High-brightness nano strontium-aluminate long-afterglow luminous material and preparation method and application thereof

A luminescent material, nano-aluminum technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of expensive surfactants, impure product chromaticity, limited application fields, etc., achieve long afterglow time, reduce calcination temperature, Energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

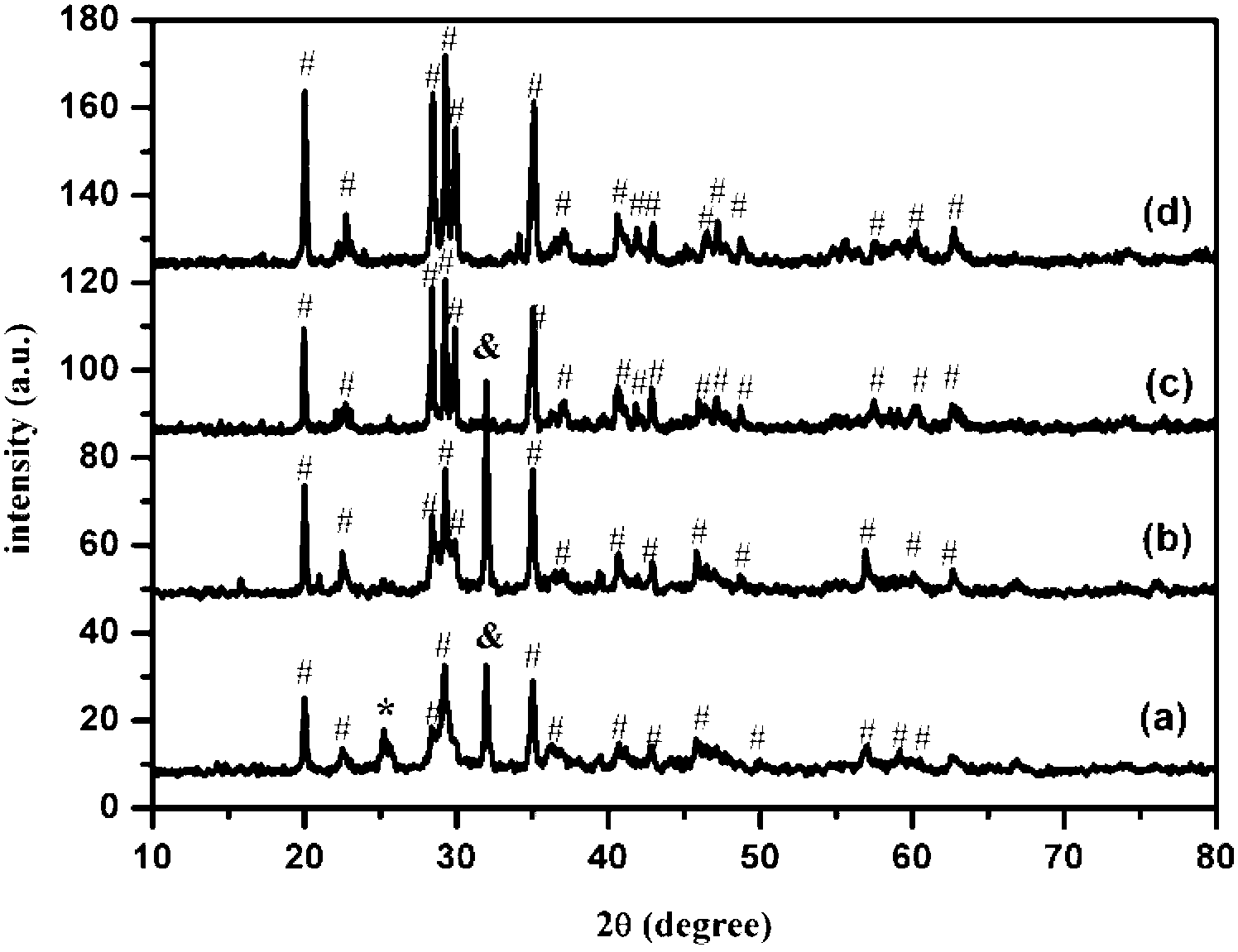

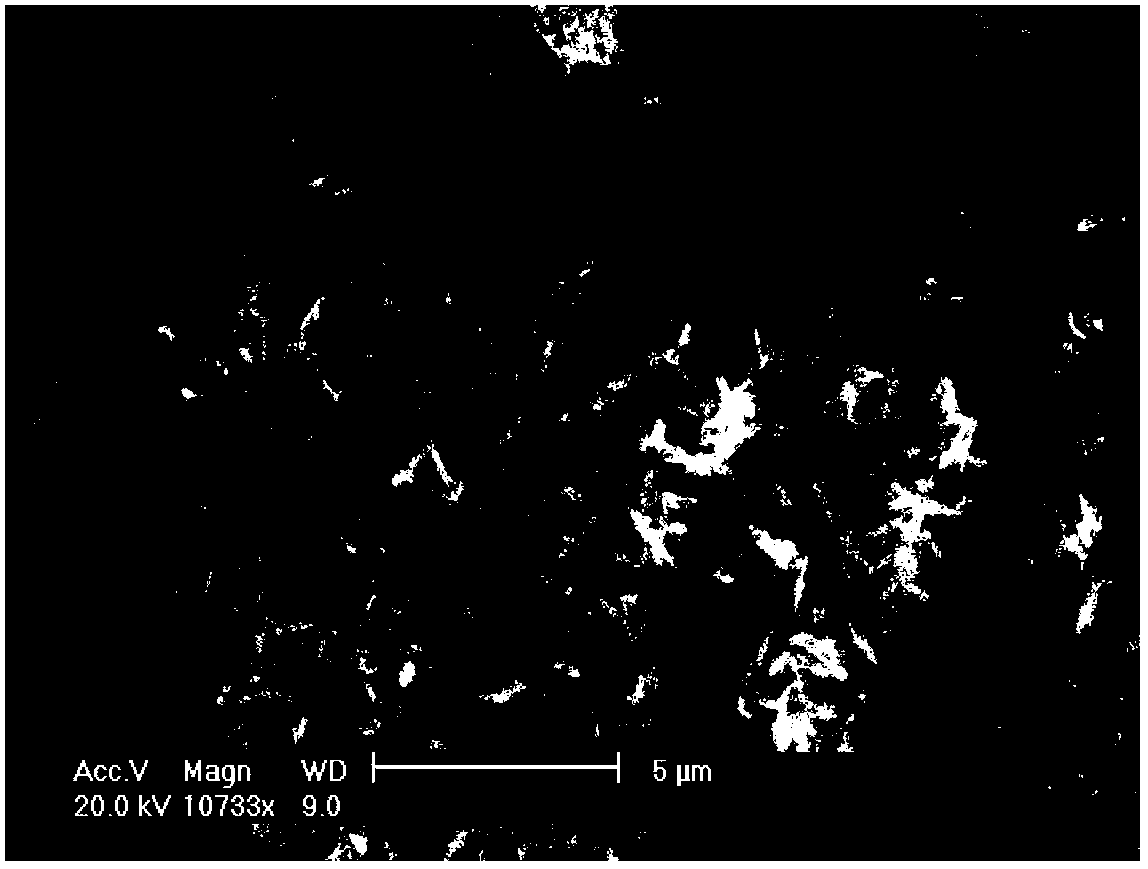

Embodiment 1

[0033] (1) Weigh 0.005 mol of strontium acetate hemihydrate, 0.01 mol of basic aluminum acetate, 0.0004 mol of europium acetate, 0.0008 mol of dysprosium acetate, and 0.020 mol of urea in a reaction vessel, then add 80 ml of absolute ethanol to it, and ultrasonically ( Model: SCQ-5201, Shanghai Shengyan Ultrasonic Instrument Co., Ltd.) After dispersing for 10 minutes, stir and dissolve, put the above solution in a closed reaction kettle, and keep it at 160°C for 6 hours to obtain a white product;

[0034] (2) Cool the white product obtained in step (1); then filter and wash the cooled white product with deionized water and ethanol, and dry at 50°C for 6 hours to obtain the precursor;

[0035] (3) Annealing the precursor obtained in step (2) in a reducing atmosphere at 950° C. for 3 hours to prepare a strontium aluminate long-lasting luminescent material.

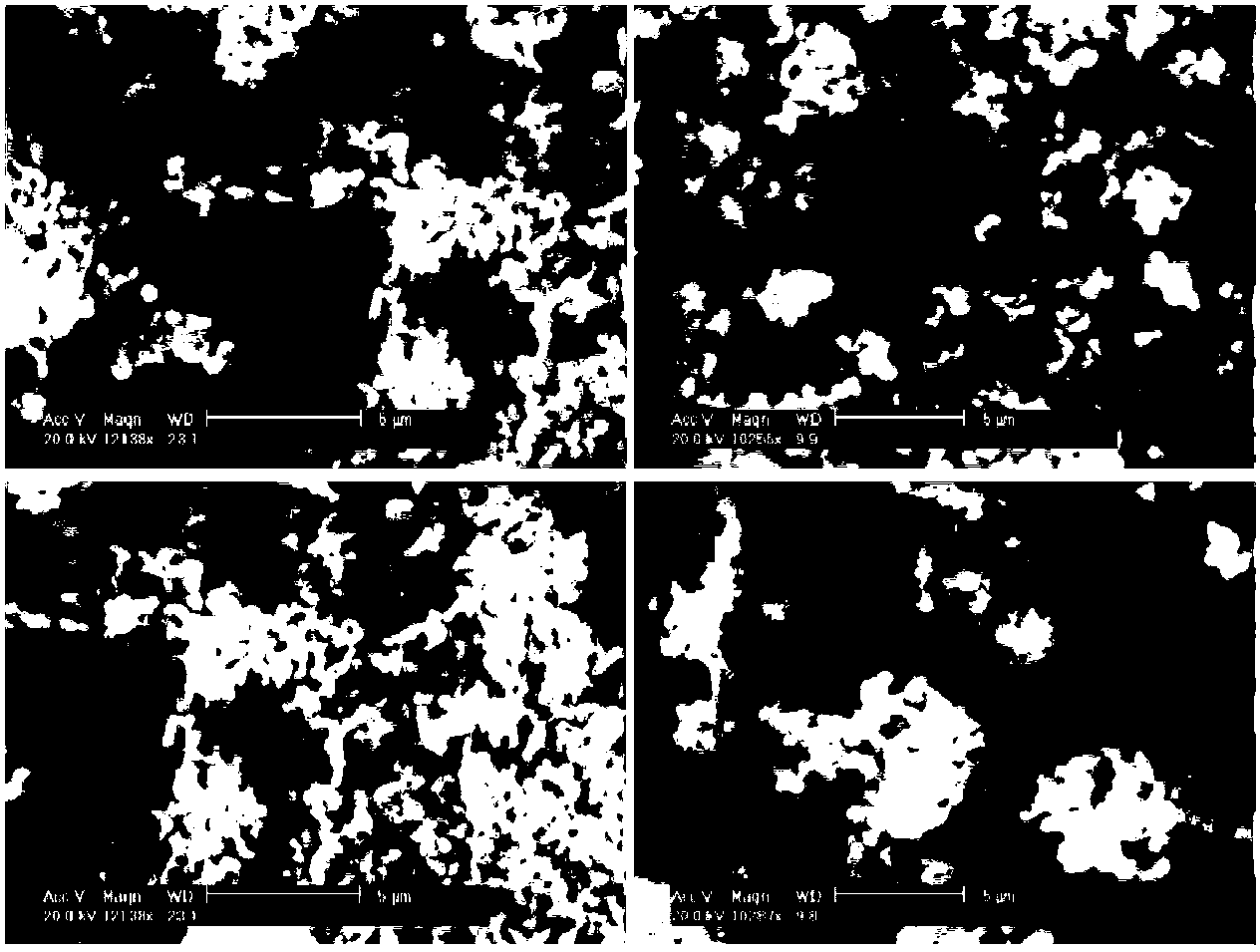

Embodiment 2

[0037](1) Weigh 0.01 mol of strontium acetate hemihydrate, 0.025 mol of basic aluminum acetate, 0.0005 mol of europium acetate, 0.0009 mol of dysprosium acetate, and 0.025 mol of urea in a reaction vessel, then add 85 ml of absolute ethanol to it, and ultrasonically ( The model is the same as Example 1.) After dispersing for 15 minutes, stir and dissolve, put the above solution in a closed reaction kettle, and keep it at 160°C for 12 hours to obtain a white product;

[0038] (2) Cool the white product obtained in step (1); then filter and wash the cooled white product with deionized water and ethanol, and dry at 70°C for 7 hours to obtain the precursor;

[0039] (3) Annealing the precursor obtained in step (2) in a reducing atmosphere at 1050° C. for 4 hours to prepare a strontium aluminate long-lasting luminescent material.

Embodiment 3

[0041] (1) Weigh 0.01 mol of strontium acetate hemihydrate, 0.030 mol of basic aluminum acetate, 0.0006 mol of europium acetate, 0.0010 mol of dysprosium acetate, and 0.060 mol of urea in a reaction vessel, then add 85 ml of absolute ethanol to it, and ultrasonically ( The model is the same as Example 1.) After dispersing for 15 minutes, stir and dissolve, put the above solution in a closed reaction kettle, and keep it at 180°C for 12 hours to obtain a white product;

[0042] (2) Cool the white product obtained in step (1); then filter and wash the cooled white product with deionized water and ethanol, and dry at 80°C for 8 hours to obtain the precursor;

[0043] (3) Annealing the precursor obtained in step (2) in a reducing atmosphere at 1150°C for 4 hours to prepare a strontium aluminate long-lasting luminescent material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com