Full-automatic elaborate selecting, grinding, polishing, cleaning, drying and sterilizing production system

A production system, fully automatic technology, applied in the direction of dry preservation of seeds, preservation of seeds through radiation/electrical treatment, grain treatment, etc., can solve the problems of drying and sterilization, incompleteness, and large footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

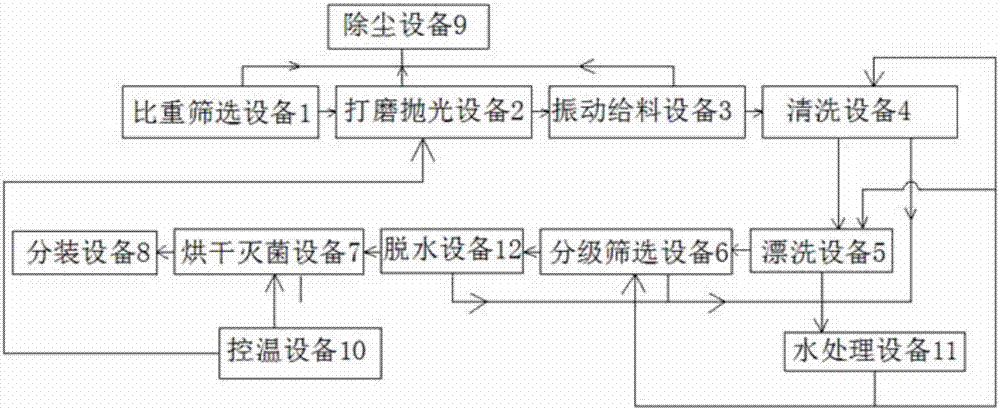

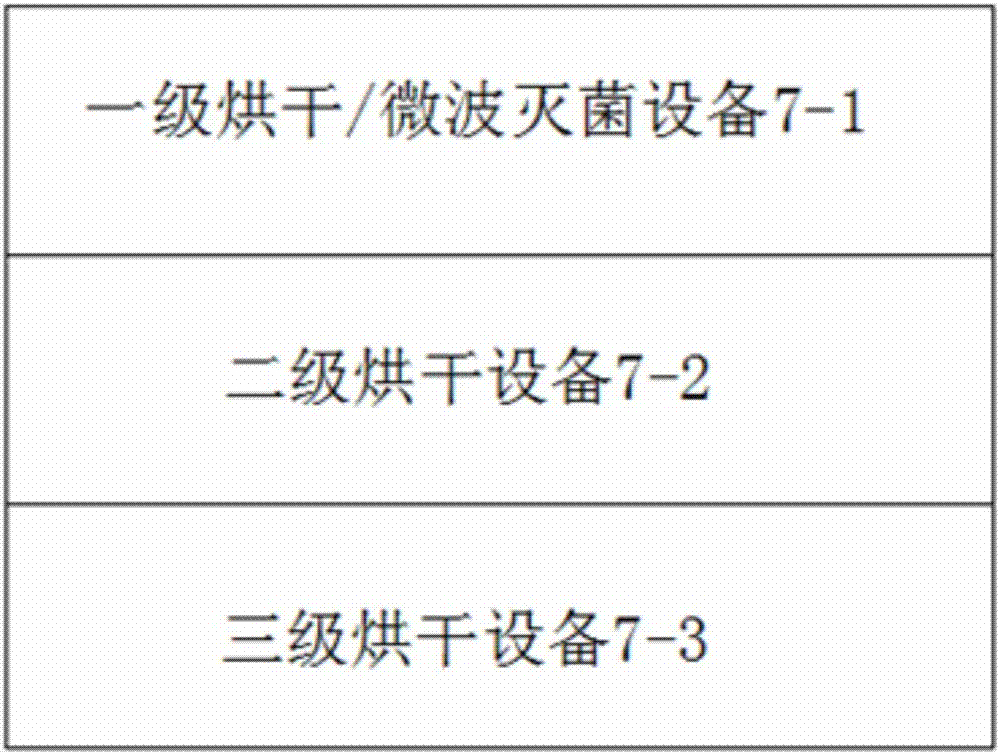

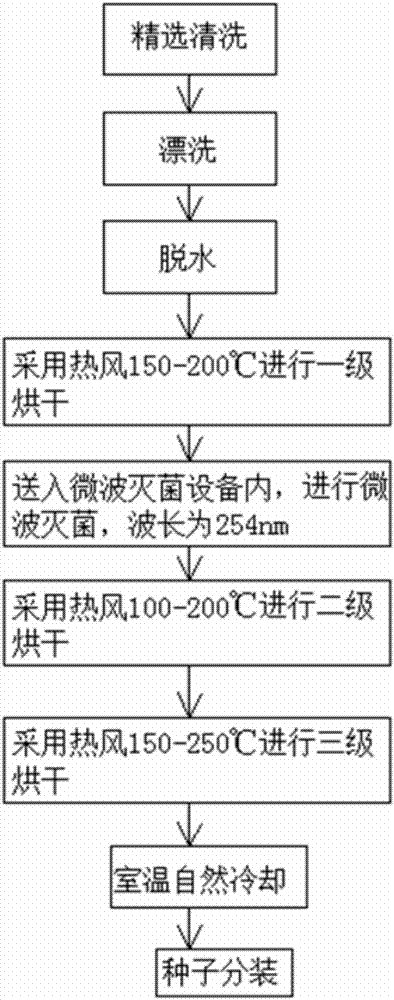

[0026] see image 3 , in the present embodiment, the selected, polished, polished, cleaned, dried, and sterilized automatic production system is used to process the imperial rice seeds. First, the specific gravity screening equipment 1 is used to screen out excellent imperial rice seeds, and then the imperial rice seeds are The rice seeds are put into cleaning equipment 4 and cleaned 3 times, the cleaned rice seeds are rinsed 2 times, and the rinsed rice seeds are input into the dehydration equipment 12 for dehydration, and the dried rice seeds are directly sent into the drying process after dewatering. The drying equipment 7 is sequentially dried in the three-layer drying chamber in the drying equipment 7. While the first-level drying is performed, the microwave sterilization equipment is used for microwave sterilization treatment. When the three-layer drying equipment is dried Afterwards, output to the sub-packaging equipment 8, sub-package after natural cooling to room temp...

Embodiment 2

[0028] see Figure 4 In this embodiment, the pumpkin seeds or medlars are processed by using the full-automatic production system of selection, grinding, polishing, cleaning, drying, and sterilization. First, the pumpkin seeds or medlars are polished and polished by the grinding and polishing equipment 2 , send the polished seeds into the vibratory feeding equipment 3, and send them into the cleaning equipment 4 by means of vibratory feeding. During the vibratory feeding process, the polished debris and dust are all sucked by the dust removal equipment 9 Cleaning equipment 4 cleans the seeds three times, and then sends them to rinsing equipment 5 for rinsing twice, and then sends the rinsed seeds to grading and screening equipment 6, and utilizes the principle of gravity of seeds with different fullness in water to classify and screen out plump seeds. The unfull seeds are scraped off, and the full seeds are sent to the dehydration equipment 12 for dehydration treatment. The de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com