Multifunctional fabric with multiple fiber layers arranged and combined according to rule and manufacturing method

A multi-functional, fiber layer technology, applied in the direction of wood layered products, chemical instruments and methods, layered products, etc., can solve the problems of inability to meet various protection performance requirements, unsatisfactory composite performance, etc., and achieve multi-functionality enhancement , cost control, good overall softness and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Implementation Example 1

[0029] The multi-functional fabric and its manufacturing method are as follows:

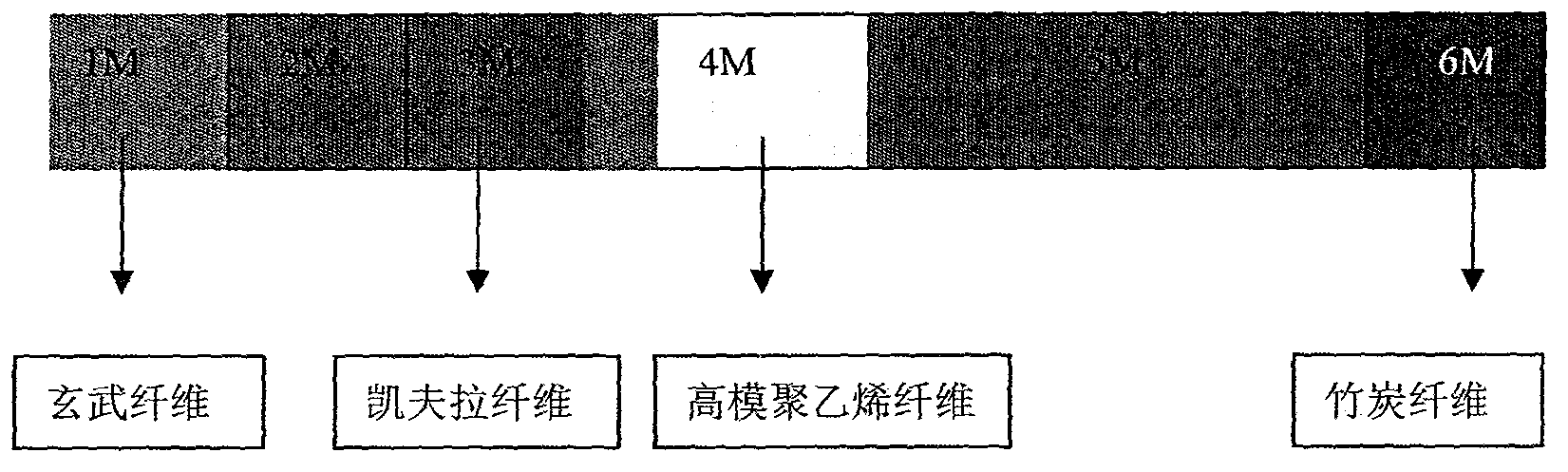

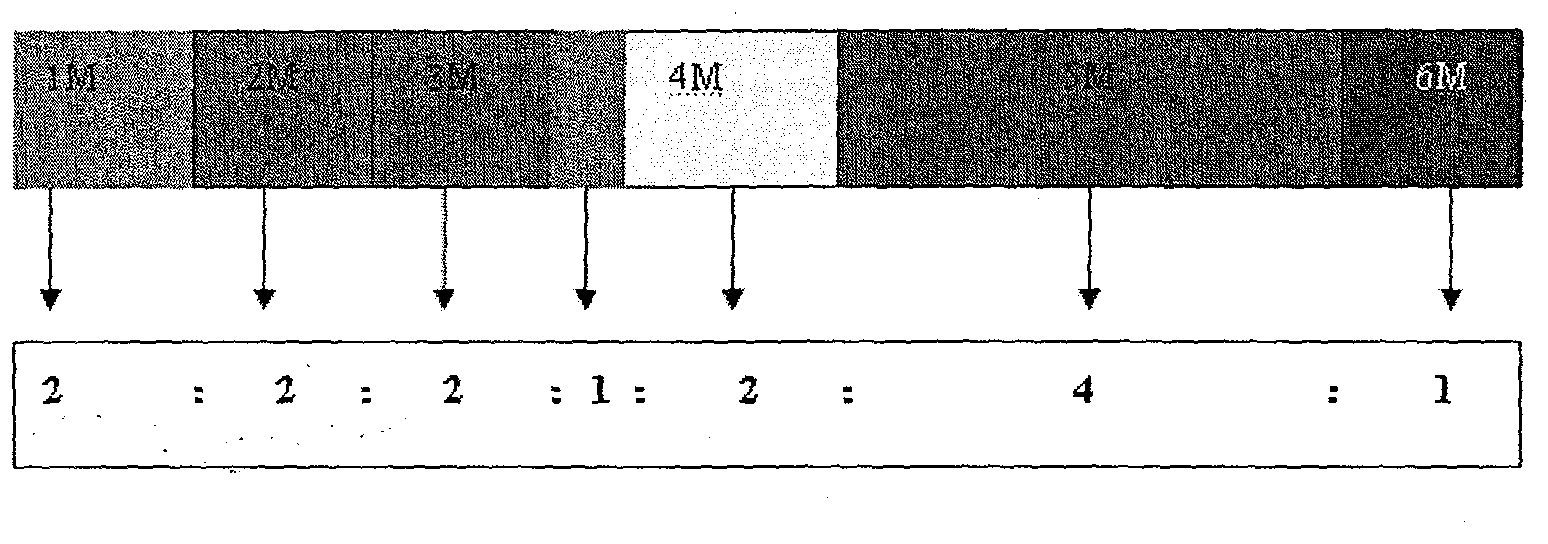

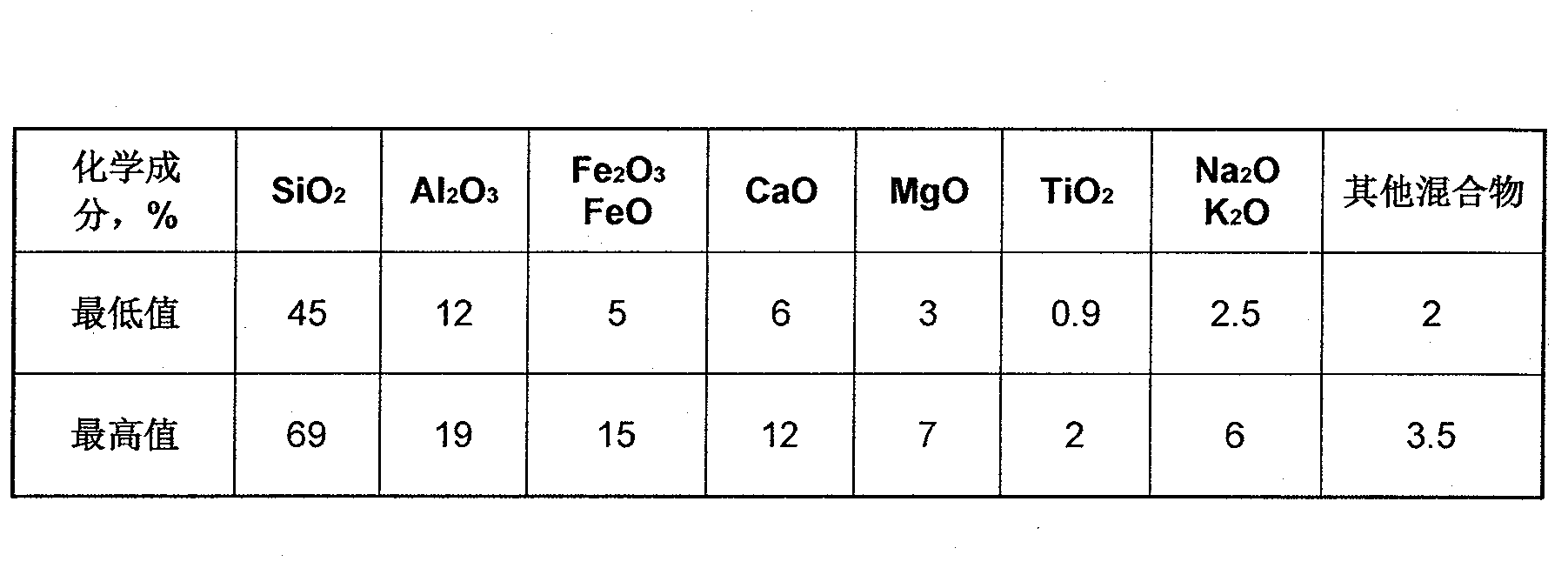

[0030] Reference attached Figure 1-7 . The multifunctional material consists of 6 parts. The first part (1M) is divided into basalt fiber (coating) woven fabric part is composed of 2 layers of basalt fiber woven fabric with fire-resistant silica gel discrete glue, coating thickness 0.2MM; the second part (2M) kevlar fiber (coating) The non-woven fabric part is made of 2 layers of kevlar fiber non-woven fabric with folded process and moderately sewn; the third part (3M) kevlar fiber non-woven fabric part is connected by rivets of 2 layers of kevlar fiber non-woven fabric with folded process The fourth part (4M) is composed of 1 layer of basalt fiber woven fabric discretely glued together with 2 layers of ultra-high molecular weight polyethylene-UHMWPE fiber (coating) non-woven fabric, and the latter coating is made of 10UM The polycarbonate glue of cubic boro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com