Toilet water tank valve and design method

A valve and water tank technology, used in flushing equipment with water tanks, water supply devices, buildings, etc., can solve the problems of complex valve structure, and achieve the effect of flexible installation position, high flushing pressure, and small flushing pressure loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

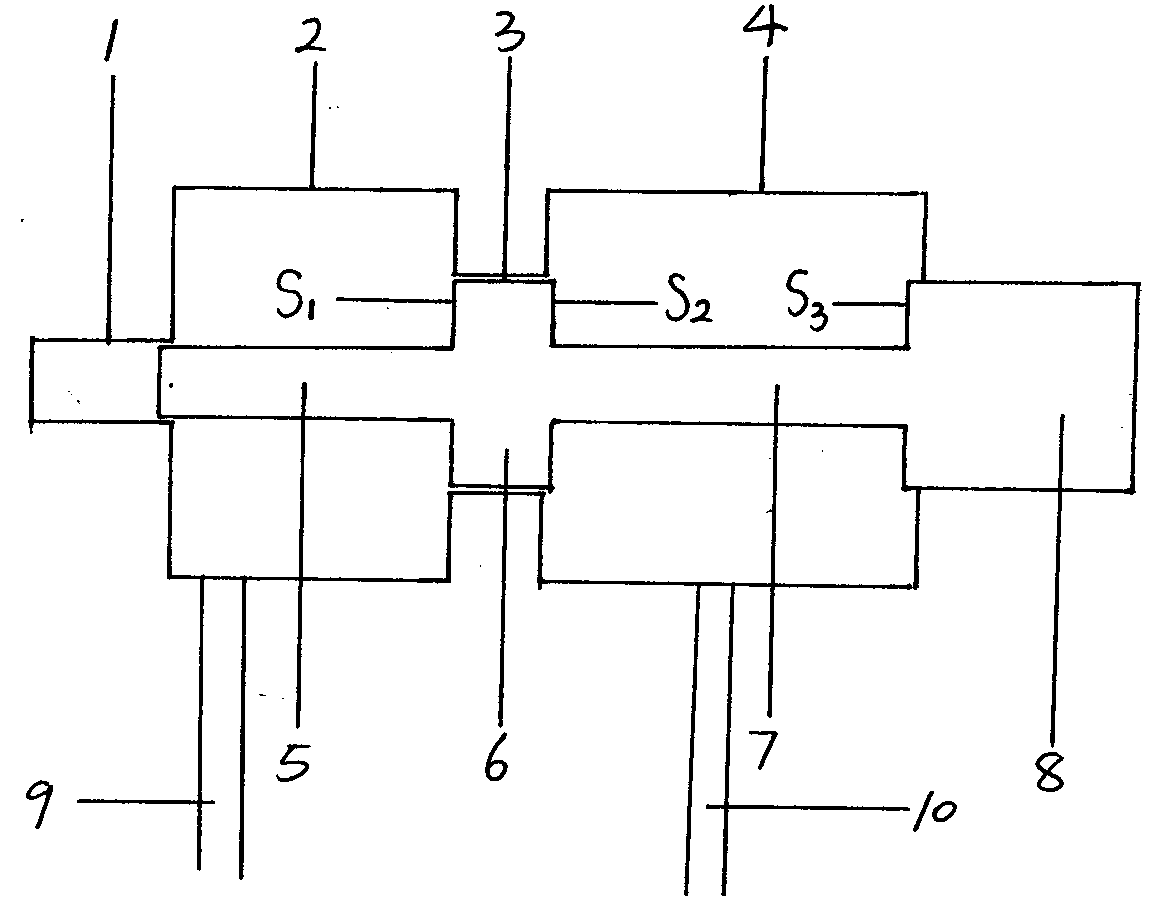

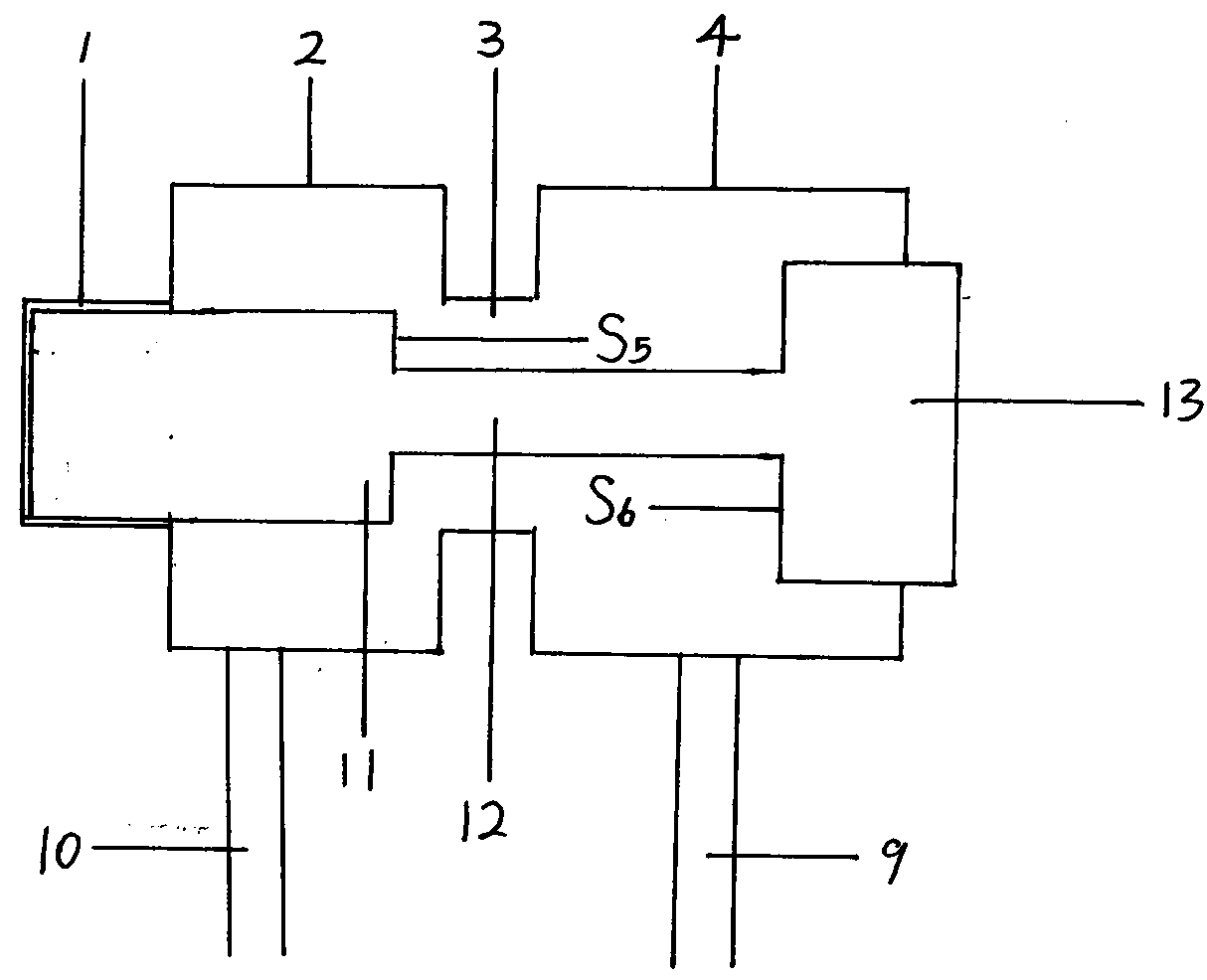

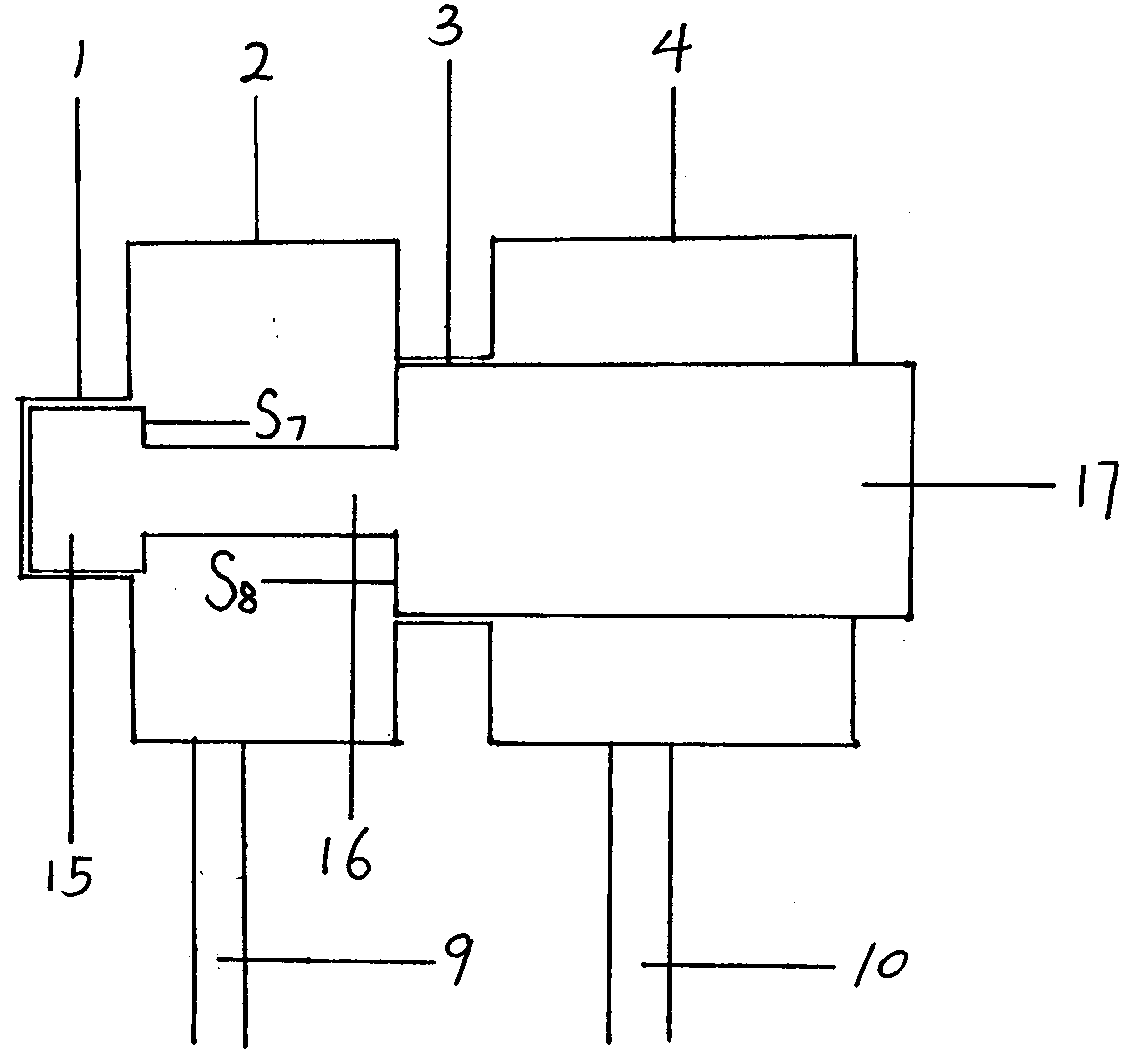

[0030] There are two types of normally closed valves, the first structure is:

[0031] The normally closed valve includes a valve cavity, a valve plug, an inlet and outlet pipe, a shaft hole, a tail shaft, and a through hole. The valve cavity has a first through hole 3, and the first through hole divides the cavity into a front cavity 4 and a first through hole. The rear cavity 2 has a first shaft hole 1, and the valve plug is composed of four parts from front to back: the first front part 8, the first middle part 7, the first sealing part 6, the first Valve plug tail shaft 5, the first front part is sealed through the front cavity, the first middle part and the first sealing part are located in the cavity, the first middle part is thinner than the first sealing part and the first front part, and the first middle part is thinner than the first sealing part and the first front part. When the first sealing part is located in the first through hole, it forms a sealed water-blocki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com