Static pressure heavy-load direct-drive high-accuracy rotating table

A rotary table, high-precision technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of reducing the dynamic response characteristics of the turntable, unable to meet large-sized workpieces, and large start-up damping, etc., to meet long-term Workpiece processing needs, fast dynamic response characteristics, and reliable work effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

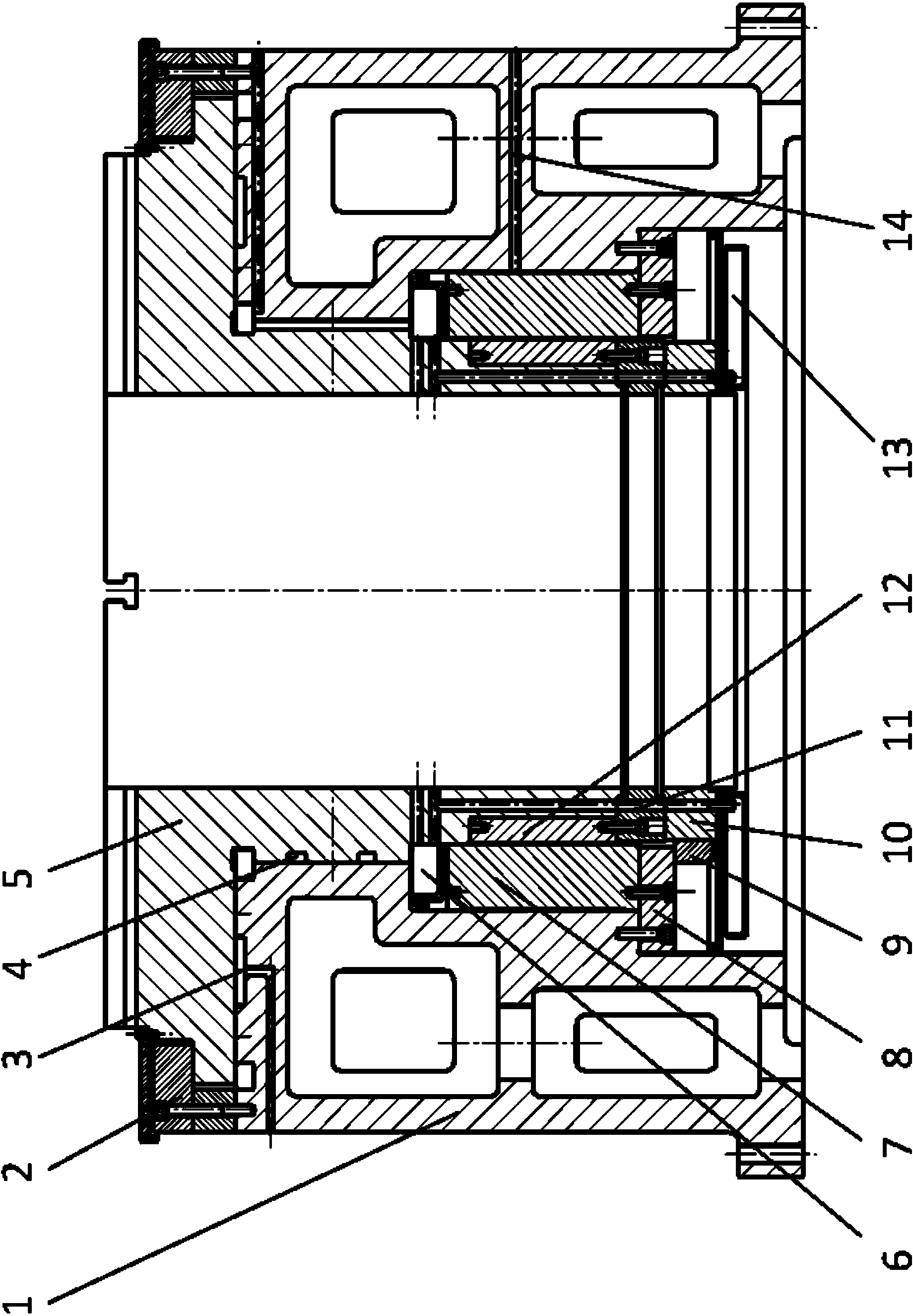

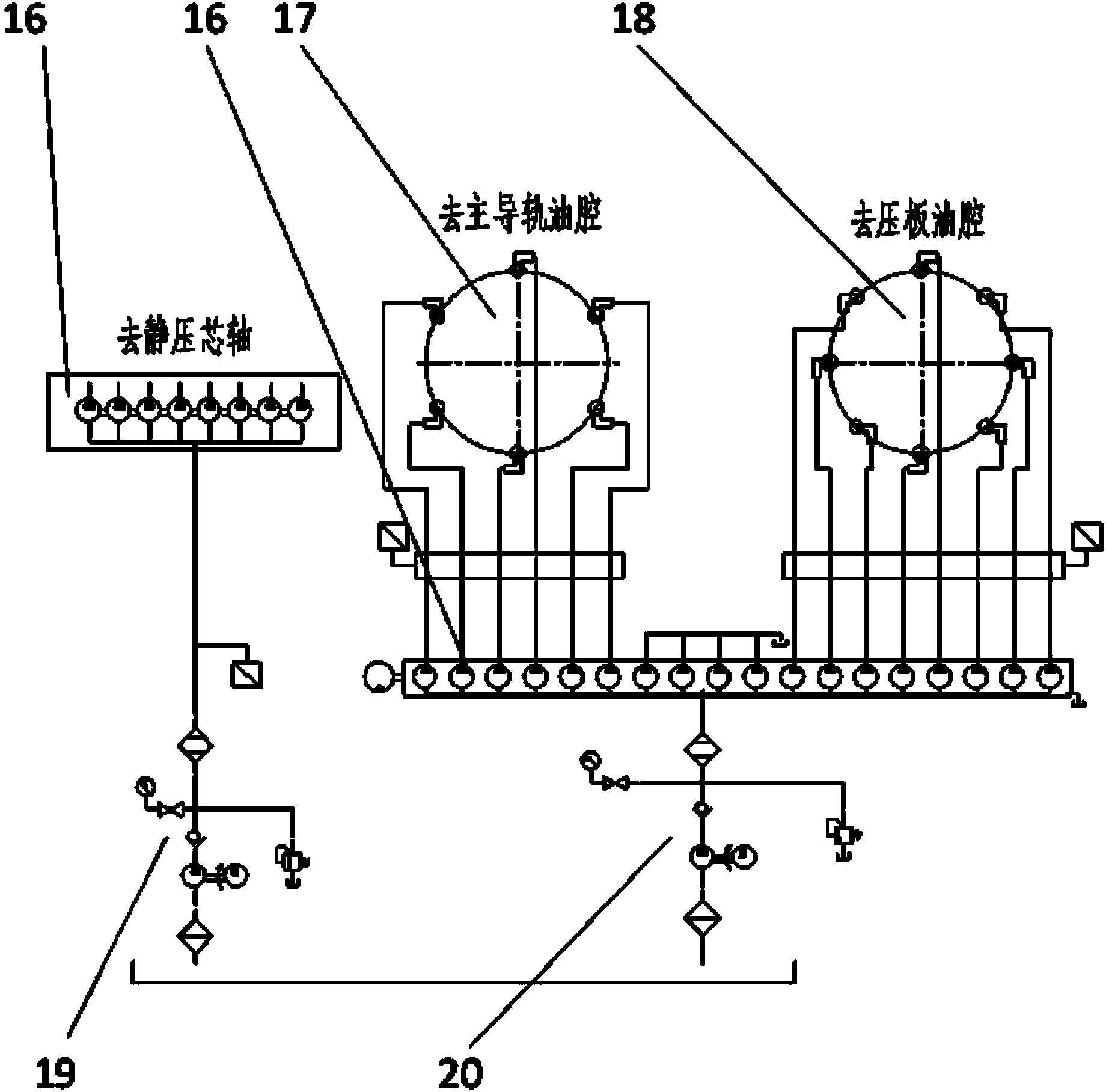

[0031] Such as figure 1 , figure 2, a static pressure heavy-duty direct-drive high-precision rotary table, including a turntable consisting of a base 1, a pressure plate 2, a main rail static pressure oil chamber 3, a static pressure mandrel oil chamber 4, a working table 5, and a static pressure oil return system 6 , torque motor stator 7, stator fixed support 8, reading head 9, steel belt grating and mounting support 10, rotor mounting support 11, torque motor rotor 12, oil collection basin 13, water cooling system 14, gear distributor 15. Multi-head pump 16, main rail oil chamber 17, pressure plate oil chamber 18, mandrel pump station system 19, guide rail pump station system 20, oil supply system and oil return system; the base 1 turntable base and the working table 5 work The radial bearing between the table tops is equipped with evenly distributed rectangular hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com