Scaly zinc-based inorganic zinc silicate heavy anti-corrosion coating and preparation method thereof

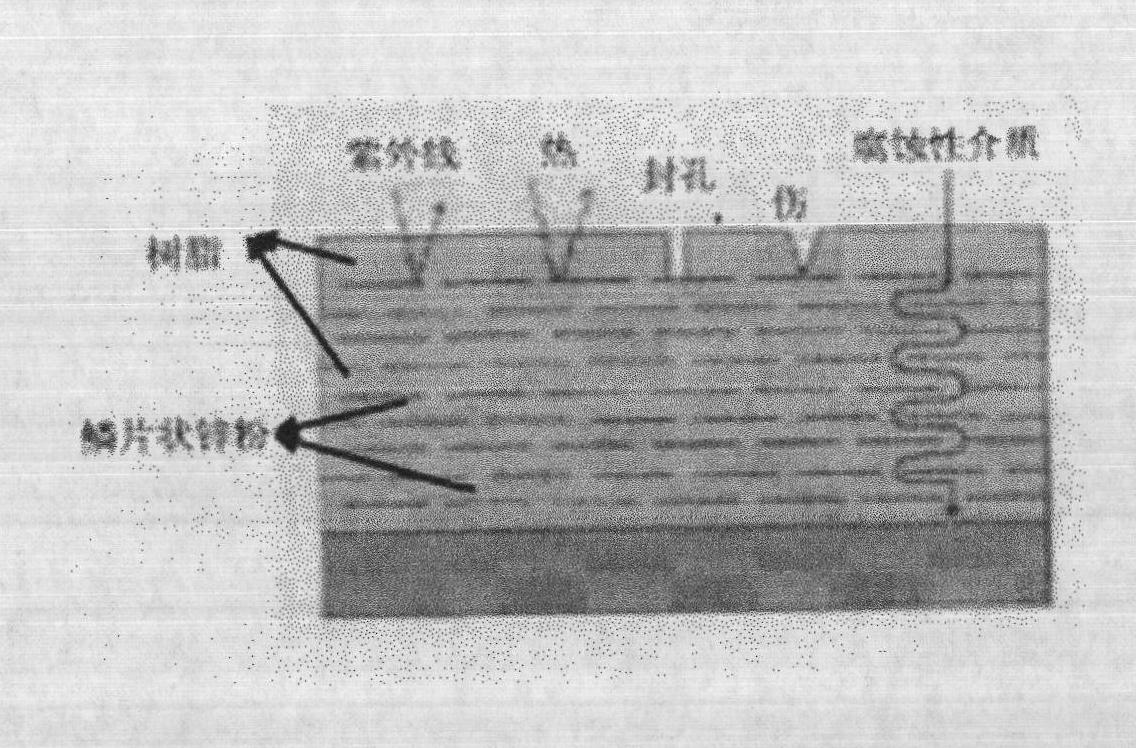

A technology of inorganic zinc silicate and flaky zinc, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of damage delamination, reduced anti-corrosion effect, easy precipitation, etc., to achieve enhanced anti-corrosion effect, Effect of reduced unevenness and large electrical contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] according to figure 1 , figure 2 Shown, a kind of scaly zinc-based inorganic zinc silicate heavy anticorrosion paint, its preparation method steps are as follows:

[0039] (1) Prepare component A for subsequent use

[0040] ①Put 12kg of absolute ethanol in a container and stir, then put in 5kg of epoxy resin E44 to dissolve it for later use;

[0041] ②Put 12kg of ethylene glycol and 6kg of xylene into a container and stir, then put 6kg of 202P (polyethylene wax) into it to disperse it for later use;

[0042] ③Mix the dissolved ① and ② in the container, then slowly add 59kg of zinc powder (flaky) to fully disperse it, and seal it tightly after dispersing;

[0043] (2) Prepare component B for subsequent use

[0044] Put 60kg tetraethyl orthosilicate, 2.5kg methyltriethoxysilane, 2.5kg r(2,3-epoxypropoxy)propyltrimethoxysilane, 10kg isopropanol, 20kg absolute ethanol into the reaction Stir in the kettle, heat up to 60°C, slowly add 5kg (about) acidified water (zinc c...

Embodiment 2

[0048] (1) Prepare component A for subsequent use

[0049] ①Put 16kg of absolute ethanol into the container and stir, then add 3kg of polyvinyl butyral to dissolve it for later use;

[0050] ②Put 16kg of 7-diol and 8kg of xylene into a container and stir, then put 4kg of 202P (polyethylene wax) into it to disperse it for later use;

[0051] ③Mix the dissolved ① and ② in the container, then slowly add 53kg of zinc powder (flaky) to fully disperse it, and seal it tightly after dispersing;

[0052] (2) Prepare component B for subsequent use

[0053] Put 50kg of tetraethyl orthosilicate, 3kg of r(2,3-glycidoxy)propyltrimethoxysilane, 12kg of isopropanol, and 25kg of absolute ethanol into the reaction kettle and stir, raise the temperature to 60°C, and slowly Add 10kg (approximately) acidified water (zinc chloride 0.5kg, hydrochloric acid 0.3kg, deionized water 9.2kg) dropwise, and react at 60-68°C for 1 hour after the dropwise addition; it can be used after cooling down and seal...

Embodiment 3

[0056] (1) Prepare component A for subsequent use

[0057] ①Put 20kg of absolute ethanol into the container and stir, then put in 1.6kg of epoxy resin E44 to dissolve it for later use;

[0058] ②Put 20kg of ethylene glycol and 10kg of xylene into a container and stir, then put 2kg of 202P (polyethylene wax) into it to disperse it for later use;

[0059] ③Mix the dissolved ① and ② in the container, then add 46.4kg of zinc powder (flaky) slowly to make it fully dispersed, and seal the package after dispersion;

[0060] (2) Prepare component B for subsequent use

[0061]Put 37.8kg of ethyl orthosilicate, 2.2kg of methyltriethoxysilane, 17kg of isopropanol, and 28kg of absolute ethanol into the reaction kettle and stir, raise the temperature to 60°C, and slowly add 15kg (approx.) of acidified water dropwise (Zinc chloride 0.75kg, hydrochloric acid 0.45kg, deionized water 13.8kg), react at 60-68°C for 1 hour after the dropwise addition; cool down, seal the package and place it fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com