Novel alumite suitable for rotary gold stamping on ultraviolet (UV) glazing oil paper

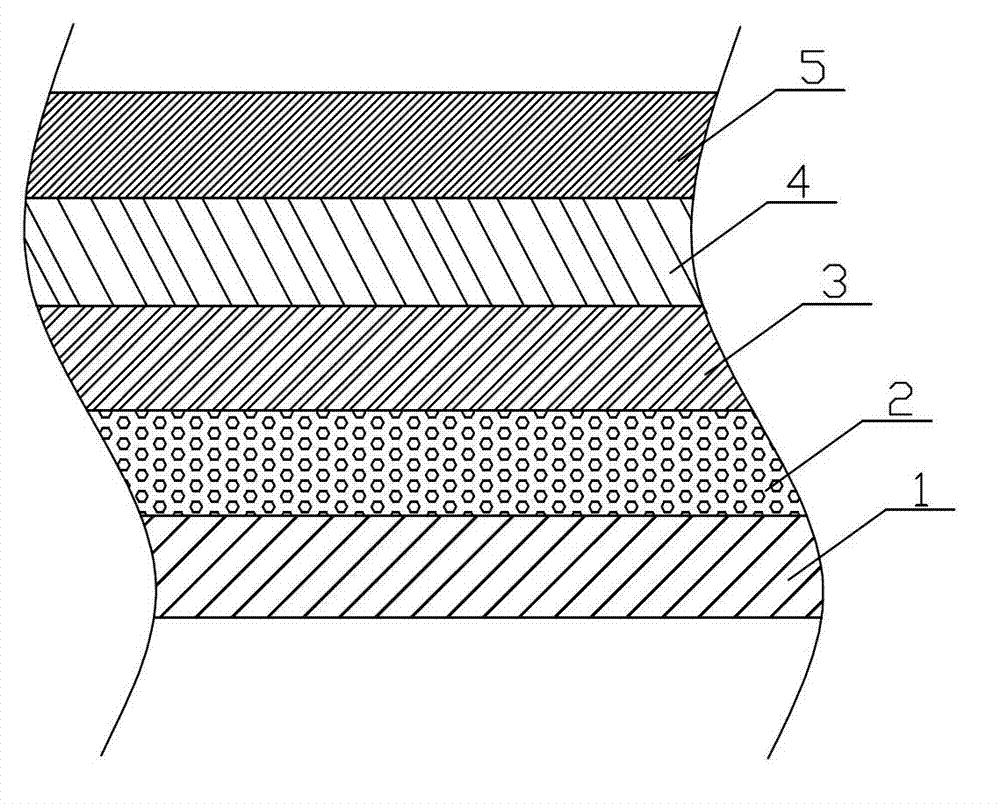

A round bronzing and anodizing aluminum technology, applied in the field of printing, can solve problems such as difficult bronzing, and achieve the effects of strong adhesion, excellent performance, and good thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] On the PET film with a thickness of 12um coated with a layer of fluoride ion modified water-based wax release agent, coat a layer of epoxy modified and acrylic resin paint with 10% metal complex dye toner according to the color requirements (environment Oxygen-modified acrylic resin accounts for 90%), and the dry coating weight is 0.7g / m 2 , where the toner content is 0.07g / m 2 , after molding and aluminum plating, apply a bonding layer according to the ratio of 10% polyurethane hot melt adhesive, 1% nano-silica, 30% toluene, 50% methyl ethyl ketone, and 9% isopropanol. Cloth weight is 0.7g / m 2 . The anodized aluminum film belt produced according to this process has been tested by the printing factory's circular pressing process, and the effective bronzing speed can be stabilized at 90m / min for continuous operation.

Embodiment 2

[0027] On the PET film with a thickness of 14um coated with a layer of fluoride ion modified water-based wax release agent, coat a layer of epoxy modified and acrylic resin coating (environment) with 12% metal complex dye toner according to the color requirements. Oxygen-modified acrylic resin accounts for 88%), and the dry coating weight is 0.7g / m 2 , where the toner content is 0.084g / m 2 , after molding and aluminizing, apply a bonding layer according to the ratio of 20% polyurethane hot melt adhesive, 2% nano-silica, 40% toluene, 30% methyl ethyl ketone, and 8% isopropanol. Cloth weight is 0.9g / m 2 . The anodized aluminum film belt produced by this process has been tested by the printing factory's circular pressing process, and the effective bronzing speed can be stabilized at 110m / min for continuous operation.

Embodiment 3

[0029] On the PET film with a thickness of 18um coated with a layer of fluoride ion modified water-based wax release agent, then coat a layer of epoxy modified acrylic resin coating (environment) with 15% metal complex dye toner according to color requirements. Oxygen-modified acrylic resin accounts for 85%), and the dry coating weight is 0.8g / m 2 , where the toner content is 0.12g / m 2 , after molding and aluminizing, apply a bonding layer according to the ratio of 14.4% polyurethane hot melt adhesive, 1.6% nano-silica, 35% toluene, 44% methyl ethyl ketone, and 5% isopropanol. The cloth weight is 0.8g / m 2 . The anodized aluminum film belt produced by this process has been tested by the printing factory's round pressing process, and the effective bronzing speed can be stabilized at 120m / min for continuous work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com