Radial engine power system

a power system and radial engine technology, applied in the direction of reciprocating piston engines, positive displacement engines, combustion engines, etc., can solve the problems of reducing unable to exploit certain characteristics of internal combustion engines, and affecting the service life of conventional engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

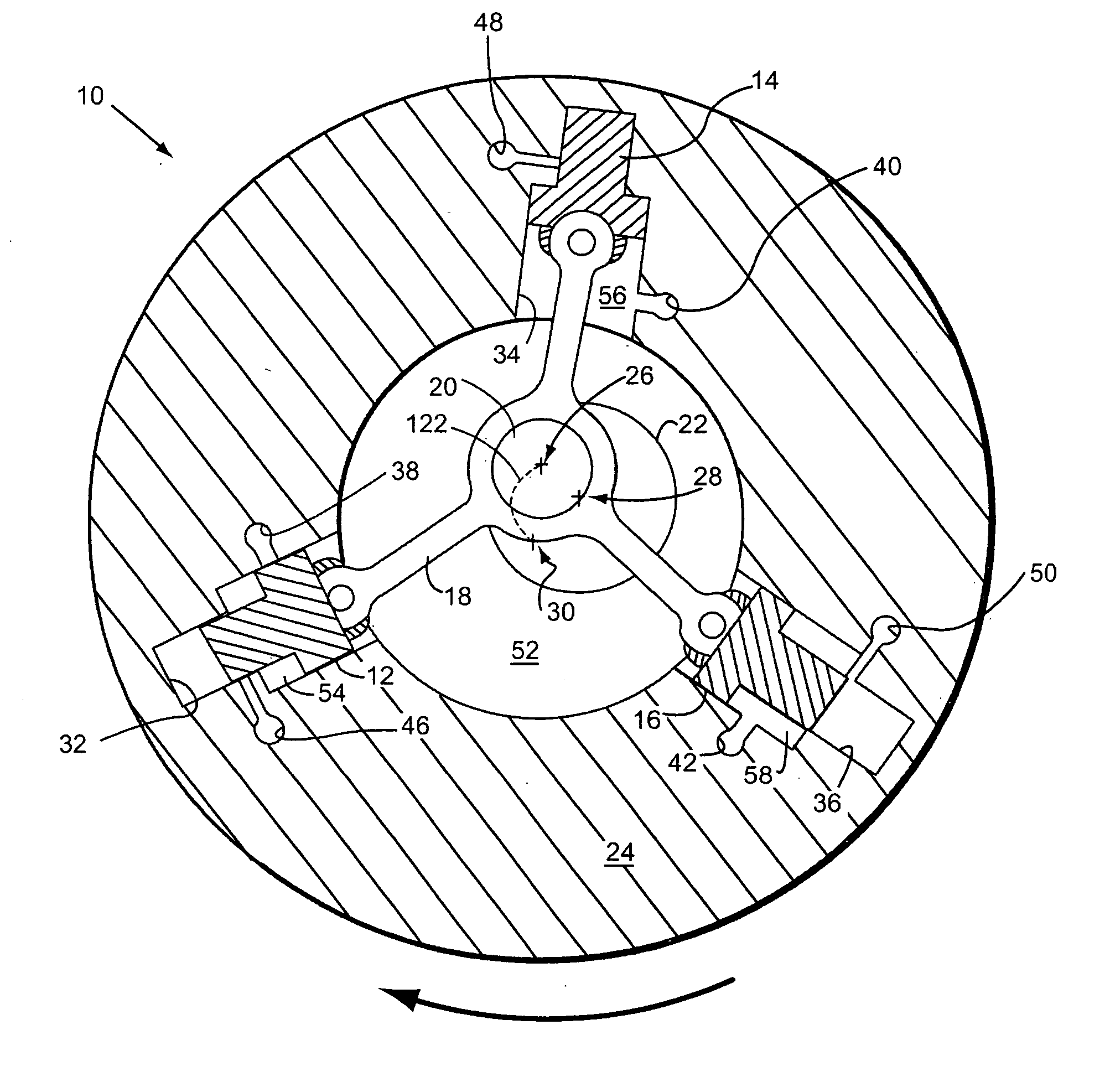

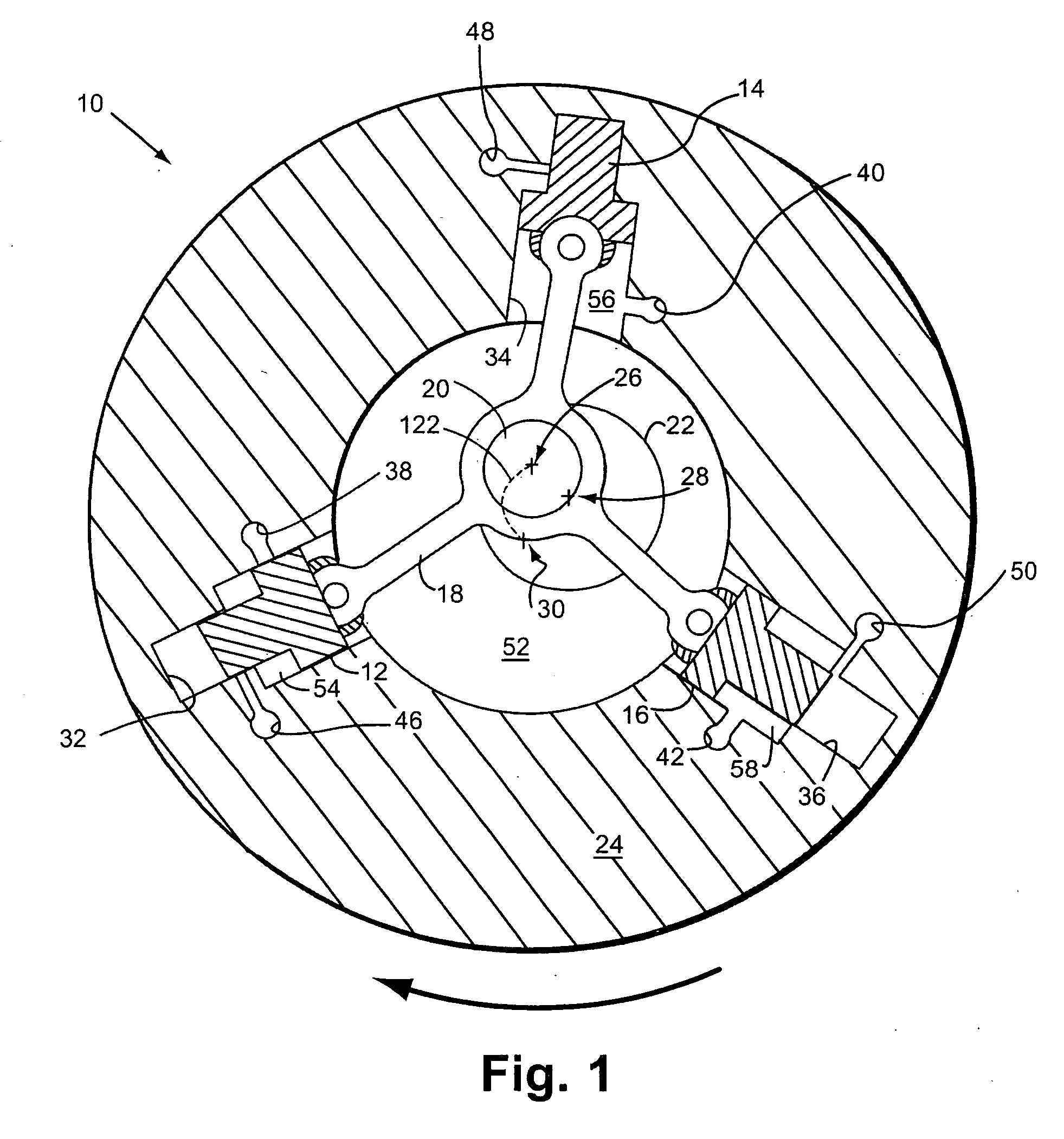

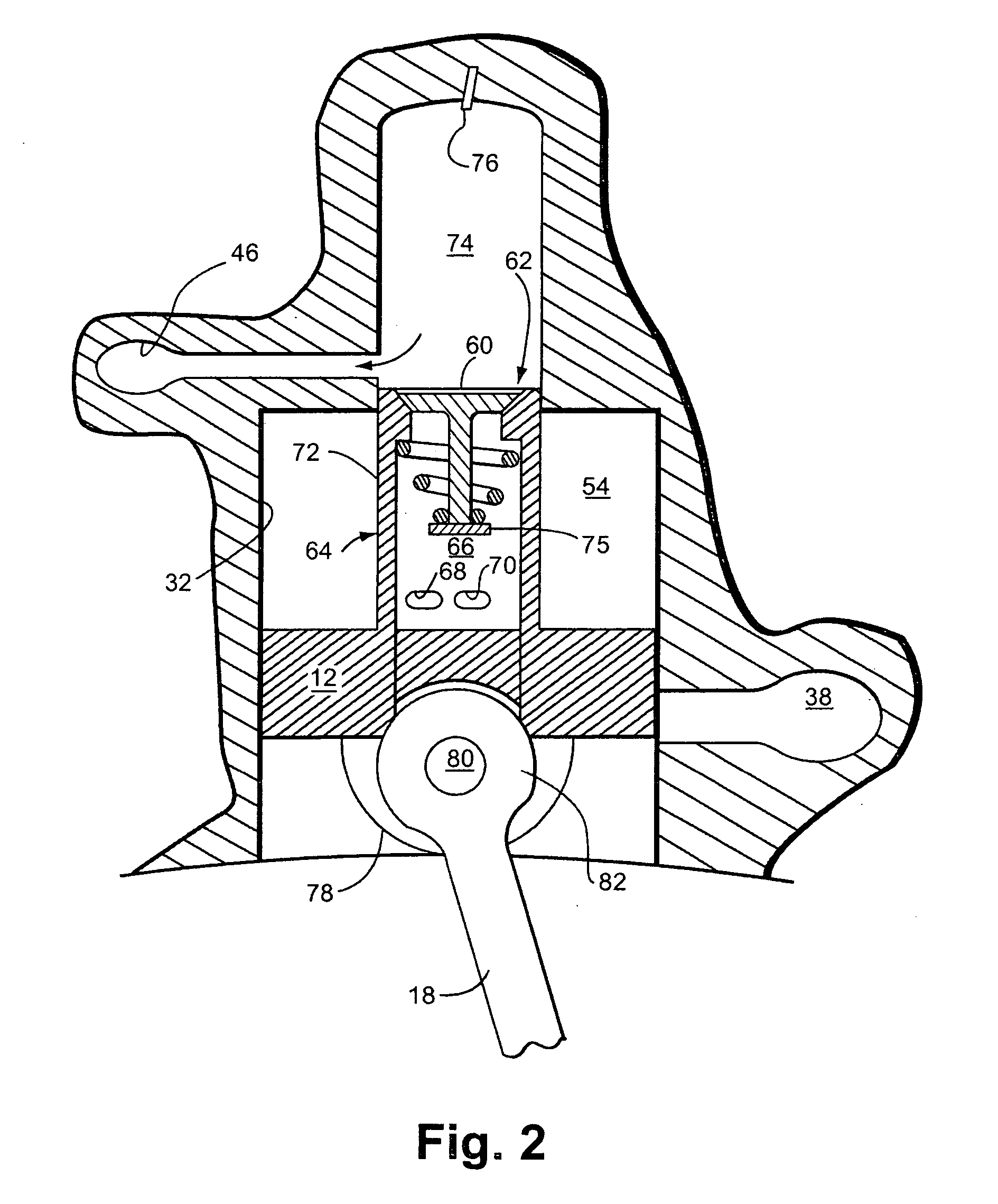

[0032] The present invention combines the attributes of a radial rotary engine 10 with an energy storage system. Referring first to FIG. 1, basic operation of a radial rotary engine will be summarized. A plurality of pistons 12, 14, 16 are pivotally connected to a multi-armed connecting rod 18 which in turn encircles a journal 20 of a crankshaft 22. Journal 20 is eccentrically located on crankshaft 22. Crankshaft 22 is located inside annular cylinder block 24. Three axes 26, 28, 30 are seen in the top plan view of FIG. 1. Axis 26 indicates the center line of journal 20. Axis 28 indicates the center line of crankshaft 22. Axis 30 indicates the rotational axis of cylinder block 24. In a radial rotary engine, crankshaft 22 is fixed to its associated vehicle (not shown in its entirety). As will be explained, cylinder block 24 rotates about stationary crankshaft 22. Pistons 12, 14, 16 and connecting rod 18 rotate in tandem with cylinder block, but in respective compound motions. Pistons ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com