Efficient stacking device for carrying goods

A stacking device and high-efficiency technology, applied in the field of stacking vehicles, can solve the problems of increasing the labor cost of the second person, understanding the state, and idle stacking vehicles, etc., so as to save equipment procurement costs, reduce physical fatigue, and improve The effect of stacking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

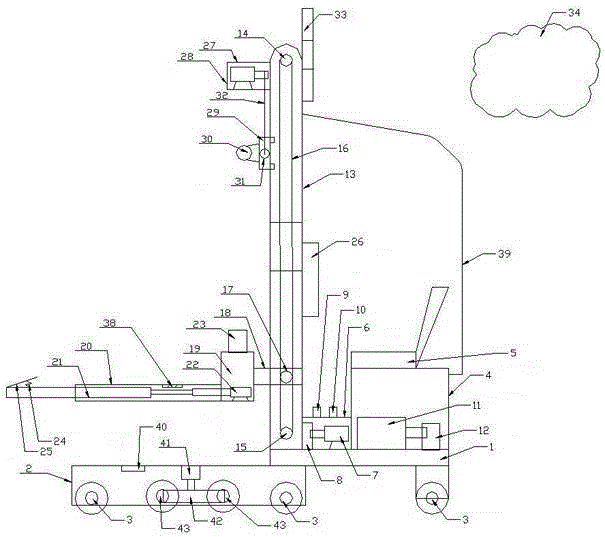

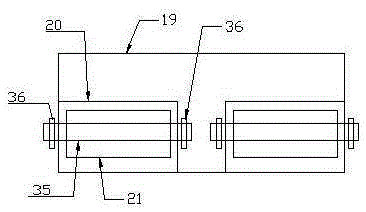

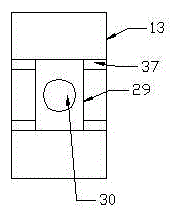

[0021] further as figure 1 As shown, in the working process, at first the second motor control pedal 10 can be used to control the third motor 11 to drive the gearbox 12 linkage drive shaft (not marked in the figure), and the movement wheel 3 controls the overall structure to move according to needs; When the location of the goods to be transported, firstly, the volume of the goods is predicted through the information fed back by the three-dimensional scanner 23 received by the monitoring module 26, and it is displayed whether the transport can be completed (that is, the support is completed); when it is displayed that it can be transported, the first First, use the second motor control pedal 10 to control the third motor 11 to drive the gearbox 12 to link the drive shaft (not shown in the figure), and the movement wheel 3 to move, so that the first fork body 20 completes the fork action, and when the goods When the volume is large, when it shows that it can be transported, on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com