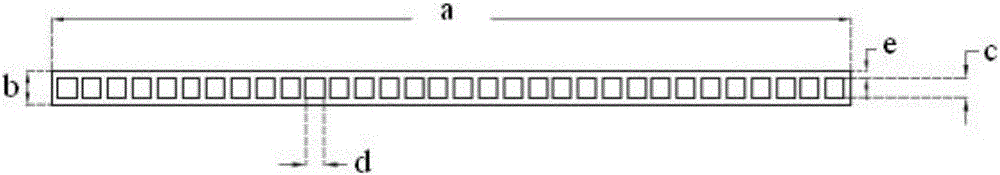

Preparation method of high-purity alumina plate ceramic membrane support

A technology of ceramic membrane support and high-purity alumina, which is applied in the field of ceramics, can solve the problems of inability to be used stably for a long time, low alumina content, and low surface finish, and achieve uniform size, good effect, and high surface finish.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

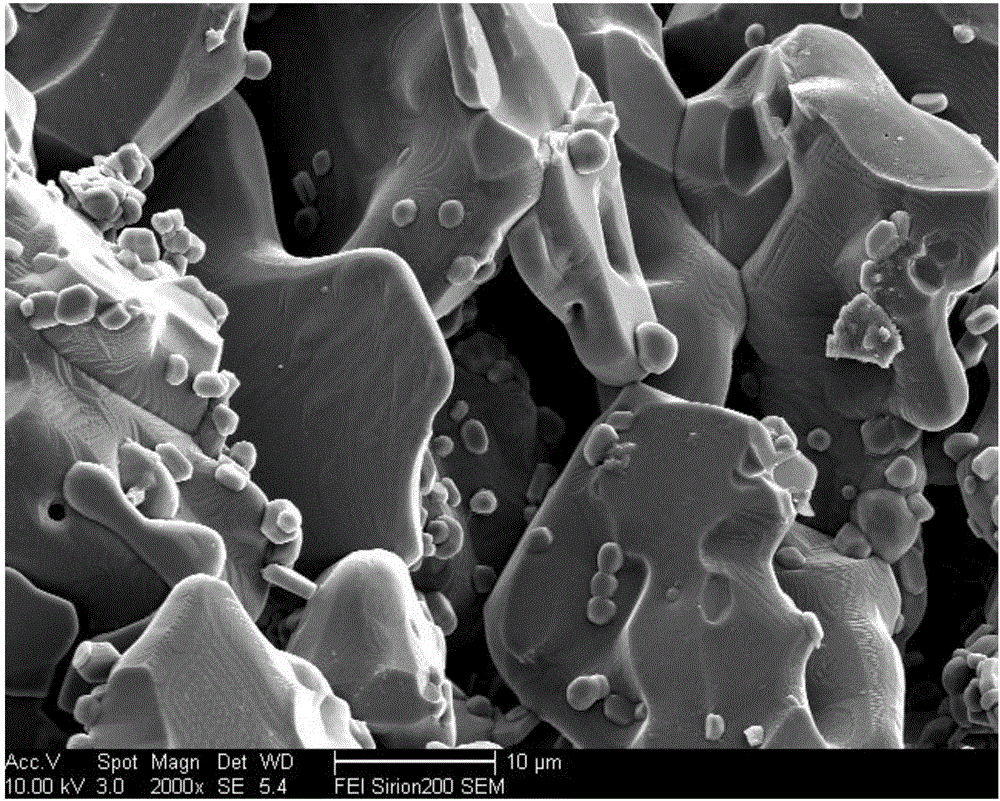

Embodiment 1

[0034] 1) Put 160g of zirconium nitrate into 6.6L of deionized water, heat and stir, slowly add 10g of oxalic acid at 90°C, stop heating after 36 hours at constant temperature, keep stirring and cool to room temperature, and set aside;

[0035] 2) Add alumina a, whose D50 is: 20 μm-35 μm; alumina b, whose D50 is: 2 μm-5 μm; lanthanum oxide, yttrium oxide and other inorganic powders in proportion 27500g:4510g:110g:49.5g into the kneader Mix for 1 hour;

[0036] 3) Add the mixed solution obtained in step 1) to the mixture obtained in step 2), and mix thoroughly for 30 minutes;

[0037] 4) Accurately weigh dextrin, PVA, glycerin, tung oil and other organic additives according to the ratio of 2090g:2145g:770g:495g, mix thoroughly, and slowly and evenly add the mixed Good organic additives, mix for 30 minutes;

[0038] 5) Move the kneaded mud into the vacuum mud refining machine, first mix and knead 5 times under the air condition of normal pressure, and then knead the mud 5 time...

Embodiment 2

[0041] 1) Put 130g of zirconium nitrate into 6L of deionized water, heat and stir, slowly add 10g of oxalic acid at 90°C, stop heating after 36 hours at constant temperature, keep stirring and cool to room temperature, and set aside;

[0042] 2) Put alumina a, whose D50 is: 20 μm-35 μm; alumina b, whose D50 is: 2 μm-5 μm, lanthanum oxide, yttrium oxide and other inorganic powders in proportion 25000g:4100g:100g:45g into the kneader and mix 1 hour;

[0043] 3) Add the mixed solution obtained in step 1) to the mixture obtained in step 2), and mix thoroughly for 1 hour;

[0044] 4) Accurately weigh dextrin, PVA, glycerin, tung oil and other organic additives according to the ratio of 1900g:1950g:700g:450g, mix thoroughly, and slowly and evenly add the mixed inorganic powder in the kneader Good organic additives, mix for 30 minutes;

[0045] 5) Move the kneaded mud into the vacuum mud refining machine, first mix and knead 5 times under the air condition of normal air pressure, a...

Embodiment 3

[0048] 1) Put 100g of zirconium nitrate into 5.4L of deionized water, heat and stir, slowly add 10g of oxalic acid at 90°C, stop heating after 36 hours at constant temperature, keep stirring and cool to room temperature, and set aside;

[0049] 2) Add alumina a, whose D50 is: 20 μm-35 μm; alumina b, whose D50 is: 2 μm-5 μm; lanthanum oxide; Mix in the machine for 1 hour;

[0050] 3) Add the mixed solution obtained in step 1) to the mixture obtained in step 2), and mix thoroughly for 30 minutes;

[0051] 4) Accurately weigh dextrin, PVA, glycerin, tung oil and other organic additives according to the ratio of 1710g:1755g:630g:405g, mix thoroughly, and slowly and evenly add the mixed Good organic additives, mix for 30 minutes;

[0052] 5) Move the kneaded mud into the vacuum mud refining machine, first mix and knead 5 times under the air condition of normal pressure, and then knead the mud 5 times under the vacuum of 0.10MPa, then put it into the extruder, and pass the special...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com