Full-automatic filled can beverage sterilization assembly line

An assembly line, fully automatic technology, applied in bottle filling, bottling machines, packaging, etc., can solve the problems of increased control complexity and equipment failure rate, partitions that cannot automatically realize circulation, and large space occupied by transfer devices, etc., to achieve The effect of improving operating efficiency, easy control, and simple assembly line structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

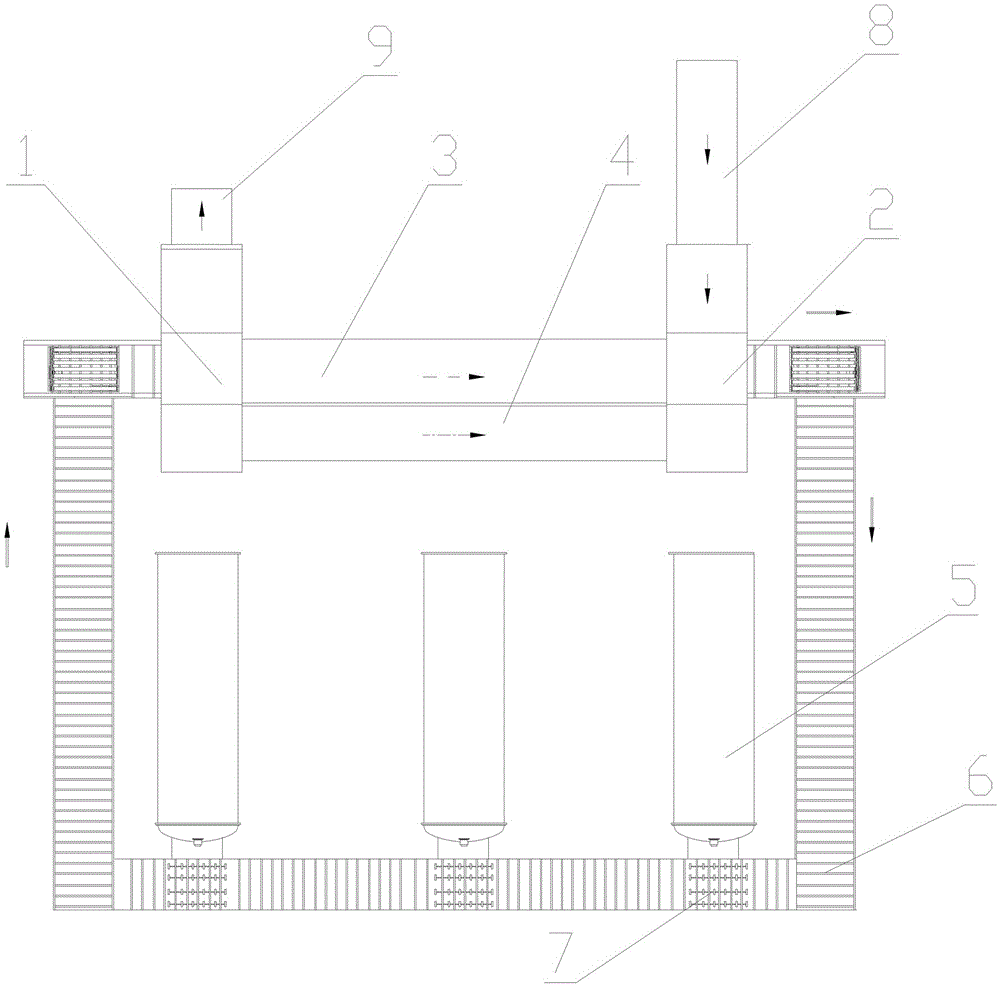

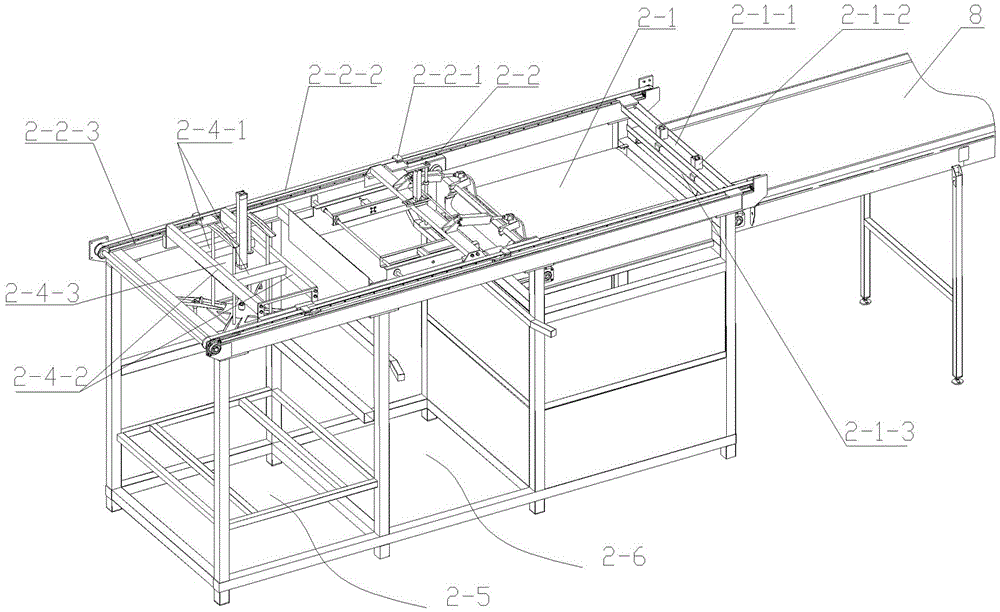

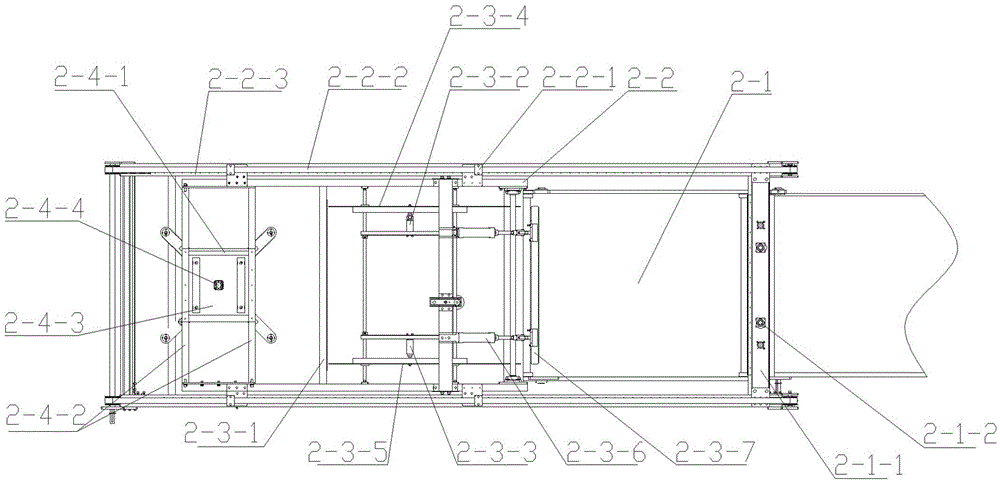

[0022] see figure 1 , the assembly line of this embodiment is set after the beverage filling and sealing stations, and includes a cage loading mechanism 2 and a cage unloading mechanism 1 connected by a sterilizing cage conveying chain 6, and a one-way An open sterilization box 5, the inside of which is provided with a two-way driven transmission roller in the box, which is docked with the sterilization cage conveyor chain 6 by means of the transmission roller outside the box; the cage loading mechanism 2 and the cage unloading mechanism 1 are respectively docked and sterilized Conveyor belt 3 for cage circulation and conveyor belt 4 for separator circulation. Filled beverages conveyed from the solid tank input chain 8 are automatically finished with solid tank sorting and cage loading and automatic partition removal at the cage loading mechanism 2, and then under the control of the main control unit, the sterilization cage is conveyed by rollers inside the box and conveyed ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com