Waste mineral oil management and control system and method

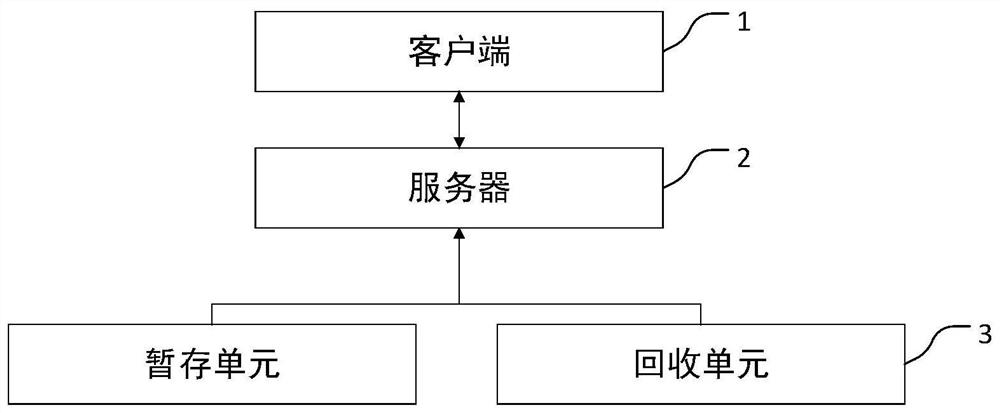

A waste mineral oil and management and control system technology, applied in sustainable waste treatment, logistics, instruments, etc., can solve the problems of low efficiency of manual inventory check, lack of technical management and control means for temporary storage sites, and inability to track the destination of hazardous waste in real time, etc. problems, to achieve the effect of improving control efficiency, preventing leakage and preventing fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0055] see Figure 8 to Figure 10 , a waste mineral oil management and control method, implemented based on a waste mineral oil management and control system described in Embodiment 1, comprising the following steps:

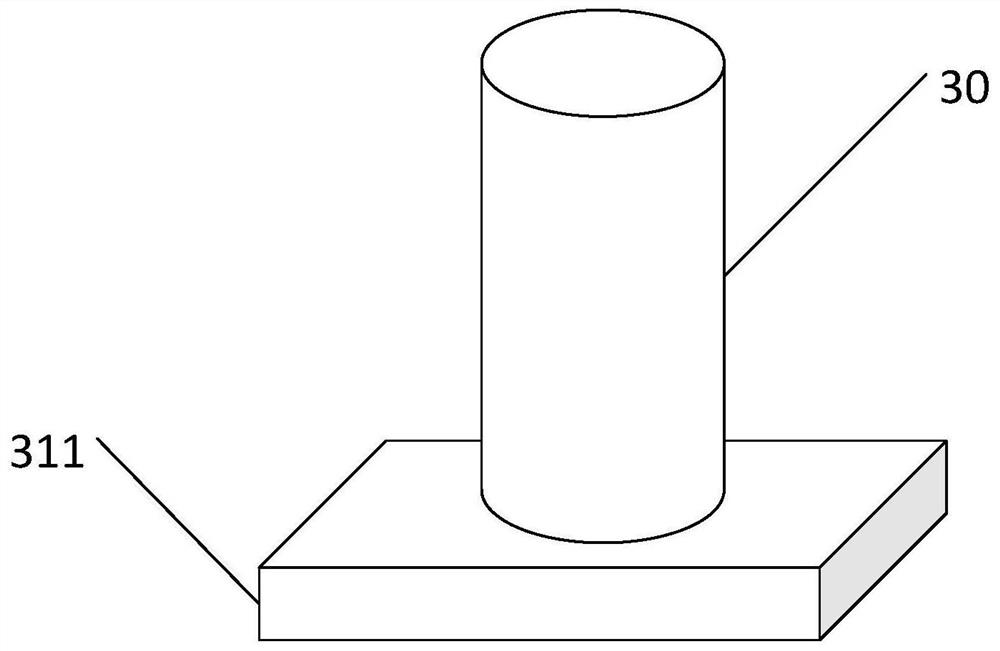

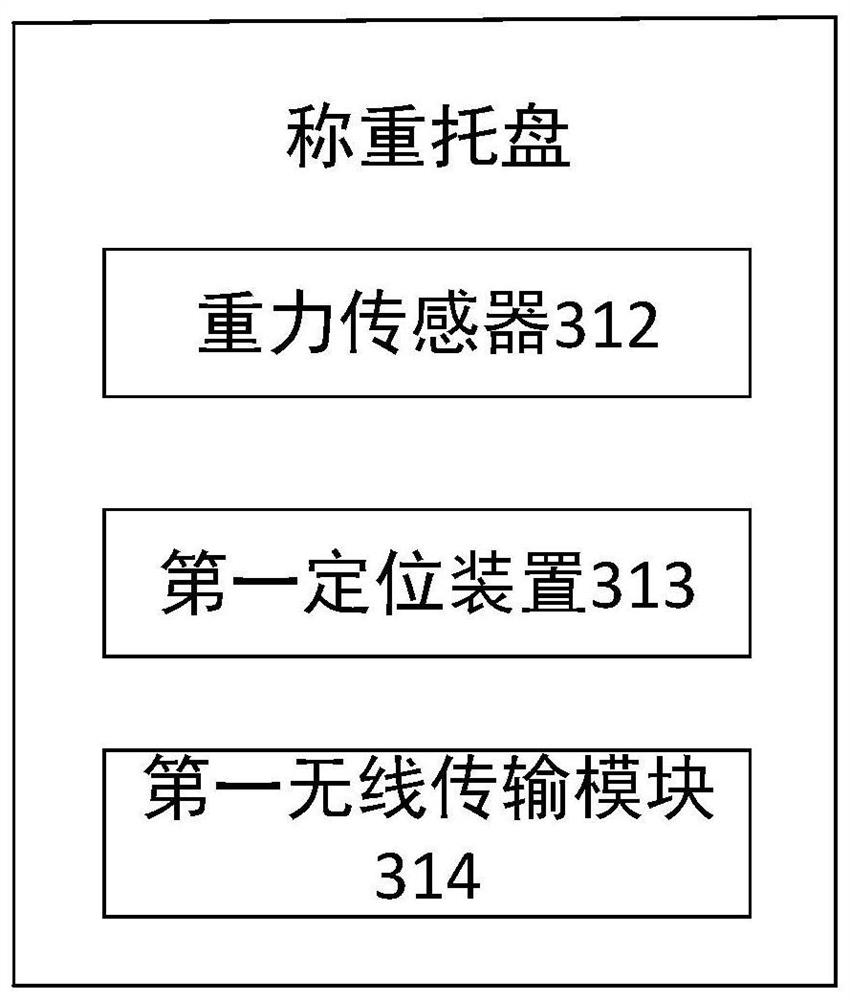

[0056] Recycling management, setting the threshold value of the gravity data of the oil collection barrel 30 on the client 1, when the gravity data of the oil collection barrel 30 of a recycling site reaches the threshold, the client 1 automatically calculates the current distance from the recycling site The nearest transport vehicle 321 and the temporary storage cabin assign the recycling task to the corresponding transport vehicle 321, and notify the positioning data of the corresponding recovery site and the positioning data of the corresponding temporary storage cabin;

[0057] Inbound management, when a new oil collection barrel 30 is delivered to the temporary storage cabin, the staff puts the oil collection barrel 30 in a storage tray 41, and scans the RF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com