A sheet glass carrying rack

A technology for flat glass and handling racks, applied in the field of stacking racks, which can solve the problems of high labor intensity, tediousness, glass collision damage, etc., and achieve the effects of saving manpower and material resources, improving safety factor, and moving glass smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

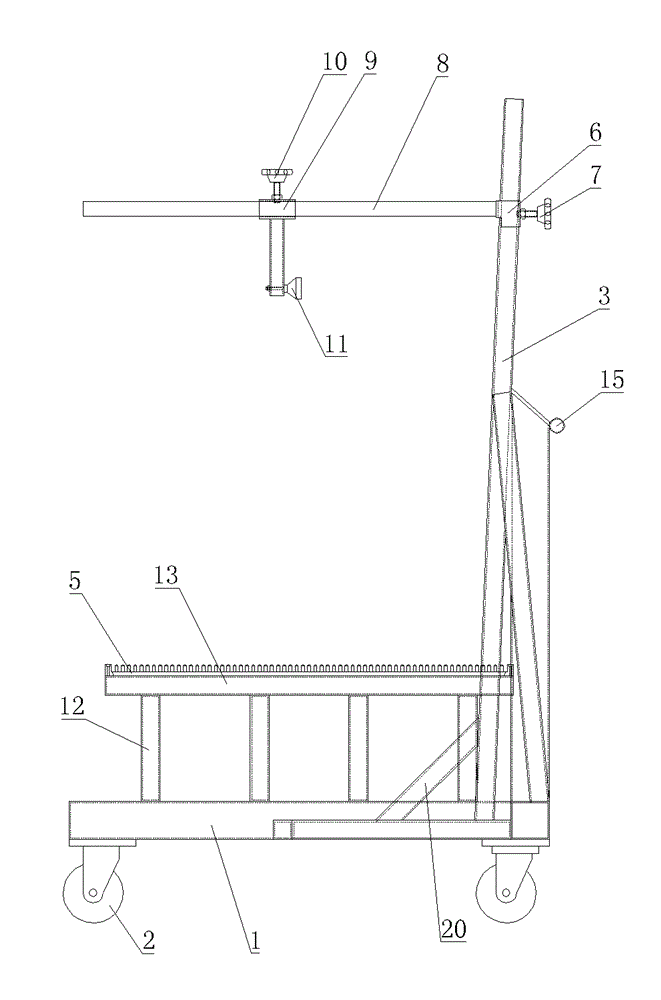

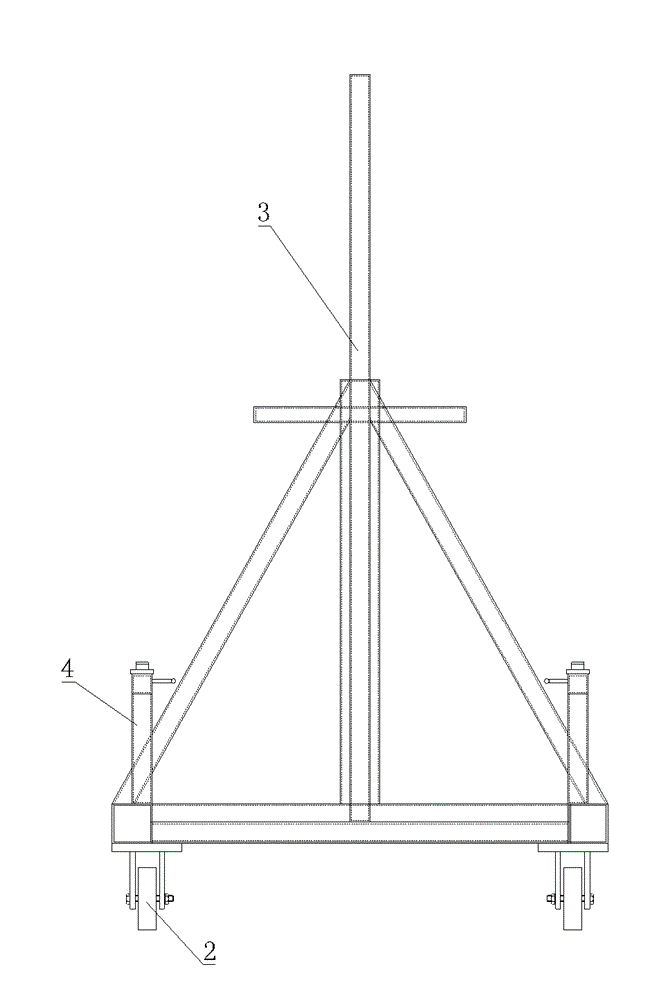

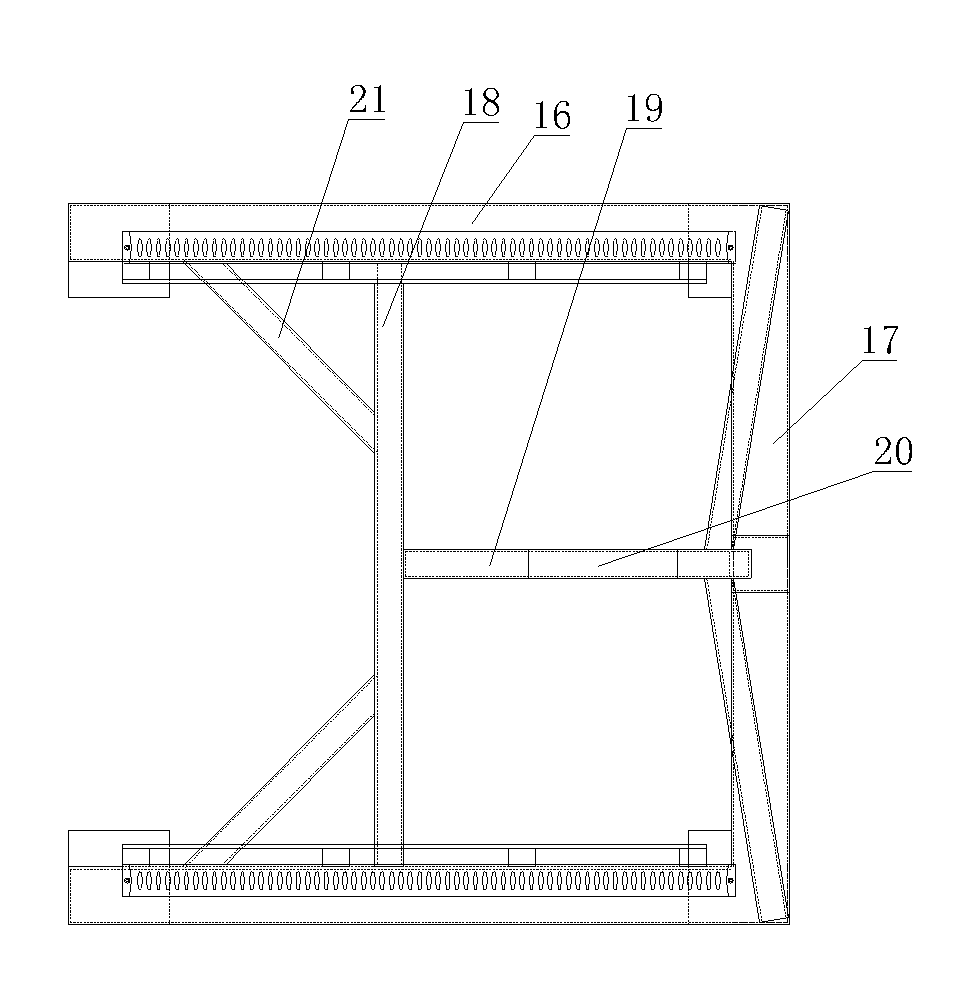

[0013] Such as figure 1 , figure 2 , image 3 As shown, the underframe 1 is included, the lower end of the underframe 1 is provided with a roller device 2, the center of the rear end of the underframe 1 is fastened with a rear upright bar 3 inclined backward, and the two sides of the underframe 1 are respectively provided with The side frame 4, the side frame 4 is provided with a rubber rack 5, the rear pole 3 is provided with a slider 6 that can slide along the rear pole 3, the rear end of the slider 6 is provided with a positioning screw hole, and the positioning bolt 7 passes through it. The slider 6 is locked on the rear pole 3 through the positioning screw hole, and the front end of the slider 5 is fastened with an upper pressing rod 8 parallel to the bottom frame 1. The compression slider 9 that the rod 8 slides, the upper end of the compression slider 9 is provided with an adjustment screw hole, and the adjustment bolt 10 passes through the adjustment screw hole to l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com