Integrated rotary power taking socket, wall-type extension socket wiring rail and light rail-type extension socket

An integrated, electric socket technology, applied in the direction of flexible/rotatable wire connectors, circuits, connections, etc., can solve problems such as large heat generation, large volume, and potential safety hazards in electricity use, to ensure electricity safety and electrical contact The effect of large area and ensuring the safety of electricity use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

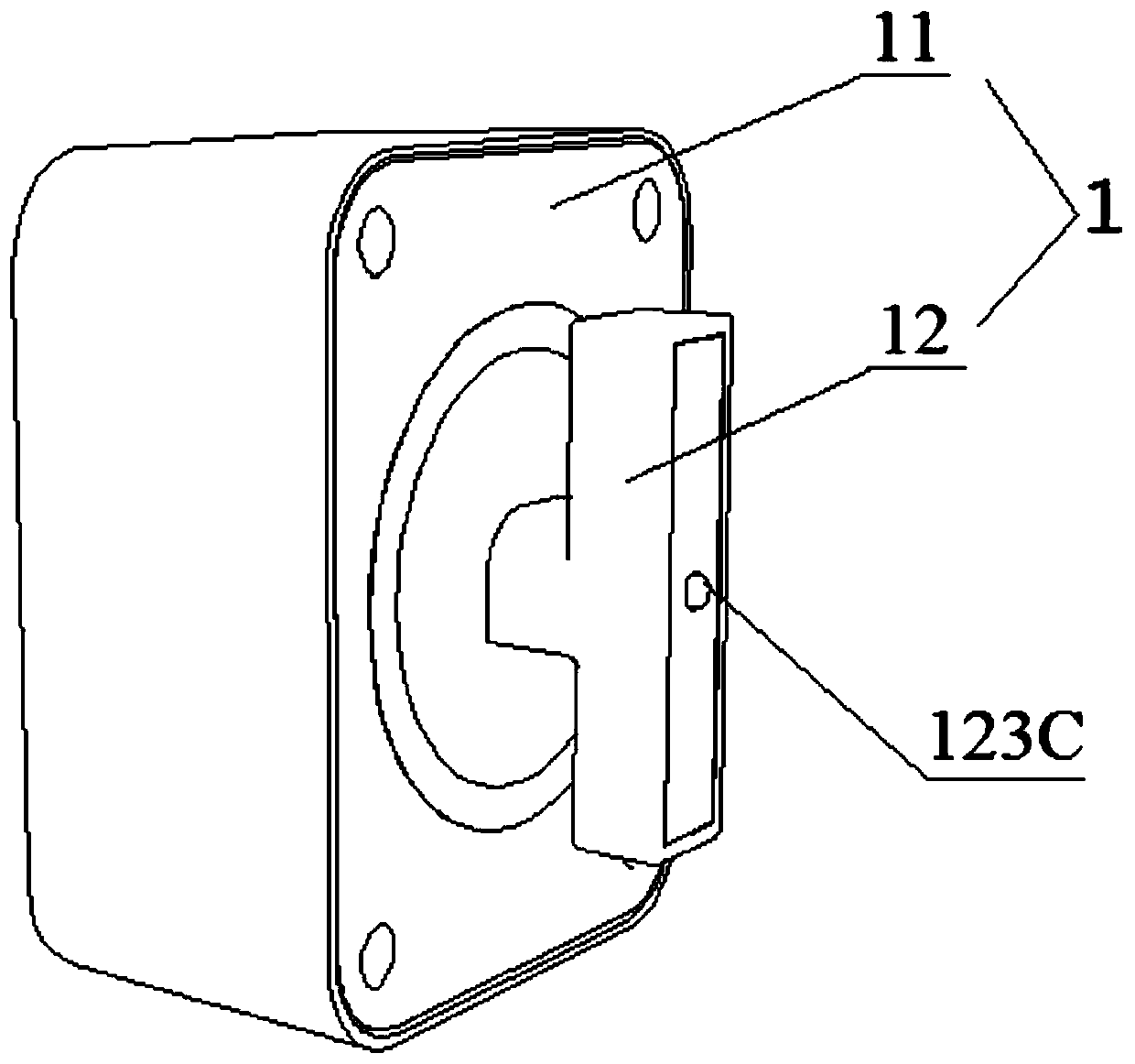

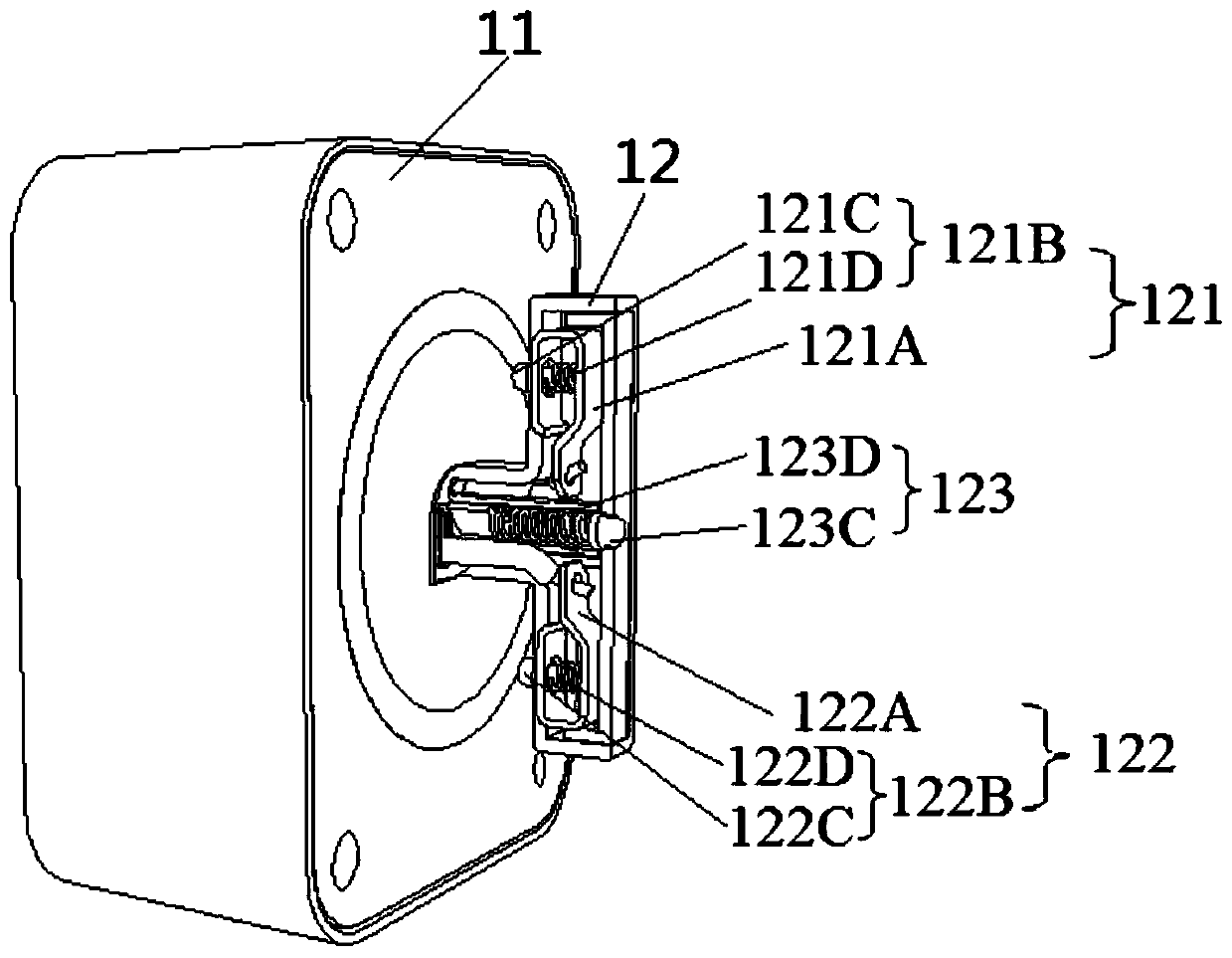

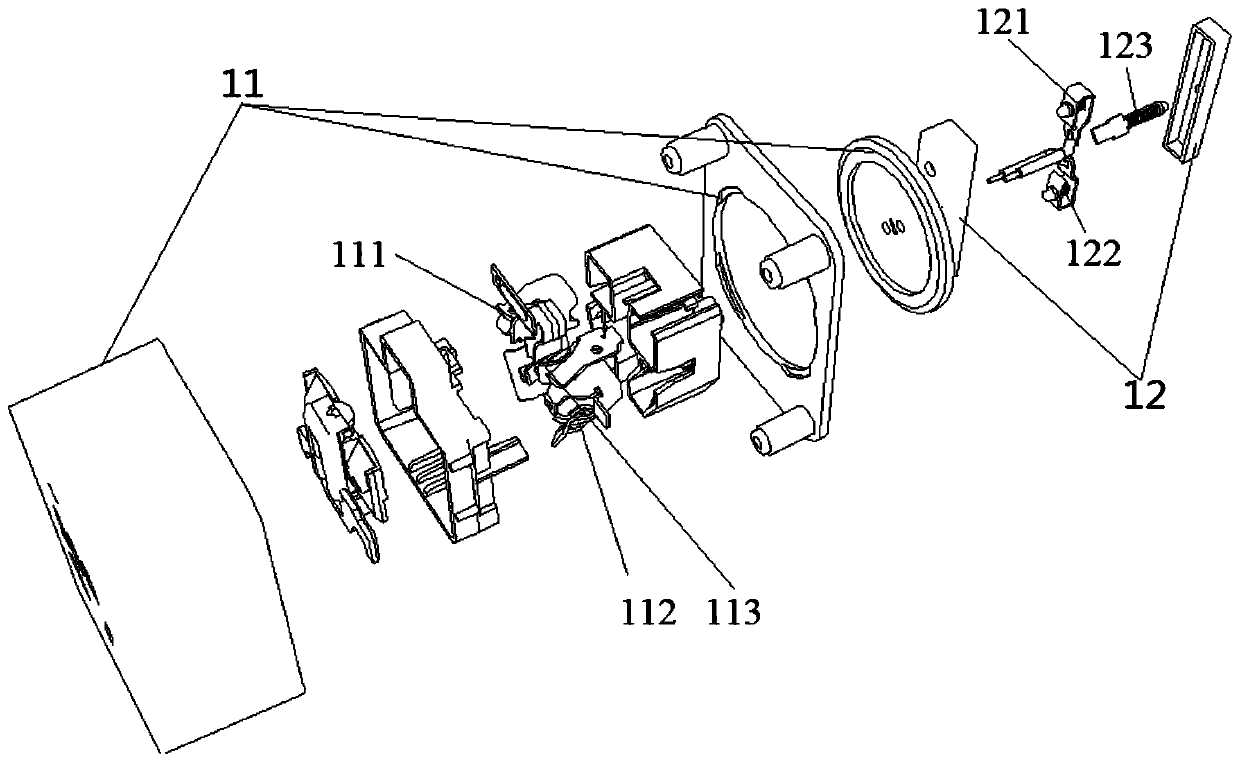

[0049] An embodiment of the present invention provides an integrated rotary power-taking socket, such as figure 1 As shown, an integrated insulating housing 1 is provided, and the integrated insulating housing 1 includes a socket housing 11 and a power-taking arm 12 drawn from the bottom of the socket housing 11 .

[0050] Such as figure 2 , image 3 As shown, the socket shell 11 is fixed with a live wire electrical plug-in assembly 111, a neutral wire electrical plug-in assembly 112 and a ground wire electrical plug-in assembly 113;

[0051] The two sides of the power-taking arm 12 are respectively provided with an elastic live-wire power-taking component 121 and an elastic neutral-wire power-taking component 122 electrically connected to the live-wire electrical plug-in component 111 and the neutral-line electrical plug-in component 112, and the middle part is provided with An elastic ground wire connection component 123 electrically connected to the ground wire electrica...

Embodiment 2

[0075] An embodiment of the present invention provides a wall-type plug-in wiring track, such as Figure 5 As shown, it includes an integrated strip-shaped insulating base frame 2 and a first electrical contact piece 3 and a second electrical contact piece 4 fixed on the length direction of the integrated strip-shaped insulating base frame 2;

[0076] The one-piece strip-shaped insulating base frame 2 includes a bottom plane 21, an upper side wall 22, a lower side wall 23, and a wall drawn from the top of the upper side wall 22 and the lower side wall 23 parallel to the bottom plane 21. The first spacer 24 and the second spacer 25;

[0077] The first electric contact piece 21 and the second electric contact piece 22 are installed on the first limit frame 24 and the second limit frame 25 respectively, and the first electric contact piece 3 and the second electric contact piece 4 The end faces of the two faces directly to the bottom plane 21 but have different heights from the ...

Embodiment 3

[0083] The embodiment of the present invention provides a light-duty track-type power strip, which is composed of the integrated rotary power-taking socket described in Embodiment 1 and a wall-type power strip wiring rail described in Embodiment 2;

[0084] Insert the power-taking arm 12 from the gap between the upper side wall 22 and the lower side wall 23 at the first moment, as Image 6 shown;

[0085] At the next moment, press down and rotate the socket shell 11 clockwise or counterclockwise, so that both sides of the power-taking arm 12 are inserted under the first electrical contact piece 3 and the second electrical contact piece 4, and the elastic The live wire power-taking terminal 121C of the live wire power-taking component 121 and the neutral-wire power-taking terminal 122C of the elastic zero-wire power-taking component 122 are electrically connected to the first electric contact 3 and the second electric contact 4, and the elastic The ground connection assembly 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com