Packing container for roll article

An article and roll-shaped technology, which is applied to the field of packaging containers for roll-shaped articles, can solve the problems of detachment of the roll-shaped articles, damage to the product itself, and difficulty in fixing the core, so as to achieve the effect of reliable transportation and prevention of independent swinging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

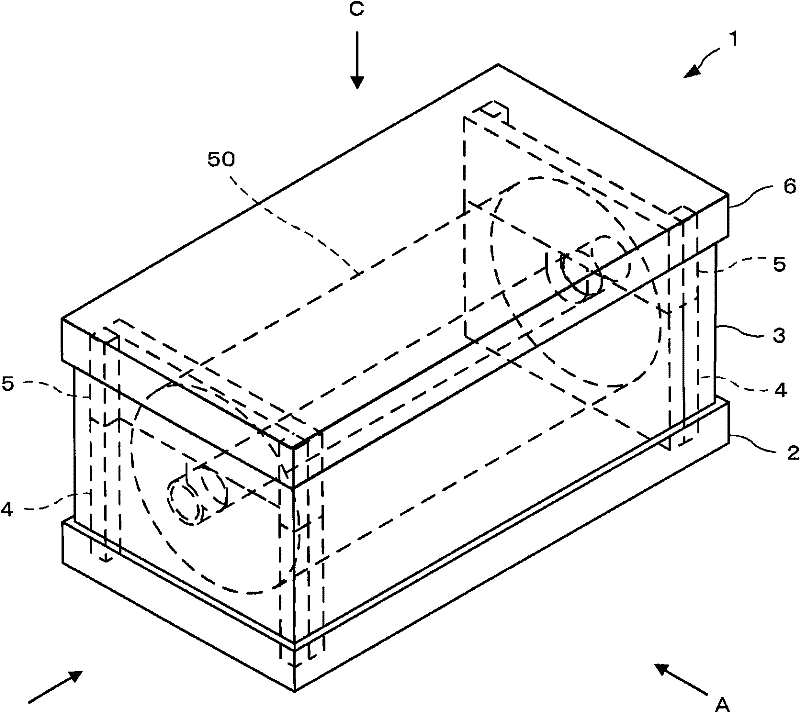

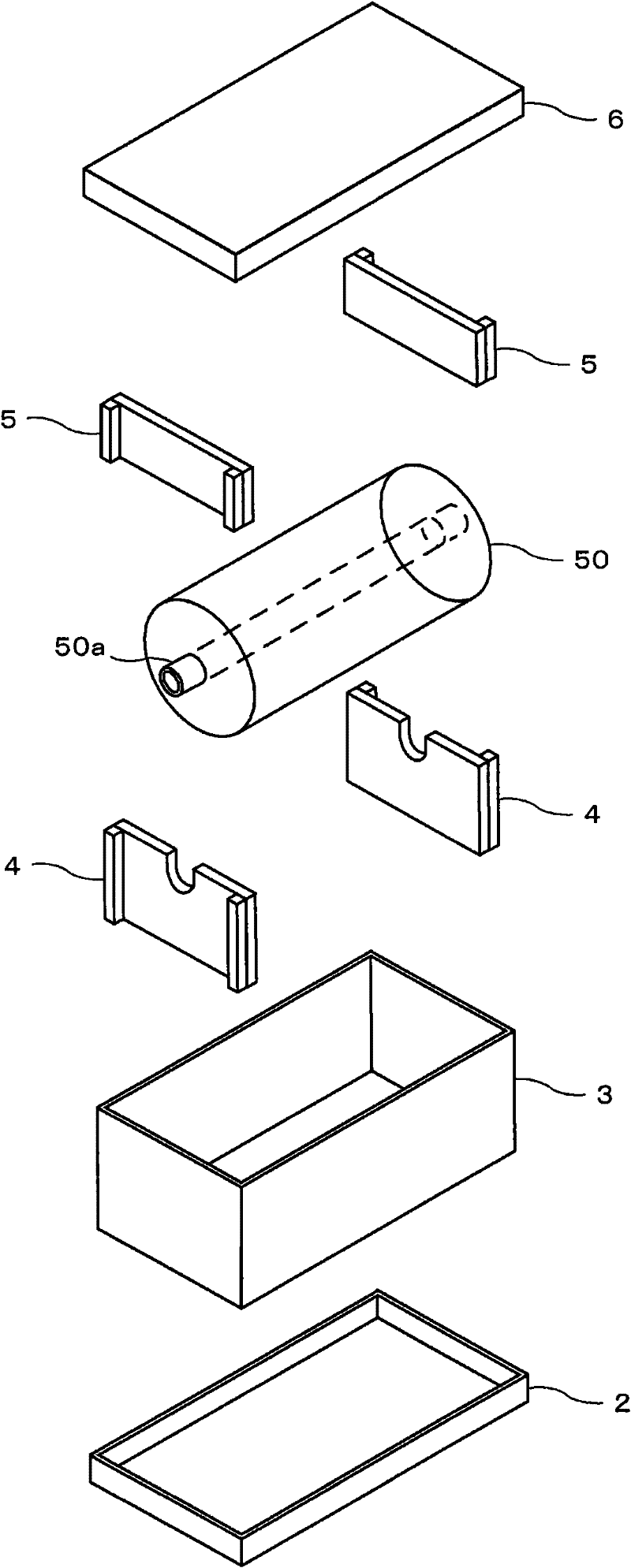

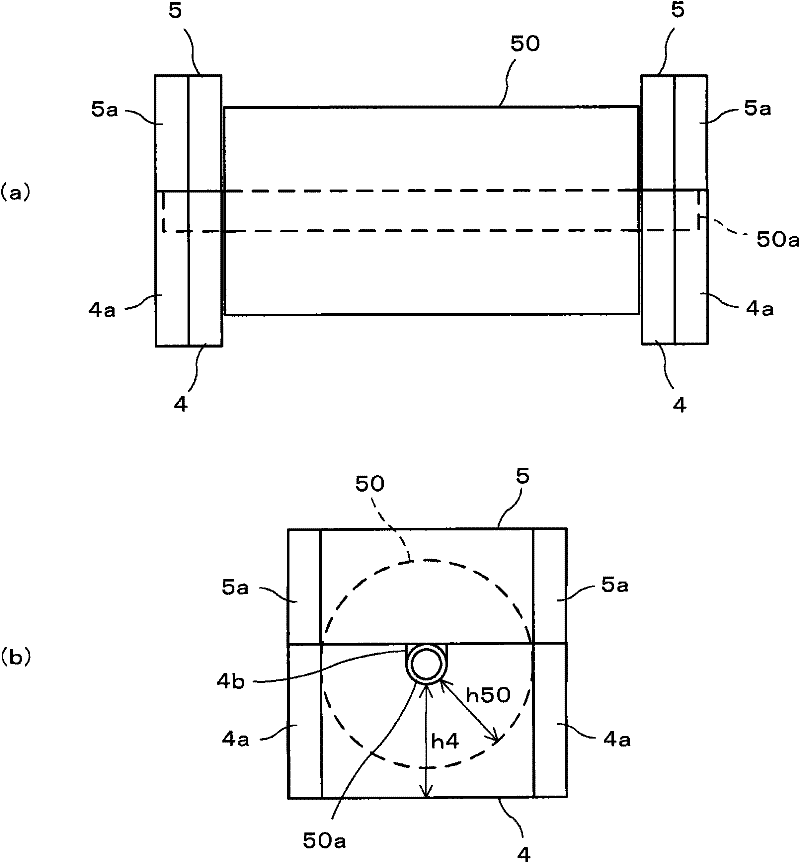

[0036] like figure 1 As shown, a packaging container 1 for roll-shaped articles according to an embodiment of the present invention is composed of a bracket 2, a side wall 3, a support member 4, a pressing member 5, and a cover 6, wherein the bracket 2 forms the bottom plate of the container body. The above-mentioned side wall 3 is loaded on the bracket 2 and forms the side surface of the container main body, and the above-mentioned support member 4 receives the roll-shaped article 50 loaded on the bracket 2 at its upper part, and supports the roll-shaped article 50 from below. The pressing member 5 presses the roll-shaped article 50 held by the supporting member from above, and the lid 6 serves as a top plate of the container main body. The packing container 1 of the roll-shaped article is made of figure 2 The container constituted by the structure shown, when these members are stacked in order, constitutes a container for accommodating the roll-shaped article 50. figure 1...

no. 2 approach

[0066] Next, another embodiment different from the above will be described. The packing container of this second embodiment differs from the above-mentioned first embodiment only in that a buffer member 7 is provided between the roll-shaped article 50, the support member 4, and the pressing member 5, and the other structures are the same. exist Figure 5 In , the positional relationship of the supporting member, the pressing member, and the winding core of the present embodiment viewed from the front direction (corresponding to the positional relationship of the first embodiment) is shown. image 3 (a)).

[0067] In the case where the roller part of the roll-shaped article 50 is held from the side by the support member 4 and the pressing member 5, since the roller part is in direct contact with the supporting member 4 and the pressing member 5, it is not possible to completely suppress the damage caused by the material of the member. Damage to the roller part or cause wrinkles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com