Preparation method of ultrahigh-purity quartz ceramic crucible

A technology of quartz ceramics and quartz crucibles, which is applied in the field of preparation of ultra-high-purity quartz ceramic crucibles, can solve the problems of restricting the development of polysilicon batteries, low photoelectric conversion efficiency, and the quality of silicon ingots, etc., and achieve improved yield, high strength, and energy saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

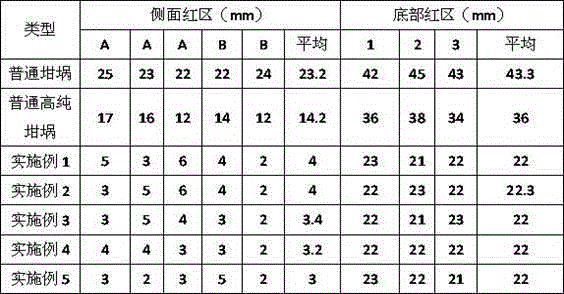

Examples

Embodiment 1

[0040] Example 1 Ultra-high purity quartz ceramic crucible 1

[0041] The preparation process is:

[0042] In step ①, choose an ordinary quartz crucible (purity less than 3N) for backup;

[0043] Step ②, select high-purity silicon powder with different particle sizes: among them, D50 is 700g of 25μm, D50 is 300g of 20μm, D50 is 1000g of 8μm, add 2000g of ultra-pure water and mix to obtain high-purity silicon powder slurry, add 4g Hydrofluoric acid with a concentration of 5wt%, soaked for 5 hours, and the high-purity silicon powder after vacuum drying is set aside;

[0044] In step ③, 1000g of high-purity silicon powder obtained in step ②, 1000g of ultrapure water, and 1000g of silica sol are uniformly mixed, and 1g of sodium polyacrylate, 1g of triethylhexyl phosphoric acid, 1g of fatty acid polyethylene glycol ester, and 1g of melon are added. Er gum, and add 1g polyoxypropylene glyceryl ether, 1g simethicone oil, fully stir for 5 hours and let stand for 10 hours to obtain ...

Embodiment 2

[0049] Example 2 Ultra-high purity quartz ceramic crucible 2

[0050] Its preparation process is:

[0051] In step ①, select an ordinary quartz crucible (purity less than 3N), rinse it with ultrapure water, and soak the rinsed crucible in a mixed solution with a concentration of 5% for 15 hours for later use; the mixed solution is NaF, hydrochloric acid , 1,4-dioxane, hydrogen peroxide mixed solution, its mass ratio is: 1:1.5:0.3:0.5.

[0052] The second step is to select high-purity silicon powder with different particle sizes, wherein the purity of high-purity silicon powder is greater than 6N, D50 is 800g of 25μm, D50 is 300g of 15μm, D50 is 900g of 8μm, and mixed with 2000g of ultrapure water to obtain High-purity silicon powder slurry, add 4g concentration and be the mixed acid of 5wt% hydrofluoric acid, hydrochloric acid, nitric acid, its mass ratio is: 1:2:2, soak 10 hours, the high-purity silicon powder after the vacuum drying waits use;

[0053] In step ③, 1000g of...

Embodiment 3

[0058] Example 3 Ultra-high purity quartz ceramic crucible 3

[0059] Its preparation process is:

[0060] In step ①, select an ordinary quartz crucible (purity less than 3N), rinse it with ultrapure water, and soak the rinsed crucible in a mixed solution with a concentration of 10% for 10 hours, and set aside; the mixed solution is NaF, hydrochloric acid , 1,4-dioxane, hydrogen peroxide mixed solution, its mass ratio is: 1:1:0.3:0.5.

[0061] In step ②, ethyl acetate, molybdenum disulfide, lanthanum oxide, carbon black, γ-(2,3-propylene oxide) propyl trimethoxysilane, diphenyl ether formaldehyde resin, sodium hydroxymethyl cellulose Mix with a certain mass ratio of 0.5:0.1:0.2:0.1:0.5:0.2:0.2, add 0.5 times the amount of ultrapure water to the mixture, stir evenly for 3 hours to form a mixture, and spray the mixture evenly through the spray equipment on the first ① The thickness of the inner surface of the crucible obtained in the first step is controlled at 0.2mm;

[0062...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com