Hexagonal sheet-like barium ferrite magnetic nanometer powder preparation method

A magnetic nano, hexagonal flake technology, applied in the field of material science, can solve the problem of low product yield and achieve the effect of good crystal form, high purity and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

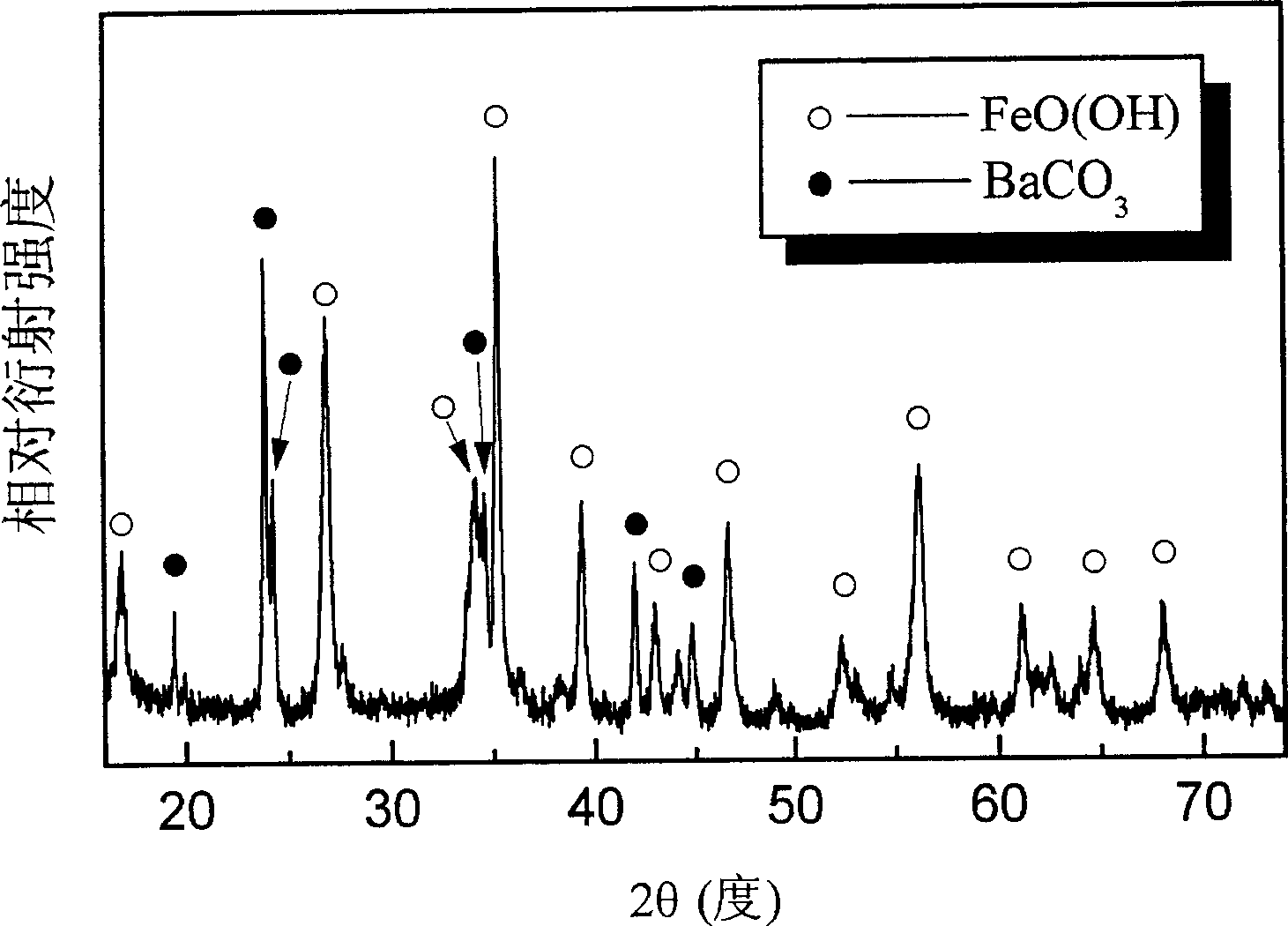

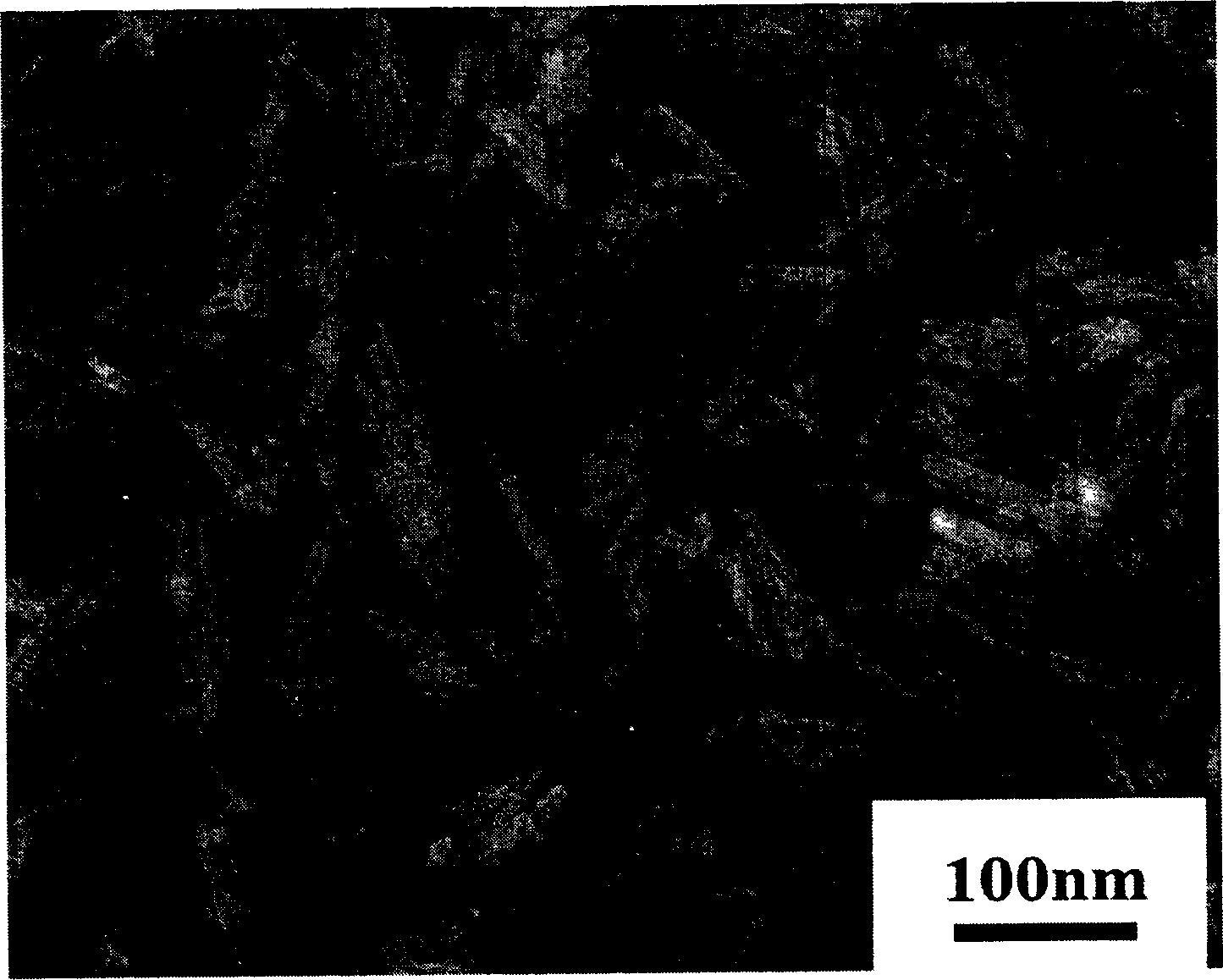

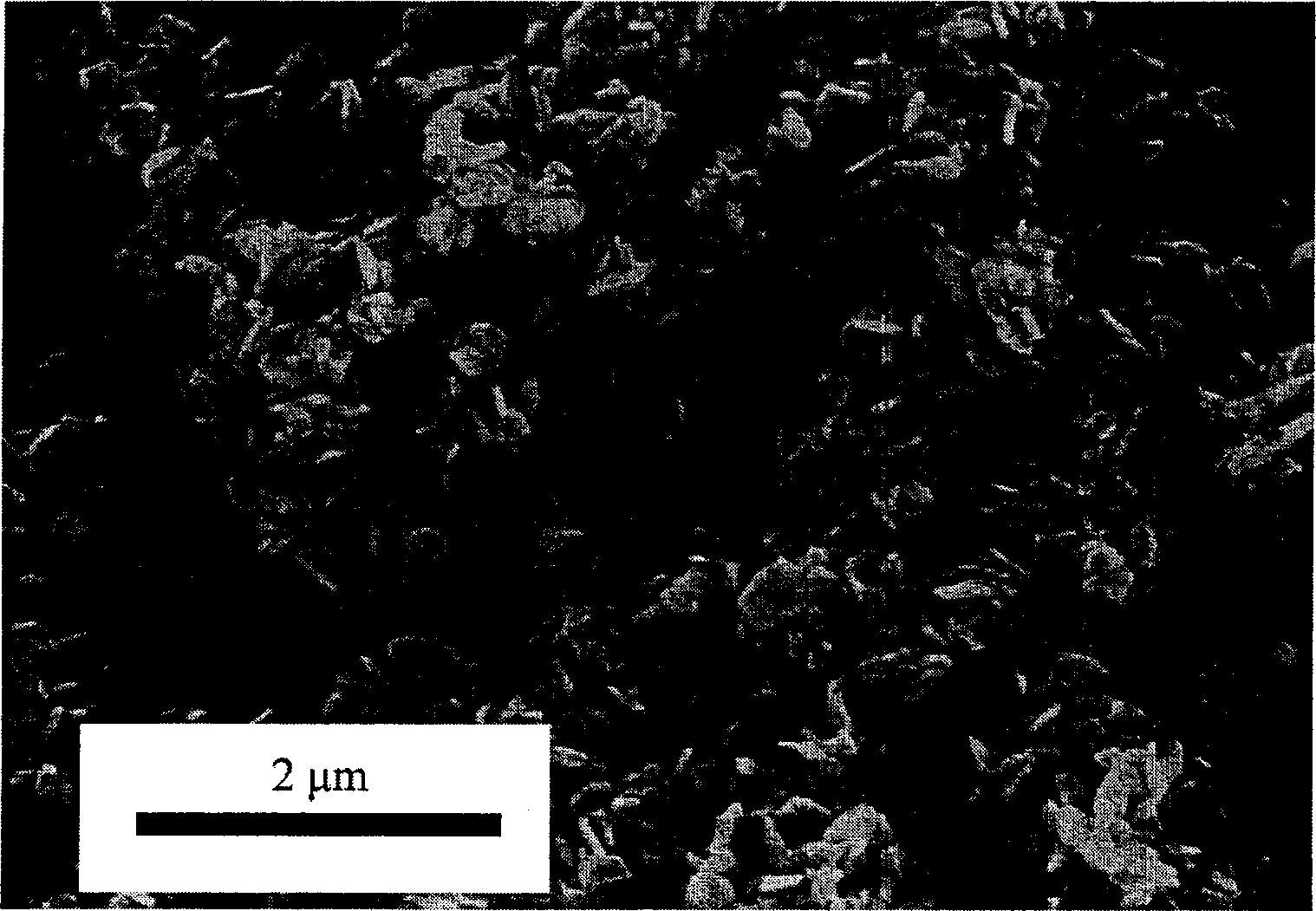

[0022] powdered BaCO 3 The mixture of FeO(OH) powder with nanoscale fineness is the precursor. In the precursor mixture, BaCO 3 The molar ratio of FeO(OH) and FeO(OH) is 1:8~1:12. according to figure 1 , figure 2 From the above, it can be known that the main components of the precursor are FeO(OH), BaCO 3 Another essential component of the precursor.

[0023] Put the precursor product into the muffle furnace, and raise the temperature at a uniform rate (10□ / min) to the required temperature of 700-900°C for calcination (the preferred calcination temperature is 740-850°C); ~3.5 hours); finally, naturally cool to room temperature with the furnace body to obtain BaFe with hexagonal sheet structure 12 o 19 Nano powder.

[0024] According to attached Figure 4 Analysis shows that the product obtained after calcination is pure BaFe 12 o 19 Phase: refer to attached Figure 4 , X-ray diffraction analysis showed that the product BaFe 12 o 19 Each characteristic diffractio...

Embodiment 2

[0027] BaCO with a fineness of nanoscale 3 The mixture of powder and FeO(OH) powder with nanoscale fineness is the precursor. In the precursor mixture, BaCO 3 The molar ratio of FeO(OH) and FeO(OH) is 1:9. according to figure 1 , figure 2 From the above, it can be known that the main components of the precursor are FeO(OH), BaCO 3 Another essential component of the precursor.

[0028] Put the precursor product into the muffle furnace, raise the temperature at a constant speed (10□ / min) to 740°C; then keep it warm for 2.5 hours; finally cool down to room temperature naturally with the furnace body, and then get BaFe with hexagonal sheet structure 12 o 19 Nano powder.

[0029] According to attached Figure 4 Analysis shows that the product obtained after calcination is pure BaFe 12 o 19 Phase: refer to attached Figure 4 , X-ray diffraction analysis showed that the product BaFe 12 o 19 Each characteristic diffraction peak of the phase (JCPDS FileNo.39-1433) is clearl...

Embodiment 3

[0032] BaCO with a fineness of nanoscale 3 The mixture of powder and FeO(OH) powder with nanoscale fineness and spindle-shaped microscopic shape is the precursor. In the precursor mixture, BaCO 3 The molar ratio of FeO(OH) and FeO(OH) is 1:12. according to figure 1 , figure 2 From the above, it can be known that the main components of the precursor are FeO(OH), BaCO 3 Another essential component of the precursor.

[0033] Put the precursor product into the muffle furnace, raise the temperature at a constant speed (10□ / min) to 850°C); then keep it warm for 3.5 hours; finally cool down to room temperature naturally with the furnace body, and then get BaFe with a hexagonal sheet structure 12 o 19 Nano powder.

[0034] According to attached Figure 4 Analysis shows that the product obtained after calcination is pure BaFe 12 o 19 Phase: refer to attached Figure 4 , X-ray diffraction analysis showed that the product BaFe 12 o 19 Each characteristic diffraction peak of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com