Tubular radiation absorbing device for a solar power plant with reduced heat losses

a solar power plant and tube technology, applied in the safety of solar heat collectors, solar heat systems, lighting and heating apparatuses, etc., can solve the problems of increased heat loss, undesirable pressure fluctuations, and reduced efficiency of tubular radiation absorption devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

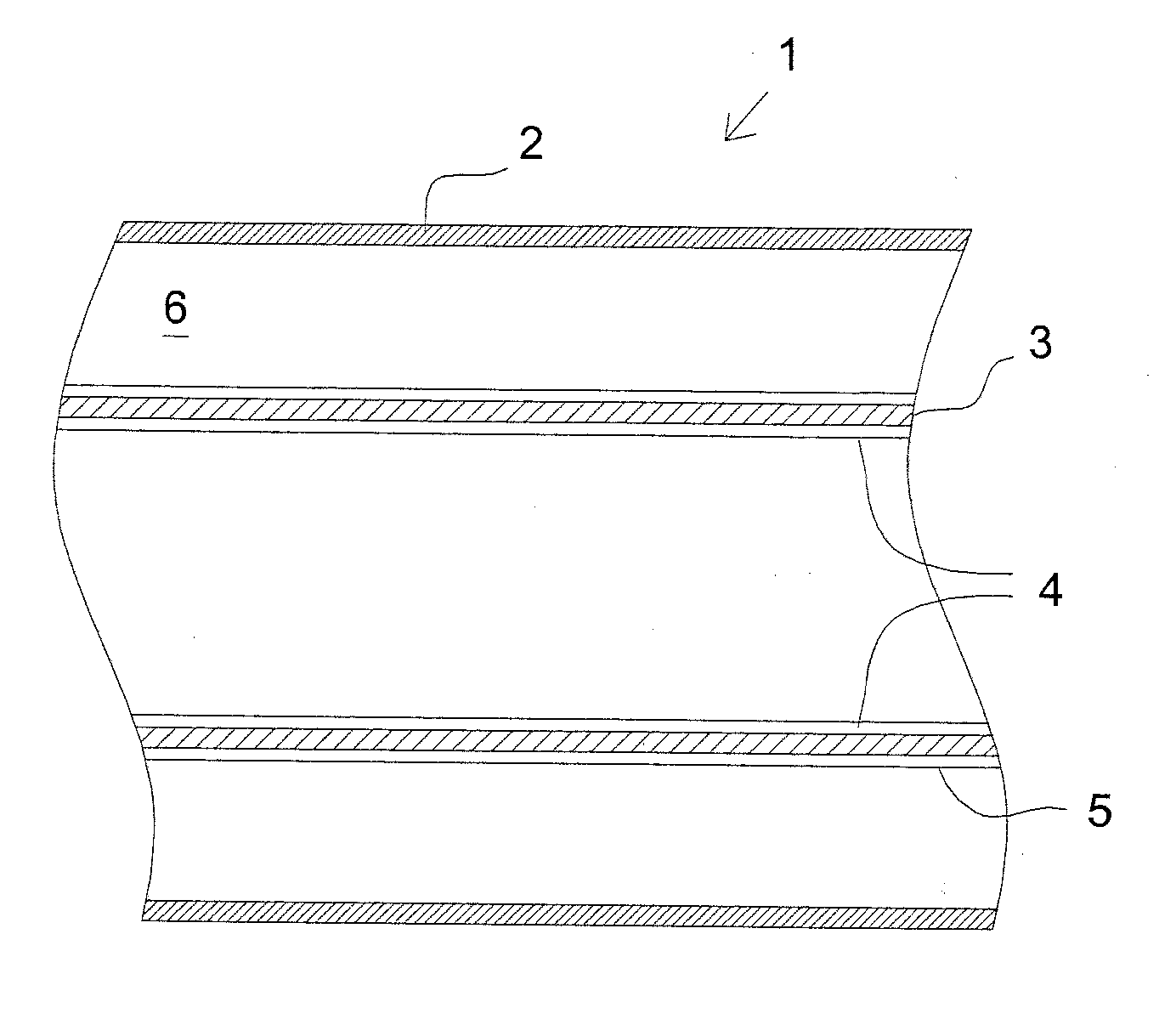

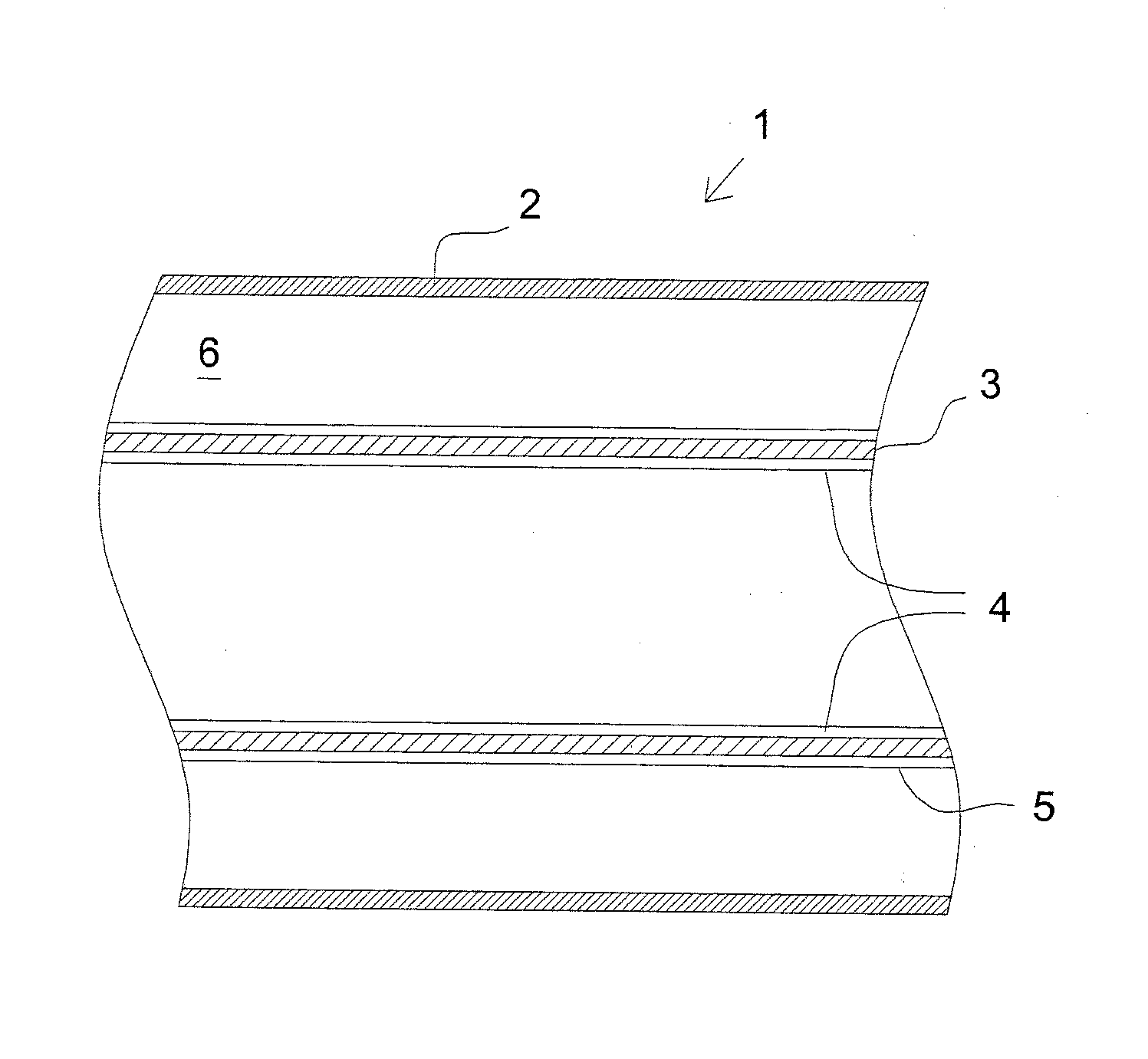

[0030] A tubular radiation absorbing device 1 for solar thermal applications is shown in the cross-sectional view in the sole FIGURE. The tubular radiation absorbing device 1 comprises a central tube 3 made of metal and, a glass tubular jacket 2 surrounding the central tube so that a ring-shaped space 6 is formed between the tubular jacket and the central tube.

[0031] A heat carrier medium, which contains free hydrogen, flows through the central tube 3, which is made of metal. The hydrogen can permeate metal and thus pass through the central tube 3 into the ring-shaped space 6. In order to prevent the free hydrogen from passing through the central tube 3, which e.g. is made from Chromium-Nickel-Molybdenum 17-12-2 Steel No. 1.4404, it is provided with a barrier coating 4 on its interior side, which contains Cr2O3.

[0032] The inner coating 4 has a thickness of e.g. 10 μm. The coating 4 comprises a first layer and a further or second layer applied to the first layer. The first layer co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com