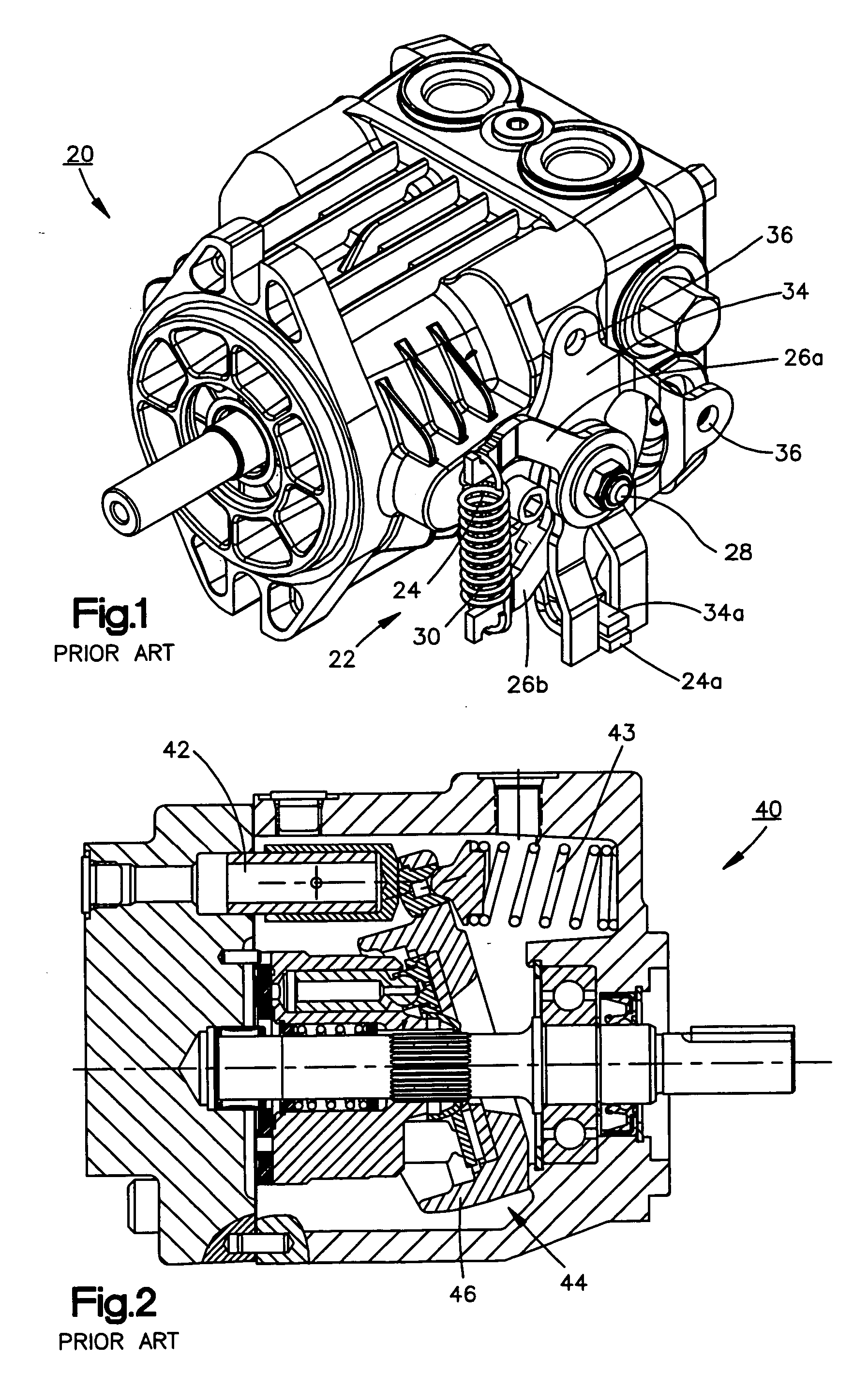

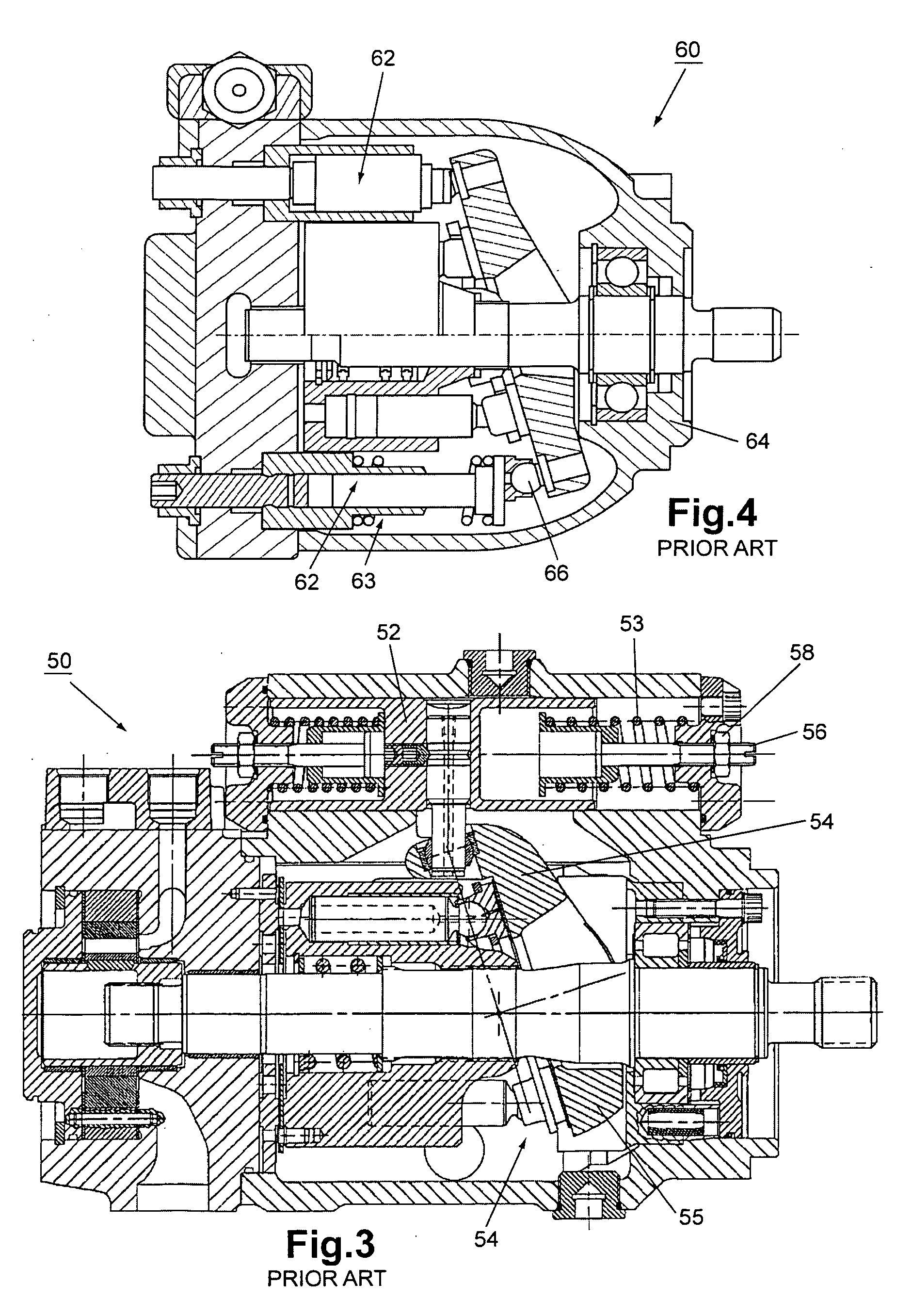

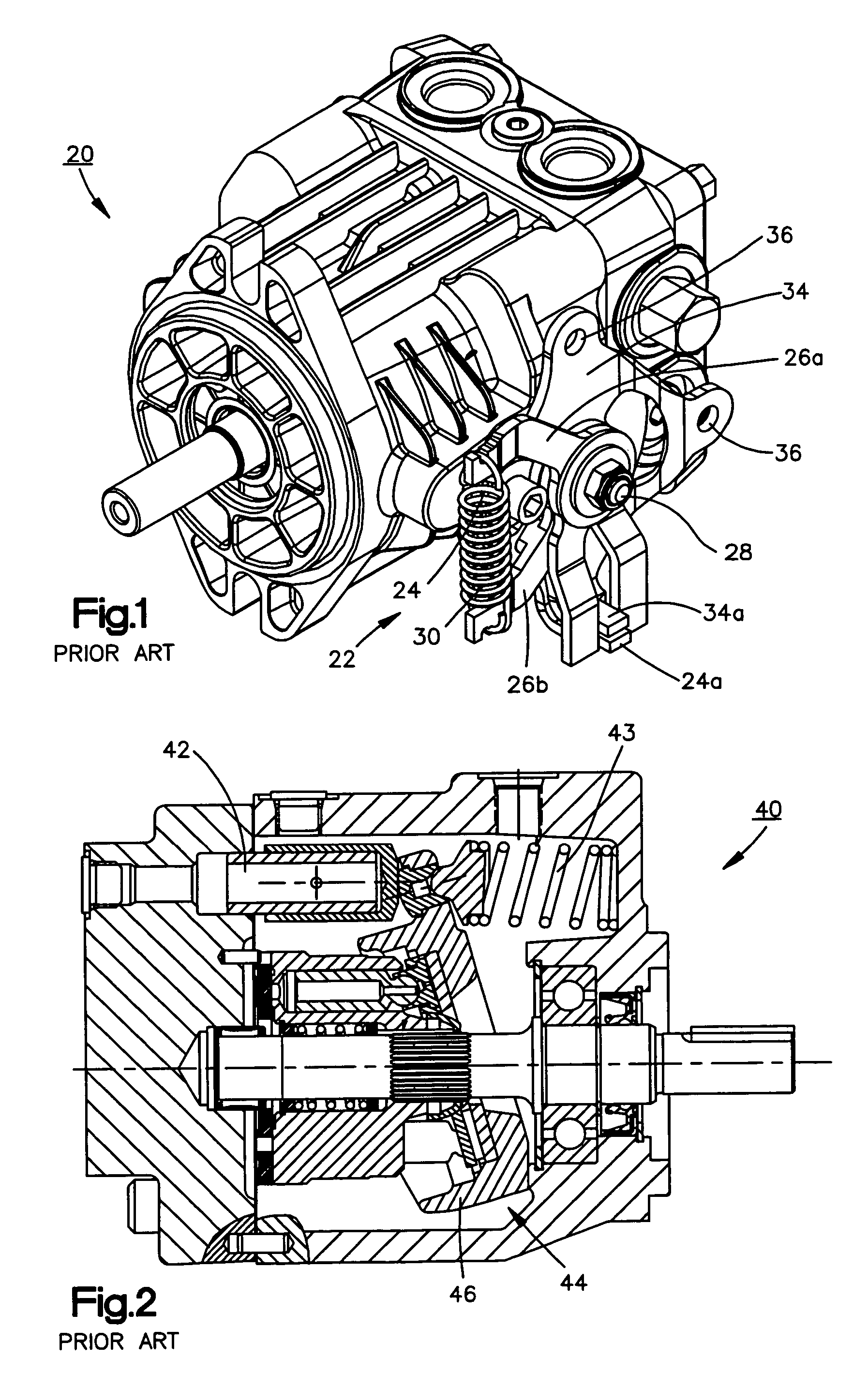

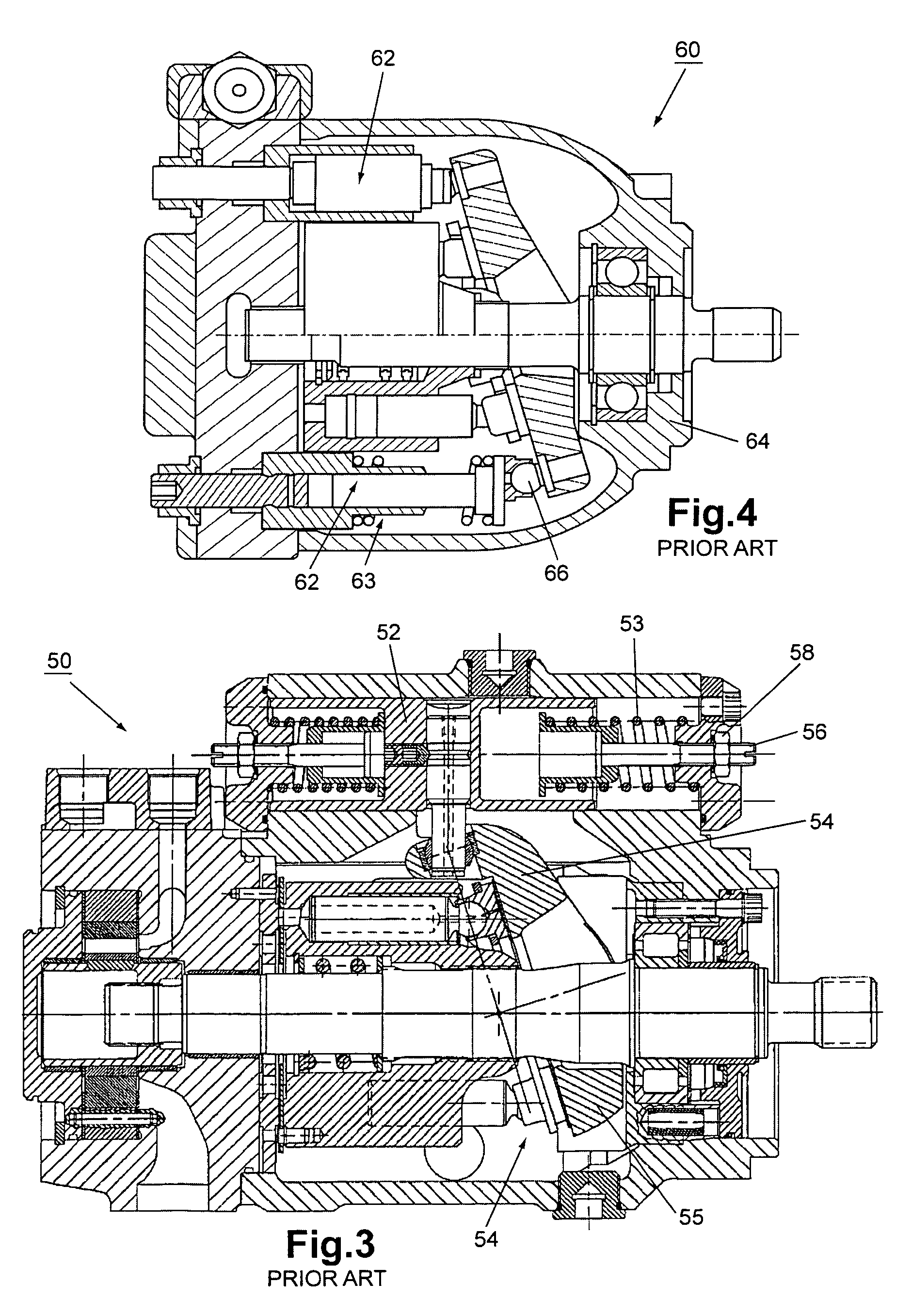

Control devices for swashplate type variable displacement piston pump

Improvements in trunnion shaft-controlled swashplate axial hydraulic piston pumps as well as hydraulic systems used in hydrostatic transmissions utilized. e.g., in zero-turn-radius (ZTR) wheeled vehicles, such as grass mowers, with one embodiment thereof pertaining to, in combination, the noted pump, devoid of any internal servo control, and a reversible power actuator, for controlling the angle of the swashplate, externally affixed to the housing containing the pump and operatively interconnected with an end of the trunnion shaft extending from the pump housing, with the power actuator being one of a rotary actuator, a fluid power axial cylinder and a rotary electronic actuator. Usage in a ZTR wheeled vehicle requires the prime mover to independently drive two hydraulic transmissions that are controlled by a human operator via a mechanical lever, either two single-axis or one dual-axis joystick control, or a steer-by-wire unit, connected with right and left power actuators

Owner:PARKER INTANGIBLES LLC

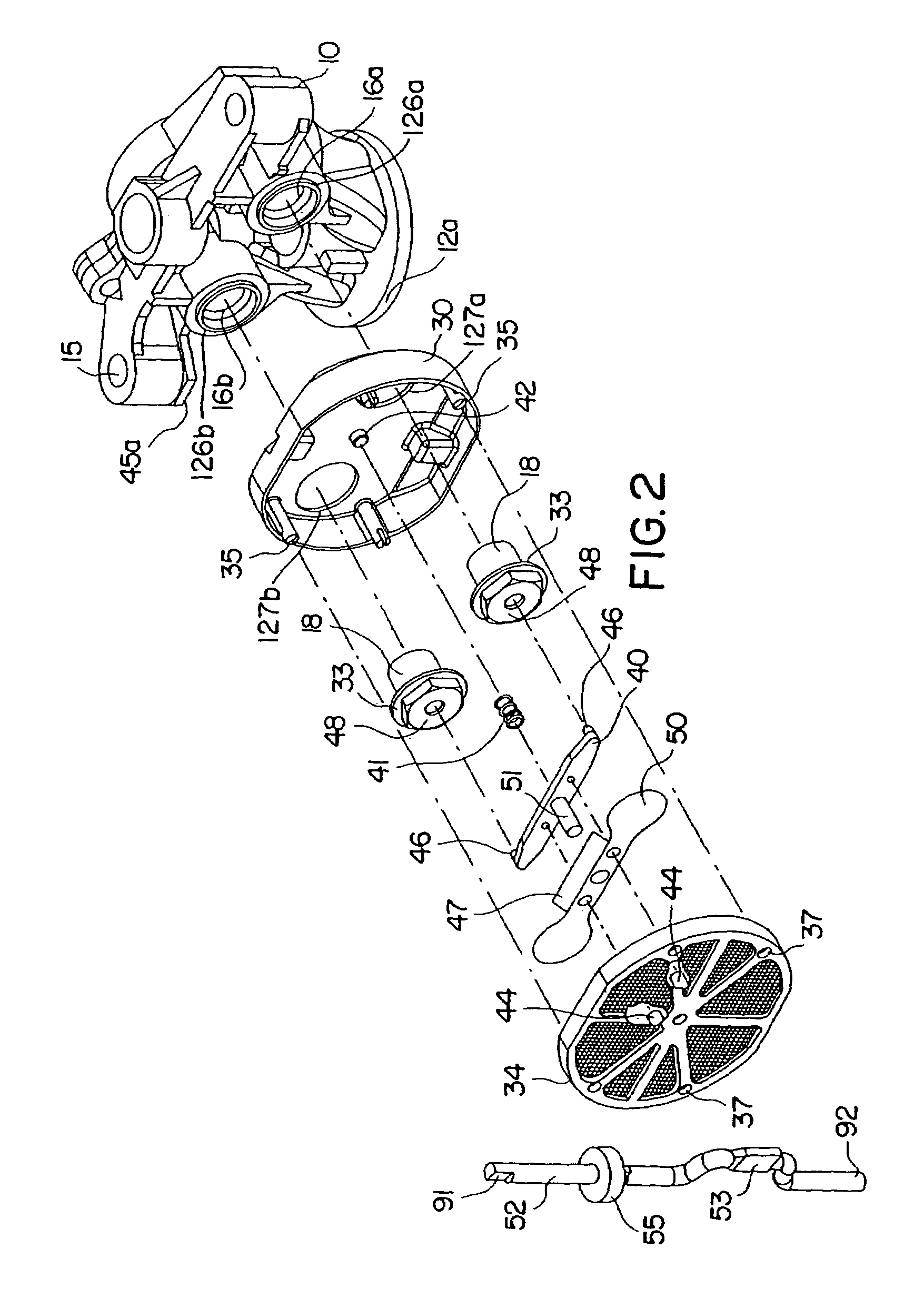

Reciprocating pistons of piston-type compressor

A piston-type compressor has seven cylinder bores formed in a cylinder block which is formed in a compressor housing. A piston is slidably disposed within each of the cylinder bores. Each of the pistons includes a cylindrical main body and an engaging portion axially extending from the cylindrical body. A drive shaft is rotatably supported in the cylinder block. A bearing couples the plate to each of the pistons, so that the pistons reciprocate within the cylinder bores upon rotation of the plate which is tiltably connected to the drive shaft. A recessed portion is formed in an interior of the cylindrical body of each piston so that the cylindrical body forms a C-shaped cross-section perpendicular to longitudinal axis of the piston. Therefore, the configuration obtains lightweight pistons while simultaneously maintaining the efficiency of the compressor.

Owner:SANDEN CORP

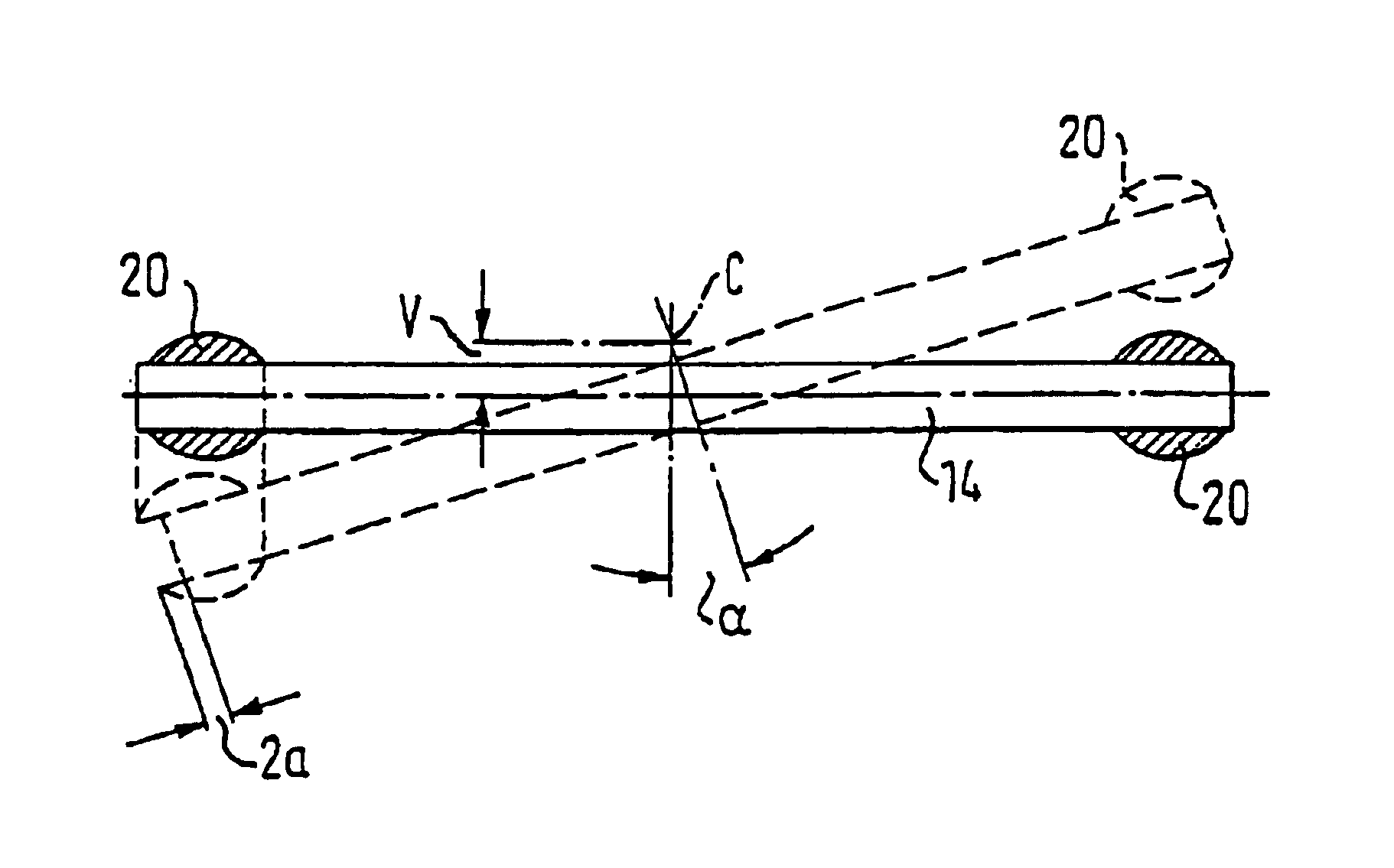

Axial piston displacement compressor

InactiveUS6766726B1Multi-stage pumpsPositive-displacement liquid enginesEffective surfaceDrive shaft

The invention relates to an axial piston displacement compressor, comprising a drive shaft (12), a disc (14) which is mounted on the drive shaft in such a way, that it can be pivoted about a pivotal axis (C) and at least one piston (18) which is provided with sliding blocks (20) that slide on a runway on the disc (14). The invention aims to reduce the maximum effective surface pressure between the disc (14) and the sliding blocks (20). To this end, the pivotal axis (C) of the disc (14) is located eccentrically in relation to the central plane of the disc.

Owner:ZEXEL VALEO COMPRESSOR EUROPE GMBH

Control devices for swashplate type variable displacement piston pump

Owner:PARKER INTANGIBLES LLC

Multilobe rotary motion asymetric compression/expansion engine

InactiveUS7578278B2Extension of timeInternal combustion piston enginesOscillating piston enginesRotary engineEngineering

Owner:GYROTON CORP

Method of slowing a hydrostatic drive work machine

A method of reducing speed in a hydrostatic drive work machine, and a hydrostatic drive work machine are provided. The method includes the steps of retarding the work machine by at least one of, upstroking a variable displacement hydraulic motor thereof, and downstroking a variable displacement pump coupled with the motor. An offgoing clutch pressure is dropped after each of the motor and pump displacements reaches a predetermined point. The steps of slowing the work machine are carried out by adjusting the respective displacements at rates based on a predetermined acceleration limit and / or a predetermined jerk limit of the work machine. The hydrostatic drive work machine further includes an electronic control module having a control algorithm recorded thereon for to neutral.

Owner:CATERPILLAR INC

Capacity control valve

A capacity control valve for a variable-capacity compressor such as used in an air-conditioning system in a motor vehicle is provided, wherein foreign matter is prevented from being caught in the sliding parts and leakage on the sliding parts is prevented from occurring by configuring the capacity control valve so that there are no sliding parts between the valving element and the housing (valve body).

Owner:EAGLE INDS

Radial piston pump

ActiveUS20090155095A1Sufficient degree of sealingReduce overall outer diameterPump controlPressure lubricationRadial piston pumpCylinder block

The invention relates to a radial piston pump having external loading. Said radial piston pump has an inner eccentric which is attached to a rotatable driveshaft, a cylinder block which has positionally fixed cylinder bores aligned radially with respect to the driveshaft, and displacement pistons which are mounted in a longitudinally movable manner in the cylinder bores, with the displacement pistons having a piston head with a short casing height, and being mounted with their piston base on the eccentric, in such a way that the piston head, during its longitudinal movement, pivots in a predetermined angle range &r about the longitudinal central axis of the associated cylinder bore.

Owner:DANFOSS POWER SOLUTIONS INC

Apparatus for and method of calculating torque of variable capacity compressor

InactiveUS20060272343A1Guaranteed uptimeCompression machines with non-reversible cycleVehicle heating/cooling devicesRisk strokeControl theory

An apparatus for calculating torque of a variable capacity compressor, including: a sensor configured to detect internal and external states of an air conditioner; an OFF-torque calculator configured to calculate and store a steady-state torque according to a state detected by the sensor just before a clutch is turned off; a start torque calculator configured to calculate a start torque according to a state detected by the sensor after the clutch is turned on; a steady-state full-stroke calculator configured to calculate a steady-state full-stroke torque based on an assumption that the compressor was in a full-stroke-state according to a state detected by the sensor after the clutch is turned on; and a determiner configured to provide, when an elapsed time after the clutch is turned on is less than a predetermined time, a maximum one of the torque values calculated by the OFF-torque calculator, start torque calculator, and steady-state full-stroke calculator.

Owner:CALSONIC KANSEI CORP +1

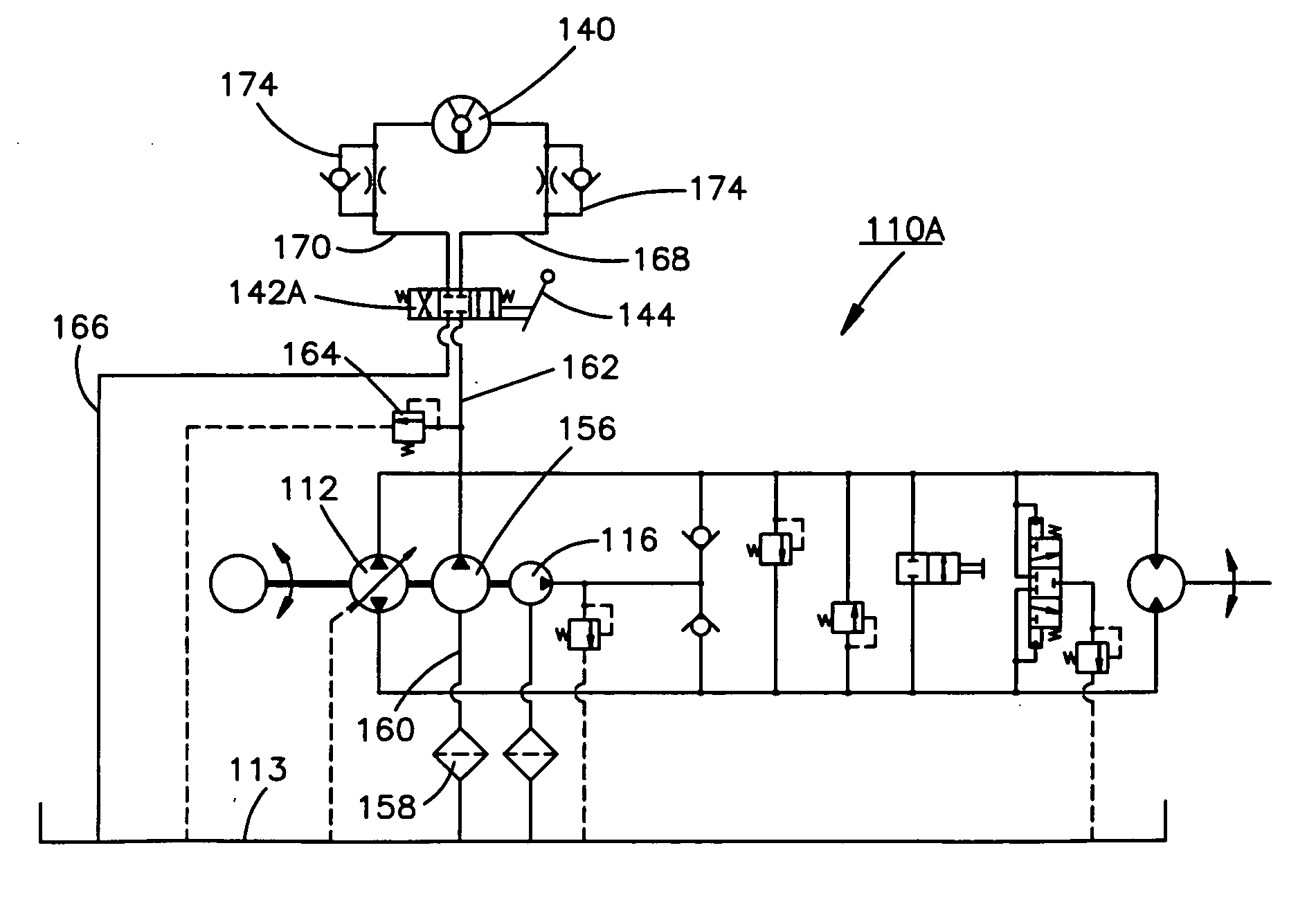

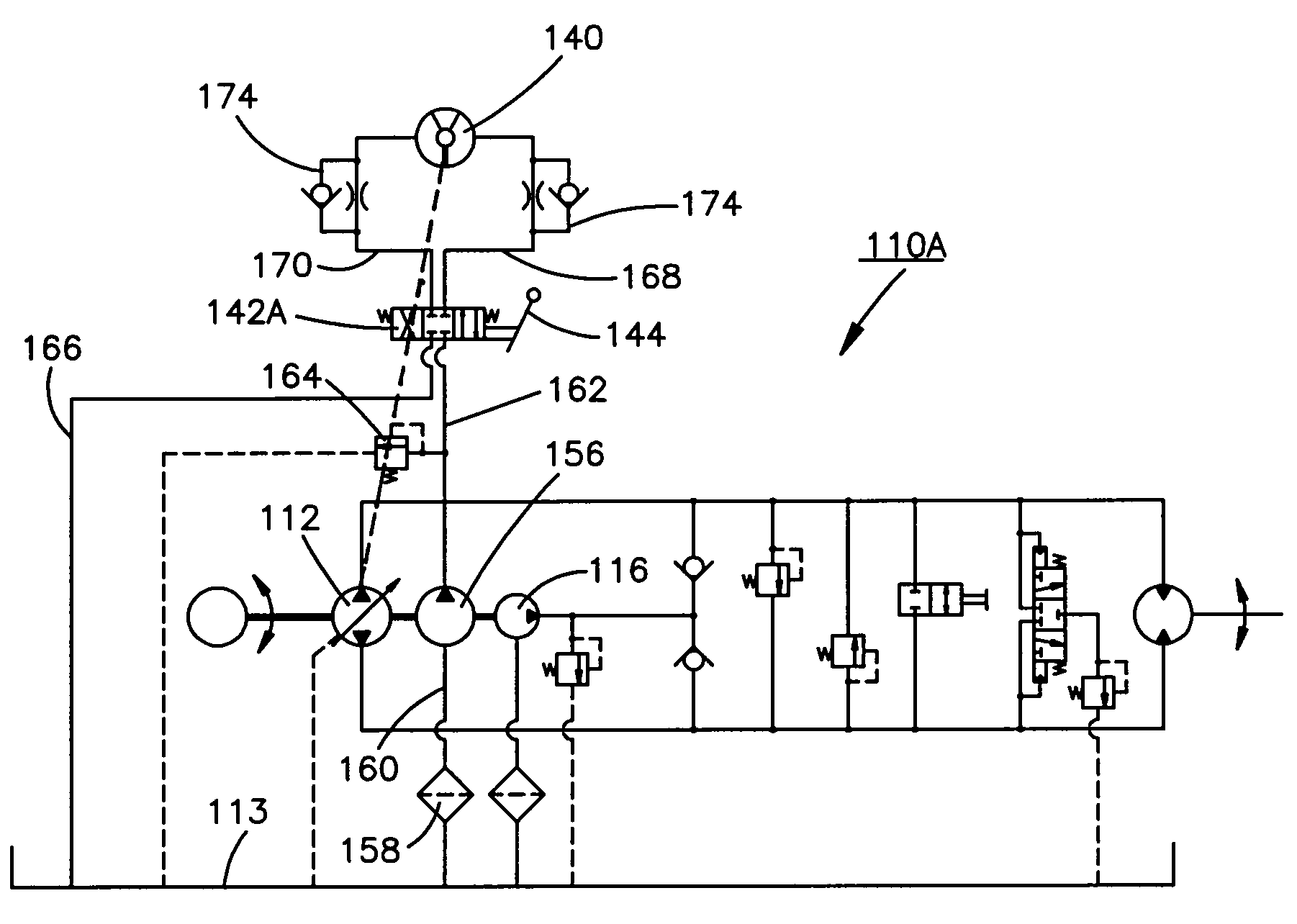

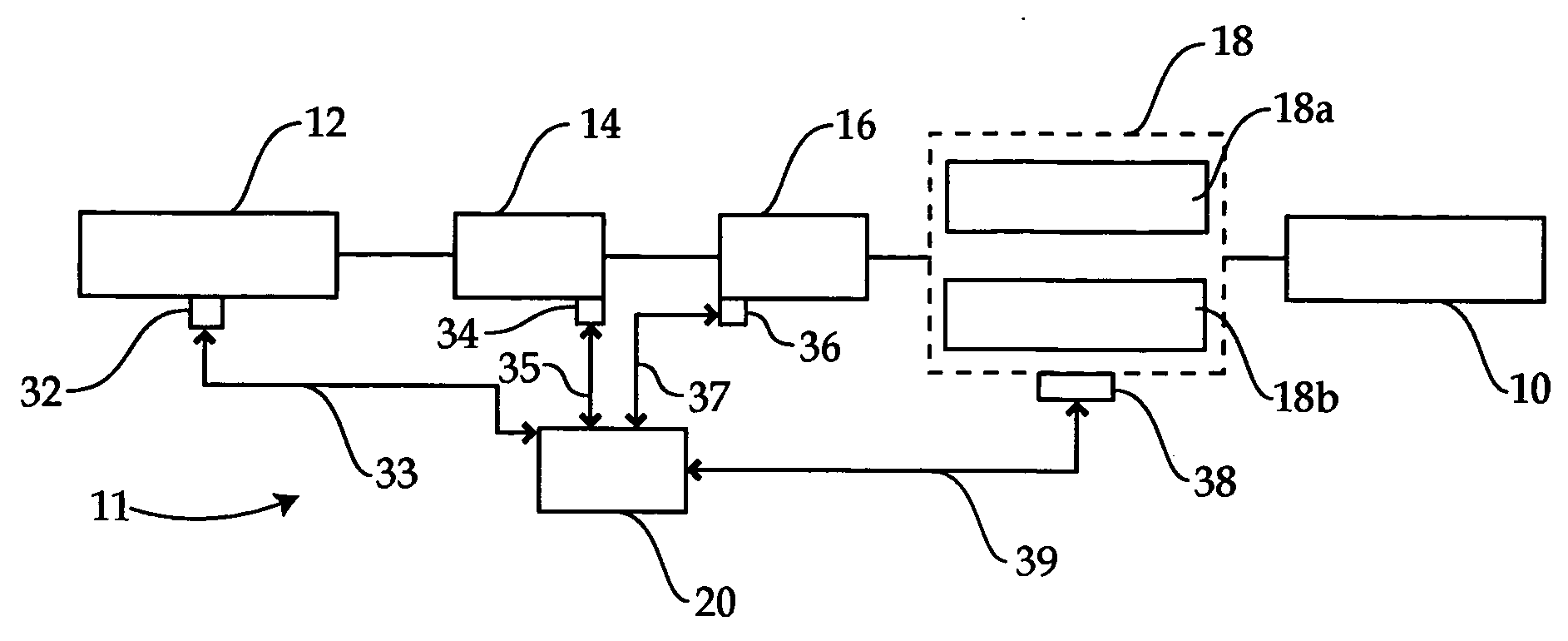

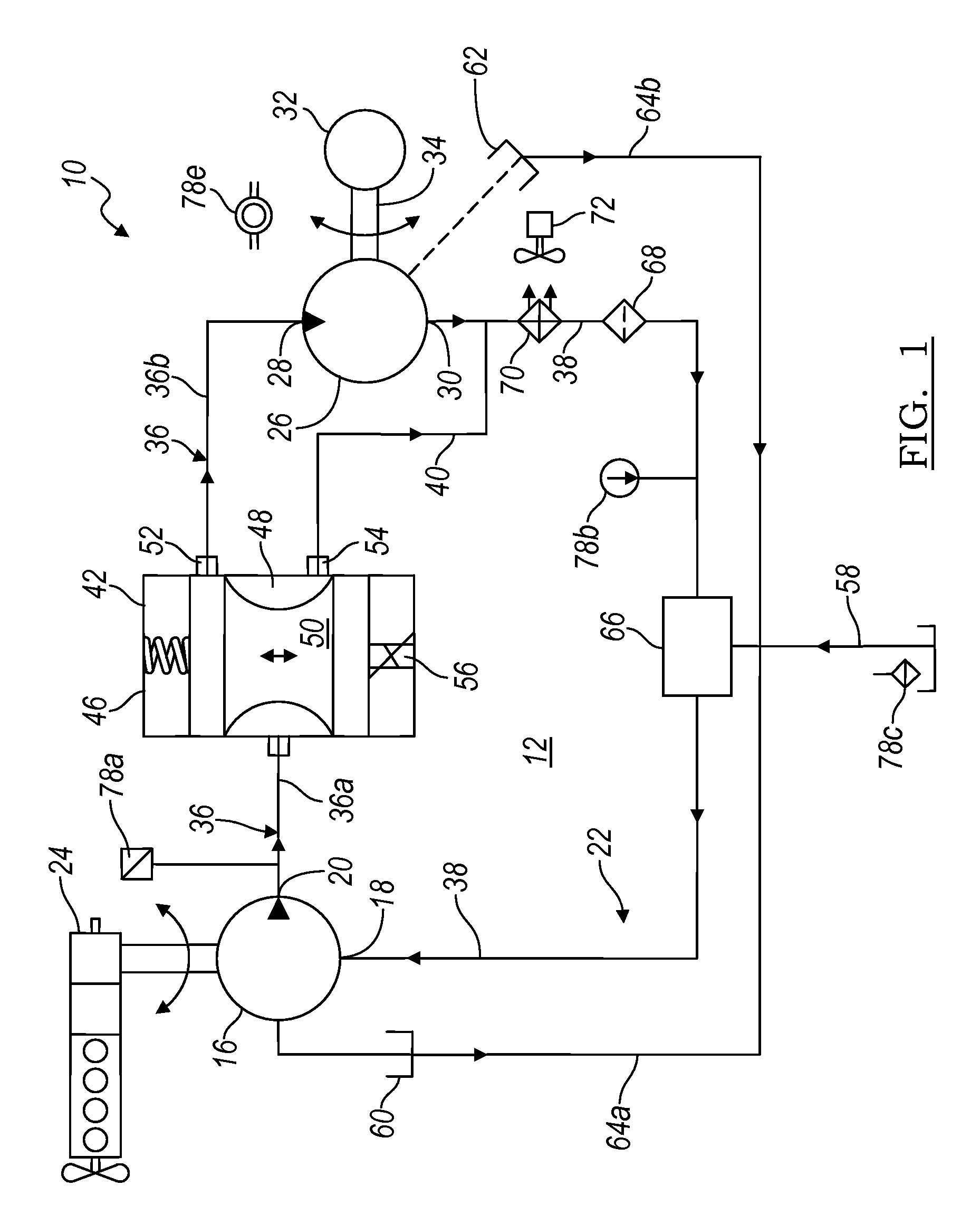

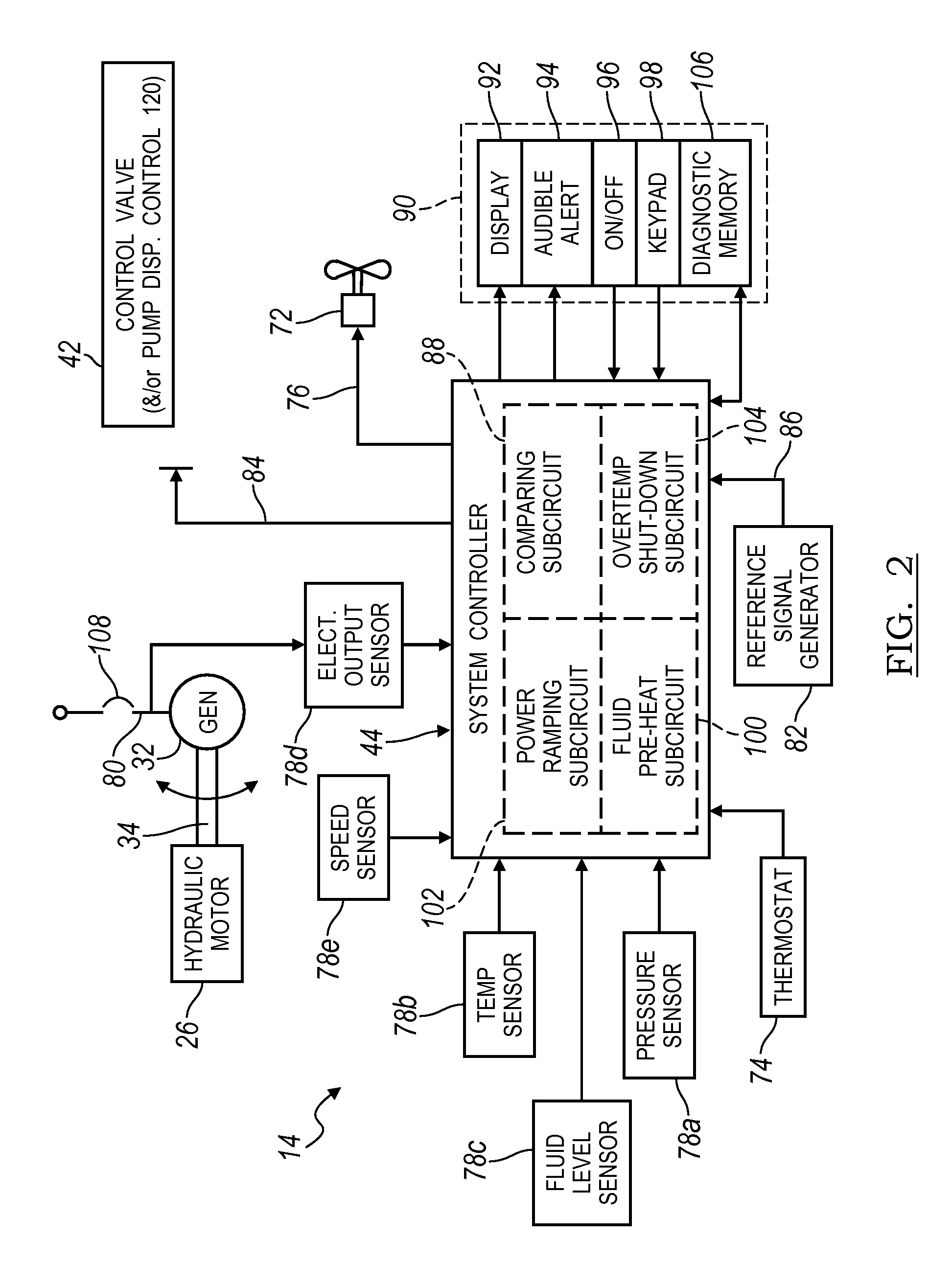

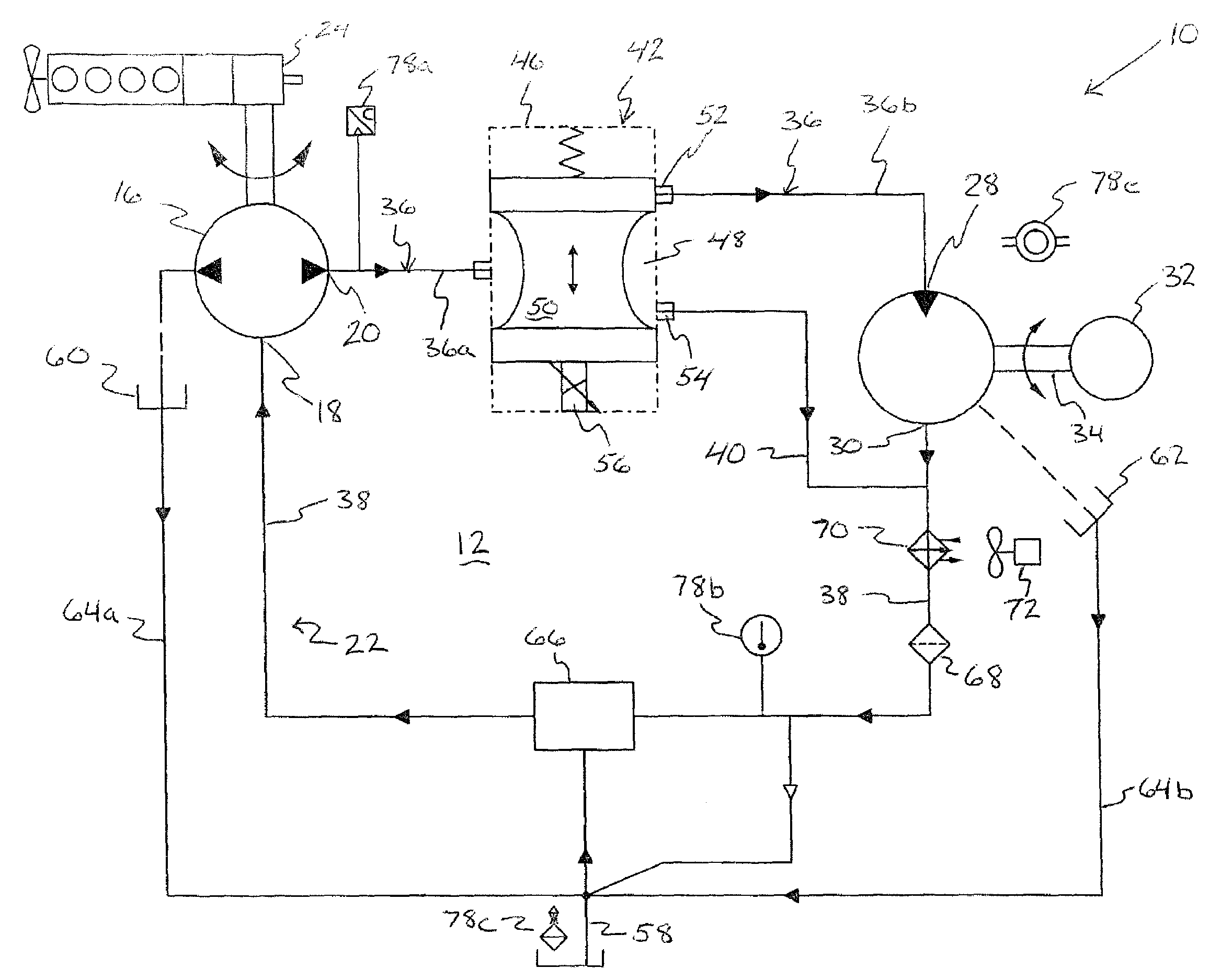

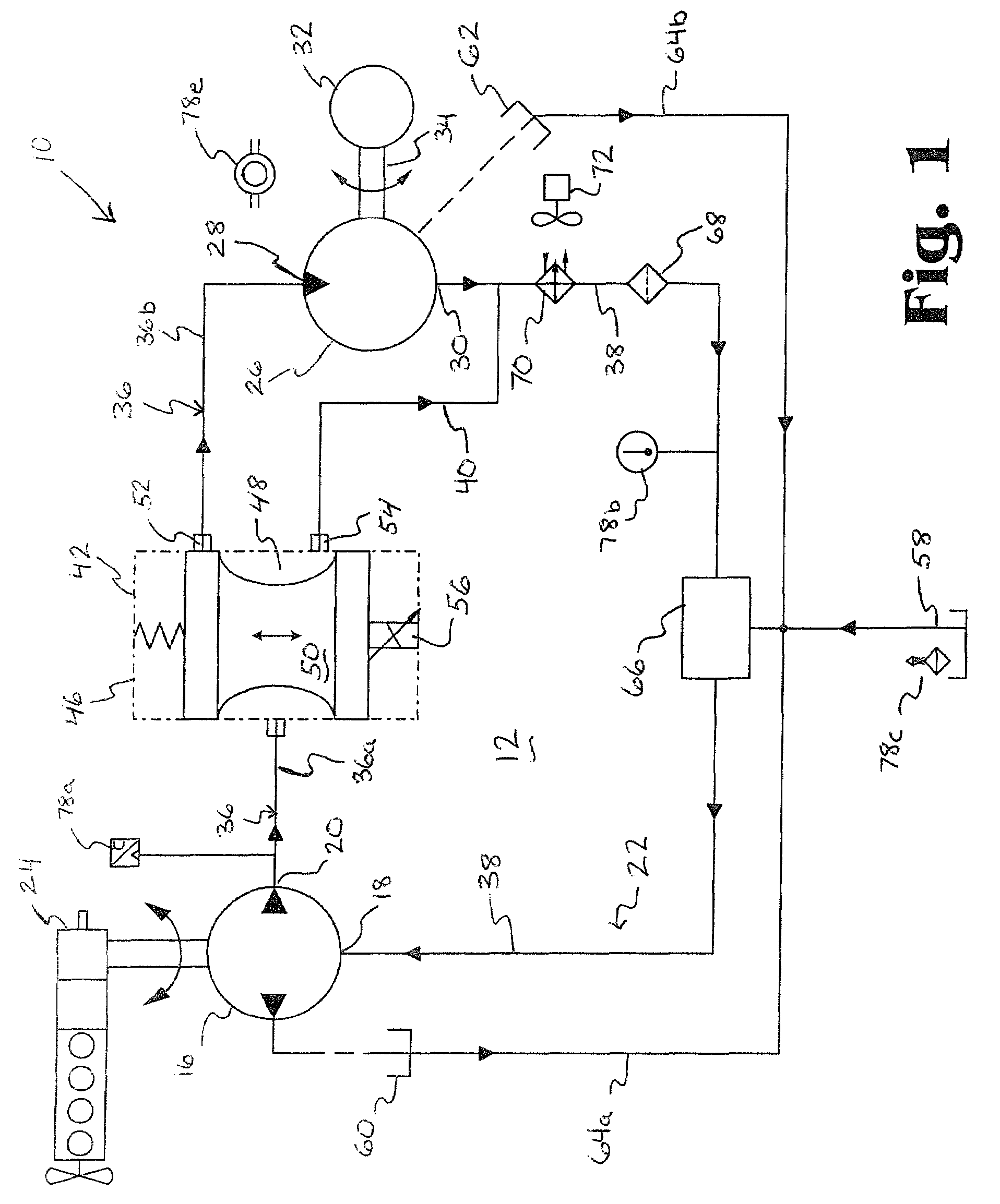

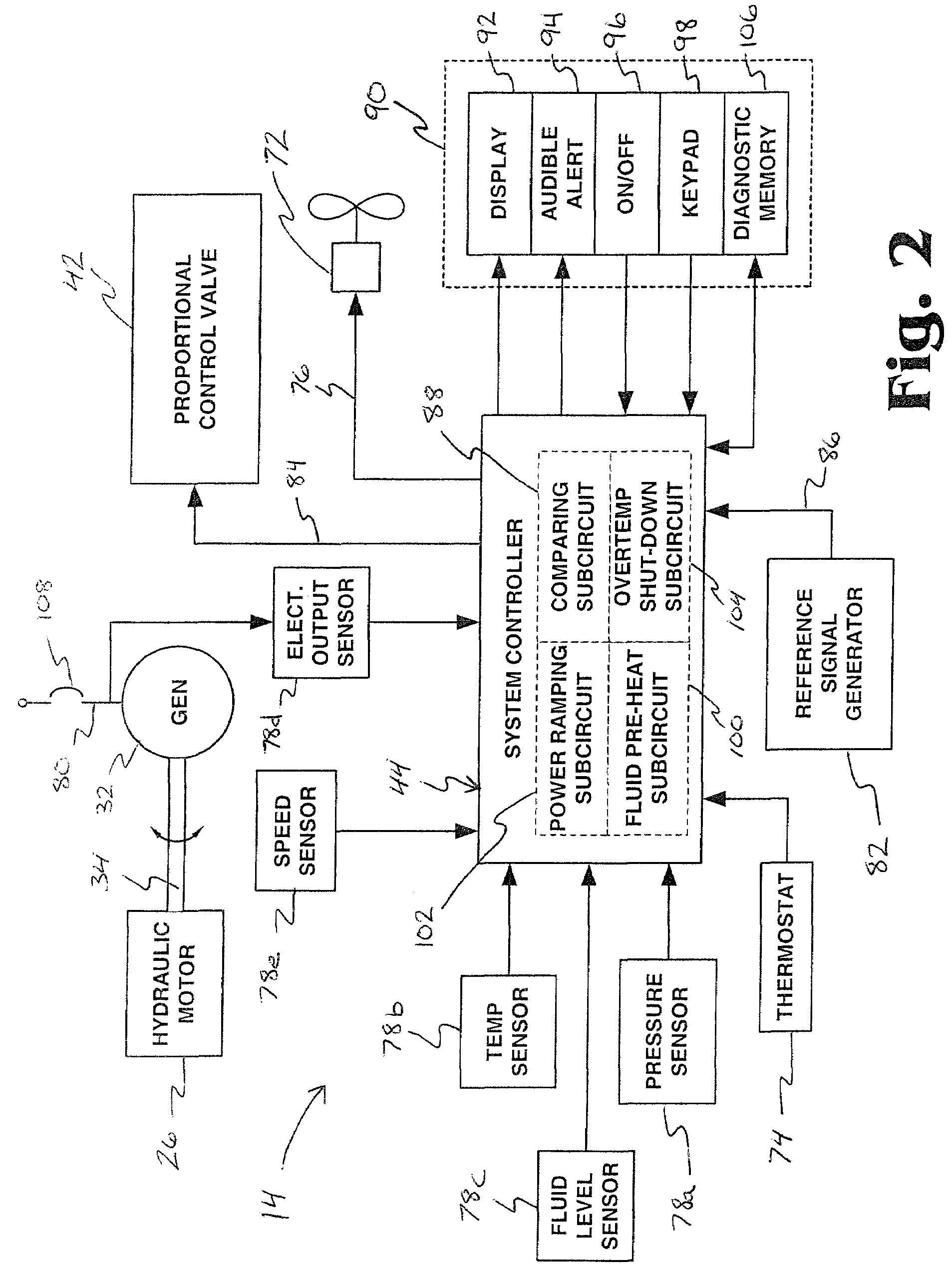

Electronic control for a hydraulically driven generator

ActiveUS20090134848A1Extend system lifeReducing warranty returnGenerator circuit arrangements controlElectric propulsion mountingHydraulic motorHydraulic pump

Hydraulic system for driving an auxiliary power source is provided, which is specifically adapted for use with a system for controlling hydraulically driven AC generator. The system includes a hydraulic pump and hydraulic motor that are connected by a fluid circuit. The hydraulic motor drivably connected to an AC generator and is operated in a manner to generate a stable AC power output. The system may include a valve which bypasses fluid around the motor or a variable displacement pump so that the fluid flow rate through the hydraulic motor is controlled in a manner to maintain the desired AC generator output level. Sensors are further provided measuring operating parameters of the system so that the controller can maintain desired operating condition limits

Owner:UUSI

Axial piston machine

ActiveUS7988428B1Reduce operating costsEasy to deployMembranesPositive displacement pump componentsMotor driveReciprocating motion

A pressure pump in a primary liquid flow is combined with a pressure exchanger for energy recovery from a secondary liquid flow. A motor-driven rotor portion, including two (primary and secondary) rotatable drum-type cylinder assemblies, is disposed between end blocks configured with input / output ports and cavities forming sliding synchronous reversing valves. Interconnected piston assemblies, including at least one primary piston and one secondary piston, are reciprocated axially by a central angled swash-plate in a progressive sequential manner by rotation of the rotor portion. The combination machine can be optimized for beneficial deployment in a reverse osmosis seawater desalination system to provide unusual simplicity, high efficiency energy recovery from the brine discharge flow and low overall operating cost.

Owner:OCEAN PACIFIC TECH

Electronic control for a hydraulically driven generator

InactiveUS7459800B2Extend system lifeLow costAuxillary drivesTelemotorsHydraulic motorOperator interface

Electronic control for a hydraulic system driving an auxiliary power source is provided, with specific application as a system for controlling the operation of a hydraulically driven AC generator. The system may includes a hydraulic pump, a hydraulic motor drivably connected to the generator, a fluid circuit for circulating fluid from the pump to the motor and back. The fluid circuit may contain a bypass conduit to bypass the motor. The system also includes a proportional servo control valve assembly for controlling the fluid circuits and a control circuit for controlling the proportional control valve assembly. The control system can be capable of controlling the flow of hydraulic fluid to the motor powering the electrical or mechanical system. Sensors for measuring the operating parameters of the system and an operator interface module can influence the operation of the system.

Owner:UUSI

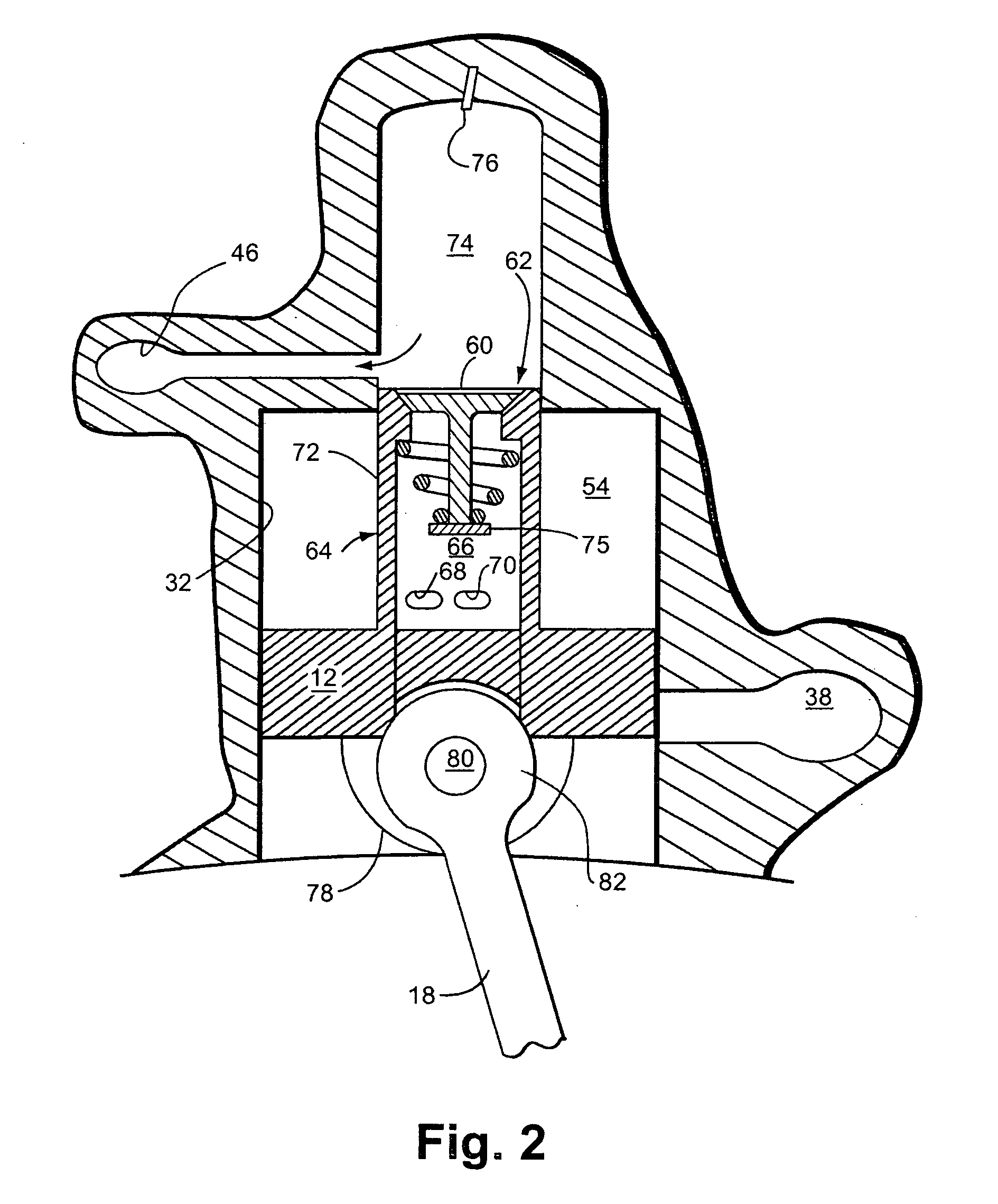

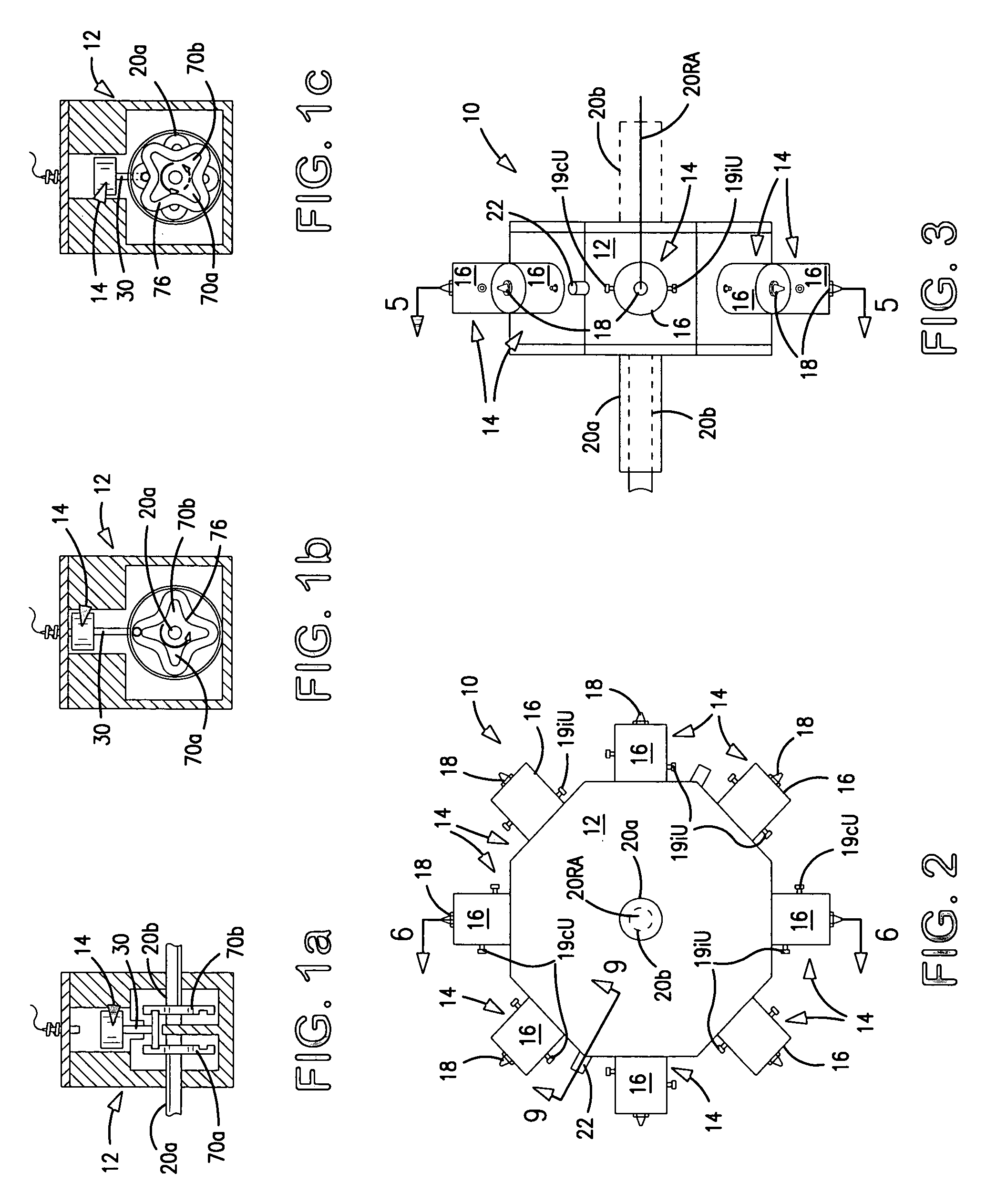

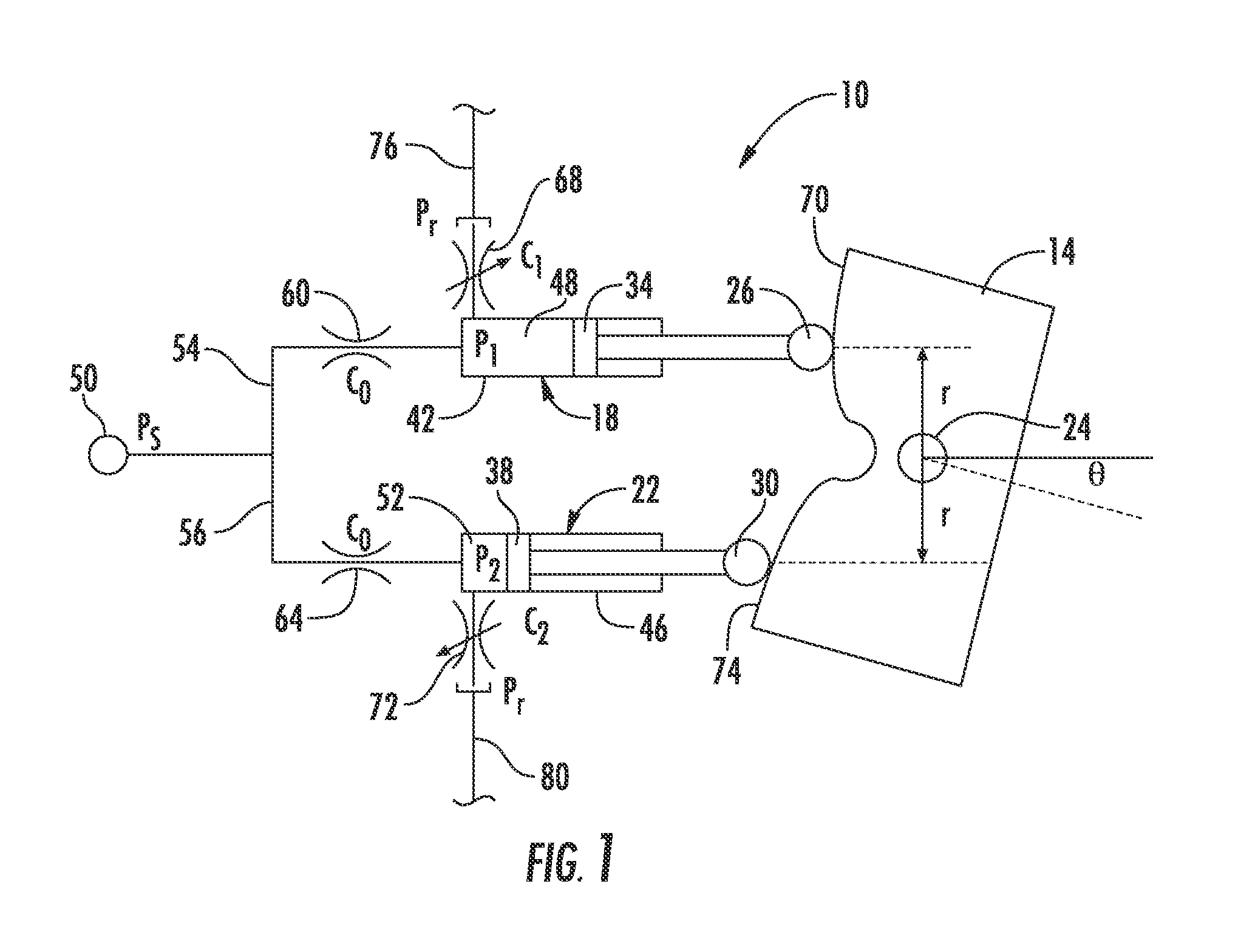

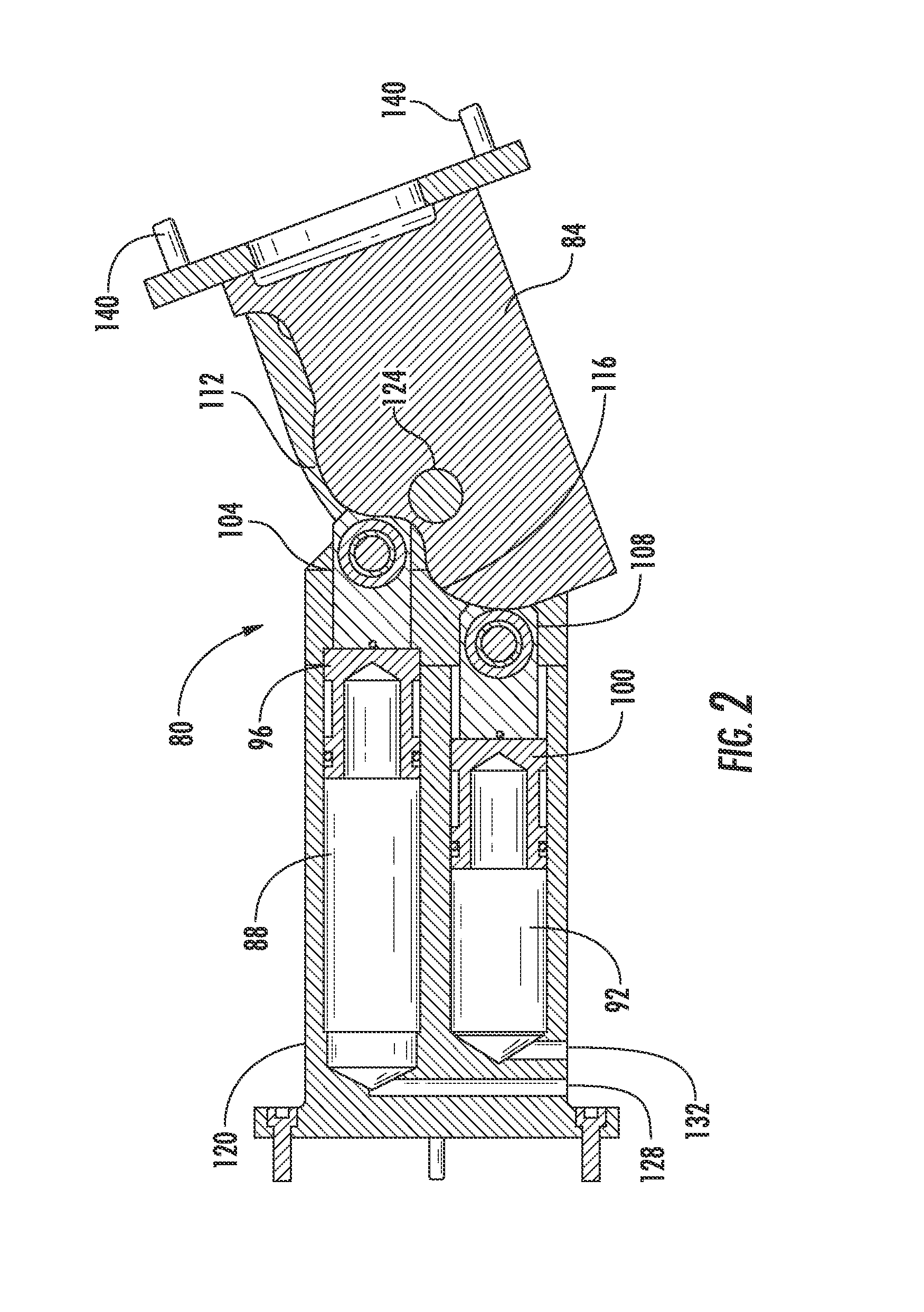

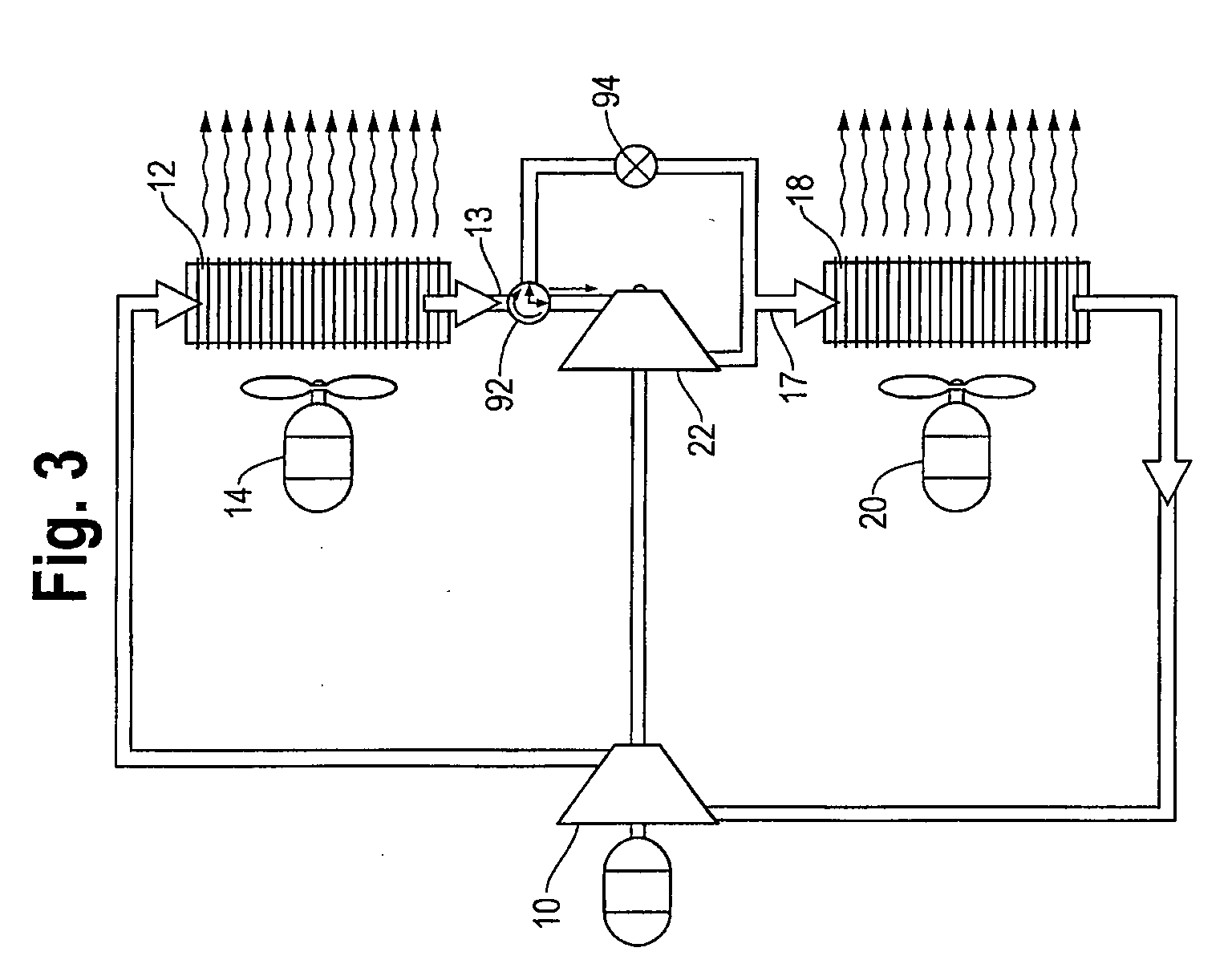

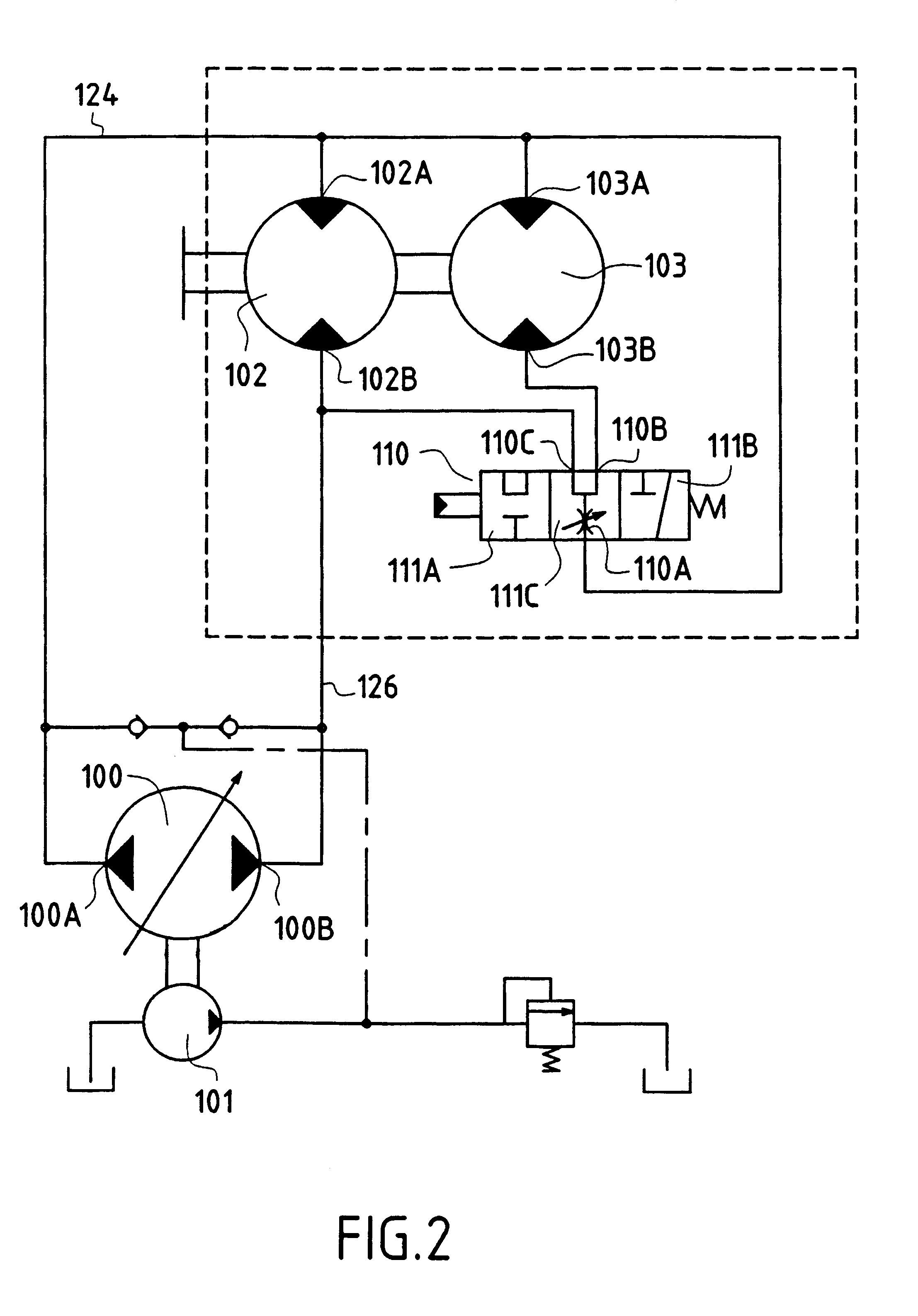

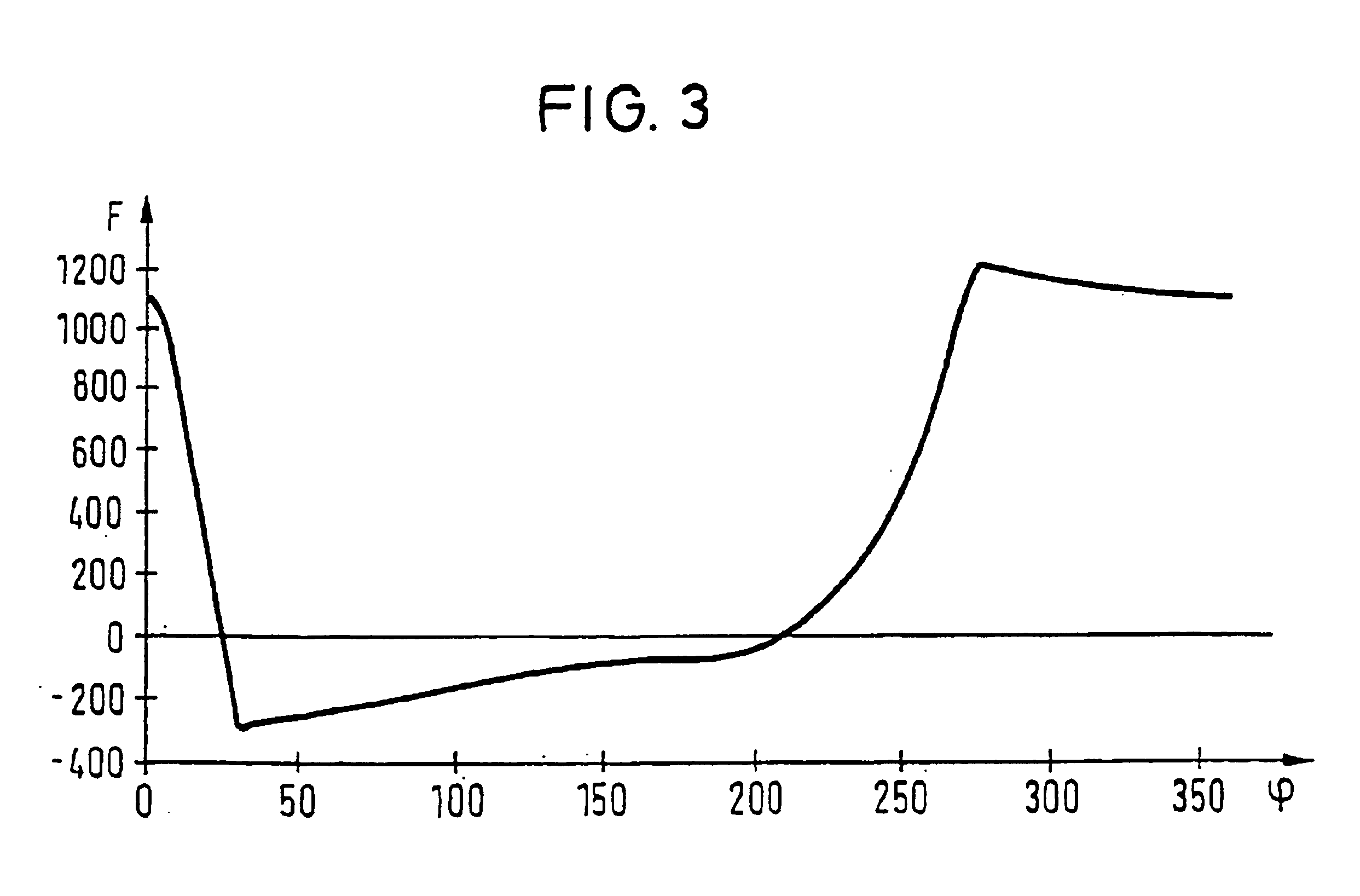

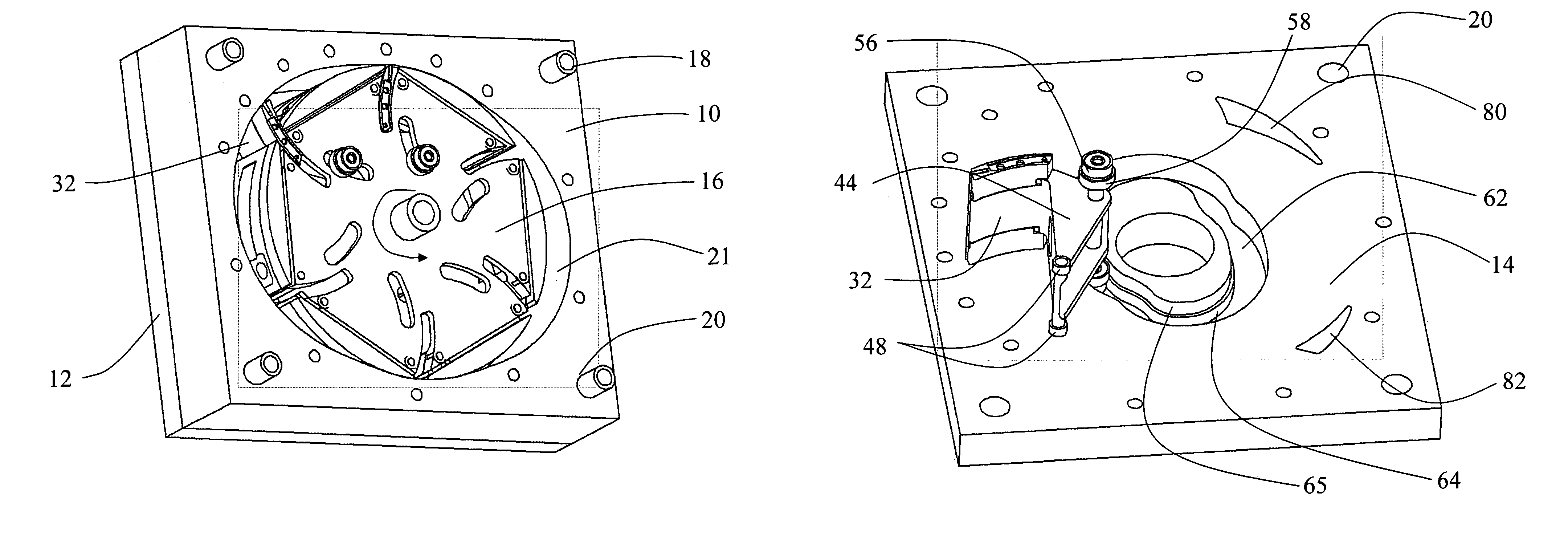

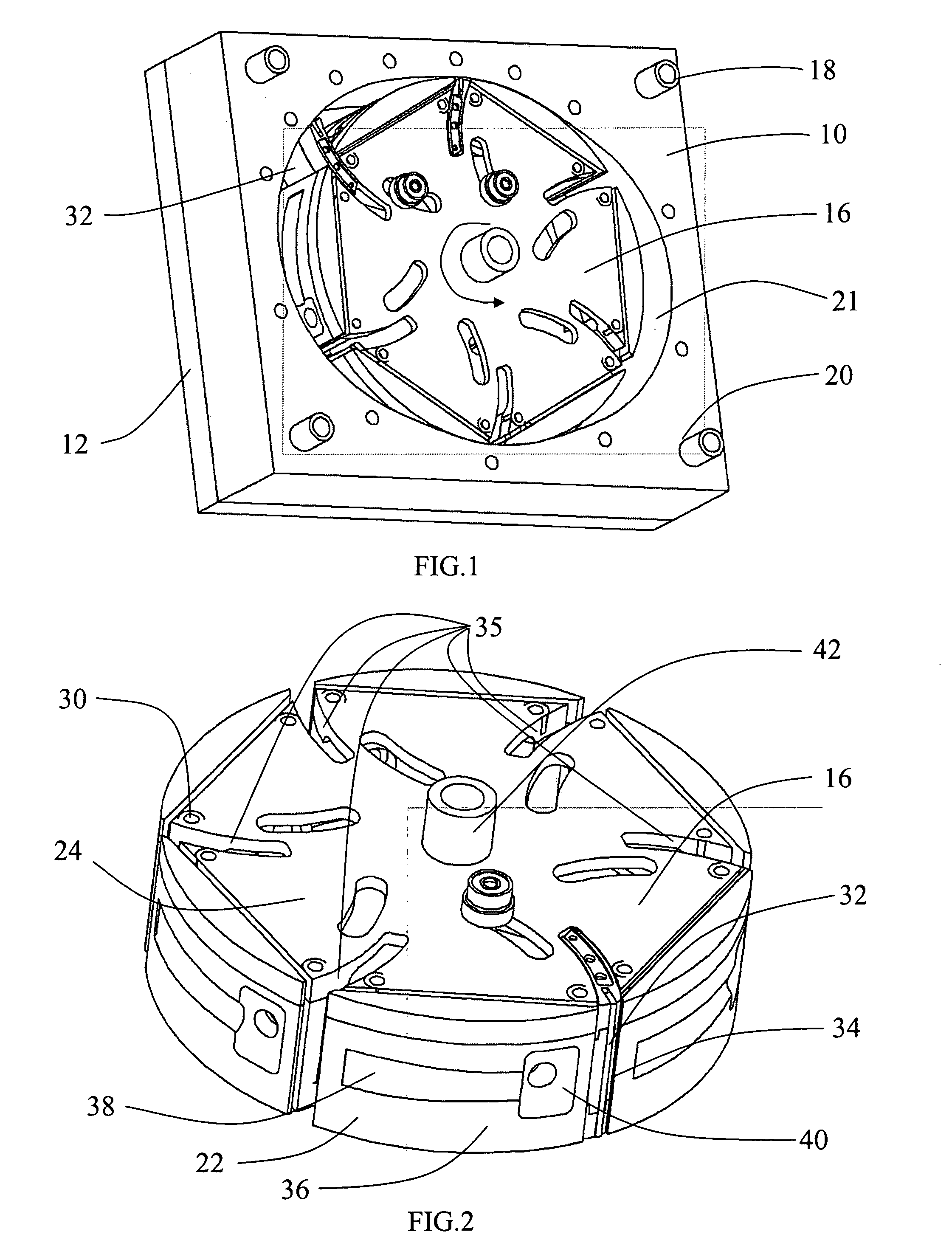

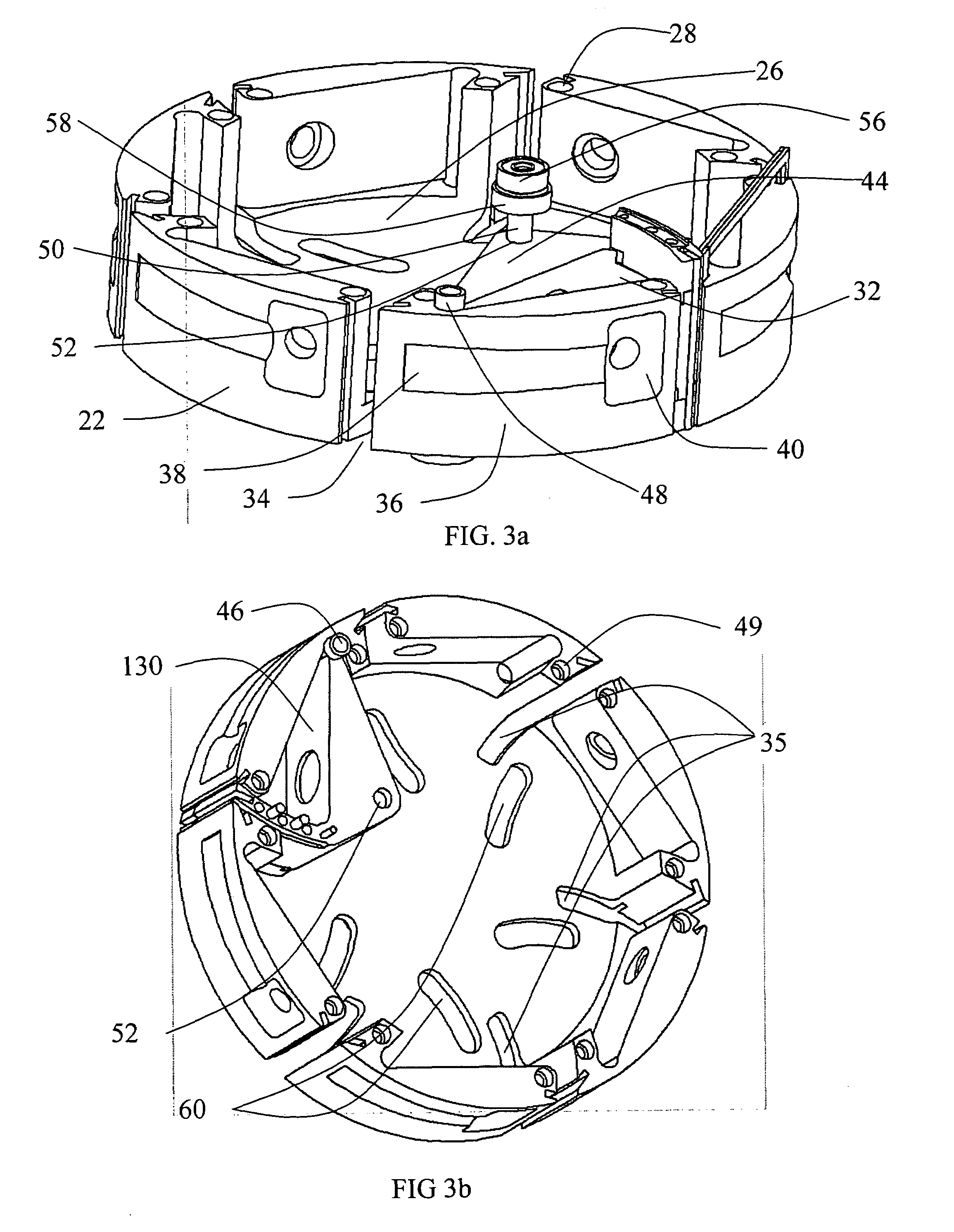

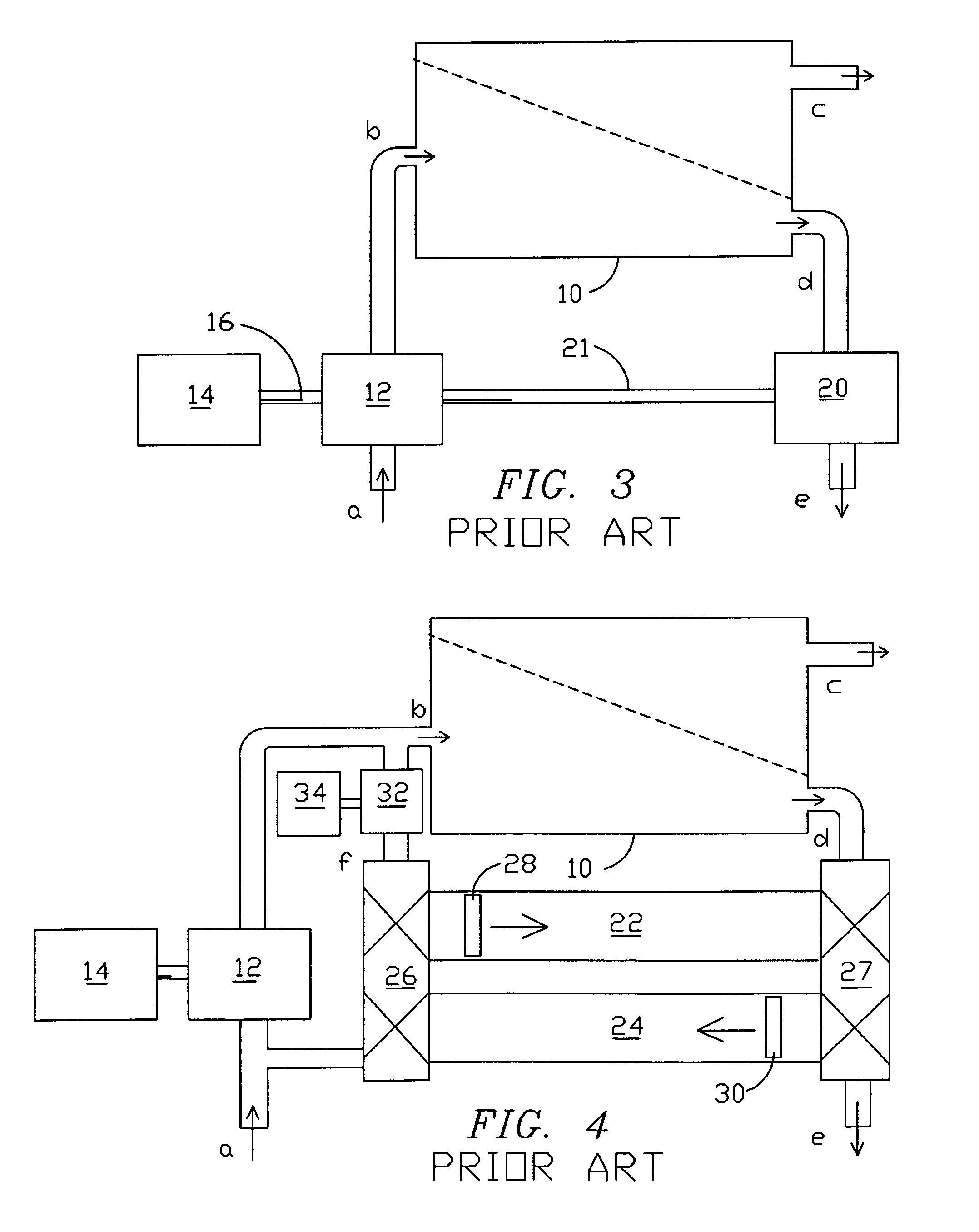

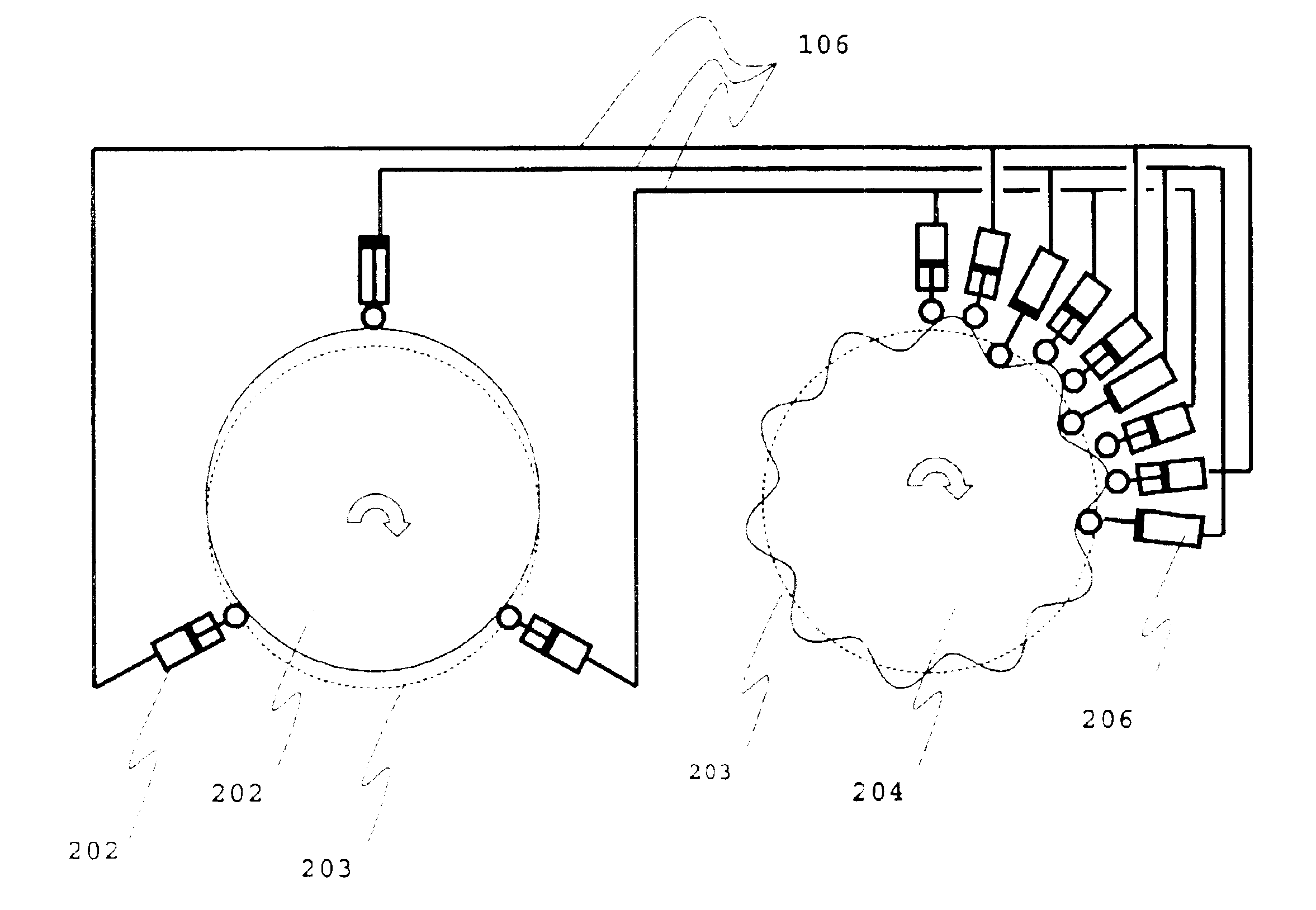

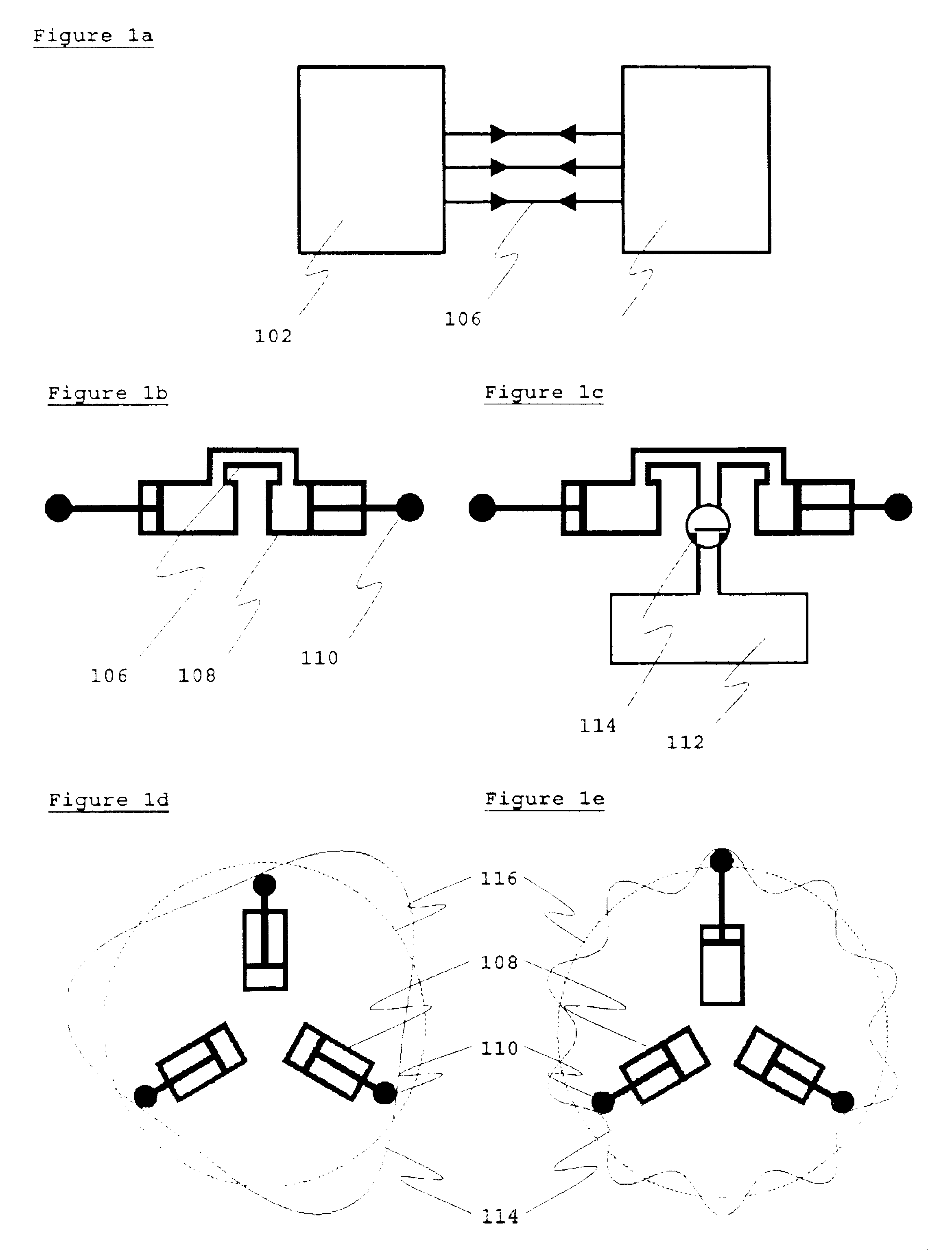

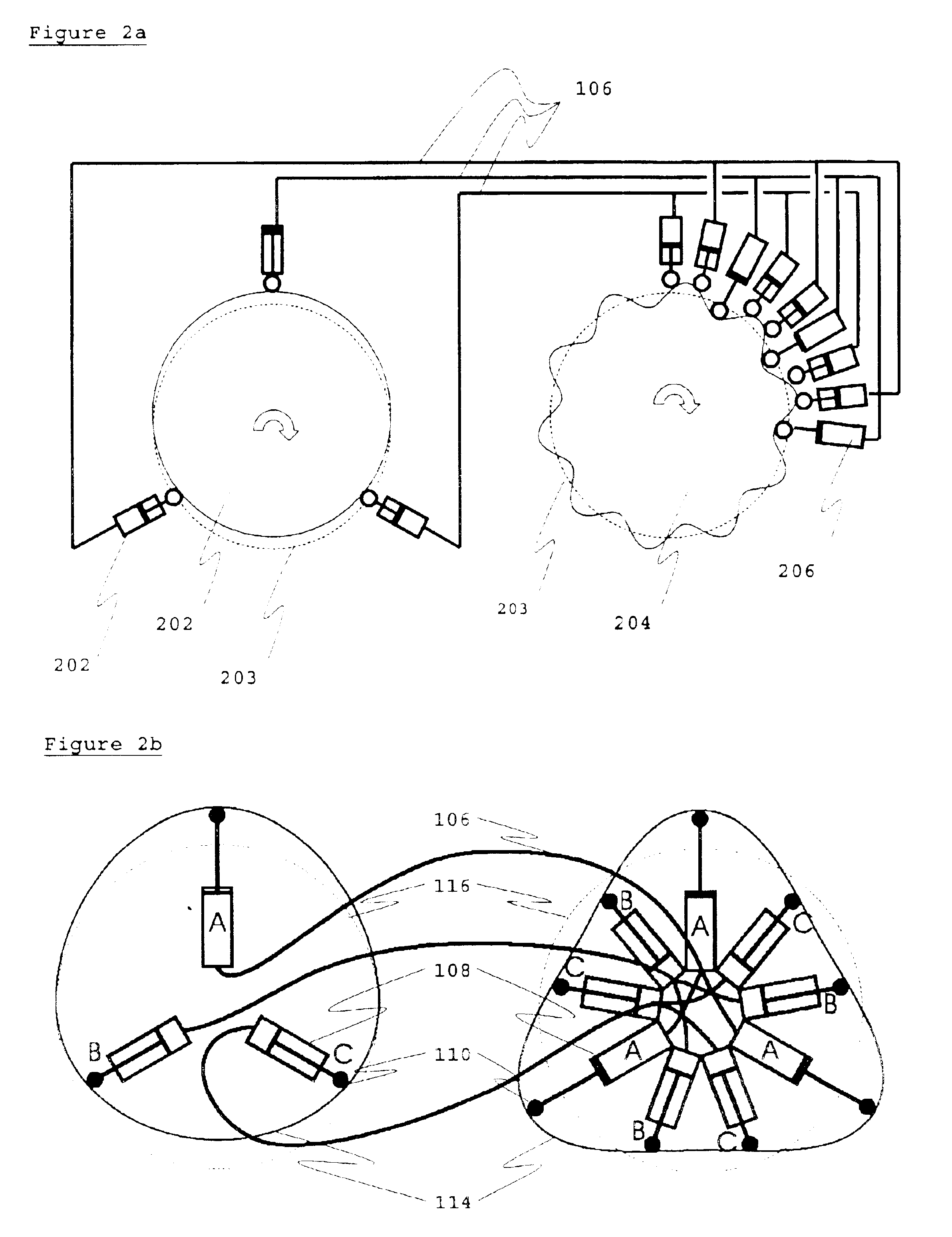

Polyphase hydraulic drive system

InactiveUS6837141B1Eliminate needEnhanced couplingFluid gearingsEngines with rotating cylindersEngineeringCam

The present invention comprises an input drive system, which provides a plurality of phases of oscillating fluid flow, and an output drive system connected directly to the input drive system that is powered by the plurality of phases of oscillating fluid flow. The input drive system comprises a plurality of pistons that are caused to move in a reciprocating fashion by a power source. The power source may be a rotating power source, such as that provided by an electric motor, a diesel or petrol engine, or a turbine system. The input drive system comprises a cam ring attached to a rotating power source, a plurality of cam rollers in contact with the cam ring; and a plurality of pistons attached to the cam rings. The output drive system comprises one or more pistons that are attached to move in a reciprocating fashion by the oscillating fluid flow provided by the input drive system. The output drive system comprises a cam ring attached to a load, a plurality of cam rollers in contact with the cam ring, and a plurality of pistons attached to the cam rings.

Owner:BOREALIS TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com