Equipment recycling and warehousing method and equipment recycling and warehousing system based on 3D vision

A storage system and equipment technology, applied in the field of storage systems, can solve the problems of inability to adapt to sorting and transportation work, high cost, and difficulty in maintaining storage efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The principles and features of the present invention will be described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

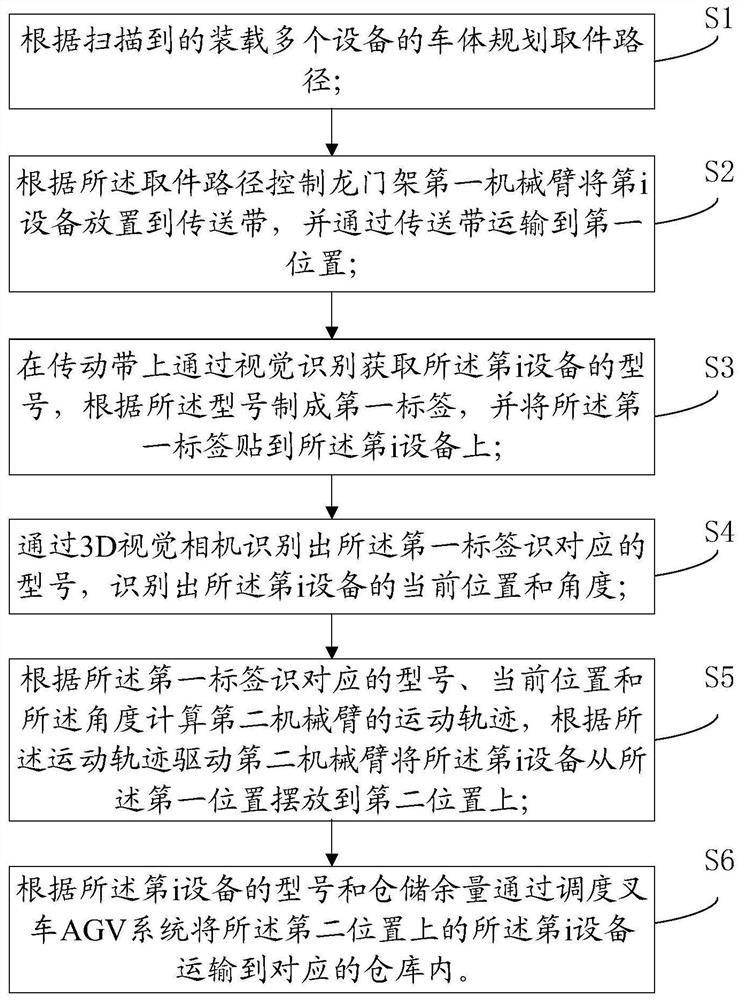

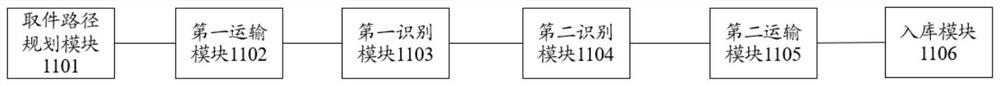

[0046] Such as figure 1 As shown, a 3D vision-based equipment recycling storage method provided by the embodiment of the present invention includes:

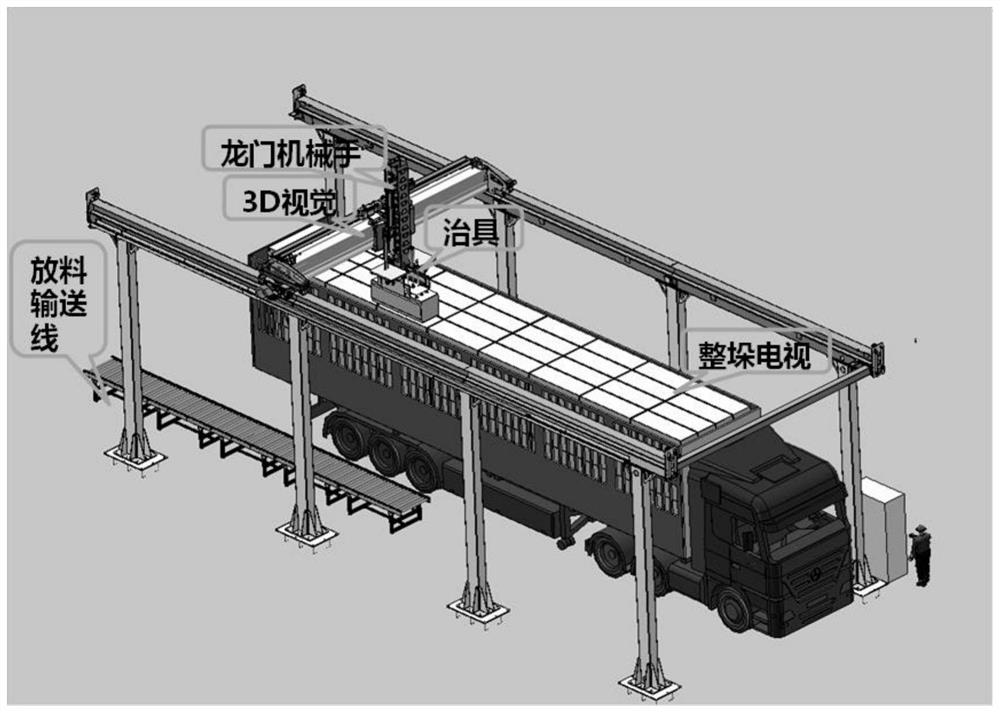

[0047] S1, planning a pick-up path according to the scanned car body loaded with multiple devices; the multiple devices may be multiple home appliances or other devices.

[0048] S2. Control the first robotic arm of the gantry according to the pick-up path to place the i-th device on the conveyor belt, and transport it to the first location through the conveyor belt; wherein, the first location may be near the appliance cage area.

[0049] S3, obtain the model of the i-th device through visual recognition on the transmission belt, make a first label according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com