Integrated drilling and dedusting mobile platform

A mobile platform, integrated technology, used in other manufacturing equipment/tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problem of sewage sludge not being treated in time, equipment and pipeline corrosion, increased pressure loss, etc. problem, to achieve the effect of excellent handling of large steel components, strong purification ability, and reduced working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

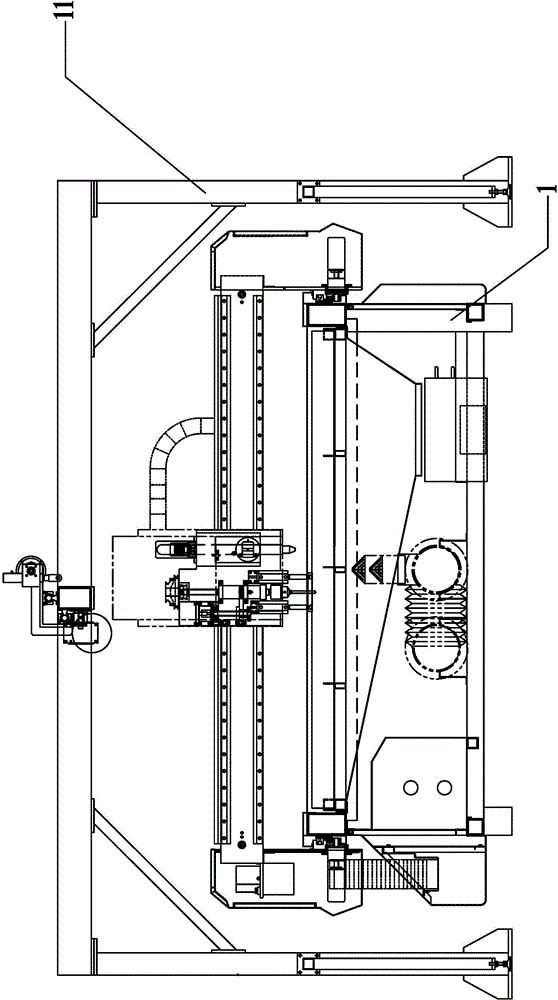

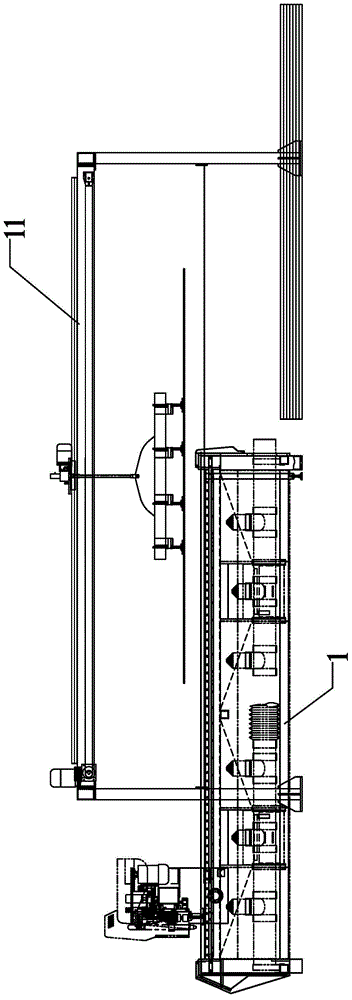

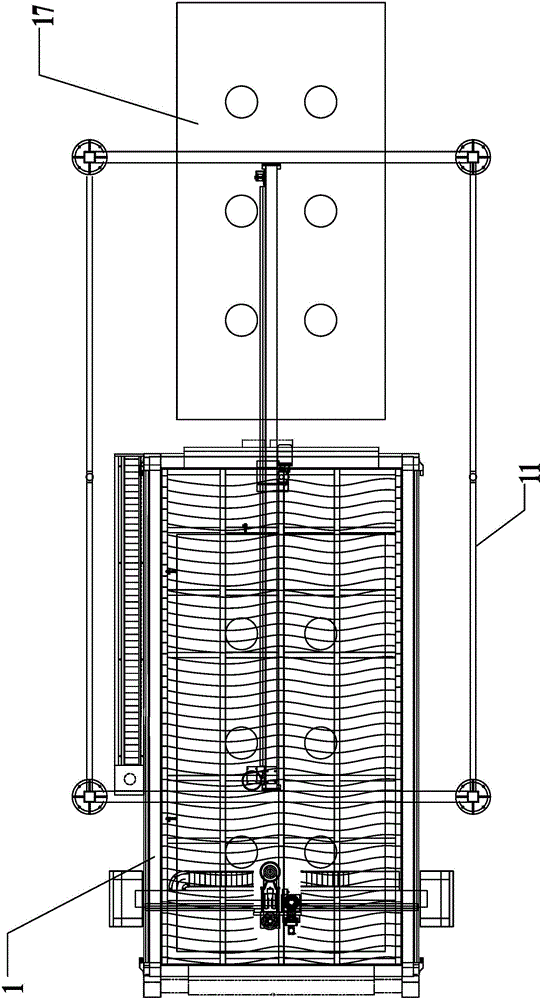

[0054] Such as Figure 1-19 Shown: an integrated drilling and dust removal mobile platform, which includes a rectangular gantry frame 11 and a processing machine tool arranged under the gantry frame 11, a fixed frame 12 is horizontally arranged in the center of the gantry frame 11, and the fixed frame 12 is fixed On the frames at both ends of the gantry frame 1 and parallel to the frames on both sides; one end of the fixed frame 12 is provided with a lifting reduction motor 13, and the side of the fixed frame 12 is provided with a synchronous belt 18 connected with the lifting reduction motor 13, fixed The frame 12 is provided with a sliding block 14 that slides back and forth. One end of the sliding block 14 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com