Fabric pattern transfer ink and preparation method thereof

A transfer method and fabric technology, applied in ink, dyeing, textiles and papermaking, etc., can solve the problems of hard hand feeling of finished products, easy staining of white background, loss of use value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Take weak acid brilliant red B, 1000 grams, dissolve it in 5000 grams of hot water, stir, after it is completely dissolved, heat it, add 2000 grams of water-soluble polyamide hot-melt resin, stir, after the resin is completely dissolved, add the remaining 5000 grams of water, adjust the viscosity to 5000mPa.s, so as to prepare the ink for flat screen printing.

[0076] Select the pattern with a flat screen printing machine, print the above ink on the BOPP film, and dry. The re-printed surface is attached to the silk fabric that has been wetted and dried with a mixed aqueous solution composed of 8% (w / w) glycerin and 2% (w / w) ammonium sulfate, and the temperature is 120°C and the pressure is 25Kg / cm 2 flat iron transfer. Then tear off the film, put it in a steaming box, and steam for 30 minutes at a temperature of 105°C. Finally, after washing and drying, the printed product is finished.

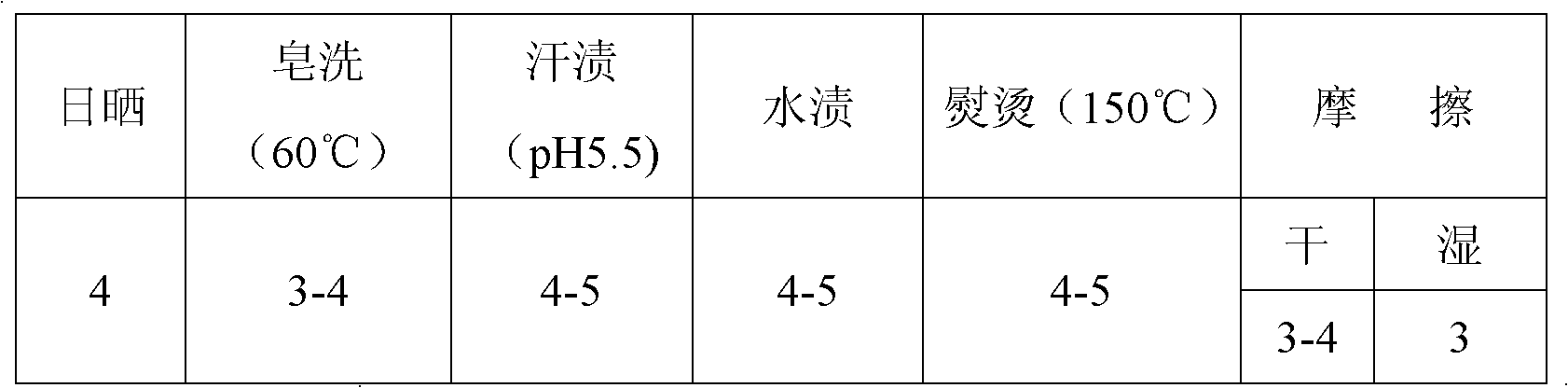

[0077] Through the test, the fastness indexes of the printed pattern are shown...

Embodiment 2

[0081] Take 1300 grams of vat green FFB, add 6000 grams of water, put it into a ball mill and grind for 48 hours, test the fineness, after the fineness is less than 5 microns, add 4000 grams of water, 2500 grams of water-soluble polyvinyl alcohol hot melt resin, continue grinding, When the resin is completely dissolved and the fineness of the dye is less than 2 microns, the remaining 2000 water is added to adjust the viscosity to 6500 mPa.s, thus making the ink for rotary screen printing.

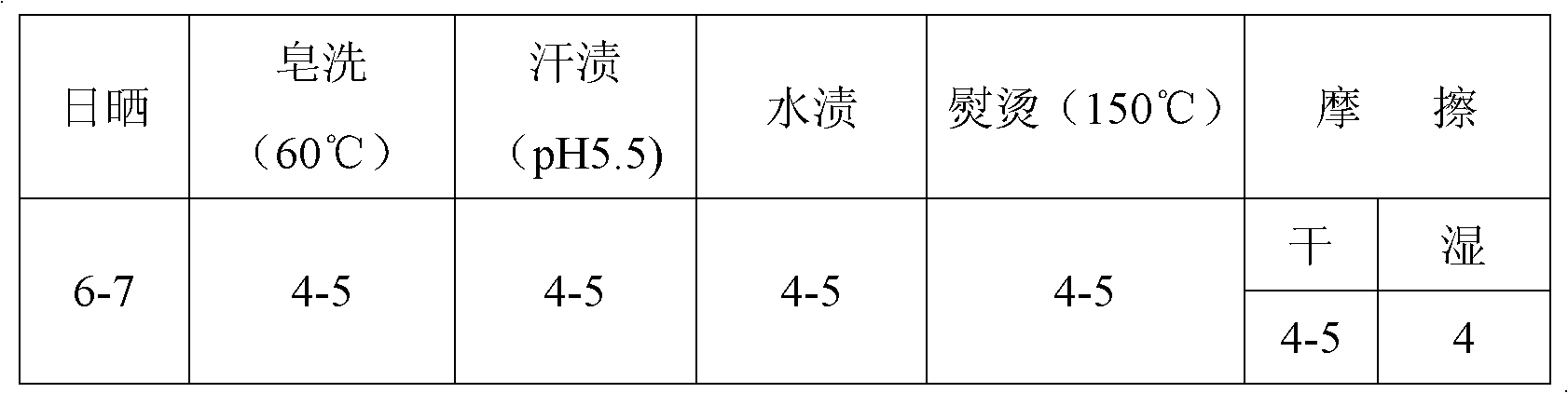

[0082] Select the pattern, print the above ink on the PET film with a rotary screen printing machine, and dry it. The re-printed surface is attached to the cotton fabric that has been wetted and dried with a mixed aqueous solution composed of 8% glycerol, 2% (w / w) sodium carbonate and 10% (w / w) hanging white blocks, and is placed in The temperature is 110℃, the pressure is 15Kg / cm 2 flat iron transfer. Then tear off the film, put it in a steaming box, and steam for 15 minutes at a tempera...

Embodiment 3

[0087] Take reactive brilliant red M-2B, 700 grams, dissolve it in 3000 grams of dimethyl sulfoxide, stir, after it is completely dissolved, add 1500 grams of water-soluble polyester hot-melt resin, stir, after the resin is completely dissolved, add 2500 grams grams of water, adjust the viscosity to (25 ° C) 17s (Zahn No. 3 cup), so that the gravure printing ink is prepared.

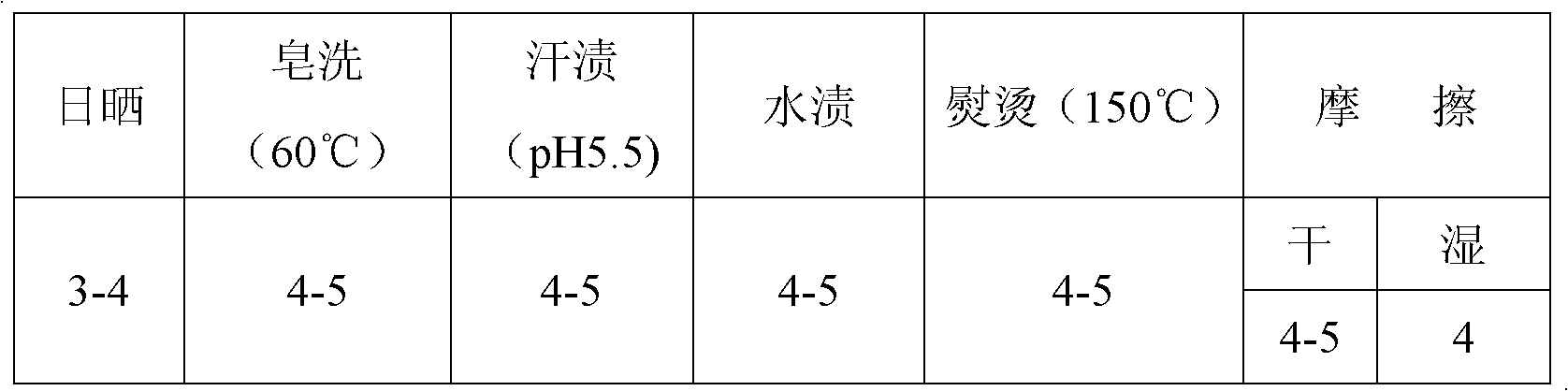

[0088] Taking the water-soluble polyester hot-melt resin as the solute, and the mixed solution of water and dimethyl sulfoxide as the solvent, the solution is coated with a PET film, the pattern is selected, and the above-mentioned ink is printed on the coated PET film with a gravure printing machine. ,drying. The reprinted surface is attached to the cotton fabric that has been wetted and dried with a mixed aqueous solution composed of 12% (w / w) urea and 2% (w / w) sodium carbonate. The temperature is 150°C, and the pressure is 10Kg / cm 2 of a pass-through ironer transfer. Then it was put into a steaming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com