Positive-displacement machine

a positive displacement and displacement technology, applied in the direction of positive displacement liquid engines, pump control, positive displacement engines, etc., can solve the problems of friction loss, cylinder-piston units of the second radial plane can be switched on or off, cylinder-piston units are always active, etc., to reduce the loss of machine energy, increase volumetric flow or torque, and increase idle volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

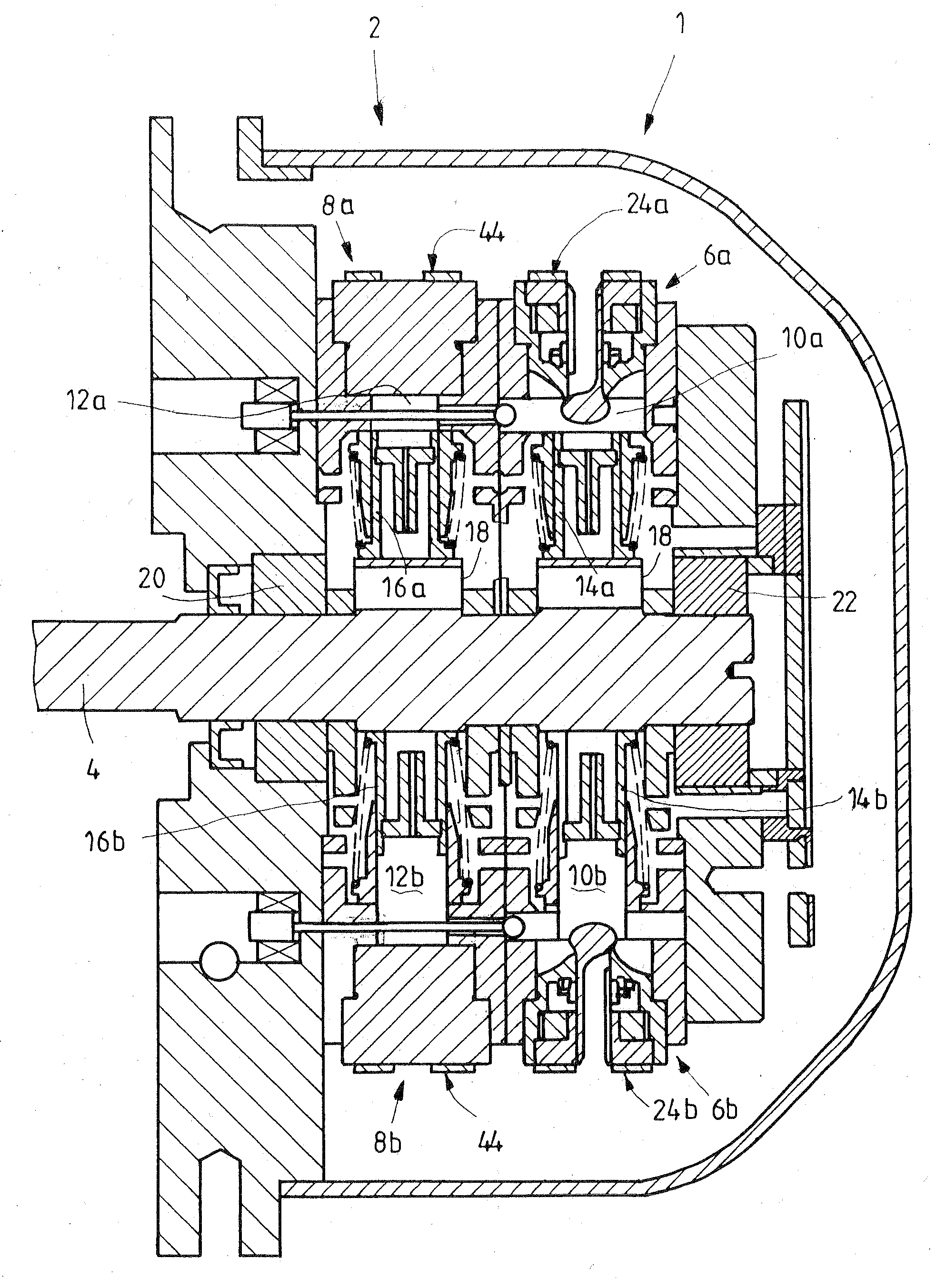

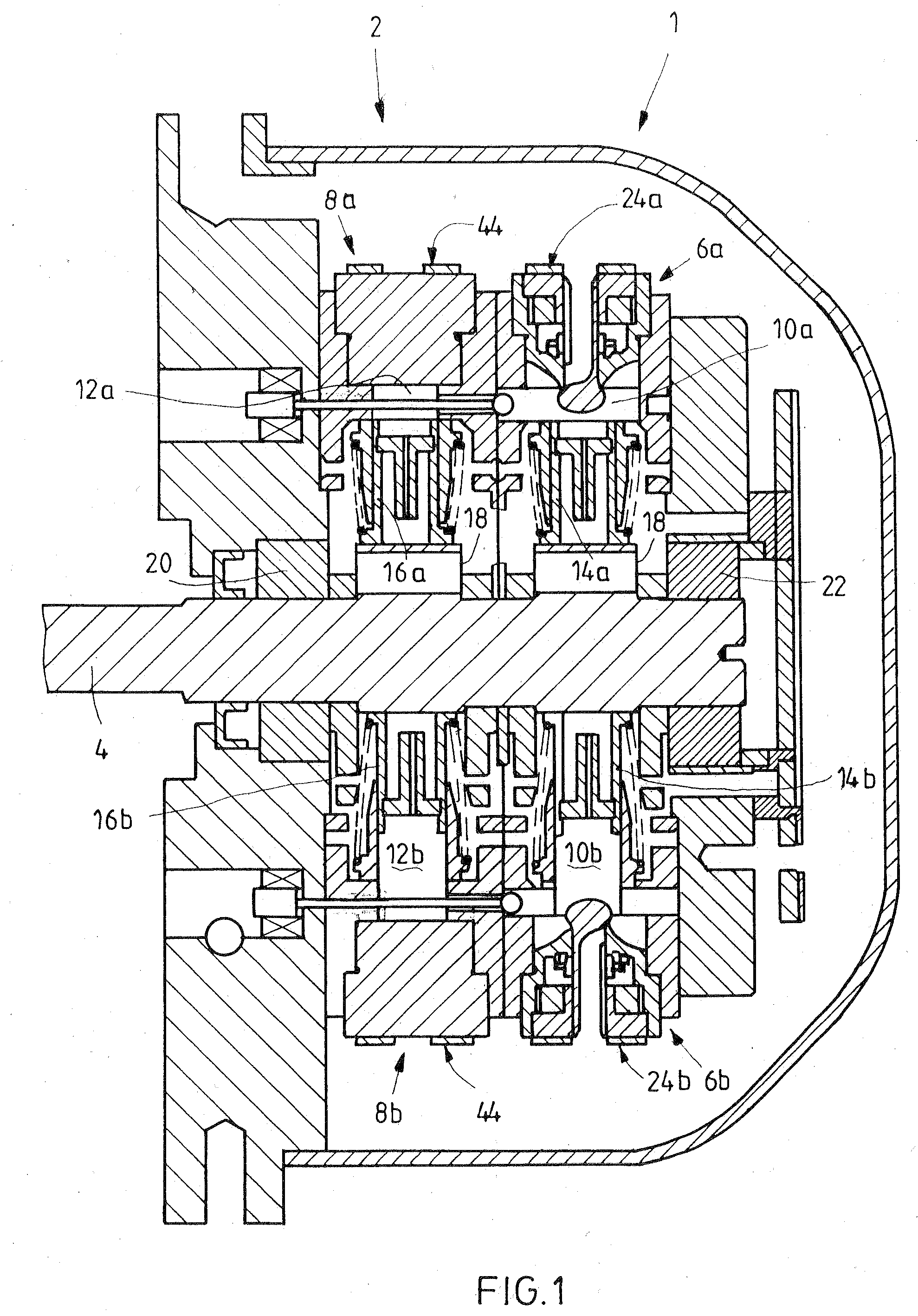

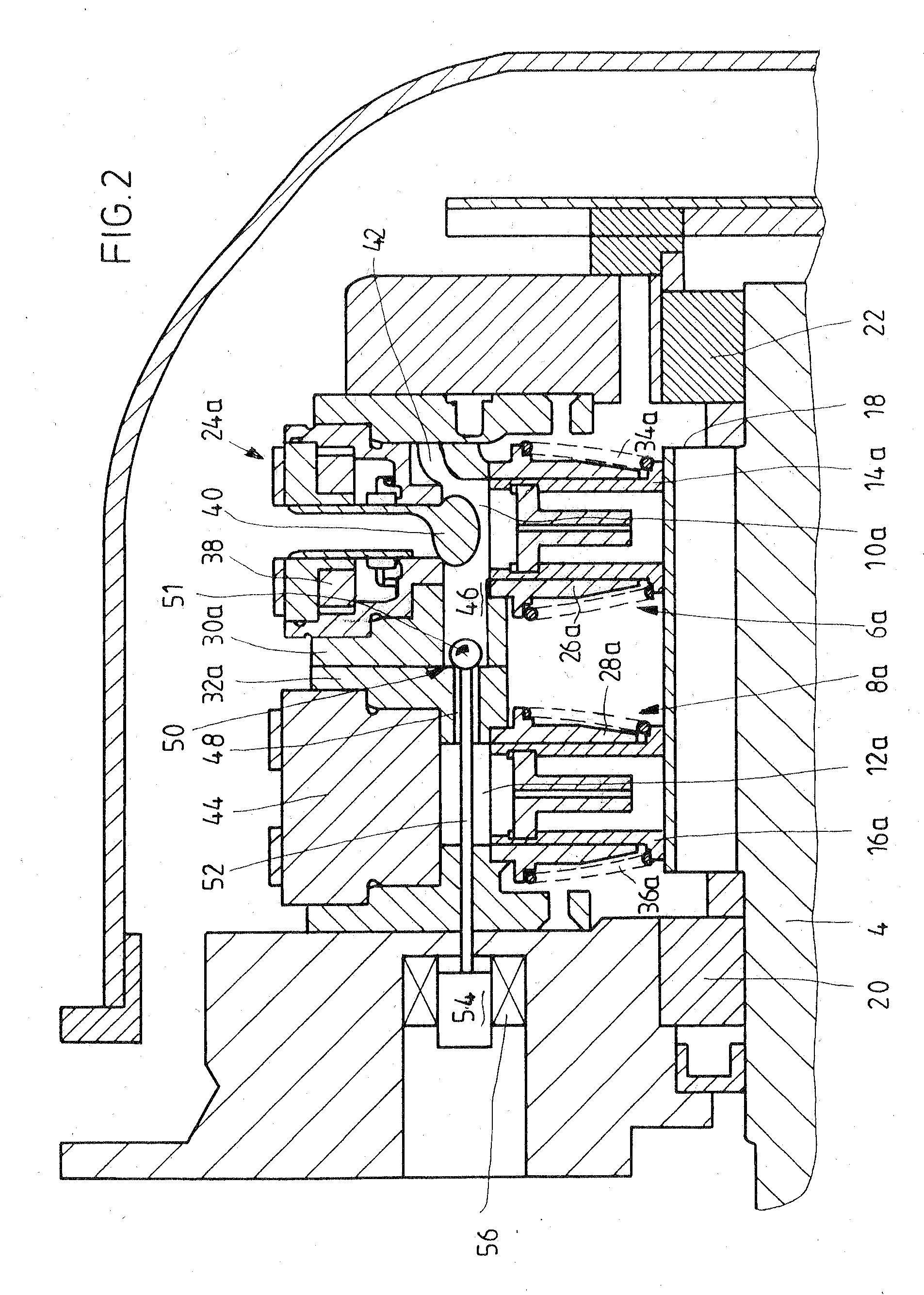

[0028]FIG. 1 shows an exemplary embodiment of a valve-controlled radial piston machine of the invention in section. It has a primary radial plane 1 and a secondary radial plane 2, and each plane 1, 2 has six cylinder-piston units, which are arranged in a star pattern around a shaft 4. Of the six units in each plane, only two units 6a, 6b and 8a, 8b, facing one another, are shown in FIG. 1. Each of the cylinder-piston units 6a, 6b, 8a, 8b has a work chamber 10a, 10b, 12a, 12b and a piston 14a, 14b, 16a, 16b; the pistons 14a, 14b, 16a, 16b are braced on an eccentric element 18 of the shaft 4.

[0029]The shaft 4, which depending on the mode of operation of the radial piston machine shown is a drive shaft or a power takeoff shaft, is supported rotatably, together with the eccentric element 18 secured to it, in the radial piston machine via two roller bearings 20, 22. FIG. 1 shows a rotary position of the eccentric element 18 in which a circumferential portion of comparatively large radius...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com