Method for preparing lithium magnalium co-doped synergic nitrogen-sulfur doped carbon-coated modified barium titanate lithium cathode material

A technology of co-doping, barium titanate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

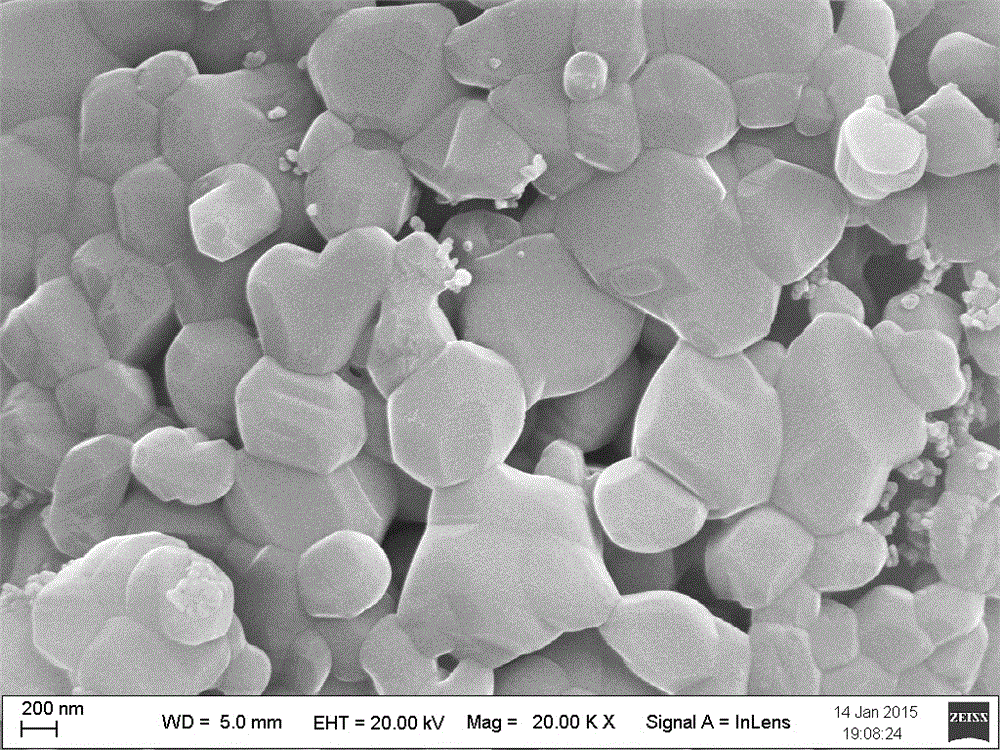

Image

Examples

Embodiment 1

[0011] Example 1: Take 0.1 mole of barium nitrate, 0.2 mole of lithium nitrate, 0.005 mole of magnesium acetate, 0.01 mole of aluminum acetate, 0.6 mole of nano-titanium dioxide (6 nm), and 0.1 mole of acetylene black at 500 rpm for 19 hours, and place After drying in an oven at 100°C, grind it in an agate mortar, then sinter the powder in a muffle furnace, first take 2 hours to raise the temperature from room temperature to 650°C, and keep the temperature at this temperature for 4 hours for pre-sintering to decompose Salts, then heated up to 980°C in 5 hours, kept at this temperature for 14 hours, and cooled naturally to room temperature to obtain lithium-site magnesium-aluminum co-doped barium lithium titanate. Next, put the obtained lithium-site magnesium-aluminum co-doped barium lithium titanate into a porcelain boat and place it in a tube atmosphere furnace, and then put another porcelain boat containing cystine into the tube atmosphere furnace, And put it at the upstream...

Embodiment 2

[0012] Example 2: Take 0.1 mole of barium nitrate, 0.2 mole of lithium nitrate, 0.02 mole of magnesium acetate, 0.01 mole of aluminum acetate, 0.6 mole of nano-titanium dioxide (6 nm), and 0.1 mole of acetylene black at 500 rpm for 19 hours, and place After drying in an oven at 100°C, grind it in an agate mortar, then sinter the powder in a muffle furnace, first take 2 hours to raise the temperature from room temperature to 650°C, and keep the temperature at this temperature for 4 hours for pre-sintering to decompose Salts, then heated up to 980°C in 5 hours, kept at this temperature for 14 hours, and cooled naturally to room temperature to obtain lithium-site magnesium-aluminum co-doped barium lithium titanate. Next, put the obtained lithium-site magnesium-aluminum co-doped barium lithium titanate into a porcelain boat and place it in a tube atmosphere furnace, and then put another porcelain boat containing cystine into the tube atmosphere furnace, And put it at the upstream ...

Embodiment 3

[0013]Example 3: Take 0.1 mole of barium nitrate, 0.2 mole of lithium nitrate, 0.01 mole of magnesium acetate, 0.01 mole of aluminum acetate, 0.6 mole of nano-titanium dioxide (6 nm), and 0.1 mole of acetylene black at 500 rpm for 19 hours, and place After drying in an oven at 100°C, grind it in an agate mortar, then sinter the powder in a muffle furnace, first take 2 hours to raise the temperature from room temperature to 650°C, and keep the temperature at this temperature for 4 hours for pre-sintering to decompose Salts, then heated up to 980°C in 5 hours, kept at this temperature for 14 hours, and cooled naturally to room temperature to obtain lithium-site magnesium-aluminum co-doped barium lithium titanate. Next, put the obtained lithium-site magnesium-aluminum co-doped barium lithium titanate into a porcelain boat and place it in a tube atmosphere furnace, and then put another porcelain boat containing cystine into the tube atmosphere furnace, And put it at the upstream o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com