Patents

Literature

75results about How to "Reduce coating thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

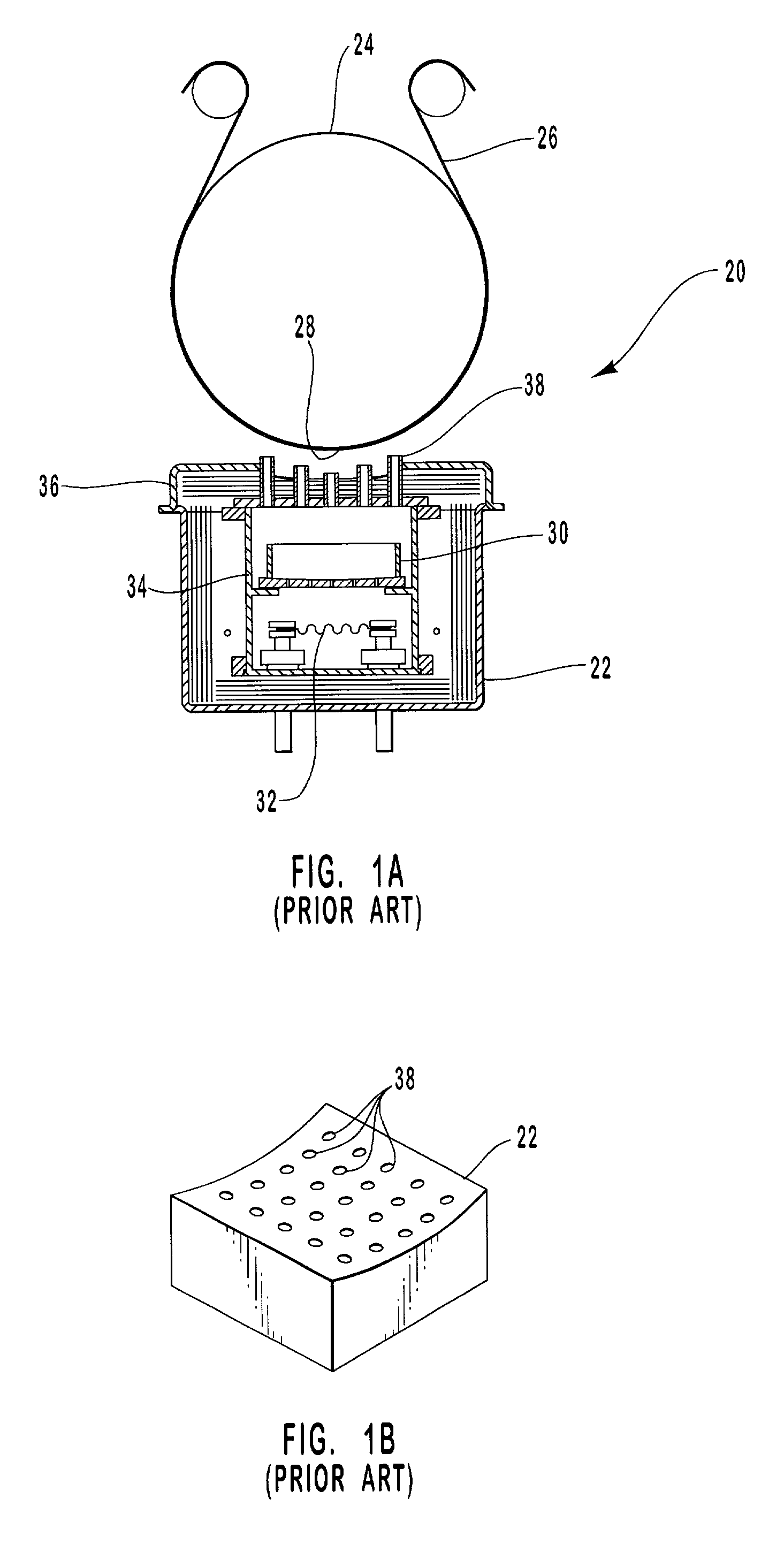

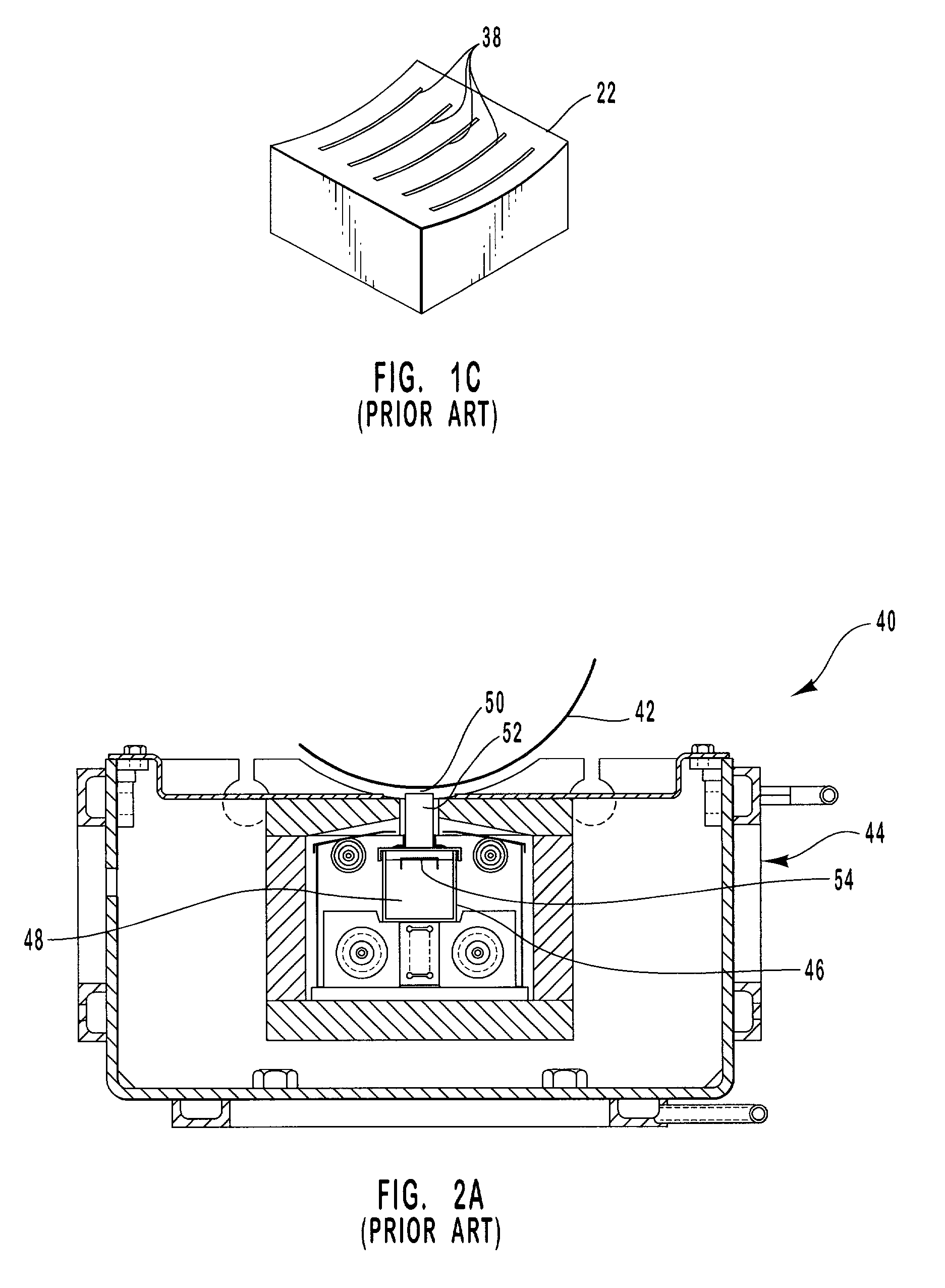

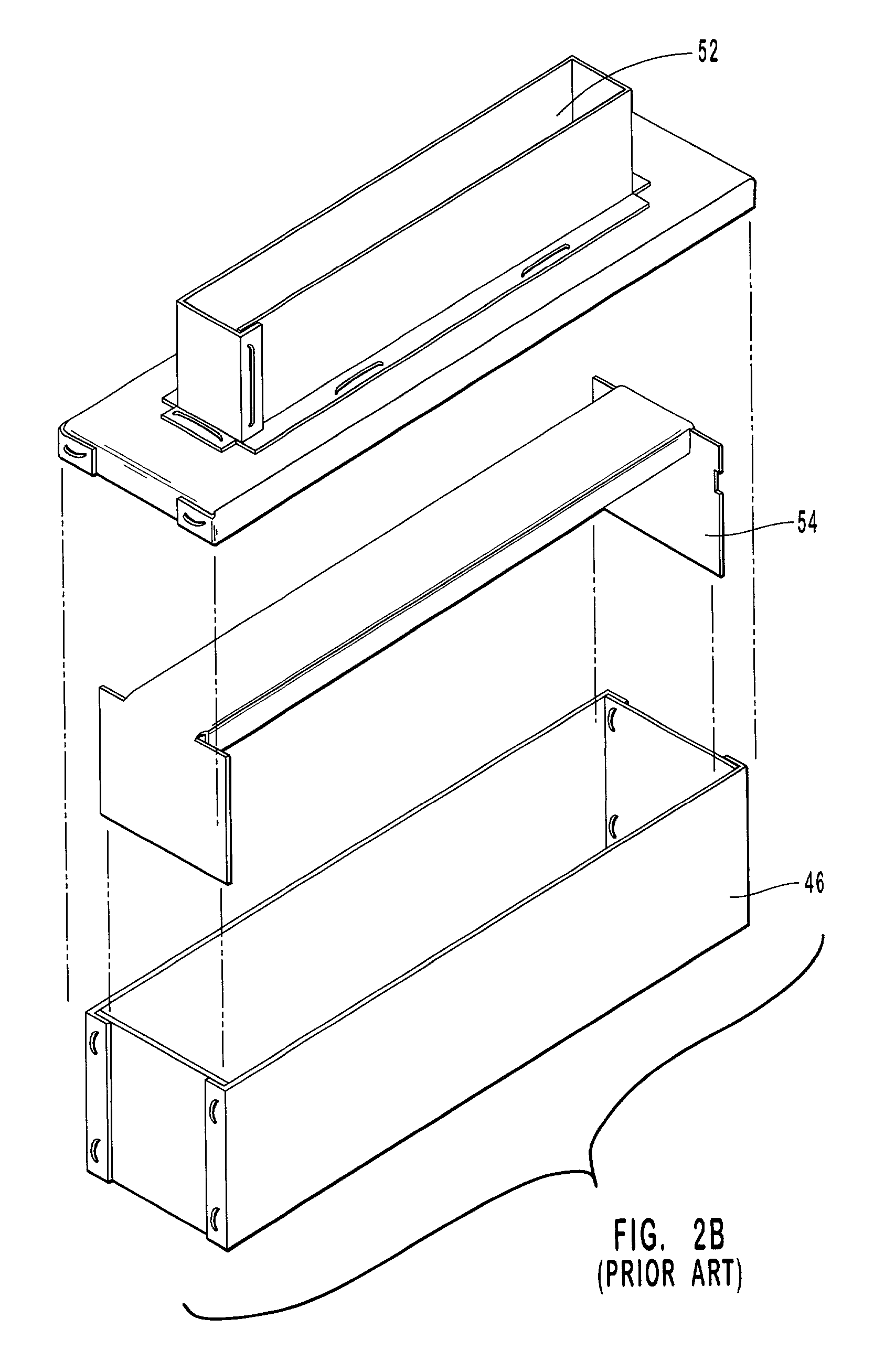

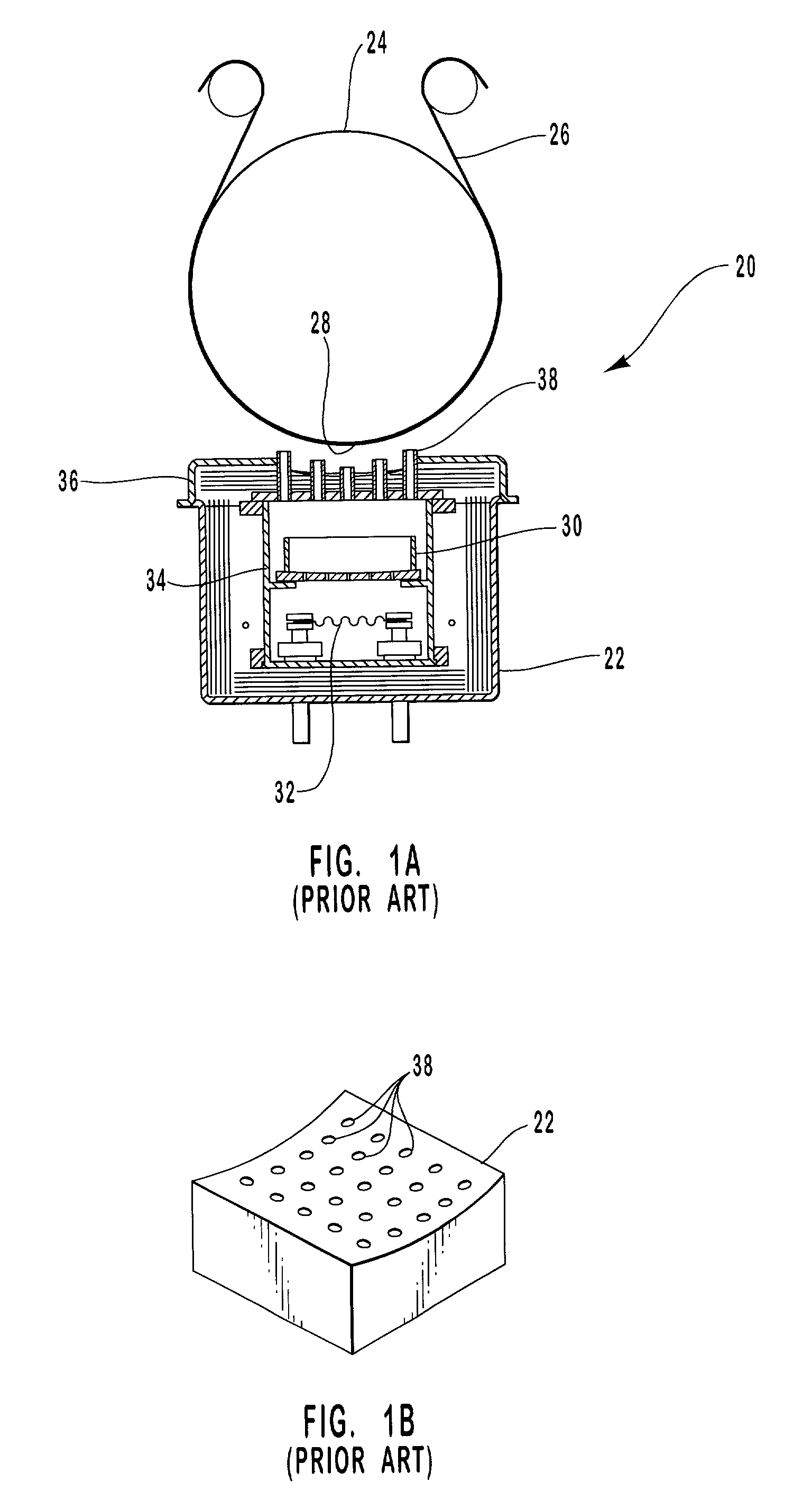

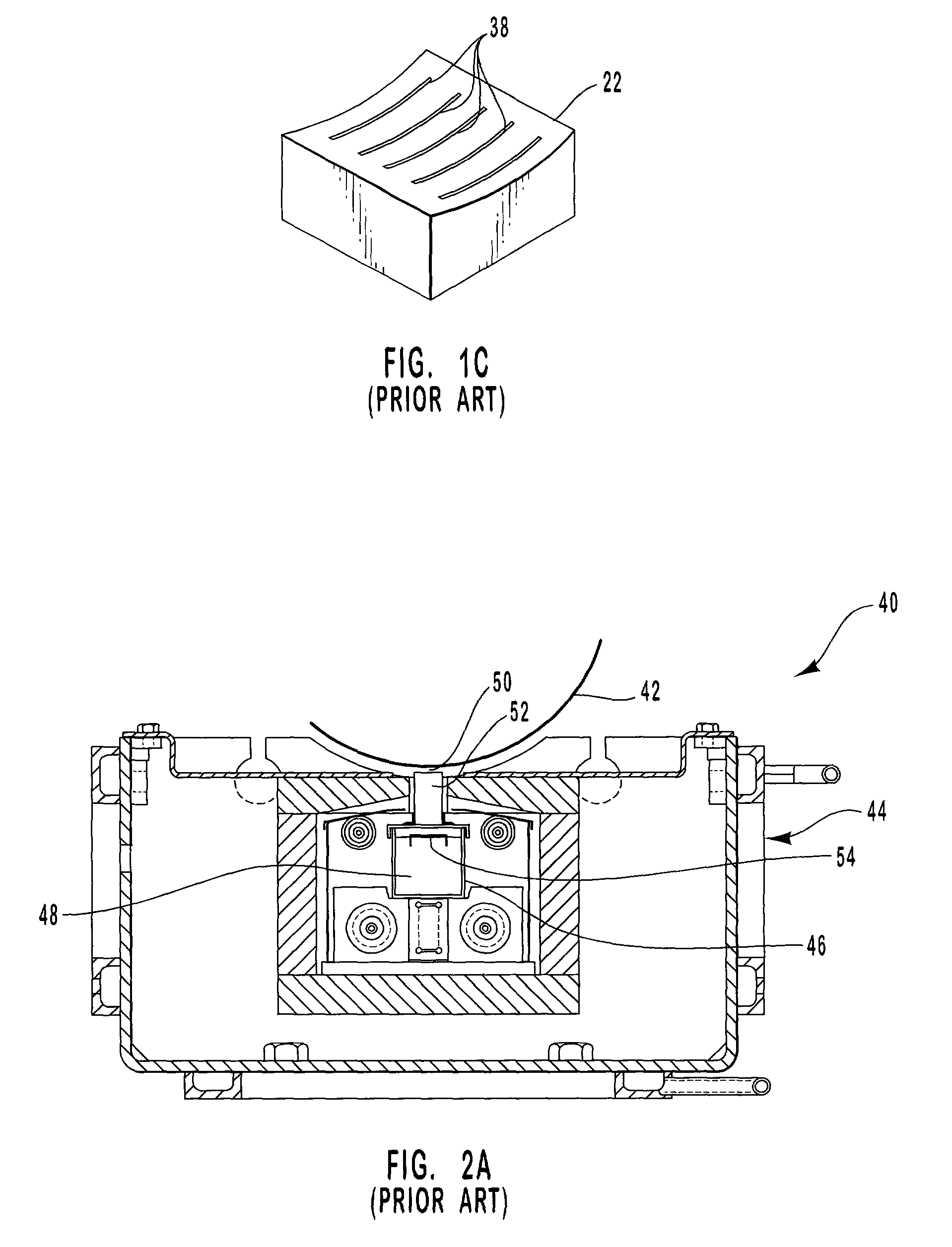

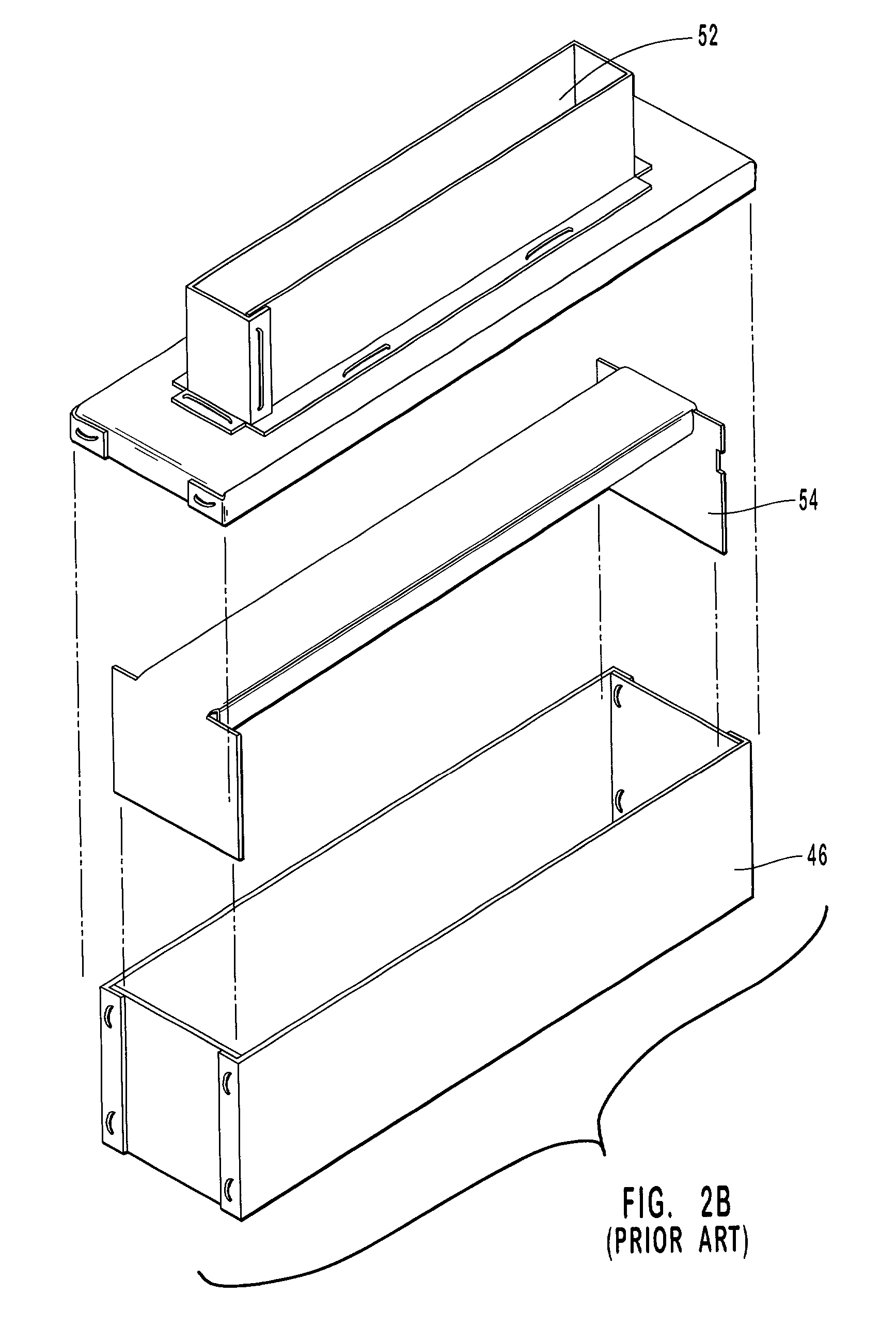

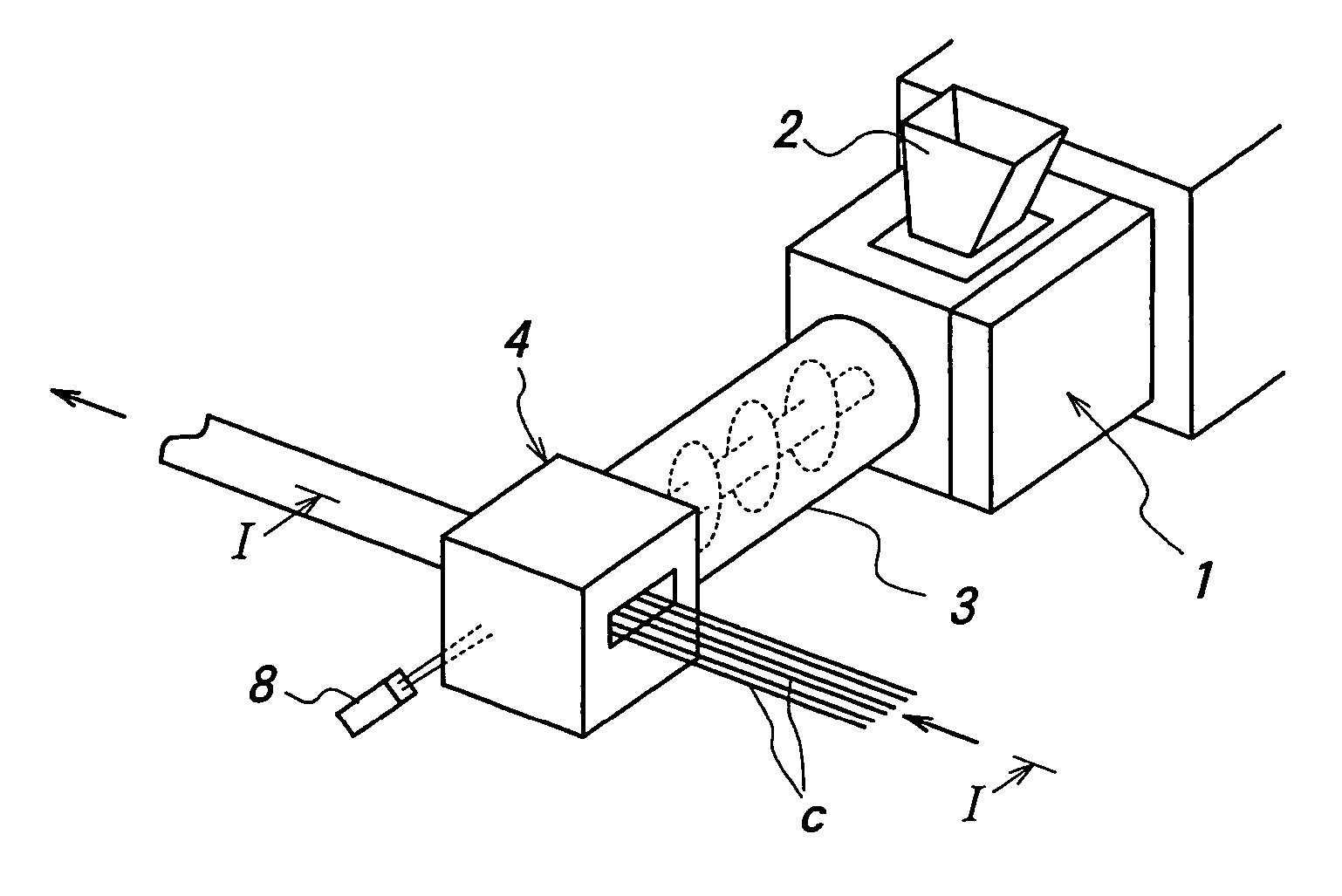

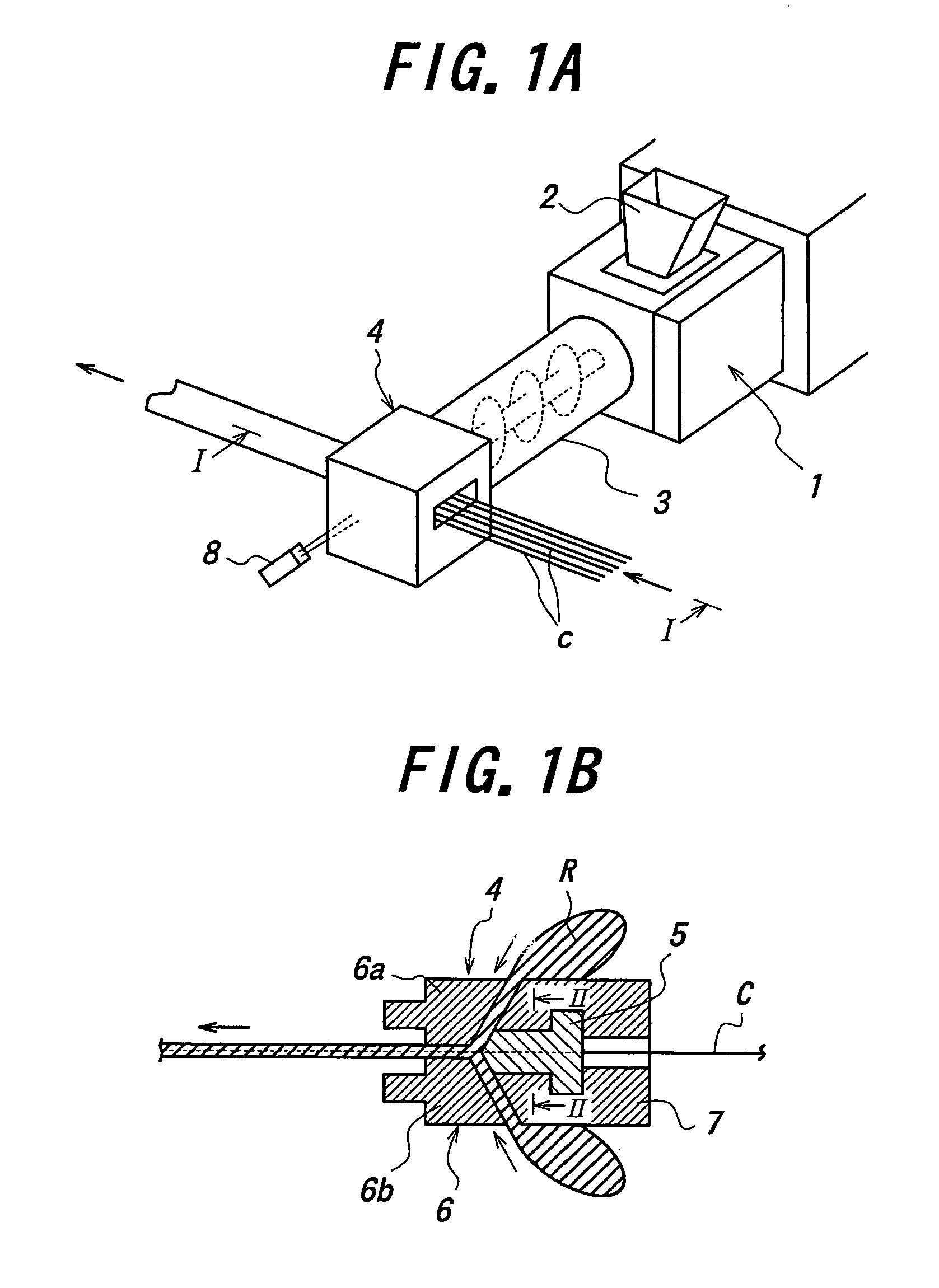

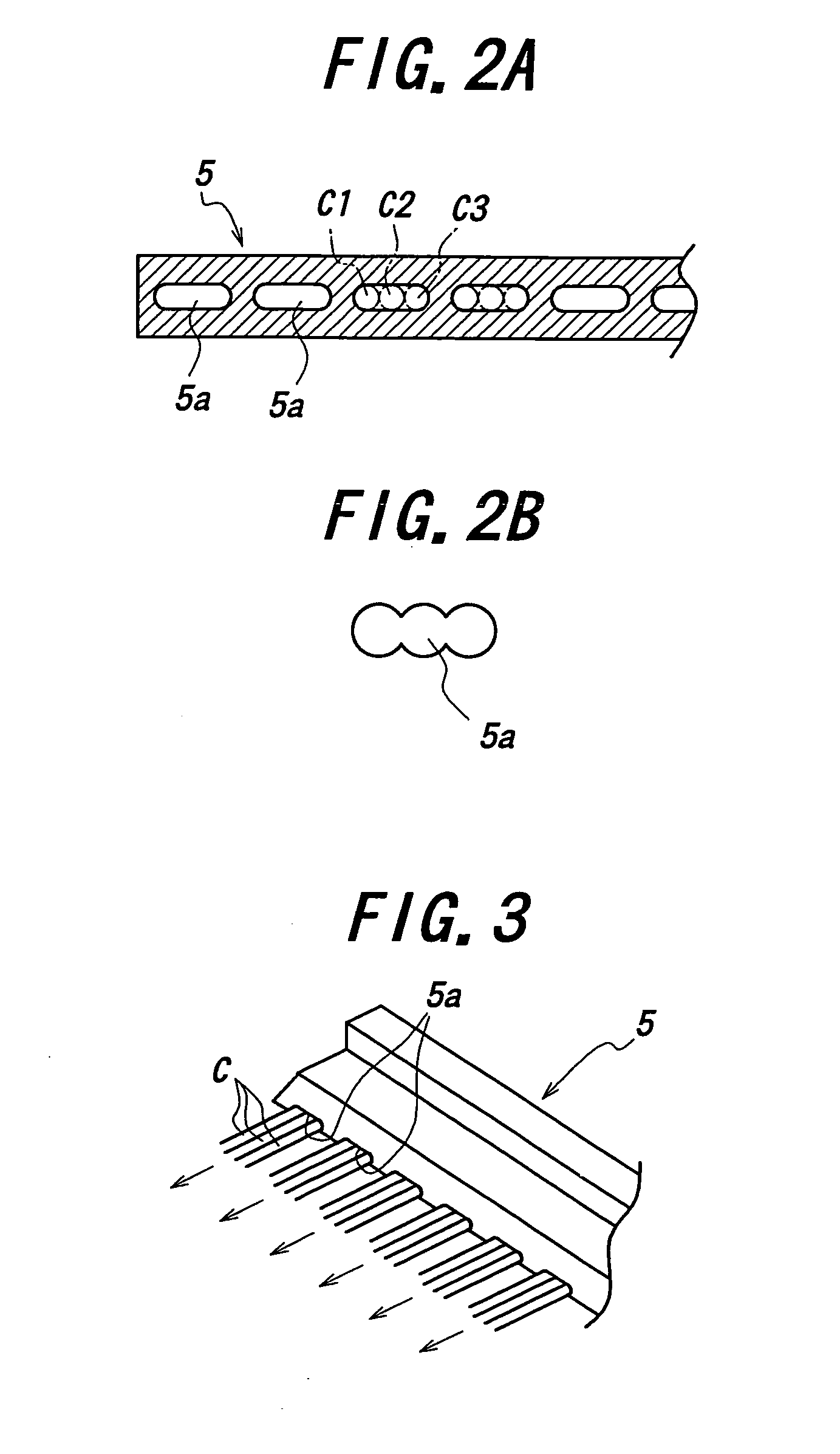

Linear aperture deposition apparatus and coating process

InactiveUS20010011524A1High and stable rateEasy to useVacuum evaporation coatingSputtering coatingParticulatesSource material

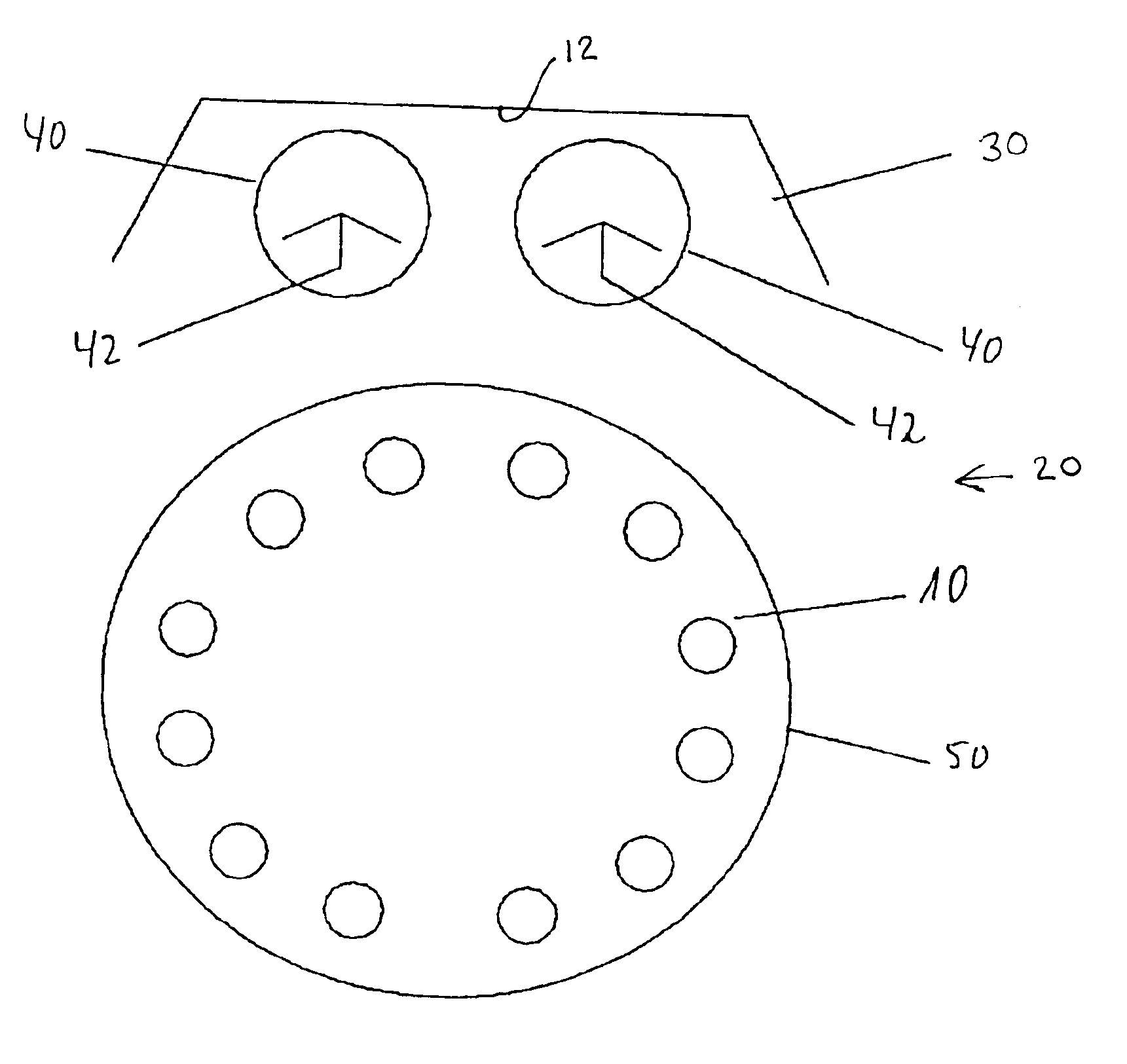

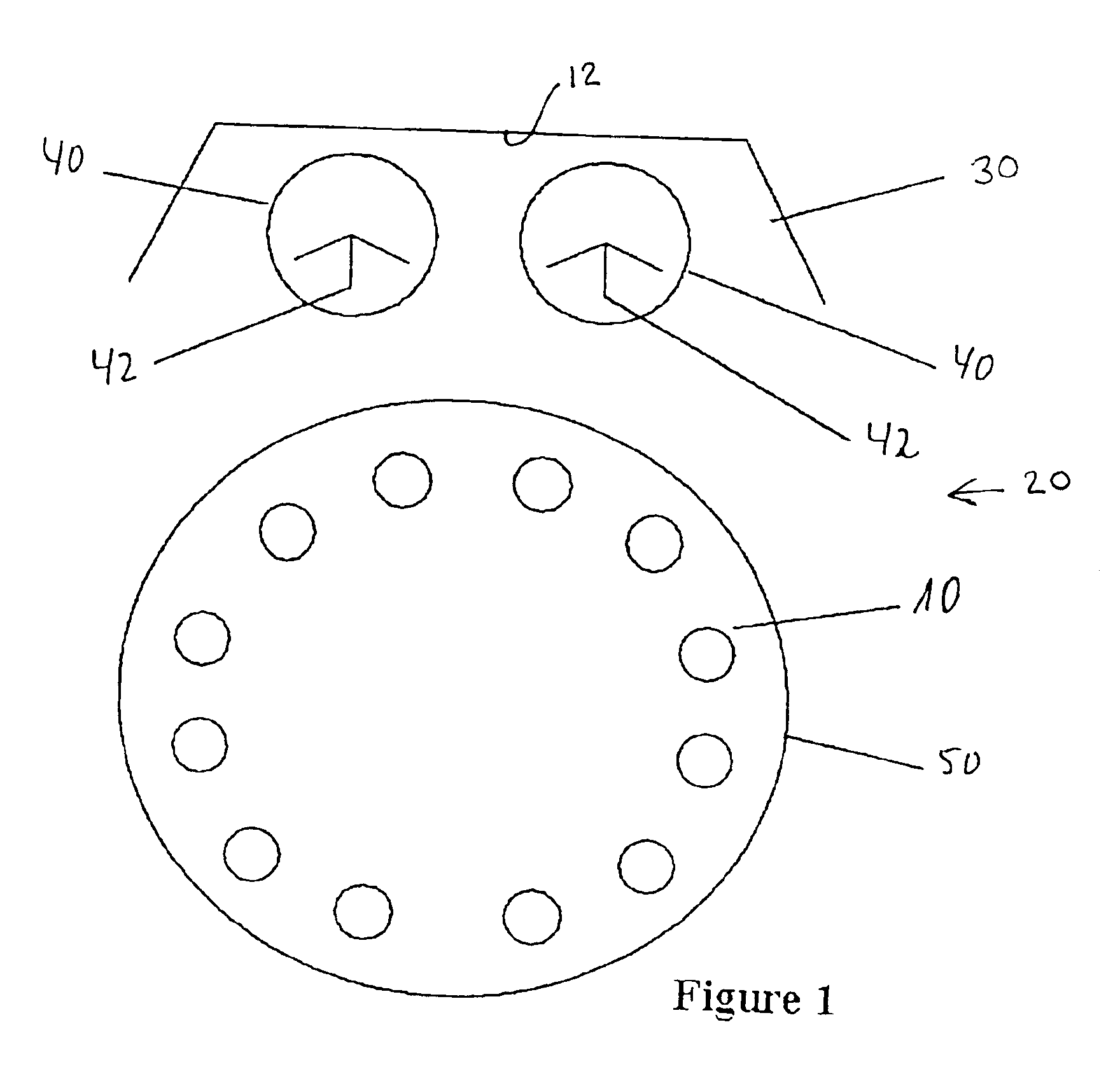

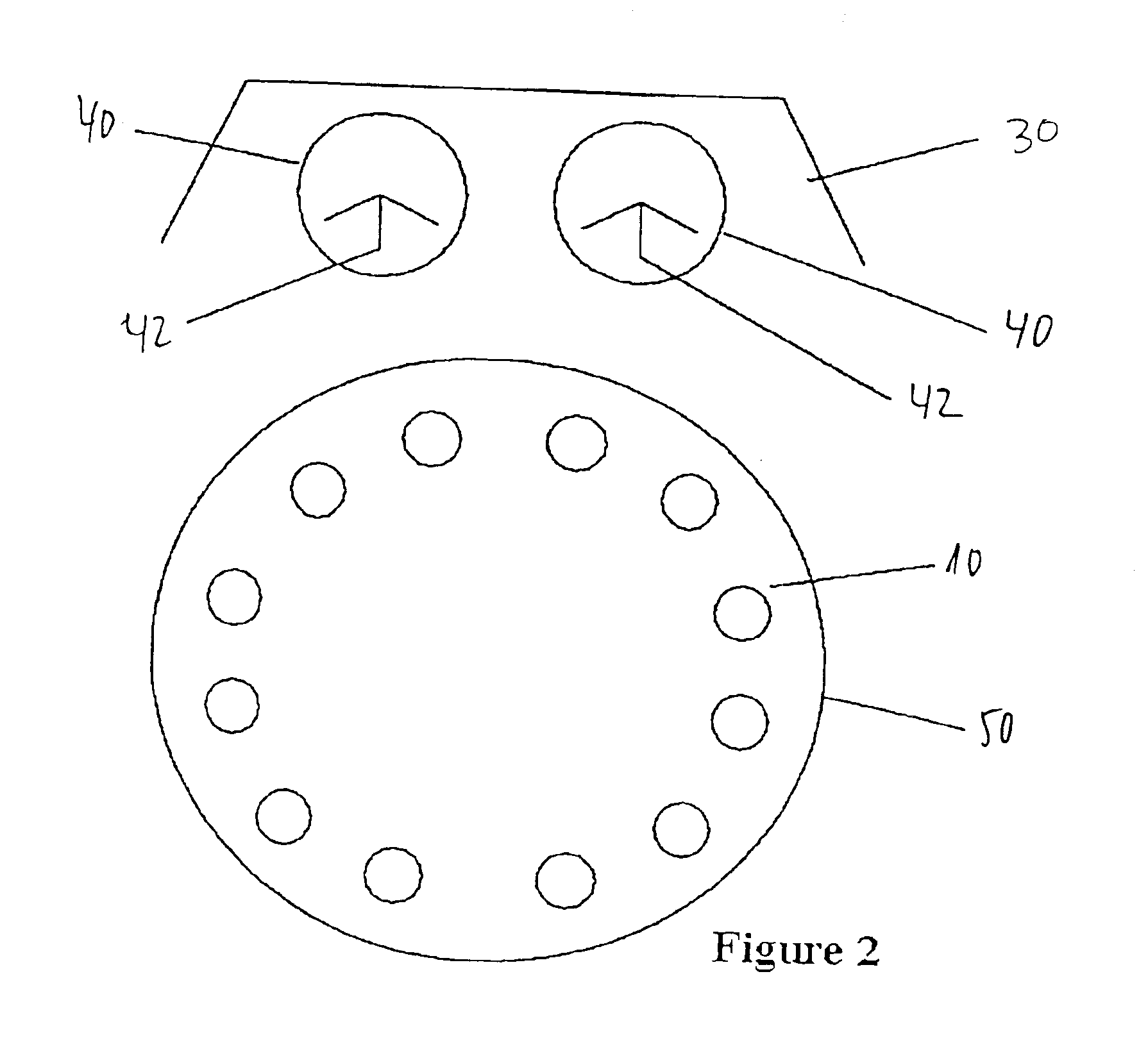

A linear aperture deposition apparatus and process are provided for coating substrates with sublimed or evaporated coating materials. The apparatus and process are particularly suited for producing flexible films having an optical interference coating with a very high surface thickness uniformity and which is substantially free of defects from particulate ejection of a source material. The apparatus includes a source box containing a source material, a heating element to sublime or evaporate the source material, and a chimney to direct the source material vapor from the source box to a substrate. A flow restricting baffle having a plurality of holes is positioned between the source material and the substrate to confine and direct the vapor flow, and an optional floating baffle is positioned on the surface of the source material to further restrict the vapor flow, thereby substantially eliminating source material spatter.

Owner:JDS UNIPHASE CORP

Linear aperture deposition apparatus and coating process

InactiveUS20010005553A1Increase temperatureShorten the lengthSynthetic resin layered productsVacuum evaporation coatingParticulatesSource material

A linear aperture deposition apparatus and process are provided for coating substrates with sublimed or evaporated coating materials. The apparatus and process are particularly suited for producing flexible films having an optical interference coating with a very high surface thickness uniformity and which is substantially free of defects from particulate ejection of a source material. The apparatus includes a source box containing a source material, a heating element to sublime or evaporate the source material, and a chimney to direct the source material vapor from the source box to a substrate. A flow restricting baffle having a plurality of holes is positioned between the source material and the substrate to confine and direct the vapor flow, and an optional floating baffle is positioned on the surface of the source material to further restrict the vapor flow, thereby substantially eliminating source material spatter.

Owner:WITZMAN MATTHEW R +3

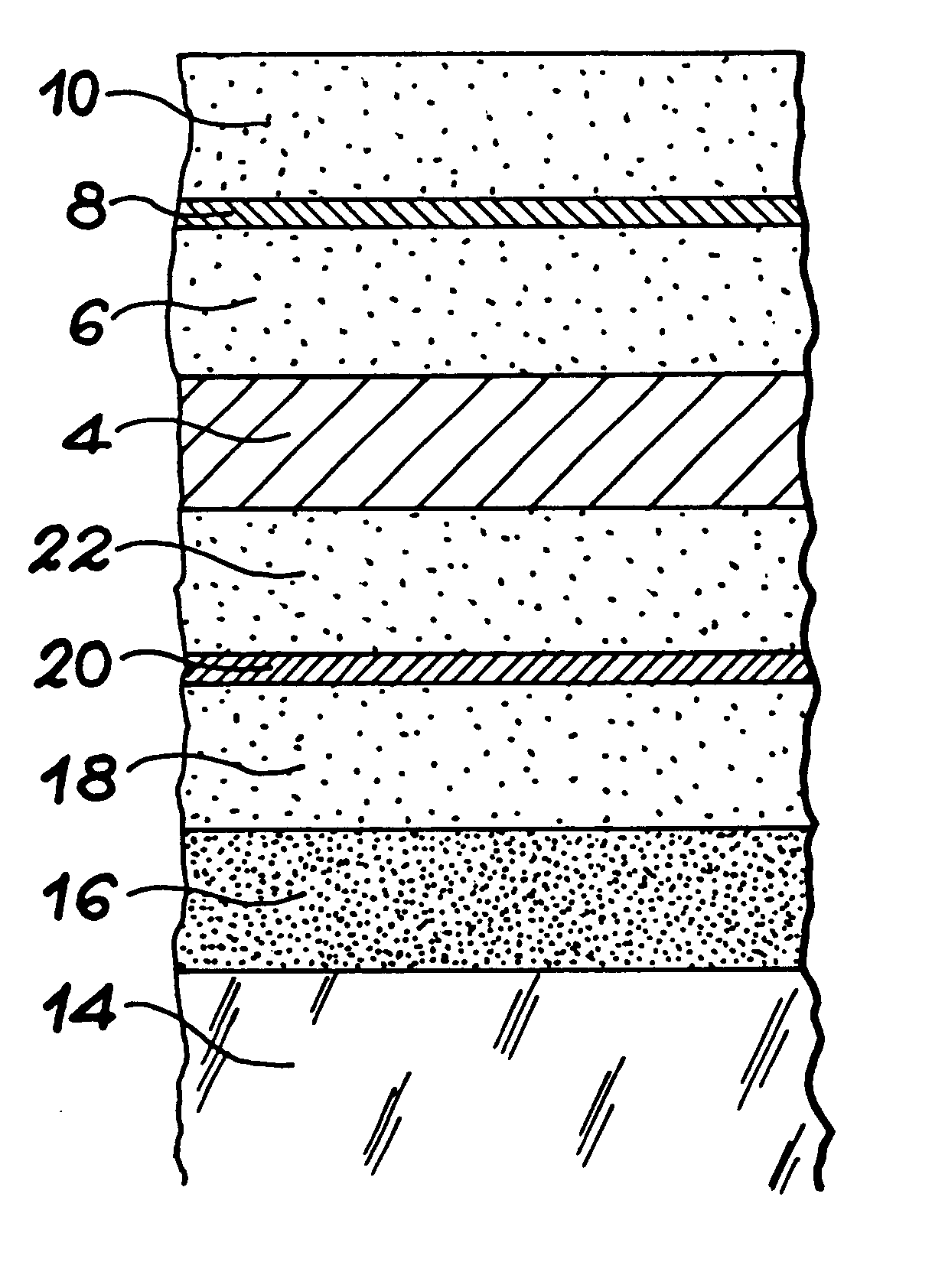

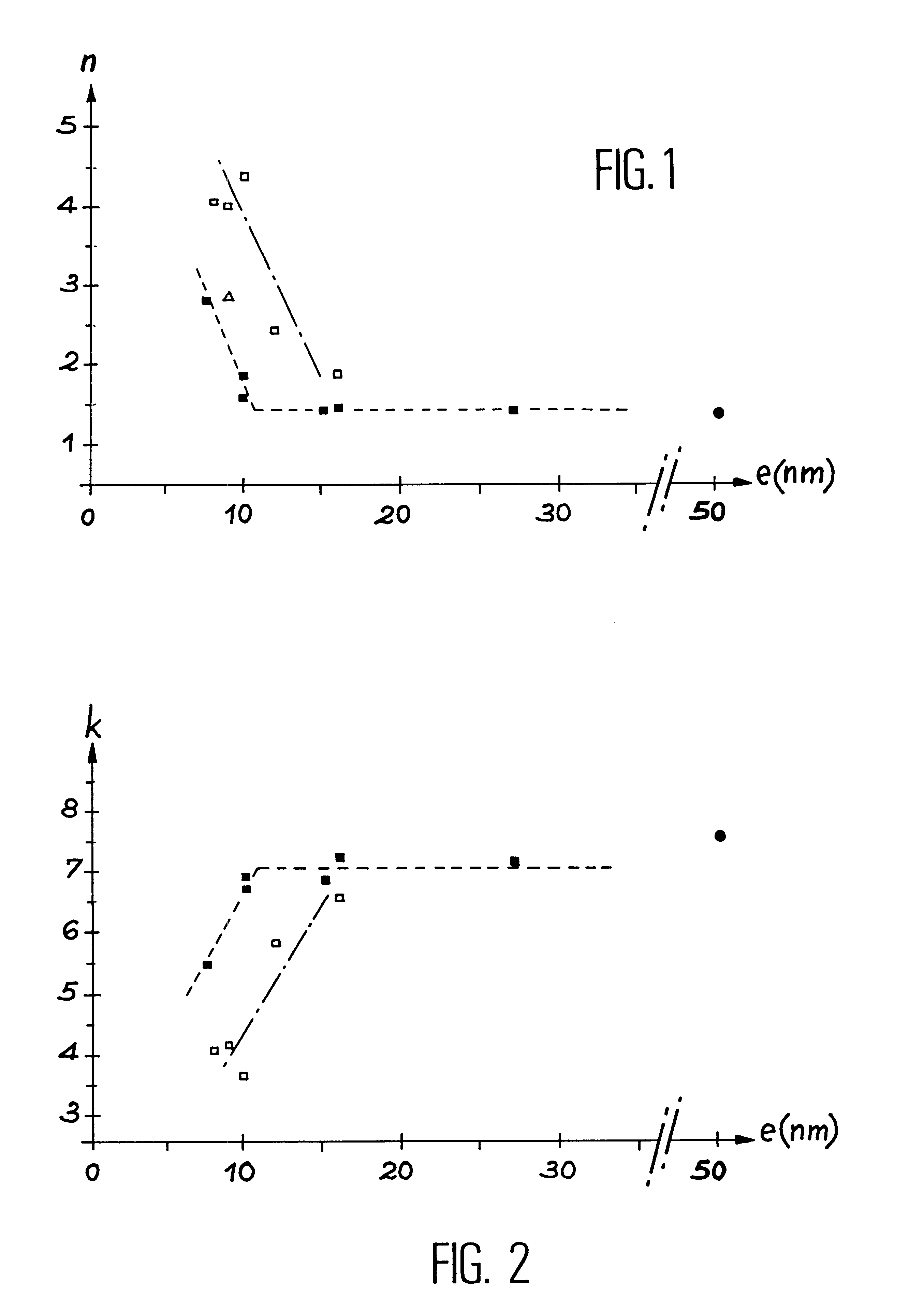

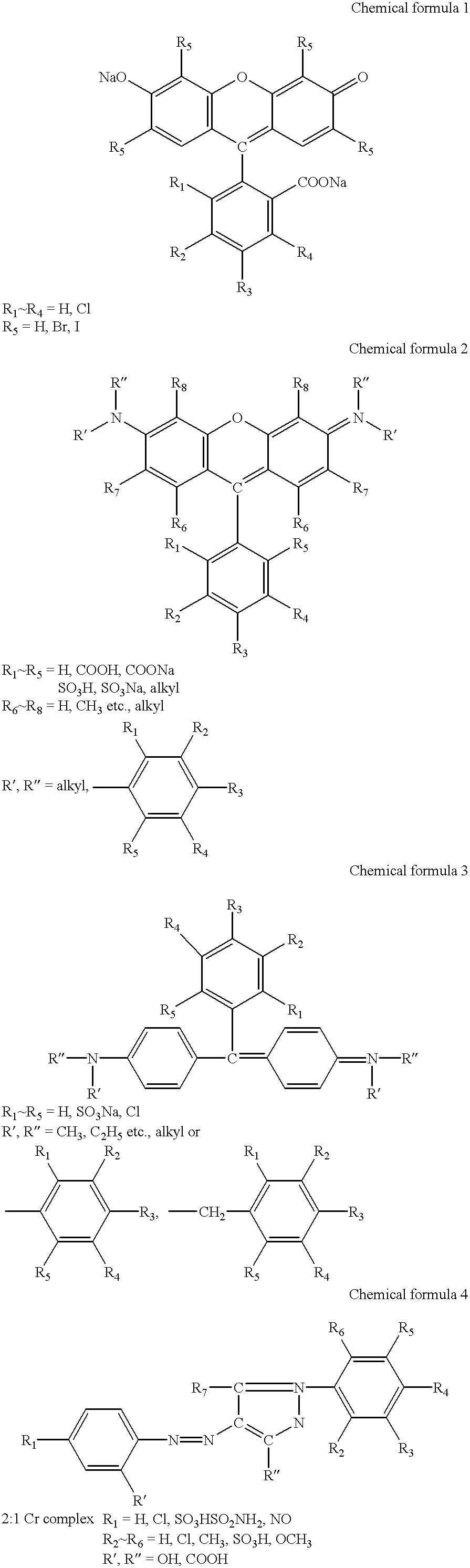

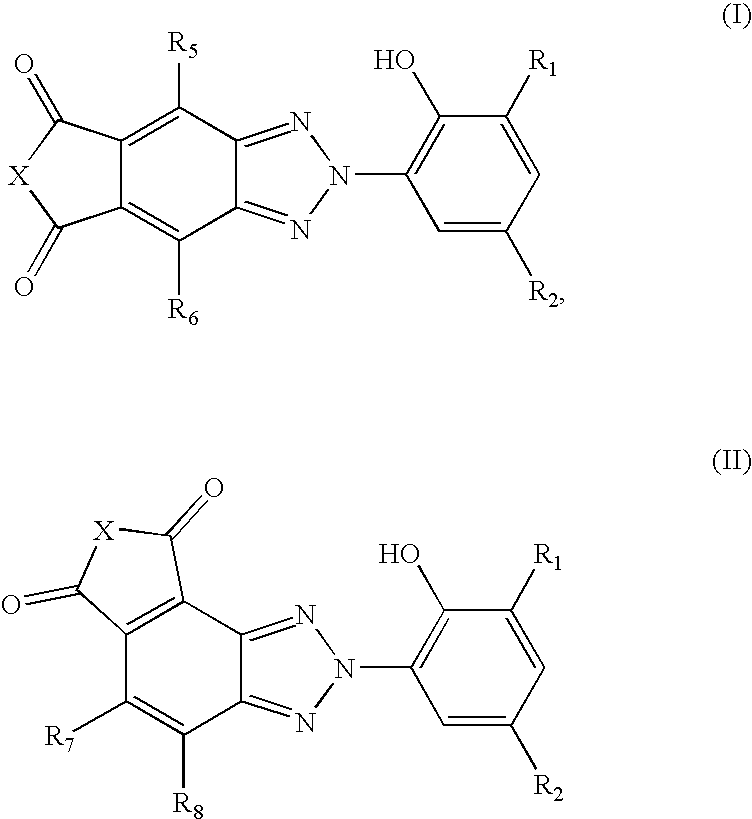

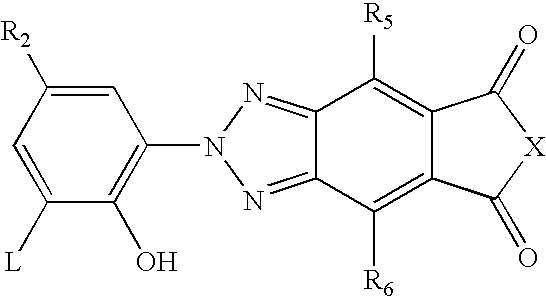

Light absorbing coating with high absorption capacity

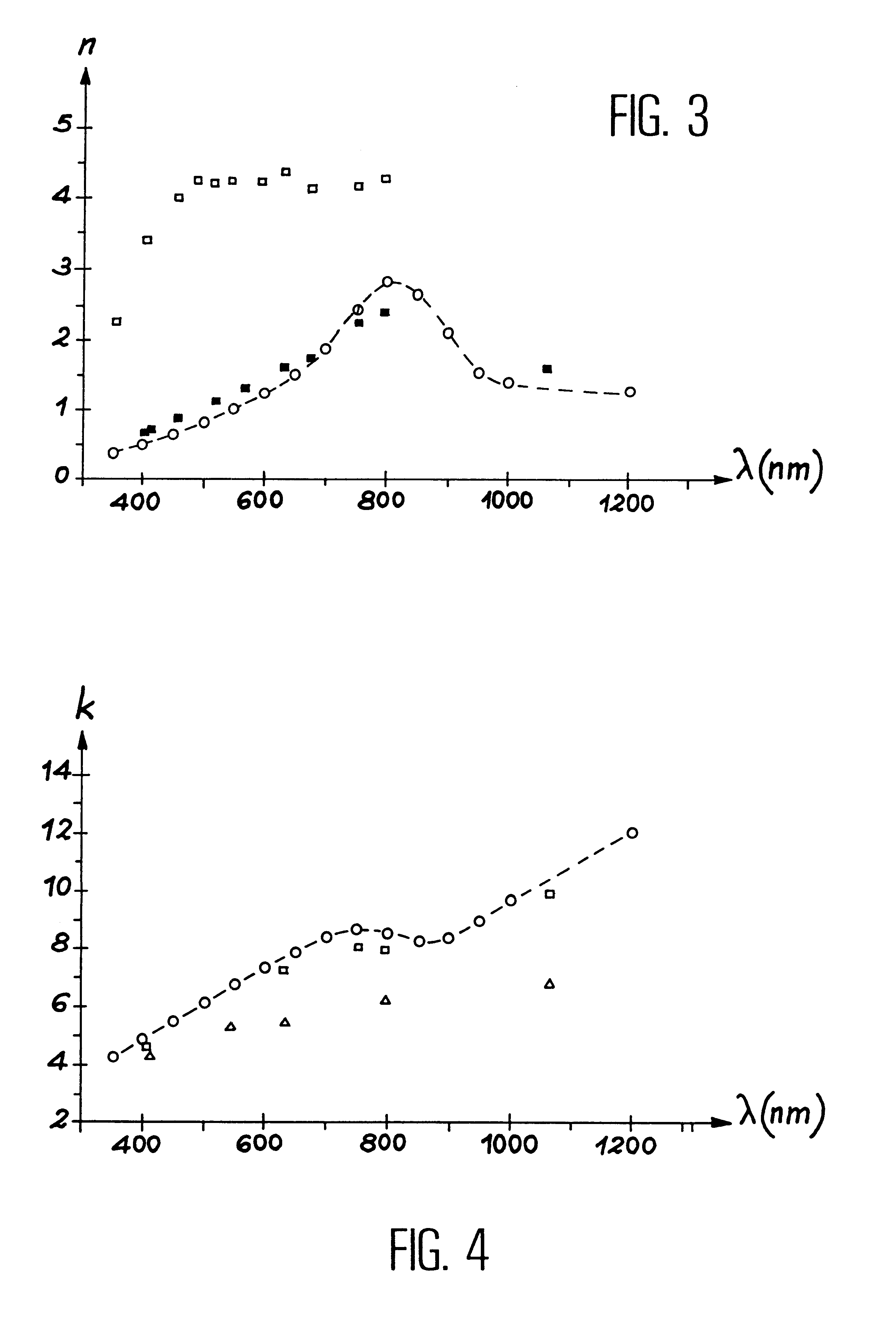

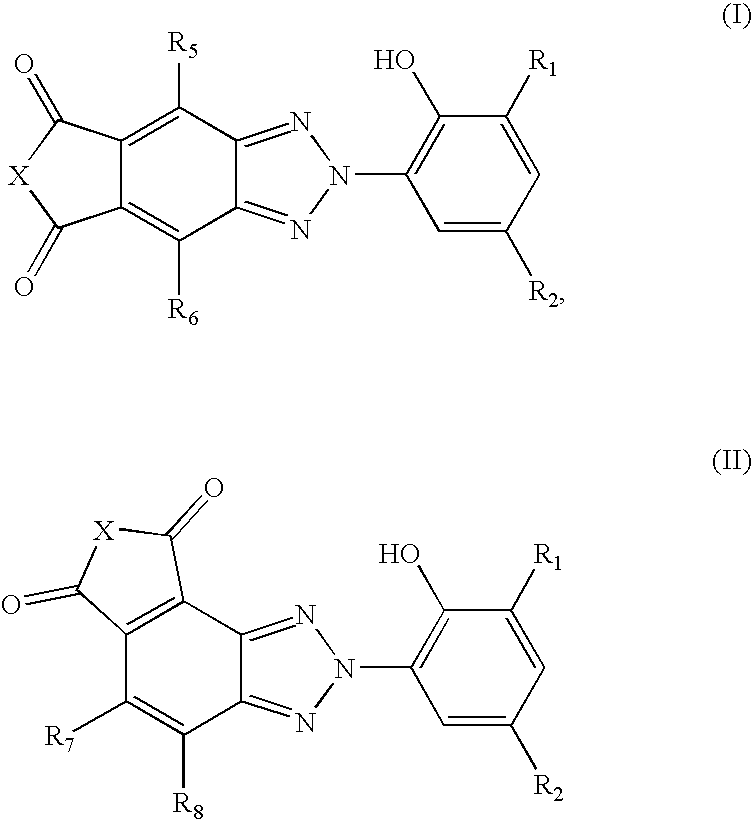

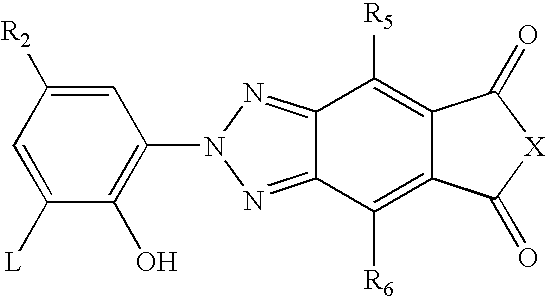

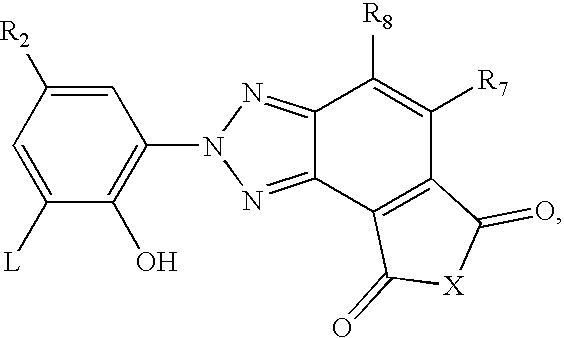

InactiveUS6335142B1Reduce coating thicknessCathode-ray/electron-beam tube vessels/containersPhotomechanical apparatusHigh absorptionThin layer

Light absorbing coating with high absorption capacity.This coating comprises at least one thin optically discontinuous metal layer (8), absorbent within a determined spectral range in the visible-near infrared range, and at least one dielectric layer (10) transparent within this range and formed on the thin layer. Application to imagery.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

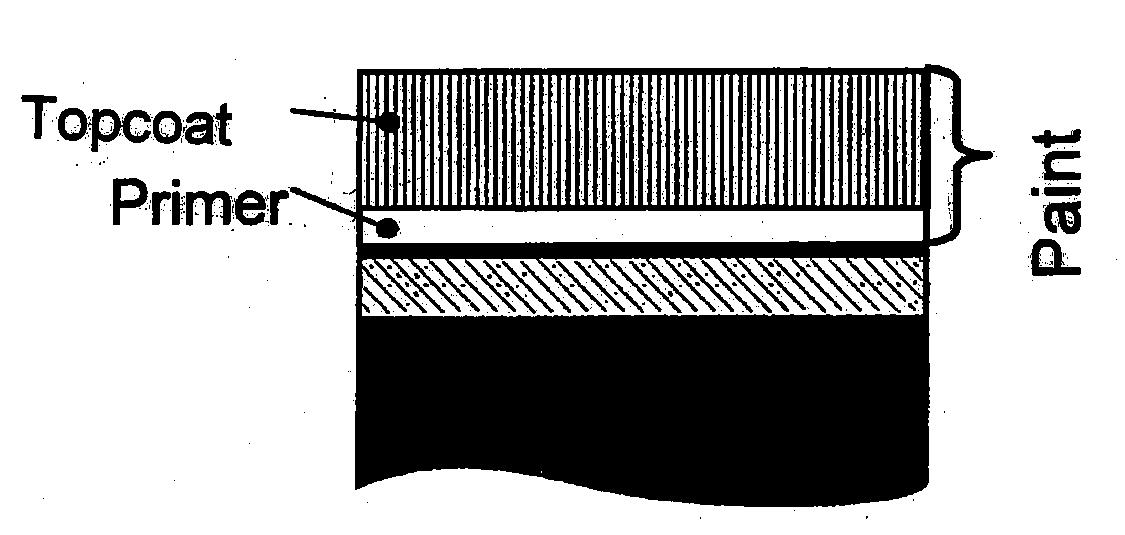

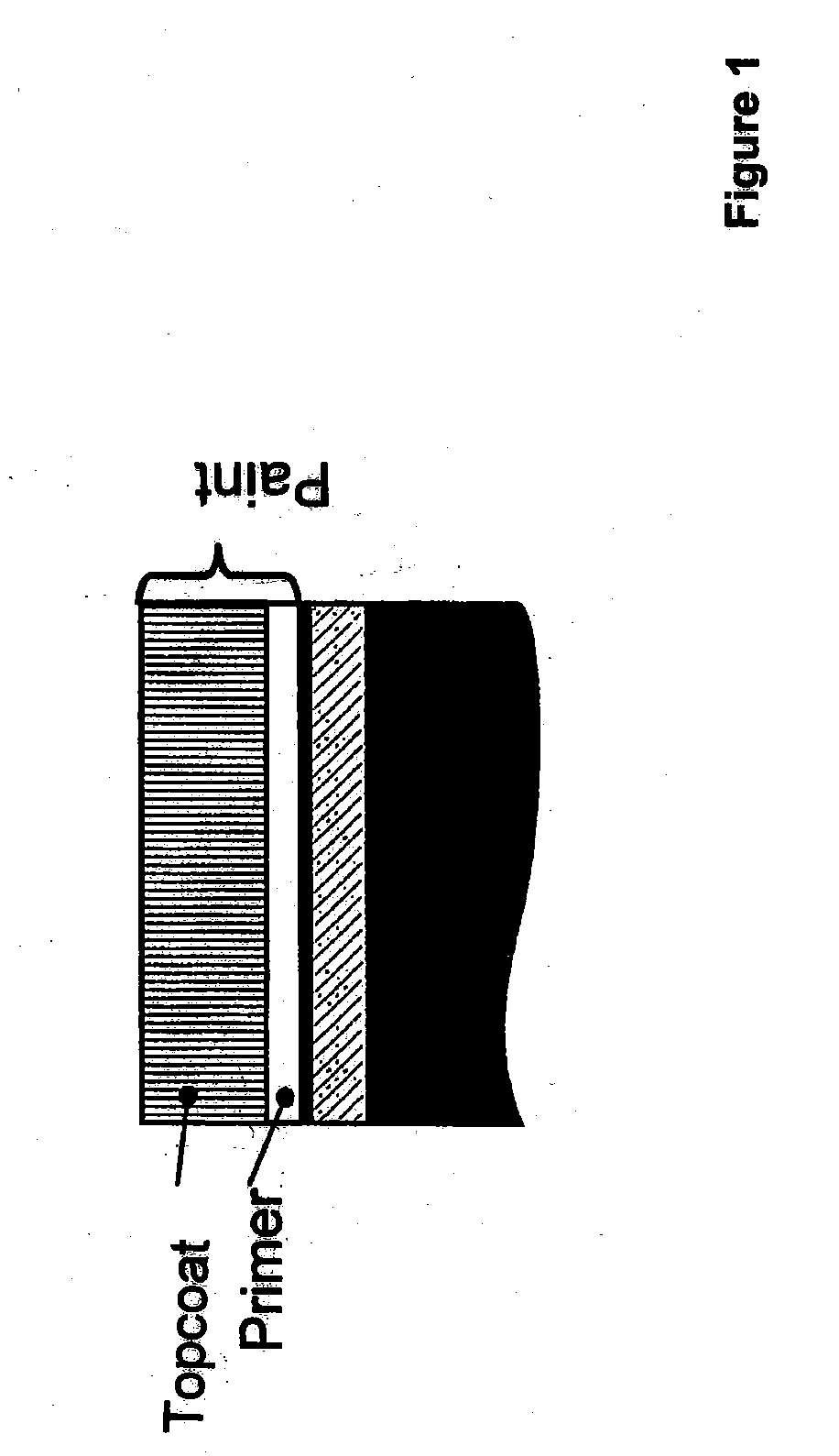

Multicoat paint systems, process for producing them, and their use in automaking

InactiveUS20090317629A1Improves UV stabilityLess influenceSynthetic resin layered productsPretreated surfacesUv absorbanceMoisture exposure

The present disclosure provides multicoat systems exhibiting ultraviolet (UV) stability after ultraviolet exposure and moisture exposure. The systems comprise at least one primer (G), at least one pigmented coating (P) disposed on a surface of the primer, and at least one ultraviolet (UV) absorber which has an absorption maximum of at least 370 nm. The pigmented coating (P) may be comprised of two or more coatings (P1), (P2) to (Pn). The multicoat systems may also comprise a transparent coating material (T) to form a transparent coating (K). The present multicoat systems demonstrate ultraviolet stability, reduced delamination of the pigmented coat from the primer and are available in a variety of shades for use in the finishing, refinishing and coating of component parts.The present disclosure also provides for a process for producing the multicoat system, and provides for the use of the system.

Owner:BASF COATINGS GMBH

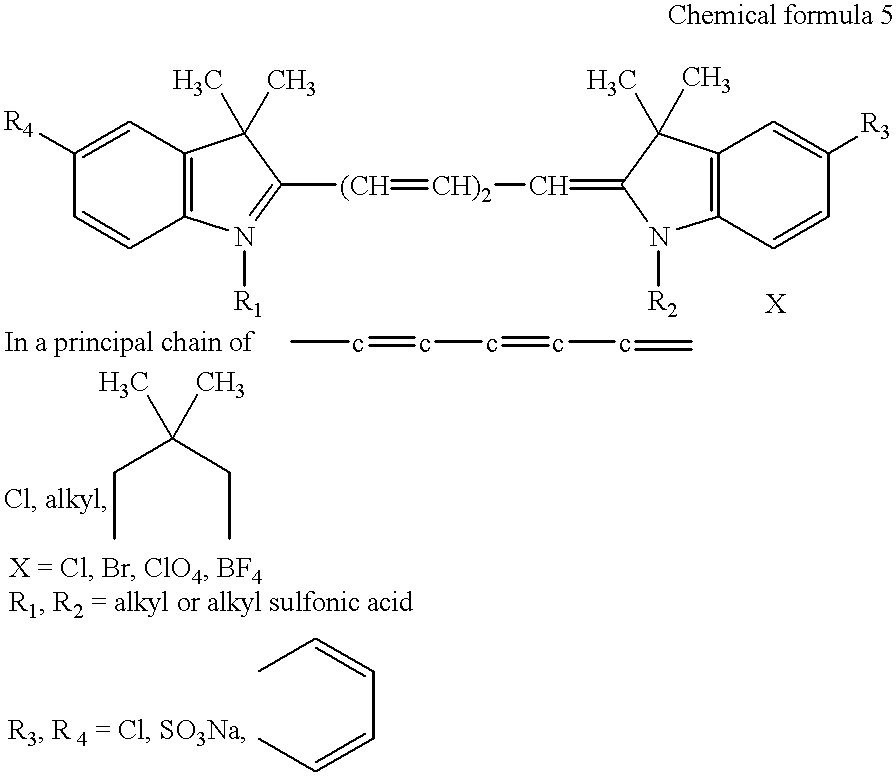

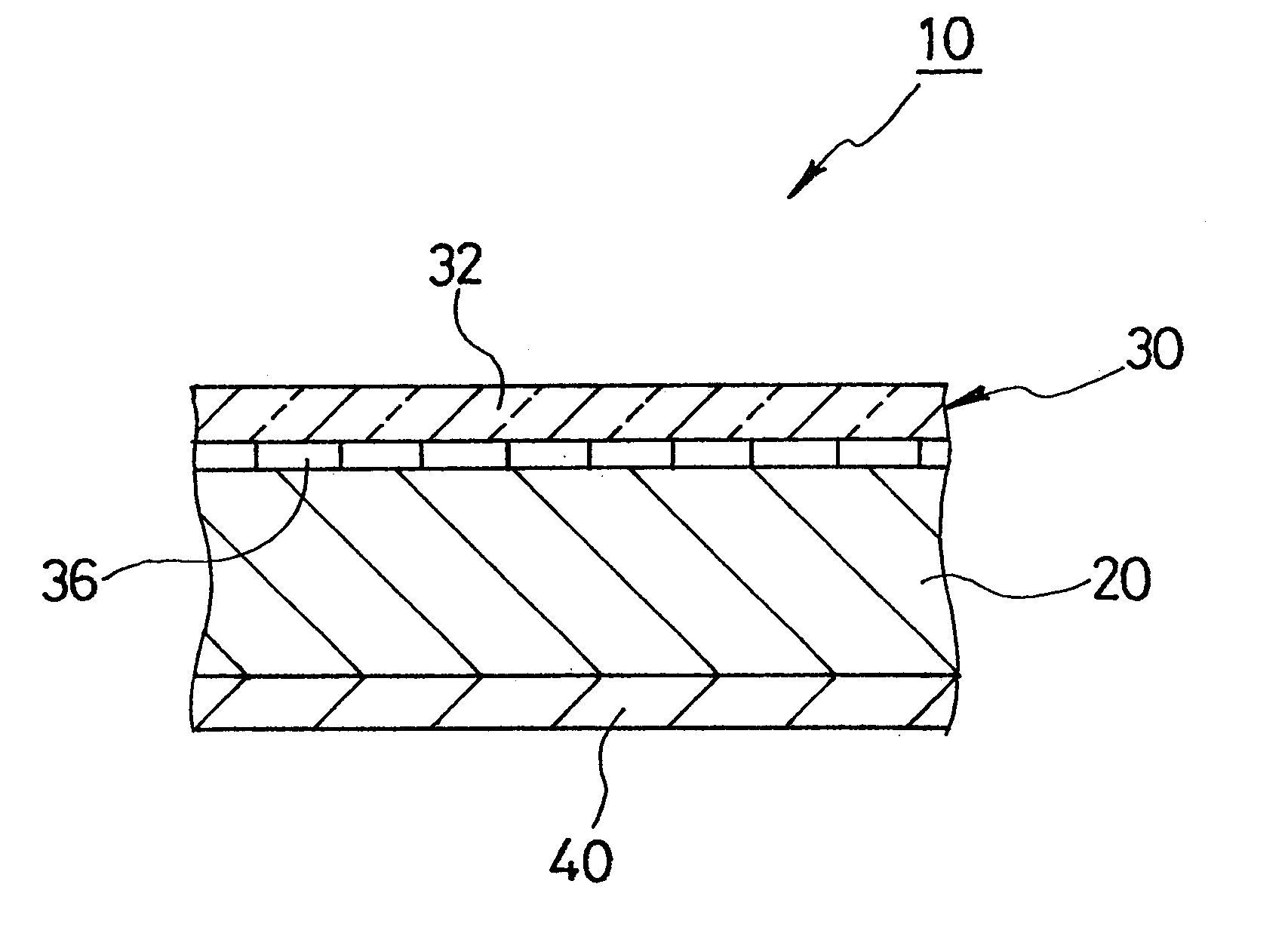

Color filter for liquid crystal displays

InactiveUS6203951B1Effective controlReduce coating thicknessOptical filtersOriginals for photomechanical treatmentOptical propertyLiquid-crystal display

A reflection-type color filter (30) is disclosed, in which light coming into one surface of a color filter layer (36) is reflected by a reflective layer (40) and allowed to pass through the color filter layer (36) twice. Colored patterns of the color filter layer (36) include resin such as polyimide and dye for dyeing the resin. The thickness of the colored patterns is 0.7 mum or less. In order to enhance light resistance, it is effective to increase the content of dye with respect to resin. The value of 0.7 mum is established in consideration of enhancement of optical characteristic and light resistance of the color filter used in the reflection type liquid crystal display device. In order to enhance light resistance, more preferably, a metal complex is added to the resin.

Owner:KYODO INSATU KK KYODO PRINTING CO LTD

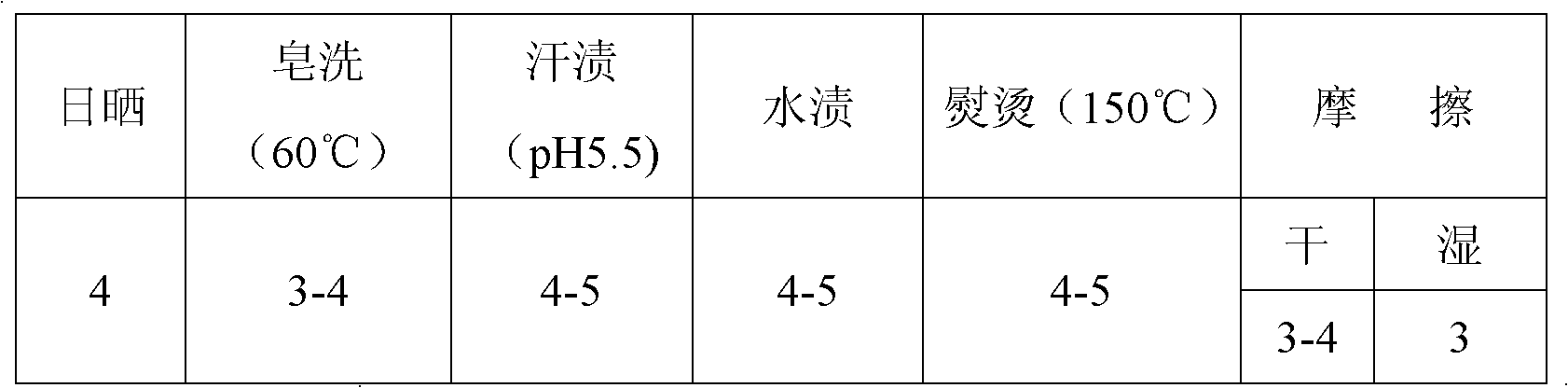

Fabric pattern transfer ink and preparation method thereof

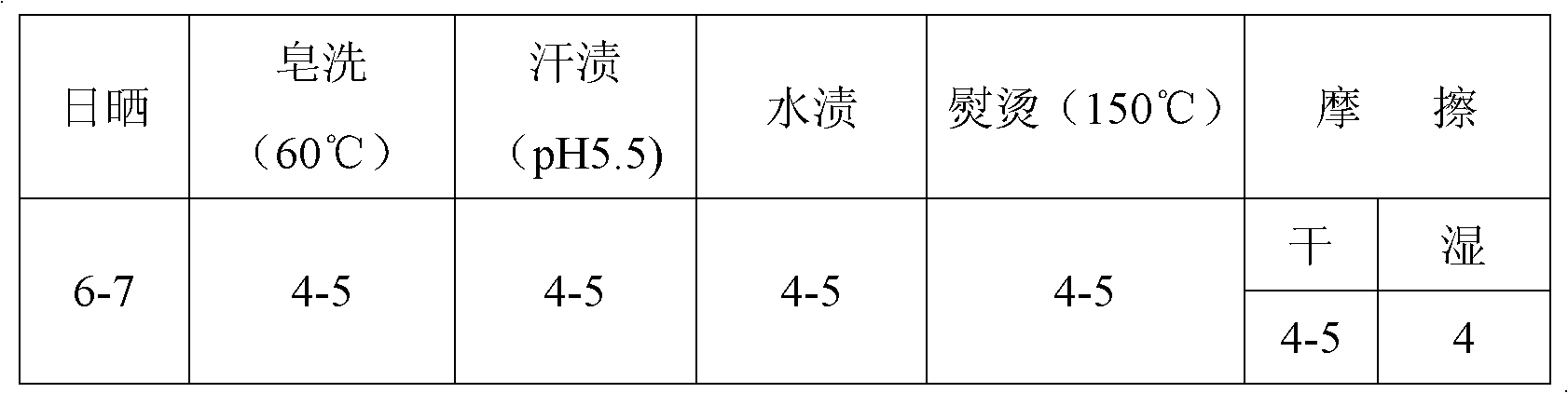

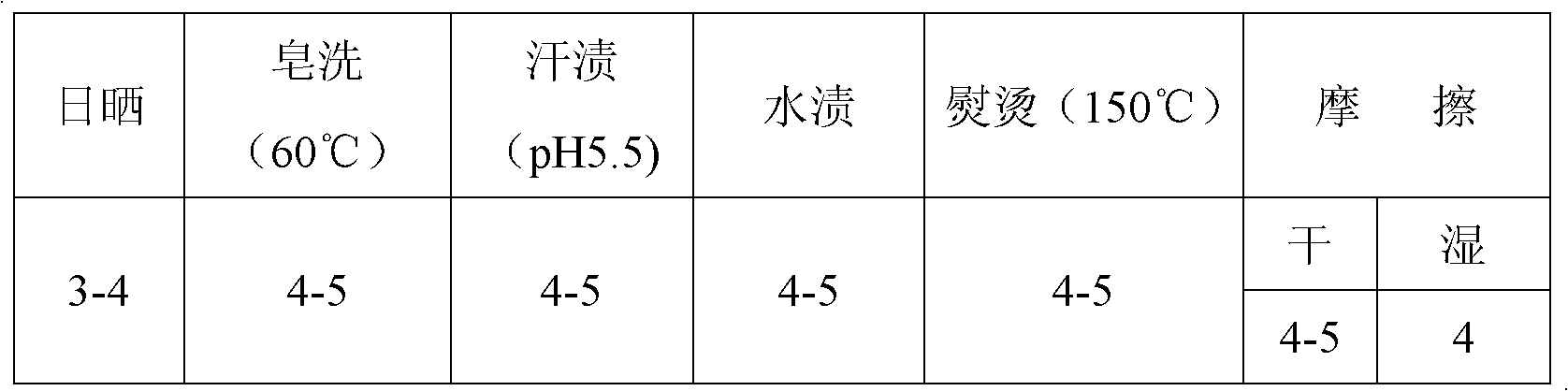

InactiveCN102161850AReduce manufacturing costReduce coating thicknessInksDyeing processOrganic solventWater soluble

The invention discloses a fabric pattern transfer ink which comprises the following components in percentage by weight: 0.1-40wt% of dye, 1-50wt% of binder and 10-98.9wt% of solvent, wherein the binder is water-soluble hot-melt resins, and the solvent is water, or an organic solvent or a mixture of the water and organic solvent. The invention also discloses a preparation method of the fabric pattern transfer ink, a fabric pattern transfer method using the ink and a fabric pattern transfer film. Compared with the prior art, large-scale industrial production of the heat transfer printing film or heat transfer printing paper of a fabric is possible through the invention, the production cost is greatly reduced, the production efficiency is remarkably improved, and the comprehensive popularization of the technology is facilitated. Moreover, the coating thickness of the prior art is also reduced, even the coating process can be saved, the equipment investment cost is lowered, and the manufacturing process is shortened.

Owner:常州涵源新印花有限公司

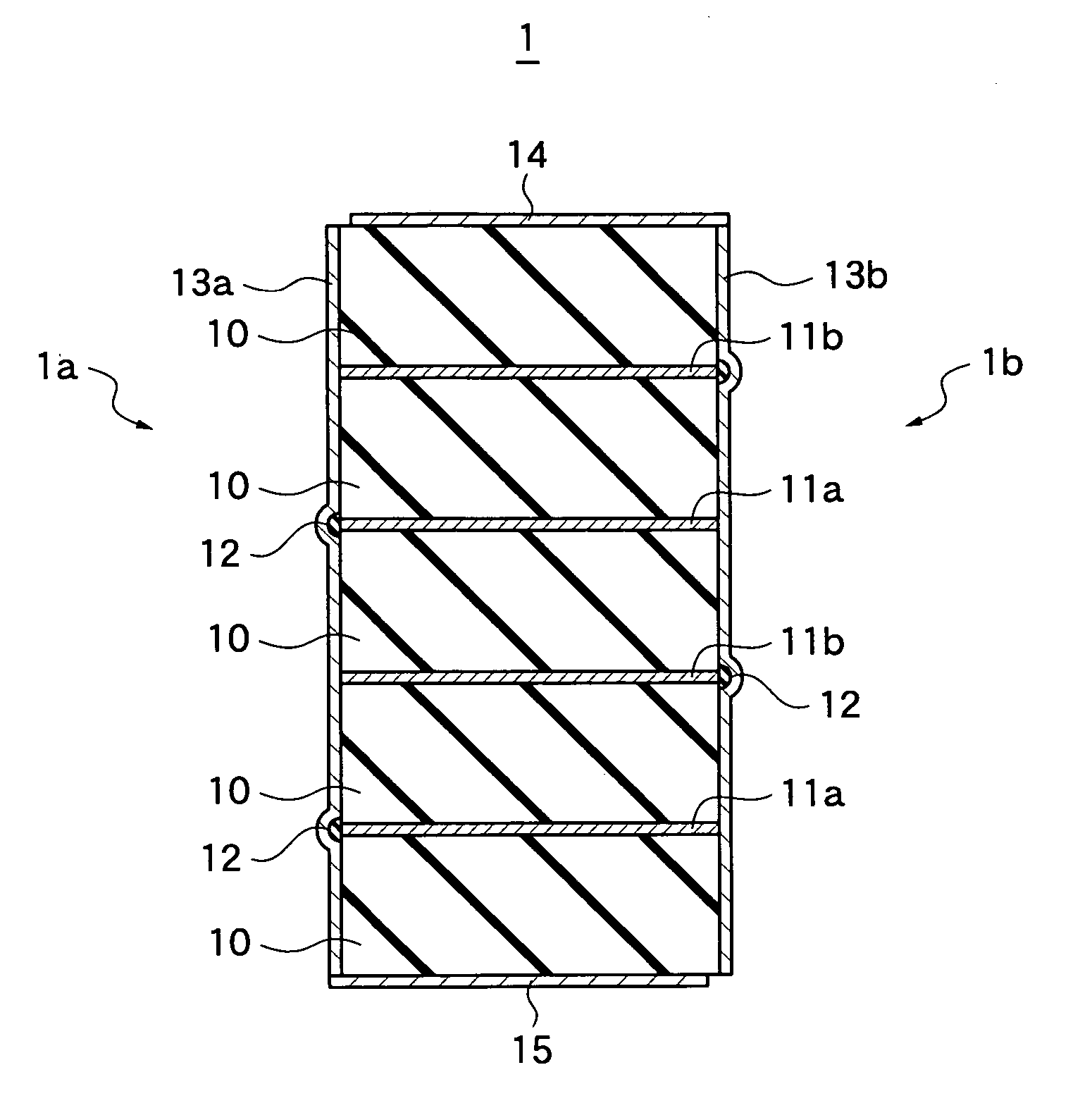

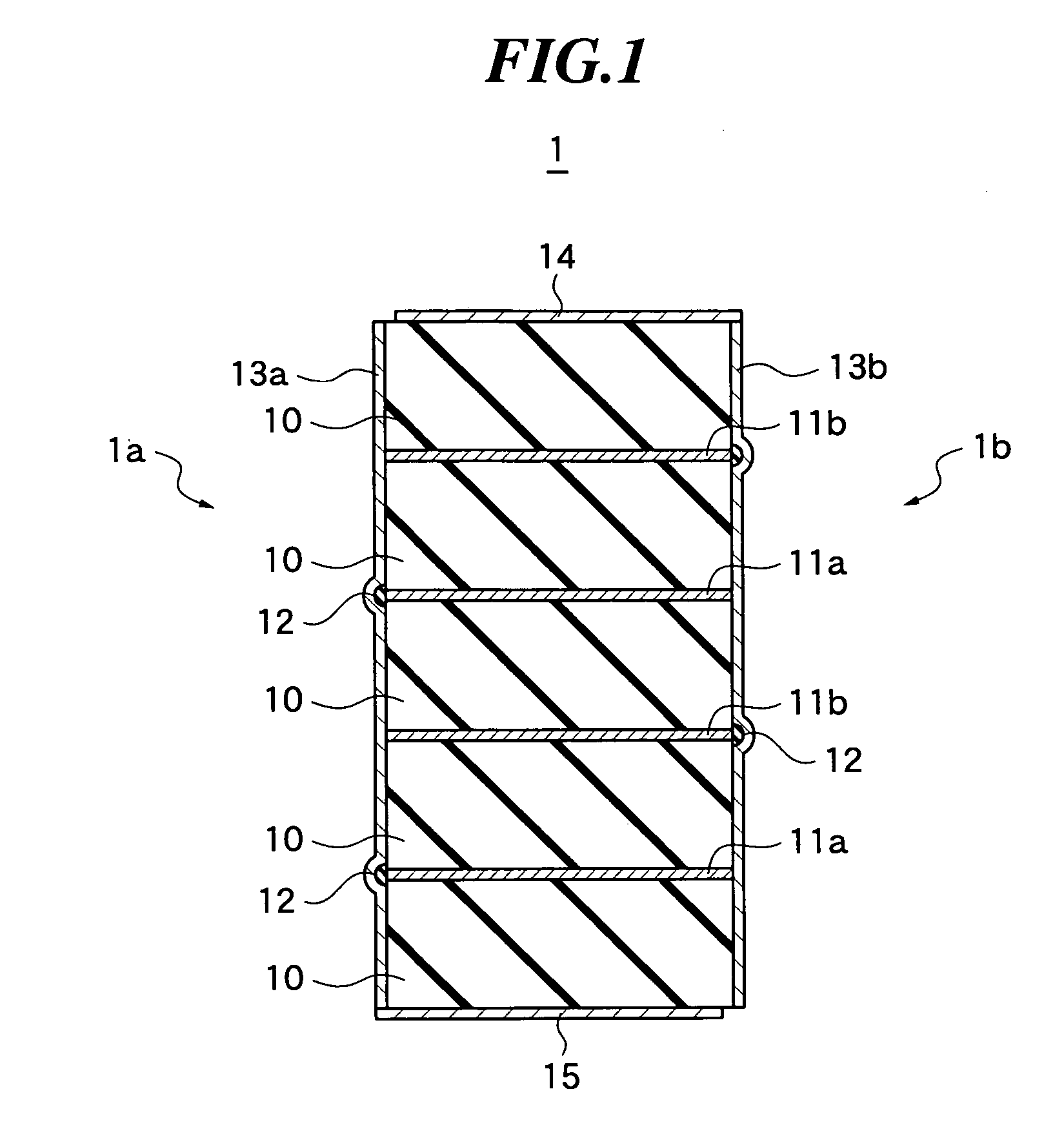

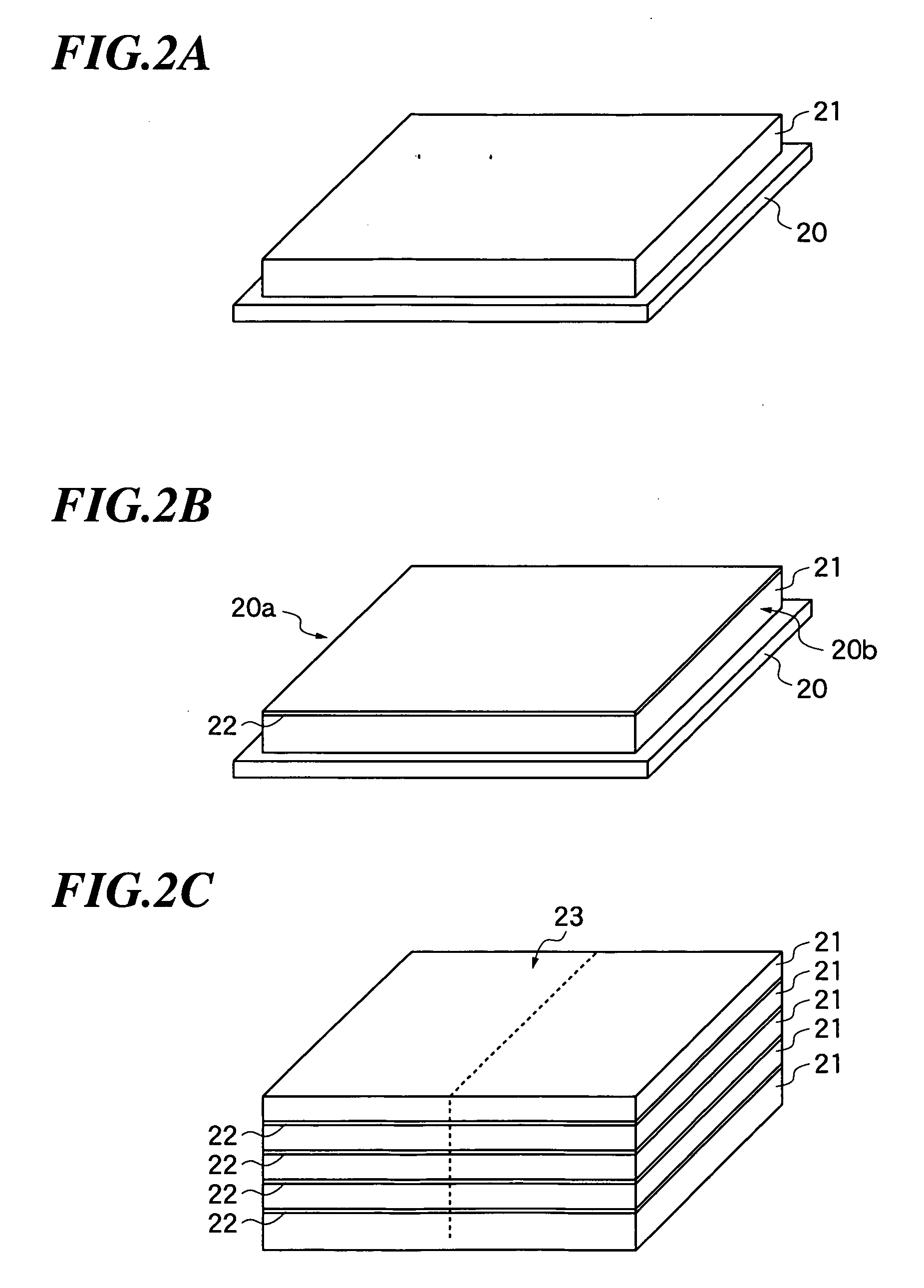

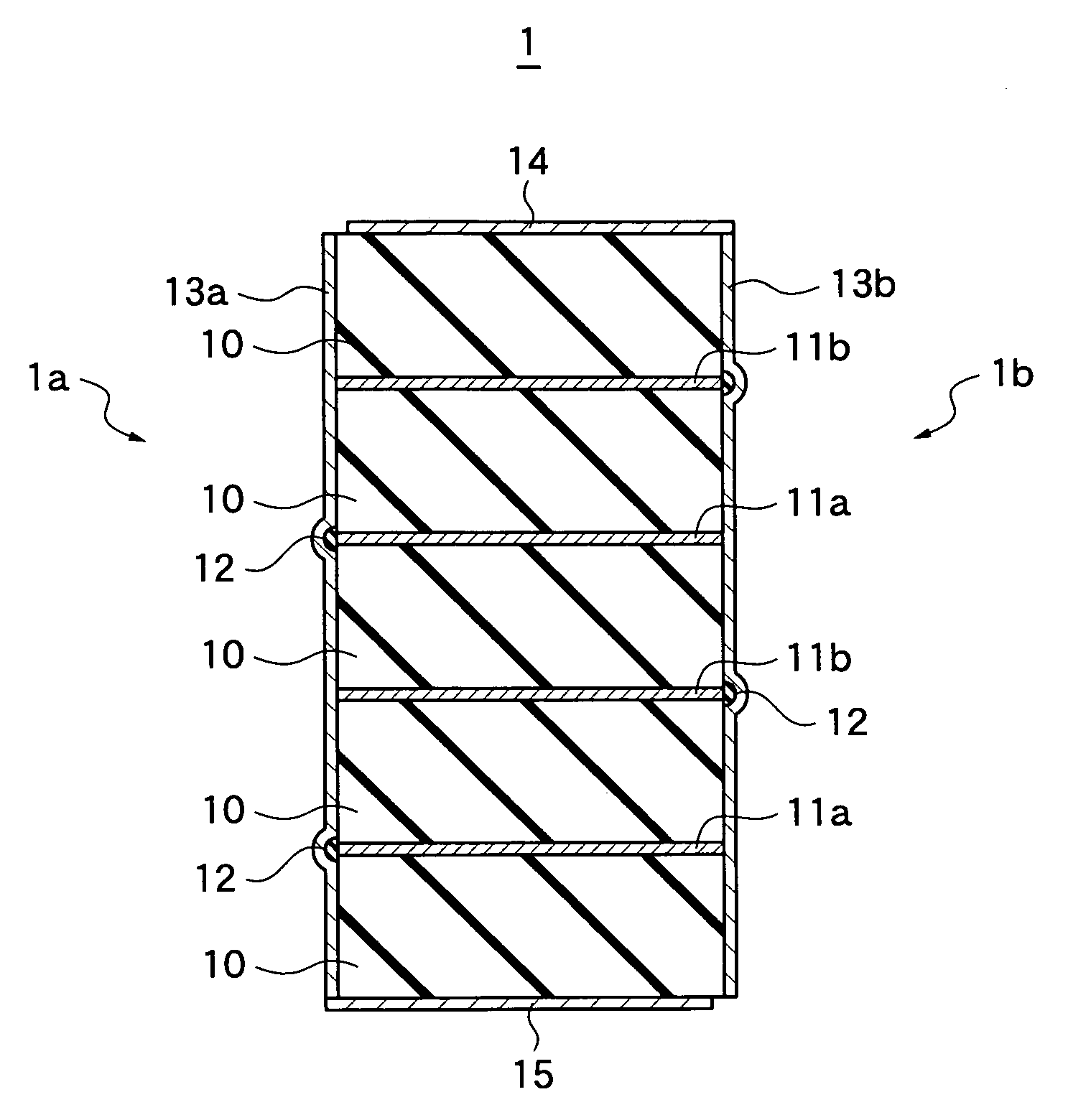

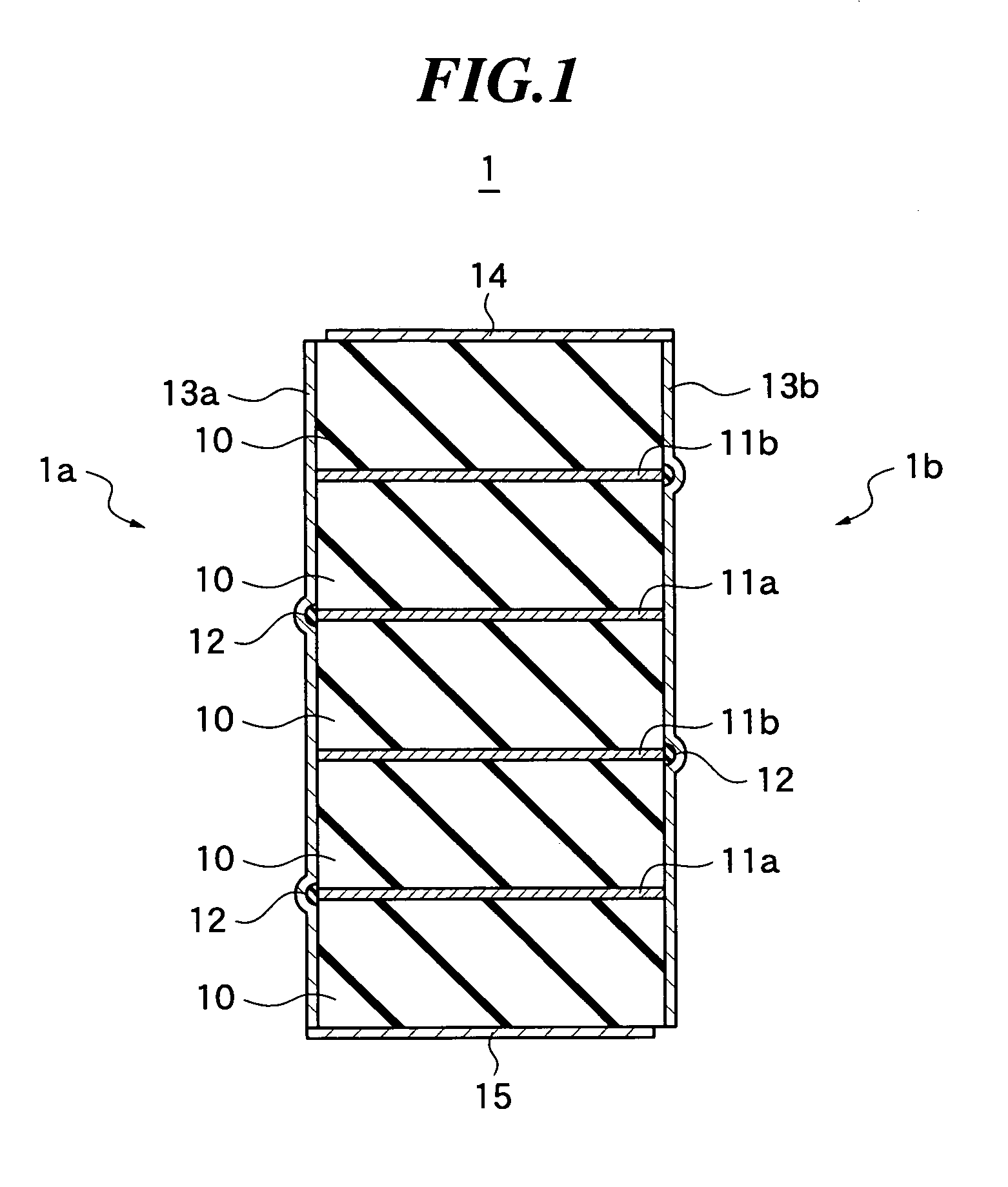

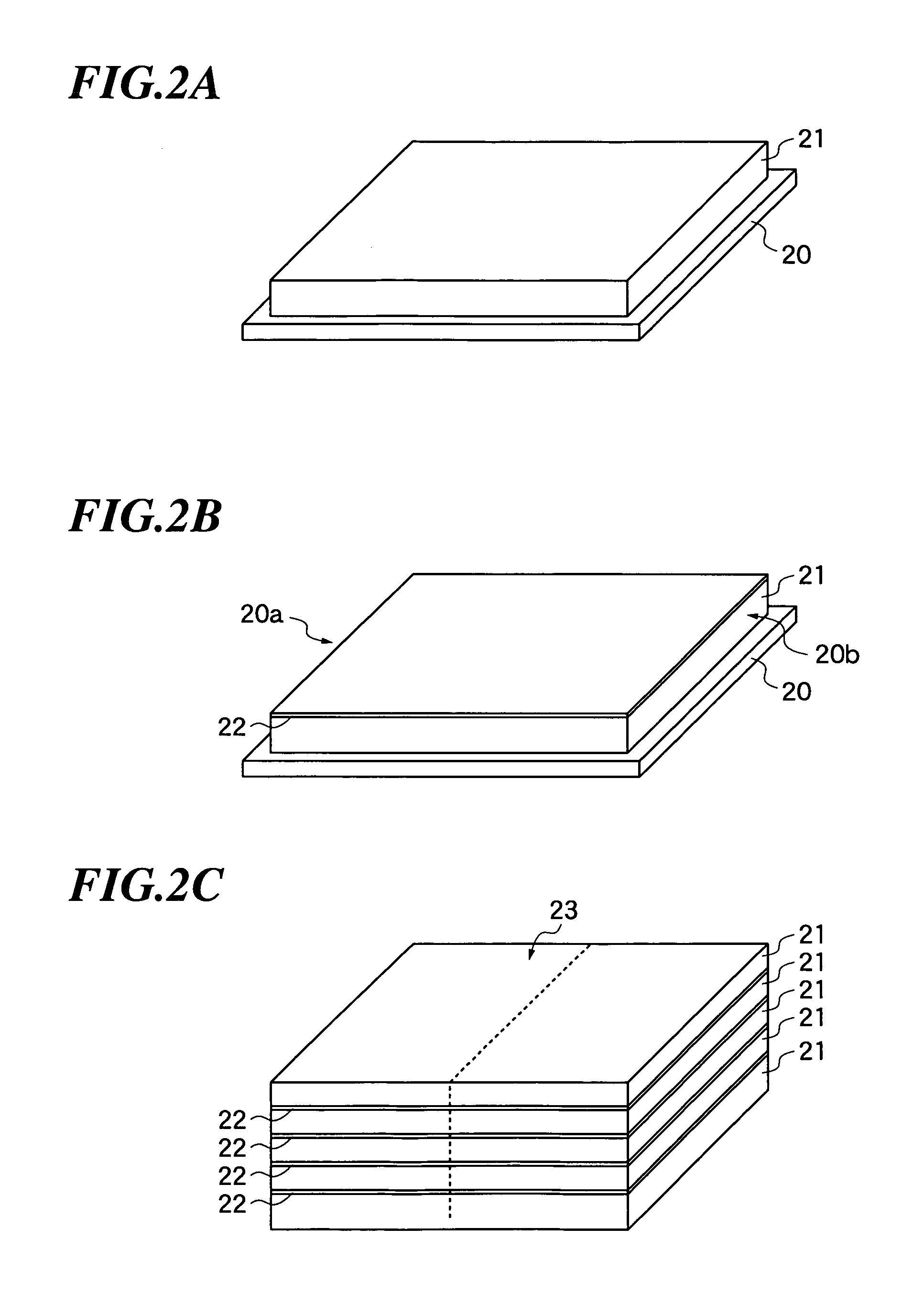

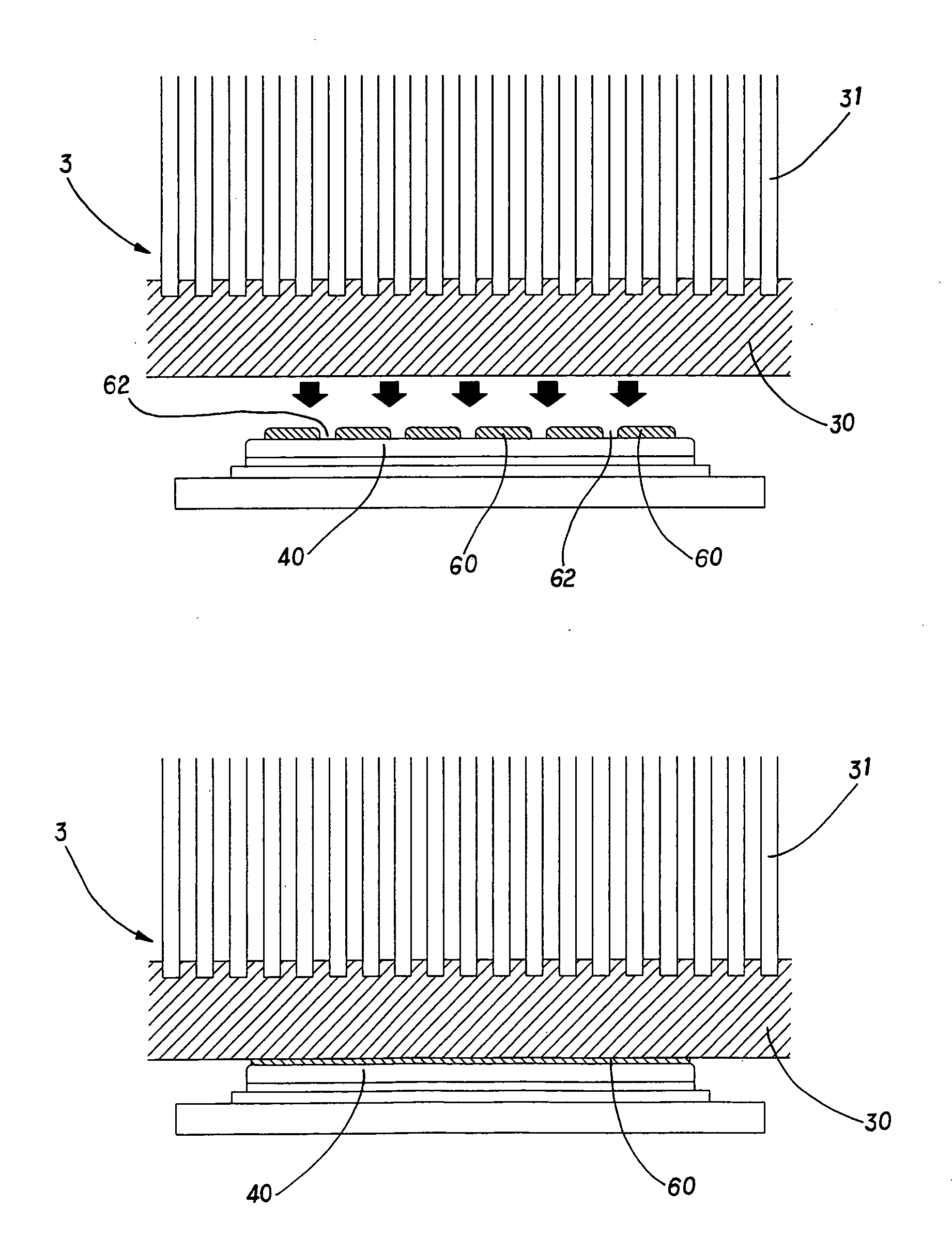

Multilayered structure, multilayered structure array and method of manufacturing the same

InactiveUS20060067029A1Well formedImprove productivityAnti-noise capacitorsPiezoelectric/electrostrictive device manufacture/assemblyProduction rateMetallic sulfide

A multilayered structure array has narrow pitches by making thinner coatings for insulating internal electrode layers from side electrodes and the productivity of the multilayered structure array is improved. The multilayered structure includes: a first internal electrode layer; a piezoelectric layer formed on the first internal electrode layer; a second internal electrode layer formed on the piezoelectric layer; a first coating formed on an end surface of the first internal electrode layer in a first side surface region of the multilayered structure and containing one of metal oxide, metal nitride, metal fluoride and metal sulfide in at least one part thereof; and a second coating formed on an end surface of the second internal electrode layer in a second side surface region of the multilayered structure and containing one of metal oxide, metal nitride, metal fluoride and metal sulfide in at least one part thereof.

Owner:FUJIFILM HLDG CORP +1

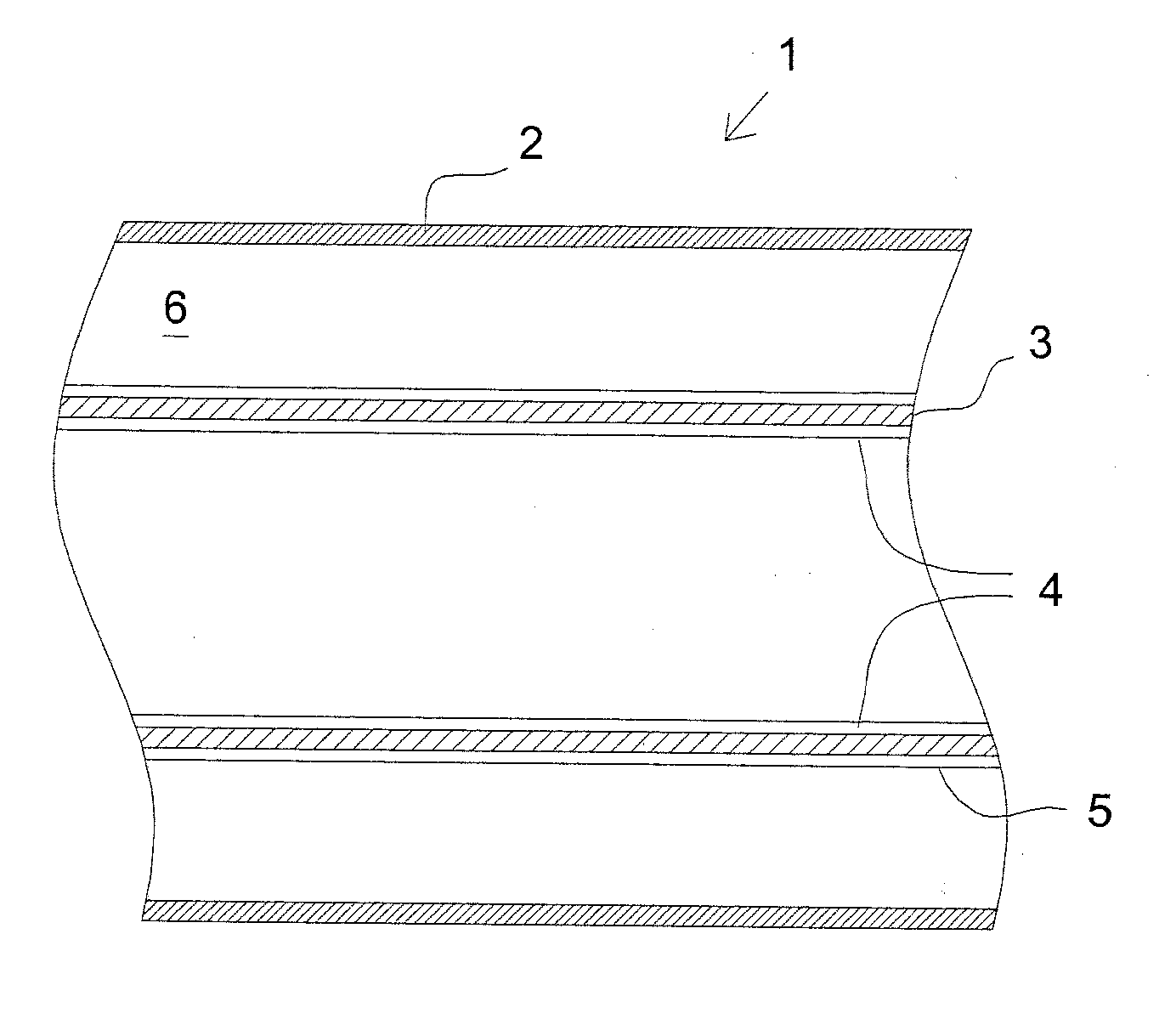

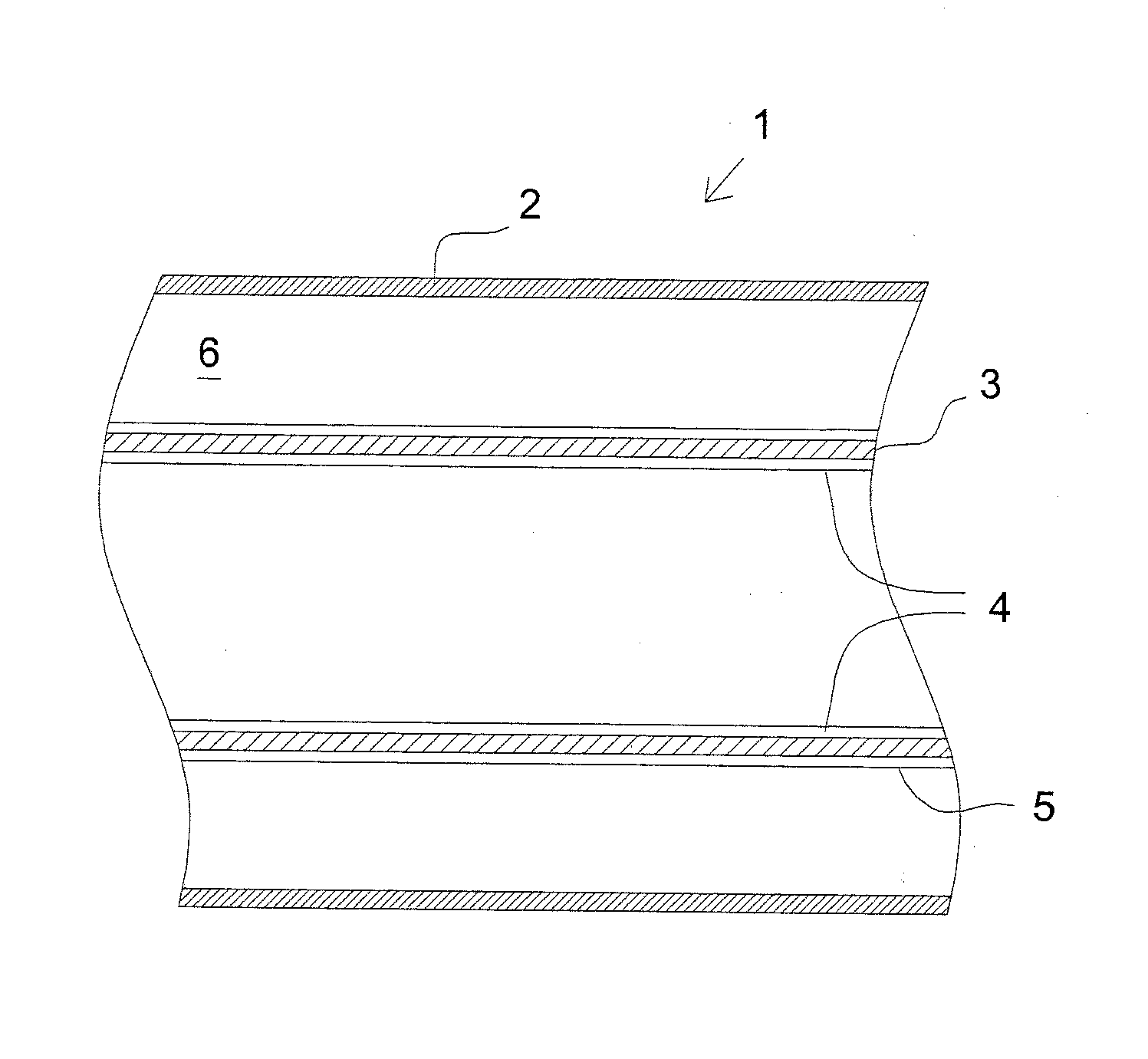

Tubular radiation absorbing device for a solar power plant with reduced heat losses

InactiveUS20070235023A1Inhibition formationObstruct passageSolar heating energySolar heat devicesHydrogenPower station

The tubular radiation absorbing device (1) for solar thermal applications includes a central tube (3) made of chromium steel, particularly stainless steel; a glass tubular jacket (2) surrounding the central tube so as to form a ring-shaped space (6); and a barrier coating (4) on at least an interior side of the central tube (3), which is substantially impermeable to hydrogen and contains chromium oxide. The barrier coating (4) is provided by a process in which the central tube (3) is treated with steam containing free hydrogen at a temperature of 500° C. to 700° C.

Owner:ALLEGIANCE CORP +1

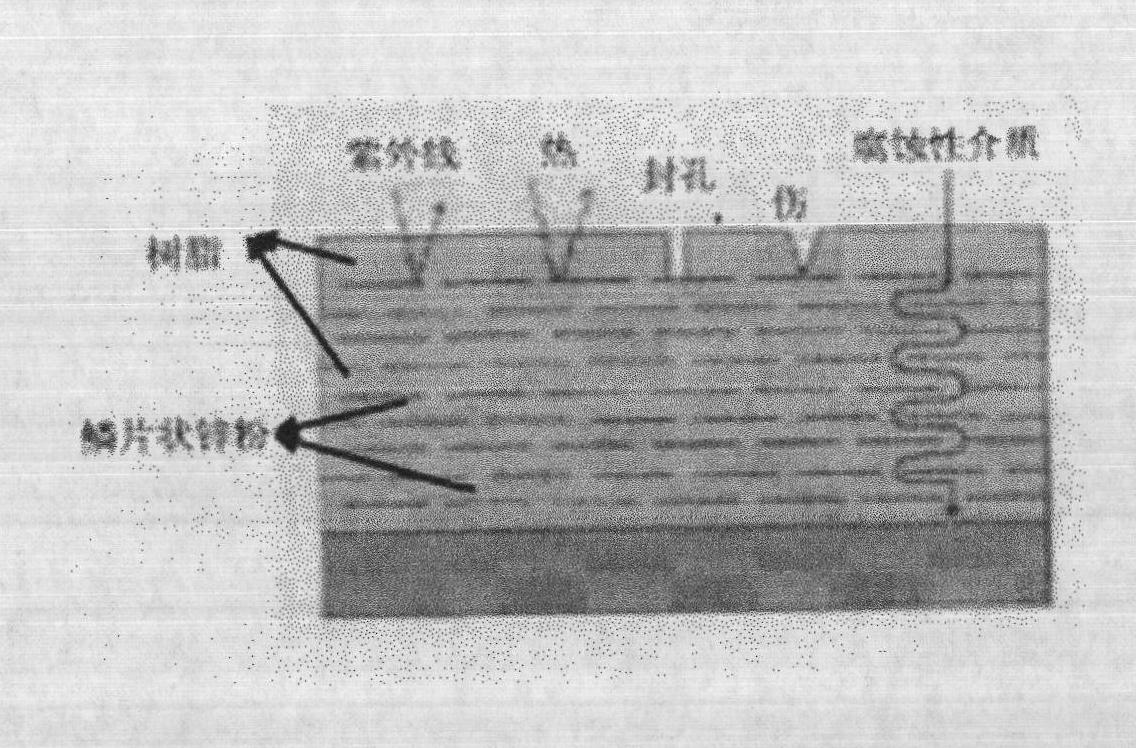

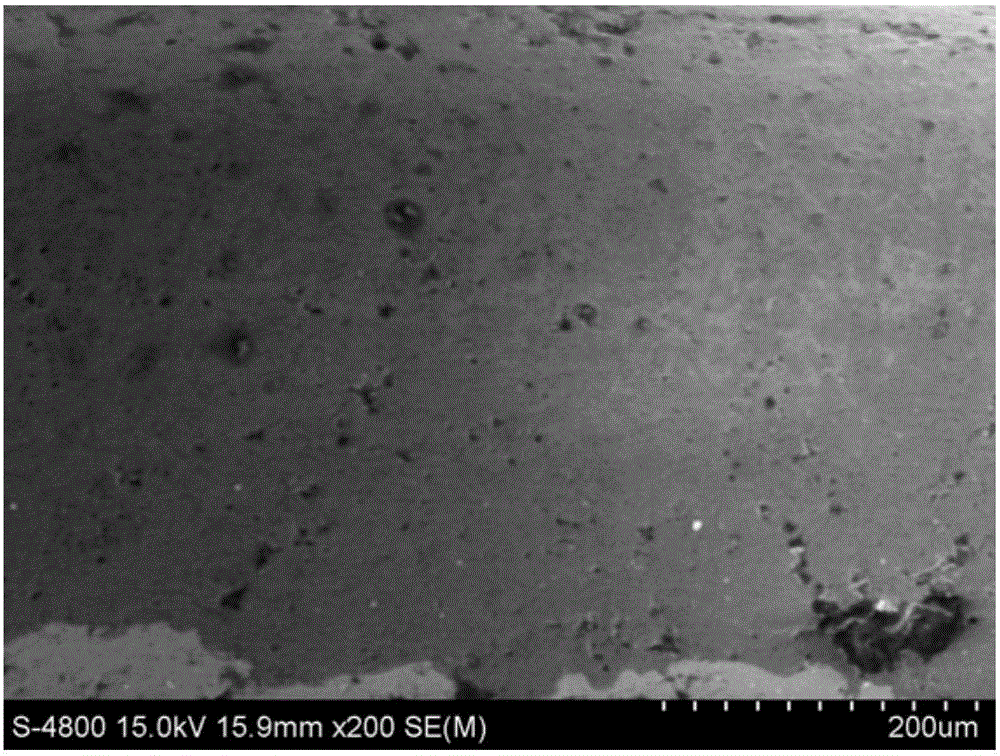

Scaly zinc-based inorganic zinc silicate heavy anti-corrosion coating and preparation method thereof

InactiveCN102002318AIncrease electrical contact areaImprove cohesionAnti-corrosive paintsEpoxy resin coatingsZincSilicon

The invention relates to scaly zinc-based inorganic zinc silicate heavy anti-corrosion coating and a preparation method thereof. The method comprises the following steps of: (1) mixing scaly zinc powder with initial film forming resin according to the weight ratio of components to obtain a component A; (2) mixing a hydrolyzing silicon solution with a modifier by stirring at intermediate speed according to the weight ratio of the components, adding a catalyst for hydrolyzing according to the weight ratio of the components and hydrolyzing to obtain a component B; and (3) mixing the component A and the component B which are prepared in the step (1) and the step (2) according to the component weight ratio of (1-1.5):1 to obtain the scaly zinc-based inorganic zinc silicate heavy anti-corrosion coating. The invention has the advantage of preparing the scaly zinc-based inorganic zinc silicate heavy anti-corrosion coating by mainly adopting domestic scaly zinc powder. Compared with traditional zinc rich primer, the invention can greatly reduce the zinc powder content and coating thickness; the traditional zinc rich primer generates large zinc fog in the coating welding process, and the scaly zinc powder primer generates less zinc fog, reduces damage to construction staffs and is a new generation product of the traditional inorganic and organic zinc rich primer.

Owner:湖北中科博策新材料研究院

Novel alumite suitable for rotary gold stamping on ultraviolet (UV) glazing oil paper

ActiveCN102896927AImprove bronzing efficiencyImprove transfer efficiencySynthetic resin layered productsThermographyInformation layerEpoxy

The invention relates to novel alumite suitable for rotary gold stamping on ultraviolet (UV) glazing oil paper. The alumite comprises a basic film layer, a film release layer, an information layer, an aluminized layer and a bonding layer, wherein the information layer comprises the following material components in percentage by mass: 85 to 90 percent of epoxy modified acrylic resin and 10 to 15 percent of metal complex dye toner; and the bonding layer comprises the following material components in percentage by mass: 10 to 20 percent of thermoplastic polyurethane hot melt adhesive, 1 to 2 percent of nano silica, 30 to 40 percent of toluene, 30 to 50 percent of butanone and 5 to 15 percent of isopropanol. The alumite has the characteristics of high gold stamping efficiency, transfer efficiency and adhesion, clear image-text edge and the like, coating thickness is reduced by 40 to 50 percent compared with that of the common alumite, and heat-conducting property is higher; and compared with the common UV flat gold stamping alumite, the alumite has the advantages that effective gold stamping speed can be improved from 40 to 60m / min to 90 to 120m / min when the alumite is applied to rotary UV gold stamping, and an optimization effect is obvious.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

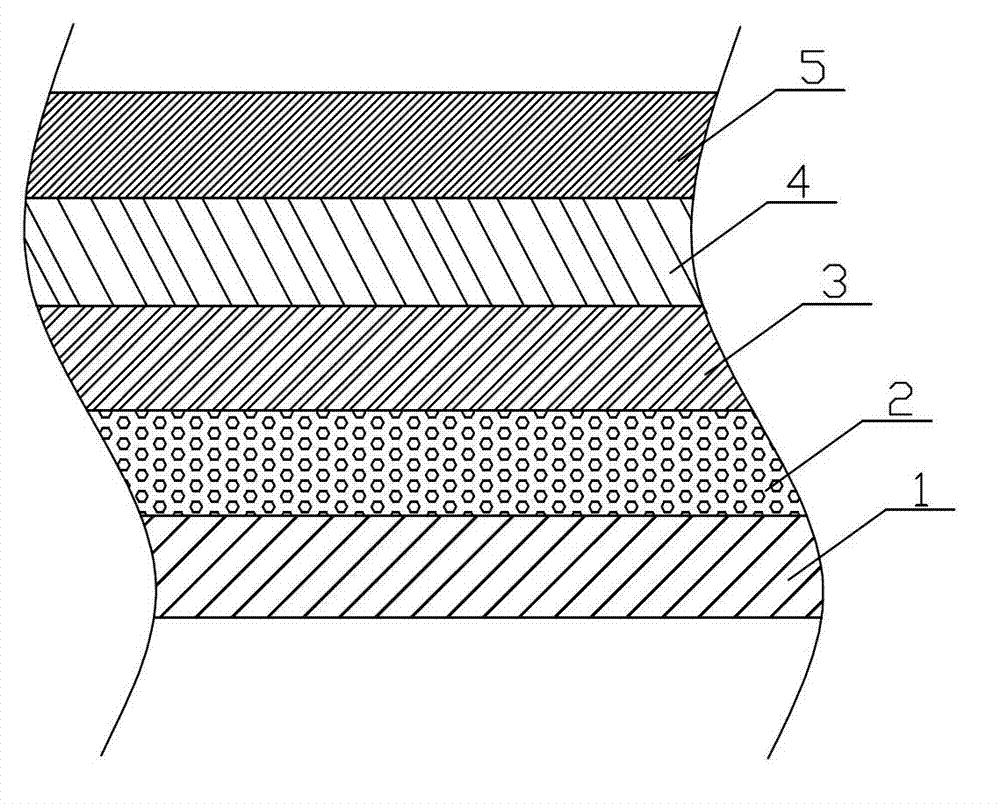

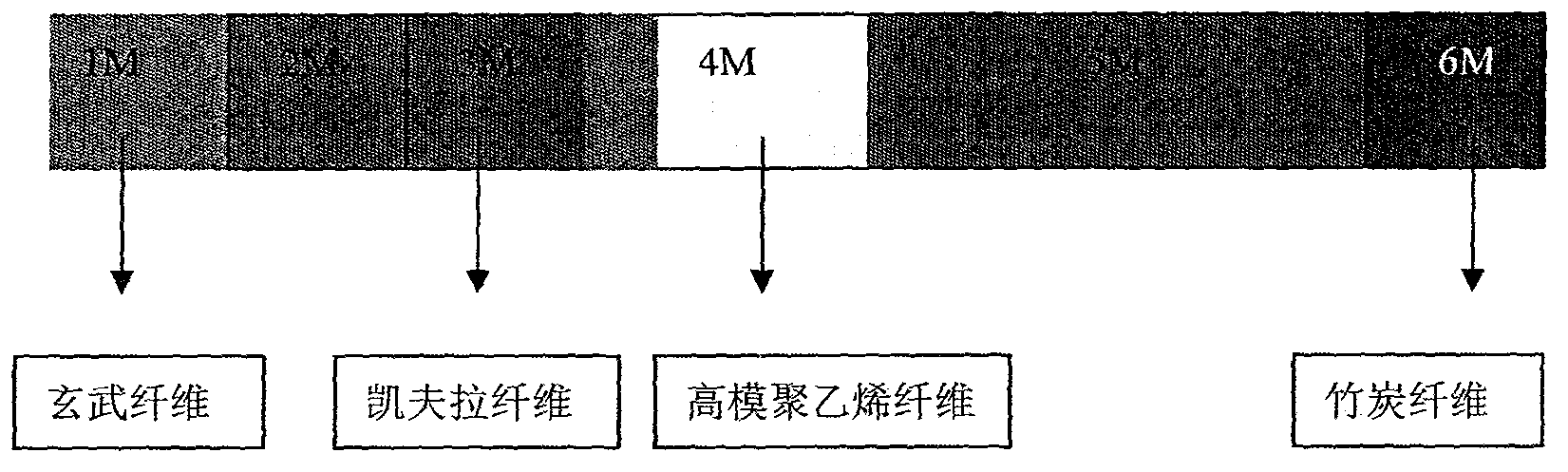

Multifunctional fabric with multiple fiber layers arranged and combined according to rule and manufacturing method

InactiveCN102963078AImprove performanceGuaranteed toughnessSynthetic resin layered productsWoven fabricsFiberDaily living

The invention discloses a multifunctional fabric with multiple fiber layers arranged and combined according to a rule and a manufacturing method; the invention is characterized in that the novel multifunctional fabric is produced by combing a selected material set according to a specific arrangement mode and a connection mode. The material set comprises fiber layers formed by basalt, Kevlar, high-modulus polyethylene, bamboo-source fibers; the arrangement mode is based on a corresponding width, proportion and sequence distributed by a specific optimized curve; the connection mode comprises colloid bonding, and physical connection; the connection method comprises track connection which accords with a specific distribution rule; the connection result is associated with the arrangement mode, that is, sliding is realized between some layers, and fixation is realized between some layers. With the technology, the multifunctional parameters of the target fabric is in an optimal state, and the fabric performance, such as flexibility, stab resistance, bullet resistance, fire resistance, high temperature resistance, water resistance, corrosion resistance, wear resistance, and aging resistance, can reach a comprehensively optimal level; each single performance can meet the corresponding international standard; and the fabric is widely applicable to production and manufacture of daily life clothes and special clothes.

Owner:刘利钊 +1

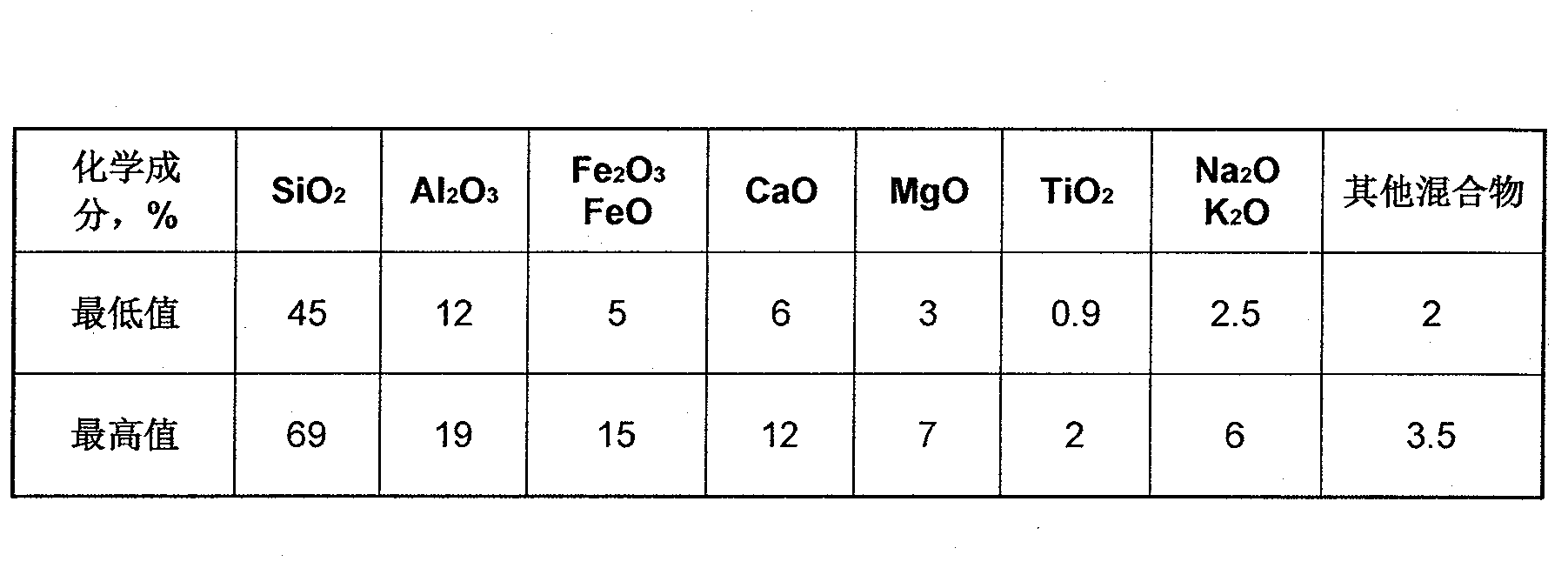

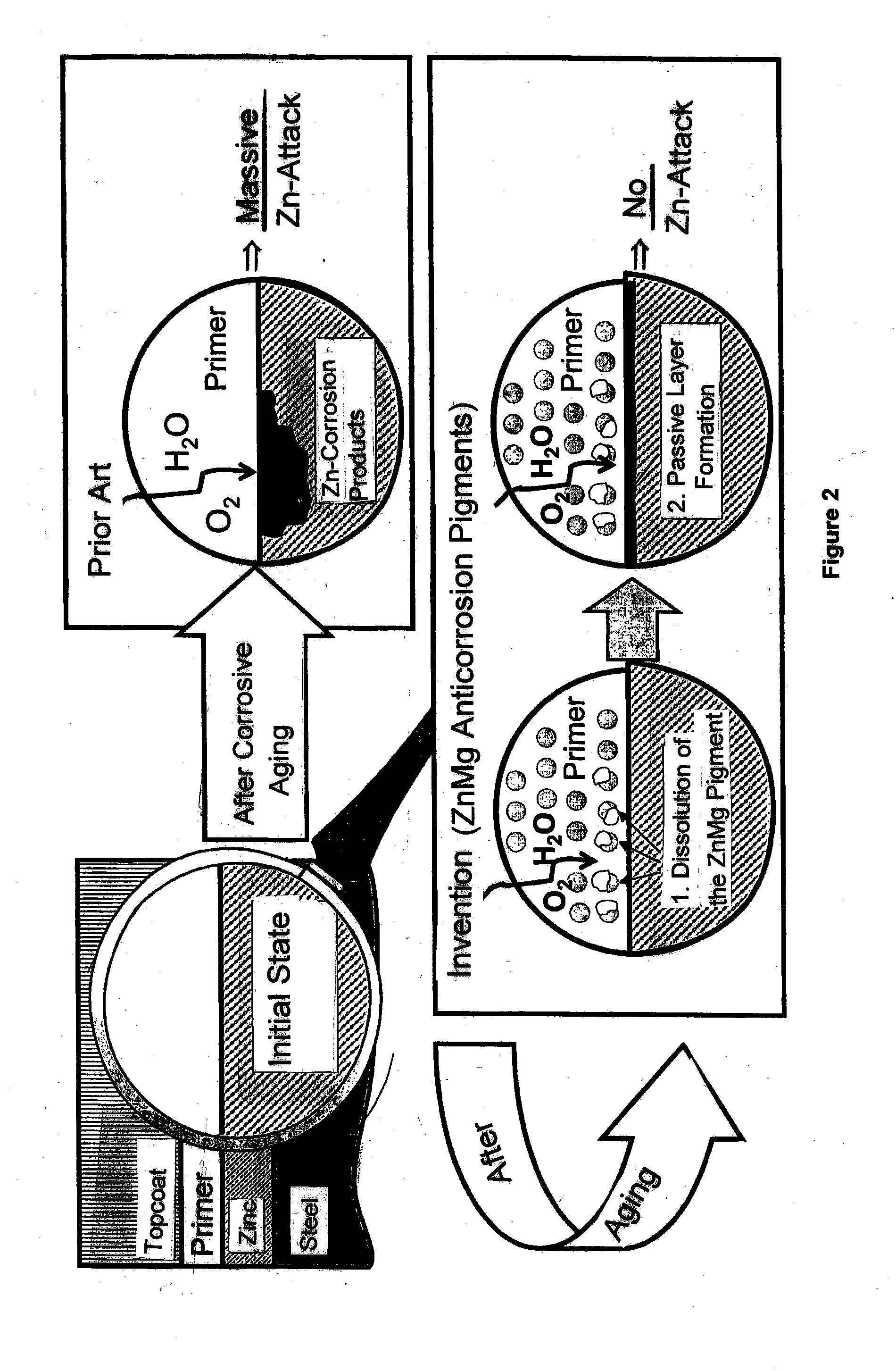

Anti-corrosion system for metals and pigment therefor

InactiveUS20100276293A1Increase in paint coverage rateLow densityPigmenting treatmentConductive materialAlloyImpurity

The invention relates to an anti-corrosion system for metals consisting of at least one finish or coating that can be applied to a metal, said finish or coating comprising an organic matrix. The organic matrix also contains anti-corrosion pigments, which are finely distributed throughout the organic matrix. The anti-corrosion pigments are formed from a metal alloy of at least two metals and optionally from inevitable impurities. The invention also relates to a corresponding anti-corrosion pigment.

Owner:VOESTALPINE STAHL GMBH

Method for producing thick crack-free coatings from hydrogen silsesquioxane resin

InactiveUS6022625AIncrease coating thicknessShorter and low temperaturePretreated surfacesSemiconductor/solid-state device manufacturingCrack freePhysical chemistry

This invention pertains to a method for producing crack-free, insoluble, greater than 1.25 mu m thick coatings from hydrogen silsesquioxane resin compositions. The method for producing the coating comprises applying a fillerless hydrogen silsesquioxane resin composition onto a substrate and thereafter heating the hydrogen silsesquioxane resin at a temperature of less than 500 DEG C. for a controlled period of time to produce the crack-free coating having a thickness of greater than 1.25 mu m. The resins may be cured in an inert or oxygen containing environment.

Owner:DOW CORNING CORP

Arc-coating process with rotating cathodes

InactiveUS6926811B2Modification can be limitedUniform layer thicknessElectric discharge tubesVacuum evaporation coatingDeposition processVacuum chamber

A method is provided for coating objects in a vacuum chamber in which a physical vapor deposition (PVD) can be carried out. The chamber has at least one anode means, at least one cathode and at least one magnetic field source. An arc can be ignited between the at least one anode means and the at least one cathode, and the cathode separates material. The at least one magnetic field can be turned relative to the at least one cathode and the objects to be coated are arranged in the chamber. The magnetic field is turned before the beginning of the coating process so that the separated material does not coat the objects to be coated in the coating process. The arc for the physical deposition process is produced by means of at least two cathodes, said cathodes are constructed as substantially cylindrical tubular cathodes and the at least one magnetic field source is constructed as a permanent or coil magnet arranged in the tubular cathodes and the tubular-cathodes turn about their cylinder axis during the coating process.

Owner:PLATIT

Multilayered structure, multilayered structure array and method of manufacturing the same

InactiveUS7054135B2Decrease pitchImprove productivityPiezoelectric/electrostrictive device manufacture/assemblyMultiple fixed capacitorsProduction rateMetallic sulfide

A multilayered structure array has narrow pitches by making thinner coatings for insulating internal electrode layers from side electrodes and the productivity of the multilayered structure array is improved. The multilayered structure includes: a first internal electrode layer; a piezoelectric layer formed on the first internal electrode layer; a second internal electrode layer formed on the piezoelectric layer; a first coating formed on an end surface of the first internal electrode layer in a first side surface region of the multilayered structure and containing one of metal oxide, metal nitride, metal fluoride and metal sulfide in at least one part thereof; and a second coating formed on an end surface of the second internal electrode layer in a second side surface region of the multilayered structure and containing one of metal oxide, metal nitride, metal fluoride and metal sulfide in at least one part thereof.

Owner:FUJIFILM HLDG CORP +1

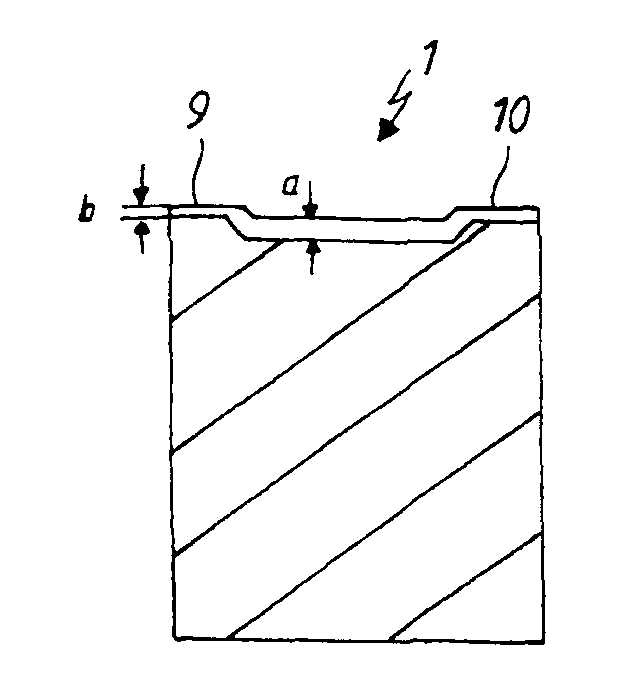

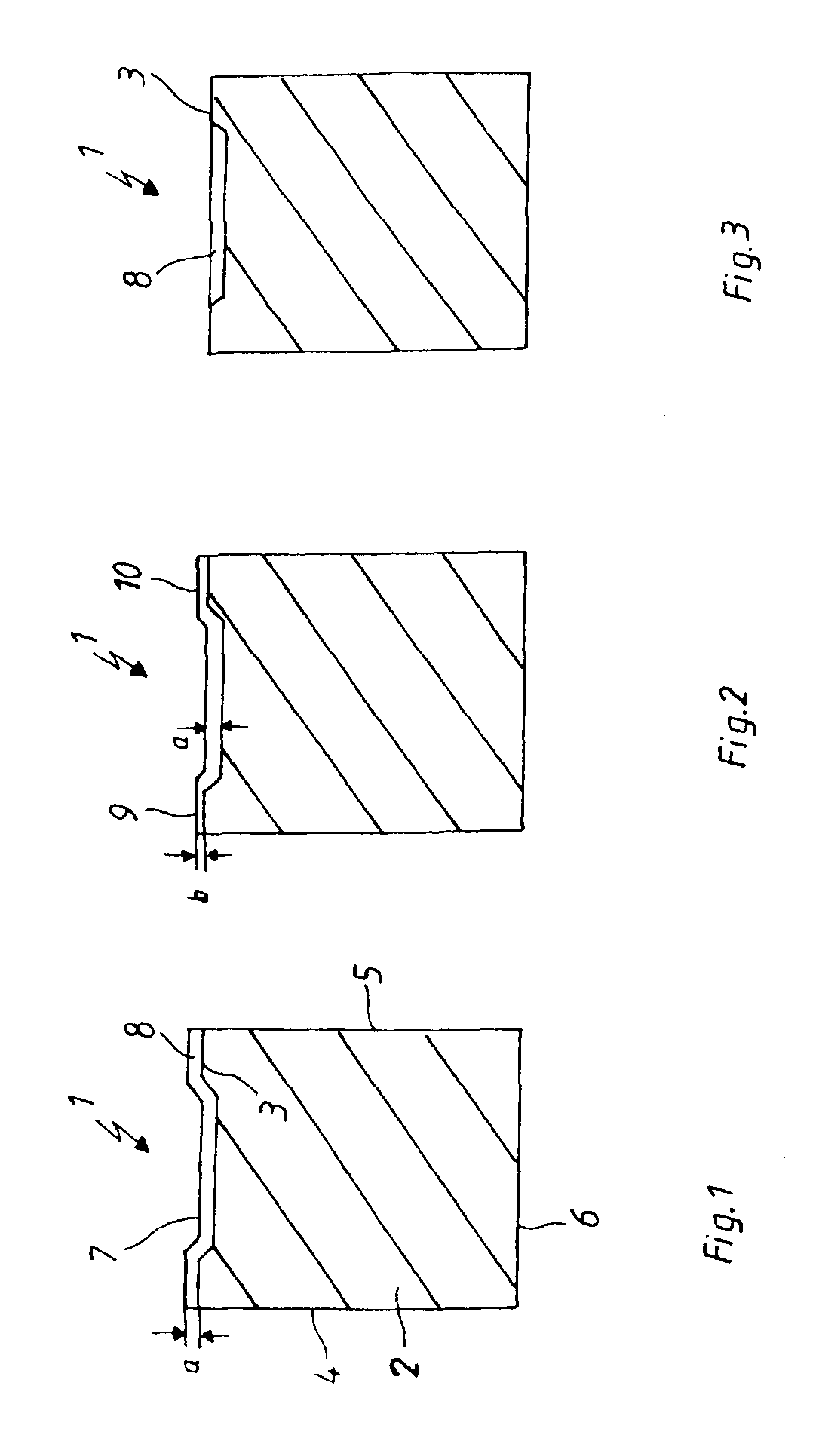

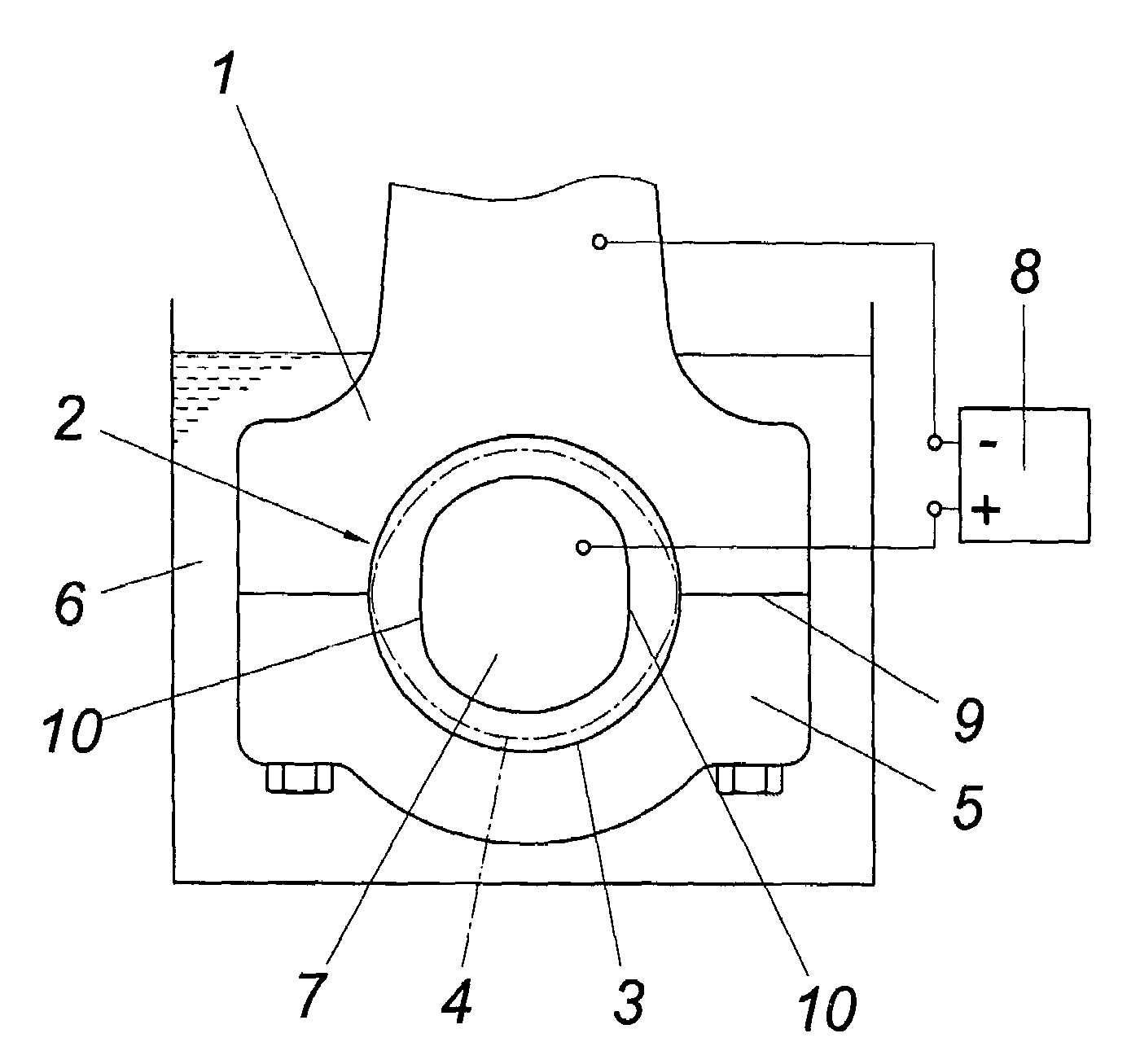

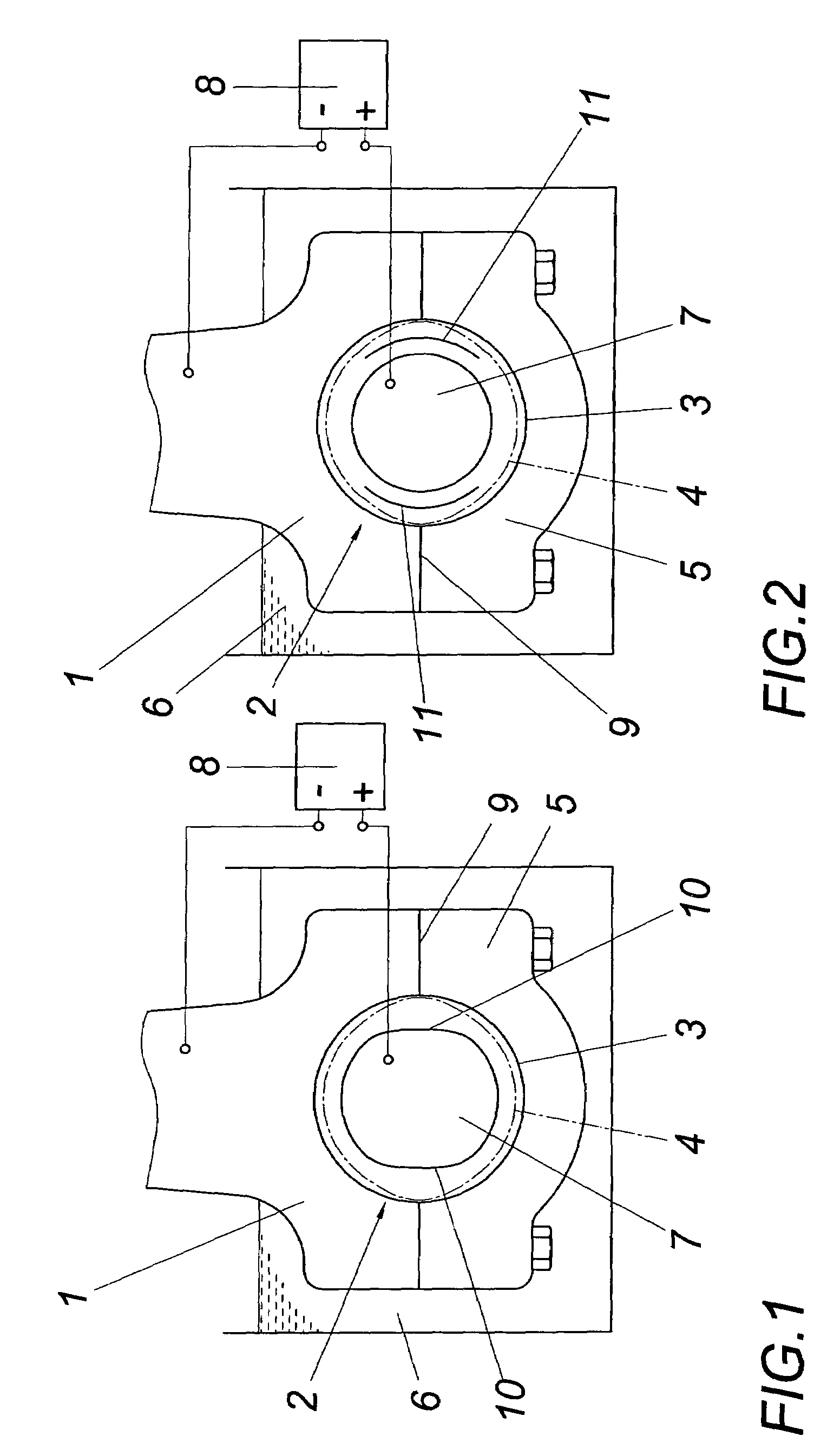

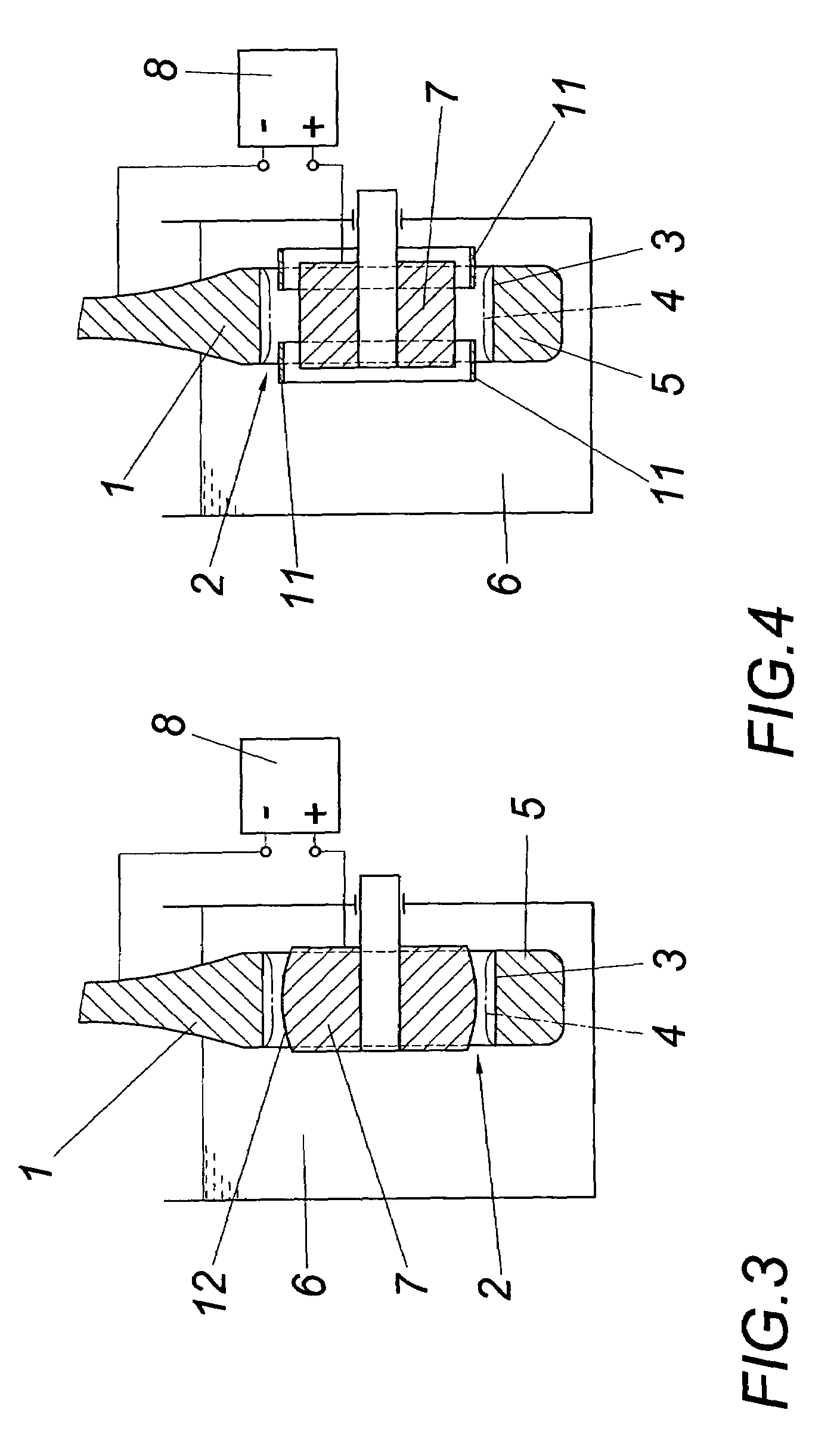

Piston ring

ActiveUS8235393B2Reduce coating thicknessImprove securityPiston ringsBraking action transmissionPiston ringEngineering

A piston ring having a base body, which comprises a running surface provided with at least one chamber, an upper and a lower flank surface, and an inner circumferential surface, wherein the running surface is provided with at least one PVD layer such that the same is adjusted to the contour of the running surface without completely filling the chamber, wherein the respective edge region is provided with a layer thickness, b that is reduced compared to the layer thickness, a of the chamber as a function of the configuration of the chamber.

Owner:FEDERAL MOGUL BURSCHEID

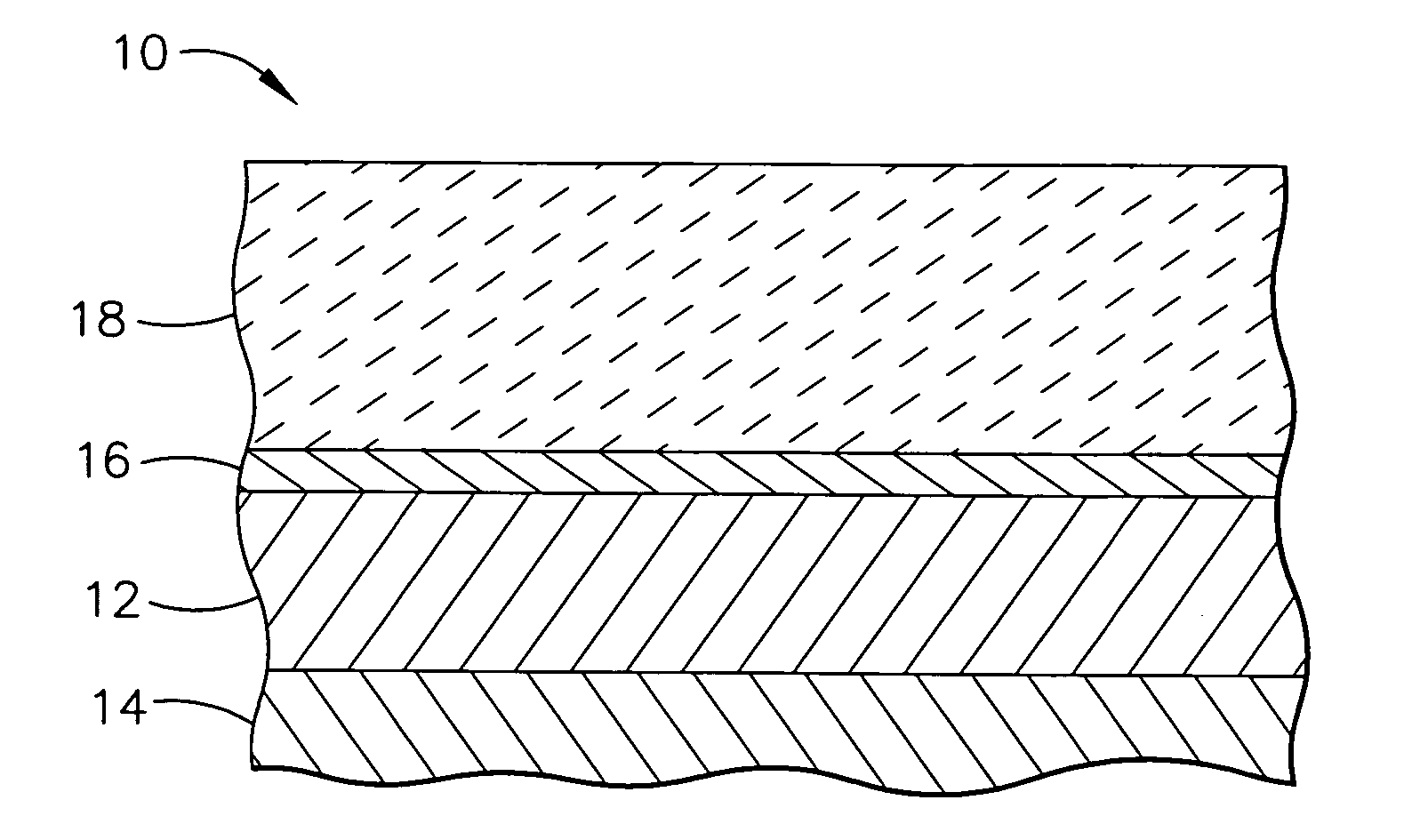

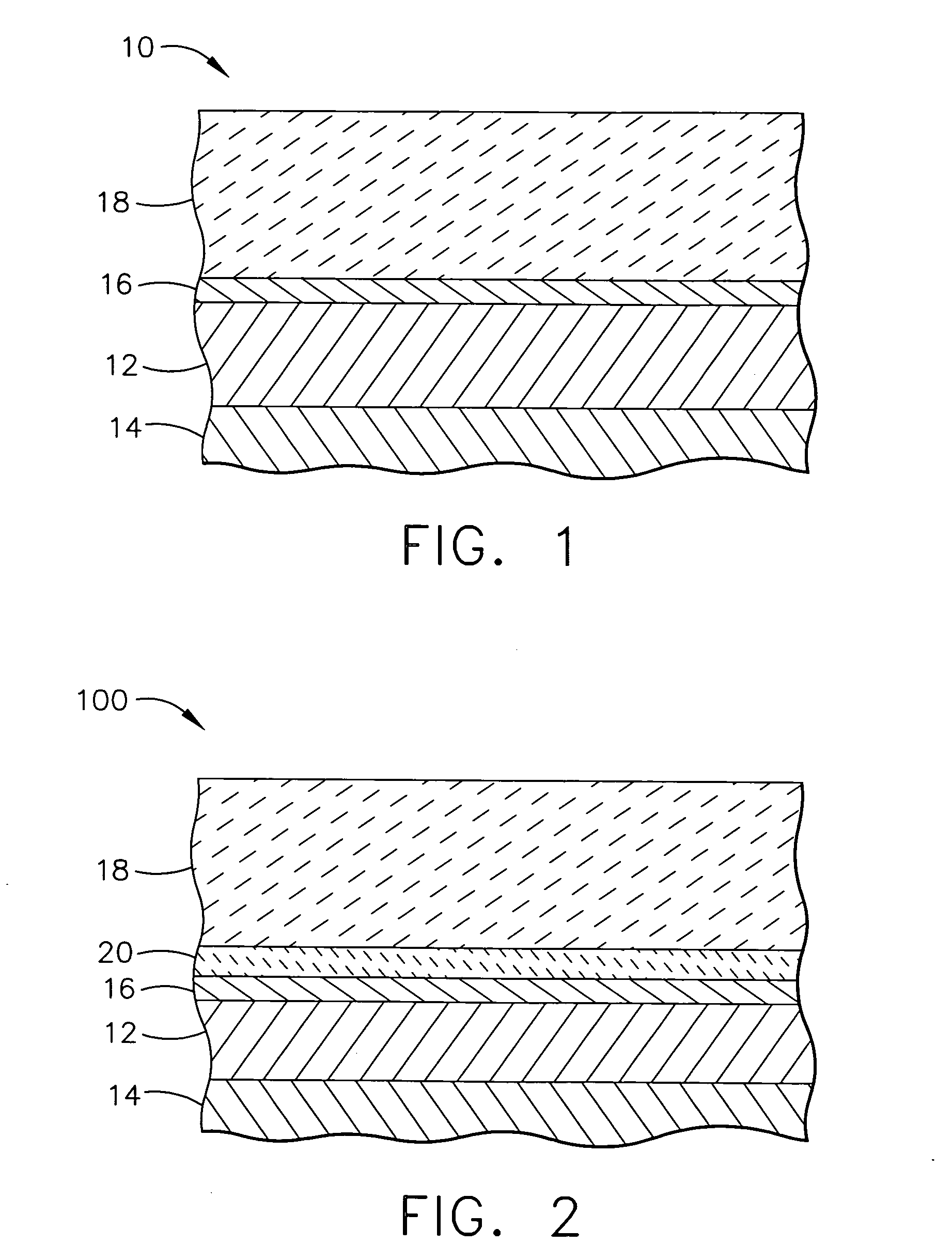

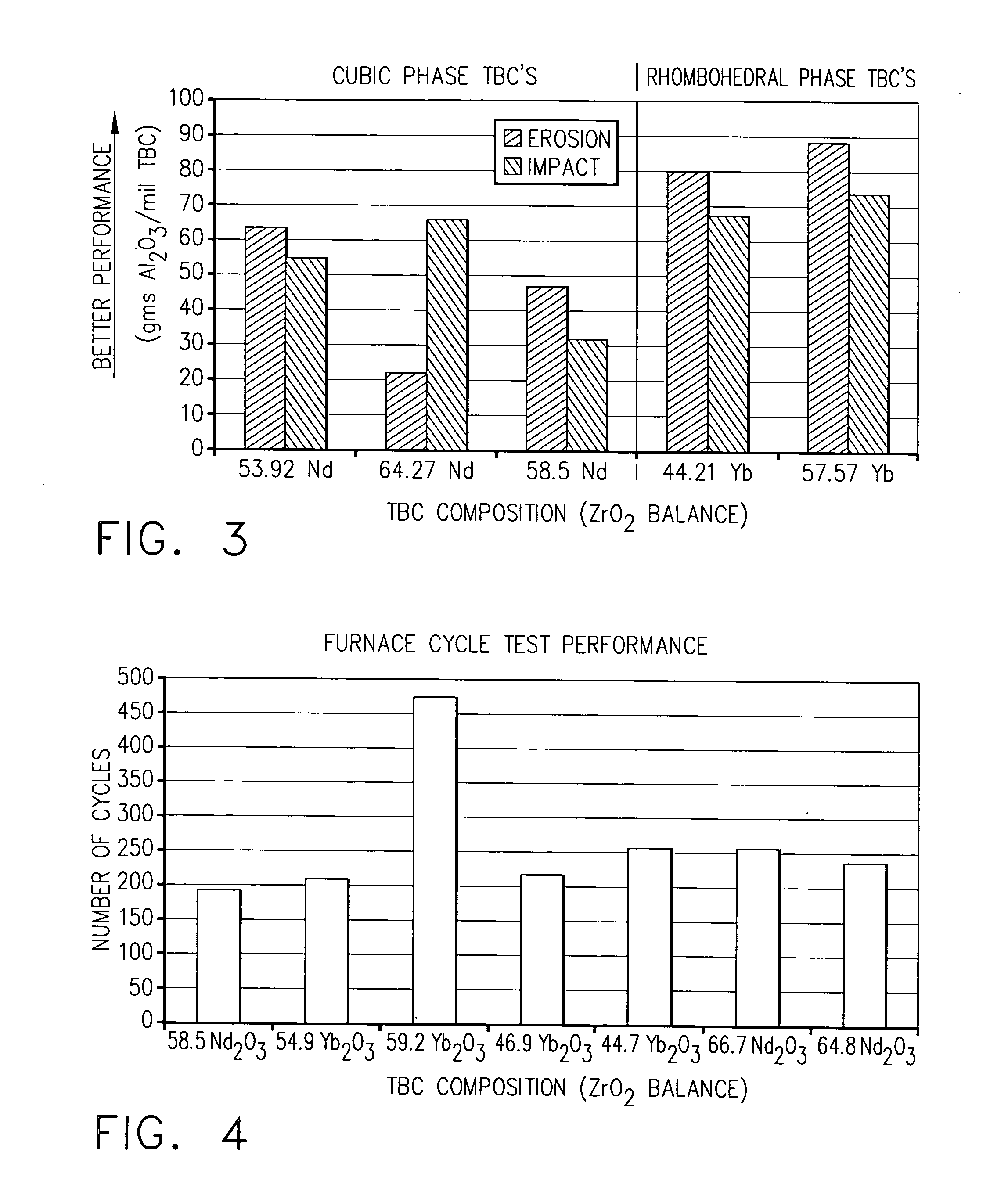

Low thermal conductivity thermal barrier coating system and method therefor

InactiveUS20060121294A1Low thermal conductivityStrong resistance to erosionLiquid surface applicatorsMolten spray coatingRare-earth elementMetallurgy

In accordance with an embodiment of the invention, a thermal barrier coating for inclusion in a thermal barrier coating system is provided. The thermal barrier coating comprises a compound having a rhombohedral phase. In accordance with another embodiment of the invention, a thermal barrier coating is provided that comprises a compound having the formula of: A4B3O12, wherein A is at least one rare earth element; and B is selected from the group consisting of Zr, Hf and mixtures thereof.

Owner:GENERAL ELECTRIC CO

Method of producing a workpiece having at least one bearing eye

InactiveUS7178238B2Thin coatingImprove fatigue strengthHot-dipping/immersion processesConnecting rod bearingsEngineeringVarying thickness

A method of producing a workpiece (1) having at least one bearing eye (2) is described, the bearing eye (2) being coated with an anti-friction coating (4), which forms a running surface deviating from a circular cylinder. In order to provide advantageous production conditions, it is suggested that the bearing eye (2) be processed for a precise fit to a circular cylinder, before the anti-friction coating (4) is galvanically deposited on the processed bearing eye surface (3) to form the running surface in a varying thickness which corresponds to the final dimensions.

Owner:MIBA GLEITLAGER GMBH

Organic based varnish or gelcoat, methods for its manufacture and use, and substrate comprising such varnish or gelcoat

InactiveUS20030162874A1Improve wear resistanceReduce coating thicknessSpecial tyresAnti-corrosive paintsPolymer scienceLacquer

Organic based and preferably clear and glossy lacquer / varnish or an organically based gel-coat with the ability to form coatings with high wear resistance, as well as method for manufacturing same, said lacquer / varnish or gel-coat comprises a controlled amount of inorganic polymer particles mainly with a size of 1-100 nm, the particles being able to form a three-dimensional network that is independent of the organic network of the lacquer or which may have bondings to this network. The polymer particles are typically a reaction product obtained by hydrolysis and condensation reactions of monomer compounds chosen among the following groups: i) M(OR)n, or ii) R'-M(OR)n, where M is a metal ion, and R is an organic group chosen among alkyl, alkenyl, aryl or combinations of such groups with from 1 to 8 carbon atoms, R'=R or R-X, where X is an organic group like e.g. amine, carboxyl or isocyanate, and n is an integer between 1 and 6. Alternatively the polymer particles are natural or synthetic clay based powders or combinations of such powders. The lacquer / varnish or gel-coat is used as protective coatings on e.g. surfaces of aluminium or steel, preferably rolled aluminium or steel.

Owner:SINTEF

Inorganic fireproof material and preparation method thereof

The invention discloses an inorganic fireproof material and a preparation method thereof, and belongs to the field of fireproof materials. A coating of the fireproof material mainly comprises alumina sol as a film forming matter, diatomite as filler and some trace auxiliaries, wherein the alumina sol is a water-based inorganic binder and has the characteristics of no toxity, high temperature resistance, high binding force, environmental protection and the like; the diatomite has porous heat insulation and can obviously prolong duration of fire resistance; the performances of the coating such as adhesive force and duration of fire resistance can be obviously enhanced by adjusting the percentage composition and the thickness of the coating. The raw materials used are all low in cost, and are non-toxic and harmless inorganic materials; the coating is expanded and foamed during the heated process to form a loosened porous expansion layer with an extremely good heat insulation effect, and meanwhile hazardous gas is not generated; the duration of fire resistance is over 60 minutes; the coating can be coated on various modern buildings with wood structures and steel structures, and can be applied to the field of fireproof coatings well.

Owner:KUNMING UNIV OF SCI & TECH

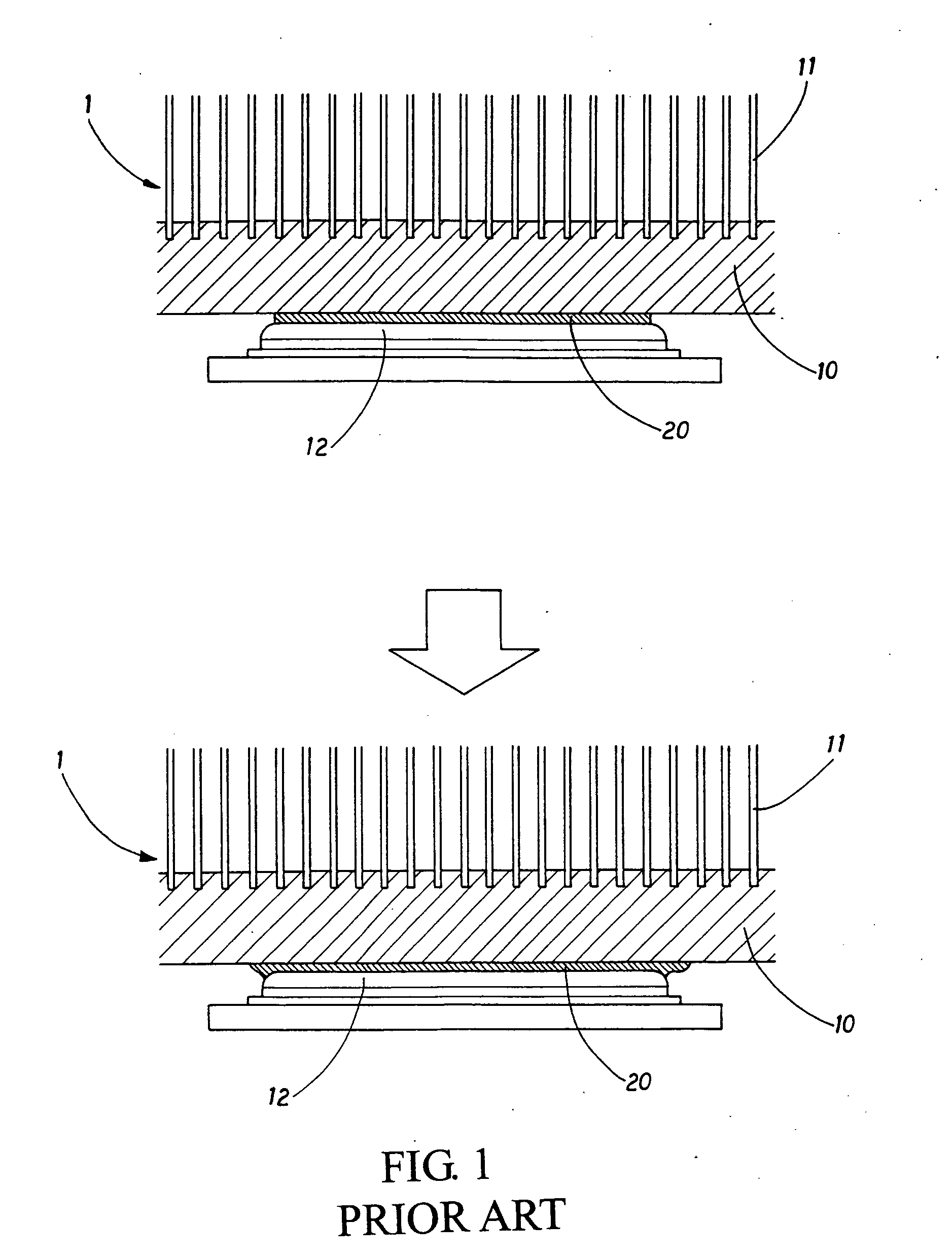

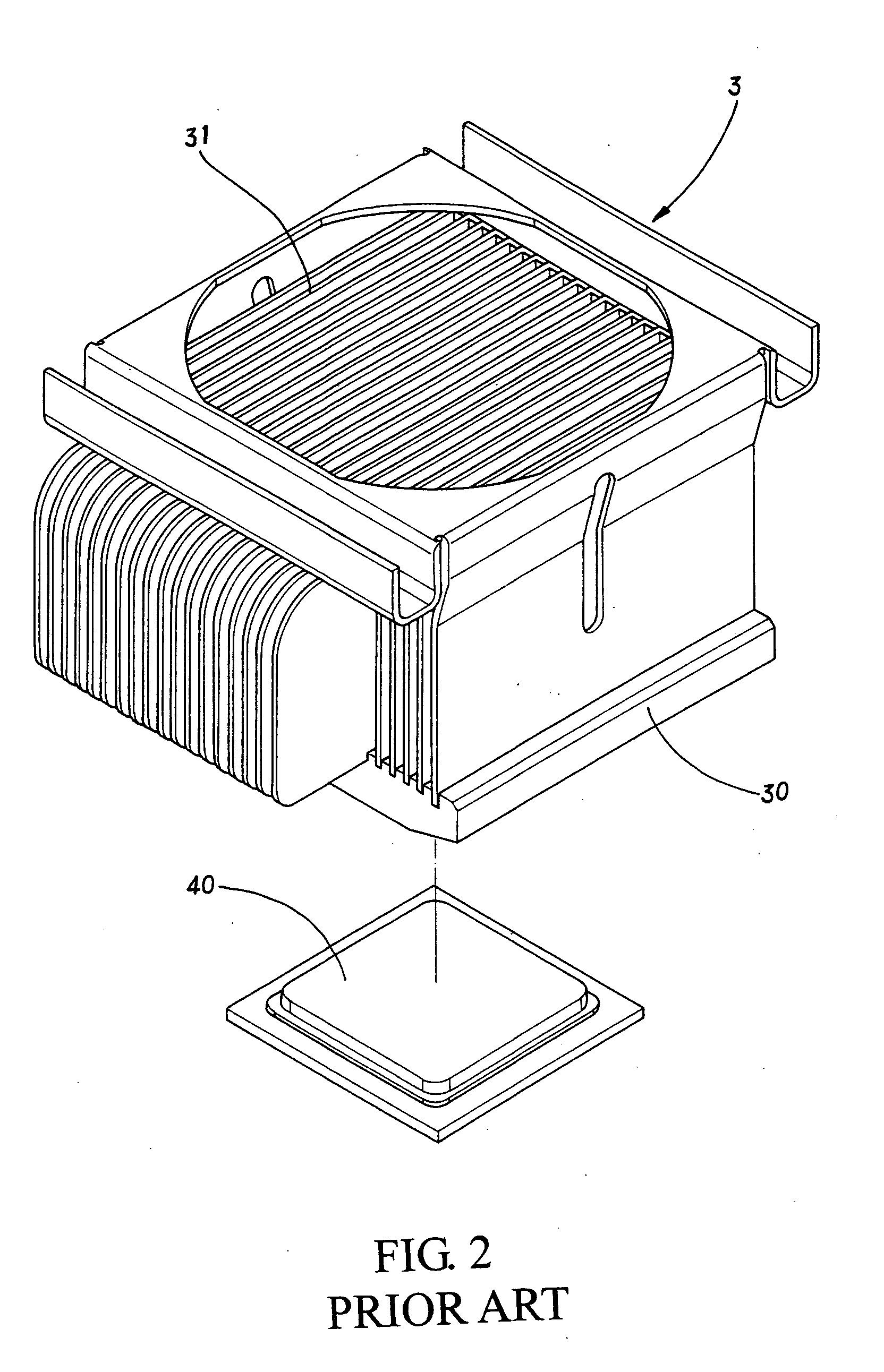

Heat dissipating device holder structure with a thin film thermal conducting medium coating

InactiveUS20080068803A1Reduce thermal resistanceImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesShortest distanceShort distance

In a heat dissipating device holder structure with a thin film thermal conducting medium coating, at least two thermal conducting medium coating blocks are set on attaching surfaces of a heat dissipating device holder and a processor, and a gap is disposed between the coating blocks, such that when the heat dissipating device holder is attached to the processor, the compressing force of the heat dissipating device holder and the processor exerted onto the thermal conducting medium coating blocks can be spread to fill the spread thermal conducting medium into a short distance of the gap, so as to achieve the best thin film coating for the thermal conducting medium and effectively lower thermal resistance and attach the heat dissipating apparatus holder tightly with the processor for the best heat dissipation effect.

Owner:CHEN SHYH MING

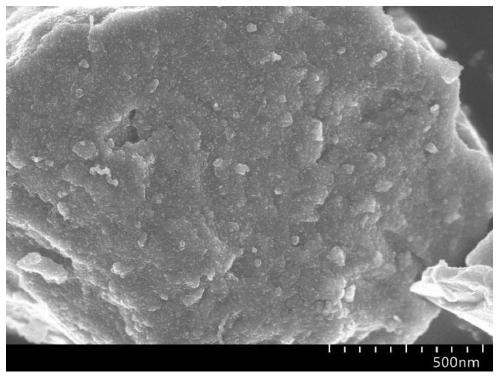

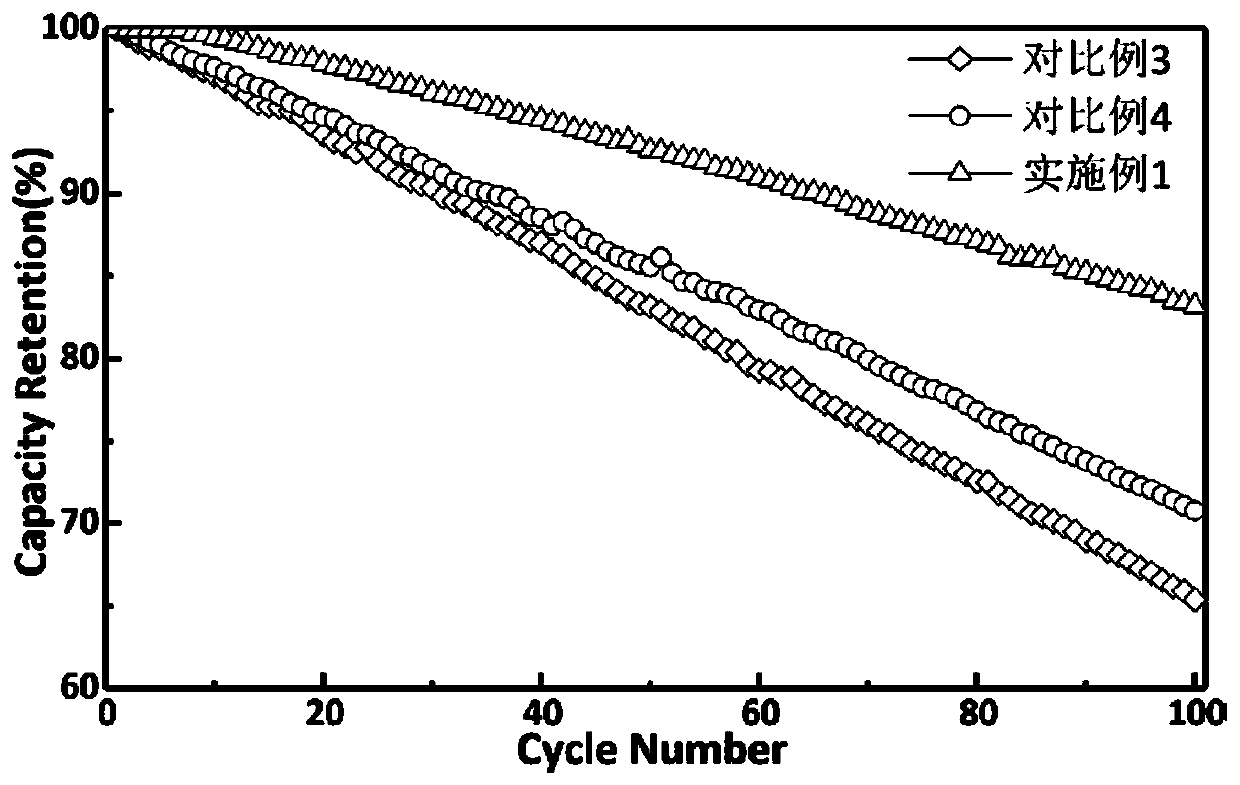

High-capacity-density lithium ion battery negative electrode

ActiveCN111384370AIncrease capacityReduce coating thicknessMaterial nanotechnologyCell electrodesSilicon particleElectrically conductive

The invention relates to a high-capacity-density lithium ion battery negative electrode. The negative electrode comprises surface-modified silicon particles, a carbon conductive agent capable of forming a conductive network, an organic polymer binder with high tensile strength and high elastic deformation characteristics, and a current collector substrate beneficial to electron conduction. The capacity of the negative electrode is greatly improved, and the compaction density is not much lower than that of the traditional graphite negative electrode, so that the negative electrode has the characteristic of high capacity density. When the negative electrode is applied to a lithium ion battery, the lithium ion battery with high energy density can be obtained. The lithium ion negative electrode is prepared by adopting common means and processes in industrial production in the current lithium battery industry; the method is simple, efficient and low in cost, and commercial production of thehigh-capacity-density lithium ion battery negative electrode can be achieved.

Owner:BERZELIUS (NANJING) CO LTD +1

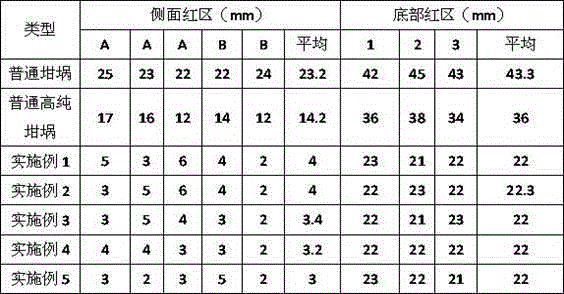

Preparation method of ultrahigh-purity quartz ceramic crucible

The invention mainly discloses an ultrahigh-purity quartz ceramic crucible and a preparation method thereof. The ultrahigh-purity quartz ceramic crucible is mainly applied to polycrystalline silicon ingots in the solar photovoltaic industry. The preparation method comprises the steps of treating solar-grade purity silica powder (6N) with different grain sizes, and then, adding silica sol, deionized water, additives and the like according to a certain ratio to prepare slurry with good dispersibility, wherein the solar-grade purity silica powder (6N) with different grain sizes is used as the main raw material; after further treating a common quartz crucible, placing the slurry on the inner surface of the common quartz crucible in a way of coating, brushing and the like; and after drying, oxidizing and sintering in a kiln with an oxidizing atmosphere to obtain the ultrahigh-purity quartz ceramic crucible. By using the preparation method, the ultrahigh-purity quartz ceramic crucible can be obtained, an ultrahigh-purity crucible is produced by breaking the bottleneck of an ultrahigh-purity quartz raw material, impurities are more effectively prevented from entering ingots, side red areas are thoroughly eliminated, bottom red areas are reduced, the conversion efficiency is increased, the cost is reduced while the stability is kept, the porosity is lower, the volume density is higher, the property is more stable, the service life is greatly prolonged, and the using cost is effectively reduced.

Owner:SINOMA JIANGSU SOLAR ENERGY NEW MATERIALS

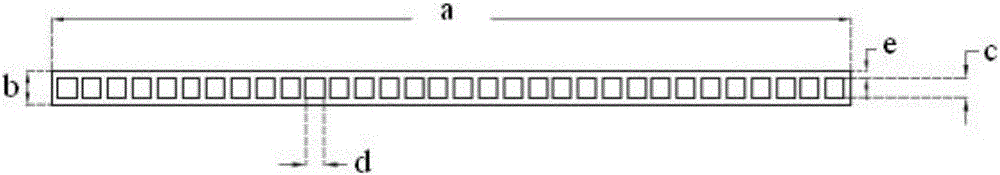

Preparation method of high-purity alumina plate ceramic membrane support

The invention provides a preparation method of a high-purity alumina plate ceramic membrane support. The preparation method comprises steps as follows: step one, zirconium nitrate is put into deionized water and is heated and stirred; step two, powder of alumina a, alumina b, lanthanum oxide and yttrium oxide is added to a kneading machine proportionally for mixing; step three, mixtures obtained in the step one and the step two are mixed; step four, dextrin, PVA (polyvinyl acetate), glycerin and tung oil are weighed proportionally and mixed sufficiently, a mixture is added to a material obtained in the step three for mixing, and a pug material is obtained; step five, the pug material is transferred to a pug mill and subjected to pugging and then is fed into an extruder, and an extruded blank is air-dried naturally; step six, the blank is placed into an oven for drying and then is placed in a kiln for sintering. The alumina content of the plate ceramic membrane support prepared with the method is 99% or higher, and while the anti-corrosion strength of the support is greatly improved and the service life of a ceramic membrane is greatly prolonged, long-term stable usage of the ceramic membrane under a strong alkali system can be guaranteed.

Owner:上海硅苑膜科技有限公司 +1

Multi-layered coatings, method for the production thereof, and use thereof in the car industry

InactiveUS8535795B2Improve stabilityLess influenceSynthetic resin layered productsPretreated surfacesUv absorbanceAuto industry

The present disclosure provides multicoat systems exhibiting ultraviolet (UV) stability after ultraviolet exposure and moisture exposure. The systems comprise at least one primer (G), at least one pigmented coating (P) disposed on a surface of the primer, and at least one ultraviolet (UV) absorber which has an absorption maximum of at least 370 nm. The pigmented coating (P) may be comprised of two or more coatings (P1), (P2) to (Pn). The multicoat systems may also comprise a transparent coating material (T) to form a transparent coating (K). The present multicoat systems demonstrate ultraviolet stability, reduced delamination of the pigmented coat from the primer and are available in a variety of shades for use in the finishing, refinishing and coating of component parts.The present disclosure also provides for a process for producing the multicoat system, and provides for the use of the system.

Owner:BASF COATINGS GMBH

Copper alloy foil

InactiveUS6939620B2Improve adhesionImprove conductivityInsulating substrate metal adhesion improvementSynthetic resin layered productsEpoxyAdhesive

For a three-layer flexible board, there is provided a copper alloy foil that requires no roughening processing, that has good adhesion with an adhesive containing an epoxy resin, that can be laminated to form a copper-clad laminate, that has a low surface roughness, and that has high conductivity and strength. The copper alloy of the foil contains at least one of 0.01-2.0 weight percent Cr and 0.01-1.0 weight percent Zr or contains 1.0-4.8 weight percent Ni and 0.2-1.4 weight percent Si. Good adhesion of the copper alloy foil to a resin substrate with an adhesive containing an epoxy resin is obtained by setting the thickness of the anticorrosive coating to less than 3 nm; the surface roughness of the copper alloy foil is below 2 μm expressed as ten-point average surface roughness (Rz); and, without roughening processing, the 180° C. peel strength, after adhesion of the copper alloy foil to the board film by means of an adhesive containing an epoxy resin, is greater than 8.0 N / cm.

Owner:JX NIPPON MINING & METALS CO LTD

Composite anti stinging face fabric in flexible light weight, and fabricating method

Owner:DONGHUA UNIV

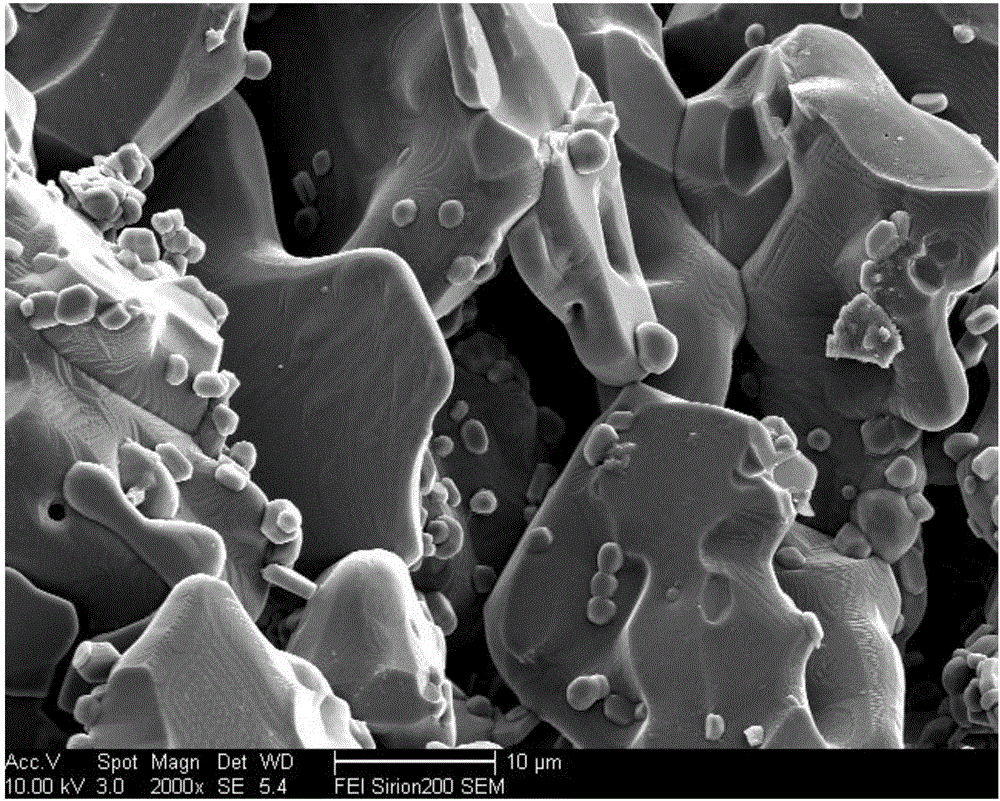

Preparation method of tungsten boride composite coating

InactiveCN107523777AHighlight substantive featuresHigh densityMolten spray coatingThermal sprayingMetallic materials

The invention discloses a preparation method of a tungsten boride composite coating, and relates to coating of boride on metal materials. The tungsten boride composite coating is synthesized through a thermal spraying in-situ reaction. The preparation method comprises the steps that tungsten oxide / boron carbide / aluminum composite powder used for thermal spraying is prepared; the base material surface needing the coating is pretreated; and the tungsten boride composite coating is prepared. The defects that the existing technology for preparing the tungsten boride composite coating is complex, high in cost, large in pollution and low in deposition efficiency, and the coating is small in thickness, low in compactness, poor in uniformity, low in toughness, poor in binding force with a base body, likely to be cracked and not suitable for being applied in large-scale industrial production are overcome.

Owner:HEBEI UNIV OF TECH

Apparatus for coating belt cord with rubber

InactiveUS20060113026A1Uniform strengthEliminate riskLamination ancillary operationsLaminationEngineeringInsulation system

In an apparatus for the coating of belt cords with rubber, plural belt cords made of a steel filament are aligned as a cord unit, and a plurality of such cord units are arranged in parallel to each other at a given pitch in the same plane, and then integrally coated with an uncured rubber through an insulation system immediately after the arrangement of these cord units in line.

Owner:BRIDGESTONE CORP

Metal antirust agent with low viscosity

InactiveCN105039946AImprove adaptabilityReduce coating thicknessMetallic material coating processesHexamethylenetetramineAlkylphenol

The invention discloses a metal antirust agent with low viscosity. The metal antirust agent with the low viscosity is prepared from, by weight, 1-hydroxybenzotriazole, triethanolamine, ethylparaben, glycerin monostearate, sodium carboxymethylcellulose, cocoanut oil fatty acid diethanol amide, alkylphenol polyoxyethylene ether, nonyl phenol polyoxyethylene ether, phytic acid, sodium nitrite, p-fluorobenzoylbut anoic acid, urotropine, hydrochloric acid and water. Compared with the prior art, the metal antirust agent with the low viscosity has the beneficial effects that the metal antirust agent is better compatible with materials and better adapts to materials such as copper and aluminum; meanwhile, the kinematic viscosity is obviously reduced, so that coating is easier and more convenient, the coating thickness of the antirust agent is reduced, and cost for rust protection is reduced.

Owner:HEFEI CITY TENVER PRECISION CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com