Patents

Literature

48 results about "Dimethylol urea" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diluent for blood cell analyzer

InactiveCN101975850AAntisepticPrevent solidificationPreparing sample for investigationBiological testingDimethylol ureaSodium azide

The invention provides a diluent for a blood cell analyzer. The diluent consists of edentate, sodium sulfate, sodium chloride, dimethylol urea, biological buffer, a betain type nonionic surfactant, sodium azide and water. The diluent solves the problems that the osmotic pressure of a bottom layer is higher than that of an upper layer and the solution is not uniform or stable when the diluent for the blood cell analyzer stands for a long time.

Owner:南京卡博生物科技有限公司

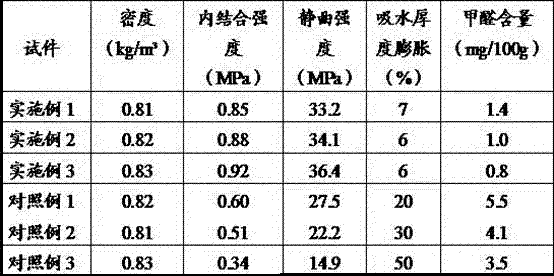

Sulfate lignin modified urea resin adhesive and preparation method thereof

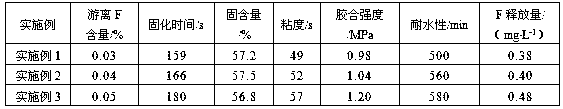

ActiveCN108531116AHigh bonding strengthLow free formaldehyde contentAldehyde/ketone condensation polymer adhesivesSulfateDimethylol urea

The invention belongs to the technical field of urea resin adhesive, and particularly relates to sulfate lignin modified urea resin adhesive and a preparation method thereof. The adhesive is preparedfrom the following raw materials in parts by weight: 100 parts of urea, 149 to 154 parts of formaldehyde solution, 8 to 15 parts of sulfate lignin, 2 to 3 parts of melamine, 1 to 2 parts of polyvinylalcohol, 0.36 to 0.41 part of alkaline catalyst, and 0.28 to 0.32 part of acidic catalyst. By selecting the sulfate lignin modified urea resin and adopting a weak acid-weak alkali-weak acid-weak alkali synthetic process, the content of a first portion of urea, a second portion of urea, a third portion of urea and a third portion of urea are reasonably configured, so that more dimethylol urea can be generated, the adhesion strength can be improved, little urea is added at the last time, the un-reacted free formaldehyde can be captured, the formaldehyde emission of the prepared plywood is ensured to reach grade E0, and the adhesion strength can reach the type-II plywood standard.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

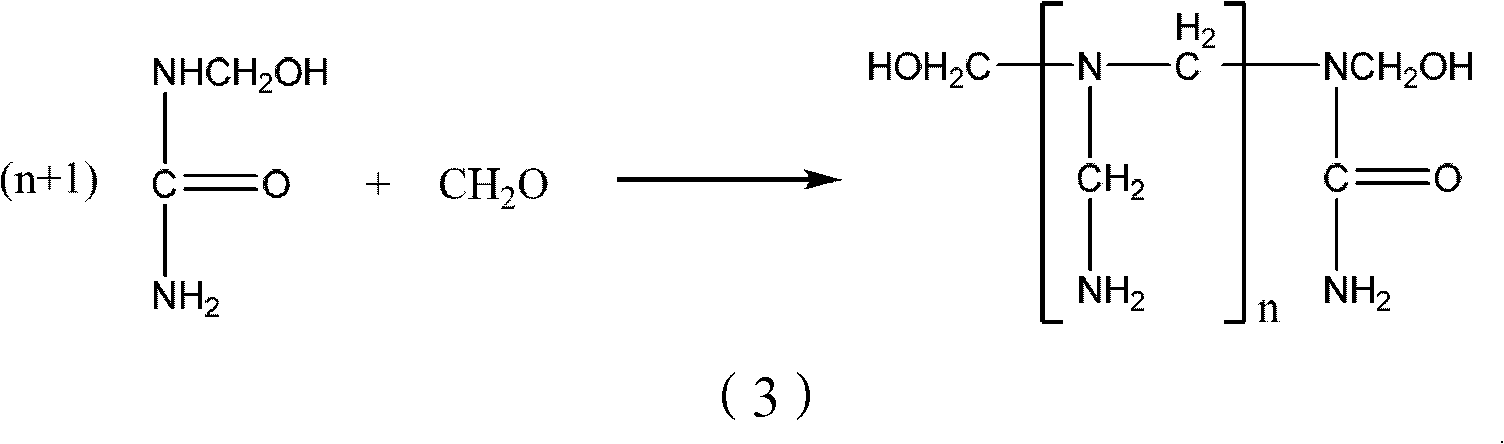

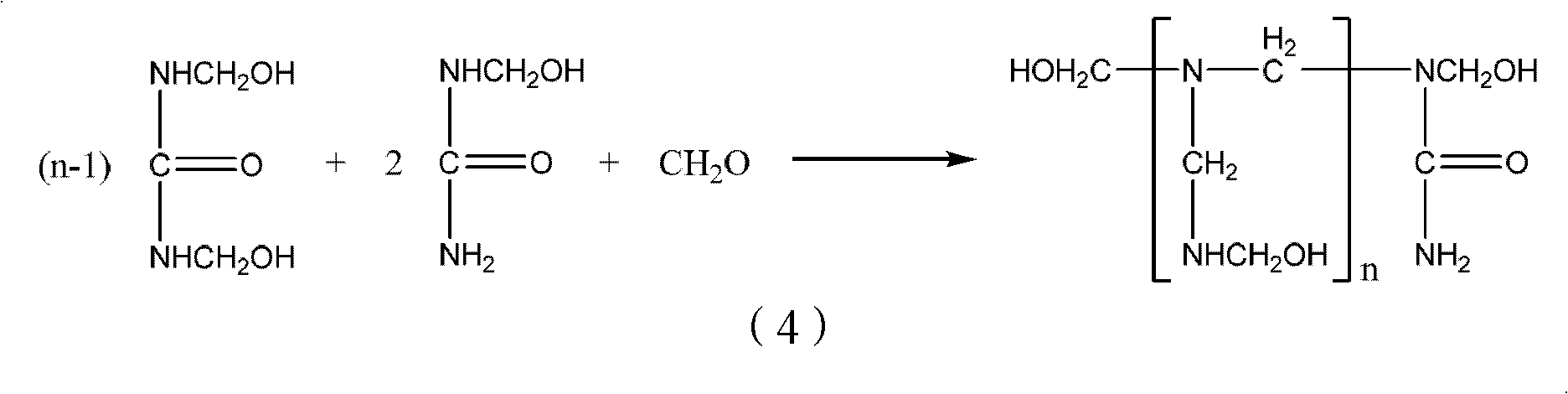

Method for synthesizing urea-formaldehyde resin

InactiveCN101987881AImprove performanceLow free formaldehyde contentReaction temperatureDimethylol urea

The invention discloses a method for synthesizing urea-formaldehyde resin. The method can reduce the content of free formaldehyde, and produce the urea-formaldehyde resin with high performance. In the method, the total molar ratio of formaldehyde to urea is 1.19, which contributes to reducing the free formaldehyde content of the urea-formaldehyde resin; the formaldehyde is added once; the urea is added for four times, wherein the dosages of the urea added in the first two times have to contribute to generating dimethylol urea, so that an addition reaction of the formaldehyde is more thorough to reduce the free formaldehyde content in the reaction to the maximum; the pH value in the reaction process is changed to meet the requirements on the pH values in different stages of the reaction process; and the appreciate reaction temperature, appreciate reaction time and appreciate urea adding time are selected.

Owner:钱彤

Diluent for blood cell analysis instrument

InactiveCN1548942AEasy to manufactureAdd diffuse effectPreparing sample for investigationIndividual particle analysisPhosphoric acidSodium sulfate

The diluent for hemocyte analyzer includes sodium hydroxide 430-470 g / L, dimethylol urea 0.8-1.2 g / L, phosphoric acid 430-470 ml / L, non-ionic surfactant 0.3-0.7 g / L, procaine hydrochloride 0.09-0.13 g / L, anhydrous sodium sulfate 1.0-9.5 g / L, and sodium chloride 0.3-0.7 g / L except water. The diluent of the present invention may be used in various kinds of hemocyte analyzer.

Owner:上海捷瑞医用试剂有限公司

Method for producing compound modified starch

The invention relates to the field of chemical adhesive, in particular to a method for producing compound modified starch. The method solves problems that existing modified starch is treated by a modification method mostly, is narrow in application range and poor in practicality, and the like. The method includes steps of (1), mixing starch with water to blend into starch slurry; (2), adding sodium hypochlorite into the starch slurry to perform oxidization reaction; (3), adding dimethylol urea which is a crosslinking agent into the mixture to perform crosslinking reaction; (4), regulating the pH (potential of hydrogen) value of the slurry to range from 7.5 to 8.5 after the reaction; and (5), performing wet screening and washing for the slurry obtained in the step (4), and then feeding the slurry into a pre-gelatinization drying machine to dehydrate and dry. Carboxyl is added into starch molecules during reaction, so that the starch molecules have the characteristics of hydrophilicity and lipophilicity and have good emulsification and dispersion effects. In addition, the dimethylol urea is added into the starch molecules for performing the crosslinking reaction, so that the compound modified starch has the advantages of stable viscosity, high water absorption, shearing resistance and alkali resistance, good film-forming property and the like, and can be applied to various fields.

Owner:赵贵喜

Crease-resistant finishing method for cellulosic fiber fabric

InactiveCN105256580ANo yellowingGuaranteed wrinkle resistanceVegetal fibresDimethylol ureaCellulose fiber

The invention relates to a crease-resistant finishing method for cellulosic fiber fabric. A durable crease-resistant finishing agent is adopted, and a double-dipping double-rolling finishing process is adopted for carrying out crease-resistant finishing on the cellulosic fiber fabric; according to parameters of the double-dipping double-rolling finishing process, the mangle expression is about 75% to 80%, pre-drying is carried out for about 1-3 min at the temperature of 80 DEG C to 90 DEG C, and baking is carried out for 2-5 min at the temperature of 120 DEG C to 180 DEG C. The crease-resistant finishing method is characterized in that the durable crease-resistant finishing agent comprises the following components by weight. The crease-resistant finishing agent is nano resin finishing liquid, dimethylol urea resin, excessive hydroxymethyl triazone and hydroxymethyl melamine are compounded as the finishing agent, meanwhile, nanometer oxides with a catalytic effect or the synergistic effect are added, and the finishing agent is prepared and used for crease-resistant finishing processing of bafta. The crease-resistant effect is guaranteed, meanwhile, the problem that the strength and abrasive resistance loss of previous crease-resistant finishing is large is relieved, and the fabric is not yellowed.

Owner:张作玮

Durability anti-crease finishing agent

InactiveCN105200767ANo yellowingGuaranteed wrinkle resistanceVegetal fibresCarboxylic saltCatalytic effect

The invention relates to a durability anti-crease finishing agent, which comprises the following main components in parts by weight: dimethylol urea resin, bis (hydroxymethyl) triazone, methylol melamine, butyl acrylate, ammonium citrate, maleic acid-acrylic acid copolymer, poly-carboxylate, fatty alcohol-polyoxyethylene ether, nanometer titania, a dispersing agent and a penetrating agent. The anti-crease finishing liquid is nanometer resin finishing liquid, the dimethylol urea resin, the excess bis (hydroxymethyl) triazone and the methylol melamine are compounded to serve as a finishing agent, and meanwhile, nanometer oxide with a catalytic effect or a synergistic effect is added to prepare the durability anti-crease finishing agent; when the durability anti-crease finishing agent is used for anti-crease finishing of cotton fabrics, while the anti-crease effect is ensured, the problem that anti-crease finishing strength loss and abrasive resistance loss are great in the past is improved; meanwhile, the fabrics have no yellowing phenomenon.

Owner:张作玮

Coat fabric finishing process

InactiveCN104480709AImprove antibacterial propertiesGood antifoulingFibre treatmentAcrylic resinDimethylol urea

The invention discloses a coat fabric finishing process. The coat fabric finishing process comprises the following steps: (1) adding 2.3 parts by mass of dimethylol urea, 1.7 parts by mass of sodium alga acid and 3.4 parts by mass of aluminum acetate into 8.7 parts by mass of deionized water, mixing and uniformly stirring; (2) slowly adding 4.2 parts by mass of acrylic resin and 1.7 parts by mass of triethanolamine at the same time, and continuing stirring until the materials are fully and uniformly mixed to prepare a finishing agent; (3) padding the fabric in an impregnating solution containing the finishing agent, and drying the fabric at the constant temperature. The fabric finished by the coat finishing process is excellent in antimicrobial property, excellent in antifouling property and strong in washing fastness.

Owner:CHANGSHU ZHONGHONG KNITTING MILL

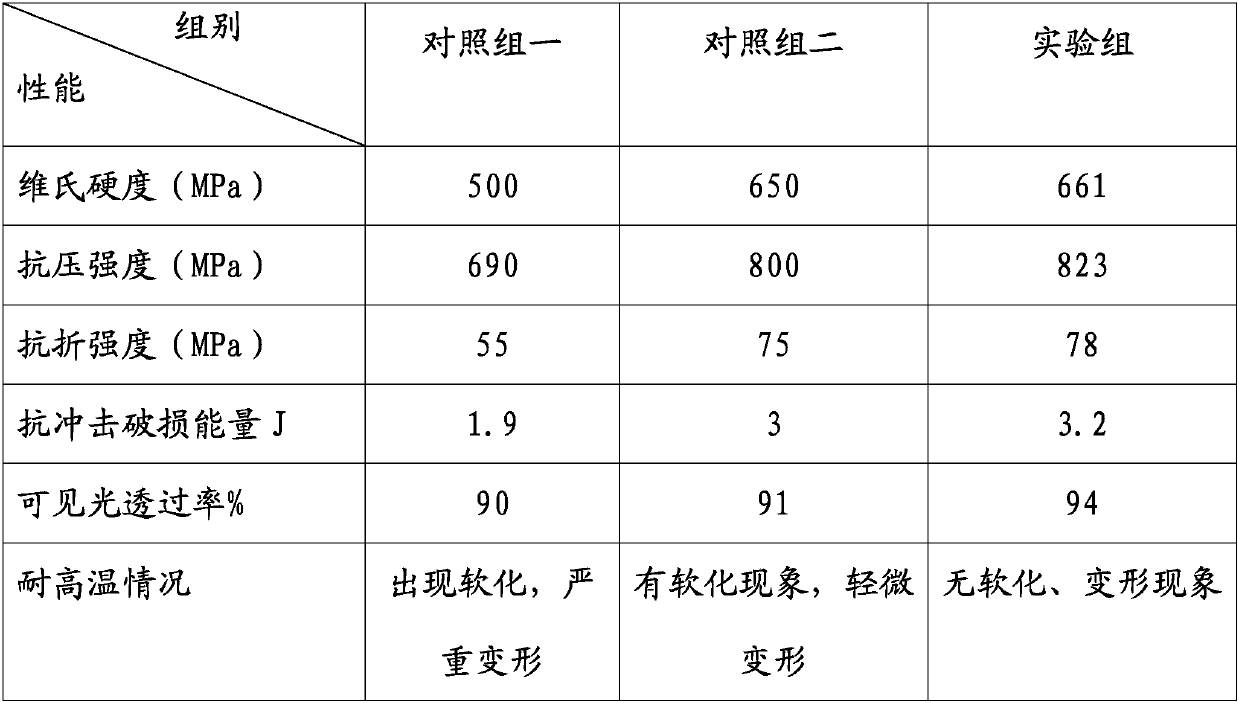

Novel high-strength glass and preparation method thereof

InactiveCN107777878AHigh mechanical strengthHigh light transmittanceGlass shaping apparatusAlloyAntimony trioxide

The invention discloses novel high-strength glass and a preparation method thereof. The novel high-strength glass is prepared from the following raw materials in parts by weight: 30 to 40 parts of quartz sand, 10 to 15 parts of boric acid, 6 to 8 parts of polyphenylene sulfide, 2 to 3 parts of chitosan, 9 to 11 parts of rutile, 5 to 7 parts of sodium silicate, 5 to 7 parts of calcium fluoride, 2 to 4 parts of barium oxide, 5 to 6 parts of borax, 1 to 2 parts of dimethylol urea, 2 to 3 parts of a tungsten-nickel-molybdenum alloy, 1 to 2 parts of antimony trioxide, 1 to 2 parts of cobalt sulfide, 1 to 2 parts of polymethylhydrosiloxane and 4 to 6 parts of lauryl polyoxyethylene ether. The glass disclosed by the invention has the advantages of great mechanical strength, good light transmission performance and high temperature resistance; and the preparation method is simple and low in cost.

Owner:吕玲

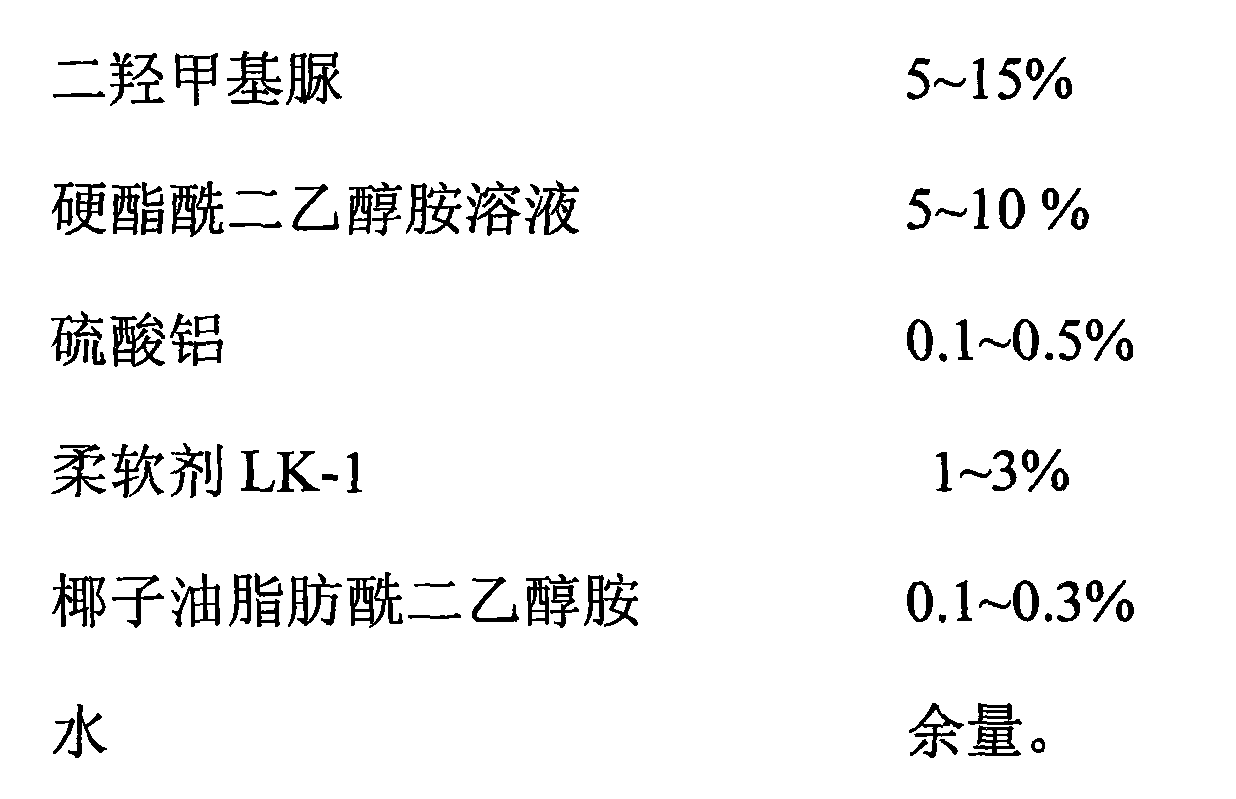

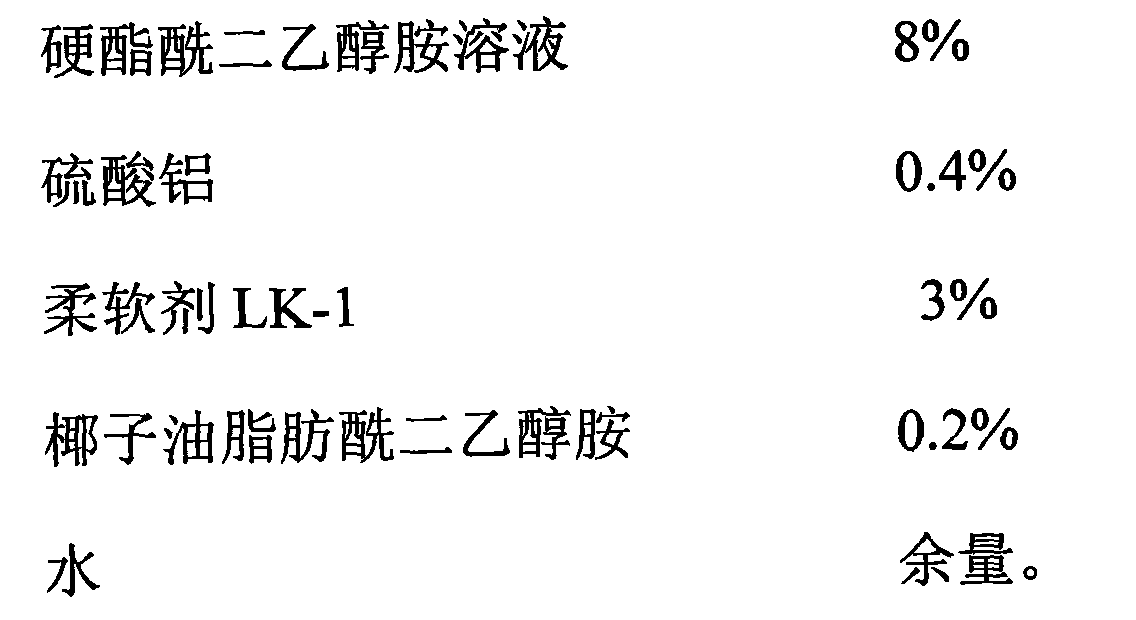

Wrinkle-resistant finishing liquor for corduroy

InactiveCN102011307AReasonable formulaImprove work performanceFibre treatmentDimethylol ureaDiethanolamide

The invention discloses wrinkle-resistant finishing liquor for corduroy, which is formed by mixing dimethylol urea, distearoyl phosphoethaolamine solution, aluminum sulfate, a softening agent LK-1, cocoanut fatty diethanolamide and water. The invention has the advantages of reasonable formula, favorable work effect and low production cost.

Owner:袁建辉

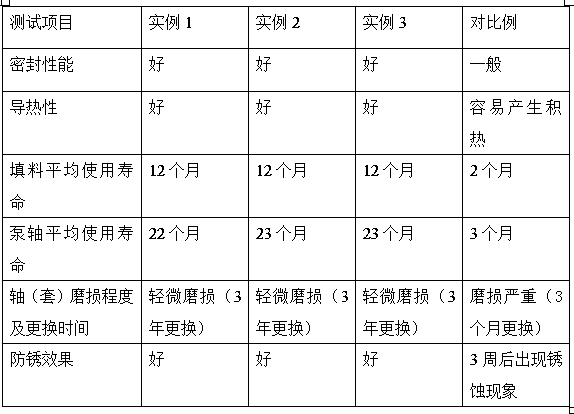

Preparation method of thixotropic self-repair sealing filler

InactiveCN108530807AImprove thixotropyQuick fixOther chemical processesVehicle sealing arrangementsCarbon compositesSiphon

The invention relates to the technical field of sealing fillers, in particular to a preparation method of a thixotropic self-repair sealing filler. Urea and formaldehyde serve as raw materials and react under alkaline conditions to form a methylol urea and dimethylol urea mixed prepolymer, the prepolymer is heated and cured to obtain a microcapsule taking epoxy-fluorine-carbon composite resin as acapsule core, siphon action generated by abrasion fracture can be enhanced by a doped carbon nanotube, so that an abrasion position of a metal coating can be rapidly repaired completely, a metal surface is not easy to rust by the aid of unsaturated resin, a rust-proof oil film on the surface of the sealing filler contains benzotriazole which can penetrate a rust-proof inner film by gasification,a special complex is generated on the metal surface, an external metal surface can be isolated from the outside, mixed raw materials such as nickel oxide, potassium oxide and potassium chloride can form a firm abrasion-resistant compact ceramic layer on the metal surface, electrochemical corrosion of the metal surface is avoided, and the preparation method is wide in application prospect.

Owner:吴刚

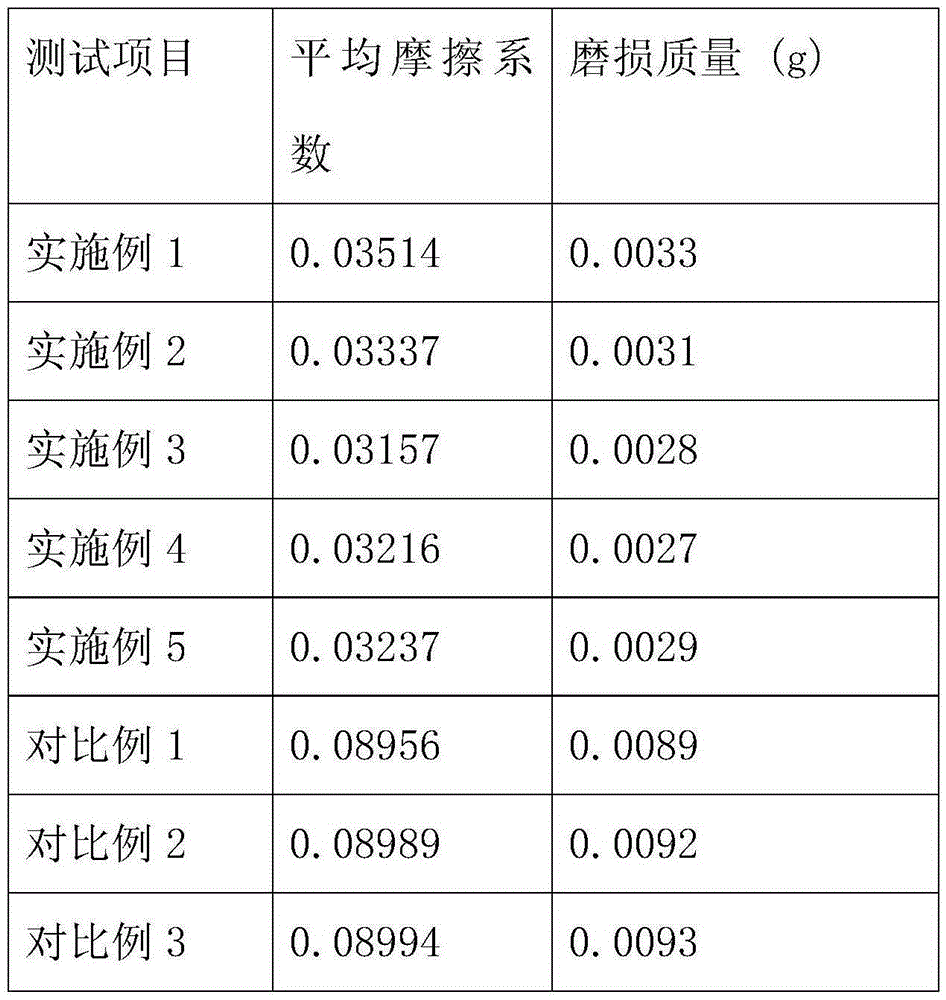

Lubricating agent for textile machine and preparation method of lubricating agent

InactiveCN105802710AImprove the lubrication effectImprove wear resistanceLubricant compositionBenzoyl peroxideEngineering

The invention discloses a lubricating agent for a textile machine and a preparation method of the lubricating agent. The lubricating agent for the textile machine is prepared from components in parts by weight as follows: 50-60 parts of lubricating oil, 4-6 parts of chlorinated paraffin, 3-6 parts of talc powder, 2-3 parts of 2-ethyl hexylphosphic mono(2-ethylhexyl) ester, 2-3 parts of benzoyl peroxide butyl acetate, 1-2 parts of magnesium zinc ferrite, 1-2 parts of campesterol, 0.5-1 part of hydroxymethyl acrylamide, 0.5-0.6 parts of dimethylol urea, 0.2-0.4 parts of 4-hydroxyl-3-methoxybenzoic acid and 0.2-0.4 parts of trimethylamine acetate. The invention further provides the preparation method of the lubricating agent for the textile machine.

Owner:WUJIANG FUHUIYUAN HOME TEXTILES CO LTD

Fatliquor for natural leather

The invention discloses a fatliquor for natural leather. The fatliquor comprises, by weight, 20-30 parts of poly-hydroxyethyl castor oil, 2-4 parts of methanol, 20-60 parts of olive oil, 2-4 parts of copper stearate, 6-8 parts of dimethylol urea resin, 10-20 parts of polyurethane, 10-30 parts of stearic acid, 8-16 parts of octanol, 4-8 parts of oleic acid, 2-4 parts of sulfuric acid, 6-12 parts of sodium hydroxide, 10-18 parts of naphthenic acid, 2-8 parts of glacial acetic acid and 8-16 parts of acrylamide. According to the fatliquor for the natural leather, preparation is easy; adopted production raw materials are non-toxic; and fabric treated with this finishing agent can prevent shrinkage and wrinkling, the shaping effect is good, ironing is free, and the fabric has the characteristics of being level, smooth, full, non-fouling and the like.

Owner:袁允兰

Adhesive for fiber board and preparation method of adhesive

InactiveCN107099268AHigh densityImprove rigidityAldehyde/ketone condensation polymer adhesivesFiberAdhesive cement

The invention discloses an adhesive for a fiber board and a preparation method of the adhesive. The p-tert-butylcatechol is taken as a crosslinking agent to produce dimethylol urea and a urea resin molecule through connection, and a urea resin is synthesized through an acid-neutral-acid-neutral-acid process, so that the molecule of the adhesive is evenly increased, a benzene ring structure is introduced into the molecular structure, the resin curing crosslinking density and rigidity of the urea resin are improved, the capability of capturing free formaldehyde is improved, the bonding strength is very high, and the formaldehyde emission is very low. The adhesive has the advantages that the unconventional p-tert-butylcatechol is used to produce a quinone structure under the actions of a catalyst and an oxidizing agent, the acid-neutral-acid-neutral-acid process is used to gradually increase the molecular chain of the urea resin and finally form a network structure, the formed resin is low in molecular weight and high in reaction activity, the basic procedure is close to the conventional process, the process is simple, the operation is simple, and the existing equipment is not transformed.

Owner:江苏苏林木业有限公司

Water treatment anti-bacterial material and preparation method thereof

InactiveCN105293649AImprove adsorption capacityGood flocculation effectWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationCelluloseIron sulfate

The invention discloses a water treatment anti-bacterial material and a preparation method thereof. The water treatment anti-bacterial material is prepared from the following components in parts by weight: 50-60 parts of aluminum sulfate, 15-20 parts of polyving alcohol, 10-12 parts of acetate fiber, 3-5 parts of hydroxymethyl cellulose, 3-5 parts of clay, 3-5 parts of starch phosphomonoester, 2-3 parts of polymeric ferric sulfate, 1-3 parts of calcium phosphate dibasic dehydrate, 0.5-1 part of dimethylol urea, 0.05-0.2 part of tetraglycidyl xylenedi-amine and 0.02-0.2 part of imarcaptoacetate dioctyltin. The invention further provides a preparation method of the water treatment anti-bacterial material.

Owner:苏州书瑞环保科技有限公司

Method for synthesizing urea-formaldehyde resin

InactiveCN101987881BImprove performanceLow free formaldehyde contentDimethylol ureaReaction temperature

The invention discloses a method for synthesizing urea-formaldehyde resin. The method can reduce the content of free formaldehyde, and produce the urea-formaldehyde resin with high performance. In the method, the total molar ratio of formaldehyde to urea is 1.19, which contributes to reducing the free formaldehyde content of the urea-formaldehyde resin; the formaldehyde is added once; the urea isadded for four times, wherein the dosages of the urea added in the first two times have to contribute to generating dimethylol urea, so that an addition reaction of the formaldehyde is more thorough to reduce the free formaldehyde content in the reaction to the maximum; the pH value in the reaction process is changed to meet the requirements on the pH values in different stages of the reaction process; and the appreciate reaction temperature, appreciate reaction time and appreciate urea adding time are selected.

Owner:钱彤

Manufacturing method of urban energy-saving and environmental-friendly cultivation medium

InactiveCN102101933AAvoid burning seedlingsIncrease matrix nutrientsCultivating equipmentsSoilless cultivationElastomerMethyl group

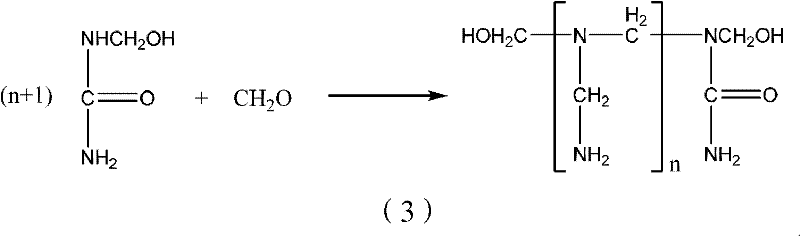

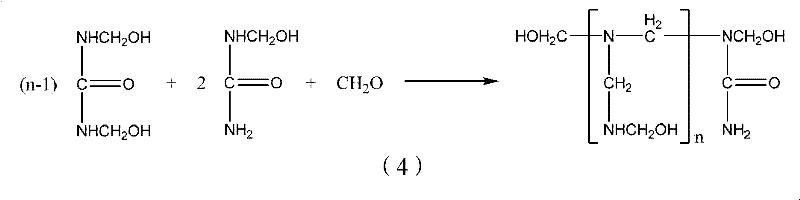

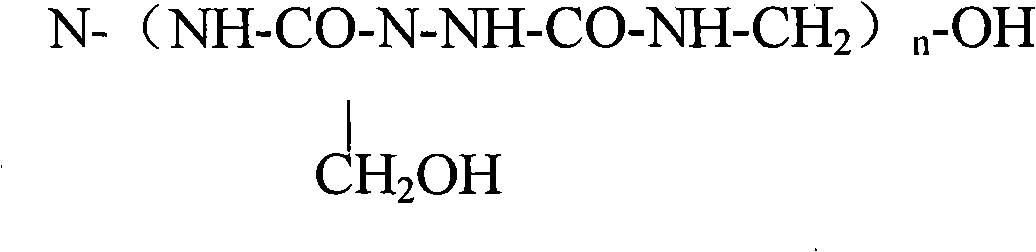

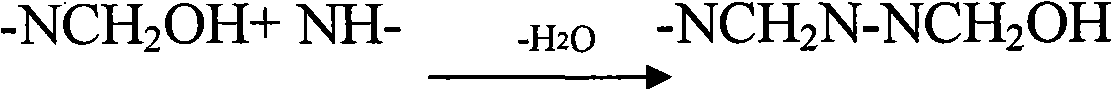

The invention relates to a manufacturing method of an urban energy-saving and environmental-friendly cultivation medium, which comprises the following implementation steps: in the first phase of an addition reaction, urea and formaldehyde are allowed to perform a hydroxymethylation reaction in a medium with a neutral or slightly alkaline pH of 7-8 to obtain monomethylol urea and dimethylol urea; further reaction is performed to obtain trimethylol urea and tetramethylol urea when the molar ratio of formaldehyde and urea (F / U) is higher; in the second phase of a polycondensation reaction, various methylol ureas are allowed to perform condensation in a weak acid condition with a pH of 4-6 to obtain a hydrophilic resin, wherein in the molecular structure, the hydroxymethyl group and the hydrogen connected to the nitrogen have a polycondensation capability; with the progress of the above reaction, the molecular weight increases gradually, and the molecular state becomes more complex, and even a network structure is formed, so the resin becomes an elastomer with a stereo configuration. The invention uses urea formaldehyde foam plastics as a novel plant cultivation medium to substitute soil, is environmental-friendly and can effectively save resources.

Owner:天津市津鸥化肥有限责任公司

Novel lubricating grease for weaving machine and preparation method of novel lubricating grease

InactiveCN105255566AImprove the lubrication effectImprove wear resistanceLubricant compositionPolyvinyl alcoholDimethylol urea

The invention discloses novel lubricating grease for a weaving machine and a preparation method of the novel lubricating grease. The novel lubricating grease is prepared from, by weight, 70-85 parts of base oil, 6-8 parts of polyvinyl alcohol, 4-6 parts of epoxy acrylic acid, 3-5 pars of bornyl isovalerate, 3-5 parts of hydroxymethyl cellulose, 1-2 parts of citronellal, 0.5-1 part of dimethylol urea, 0.5-0.8 part of 4-guanidine butyric acid, 0.2-0.4 part of imarcaptoacetate dioctyltin and 0.02-0.8 part of succinic acid. The invention further provides the preparation method of the lubricating grease for the weaving machine.

Owner:付淑珍

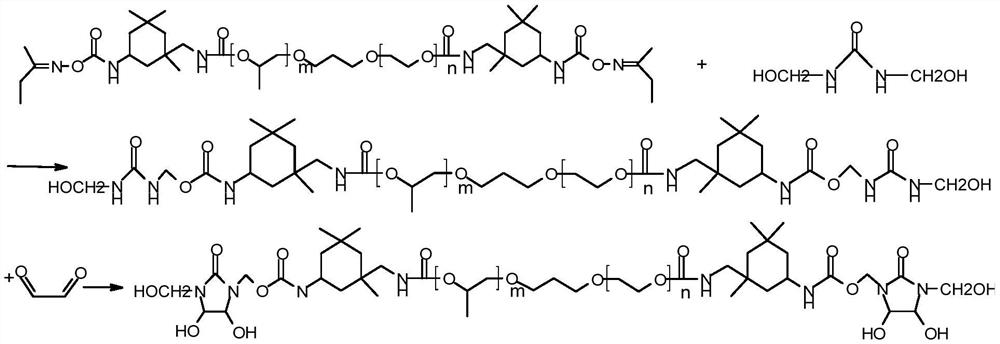

Preparation method of polyurethane modified non-ironing resin with improved strong hand feeling

InactiveCN111793202AGuaranteed validityGood non-ironing effectWrinkle resistant fibresGrip property fibresCelluloseFiber

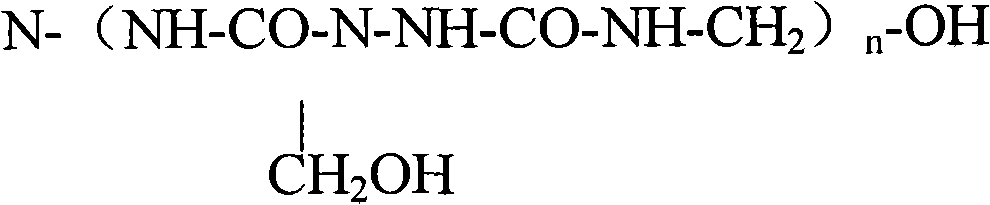

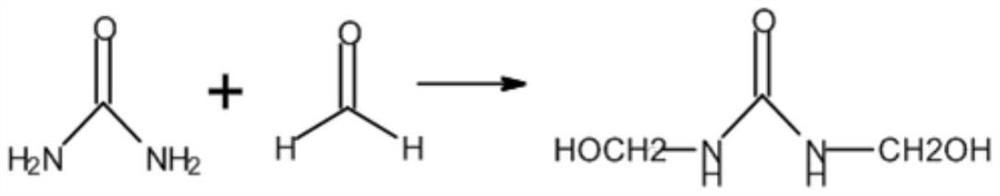

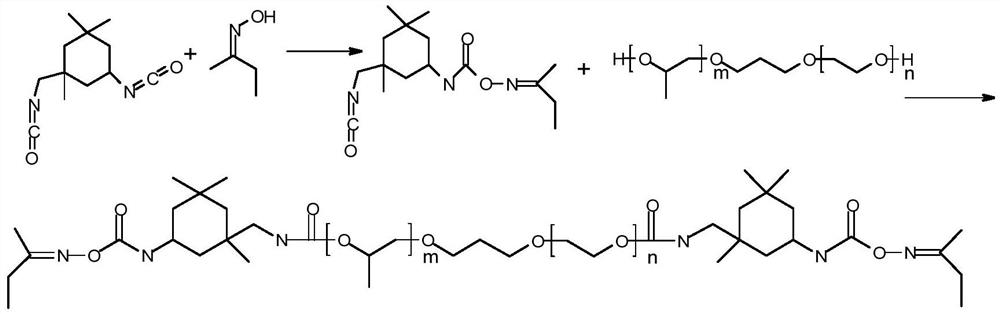

The invention belongs to the technical field of preparation of textile assistants, and particularly relates to a preparation method of polyurethane modified non-ironing resin with improved strong handfeeling. The preparation method comprises the following steps: preparing dimethylol urea from urea and formaldehyde; preparing a polyurethane prepolymer from aliphatic diisocyanate and a sealing agent, carrying out a reaction on propylene glycol polyoxyethylene polyoxypropylene ether, the polyurethane prepolymer and a catalyst, adding the dimethylol urea and dioxane, and carrying out a reaction;and finally adding glyoxal, continuously reacting, and adding water to adjust the water content after the reaction is finished so as to obtain the product. According to the invention, the product of areaction of a polyoxyethylene polyoxypropylene ether block copolymer and isocyanate is cross-linked with a traditional 2D resin, wherein the polyether block is attached to the surface of the fiber soas to enhance the lubricity of the fiber, improve the hand feeling of the fabric and make the fiber slide within a limited range when being stressed to achieve the purpose of reducing strength loss,and the effectiveness of cross-linking of resin and cellulose is ensured through polyhydroxy structures at the two ends, so that the non-ironing property is still good.

Owner:ZIBO LURUI FINE CHEM CO LTD

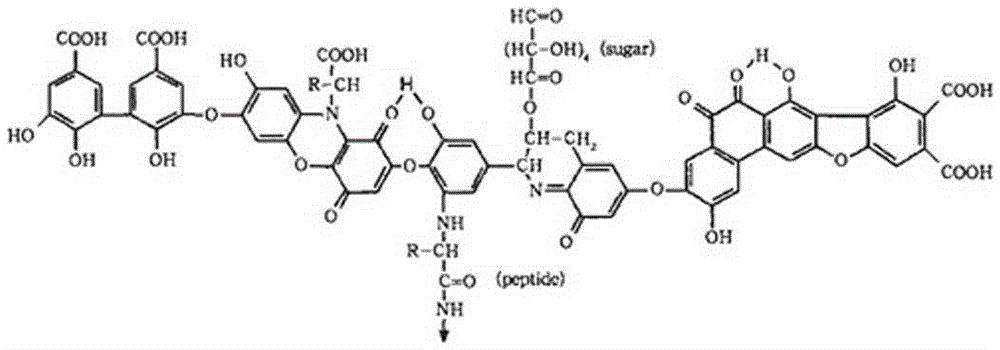

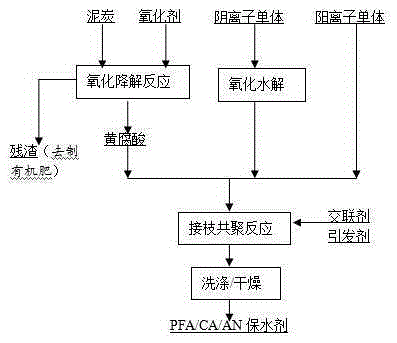

Oxidized peat fulvic acid composite water retaining agent and preparation method thereof

InactiveCN105384882AReduce energy consumptionImprove responseAgriculture tools and machinesBuilding constructionsMeth-Ethyl group

An oxidized peat fulvic acid composite water retaining agent is prepared from, by mass, 50-60 parts of oxidized peat fulvic acid, 15-25 parts of cationic compound monomers, 8-15 parts of anionic compound monomers, 0.1-0.8 part of a cross-linking agent and 0.4-3.8 parts of initiator. The oxidized peat fulvic acid is prepared from, by mass, 1 part of oxidized peat, 0.05-0.20 part of an oxidizing agent and 2.95-8 parts of industrial pure water. The cationic compound monomer is one of (3-methacrylamidipropyl) trimethyl ammonium chloride, methyl acrylyl ethyl trimethyl ammonium iodide, (3-acrylamidopropyl)trimethyl ammonium chloride, dimethylaminoethyl methacrylate, N,N-dimethylaminoethyl acrylate and 2-diethylaminoethyl methacrylate. The cross-linking agent is composed of, by mass, 5-8 parts of N,N-methylene bisacrylamide and 0.5-3 parts of glycerine or ethylene glycol diglycidyl ether or dimethylol urea. The initiator is prepared from, by mass, 5 parts of ammonium persulfate and 1-4 parts of potassium sulfite.

Owner:SHANXI AGRI UNIV

Finishing process of linen fabric

InactiveCN105332270AGood antibacterialImprove wrinkle resistanceVegetal fibresPhosphatePolyhexamethylene guanidine

The invention discloses a finishing process of linen fabric. The finishing process includes the following steps of firstly, putting, by mass, 1-2 parts of sodium silicate, 2.6 parts of titanium tetraisopropanolate, 1.4 parts of silver inorganic zeolite antibacterial master batches and 1.1 parts of nanoscale magnesium hydrate into 27 mass weights of deionized water, and conducting mixing and even stirring; secondly, slowly adding, by mass, 3.2 parts of block polyoxyethylene-polyoxypropylene ether, 2.6 parts of polyhexamethylene guanidine phosphate, 1.7 parts of dimethylol urea and 3.1 parts of sodium borate at the same time, continuing to conduct stirring till the components are sufficiently and evenly mixed, and obtaining finishing liquid; thirdly, conducting padding on the fabric in the finishing liquid, taking out the fabric to be dried at a constant temperature. The fabric finished through the finishing process has excellent antibacterial, anti-wrinkle, flame-retardant and antistatic performance, and is high in washability.

Owner:SUZHOU YIDIANYUAN APPLE CLOTHING CO LTD

Ironing-free finishing agent for dacron

InactiveCN106906665AEasy to makeGood shaping effectStain/soil resistant fibresLiquid repellent fibresZinc nitrateSizing

The invention discloses an ironing-free finishing agent for dacron, which comprises the following components in parts by weight: 60-80 parts of dimethylol urea resin, 10-20 parts of polyurethane, 10-20 parts of crylic acid, 10-20 parts of zinc nitrate, 6-12 parts of ammonium citrate, 20-30 parts of triethanolamine, 10-18 parts of magnesium chloride hexahydrate, 4-8 parts of glycerinum rosin resin, 8-16 parts of polydivinyl acetylene, 10-18 parts of naphthenic acid, 2-8 parts of glacial acetic acid, 8-16 parts of acrylamide, 5-15 parts of vinyl chloride-vinyl ester and 80-120 parts of deionized water. The ironing-free finishing agent for dacron, provided by the invention, is simply prepared; the nontoxic production raw materials are selected; the fabric treated with the finishing agent is shrink-proof and crease-resistant, has a good sizing effect, is ironing-free and has the characteristics of stiffness, fullness, no fouling, and the like.

Owner:陶洪燕

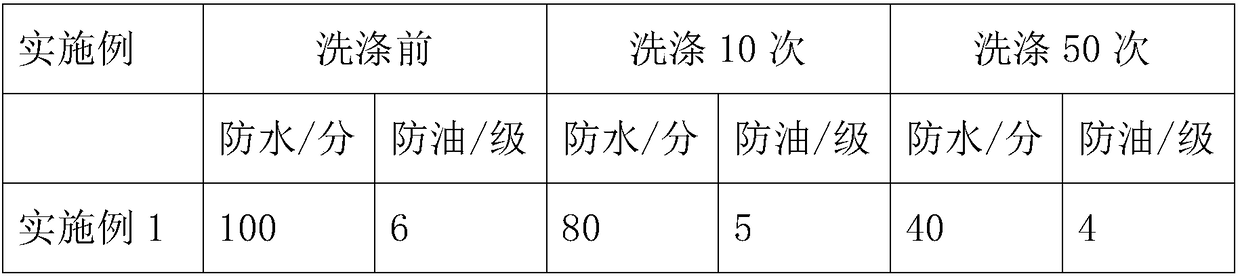

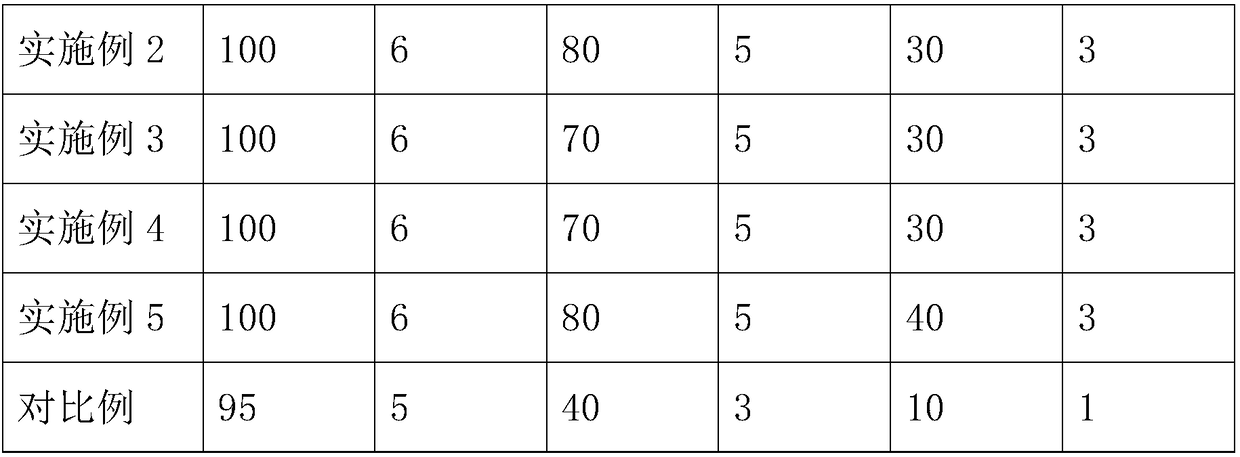

Strong washing resistance waterproof coating adhesive finishing agent for textile and preparation method thereof

The invention discloses a strong washing resistance waterproof coating adhesive finishing agent for textile. The finishing agent comprises the following raw materials in parts by weight: 10 to 20 parts of acrylic perfluorooctane ethyl ester, 20 to 30 parts of acrylic acid butyl ester, 1 to 3 parts of gas-solid titanium dioxide, 10 to 15 parts of higher aliphatic alcohol acrylate, 1 to 4 parts of nonionic hydrophobic modified ethylene oxide polyurethane copolymer, 2 to 4 parts of polyether silicone oil, 1.5 to 3 parts of dimethylol urea, 0.5 to 1 part of zinc nitrate hexahydrate, 0.2 to 0.5 part of a catalyst, and 100 to 140 parts of water. The finishing agent has the advantages that the acrylic perfluorooctane ethyl ester, acrylic acid butyl ester and higher aliphatic alcohol acrylate arein reaction under the action of the catalyst, and then are in reaction with the gas-solid titanium dioxide, nekal, polyether silicone oil, dimethylol urea, zinc nitrate hexahydrate and nonionic hydrophobic modified ethylene oxide polyurethane copolymer, so that the finishing agent with excellent water resistance and oil-proof effect is obtained.

Owner:佛山慧创正元新材料科技有限公司

After-finishing process of dacron fabric

InactiveCN105297421AExcellent flame retardantGood antibacterialFibre treatmentCarboxylic saltEthyl acetate

The invention discloses an after-finishing process of a dacron fabric. The after-finishing process comprises the following steps: (1) adding the following components into 37 parts of de-ionized water in parts by mass: 1-2 parts of resorcinol, 3.3 parts of aniline-3,5-disulfonic acid, 2.9 parts of potassium sorbate and 0.7 part of zinc stearate, and mixing and uniformly stirring; (2) slowly adding the following components in parts by mass: 1.9 parts of nonylphenol ethoxylate carboxylate, 2.8 parts of ethyl acetate, 1.1 parts of sodium benzoate and 2.4 parts of dimethylol urea, and further stirring until the components are sufficiently and uniformly mixed to prepare a finishing agent; and (3) padding a fabric into an impregnation solution containing the finishing agent to be subjected to padding treatment, and drying at a constant temperature. According to the after-finishing process of the dacron fabric, provided by the invention, the finished fabric has excellent inflaming retarding, antibacterial, anti-wrinkle and anti-static performances, and strong washing fastness.

Owner:常熟市华谊织造有限公司

Waterproof oil-proof anti-wrinkling finishing agent

InactiveCN106906659AEasy to makeGood shaping effectStain/soil resistant fibresLiquid repellent fibresBenzoyl peroxideDibenzoyl Peroxide

The invention discloses a waterproof oil-proof anti-wrinkling finishing agent which comprises the following components in parts by weight: 100-160 parts of dimethylol urea, 20-60 parts of sodium carbonate, 40-60 parts of poly-isobutyl ester, 20-40 parts of aluminum hydroxide, 12-24 parts of phosphotriester, 20-40 parts of aluminum sulfate, 20-40 parts of trimethylol melamine, 20-30 parts of lauryl methacrylate, 20-30 parts of zinc nitrate hexahydrate, 10-20 parts of benzoyl peroxide and 600-800 parts of deionized water. The waterproof oil-proof anti-wrinkling finishing agent provided by the invention is simply prepared; nontoxic production raw materials are selected; and the fabric treated with the finishing agent is shrink-proof and anti-wrinkling, has a good sizing effect, is ironing-free and has the characteristics of stiffness, fullness, no fouling, and the like.

Owner:陆亚洲

Water and oil-repellent anti-wrinkling finishing agent for baffeta

InactiveCN106906639AEasy to makeGood shaping effectStain/soil resistant fibresLiquid repellent fibresBenzoyl peroxideGlycerol

The invention discloses a water and oil-repellent anti-wrinkling finishing agent for baffeta. The water and oil-repellent anti-wrinkling finishing agent for baffeta comprises the following components in parts by weight: 100-160 parts of dimethylol urea resin, 40-60 parts of magnesium chloride hexahydrate, 100-160 parts of aluminum sulfate, 80-100 parts of trimethylol melamine, 20-30 parts of methacrylic glycerol trilaurate, 20-30 parts of zinc nitrate hexahydrate, 40-60 parts of poly-isobutyl ester, 20-40 parts of aluminum hydroxide, 12-24 parts of phosphotriester, 12-18 parts of antimonous oxide, 10-20 parts of benzoyl peroxide and 600-800 parts of deionized water. The water and oil-repellent anti-wrinkling finishing agent for baffeta is simply prepared; the nontoxic production raw materials are selected; the baffeta treated with the finishing agent is shrink-proof and anti-wrinkling, has a good sizing effect, is ironing-free and has the characteristics of stiffness, fullness, no fouling, and the like.

Owner:陆亚洲

Finishing liquid for wrap/weft knitting fabrics

InactiveCN104562662AImprove hydrophilicityImprove permeabilityFibre treatmentDimethylol ureaDiethanolamide

The invention discloses finishing liquid for wrap / weft knitting fabrics. The finishing liquid is prepared from the following components in parts by weight: 1.3 parts of butyl acrylate, 2.5 parts of dimethylol urea, 3.4 parts of triethanolamine, 0.6 part of fluorinated polysiloxane resin, 1.7 parts of dibutyl ester, and 0.5 part of coconut fatty acid diethanolamide. The finishing liquid for the wrap / weft knitting fabrics is high in hydrophily and permeability, and the tensile resistant performance and the antifouling performance of the fabrics can be improved.

Owner:常熟市海虞富盛经纬编织造厂

Strong washing resistant waterproofing agent for textiles and preparation method thereof

InactiveCN108570854AStrong washing resistanceGood water and oil repellent effectLiquid repellent fibresGrip property fibresFatty alcoholAlkyl Glyceryl Ethers

The invention discloses a strong washing resistant waterproofing agent for textiles. The strong washing resistant waterproofing agent is prepared from the following raw materials in parts by weight: 10-20 parts of perfluorooctyl acrylate, 20-30 parts of n-butyl acrylate, 1-3 parts of fumed titanium dioxide, 10-15 parts of high-grade fatty alcohol acrylate, 1-4 parts of nekal, 2-5 parts of alkyl glyceryl ether sulfonate, 2-4 parts of polyether silicone oil, 1.5-3 parts of dimethylol urea, 0.5-1 part of zinc nitrate hexahydrate, 0.2 to 0.5 part of catalyst, and 100 to 140 parts of water. According to the invention, perfluorooctyl acrylate, n-butyl acrylate and high-grade fatty alcohol acrylate innovatively react in the presence of the catalyst, and fumed titanium dioxide, nekal, alkyl glyceryl ether sulfonate, polyether silicone oil, dimethylol urea and zinc nitrate hexahydrate are blended for reacting to obtain the waterproofing agent for textiles with good water and oil repellency andstrong washing resistance.

Owner:佛山慧创正元新材料科技有限公司

Nano soil restoration material and preparation method thereof

InactiveCN105505397AGood restorativeImprove repair effectOrganic fertilisersSoil conditioning compositionsAluminateSodium Bentonite

The invention discloses a nano soil restoration material and a preparation method thereof. The nano soil restoration material is prepared from the following components in parts by weight: 50 to 55 parts of bentonite, 12 to 15 parts of coal ash, 3 to 5 parts of magnesium nitrate, 2 to 4 parts of nano barium oxide, 1 to 3 parts of polysilicate aluminium ferric, 1 to 2.5 parts of stachydrine, 1 to 2 parts of dimethylol urea calcium aluminate, 1 to 2 parts of magnesium aluminosilicate, 1 to 2 parts of yellow phopholipid, 0.8 to 1.5 parts of triazine trisodium salt, and 0.5 to 0.8 part of sodium cocoyl glycinate. The invention further provides the preparation method of the nano soil restoration material.

Owner:JIANGSU GAIYA ENVIRONMENTAL SCI & TECH CO LTD

A kind of wear-resistant antiskid concrete and its construction method

InactiveCN104045288BImprove skid resistanceImprove wear resistanceSolid waste managementWear resistantSlag

The invention discloses wear-resistant anti-skidding concrete and a construction method thereof. The concrete comprises the following raw materials in parts by weight: 100-120 parts of silicate cement, 40-90 parts of sands, 10-30 parts of oxalaldehyde, 50-60 parts of dihydroxymethyl urea, 40-65 parts of aluminum chloride, 70-80 parts of sodium aliphatate, 80-100 parts of ammonium chloride, 10-60 parts of limestones, 30-42 parts of coal ash, 45-85 parts of desulfurized fly ash, 75-95 parts of steel slags, 10-55 parts of potassium nitrate, 15-20 parts of glass dust, 55-100 parts of an accelerant and 80-120 parts of water. The construction method of the concrete comprises the following steps: uniformly mixing silicate cement, sands, oxalaldehyde, dihydroxymethyl urea, aluminum chloride, sodium aliphatate, potassium nitrate, glass dust and water; heating to 180-200 DEG C; stirring for 20-30s; adding the accelerant; uniformly stirring; then, adding residual raw materials and uniformly stirring. The wear resistance of the concrete disclosed by the invention is remarkably improved, and the concrete has a good anti-skidding performance.

Owner:江苏大江建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com