Method for preparing 5-hydroxymethylfurfural, catalyst thereof and preparation method of catalyst

A technology of hydroxymethylfurfural and catalyst, which is applied in the field of producing 5-hydroxymethylfurfural, can solve the problems of poor catalytic performance of the catalyst, low conversion rate of raw materials, poor cycle stability, etc., and achieve good and excellent catalytic activity. Reproducibility and productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

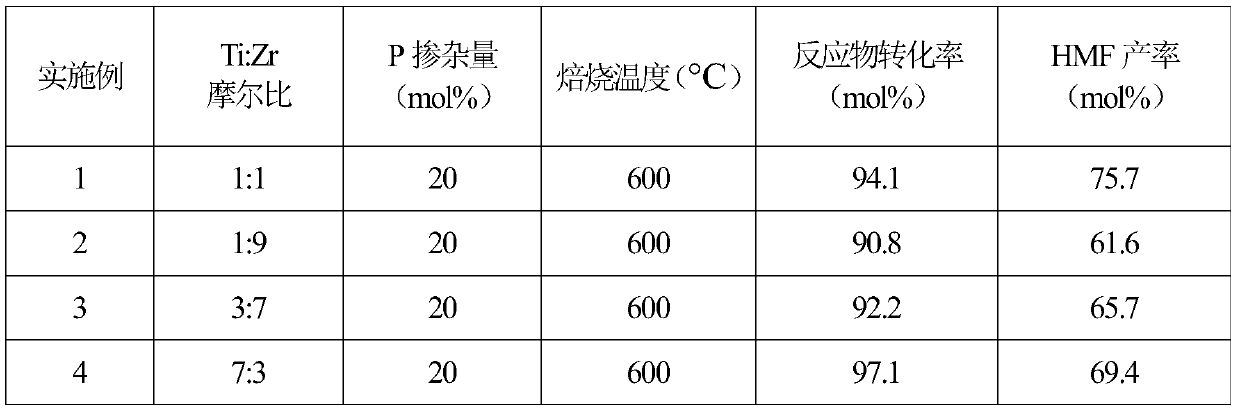

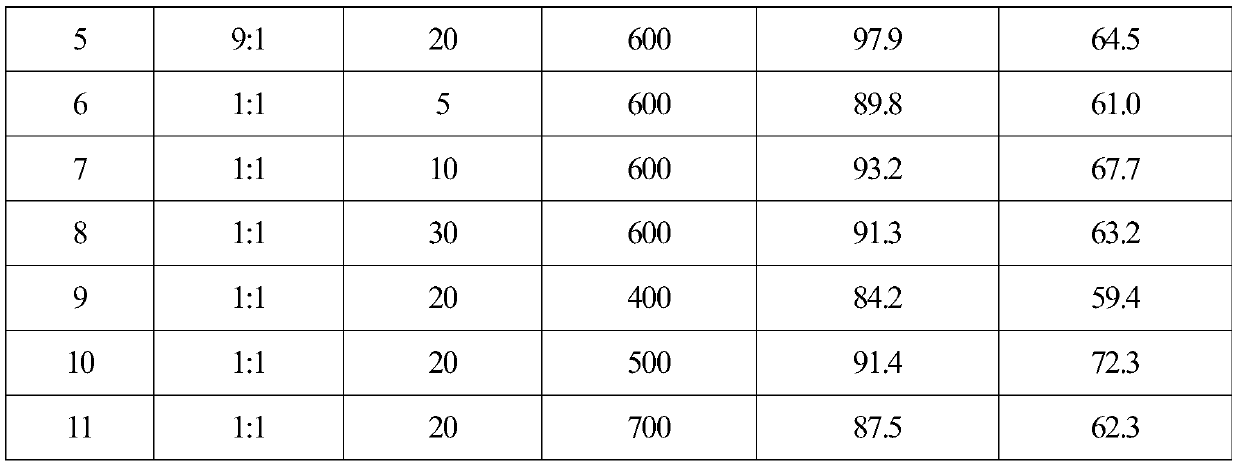

Embodiment 1

[0044] Preparation of catalyst:

[0045] (1) Dissolve 0.05mol (14.211g) isopropyl titanate and 0.05mol (19.184g) zirconium n-butoxide in 4mol (240g) isopropanol. Stir the resulting solution uniformly, add 0.02mol (1.96g) phosphoric acid, and then stir for 3h. Then, the solution was allowed to stand at room temperature for 24 hours and then placed in an oven at 110° C. for drying for 12 hours to obtain a gel.

[0046] (2) Calcining the obtained gel at 600° C. for 6 hours to obtain the catalyst. The molar ratio of titanium and zirconium in the catalyst is 1:1, and the doping amount of phosphorus is 20% of the total moles of metal elements.

Embodiment 2~5

[0048] Using the same preparation method as in Example 1, the difference is that the amount of isopropyl titanate in step (1) is 0.01 mol, 0.03 mol, 0.07 mol, 0.09 mol, and the amount of zirconium n-butoxide is 0.09 mol, 0.07 mol, respectively , 0.03mol, 0.01mol, the molar ratios of titanium and zirconium in the catalyst are 1:9, 3:7, 7:3, and 9:1 respectively.

Embodiment 6~8

[0050] The same preparation method as in Example 1 is used, except that the amount of phosphoric acid in step (1) is 0.005 mol, 0.01 mol, and 0.03 mol, respectively. It is obtained that the doping amount of phosphorus in the catalyst is 5%, 10%, and 30% of the total moles of metal elements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com