Composite anti stinging face fabric in flexible light weight, and fabricating method

A fabric and lightweight technology, applied in the field of flexible lightweight composite stab-resistant fabric and its manufacturing, can solve the problems of high price, low weaving density, and insufficient strength to be fully utilized, so as to achieve a softness and elasticity, and reduce blunt trauma. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

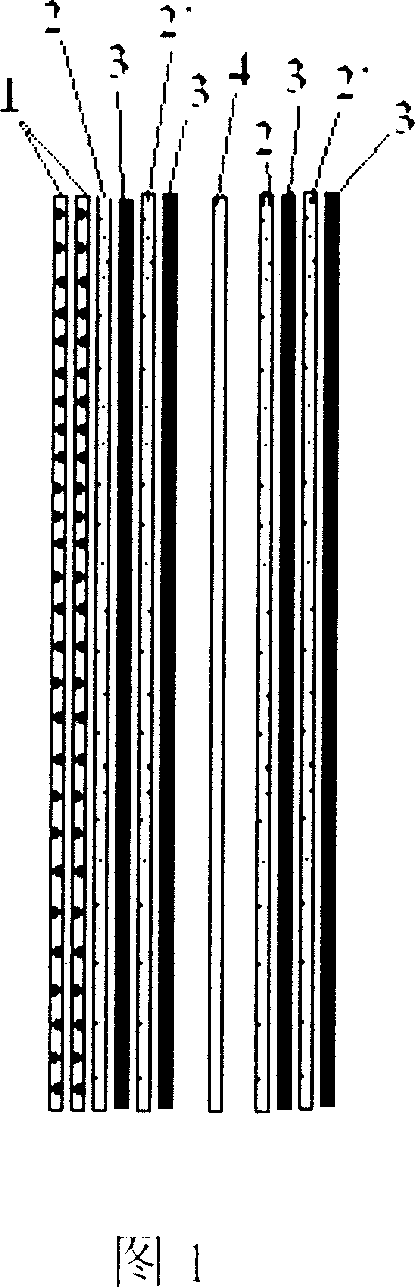

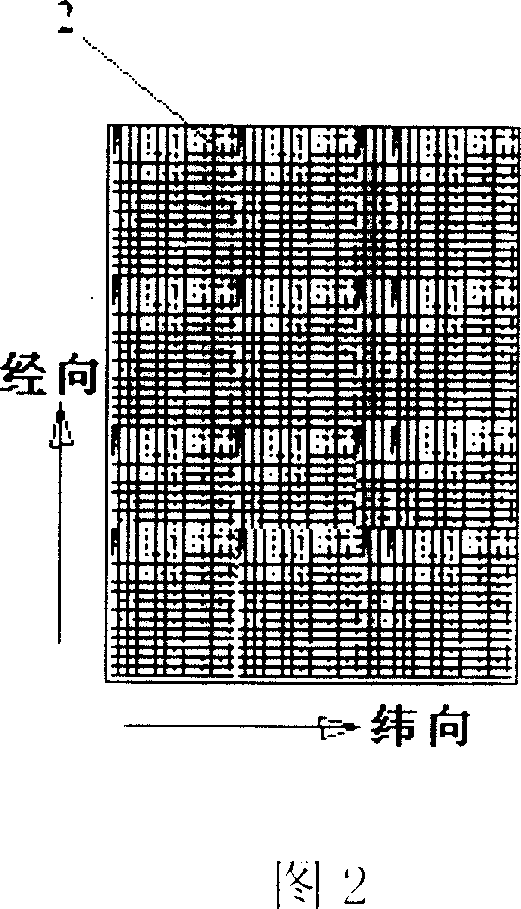

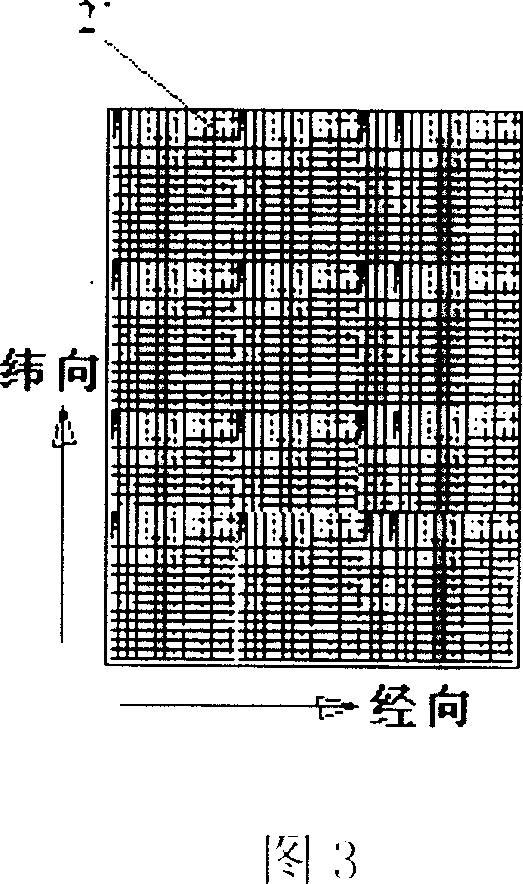

[0021] Referring to accompanying drawings 1 to 3, the stab-resistant fabric includes 4 parts, using ultra-high molecular weight polyethylene yarn as raw material, and from outside to inside are 1 layer of coated woven fabric 1, 3 layers of woven fabric 2 and 2 layers of woven fabric 2 'cross-laminated with 5 layers of non-woven fabric 3, 1 layer of non-woven fabric 4, 2 layers of woven fabric 2 and 3 layers of woven fabric 2' and 5 layers of non-woven fabric 3 cross-laminated. All of the sections described stack freely within and between sections. The square meter weight of the stab-resistant fabric is 4.1kg / m 2 , the thickness is 14.7mm. According to the measurement, the anti-stab performance meets the standard of GA68-2003 "stab-resistant clothing", and can reach the first level of NIJ0115.00 high-energy level protection level.

[0022] The manufacturing method of the stab-resistant fabric comprises the following steps: a. using ultra-high molecular weight polyethylene yar...

Embodiment 2

[0024] Referring to accompanying drawings 1 to 3, the anti-stab fabric includes 4 parts, which use various fiber aggregates of ultra-high molecular weight polyethylene as raw materials, and are 3-layer coated woven fabric 1, 2-layer woven fabric 2 and 2 from outside to inside. Layers of woven fabric 2' and 4 layers of non-woven fabric 3 are cross-laminated, 4 layers of non-woven fabric 4, 2 layers of woven fabric 2, and 2 layers of woven fabric 2' are cross-laminated with 4 layers of non-woven fabric 3. Sparse quilting in each of the partial layers. The square meter weight of the stab-proof fabric is 4.0kg / m 2 , the thickness is 13.6mm. According to the measurement, the anti-stab performance meets the standard of GA68-2003 "stab-resistant clothing", and can reach the first level of NIJ0115.00 high-energy level protection level.

[0025] The manufacturing method of described anti-stab fabric comprises the following steps: a. using ultra-high molecular weight polyethylene yarn...

Embodiment 3

[0027] Referring to accompanying drawings 1 to 3, the anti-stab fabric includes 4 parts, using various fiber aggregates of ultra-high molecular weight polyethylene as raw materials, and from the outside to the inside are 2 layers of coated woven fabric 1, 2 layers of woven fabric 2 and 2 Layers of woven fabric 2' and 4 layers of non-woven fabric 3 are cross-laminated, 4 layers of non-woven fabric 4, 2 layers of woven fabric 2, and 2 layers of woven fabric 2' are cross-laminated with 4 layers of non-woven fabric 3. Sparsely quilted interior of each section allows for free stacking of interior sections. The square meter weight of the stab-proof fabric is 4.3kg / m 2 , the thickness is 14.0mm. According to the measurement, the anti-stab performance meets the standard of GA68-2003 "stab-resistant clothing", and can reach the first level of NIJ0115.00 high-energy level protection level.

[0028] The manufacturing method of described anti-stab fabric comprises the following steps: a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com